Page 1

GENERAL SAFETY RULES

WARNING! Read and understand all instructions. Failure to follow all instructions listed

below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust

or fumes.

• Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Double insulated tools are equipped with a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized outlet only one way. If the plug does not fit

fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install a polarized outlet. Do not change the plug in any way.Double insulation

eliminates the need for the three wire grounded power cord and grounded power sup-

ply system.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked “W-A”

or “W.” These cords are rated for outdoor use and reduce the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use tool while tired or under the influence of drugs, alcohol, or

medication. Amoment of inattention while operating power tools may result in serious per-

sonal injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing , and gloves away from moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts. Air vents cover moving parts and should be avoided.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. Awrench or a key that

is left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss

of control.

• Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments, changing accessories, or storing the tool. Such preventative safety measures reduce the risk

of starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

KEY INFORMA TION YOU SHOULD KNOW :

• A sharp blade will improve performance dramatically.

• A dull blade will cause slow, inefficient cutting.

• Always support work properly. (See illustrations on work support in this manual.)

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE

SERVICIO Y PÓLIZA DE GARANTÍA. ADVERTENCIA:

LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

INSTRUCTION MANUAL

Catalog Nos. CS1000, CS1010, CS1020

7777----1111////4444”””” ((((111188884444mmmmmmmm)))) CCCCiiiirrrrccccuuuullllaaaarrrr SSSSaaaawwwwss

ss

Cat. # CS1000, CS1010, CS1020 Form. # 605806-00 (OCT02-2) Copyright © 2002 Black & Decker Printed in China

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-54-HOW-TO (544-6986)

IF YOU SHOULD EXPERIENCE APROBLEM

WITH YOUR BLACK &DECKER PRODUCT,

CALL 1-800-54-HOW-TO (544-6986)

BEFORE YOU CALL, HA VE THE FOLLOWING INFORMATION AVAILABLE, CAT ALOG No.,

TYPE No., AND DATE CODE (e.g. 0130M). IN MOSTCASES, ABLACK & DECKER REPRE-

SENTATIVE CAN RESOL VE YOUR PROBLEM OVER THE PHONE. IF YOU HAVE ASUGGES-

TION OR COMMENT, GIVE US ACALL. YOUR FEEDBACK IS VITALT O BLACK & DECKER.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tools operation. If damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on

another tool.

SERVICE

• Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

SPECIFIC SAFETY RULES

DANGER! Keep hands away from cutting area and blade. Keep your second hand

on auxiliary handle, or motor housing. If both hands are holding the saw, they cannot be

cut by the blade.

• Keep your body positioned to either side of the saw blade, but not in line with the saw

blade. KICKBACK could case the saw to jump backwards. (See “Causes and Operator

Prevention of Kickback.”)

• Do not reach underneath the work. The guard can not protect you from the blade below

the work.

• Check lower guard for proper closing before each use. Do not operate saw if lower

guard does not move freely and close instantly. Never clamp or tie the lower guard

into the open position. If saw is accidentally dropped, the lower guard may be bent. Raise

the lower guard with the Retracting Handle and make sure it moves freely and does not

touch the blade or any other part, at all angles and depth of cut.

• Check the operation and condition of the lower guard spring. If the guard and the

spring are not operating properly, they must be serviced before use. Lower guard may

operate sluggishly due to damaged parts, gummy deposits, or a buildup of debris.

• Lower guard should be retracted manually only for special cuts such as “Pocket

Cuts” and “Compound Cuts.” Raise lower guard by Retracting Handle. As soon as

blade enters the material, lower guard must be released. For all other sawing, the lower

guard should operate automatically.

• Always observe that the lower guard is covering the blade before placing saw down

on bench or floor. An unprotected, coasting blade will cause the saw to walk backwards,

cutting whatever is in its path. Be aware of the time it takes for the blade to stop after switch

is released.

• NEVER hold piece being cut in your hands or across your leg. It is important to support

the work properly to minimize body exposure, blade binding, or loss of control.

• Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will also

make exposed metal parts of the tool “live” and shock the operator.

• When ripping, always use a rip fence or straight edge guide. This improves the accuracy of cut and reduces the chance for blade binding.

• Always use blades with correct size and shape (diamond vs. round) arbor holes.

Blades that do not match the mounting hardware of the saw will run eccentrically, causing

loss of control.

• Never use damaged or incorrect blade washers or bolts. The blade washers and bolt

were specially designed for your saw, for optimum performance and safety of operation.

CAUSES AND OPERATOR PREVENTION OF KICKBACK:

• Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the workpiece toward the operator.

• When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and the

motor reaction drives the unit rapidly back toward the operator.

• If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade

can dig into the top surface of the wood causing the blade to climb out of the kerf and jump

back toward operator.

• Kickback is the result of tool misuse and/or incorrect operating procedures or conditions and

can be avoided by taking proper precautions as given below.

a. Maintain a firm grip with both hands on the saw and position your body and arm to

allow you to resist KICKBACK forces. Kickback forces can be controlled by the opera-

tor, if proper precautions are taken.

b. When blade is binding, or when interrupting a cut for any reason, release the trig-

ger and hold the saw motionless in the material into the blade comes to a complete

stop. Never attempt to remove the saw from the work or pull the saw backward

while the blade is in motion or KICKBACK may occur. Investigate and take corrective

actions to eliminate the cause of blade binding.

c. When restarting a saw in the workpiece, center the saw blade in the kerf and check

that the saw teeth are not engaged into the material. If saw blade is binding, it may

walk up or KICKBACK from the workpiece as the saw is restarted.

d. Support large panels to minimize the risk of blade pinching and KICKBACK. Large

panels tend to sag under their own weight. Support must be placed under the panel on

both sides, near the line of cut and near the edge of the panel.

e. Do not use dull or damaged blade. Unsharpened or improperly set blades produce nar-

row kerf causing excessive friction, blade binding, and KICKBACK.

f. Blade depth and bevel adjusting locking levers must be tight and secure before

making cut. If blade adjustment shifts while cutting, it may cause binding and KICKBACK.

g. Use extra caution when making a “Pocket Cut” into existing walls or other blind

areas. The protruding blade may cut objects that can cause KICKBACK.

SAVE THESE INSTRUCTIONS

ADDITIONAL SAFETY RULES: CIRCULAR SAWS

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

CAUTION: Wear appropriate hearing protection during use. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

• Snagging the lower guard on a surface below the material being cut can momentarily

reduce operator control. The saw can lift partially out of the cut increasing the chance of

blade twist. Ensure there is sufficient clearance under the workpiece.

• When necessary to raise lower guard manually, use the retracting lever.

• KEEP THE BLADES CLEAN AND SHARP. Sharp blades minimize stalling and kickback.

The use of dull and/or dirty blades can increase the saw loading causing the operator to push

harder which promotes twisting.

DANGER: KEEP HANDS AWAYFROM CUTTING AREA. Keep hands away from blades.

Never place hands in front of or behind the path of the blade while cutting. Do not reach

underneath work while blade is rotating. Do not attempt to remove cut material when blade is

moving.

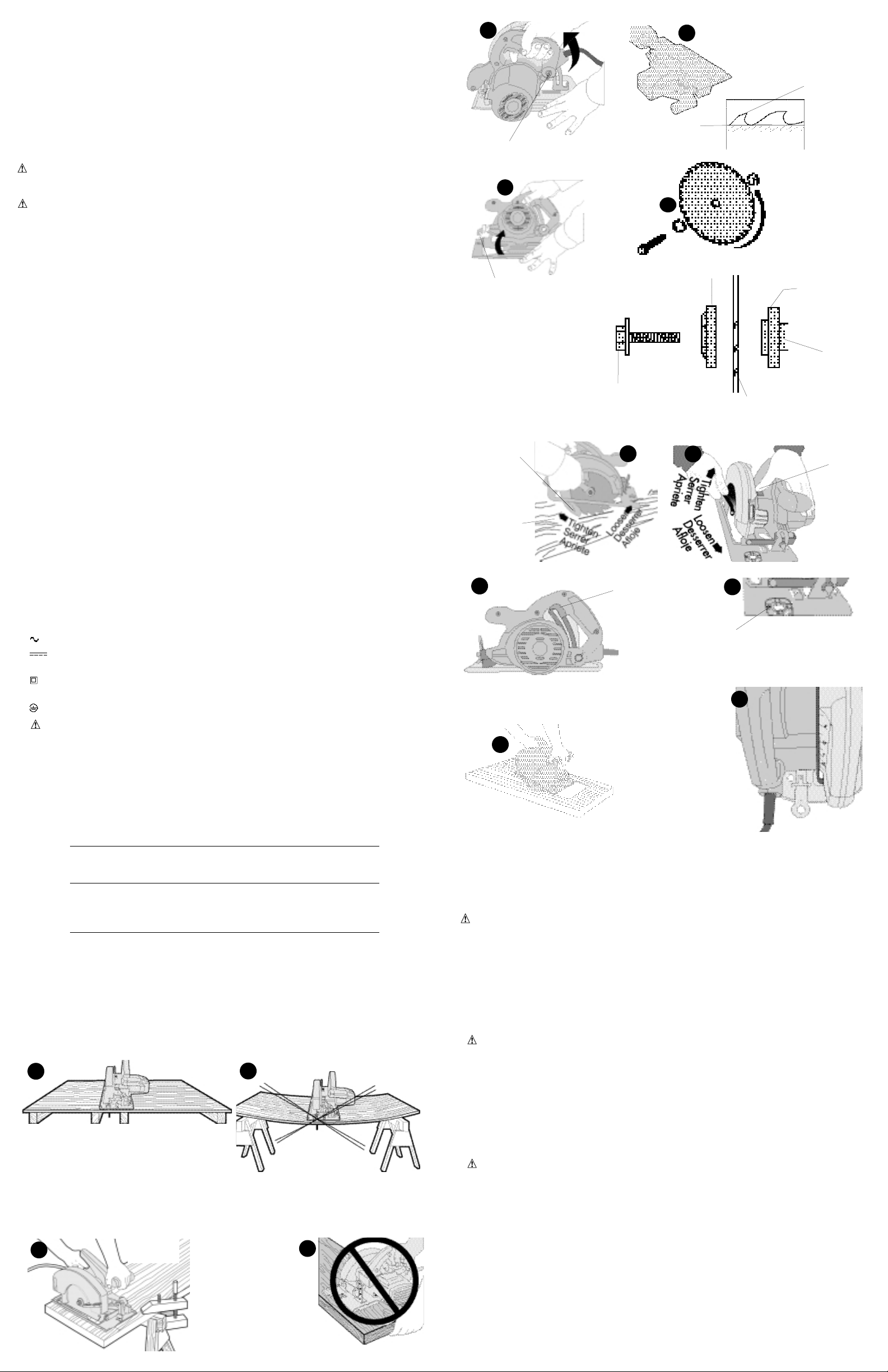

• SUPPORT LARGE PANELS. Large panels must be supported as shown (Fig. 1) in this

manual to minimize the risk of blade pinching and kickback. When cutting operation requires

the resting of the saw on the workpiece, the saw shall be rested on the larger portion and the

smaller piece cut off.

• USE ONLY CORRECT BLADES AND BLADE ASSEMBLY COMPONENTS WHEN

MOUNTING BLADES. Do not use blades with incorrect size holes. Never use defective or

incorrect blade washers or bolts. Follow blade assembly procedures.

Page 2

• ADJUSTMENTS. Before cutting be sure depth and bevel adjustments are tight.

• SUPPORT AND SECURE THE WORK PROPERLY. Insure that the material to be cut is

clamped (Fig. 3) and solidly supported and balanced on a strong, stable and level work

surface. Support the work so that the wide portion of the saw shoe is on the portion of the

material that doesn’t fall after the cut is made. Never hold cut off piece by hand (Fig. 4 ).

KICKBACK from blade pinch can result. Keep both hands on saw at all times.

• STAY ALERT AND EXERCISE CONTROL. Keep body positioned to one side of blade.

Always maintain a firm grip and control of saw with both hands. Do not change hand grip or

body position while saw is running. Take precaution to avoid injury from cut off pieces and

other falling material during operation.

• VIEWING WINDOW MUST BE IN PLACE AT ALL TIMES and it must stay closed against

the upper guard of the saw at all times when operating the saw. (Model CS1020 only)

• DISCONNECT SAW FROM POWER SOURCE before attempting to clean the viewing

window. (Model CS1020 only)

WARNING: Do not operate your saw if window becomes damaged or fails to stay in place

as noted above. Take your saw to your closest Black & Decker Service Center or authorized

service facility. (Model CS1020 only)

DANGER: RELEASE SWITCH IMMEDIATEL YIF BLADE BINDS OR SAW STALLS.

GUARD AGAINST KICKBACK

• KICKBACK CAN BE CAUSED BY the saw blade becoming pinched, twisted or bound while

cutting, or when the saw stalls. When the blade becomes twisted or misaligned in the cut, the

teeth at the back edge of the blade can dig into the top surface of the wood causing the blade

to climb out of the cut and move suddenly back toward the operator.

TO REDUCE THE RISK OF KICKBACK

• Keep a firm grip on saw with both hands at all times.

• Stay alert – exercise control.

• Support long overhanging materials. As the material is cut and weakens, it will sag, causing

a pinched blade.

• Support large panels as shown (Fig. 1). Material supported only at the ends (Fig. 2) will lead

to blade pinching.

• Avoid sawing overhead. Material can sag and will pinch blade.

• Keep blades sharp and clean.

• Use fence or straight edge guide when ripping. Be careful as the cut off strip can sag or twist,

closing the cut and pinching the blade, leading to KICKBACK.

• Don’t force tool. Wood variables such as knots, hardness, toughness, wetness, pressure

treated and freshly cut green lumber can heavily load the saw which can lead to stalling.

Push the saw slower when this occurs.

• Don’t remove saw from work during a cut while the blade is moving.

• Allow saw to reach full speed before blade contacts material to be cut. Starting the saw with

the blade against the work or pushed forward into cut can lead to stalling or sudden

backward movement of saw.

• Never attempt to lift saw when making a bevel cut. This leads to blade binding and stalling.

• Always secure work to prevent workpiece movement during cut.

• Do not try to force saw back on line if your cut begins to go off line. This can cause

KICKBACK. Stop saw and allow blade to coast down to a stop. Withdraw from cut and start a

new cut on the line.

• Set depth adjustment of saw such that one tooth of the blade projects below the workpiece

as shown in (Fig. 6).

• Do not back up a rotating blade in the cut. Twisting the saw can cause the back edge of the

blade to dig into the material, climb out of the work and run back toward the operator.

• Avoid cutting nails. Inspect for and remove all nails from lumber before cutting.

The label on your tool may include the following symbols.

V..............volts

A..............amperes

Hz............hertz

W ............watts

min ..........minutes

............alternating current

........direct current

no............no load speed

............Class II Construction

…/min......revolutions or reciprocation per minute

............earthing terminal

............safety alert symbol

EXTENSION CORDS

When using an extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. The following table shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the

gage number, the heavier the cord

Minimum Gage for Extension Cords

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0- 6 18 16 1614

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

MOTOR

Be sure your power supply agrees with nameplate marking. 120 Volts AC means your tool will

operate on standard 60 Hz household power. Do not operate AC tools on DC. Arating of 120

volts AC/DC means that your tool will operate on standard 60 Hz AC or DC power. This

information is printed on the nameplate. Lower voltage will cause loss of power and can

result in over-heating. All Black & Decker tools are factory-tested; if this tool does not

operate, check the power supply. This tool is AC only.

ASSEMBLY/ADJUSTMENT SET-UP

CUTTING DEPTH ADJUSTMENT

Adjust depth of cut using depth adjustment lever. See (Figs. 5 & 6) for proper setting. Tighten

lever securely.

BEVEL ANGLE ADJUSTMENT

Adjust bevel angle (Fig. 7) using bevel adjustment knob and bevel scale. Tighten knob

securely.

WARNING: Always unplug saw from power supply before any of the following operations.

AT TACHING AND REMOVING THE BLADE

NOTE: The first time the blade bolt is removed from saw without a blade installed, it

may be necessary to place the blade wrench on the bolt head and tap it sharply in the

counter clockwise direction.

Retract lower guard and assemble blade and clamp washer as shown (Fig. 8). Insure large

surface of washer is toward blade. Use scrap wood (Model CS1000 & CS1010) or spindle

lock (Model No. CS1020K only) to prevent spindle rotation.

Tighten blade securely as shown (Fig. 9A(Model CS1000 & CS1010) or Fig. 9B (Model No.

CS1020K only). Never engage spindle lock while blade is turning.

OPERATING INSTRUCTIONS

WARNING: To reduce the risk of serious personal injury, read, understand and follow all

important safety warnings and instructions prior to using tool.

GENERAL CUTS (IMPORT ANT: READ SAFETY WARNINGS AND INSTRUCTIONS. )

GUARD AGAINST KICKBACK

With unit unplugged, follow all assembly, adjustment and set up instructions.

Make sure lower guard operates. Select the proper blade for the material to be cut.

• Measure and mark work for cutting.

• Support and secure work properly (See Safety Rules and Instructions).

• Use appropriate and required safety equipment (See Safety Rules).

• Secure and maintain work area (See Safety Rules).

• With plug inserted and guard closed, make sure switch turns saw on and off.

WARNING: It is important to support the work properly and to hold the saw firmly to

prevent loss of control which could cause personal injury. Fig. 3 illustrates recommended

hand position.

SWITCH

To operate the tool, depress the trigger switch shown in Fig. 10. The tool will continue to run

as long as the trigger is depressed.

To turn the tool off, release the trigger switch. There is no provision for locking the tool on,

and the switch should never be locked on by any other means.

KERF PLATE ADJUSTMENT (MODEL CS1020KONLY)

Adjust kerf plate (Fig. 11) to read zero when the bevel scale reads zero by loosening the kerf

plate screw and sliding the plate as necessary. Align mark on kerf plate with drawn pencil line

and advance blade into cut. The kerf plate has lines for zero bevel and 45 degree bevel

cutting.

POCKET CUTTING (SEE FIG. 12)

POCKET CUTTING IS USED TO CUTA HOLE IN APIECE OF MATERIAL WITHOUT CUTTING

FROM THE SIDE.

• Measure and mark work.

1

2

3

Correct

Correct

Correcto

Correct

Correct

Correcto

Wrong

Incorrect

Incorrecto

Material bends on blade causing heavy loads or kickback

Le matériau plie au contact de la lame causant de lourdes

surcharges ou des rebonds.

El material oprime el disco ocasionando sobrecarga o contragolpe

Support work near cut

Soutenir la pièce près de la ligne de coupe.

Apoye la pieza cerca del corte

4

Wrong

Incorrect

Incorrecto

9b

Spindle lock

Dispositif de

verrouillage de

l’arbre

Seguro de la

flecha

7

Bevel adjustment knob

Bouton de réglage pour coupes en biseau

Perilla de ajuste de bisel

8

Blade

Lame

Disco

Outer clamp washer

Rondelle de fixation externe

Roldana de sujeción exterior

Saw spindle

Arbre de la scie

Flecha de la sierra

Blade clamping screw

Vis de fixation de la lame

Tornillo de sujeción del disco

Inner clamp washer

Rondelle de fixation interne

Roldana de sujeción interior

Direction of teeth

Sens des dents

Dirección de los dientes

For pocket cuts only

Pour coupes en retrait seulement

Solamente para cortes de bolsillo

Warning:When blade starts

cutting, release retraction

lever immediately

Avertissement : Lorsque la

lame commence à découper,

relâcher immédiatement le

ressort de rappel.

Advertencia: Cuando el

disco inicie el corte, suelte

inmediatamente la palanca

del mecanismo retráctil

9a

Scrap lumber

Bout de bois inutile

Madera de desperdicio

Lower guard

Protecteur inférieur

Guarda inferior

12

5

Depth adjustment knob

Bouton de réglage de la profondeur

Perilla de ajuste de profundidad

6

Tip of tooth

Bout de la dent

Punta del diente

Surface of wood

Surface du bois

Superficie de madera

Proper depth:one tooth below surface of wood

Profondeur appropriée: une dent sous la

surface du bois.

Profundidad correcta: un diente debajo de la

superficie de madera

10

Trigger switch

Interrupteur à détente

Gatillo interruptor

11

13

Kerf plate screw

Vis de la plaquette amovible

Tornillo de la placa de corte

Page 3

l'outil avec le doigt sur l'interrupteur ni brancher un outil dont l'interrupteur est en position

sous tension.

• Enlever les clés de réglage avant de mettre l'outil sous tension. Une clé qui est laissée

sur une pièce rotative de l'outil présente des risques de blessures.

• Ne pas dépasser sa portée. Garder son équilibre en tout temps. On s'assure d'une

meilleure maîtrise de l'outil dans des situations imprévues grâce à une position stable et un

bon équilibre.

• Porter de l'équipement de sécurité. Toujours porter des lunettes de sécurité. Dans

certaines conditions, il faut porter des masques respiratoires, des chaussures

antidérapantes, un casque de sécurité ou des protège-tympans.

UTILISATION ET ENTRETIEN DE L'OUTIL

• Utiliser des pinces de serrage ou de tout autre moyen pratique afin de fixer et de

soutenir la pièce à ouvrer sur une plate-forme stable. La pièce est instable lorsqu'elle

est retenue par la main ou le corps de l'utilisateur. Cela présente des risques de perte de

maîtrise de l'outil.

• Ne pas forcer l'outil. Utiliser l'outil approprié à la tâche. L'outil approprié fonctionne

mieux et sûrement lorsqu'on s'en sert à son rendement nominal.

• Ne pas se servir de l'outil lorsque l'interrupteur est défectueux. Le cas échéant, l'outil

est dangereux et il faut le réparer.

• Débrancher l'outil de la source d'alimentation avant de le régler, d'en remplacer les

accessoires ou de le ranger. On minimise de la sorte le risque de démarrage accidentel de

l'outil.

• Ranger l'outil hors de portée des enfants et de toute autre personne qui n'en connaît

pas le fonctionnement. L'outil est dangereux entre les mains de ces personnes.

• Prendre soin des outils. S'assurer que les outils de coupe sont tranchants et propres.

Des outils bien entretenus à arêtes tranchantes ont moins tendance à se coincer et ils se

maîtrisent mieux.

• Vérifier l'alignement et les attaches des pièces mobiles, le degré d'usure des pièces

ainsi que tout autre facteur susceptible de nuire au bon fonctionnement de l'outil.

Faire réparer un outil endommagé avant de s'en servir. Des outils mal entretenus sont la

cause de nombreux accidents.

• Utiliser seulement les accessoires recommandés par le fabricant. Des accessoires qui

conviennent à un outil peuvent présenter des risques avec un autre outil.

ENTRETIEN

• Confier l'entretien de l'outil seulement à du personnel qualifié. Le non-respect de la

présente directive présente des risques de blessures.

• Lors de l'entretien de l'outil, utiliser seulement des pièces de rechange identiques.

Respecter les consignes relatives à l'entretien du présent guide d'utilisation. Il y a

risque de secousses électriques ou de blessures lorsqu'on utilise des pièces non autorisées

ou lorsqu'on ne respecte pas les consignes relatives à l'entretien.

CONSIGNES DE SÉCURITÉ PARTICULIÈRES

DANGER! Garder les mains éloignées des zones de coupe et de la lame. Toujours

tenir l’outil en plaçant une main sur la poignée auxiliaire ou le carter du moteur; on

protège ses mains en les utilisant toutes les deux pour tenir l’outil.

• Toujours se placer d’un côté ou de l’autre de la lame en évitant de se tenir dans son

trajet, car la scie pourrait reculer brusquement par suite d’un REBOND. (Voir la section

«Causes du rebond et mesures préventives» du présent manuel).

• Ne pas mettre les mains sous l’ouvrage car il n’y a aucune protection contre la lame à cet

endroit.

• Vérifier le protège-lame inférieur afin de s’assurer qu’il soit bien fermé avant d’utiliser

l’outil; ne pas faire fonctionner ce dernier si le protège-lame ne se déplace pas

librement ou s’il ne se ferme pas instantanément. Ne jamais le bloquer en position

ouverte. Si on échappe la scie, soulever le protège-lame inférieur au moyen du levier

d’escamotage et le vérifier afin de s’assurer qu’il n’y ait aucun dommage, qu’il se déplace

librement et qu’il n’entre pas en contact avec la lame ou toute autre pièce de l’outil, quel que

soit l’angle et la profondeur de coupe.

• S’assurer que le ressort du protège-lame inférieur soit en bon état de

fonctionnement; sinon, on doit lui faire subir un entretien avant d’utiliser l’outil. Le

protège-lame peut être difficile à déplacer en présence de pièces endommagées, de dépôts

gommeux ou de débris accumulés.

• On ne doit escamoter manuellement le protège-lame inférieur que pour réaliser une

coupe spéciale, complexe ou à partir de l’intérieur d’un matériau. Pour ce faire, on

doit le soulever au moyen du levier d’escamotage, relâchant ce dernier dès que la

lame mord dans l’ouvrage. Le protège-lame s’escamote automatiquement pour tous les

autres types de coupe.

• Toujours s’assurer que le protège-lame inférieur recouvre la lame avant de déposer la

scie sur le plancher ou sur un établi, car, sans protection, une lame qui tourne encore fait

reculer la scie, coupant tout ce qui se trouve sur son passage. Il est en outre bon de savoir

combien de temps la lame prend pour s’arrêter une fois l’interrupteur relâché.

• Ne JAMAIS tenir l’ouvrage dans ses mains ou le placer de travers sur ses jambes pour

le couper. Il est important de soutenir l’ouvrage correctement afin d’éviter d’exposer des

parties du corps à la lame, de coincer cette dernière ou encore, de perdre la maîtrise de

l’outil.

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsqu’il risque d’entrer en

contact avec des fils cachés ou son propre cordon, car de tels contacts peuvent mettre

les pièces métalliques de l’outil sous tension, engendrant des risques de choc électrique.

• Toujours utiliser un guide de refend ou de bord droit lorsqu’on effectue une coupe en

long afin d’assurer la précision de cette dernière et d’éviter de coincer la lame.

• Toujours utiliser une lame munie d’un arbre dont les orifices sont de dimension et de

forme appropriées (ronds ou en losanges); les lames qui ne correspondent pas aux

éléments de fixation de la scie tourneront de manière excentrique, faisant perdre la maîtrise

de l’outil.

• Ne jamais utiliser de rondelles ou de boulons endommagés ou autres que ceux qui ont

été conçus pour la scie, afin d’obtenir un rendement optimal et de travailler en toute sécurité.

AVERTISSEMENT : ne pas utiliser cet outil pour effectuer l’élagage d’arbres ou de

feuillage.

CAUSES DU REBOND ET MESURES PRÉVENTIVES

• Le rebond est une réaction soudaine de l’outil causée par une lame pincée, bloquée ou mal

alignée, occasionnant la perte de maîtrise de la scie, qui se soulève et se détache de

l’ouvrage en direction de l’opérateur.

• Lorsque la lame reste coincée ou est immobilisée par une entaille qui se referme, l’arrêt de la

lame et la réaction du moteur entraîne un recul brusque de l’outil vers l’opérateur.

• Si la lame se tord ou est mal alignée, les dents arrière peuvent s’engager sur le dessus de

l’ouvrage, faisant grimper la lame hors de l’entaille et rebondir l’outil en direction de

l’opérateur.

• Le rebond découle d’une mauvaise utilisation ou du mauvais fonctionnement de l’outil; on

peut l’éviter en prenant les précautions suivantes.

a.Tenir fermement l’outil des deux mains et placer le corps et les bras de manière à

pouvoir maîtriser les effets du REBOND; le rebond peut être maîtrisé si l’opérateur prend

les précautions nécessaires.

b.Lorsque la lame se coince ou qu’on veut interrompre une coupe pour quelque raison

que ce soit, relâcher l’interrupteur à gâchette et maintenir la scie immobile dans

l’ouvrage, jusqu’à ce que la lame s’arrête complètement. Ne jamais tenter de retirer la

scie de l’ouvrage ou de la tirer vers soi avant que la lame ne se soit immobilisée

complètement afin d’éviter le REBOND. Vérifier l’ouvrage afin de déterminer la cause du

coincement et de prendre les mesures correctives qui s’imposent.

c.Lorsqu’on remet la scie en marche, centrer la lame dans l’entaille et s’assurer que les

dents ne soient pas engagées dans l’ouvrage. Si la lame se coince, la scie peut grimper

hors de l’entaille ou faire un REBOND lorsqu’on la redémarre.

d.Soutenir les grands panneaux afin d’éviter autant que possible de coincer la lame et

d’engendrer un REBOND. Les grands panneaux tendent à s’affaisser sous leur poids et

doivent être soutenus de chaque côté, près de la ligne de coupe et du bord du panneau.

e.Ne pas utiliser de lames usées ou endommagées, car celles-ci produisent des entailles

plus étroites, ce qui peut causer une friction excessive, coincer la lame et engendrer un

rebond.

f. Bien verrouiller les leviers de réglage de profondeur et d’angle de biseau avant

d’amorcer une coupe; si ces leviers se déplacent durant la coupe, la lame peut se coincer

et entraîner un REBOND.

g.On doit faire particulièrement attention lorsqu’on effectue une coupe «interne» dans

un mur ou endroit difficile à voir, car la lame peut couper des objets cachés qui risquent

d’occasionner un REBOND.

CONSERVER CES DIRECTIVES

CONSIGNES DE SÉCURITÉ ADDITIONNELLES CONCERNANT LES

SCIES CIRCULAIRES

AVERTISSEMENT : certains outils électriques, tels que les sableuses, les scies, les

meules, les perceuses ou certains autres outils de construction, peuvent produire de la

poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des

malformations congénitales ou pouvant être nocifs pour le système reproductif. Parmi ces

produits chimiques, on retrouve :

MESURES DE SÉCURITÉ

AVERTISSEMENT : Lire et comprendre toutes les directives. Le non-respect de toutes

les directives suivantes présente des risques de secousses électriques, d'incendie ou de

blessures graves.

CONSERVER CES MESURES.

ZONE DE TRAV AIL

• S'assurer que la zone de travail est propre et bien éclairée. Des établis encombrés et

des endroits sombres présentent des risques d'accidents.

• Ne pas utiliser des outils électriques en présence de vapeurs explosives (comme

celles dégagées par des liquides, des gaz ou des poussières inflammables). Les

étincelles générées par le moteur des outils électriques peuvent enflammer les poussières

ou les vapeurs.

• Éloigner les curieux, les enfants et les visiteurs de la zone de travail lorsqu'on utilise

un outil électrique. Une distraction peut entraîner la perte de maîtrise de l'outil.

MESURES DE SÉCURITÉ RELATIVES À L'ÉLECTRICITÉ

• Les outils à double isolation comportent une fiche polarisée (une lame plus large que

l'autre). La fiche n'entre que d'une façon dans une prise polarisée. Lorsque la fiche

n'entre pas à fond dans la prise, essayer de nouveau après avoir inversé les broches

de la fiche. Si la fiche n'entre toujours pas dans la prise, communiquer avec un

électricien certifié afin de faire installer une prise polarisée. Ne modifier en aucune

façon la fiche. La double isolation élimine le besoin d'un cordon trifilaire mis à la terre et

d'un système d'alimentation mis à la terre.

• Éviter de toucher à des surfaces mises à la terre comme des tuyaux, des radiateurs,

des cuisinières et des réfrigérateurs. Les risques de secousses électriques sont plus

élevés si le corps de l'utilisateur est mis à la terre.

• Protéger les outils électriques de la pluie ou des conditions mouillées. Une infiltration

d'eau dans l'outil augmente les risques de secousses électriques.

• Manipuler le cordon avec soin. Ne jamais se servir du cordon afin de transporter

l'outil ni tirer sur le cordon pour débrancher l'outil. Éloigner le cordon des sources de

chaleur, des flaques d'huile, des arêtes tranchantes et des pièces mobiles.

Remplacer immédiatement les cordons endommagés. Les cordons endommagés

augmentent les risques de secousses électriques.

• Lorsqu'on utilise un outil électrique à l'extérieur, se servir d'un cordon de rallonge

prévu pour l'extérieur, portant la mention "W -A" ou "W". Ces cordons sont conçus pour

servir à l'extérieur et minimisent les risques de secousses électriques.

SÉCURITÉ PERSONNELLE

• Demeurer vigilant, prendre soin et faire preuve de jugement lorsqu'on utilise un outil

électrique. Ne pas s'en servir lorsqu'on est fatigué ou affaibli par des drogues, de

l'alcool ou des médicaments. De graves blessures peuvent résulter d'un moment

d'inattention lors de l'utilisation d'un outil électrique.

• Porter des vêtements appropriés. Éviter de porter des vêtements amples ou des

bijoux. Recouvrir la chevelure si elle est longue. Éloigner les cheveux, les vêtements

et les gants des pièces en mouvement qui peuvent les happer.

• Éviter les démarrages accidentels. S'assurer que l'interrupteur est en position hors

tension avant de brancher l'outil. Afin d'éviter les risques de blessures, ne pas transporter

RENSEIGNEMENTS IMPORTANTS

• Une lame affûtée améliore grandement le rendement.

• Une lame émoussée donne une coupe lente et inefficace.

• Toujours soutenir la pièce à couper . (Voir les figures appropriées dans le présent

guide.)

• Tilt saw forward and rest front of the shoe on material to be cut. Align so that cut will begin

at the back of the drawn rectangle.

• Using the retracting lever, retract blade guard to an upward position, with the blade just

clearing the material, start motor and gradually lower the saw into the material.

WARNING: As blade starts cutting the material, release the retracting lever immediately.

• Never tie the blade guard in a raised position.

• When the shoe rests flat on the material being cut, complete the cut in forward direction.

• Allow the blade to come to a complete stop before lifting saw from material.

• When starting each new cut, repeat the above steps.

BLADE VIEWING WINDOW (MODEL CS1020 ONLY)

Y our saw features a blade viewing window through which you can look at the blade as it cuts,

therefore enhancing cutting accuracy. Follow layout lines easily without leaning over at

awkward angles just to see the blade. To clean the window, first T urn Of f and Unplug the Saw

and then, lift up the window so that you can reach beneath it to clean with a soft cloth. If

necessary a little mild soap and water may be used. When you release the window, its

internal spring will hold it tightly against the upper guard.

WRENCH STORAGE

The blade wrench can be stored on the saw shoe as shown in Figure 13.

RIPPING

Your saw is not equipped with a rip fence. If installing a rip fence, insure the fence fits snug in

slots.

If you do not have a proper fitting fence, use a straight edge guide in contact with the edge of the

shoe to improve accuracy of cut and reduce the possibility of binding and kickback.

MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this manual) should be performed by authorized

service centers or other qualified service organizations, always using identical replacement

parts.

LUBRICATION

Black & Decker tools are properly lubricated at the factory and are ready for use.

ACCESSORIES

Recommended accessories for use with your tool are available from your local retailer.

WARNING: The use of any accessory not recommended for use with this tool could be

hazardous. Use only 7-1/4 “ (184mm) blades with 5/8” diameter arbor. Exception: 7" (175

mm) abrasive blades can be used.

When cutting metal, be careful of hot sparks which are thrown by the blade.

SERVICE INFORMATION

Black & Decker offers a full network of company-owned and authorized service locations

throughout North America. All Black & Decker Service Centers are staffed with trained

personnel to provide customers with efficient and reliable power tool service.

Whether you need technical advice, repair, or genuine factory replacement parts, contact the

Black & Decker location nearest you. To find your local service location, refer to the yellow

page directory under “Tools—Electric” or call: 1-800-544-6986.

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material

or workmanship. The defective product will be replaced or repaired at no charge in either of

two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom

it was purchased (provided that the store is a participating retailer). Returns should be made

within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the

sale). Proof of purchase may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required. Black & Decker owned and authorized Service Centers are listed under “ToolsElectric” in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights and

you may have other rights which vary from state to state and province to province. Should

you have any questions, contact the manager of your nearest Black & Decker Service

Center. This product is not intended for commercial use.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

GUIDE D’UTILISATION

Page 4

Une tension inférieure à celle indiquée pourrait entraîner une perte de puissance et une

surchauffe. Tous les outils Black & Decker sont soumis à des essais en usine; si cet outil ne

fonctionne pas, on doit d’abord vérifier l’intensité nominale du cordon d’alimentation. Cet outil

ne doit être branché que dans une prise de courant alternatif.

ASSEMBLAGE ET RÉGLAGE

RÉGLAGE DE LA PROFONDEUR DE COUPE

Régler la profondeur de coupe au moyen du levier de réglage de profondeur, conformément

aux figures 5 et 6; serrer fermement ce dernier.

RÉGLAGE DE L’ANGLE DE BISEAU

Régler l’angle de biseau (fig. 7) au moyen du bouton de réglage de l’angle de biseau et de

l’échelle de coupe en biseau, puis serrer fermement le bouton.

AVERTISSEMENT : toujours débrancher la scie de la source d’alimentation avant

d’effectuer les opérations suivantes.

INSTALLATION ET RETRAIT DE LA LAME

REMARQUE : la première fois qu’on retire le boulon de la lame de la scie avant qu’une

lame n’ait été installée, il peut s’avérer nécessaire d’utiliser la clé de réglage de lame,

et de tourner vers la gauche en donnant des petits coups secs.

Escamoter le protège-lame inférieur, puis assembler la lame et les rondelles de retenue, tel

qu’illustré à la figure 8. S’assurer que la grande surface de la rondelle soit dirigée vers la

lame. Utiliser une pièce de bois (modèles CS1000 et CS1010) ou bloquer le dispositif de

verrouillage de la broche (modèle CS1020K) pour empêcher celle-ci de tourner. Serrer

fermement la lame, tel qu’illustré à la figure 9A ou 9B. Ne jamais engager le dispositif de

verrouillage de la broche lorsque la lame tourne.

MODE D’EMPLOI

AVERTISSEMENT : afin de réduire les risques de blessures graves, on doit lire,

comprendre et suivre toutes les consignes de sécurité et les directives contenues dans le

présent manuel avant d’utiliser l’outil.

COUPES ORDINAIRES (IMPORT ANT : LIRE TOUTES LES CONSIGNES DE SÉCURITÉ

ET TOUS LES AVERTISSEMENTS CONTENUS DANS LE PRÉSENT MANUEL.)

PRENDRE LES MESURES PRÉVENTIVES QUI S’IMPOSENT POUR EMPÊCHER

L ’EFFET DE REBOND.

Débrancher l’outil, puis suivre les directives d’assemblage et de réglage prescrites. S’assurer

que le protège-lame inférieur fonctionne bien, puis sélectionner la lame qui convient au

matériau à couper. Ensuite, on doit :

• mesurer et tracer la section à couper;

• bien soutenir et fixer la pièce, conformément aux règles de sécurité;

• utiliser le matériel de sécurité approprié, conformément aux règles de sécurité;

• garder la zone de travail propre et sécuritaire, conformément aux règles de sécurité;

• insérer la fiche et fermer le dispositif de protection, en s’assurant que l’interrupteur puisse

mettre la scie en position de marche ou d’arrêt.

AVERTISSEMENT : il est important de bien soutenir la pièce et de tenir fermement la scie

afin d’éviter de perdre la maîtrise de l’outil et de subir des blessures. La figure 3 illustre la

position recommandée des mains.

INTERRUPTEUR

Pour mettre l’outil en marche, appuyer sur l’interrupteur à gâchette (fig. 10). L’outil continue

de fonctionner tant qu’on appuie sur l’interrupteur.

Relâcher l’interrupteur à gâchette pour arrêter l’outil; ce dernier n’est doté d’aucun dispositif

de verrouillage en position de marche; ne jamais le verrouiller dans cette position par

quelque moyen que ce soit.

RÉGLAGE DE LA PLAQUE AMOVIBLE (MODÈLE CS1020K SEULEMENT)

On peut régler la plaque amovible (figure 11) à zéro quand l'échelle de coupe en biseau est

elle aussi à zéro en desserrant la vis appropriée et en glissant la plaque jusqu'à la position

voulue. Aligner la marque sur la plaque avec celle tracée sur la pièce, et enfoncer la lame

dans la coupe. La plaque est dotée de réglages en biseau de zéro et de 45 degrés.

COUPE EFFECTUÉE À L’INTÉRIEUR DU MATÉRIAU (FIG. 12)

CE TYPE DE COUPE CONSISTE À TAILLER UN TROU AU MILIEU D’UNE PIÈCE SANS

EN COUPER LES CÔTÉS. POUR CE FAIRE, ON DOIT:

• mesurer et tracer la section à couper;

• pencher la scie vers l’avant et appuyer le devant du patin sur le matériau à couper, de

manière à amorcer l’entaille à l’arrière du trait de coupe;

• soulever le protège-lame au moyen du levier d’escamotage, en s’assurant que la lame

n’entre pas en contact avec le matériau; démarrer le moteur et baisser graduellement la

lame dans le matériau.

AVERTISSEMENT :dès que la lame mord dans le matériau, relâcher immédiatement le

levier d’escamotage.

• Ne jamais bloquer le protège-lame en position soulevée.

• Une fois le patin complètement à plat sur le matériau à couper, terminer la coupe en faisant

avancer la scie.

• Attendre que la lame s’immobilise complètement avant de soulever la scie hors du

matériau.

• Reprendre les étapes décrites ci-dessus chaque fois qu’on amorce une nouvelle coupe.

FENÊTRE D'INSPECTION DE LA LAME (MODÈLE CS1020 SEULEMENT)

Cette scie est munie d'une fenêtre qui permet de voir la lame pendant la coupe, ce qui

augmente la précision de cette dernière en permettant de suivre les marques de coupe sans

avoir à se pencher en position précaire. Pour la nettoyer, on doit d'abord arrêter et

débrancher l'outil, puis soulever la fenêtre afin de pouvoir la nettoyer au moyen d'un chiffon

doux. Le cas échéant, on peut aussi utiliser un peu d'eau et de savon doux. Lorsqu'on

relâche la fenêtre, son ressort interne la retient contre le protège-lame supérieur.

RANGEMENT DE LA CLÉ

On peut ranger la clé de réglage de lame sur la patin de la scie, tel qu’illustré à la figure 13.

COUPES EN LONG

La scie n’est pas munie d’un guide de refend. Si on utilise un tel guide, on doit s’assurer qu’il

puisse s’insérer adéquatement dans les fentes.

À défaut d’un guide de refend, on peut utiliser un guide de bord droit et le placer contre le

bord du patin, ce qui permettra d’améliorer la précision de la coupe sans risquer de coincer la

lame ou de causer des rebonds.

ENTRETIEN

Nettoyer l’outil au moyen d’un savon doux et d’un linge humide seulement. Ne jamais laisser

de liquide s’infiltrer à l’intérieur de l’outil ni tremper ce dernier dans un liquide quelconque.

IMPORTANT : pour assurer la SÉCURITÉ et la FIABILITÉ de cet outil, toutes les opérations

de réparation, d’entretien et de réglage (autres que celles décrites aux présentes) doivent

être effectuées par un centre de service autorisé ou qualifié; seules des pièces de rechange

identiques doivent être utilisées.

LUBRIFICATION

Les outils Black & Decker sont lubrifiés en usine et sont donc prêts à être utilisés.

ACCESSOIRES

Les accessoires recommandés pour cet outil sont vendus séparément chez un détaillant

local.

AVERTISSEMENT :l’usage d’un accessoire non recommandé peut présenter un danger.

N’utiliser que des lames de 184 mm (7 _ po) ayant un orifice d’arbre de 16 mm (5/8 po) de

diamètre; on peut aussi utiliser des lames abrasives de 175 mm (7 po).

Lorsqu’on coupe du métal, on doit se protéger contre les étincelles projetées par la lame.

INFORMATION SUR LES SERVICES

Black & Decker dispose d’un réseau complet composé de centres de service et de centres

autorisés situés partout en Amérique du Nord. Tous les centres de service Black & Decker

sont dotés de personnel qualifié en matière d’outillage électrique; ils sont donc en mesure

d’offrir à leur clientèle un service efficace et fiable.

Pour obtenir un conseil technique ou une pièce d’origine ou pour faire réparer un outil, on

peut communiquer avec le centre Black & Decker le plus près. Pour obtenir le numéro de

téléphone, consulter les pages jaunes sous la rubrique «Outils - électriques» ou composer le

1 800 544-6986.

GARANTIE COMPLÈTE DE DEUX ANS POUR USAGE RÉSIDENTIEL

Black & Decker (U.S.) Inc. garantit ce produit pour une période de deux ans contre tout

défaut de matériel ou de fabrication. Le produit défectueux sera réparé ou remplacé sans

frais, suivant l’une des deux méthodes suivantes.

La première méthode consiste en un échange seulement. On doit retourner le produit au

détaillant qui l’a vendu (pourvu qu’il s’agisse d’un détaillant participant), en respectant les

délais stipulés dans sa politique relative aux échanges (normalement de 30 à 90 jours après

la vente). Une preuve d’achat peut être requise. On doit vérifier la politique de retour du

détaillant pour tout produit retourné après le délai prescrit pour les échanges.

La deuxième méthode consiste à apporter ou à envoyer le produit (prépayé) à un centre

Black & Decker ou à un centre de service autorisé aux fins de réparation ou de

remplacement, selon notre choix. Une preuve d’achat peut être requise. Les centres Black &

• le plomb dans les peintures à base de plomb,

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie,

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (comme

l’arséniate de cuivre et de chrome).

Le risque associé à de telles expositions varie selon la fréquence avec laquelle on effectue

ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit

bien aéré et utiliser le matériel de sécurité approprié, tel un masque anti-poussières

spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres outils

électriques. Porter des vêtements de protection et nettoyer les parties exposées du

corps avec de l’eau savonneuse. S’assurer de bien se protéger afin d’éviter

d’absorber par la bouche, les yeux ou la peau des produits chimiques nocifs.

MISE EN GARDE : porter un dispositif de protection personnel anti-bruit approprié

durant l’utilisation. Sous certaines conditions et pendant toute la durée de l’utilisation, le bruit émanant de ce produit pourrait contribuer à la perte d’audition.

• Si le protège-lame inférieur s’accroche sur une surface sous l’ouvrage, on risque de

perdre momentanément la maîtrise de l’outil;la scie peut alors se soulever partiellement

et sortir de l’ouvrage, augmentant les risques de torsion de la lame. S’assurer qu’il y ait

suffisamment de jeu sous l’ouvrage.

• Au besoin, on peut soulever manuellement le protège-lame au moyen du levier

d’escamotage.

• MAINTENIR LES LAMES PROPRES ET BIEN AIGUISÉES. Maintenir les lames aiguisées

en tout temps afin de réduire au minimum les risques de calage et de rebond. Les lames

usées ou sales peuvent augmenter l’encrassement de l’outil, forçant l’opérateur à exercer

une plus grande pression sur la scie et augmentant ainsi les risques de torsion de la lame.

DANGER : GARDER LES MAINS ÉLOIGNÉES DES ZONES DE COUPE. Garder les

mains éloignées des lames. Ne jamais mettre les mains devant ou derrière le trajet de la

lame durant la coupe. Ne pas mettre les mains sous l’ouvrage ou tenter de retirer les

sections coupées lorsque la lame tourne encore.

• SUPPORT DE GRANDS P ANNEAUX.On doit soutenir les grands panneaux, tel qu’illustré

à la figure 1 du présent manuel, afin d’éviter autant que possible de coincer la lame et de

causer des rebonds. Si la scie doit être déposée sur l’ouvrage pour effectuer une coupe

particulière, on doit l’appuyer sur la plus grande section de l’ouvrage et couper la section la

plus courte.

• N’UTILISER QUE LES LAMES ET LES COMPOSANTS APPROPRIÉS. Ne pas utiliser de

lames dont le trou central est de diamètre inapproprié. Ne jamais fixer la lame au moyen de

rondelles ou de boulons endommagés ou de dimension incorrecte. Toujours suivre les

directives d’assemblage prescrites.

• RÉGLAGES. Avant de procéder à la coupe, s’assurer que les leviers de réglage de la

profondeur et de l’angle de biseau soient bien serrés.

• BIEN FIXER ET SOUTENIR L’OUVRAGE.S’assurer que le matériau à couper soit fixé (fig.

3) et soutenu solidement, en bon équilibre, sur des appuis stables, solides et de niveau.

Soutenir l’ouvrage de manière à ce que la section la plus large du patin soit placée sur la

section solidement soutenue de l’ouvrage, non sur celle qui se détachera. Ne jamais tenir

les sections coupées avec les mains (fig. 4); la lame pourrait se coincer et causer des

REBONDS. Tenir fermement l’outil des deux mains en tout temps.

• FAIRE PREUVE DE VIGILANCE AFIN DE MAINTENIR LA MAÎTRISE DE L’OUTIL.

Toujours se placer d’un côté ou de l’autre de la lame. Toujours tenir fermement l’outil des

deux mains afin de bien le maîtriser. Ne pas déplacer les mains ou changer de position

durant la coupe. Prendre les précautions nécessaires pour ne pas subir de blessures

lorsque les sections coupées ou tout autre matériau se détachent durant la coupe.

• S’ASSURER QUE LA FENÊTRE D’INSPECTION SOIT TOUJOURS BIEN RETENUE EN

POSITION FERMÉE contre le protège-lame supérieur lorsqu’on utilise la scie (modèle

CS1020 seulement).

• DÉBRANCHER LA SCIE DE LA SOURCE D’ALIMENTATION avant de nettoyer la fenêtre

d’inspection (modèle CS1020 seulement).

AVERTISSEMENT : ne pas faire fonctionner la scie lorsque la fenêtre est endommagée

ou qu’elle refuse de se fermer contre le protège-lame supérieur. Si tel est le cas, apporter

l’outil à un centre de service Black & Decker ou à un centre de service autorisé (modèle

CS1020 seulement).

DANGER : RELÂCHER IMMÉDIATEMENT L’INTERRUPTEUR SI LA LAME RESTE

COINCÉE OU LE MOTEUR CALE.

MESURES PRÉVENTIVES CONTRE LES REBONDS

• LE REBOND EST CAUSÉ PAR le coincement, la torsion ou l’immobilisation de la lame

durant la coupe, ou par le calage du moteur de l’outil. Lorsque la lame se tord ou devient

mal alignée dans l’entaille, les dents arrière peuvent s’engager sur le dessus de l’ouvrage,

faisant grimper la lame hors de l’entaille et rebondir l’outil en direction de l’opérateur.

POUR RÉDUIRE LES RISQUES DE REBOND, ON DOIT :

• Tenir l’outil fermement des deux mains en tout temps.

• Rester vigilant afin de garder la maîtrise de l’outil.

• Bien soutenir les longs ouvrages en porte-à-faux, car ces derniers tendent à s’affaisser

sous leur poids à mesure que la coupe l’affaiblit, ce qui entraîne le coincement de la lame.

• Soutenir les grands panneaux, tel qu’illustré à la fig. 1; de tels ouvrages soutenus

seulement aux extrémités (fig. 2) risquent de causer le pincement de la lame.

• Éviter de couper des matériaux situés au-dessus de soi; ces derniers pourraient s’affaisser

et coincer la lame.

• Maintenir les lames propres et bien aiguisées.

• Toujours utiliser un guide de refend ou de bord droit pour effectuer des coupes en long;

s’assurer d’éviter que la section coupée ne s’affaisse ou se torde, ce qui pourrait entraîner

la fermeture de l’entaille et le pincement de la lame, et causer un REBOND.

• Ne pas forcer l’outil. Dans le cas de pièces de bois, tels que la présence de nœuds, la

dureté, la résilience, l’humidité et le type de bois (bois de sciage traité sous pression, bois

vert fraîchement coupé, etc.) sont autant de facteurs qui risquent de causer l’encrassement

de l’outil, entraînant ainsi le calage du moteur. Si tel est le cas, exercer une pression

moindre sur l’outil.

• Ne pas soulever l’outil hors de l’entaille lorsque la lame tourne encore.

• On doit attendre que la scie ait atteint sa vitesse maximale avant de la faire entrer en

contact avec le matériau à couper. Ne jamais la faire démarrer lorsque la lame est déjà

dans l’entaille ou placée contre le matériau; cela risque de faire caler le moteur et de causer

un rebond.

• Ne jamais tenter de soulever la scie lorsqu’on effectue une coupe en biseau afin d’éviter de

coincer la scie ou de caler le moteur.

• Toujours immobiliser l’ouvrage afin de l’empêcher de bouger durant la coupe.

• Ne pas forcer la scie vers la ligne de coupe si elle s’en éloigne afin d’éviter les risques de

REBOND. On doit plutôt arrêter l’outil, attendre qu’il s’arrête graduellement, puis le soulever

hors de l’entaille et amorcer une nouvelle coupe sur la ligne voulue.

• Placer le levier de réglage de profondeur de manière à ce qu’une dent dépasse sous

l’ouvrage, tel qu’illustré à la figure 6.

• Ne pas faire reculer la scie lorsque la lame tourne encore dans l’entaille; si la scie se tord, la

partie arrière de la lame pourrait s’enfoncer dans l’ouvrage, soulevant ainsi l’outil hors du

matériau et vers l’opérateur.

• Éviter de couper des clous; s’assurer que le bois de sciage soit exempt de toute ferrure

avant de procéder à la coupe.

L’étiquette de l’outil peut comporter les symboles suivants.

V ....................................volts A..........................ampères

Hz ..................................hertz W ........................watts

min..................................minutes ......................courant alternatif

................................courant continu

n

o........................sous vide

....................................

construction de classe II

........................borne de terre

..................................symbole d´avertissement .../min ..................tours ou courses

à la minute

MOTEUR

On doit s’assurer que l’intensité nominale du cordon d’alimentation corresponde à celle

indiquée sur la plaque signalétique; sur cette dernière, la mention «120 V c.a.» signifie que

l’outil ne doit être branché que dans une prise résidentielle standard de courant alternatif de

60 Hz et non pas dans une prise de courant continu, alors que «120 V c.a. / c.c.» signifie

que l’outil peut fonctionner sur une prise standard de 60 Hz de courant alternatif ou continu.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V De 0 à 25 De 26 à 50 De 51 à 100 De 101 à 150

240 V De 0 à 50 De 51à 100 De 101 à 200 De 201 à 300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

Page 5

REGLAS GENERALES DE SEGURIDAD

ADVERTENCIA: Lea y comprenda todas las instrucciones. No seguir todas las

instrucciones enlistadas a continuación puede resultar en choque eléctrico, incendio y(o)

lesiones personales de gravedad.

CONSERVE ESTAS INSTRUCCIONES

AREA DE TRABAJO

• Conserve su área de trabajo limpia y bien iluminada. Las bancas amontonadas y las

zonas oscuras propician los accidentes.

• No opere herramientas eléctricas en atmósferas explosivas, como en presencia de

líquidos, gases o polvos inflamables. Las herramientas eléctricas producen chispas que

pueden originar la ignición de los polvos o los vapores.

• Conserve a observadores, niños y visitantes alejados mientras opera una

herramienta eléctrica. Las distracciones pueden ocasionar que pierda el control.

SEGURIDAD ELECTRICA

• Las herramientas con doble aislamiento están equipadas con una clavija polarizada

(con una pata más ancha que la otra.) Esta clavija se acoplará únicamente en una

toma de corriente polarizada de una manera. Si la clavija no se acopla al contacto,

inviértala. Si aún así no se ajusta, comuníquese con un electricista calificado para

que le instalen una toma de corriente polarizada apropiada. El doble aislamiento

elimina la necesidad de cables con tres hilos y sistemas de alimentación con conexión a

tierra.

• Evite el contacto corporal con superficies aterrizadas tales como tuberías,

radiadores, hornos y refrigeradores. Hay un gran riesgo de choque eléctrico si su cuerpo

hace tierra.

• No exponga las herramientas eléctricas a la lluvia o a condiciones de mucha

humedad. El agua que se introduce en las herramientas aumenta el riesgo de descargas

eléctricas.

• No maltrate el cable. Nunca tome el cable para transportar una herramienta ni para

desconectarla de la toma de corriente. Consérvelo alejado de calor aceite, bordes

afilados o piezas móviles. Cambie inmediatamente los cables dañados. Los cables

dañados aumentan el riesgo de choque eléctrico.

• Cuando opere una herramienta eléctrica a la intemperie, utilice una extensión

marcada "W-A" o "W". Estas extensiones están clasificadas para uso a la intemperie y

para reducir el riesgo de choques eléctricos.

SEGURIDAD PERSONAL

• Esté alerta, concéntrese en lo que está haciendo. Recurra al sentido común cuando

opere una herramienta eléctrica. No opere ninguna herramienta si se encuentra

fatigado o bajo la influencia de drogas, alcohol o medicamentos. Un momento de

desatención mientras se operan herramientas eléctricas puede ocasionar lesiones graves.

• Vístase de manera adecuada. No tenga puestas ropas o artículos de joyería flojos.

Cubra su cabello si lo tiene largo. Conserve su cabello, sus ropas y guantes alejados

de las piezas móviles. Las piezas de vestir flojas, las joyas y el cabello largo pueden

resultar atrapados por las piezas móviles.

• Evite el encendido accidental. Asegúrese que el interruptor esté en posición de

apagado antes de conectar. Sostener una herramienta con el dedo en el interruptor o

conectarla sin fijarse si el interruptor está en posición de encendido propicia los accidentes.

• Retire las llaves de ajuste antes de encender la herramienta. Una llave que se deja en

una pieza giratoria puede ocasionar lesiones personales.

• No se sobreextienda. Conserve siempre los pies bien apoyados, al igual que el

equilibrio. La posición correcta de los pies y el equilibrio permiten controlar mejor la

herramienta en situaciones inesperadas.

• Utilice equipo de seguridad. Siempre utilice protección en los ojos. Se deben utilizar

mascarillas contra polvo, zapatos antiderrapantes, casco o protectores para los oídos para

tener las condiciones apropiadas.

USO Y CUIDADOS DE LA HERRAMIENTA

• Utilice prensas u otros medios prácticos para asegurar y apoyar la pieza de trabajo

en una plataforma estable. Sujetar las piezas con la mano o contra su cuerpo es inestable

y puede originar la pérdida de control.

• No fuerce la herramienta. utilice la herramienta apropiada para su aplicación. La

herramienta apropiada hará el trabajo mejor y de manera más segura bajo las

especificaciones para las que se diseñó.

• No utilice la herramienta si el interruptor no enciende y apaga. Cualquier herramienta

que no pueda controlarse por medio del interruptores peligrosa y debe reemplazarse.

• Desconecte la clavija de la toma de corriente antes de hacer cualquier ajuste, cambio

de accesorios o de guardar la herramienta. Tales medidas de seguridad preventivas

reducirán el riesgo de que la herramienta se encienda accidentalmente.

• Guarde las herramientas fuera del alcance de los niños y de otras personas no

capacitadas. Las herramientas son peligrosas en manos de personas no capacitadas.

• Cuide sus herramientas. Conserve las herramientas de corte afiladas y limpias. Las

herramientas que reciben un mantenimiento adecuado, con piezas de corte afiladas,

difícilmente se atascan y son más fáciles de controlar.

• Verifique la alineación de las piezas móviles, busque fracturas en las piezas y

cualesquiera otras condiciones que puedan afectar la operación de las herramientas.

Si está dañada, lleve su herramienta a servicio antes de usarla de nuevo. Muchos

accidentes se deben a herramientas con mantenimiento pobre.

• Solamente use accesorios que el fabricante recomiende para su modelo de

herramienta. Los accesorios que estén diseñados para una herramienta, pueden volverse

peligrosos cuando se emplean con otra.

SERVICIO

• El servicio a las herramientas lo debe efectuar únicamente personal calificado. El

servicio o mantenimiento realizado por personal no calificado puede originar riesgos de

lesiones.

• Cuando efectúe servicio a una herramienta, utilice únicamente refacciones idénticas.

Siga las instrucciones de la sección de Mantenimiento de este manual. El empleo de

piezas no autorizadas o no seguir las instrucciones de mantenimiento puede originar riegos

de choque eléctrico o lesiones.

REGLAS DE SEGURIDAD ESPECÍFICAS

¡PELIGRO! Mantenga las manos alejadas de la hoja y el área de corte. Mantenga

la otra mano sobre la perilla auxiliar , o cubierta del motor. Si ambas manos sostienen la

sierra, la hoja no puede cortarlas.

• Mantenga su cuerpo a un lado de la hoja de sierra, pero no en línea con la hoja. El

rebote brusco de la sierra podría hacerlo saltar hacia atrás. (Vea “Causas de rebote y

prevención del operador.”)

• No se incline por debajo de la pieza de corte. El protector no podrá protegerlo de la hoja

debajo de la pieza.

• Verifique que el protector inferior se cierra corr ectamente cada vez antes de usar. No

opere la sierra si el protector inferior no se mueve libremente y se cierra al instante.

Nunca sujete o amarre el protector inferior en la posición abierta. Si la sierra se cae

accidentalmente, el protector inferior puede torcerse. Levante el protector con el mango de

retracción y asegúrese de que se mueve libremente y no toca la hoja u otra parte, a todos

los ángulos y profundidad del corte.

• Verifique la operación y condición del resorte del pr otector inferior. Si el protector y el

resorte no operan correctamente, se les debe dar servicio antes de usar. El protector

inferior podría funcionar lentamente debido a partes dañadas, depósitos gomosos, o

acumulación de residuos.

• El protector inferior debe retractarse manualmente sólo para cortes especiales como

“Cortes internos” y “Cortes compuestos.” Levante el protector inferior con el mango

de retracción. Tan pronto como la hoja penetra el material, se debe liberar el

protector. Para todo otro tipo de aserrado, el protector inferior debe funcionar

automáticamente.

• Asegúrese siempre de que el protector inferior cubre la hoja antes de poner la sierra

sobre el banco o piso. Una hoja sin protector y aun rodando, hará que la sierra camine

hacia atrás, cortando lo que se le atraviese en el camino. Esté consciente del tiempo que le

toma a la hoja parar después de soltar el interruptor.

• NUNCA sostenga la pieza a cortar en las manos o sobre la pierna. Es importante

apoyar la pieza adecuadamente para minimizar la exposición corporal, el trabado de la hoja

o pérdida de control.

• Sostenga la herramienta por las superficies de agarre con aislamiento al ejecutar una

operación donde la herramienta para corte pueda hacer contacto con el cableado

oculto o el cable de la misma. El contacto con un cable con corriente hará que las partes

expuestas de la herramienta que sean de metal, tengan corriente y proporcionen un

electrochoque al operador.

• Al hacer cortes longitudinales, utilice siempre una guía de corte o de canto recto.

Esto mejora la exactitud del corte y reduce la posibilidad de que la hoja se atasque.

• Use siempre hojas de tamaño y forma adecuada para los agujeros del eje

(adiamantado versus redondo). Las hojas que no encajan en el herraje de montaje de la

sierra correrán excéntricamente, ocasionando pérdida de control.

• No use nunca arandelas o tornillos de sierra dañadas o incorrectas. Las arandelas y

tornillos de sierra fueron diseñados específicamente para óptimo rendimiento y operación

segura de la sierra.

ADVERTENCIA: No use este producto para podar árboles o follaje.

CAUSAS DEL REBOTE Y PREVENCIÓN DEL OPERADOR.

• El rebote es una reacción repentina de una hoja de sierra enganchada, atascada o

descentrada, que descontrola la sierra haciéndola elevarse fuera de la pieza de corte en

dirección hacia el operador.

• Cuando la hoja queda enganchada o retenida fuertemente por el corte cerrando el paso, la

hoja se traba y la reacción del motor impulsa a que la unidad retroceda rápidamente hacia

el operador.

• Si la hoja se tuerce o se descentra en el corte, los dientes del borde posterior de la hoja

puede penetrar dentro de la superficie de la madera haciendo que la hoja se lance fuera del

corte y salte retrocediendo hacia el operador

• El rebote es el resultado del maltrato a la herramienta y /o por procedimientos o condiciones

no apropiadas y puede evitarse tomando las precauciones adecuadas que se dan a

continuación.

a.Sostenga la sierra firmemente con las dos manos y ponga su cuerpo y su brazo en

posición que le permita resistir las fuerzas del REBOTE. El operador puede controlar las

fuerzas del rebote si se toman las precauciones del caso.

b.Cuando la hoja se atasca, o cuando usted interrumpe un corte por alguna razón,

suelte el interruptor de disparo y mantenga la sierra inmóvil dentro del material hasta

que la hoja se pare completamente. No trate nunca de quitar la sierra de la pieza de

corte o tirar la sierra hacia atrás si la hoja todavía está en movimiento. Podría ocurrir

un REBOTE. Investigue la causa de atascamiento de la hoja. y tome las medidas

correctivas para eliminarla.

c.Al volver a arrancar la sierra dentro de la pieza de corte, centre la hoja en el corte y

verifique que los dientes de la sierra no están enganchados en el material. Si la hoja

se atascara, ésta podría salirse o REBOTAR de la pieza de corte al momento de volver a

arrancar la sierra.

d.Dé apoyo a paneles grandes para minimizar el riesgo de presión y REBOTE de la hoja.

Los paneles grandes tienden a doblegarse por su propio peso. Se debe poner apoyos

debajo del panel en ambos lados, cerca de la línea de corte y del borde del panel.

e.No use hojas sin filo o dañadas. Hojas sin filo o mal fijadas producen un corte estrecho y

fricción excesiva, atascamiento de la hoja y rebote.

f. Las palancas de bloqueo para el ajuste de profundidad y biselado deben estar

sólidamente apretados antes de hacer el corte. Si el ajuste de la hoja se desplaza

mientras usted corta, puede atascarse y REBOTAR.

g.Tenga gran precaución al hacer un corte interno en paredes existentes u otras áreas

ciegas. La hoja proyectada puede cortar objetos que ocasionen REBOTE. Guarde estas

instrucciones.

GUARDE ESTAS INSTRUCCIONES

REGLAS DE SEGURIDAD ADICIONALES: SIERRAS CIRCULARES

ADVERTENCIA: El polvo creado al lijar, aserrar, pulir, taladrar o realizar otras actividades

de la construcción, contiene substancias químicas que se sabe producen cáncer, defectos de

nacimiento u otros defectos del sistema reproductor. Algunos ejemplos de esos productos

químicos son:

• El plomo de las pinturas a base de plomo,

• La sílice cristalina de los ladrillos, del cemento y de otros productos de albañilería, y

• El arsénico y el cromo de la madera tratada químicamente (CCA).

El riesgo que se corre a causa del contacto con esos productos varía según la frecuencia con

que usted realice este tipo de trabajos. Con el fin de reducir su exposición a esas substancias

químicas, trabaje en un área bien ventilada y utilice un equipo de seguridad reglamentario, tal

como una máscara contra el polvo especialmente diseñada para filtrar partículas microscópicas.

• Evite el contacto prolongado con el polvo proveniente del lijado, aserrado, amolado y

taladrado eléctrico y otras actividades de construcción. Use vestimenta protectora y

lave todas las áreas expuestas con agua y jabón. De entrar polvo en sus ojos, boca, o

que este permanezca sobre su piel puede promover la absorción de químicos

dañinos.

ATENCIÓN: Use protección auditiva apropiada cuando usa la herramienta. Bajo ciertas condiciones y el tiempo que se usa la herramienta, el ruido proveniente de este producto podría contribuir a pérdida auditiva.

• Si el protector inferior queda enganchado sobre una superficie por debajo del

material que se está cortando puede reducir momentáneamente el control del

operador. La sierra puede elevarse parcialmente fuera del corte aumentando así la posible

torcedura de la hoja. Asegúrese de tener espacio suficiente debajo de la pieza a cortar.

• Use la palanca de retracción cuando es necesario levantar el protector inferior

manualmente.

• MANTENGA LAS HOJAS LIMPIAS Y AFILADAS. Las hojas afiladas minimizan el

atascamiento y el rebote. Usar hojas sin filo y/o sucias va en menoscabo de la eficiencia de

la sierra, lo que hace que el operador arremeta con más fuerza y provoque torceduras a la

hoja.

PELIGRO: MANTENGA LAS MANOS ALEJADAS DEL ÁREA DE CORTE. Mantenga

las manos alejadas de las hojas. Nunca coloque las manos delante o detrás del recorrido de

la hoja mientras corta. No se incline debajo de la pieza de corte mientras la hoja está

girando. No trate de quitar material cortado cuando la hoja está en movimiento.

• DÉ APOYO A LOS PANELES GRANDES. Los paneles grandes deben tener un soporte

como se ilustra (Fig. 1) en este manual para minimizar el riesgo de hoja enganchada y

rebote. Cuando la operación de corte requiere que la sierra descanse sobre la pieza de

corte, ésta deberá descansar sobre la porción más grande mientras se corta la porción

menor.

• USE SÓLO HOJAS Y SUS COMPONENTES IDÓNEOS AL MONTAR LAS HOJAS. No

use hojas con agujeros de tamaño incorrecto. No use nunca arandelas o tornillos de hoja

defectuosos. Siga los procedimientos para montar las hojas.

• AJUSTES. Antes de cortar asegúrese de que los ajustes de profundidad y biselados están

sólidamente fijados.

• APOYE Y AFINQUE EL TRABAJO ADECUADAMENTE. Asegúrese de que el material a

cortar está bien afianzado (Fig. 3) y sólidamente apoyado y balanceado sobre una

superficie fuerte, estable y nivelada. Apoye la pieza de manera que la porción más ancha de

la calza está puesta sobre la porción del material que no se cae después de haber hecho el