9830B Series

USER MANUAL

Model: 9832B, 9833B

High Power Programmable AC Power Sources

1

1 Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must

be followed during all phases of operation, service, and repair of this instrument.

Before applying power to this instrument:

Read and understand the safety and operational information in this manual.

Apply all the listed safety precautions.

Verify that the voltage selector at the line power cord input is set to the correct line

voltage. Operating the instrument at an incorrect line voltage will void the warranty.

Make all connections to the instrument before applying power.

Do not operate the instrument in ways not specified by this manual or by B&K Precision.

Failure to comply with these precautions or with warnings elsewhere in this manual violates the

safety standards of design, manufacture, and intended use of the instrument. B&K Precision

assumes no liability for a customer’s failure to comply with these requirements.

Category rating

The IEC 61010 standard defines safety category ratings that specify the amount of electrical

energy available and the voltage impulses that may occur on electrical conductors associated

with these category ratings. The category rating is a Roman numeral of I, II, III, or IV. This rating

is also accompanied by a maximum voltage of the circuit to be tested, which defines the voltage

impulses expected and required insulation clearances. These categories are:

Category I (CAT I): Measurement instruments whose measurement inputs are not intended to

be connected to the mains supply. The voltages in the environment are typically derived from a

limited-energy transformer or a battery.

Category II (CAT II): Measurement instruments whose measurement inputs are meant to be

connected to the mains supply at a standard wall outlet or similar sources. Example

measurement environments are portable tools and household appliances.

Category III (CAT III): Measurement instruments whose measurement inputs are meant to be

connected to the mains installation of a building. Examples are measurements inside a

building's circuit breaker panel or the wiring of permanently-installed motors.

Category IV (CAT IV): Measurement instruments whose measurement inputs are meant to be

connected to the primary power entering a building or other outdoor wiring.

i

Do not use this instrument in an electrical environment with a higher category rating than what

is specified in this manual for this instrument.

You must ensure that each accessory you use with this instrument has a category rating equal

to or higher than the instrument's category rating to maintain the instrument's category rating.

Failure to do so will lower the category rating of the measuring system.

Electrical Power

This instrument is intended to be powered from a CATEGORY II mains power environment. The

mains power should be between 190 V to 250 V RMS. Use only the power cord supplied with

the instrument and ensure it is appropriate for your country of use.

Ground the Instrument

To minimize shock hazard, the instrument chassis and cabinet must be connected to an

electrical safety ground. This instrument is grounded through the ground conductor of the

supplied, three-conductor AC line power cable. The power cable must be plugged into an

approved three-conductor electrical outlet. The power jack and mating plug of the power cable

meet IEC safety standards.

Do not alter or defeat the ground connection. Without the safety ground connection, all

accessible conductive parts (including control knobs) may provide an electric shock. Failure to

use a properly-grounded approved outlet and the recommended three-conductor AC line

power cable may result in injury or death.

Unless otherwise stated, a ground connection on the instrument's rear panel is for a reference

of potential only and is not to be used as a safety ground.

Do not operate in an explosive or flammable atmosphere

ii

Do not operate the instrument in the presence of flammable gases or vapors, fumes, or finelydivided particulates.

The instrument is designed to be used in office-type indoor environments. Do not operate the

instrument

In the presence of noxious, corrosive, or flammable fumes, gases, vapors, chemicals, or

finely-divided particulates.

In relative humidity conditions outside the instrument's specifications.

In environments where there is a danger of any liquid being spilled on the instrument or

where any liquid can condense on the instrument.

In air temperatures exceeding the specified operating temperatures.

In atmospheric pressures outside the specified altitude limits or where the surrounding

gas is not air.

In environments with restricted cooling air flow, even if the air temperatures are within

specifications.

In direct sunlight.

This instrument is intended to be used in an indoor pollution degree 2 environment. The

operating temperature range is 0 °C to 40 °C and 20% to 80% relative humidity, with no

condensation allowed.

Measurements made by this instrument may be outside specifications if the instrument is used

in non-office-type environments. Such environments may include rapid temperature or

humidity changes, sunlight, vibration and/or mechanical shocks, acoustic noise, electrical noise,

strong electric fields, or strong magnetic fields.

Do not operate instrument if damaged

If the instrument is damaged, appears to be damaged, or if any liquid, chemical, or other

material gets on or inside the instrument, remove the instrument's power cord, remove the

instrument from service, label it as not to be operated, and return the instrument to B&K

Precision for repair. Notify B&K Precision of the nature of any contamination of the instrument.

Clean the instrument only as instructed

iii

Do not clean the instrument, its switches, or its terminals with contact cleaners, abrasives,

lubricants, solvents, acids/bases, or other such chemicals. Clean the instrument only with a

clean dry lint-free cloth or as instructed in this manual.

Not for critical applications

This instrument is not authorized for use in contact with the human body or for use as a

component in a life-support device or system.

Do not touch live circuits

Instrument covers must not be removed by operating personnel. Component replacement and

internal adjustments must be made by qualified service-trained maintenance personnel who

are aware of the hazards involved when the instrument's covers and shields are removed.

Under certain conditions, even with the power cord removed, dangerous voltages may exist

when the covers are removed. To avoid injuries, always disconnect the power cord from the

instrument, disconnect all other connections (for example, test leads, computer interface

cables, etc.), discharge all circuits, and verify there are no hazardous voltages present on any

conductors by measurements with a properly-operating voltage-sensing device before touching

any internal parts. Verify the voltage-sensing device is working properly before and after

making the measurements by testing with known-operating voltage sources and test for both

DC and AC voltages. Do not attempt any service or adjustment unless another person capable

of rendering first aid and resuscitation is present.

Do not insert any object into an instrument's ventilation openings or other openings.

Hazardous voltages may be present in unexpected locations in circuitry being tested when a

fault condition in the circuit exists.

Fuse replacement

Fuse replacement must be done by qualified service-trained maintenance personnel who are

aware of the instrument's fuse requirements and safe replacement procedures. Disconnect the

instrument from the power line before replacing fuses. Replace fuses only with new fuses of

the fuse types, voltage ratings, and current ratings specified in this manual or on the back of the

iv

instrument. Failure to do so may damage the instrument, lead to a safety hazard, or cause a

fire. Failure to use the specified fuses will void the warranty.

Servicing

Do not substitute parts that are not approved by B&K Precision or modify this instrument.

Return the instrument to B&K Precision for service and repair to ensure that safety and

performance features are maintained.

For continued safe use of the instrument

Do not place heavy objects on the instrument.

Do not obstruct cooling air flow to the instrument.

Do not place a hot soldering iron on the instrument.

Do not pull the instrument with the power cord, connected probe, or connected test

lead.

Do not move the instrument when a probe is connected to a circuit being tested.

v

This product is subject to Directive 2002/96/EC of the

European Parliament and the Council of the European

Union on waste electrical and electronic equipment

(WEEE), and in jurisdictions adopting that Directive, is

marked as being put on the market after August 13, 2005,

and should not be disposed of as unsorted municipal waste.

Please utilize your local WEEE collection facilities in the

disposition of this product and otherwise observe all

applicable requirements.

Compliance Statements

Disposal of Old Electrical & Electronic Equipment (Applicable in the European

Union and other European countries with separate collection systems)

CE Declaration of Conformity

This instrument meets the requirements of EMC Directive 2014/30/EU Electromagnetic

Compatibility Directive and the following standards.

EMC Directive

- EN 61326-1:2013 Class A

- EN 61326-2-1:2013

- EN 61000-3-12:2011

- EN 61000-3-11:2000

- EN 61326-1:2013 (industrial locations)

- EN 610000-4-2:2009

- EN 610000-4-3:2006+A1:2008+2010

- EN 610000-4-4:2012

- EN 610000-4-5:2014

- EN 610000-4-6:2010

- EN 610000-4-8:2010

- EN 610000-4-34:2007+A1:2009

vi

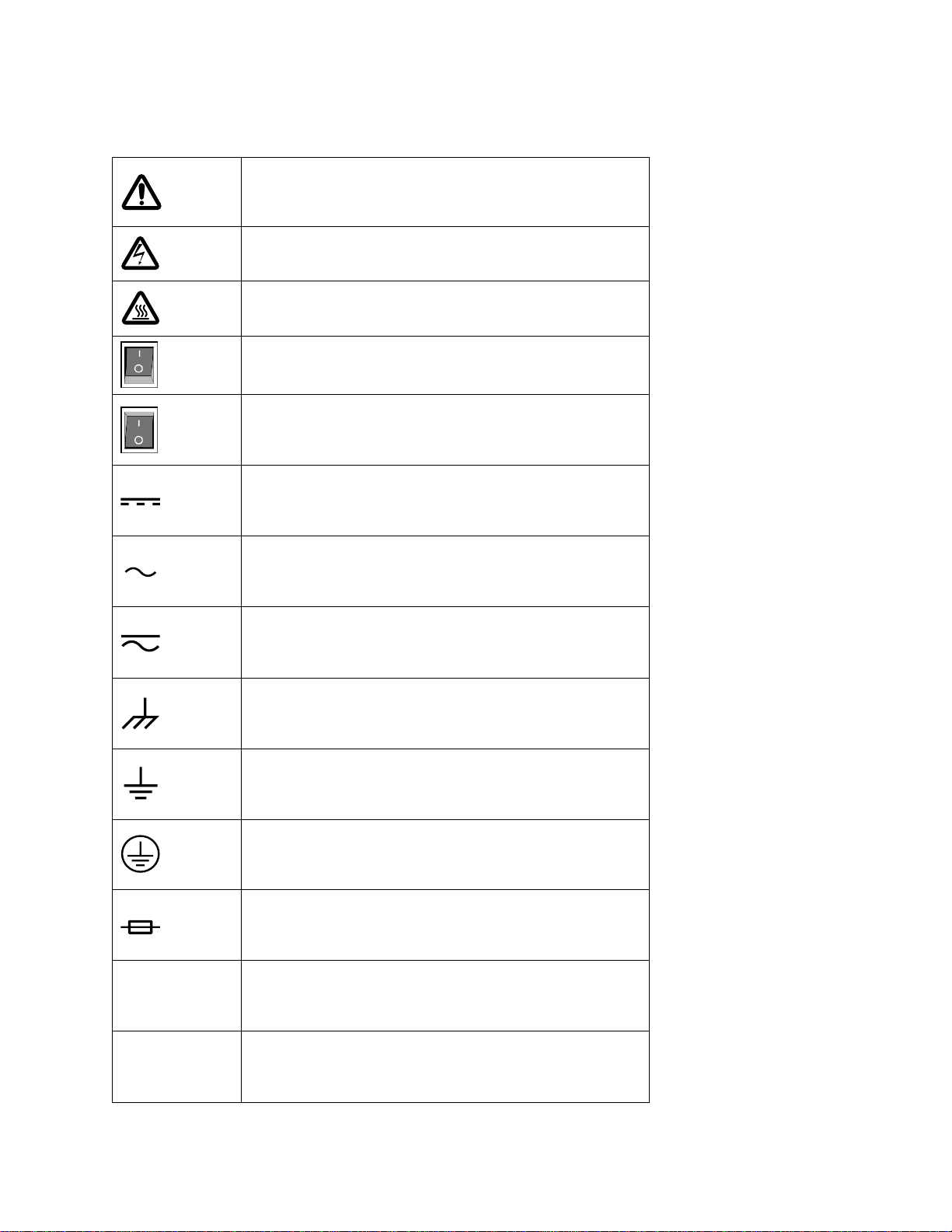

Refer to the user manual for warning information

to avoid hazard or personal injury and prevent

damage to instrument.

Electric Shock hazard

Hot surface

On (Power). Press the “I” at the top of the power

switch to turn the instrument ON.

Off (Power). Press the “O” at the bottom of the

power switch to turn the instrument off.

Direct current (DC)

Alternating current (AC)

Direct and alternating current (DC + AC)

Chassis (earth ground) symbol

Ground terminal

Protective earth ground

Fuse Symbol

CAT I

(1000V)

IEC Measurement Category I. Inputs may be

connected to mains (up to 1000 VAC) under

Category I overvoltage conditions.

CAT II

(300V)

IEC Measurement Category II. Inputs may be

connected to mains (up to 300 VAC) under

Category II overvoltage conditions.

Safety Symbols

vii

CAUTION indicates a hazardous situation which, if

not avoided, will result in minor or moderate injury

WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury

DANGER indicates a hazardous situation which, if

not avoided, will result in death or serious injury.

NOTICE is used to address practices not related to

physical injury.

Safety instructions (or equivalent) signs indicate

specific safety-related instructions or procedures

viii

2 Notations

TEXT – Denotes a softkey.

TEXT – Denotes a front panel key.

ix

Table of Contents

1 Safety Summary ............................................................................................................... i

Compliance Statements ............................................................................................................... vi

Safety Symbol ............................................................................................................................. vii

2 Notations ........................................................................................................................ ix

3 General Information ........................................................................................................ 1

3.1 Package Contents .............................................................................................................. 1

3.2 Product Dimensions ........................................................................................................... 2

3.3 Installation ......................................................................................................................... 3

3.4 Front Panel......................................................................................................................... 4

3.5 Rear Panel .......................................................................................................................... 6

4 Display Overview ............................................................................................................ 7

4.1 Display Description ............................................................................................................ 7

5 Getting Started.............................................................................................................. 10

5.1 Input Power Requirements ............................................................................................. 10

5.1.1 North American Split Phase Power .................................................................... 10

5.1.2 Fuse .................................................................................................................... 12

5.2 Preliminary Check ............................................................................................................ 12

5.2.1 Power-on Procedure .......................................................................................... 12

5.2.2 Warm-up Time ................................................................................................... 13

5.2.3 Power-off Procedure .......................................................................................... 13

5.3 Sense Lines ....................................................................................................................... 13

6 Menu Tree .................................................................................................................... 15

7 Front Panel Operation ................................................................................................... 16

7.1 Configure Voltage and Frequency Output....................................................................... 16

7.1.1 Setting voltage .................................................................................................... 16

7.1.2 Setting frequency ............................................................................................... 16

7.1.3 Setting Voltage ................................................................................................... 17

7.2 Program Settings ............................................................................................................. 18

7.2.1 Step Mode .......................................................................................................... 18

7.2.2 List Mode ............................................................................................................ 20

7.2.3 Pulse Mode ......................................................................................................... 25

8 Configure Menu ............................................................................................................ 27

x

8.1 Config 1 ............................................................................................................................ 27

8.2 Config 2 ............................................................................................................................ 28

8.3 Limits ................................................................................................................................ 30

9 System Settings ............................................................................................................. 32

9.1 System Setup ................................................................................................................... 32

9.2 Communication Setup ..................................................................................................... 33

9.3 System Error .................................................................................................................... 34

9.4 System Next ..................................................................................................................... 35

9.5 Recall Default ................................................................................................................... 35

10 Save .............................................................................................................................. 37

10.1 Save Config ...................................................................................................................... 37

10.2 Save Screen ...................................................................................................................... 38

10.3 Recall Configuration ........................................................................................................ 38

11 3-Phase Operation ........................................................................................................ 40

11.1 Setup and Configuration .................................................................................................. 40

11.2 3-Phase Adapter Digital I/O Pin Definitions .................................................................... 42

11.3 3-Phase Output Wiring .................................................................................................... 43

11.4 Phase Control Software ................................................................................................... 44

11.4.1 Operation Modes Overview .............................................................................. 44

11.4.2 Setup and Configuration .................................................................................... 46

11.4.3 Three-Phase Application Mode ......................................................................... 46

11.4.4 Multi-Phase Application Mode .......................................................................... 49

12 Remote Interface Operation .......................................................................................... 53

12.1 Interface Connection ....................................................................................................... 53

12.1.1 RS232 ................................................................................................................. 53

12.1.2 USBVCP (virtual COM) ....................................................................................... 53

12.1.3 USBTMC ............................................................................................................. 54

12.1.4 GPIB ................................................................................................................... 54

12.1.5 LAN (Ethernet) ................................................................................................... 54

12.1.6 Web server ......................................................................................................... 54

13 Digital I/O ..................................................................................................................... 58

13.1 External Voltage Control.................................................................................................. 59

13.1.1 AC Couple........................................................................................................... 60

13.1.2 DC Couple .......................................................................................................... 60

13.2 Trigger In .......................................................................................................................... 60

xi

13.3 15 VDC ............................................................................................................................. 61

13.4 Output Status Detection .................................................................................................. 62

13.4.1 /SYNC ................................................................................................................. 62

13.4.2 /Fault_out .......................................................................................................... 63

13.4.3 /Transient .......................................................................................................... 63

13.5 Remote_Inhibit ................................................................................................................ 64

13.6 Tx / Rx .............................................................................................................................. 64

13.7 Event_SW ......................................................................................................................... 65

13.8 Analog input (BNC) .......................................................................................................... 66

14 Built-in Harmonic Wave................................................................................................. 68

15 Calibration .................................................................................................................... 83

15.1 AC Voltage Calibration ..................................................................................................... 83

15.1.1 300V range calibration ...................................................................................... 84

15.1.2 150V range calibration ...................................................................................... 85

15.1.3 DC Voltage Calibration ....................................................................................... 85

15.1.4 AC Current Calibration ....................................................................................... 86

15.1.5 Restore to Factory Default (RECALL DATA) ....................................................... 87

15.1.6 External Voltage Calibration .............................................................................. 88

16 Specifications ................................................................................................................ 91

17 LIMITED THREE-YEAR WARRANTY ................................................................................. 94

xii

3 General Information

The B&K Precision 9830B series are low distortion single phase AC power sources delivering a

maximum of 3000 VA, 300 Vrms, 30 Arms /97.5 Apk. The Output frequency is adjustable from

45 Hz to 1200 Hz. All models are capable of outputting AC, DC or AC+DC. Predefined waveforms

include sine, square, clipped sine and THD waveforms. Standard remote interface include

USBVCP and USBTMC-compliant. RS232, LAN, and GPIB interfaces are available to provide

flexibility for remote operation.

Features

Output AC, DC or AC+DC

3-Phase capability using 3 AC sources and the 3-Phase kit (TL983P-KIT)

Built-in power factor correction (PFC) circuit at the AC input

Low harmonic distortion

Power Line Disturbance simulation

Step, pulse and list modes

Adjustable phase angle control

Built-in and user definable waveforms

Digital I/O port for external trigger, remote inhibit, command completion, failure status,

Analog input for external control

Comprehensive protection modes including OVP, OCP, OTP, fan failure, key lock

3.1 Package Contents

Please inspect the instrument mechanically and electrically upon receiving it. Unpack all items

from the shipping carton, and check for any obvious signs of physical damage that may have

occurred during transportation. Report any damage to the shipping agent immediately. Save

the original packing carton for possible future reshipment. Every instrument is shipped with the

following contents:

1 x 9832B or 9833B AC Power Source

1 x AC input power cord

1 x Certificate of calibration

1 x Test report

Verify that all items above are included in the shipping container. If anything is missing, please

contact B&K Precision.

1

Note: Check that you have the most current User manual. This is available for download at

www.bkprecision.com

3.2 Product Dimensions

Figure 1 - Dimensions

2

1

Step 1

2

3

4

Step 2

5

Step 3Step 4

6

3.3 Installation

The following diagram shows how to install the optional rack mount kit.

Figure 2 - Rack Mount Kit

3

①

Power ON/OFF

②

USB disk port

③

VFD

④

Softkeys

⑤

Function keys & Indicator LEDs

⑥

Number keys

⑦

Function keys

⑧

Rotary knob

⑨

Direction keys

3.4 Front Panel

Figure 3 - Front Panel

4

Key

Definition

Frequency key, press to set the output frequency

Voltage key, press to set the output voltage

Press to lock the keyboard,

(Keyboard is locked when LED is illuminated).

Output On/Off key, press to enable/disable voltage

output, (Output is On when LED is illuminated).

to

Number key 1 to 9 for direct numeric entry.

Set the number entered to a positive or negative

value.

Main function: decimal point

Secondary function: switch from remote control to

local control

Escape key, press to escape the settings menu or

cancel the current settings

Save key, store configurations and settings into the

internal memory or a USB disk

Recall key, recall data from internal storage or

external USB disk

Enter key, press to confirm the settings change

Rotary, to adjust value or make up/down selection

(press it for ENTER function)

Up/Down/Left/Right direction keys

Confirm key, press to confirm the settings

5

⑩

AC output terminal

⑪

Remote sense terminal

⑫

ANALOG connector

⑬

DIGITAL Input /Output

⑭

LAN port

⑮

USB port (USBVCP or USBTMC)

⑯

GPIB port

⑰

Ground wire

⑱

AC input terminal

3.5 Rear Panel

Figure 4 - Rear Panel

6

4 Display Overview

The power on screen shows the model number and self-test status. The Interface, and Power

module should indicate OK. The (Real Time Clock), RTC will show the battery voltage. When the

self-test completes, the instrument will advance to the Settings and Measure screen. This

process takes approximately 7 seconds. If an error does occur, the instrument must be returned

for service.

Figure 5 - Power on screen

4.1 Display Description

At the top right of the screen the remote and output status are displayed. Each of the blue

softkeys will have a corresponding label to the left. These labels will change on each screen to

show different options. Settings Fields have a black background. Settings Fields can be selected

by using arrow keys to move to the field and press enter to select and modify the value in the

field. Press the Enter key again to confirm the change or press the Esc key to cancel the change.

7

Parameter

Description

Volts (rms)

AC output Vrms setting

Volts (DC)

DC output setting

Freq (Hz)

Output frequency setting

Sync source

Select Phase or Immed (immediate)

Phase Ctrl

Set ‘Master’ or ‘Slave’ for 3-phase operation

Phase (deg)

Phase angle setting

Figure 6 - Display Description

The instrument provides 3 display screen options for accessing commonly used measurements

and settings. Each of these screens can be selected by pressing the Display x of x softkey

repeatedly.

Display 2 of 3

This display shows all 12 power measurements and an output timer.

Figure 7 - Display 1 of 3

Table 1 – Display 1 of 3 Settings

8

Figure 8 - Display 2 of 3

Display 3 of 3

This displays shows a graphical representation of the settings, output measurements and

waveforms.

Figure 9 - Display 3 of 3

Press the ◄ ► keys to select and view V (voltage waveform) or A (current waveform). Then

press the ▲ ▼ key to change the scale until the complete waveform is visible.

9

Connection of the 9832B or 9833B to an AC power source should be made by a

qualified electrician or other qualified personnel. Incorrect wiring may damage the

source or cause a fire hazard.

The included AC power cord is safety certified for this instrument operating in the

rated range. If an extension cable is added, be sure that it can meet the required

power ratings for this instrument. Any misuse with wrong or unsafe cables will

void the warranty.

5 Getting Started

Before connecting and powering up the instrument, please review and go through the

instructions in this chapter.

5.1 Input Power Requirements

The AC input accepts line voltage input within:

Voltage: 190 V – 250 V

Frequency: 47 Hz – 63 Hz

Maximum power consumption: 9832B: 2500 VA; 9833B: 3800 VA

Before connecting to an AC outlet or external power source, make sure that the power switch is

in the OFF position and verify that the AC power cord, including the extension line, is

compatible with the rated voltage/current and that there is sufficient circuit capacity for the

power supply.

Follow the illustrations below to connect the new AC power cord to the AC input of the source

in the rear panel.

5.1.1 North American Split Phase Power

Split phase is commonly used in North American to provide 208 to 240 Volts. This

requires two wires that are both hot. For example 110 V and, 110 V resulting in 220 V

across them. The included cable may be used in most regions by adding a band of blue

electrical tape on each end of the white wire to identify both the black and white with

blue band as hot. The green trace yellow wire is always used for ground and must be

connected properly. Check with your local Authority Having Jurisdiction for clarification.

The power cable that is shipped with the instrument is preassembled from the factory.

The following instruction will provide information for changing the power cable for split

phase.

1. Verify that the source power in your facility can provide the minimum voltage and

10

Remove 4 screws

current required to operate the instrument.

2. Using the power cable provided, identify the end that plugs into the instrument.

Before disassembling the black hooded connector, make a note of how the unit is

assembled from the factory so it can be correctly reassembled.

3. Remove the 4 screws from the bottom of the hooded connector as shown and place

the upper and the upper and lower hood pieces and screws to the side.

The black, white, and green wires should now be clearly visible. Use a screwdriver to

unscrew and release the white wire only.

Add a band of blue electrical tape or heat shrink to each end of the white wire.

1. Return the white wire into the green connecter and tighten the screw. Verify all

three wires are secured in the connector.

2. Closely inspect each of the wires at the enter point of the green connector to

verify none of the copper strands are bridging over to the wrong terminal

causing a short.

3. Carefully reassemble the hood so the Latch Fingers and Caution Label are facing

11

Any disassembling of the case or fuse changes not performed by an authorized

service technician will void the warranty of the instrument.

Caution

Label

Latch

Fingers

Key

Section

Key section

up and reinstall the 4 screws into the hood. The green connector should be

locked in place.

4. Using the (2) screws provided with the cable, secure the assembled connector to

the back of the instrument as shown in Figure 10 – Securing. Note: Use only the

screws provided.

The green (trace yellow) wire connects to electrical ground (required). The black wire

connects to L (Line 1) and the white with blue band connects to N (Line 2).

5.1.2 Fuse

The factory installed fuse will meet the requirements when the instrument is operated

with the specified Input Power requirements. This source is a switching mode power

supply. The fuse installed inside should not fail under normal operation. If the fuse has

blown, it may be an indication of a more serious malfunction inside of the source. In this

event, contact B&K Precision.

5.2 Preliminary Check

5.2.1 Power-on Procedure

1. Complete the following steps to verify that the source is ready for use.

Figure 10 - Securing the power cable

2. Verify AC Input Voltage

3. Verify and check to make sure proper AC voltages are available to power the

12

Do not connect multiple power supplies in series or parallel as this may cause

damage or a malfunction.

When the AC input voltage is lower than 190 VAC, the source will activate an inner

over temperature protector and cut off the output in response to the condition. To

ensure that the entire test process can be completed smoothly, confirm that the

input AC voltage is within the specified range.

When the AC input frequency is outside the range of 47 to 63 Hz, the source will

beep. To ensure the normal operation of the source, please make sure the AC

input frequency is within the required range.

instrument. The AC voltage range must meet per the acceptable specifications.

4. Connect Power

5. Connect specified AC power cord and verify the hood is in place and correctly

secured to rear panel.

6. Press the power switch to the “|” ON position to turn ON the instrument.

It will take a few seconds before the fans power on and the self-test begins.

5.2.2 Warm-up Time

The 9830 series is fully operable upon switching the power on. However, to reach the

specified equipment accuracy, please allow the source to warm up for at least 15

minutes.

5.2.3 Power-off Procedure

When the instrument is not in use, make sure to set the front panel power switch to the

OFF position. After the power switch is turned off the internal fans will continue to run

for approximately 5-10 seconds to discharge the internal capacitors per safety

requirements. Once the discharge process is complete, the instrument will carry out an

automatic shutdown process of approximately 2-8 seconds. Do not turn the power back

on until the instrument has completed a full shut down cycle.

5.3 Sense Lines

The source can be configured as local sense or remote sense to compensate the voltage

drop of the test leads. The following diagram shows how to connect the load by local

sense or remote sense configurations.

When local sense is selected, the sense end L is connected to the output end L and

sense end N is connected to the output end N, whereas the output end L is connected to

the load end L and output end N is connected to the load end N. When this sensing

mode is selected, the wires connecting between the sense ends to the load end must be

13

as short as possible. The local sense is the default configuration. When remote sense is

selected, both the sense end L and output end L are connected to the load end L,

whereas both sense end N and output end N are connected to the load end N.

Figure - 11 Sense Lines

14

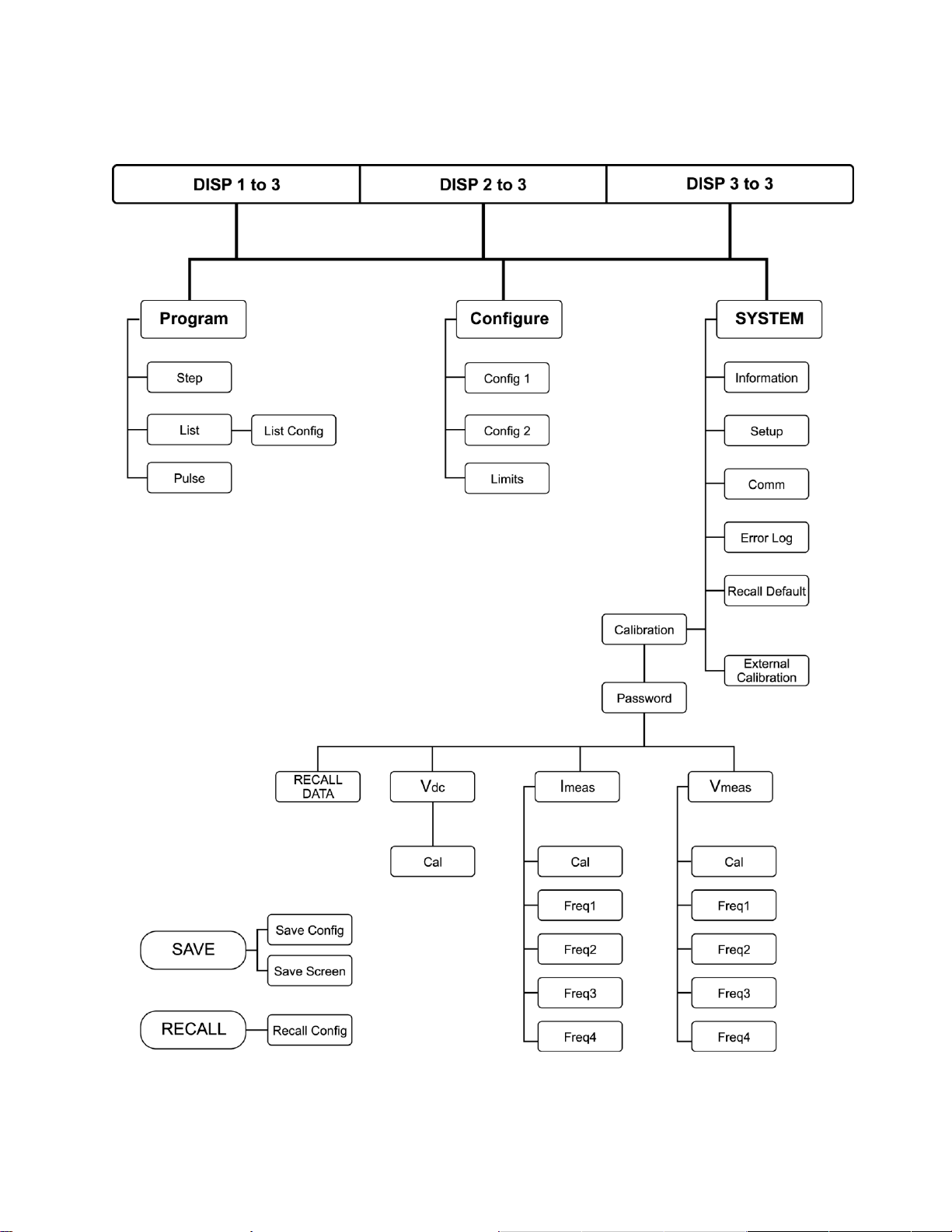

6 Menu Tree

15

NOTES:

1) The values of some settings are strings, for example, Sync Source = IMMED (or PHASE). These

settings can be set by the arrow keys (▲ ▼ ◄ ►) or the rotary knob.

2) When the output status is ON, any changes to the displayed values of Volts(rms), Volts(DC) or

FREQ are immediately reflected at the output.

3) Except for Volts(rms), Volts(DC) and FREQ, the ENTER key must be pressed to confirm the new

output value and save the new settings to memory. Changes can be cancelled by pressing the ESC

key before the ENTER key.

7 Front Panel Operation

7.1 Configure Voltage and Frequency Output

7.1.1 Setting voltage

Press VOLT or the ▲ ▼ (arrow keys) to move the cursor to Volts (rms). Then press the

ENTER key.

There are three ways to set the value of the output voltage:

1. Press the number keys 1, 1, 0, . , 0 and Enter to set Volts(rms) = 110.0 V.

2. Use the ◄ ► keys to select the hundreds digit then press the arrow keys ▲ or

▼ repeatedly until the value reaches 110.0 and press the Enter or OK key to

confirm.

3. Use ◄ ► keys to the hundreds digit then use the rotary knob until the value

reaches 110.0. Press the Enter or OK key or push in on the rotary knob to

confirm.

7.1.2 Setting frequency

Press FREQ or arrow key (▲ ▼) to move the cursor to the Freq (Hz). Then press the

ENTER or OK key.

There are three ways to set the value of output frequency:

1. Press number key 6, 0, Enter or OK to set Freq (Hz) = 60.

2. Use ◄ ► keys to the hundreds digit then press arrow keys (▲or ▼) repeatedly

until the value reaches 60. Press Enter or OK key to confirm.

Use ◄ ► keys to select the hundreds digit then rotate the rotary knob until the value

reaches 60. Press Enter or OK key or press in on the rotary knob to confirm the change.

16

Vac

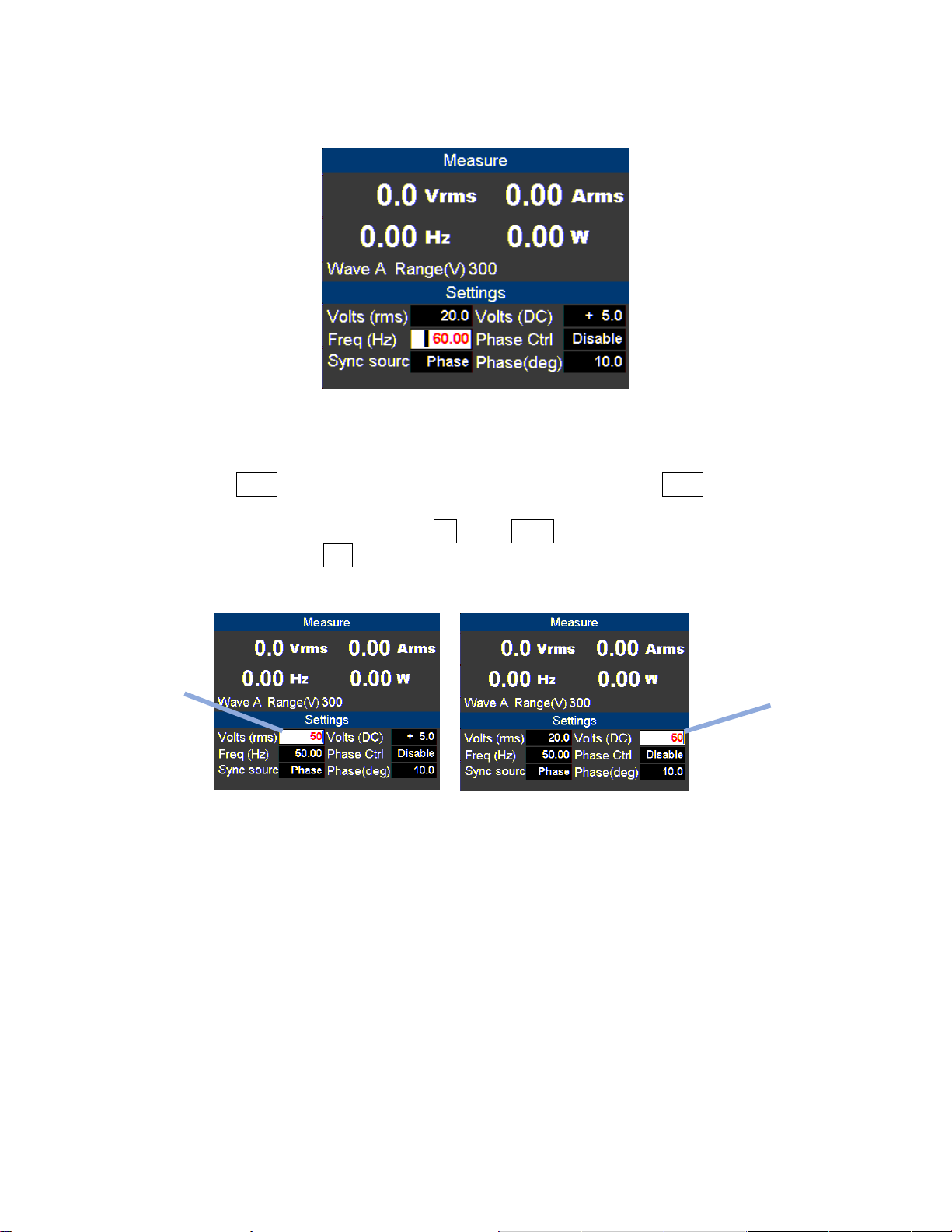

7.1.3 Setting Voltage

Press the VOLT key, and a small window will pop-up. Pressing the VOLT key again will

switch between VAC and VDC (when the coupling mode is “AC+DC”). Press the number

keys to set the value, and press the OK or the Enter key to confirm the change.

Optionally, press the ESC key to cancel the setting change.

Figure 12 - Setting Frequency

Figure 13 - Setting Voltage. Vac left, Vdc right.

17

Parameters

Range

Description

Volts (rms)

0 to 300.0 Vrms

Initial AC output voltage

dVac

0 to ±300.0 Vrms

In/decrement of VAC per

step

Volts (DC)

-424.0 to 424.0 V

Initial DC output voltage

dVdc

-424.0 to 424.0 V

Increment/decrement of

VDC per step

Freq.

43 to 1200.0 Hz

Initial output frequency

dF

±43 to 1200.0 Hz

Increment/decrement of

FREQ. per step

Set Time

0 to 100000 ms

Set the time interval of

one step

Count

1 to 99

Set how many steps to

run

Sync Source

Immed, Phase

Select the mode of

output transient phase

Phase (deg)

0.0゜ to 359.7゜

Set the angle of output

transient

7.2 Program Settings

Press the Program softkey in the Setting and Measurement page to enter Program

mode. There are three modes for the user to choose from to simulate Power Line

Disturbances. They are:

Step Output settings step-up or step-down based on user criteria.

List Change the output sequentially by individual settings included in a list.

Pulse Trigger pulse signals periodically.

7.2.1 Step Mode

Step Mode has 10 parameters that can be set by the user. The following table describes

each parameter with its range and description.

Table 2 - Step Mode Parameters

18

Parameters

Settings

Volts(rms)

40

dVac

+20

Volts(DC)

+0

dVdc

0

Freq.

50

dF

0.0

Set Time

80

Count

4

Sync Source

Phase

Phase(deg)

0.0

Step Mode Operation Steps

The following example for Step Mode waveform shows 4 steps starting at 40 volts and

increasing 20 volts at each step. The instrument will dwell for 80 ms at each step.

Press the Step softkey.

Figure 14 - Step Mode Example Output

Table 3- Step Mode Example Parameters

Figure 15 - Step Page

19

Parameters

Range

Description

List

0 to 9

Index of LIST

Infinite

ON or OFF

ON: Infinite output

OFF: Based on Repeat value

Repeat

0 to 99

Repeat sequence

Base

Time or Cycle

Select the unit for timing the

running of LIST

Sync Source

Immed or Phase

Select the mode of output

transient phase

Phase (deg)

0.0 to 359.7

Set the angle of output transient

1. Use the arrow keys (▲ ▼ ◄ ►) to move the cursor to the wanted parameter of

the STEP setting page.

2. Press the ENTER key to adjust the parameter. Then press the ENTER key again to

change its value.

3. When finished editing all the parameters, press On/Off key to activate the Step

mode.

Using an oscilloscope you should observe a wavfore as shown in Figure 16 - Oscilloscope

view of Step waveform example.

Figure 16 - Oscilloscope view of Step waveform example

The instrument will continuosly output the final waveform of Step mode until the

On/Off key is pressed.

7.2.2 List Mode

List mode is the only mode with two pages of parameters. The first page of parameters is

common to all the Second page parameters. Only one first page is needed per list. The

first page, Table 4 - List Parameters, First Page is displayed when the List softkey is

pressed and the second page, Table 5 - List Config Parameters, Second Page is displayed

when the List Config softkey is pressed.

Table 4 - List Parameters, First Page

20

Parameters

Range

Description

List No.

0 to 9

Show configuration of a LIST

Step No.

0 to 99

Show current edit step of list

Volts (rms) Start

0 to 300

Set starting AC voltage

Volts (rms) End

0 to 300

Set ending AC voltage

Volts (DC) Start

-424.0 to 424.0

Set starting DC voltage

Volts (DC) End

-424.0 to 424.0

Set ending DC voltage

Freq. (Hz) Start

43 to 1200.0

Set starting frequency

Freq. (Hz) End

43 to 1200.0

Set ending frequency

Time (ms)

0 to 999999

Set the time interval for running

the specified configuration

CYCLE

0 to 999999

Set the period for running the

specified configuration

Steps

0 to 200

Set the number of steps the

specified configuration will be

divided into

Parameters

Step 1

Step 2

Step 3

List No.

0 0 0

Step No.

0 1 2

Volts (rms) Start

80

60

40

Volts (rms) End

0 0 0

Volts (DC) Start

0 0 0

Volts (DC) End

0 0 0

Freq. (Hz) Start

50

50

50

Freq. (Hz) End

50

50

50

Time (ms)

100

60

20

Steps

5 3 2

Table 5 - List Config Parameters, Second Page

In the following example 3 new steps will be added to List No. 0.

Figure 17 - List Mode Waveform

Table 6 – Step parameters

21

Parameters

Example Settings

List

0

Infinity

OFF

Repeat

02

Base

Time

Sync Source

Phase

Phase (deg)

0.0

Table 7 - List Mode First Page

List operation pages

Press the List softkey, refer to List Parameter Table for settings details.

Figure 18 - List Mode first page

Refer to Table 6 – List Mode First Page. The first page parameters are common to all the

steps added under the second page parameters. This first page only needs to be

configured once for List 0. Use the arrow keys (▲ ▼ ◄ ►) to move the cursor to the

wanted parameter of the List page. Then press the ENTER Key to change its value.

Configure all the parameters for the List mode first page.

When all of the values for the First page have been configured, press List Config softkey

to move to the Second page. The Step No. will indicate “New” as the values have not

been stored in memory yet. Empty Step 100 and current Step 0 will be indicated in the

22

Parameters

Values

Volts (rms) Start

80

Volts (rms) End

0

Volts (DC) Start

0

Volts (DC) End

0

Freq. (Hz) Start

50

Freq. (Hz) End

50

Time (ms)

100

Steps

5

yellow boxes when no entries are stored in any List.

Figure 19 - List Mode second page

Refer to Error! Reference source not found.. Use the arrow key (▲ ▼) to move the

cursor to the wanted parameter of List Step Configuration page. Press the ENTER key to

change its value, then press the ENTER key again to confirm the change.

Figure - List 0, User Step 1 Values

After all of the values from have been entered, press the Add Step softkey to enter all

the changes in to memory and create a new step in List No. 0. The Empty Step will

change to 99 and Current Step will change to 1.

Figure 20 – List Mode Add Step

Refer to Figure 21 - List 0, Step 2 Values

23

Parameters

Values

Volts (rms) Start

60

Volts (rms) End

0

Volts (DC) Start

0

Volts (DC) End

0

Freq. (Hz) Start

50

Freq. (Hz) End

50

Time (ms)

60

Steps

3

Parameters

Settings

Volts (rms) Start

40

Volts (rms) End

0

Volts (DC) Start

0

Volts (DC) End

0

Freq. (Hz) Start

50

Freq. (Hz) End

50

Time (ms)

20

Steps

2

Volts (rms) Start

40

Volts (rms) End

0

. Use the arrow keys (▲ ▼) to move the cursor to the wanted parameter of List Step

Configuration page. Press the ENTER key to change its value, then press the ENTER key

again to confirm the change.

Figure 21 - List 0, Step 2 Values

After all of the values have been entered, press the Add Step softkey to enter these

changes in to memory and add a new step in List No. 0. The page with Empty Step field in

yellow will change to 98 and Current Step to 2.

Figure 22 - Add New Step

Table 8 - List Mode Parameters

After all of the values have been entered, press the Add Step softkey to enter these

24

Parameters

Range

Description

Volts (rms)

0 to 300.0 Vrms

Set the AC voltage of a pulse

Volts (DC)

-424.0 to 424.0 V

Set the DC voltage of a pulse

Freq.

43 to 1200.0Hz

Set the frequency of a pulse

Duty

0 to 100.0 %

Set the duty cycle for the pulse

holding (% of period time)

Period

0 to 100000ms

Set the pulse to pulse period

Count

1 to 99

Set how many pulses to generate

Sync Source

Immed, Phase

Select the mode of output

transient phase

Phase

0.0゜ to 359.7゜

Set pulse phase angle

Table 9 - Pulse Mode

ParametersParameters

Settings

Volts (rms)

100

Freq.

50

Duty (%)

25

Period(ms)

80

Count

4

Sync Source

Phase

Phase (deg)

90

changes in to memory and add a new step in List No. 0. The page with Empty Step field in

yellow will change to 97 and Current Step to 3. All of the steps 0, 1 and 2 have been

entered.

Press the ESC key to exit. Make sure Set Repeat is = to 1 and press On/Off key to activate

the List mode.

Figure 23 - Oscilloscope view of List mode waveform example

7.2.3 Pulse Mode

The following example will describe how to setup the Pulse Mode.

Table 10 – Pulse Mode Settings

25

Pulse Mode Operation Steps

1. Press Pulse softkey.

2. Use the arrow key (▲ ▼) to move the cursor to the wanted parameter.

3. Press the ENTER key to change its value then press the ENTER key again to

confirm.

Figure 24 - Pulse mode page

4. When finishing editing the parameters press the On/Off key to active the Pulse

mode.

Figure 25 - Oscilloscope view of Pulse waveform example

26

Configurations

Range

Description

Range

150 V, 300 V

Select the range of AC output voltage

Couple

AC, DC or

AC+DC

Select the coupling of output voltage

Power On State

OFF, LAST, USER

OFF: When power on, the output is OFF.

LAST: When power on, the settings will

restore to the pre-shutdown state.

USER: When power on, users need to set the

output value and status. (Volts(rms),

Volts(DC), Freq, Sync Source )

Inrush Current

Measurement

Time (ms)

0 to 10000 ms

Set the time interval to measure Inrush

current

Inrush Current

Delay Time (ms)

0 to 10000 ms

Set the delay time to measure Inrush current

8 Configure Menu

In Setting and Measure page, press Configure key to open the Configuration page. The

Configuration page includes three softkey options:

1. Config 1 (default)

2. Config 2

3. Limits

Each of these pages will be explained below with more detail.

8.1 Config 1

Configurations listed below can be edited in this Configuration 1 page.

Figure 26 - Default Configuration 1 Menu

Table 11 - Config 1 Configurations

27

Configurations

Range

Description

Waveform Select

A or B

Select to output waveform A or B

Waveform A Type

SINE, SQUA, CSIN (clipping

sine), THD0-29 (harmonic

distortion sine), USER0-4

(user designed waveform)

** SQUA, CSIN (clipping sine), THD

(harmonic distortion sine), USER

(user define waveform) only for

Frequency ≦100Hz

Waveform A Index

(waveform A clip

level (%))

0-29

(0.0 to 100.0%)

When waveform A is THD, set index

When waveform A is CSIN (clipping

sine), set the clip level %

Waveform B Type

SINE, SQUA, CSIN (clipping

sine), THD0-29 (harmonic

distortion sine), USER0-4

(user design waveform)

** SQUA, CSIN (clipping sine), THD

(harmonic distortion sine), USER

(user define waveform) only for

Frequency ≦100Hz

Waveform B Index

(waveform B clip

level (%))

0-29

(0.0 to 100.0%)

When waveform B is THD, set index

When Waveform B is configured as

a CSIN (clipping sine), set the clip

level %

Press the arrow key (▲ ▼) to move the cursor to the wanted configuration. Press

ENTER key to change its value, then press ENTER key to confirm.

Figure 27 - Configuration 1

Move the cursor to Range (V) then Press ENTER key. Press 300 V key to put the supply

in the high voltage range, then press Enter key to confirm.

Or use ▲ ▼ keys (or Rotary) to set the value of Range (V) and other configurations. Use

▲ ▼ keys (or Rotary) to choose other configurations.

8.2 Config 2

Configurations listed below can be edited in Configuration 2 page.

28

Output Timer

ON or OFF

Enable/disable the output timer.

Note: This function is available in

display 2 of 3 only.

Timer Setting

(H/M/S)

0 to 99 (hours) : 0 to 59

(minutes): 0 to 59

(seconds)

Set the timing interval of output

timer. When the output is turned

on the timer will count down to 0

and turn the output off.

External Ref.

OFF or LEVEL or AMP

Enable/disable the input of the

external reference signal

OFF: Function disable.

LEVEL: Input DC reference voltage

(0 to ±10 V) via the digital IO

connector to control output

voltage.

AMP: Input reference waveform to

BNC connector (-6 to +6 V) to

control output waveform.

Note: If the input frequency is over

1200 Hz, the amplitude of output

will diminish.

Remote Inhibit

ON or OFF

Remote shutdown function.

Transient

ON or OFF

When output voltage is changed,

the instrument will output a pulse

signal on “Trans” at the digital I/O

terminal.

29

Configurations

Range

Description

Volts (rms)

0.0 to 306.0 Vrms

Set the limit value of AC output voltage

Volts (Vp) +

0.0 to 427.0 V

Set the limit value of positive DC output

voltage

Volts (Vp) -

-427.0 to 0.0 V

Set the limit value of negative DC output

voltage

A

0.00 to 33.00 A

Set the limit value of AC output current

A Delay (ms)

0 to 10000 ms

Set the time delay to activate protection

when the current limit is reached

Power

0 to 3300.00 VA

Set the limit value of output power

Press the arrow key (▲ ▼) to move the cursor to the wanted configuration. Press the

ENTER key to change its value then press the ENTER again key to confirm.

See the example below:

Move the cursor to Waveform Select, then press OK or Enter. Press the A softkey then

press OK or Enter to confirm. Use ▲ ▼ keys (or Rotary knob) to select the other

configurations.

8.3 Limits

The Configuration Limits page is used to set user-defined voltage, current and power

limits.

Figure 28 - Configuration 2 page

Table 12 - Limits descriptions

30

NOTE: If the output exceeds the limit value the Instrument will stop and the output will display an error

message. Press the Esc key to close the message window.

Press the arrow key (▲ ▼) to move the cursor to the wanted configuration. Press

ENTER key to change its value, then press ENTER key to confirm.

Move the cursor to Volts (rms). Use ▲ ▼ keys (or Rotary knob) to set the value of Volts

(rms) limit and other configurations. Then press OK or Enter key to confirm this setting.

Use ▲ ▼ keys (or Rotary knob) to select other configurations.

Figure 29 - Configure Limits

31

Configurations

Range

Description

Date

YY/MM/DD

Set the date (year/month/day)

Time

HH:MM:SS

Set the time (hour/minute/seconds)

Brightness

0 to 9

The level of the LCD brightness

Beep

ON or OFF

Enable/disable the buzzer

9 System Settings

9.1 System Setup

The System Setup page is used to set Date, Time, Brightness and Beep.

Figure 30 - System Setup

Press the arrow keys (▲ ▼) to move the cursor to the wanted configuration. Press the

ENTER key to change its value and then press the ENTER key again to confirm the

changes.

Table 13 - System Setup Configurations

32

Configurations

Range

Description

Comm. Type

USBVCP, USBTMC,

GPIB, LAN, RS232

USBVCP: USB Virtual Com Port (19200,

N, 8, 1)

USBTMC: USB Test and Measurement

Class. (NI VISA Driver is needed)

GPIB: General-Purpose Interface Bus

LAN: Local Area Network

RS232: (On Digital I/O board 19200, N,

8, 1)

GPIB Address

1 to 30

Set the GPIB address

IP Mode

DHCP (Auto), Manu,

(STATIC)

Select how to assign the IP.

DHCP: Auto assigns IP.

Manu: Assign IP address, subnet mask,

and gateway manually.

IP Address

XXX : XXX : XXX : XXX

IP address

Subnet Mask

XXX : XXX : XXX : XXX

Subnet mask

Gateway

XXX : XXX : XXX : XXX

Gateway

9.2 Communication Setup

The Communication Setup page is used to select and configure the communications

ports.

Figure 31 - Communication Setup

Press the arrow keys (▲ ▼) to move the cursor to the wanted configuration. Press the

ENTER key to change its value and then press the ENTER key again to confirm the

changes.

Table 14 - Communication Configurations

33

Error Code

Definition

0x00000080

FW_VerError

0x00000040

SW_EShoutdown

0x00000020

SW_OVAP Software

0x00000010

SW_OPP Software

0x00000008

SW_OVP

0x00000004

SW_OCP

0x00000002

SW_CAN2Error

0x00000001

SW_CAN1Error

0x00018000

AC Input Fail

0x00040000

HW Over Voltage

0x88E00000

HW Over Current

0x33180000

Over Temperature

0x00004000

FAULT_FAN_FAIL

0x00002000

FAULT_CURR_LIMIT

0x00001000

FAULT_CURR_OVSPEC

0x00000800

AC Input too low

0x00000400

AC Input too high

0x00000200

PFC Vbus too high

0x00000100

AC Input Freq. Error

9.3 System Error

The System Clear Error page is used to view and clear the error log. Use + - key or

rotary knob to see other error messages.

Figure 32 System Error Log

To clear the error log Press the arrow key (▲ ▼) to move the cursor to Clear Error?

(Yes/No) then press the ENTER key to change its value. Select YES, then press ENTER key

again to clear error log. The log errors cannot be recovered once it has been cleared.

34

Config 1(2) Field

Value

Volts (rms)

50

Volts (DC)

0

Freq (Hz)

60

Sync source

Phase

Phase (deg)

0.0

Range(V)

300

Couple

AC

Power On State

Off

(User) On/Off State

Off

(User) Volts(rms)

0

(User) Volts(dc)

0

Table 15 - Error Code Definitions

9.4 System Next

The System Next page is used to access to system defaults and calibration functions.

Figure 33 - System Next Page

9.5 Recall Default

Press System softkey, then press Next softkey to go to the next function page. At the System

Next screen press Recall Default softkey. Press an arrow key (▲ ▼) to move the cursor to

Reset all config? Press ENTER key, then press the Yes softkey to reset all configurations.

Figure 34 - Recall Default

35

(User) Freq(Hz)

60

(User) Sync Source

Phase

(User) Phase(deg)

0

(Inrush) Measurement Time(ms)

0

(Inrush) Delay Time(ms)

0

Waveform Select

A

Waveform A Type

Sine

Wave A Index

----, 0

Waveform B Type

Sine

Wave B Index

----, 0

Wave B

Index 0

Output Timer

Off

Timer Setting

--:--:--

External Ref.

Off

Remote Inhibit

Off

Transient

Off

Table 16 - Default Values

36

10 Save

The Instrument can save data and screen shots into the USB disk (only FAT format is

supported).

Figure 35 - Save Menu

10.1 Save Config

Press Save Config softkey to store all configurations and settings into the internal

memory (CFGFile01.cfg to CFGFile09.cfg) or into a USB disk (CFGFile10.cfg to

CFGFile99.cfg). Use the number keys to enter the file name. Then press OK or ENTER

key to confirm or press ESC key to cancel.

Figure 36 - Save Config

37

10.2 Save Screen

Plug in a USB disk, then press the Save Screen softkey to take a screen shot and store

the image to a USB disk (SCRFile000.bmp to SCRFile999.bmp). Use number keys to enter

the file name. Then press OK or ENTER key to confirm or press ESC key to cancel.

Figure 37 - Save Screen

10.3 Recall Configuration

Figure 38 - Recall page

38

Press Recall Config softkey to recall configurations and settings from internal memory

(CFGFile01.cfg to CFG09File.cfg) or from a USB disk (CFGFile10.cfg to CFGFile99.cfg).

Use the number keys to enter the file name. Then press OK or ENTER key to confirm, or

press ESC key to cancel.

Figure 39 - Recall File Selection

39

3-Phase kit option (TL983P-KIT)

11 3-Phase Operation

Three-Phase or Multi-Phase operation requires the three 9832B or 9833B AC sources and the 3Phase kit (model TL983P-KIT) which includes three phase sync modules and two straight

through (pin to pin) RJ45 communication cables for 3-Phase operation. Replacement modules

(model TL983P) are sold separately. Additional phases require additional modules and RJ45

communication cables.

Limitations

9830B Series programming features including step, list, pulse, and amplifier mode are disabled

in 3-phase mode. Several configuration settings (Config 1 and Config 2) remain enabled in 3phase mode. Range, coupling mode, power on state, and inrush current measurement settings

can be adjusted in 3-phase mode under the Config 1 menu. Under the Config 2 menu, external

reference and transient settings are disabled in 3-phase mode.

11.1 Setup and Configuration

The 9830B Series 3-phase operation uses a master/slave configuration. 3-phase operation

requires three identical 9832B or 9833B models. One AC source will be set to master with the

remaining set to slaves.

1) Rear panel configuration

Power off and disconnect the AC sources from AC input. Connect one TL983P module to

the Digital I/O (DB25) bus connecter to the rear of each AC source using the included

screws and washers to hold them firmly in place. Use a standard Ethernet (RJ45) type

connector to daisy chain modules as shown in the following figure.

40

Do not set more than one AC source to ‘Master’ as this may cause damage or a

malfunction.

RJ45 cables

Master

Figure 11.1: Phase control setting

Additional phases require additional AC sources and TL983P modules.

2) Front panel configuration

After verifying the TL983P adapters are properly wired on the rear panel, the AC sources

must be configured from the front panel. 3-phase operation is enabled by setting the

phase control field on each AC source.

The options for phase control are Master, Slave, or Disable. The master must be set first.

Any one of the three connected AC sources can be set to master. Use the directional key

pad to highlight the phase control field, use the soft key to select master, and press enter

to confirm (Figure 11.1).

41

TL983P

Pin

9830B Digital

I/O pin

Function

1

23

RX

2

11

TX

3

10

GND

4

19

Remote inhibit

5 4 AC ON

6

16

Fault out

7

Reserved

-

8

Reserved

-

The 8-pin digital I/O terminal block on the rear of the

TL983P adapter preserves commonly used signals. See

Table 11.2 for the pin definitions. To insert a wire into

the digital I/O block: press the orange tab in, insert

wire, and release the tab to hold the wire in place.

Digital I/O pinout

Similarly, after setting the master set ‘Phase Ctrl’ of the remaining two AC sources to

‘Slave’. The slaves will automatically connect to the master.

This completes the set-up process for three phase operation.

3) 3-Phase parameters and output

3-Phase parameters include: Voltage (rms), Frequency (Hz), and Phase (deg). The

reference phase of the master is always fixed at 0 degrees. The phase angle of slave

sources can be adjusted from 0 to 359.7 degrees.

The coupling mode can be changed to AC+DC in 3-phase mode to add a positive or

negative DC offset to the AC signal. The DC offset can be set from -424 V to +424 V.

Output of the system is controlled by the master. Enabling/disabling the output of the

master also enables/disables the output of slave instruments.

11.2 3-Phase Adapter Digital I/O Pin Definitions

Table 11.2: TL983P pin definitions

42

Neutral

Line

Line

Line

Neutral

11.3 3-Phase Output Wiring

The 9830B Series supports a Y-configuration in 3-phase mode.

Connect the N(-) terminals on the rear panel together as shown in Figure 11.3

43

11.4 Phase Control Software

The 9830B Series Phase control software can be downloaded from bkprecision.com by visiting

the 9830B product page and clicking the ‘Docs & Software’ tab.

Phase control software allows you to easily control 9832B/9833B models in three-phase or

multi-phase modes with data logging and live output monitoring capabilities.

11.4.1 Operation Modes Overview

After launching the Phase Control Software you will be prompted to select ‘Three-Phase

Application Mode’ or ‘Multi-Phase Application Mode’.

The same setting and range limitations that apply to front panel operation also apply

when using the software with the exception of DC offset control.

Three-phase application mode

This mode is intended strictly for 3-Phase Operation using three 9832B or 9833B

models. Setting parameters: Voltage (Vrms), Frequency (Hz), and Range apply to all

three connected AC Sources. These parameters must be the same for all three AC

Sources. Phase (degrees) difference between each AC source is 120° and cannot be

changed. Master is fixed at 0°, Slave 1 is fixed at 120°, and Slave 2 is fixed at 240°.

44

Three-Phase Application Mode Control Panel

Multi-phase Application Mode

This mode is intended for applications requiring control over more than three phases or

when the user wants independent control of each AC source Voltage (Vrms) and Phase

(degrees) parameters. Up to 31 instruments can be connected in multi-phase

application mode.

Multi-Phase Application Mode Control Panel

45

Computer/USB hub

11.4.2 Setup and Configuration

Before attempting to connect to a computer, the 9832B/9833B AC Power Sources must be

properly configured from the front panel and connected using phase sync adapter modules.

See the 3-Phase Operation section above for instructions.

On the front panel, set each AC source to ‘USBVCP’ in the communication settings.

Figure 40 - Communication Setup

Press the arrow keys (▲ ▼) to move the cursor to the wanted configuration. Press the

ENTER key to change its value and then press the ENTER key again to confirm the

changes.

11.4.3 Three-Phase Application Mode

After following the configuration steps you can now connect the 9832B/9833B AC Power

Sources to your computer using a standard USB communication cable.

Each AC Source must be connected to your computer or USB hub independently as shown:

Phase control software requires a USB COMM connection, and does not support RS232

connections.

46

1. Open the phase control software and click the icon to open the windows device

manager. Three connected AC Sources should be displayed under ‘Ports (COM & LPT)’ in

the device manager as shown:

If they are missing or shown with an error power off and disconnect the AC Sources from

the computer. Power back on and connect AC Sources to the computer one at a time.

2. Click ‘Refresh’ and the software will automatically search for connected AC sources and

assign one master and two slaves. Alternatively, you can use the dropdown to manually

assign master and slave AC sources.

3. Click ‘Connect’ to complete the setup process. A successful connection is indicated by

the green light as shown:

Setting Parameters

Set Voltage (Vrms), Frequency (Hz), and Range (either 150 Vrms or 300 Vrms) for the whole 3Phase system.

47

Click ‘Set’ to send the parameters and prepare the 3-Phase system for output.

Output

Click ‘Output On’ to enable the output of the 3-Phase system. Fields will be highlighted in green

when the output is enabled.

The Output Monitor panel displays live Voltage (Vrms), Current (Arms), Power (VA), and Power

(W).

Click ‘Output Off’ to disable the output of the system.

Data Logging

This software is capable of logging time, voltage (Vrms), current (Arms), power (VA), and power

(W) at user-defined sampling intervals for each AC Source. Data is exported as a .CSV file.

To enable data logging, click ‘Setting’ located in the Output Monitoring panel and the following

menu will appear:

48

Computer/USB hub

Check the box to enable data logging and set the desired sampling interval. The sampling

interval is displayed in seconds (s). Data logging will start when the output is enabled.

Output Timer

The output timer is used to disable the output after a certain period of time. The timer can be

set from 1 second to over 277 hours.

To enable output timer, click ‘Setting’ and the following menu will appear:

Check the box under ‘Timer setting’ to enable the timer. Set the desired time in seconds (s) and

click ‘Ok’ to confirm. The timer will start when the output is enabled.

11.4.4 Multi-Phase Application Mode

Communication Setup

After following the configuration steps in Section 3 above you can now connect the

9832B/9833B AC Power Sources to your computer using a standard USB communication cable.

Each AC Source must be connected to your computer or USB hub independently as shown:

Phase control software requires a USB COMM connection, and does not support RS232

connections.

49

Set parameters for the selected AC Source

1. Click the icon to open the windows device manager. Three connected AC Sources

should be displayed under ‘Ports (COM & LPT)’ as shown:

If they are missing or shown with an error power off and disconnect the AC Sources from

the computer. Power back on and connect AC Sources to the computer one at a time.

2. Click ‘Scan’ and the software will automatically connect to and assign AC sources for

multi-phase operation. There will be one master with the remaining connected AC

sources set to slave.

Setting Parameters

Set Voltage (Vrms), Phase (degrees), and Range (either 150 Vrms or 300 Vrms) for each AC

source or the whole multi-phase system. The phase value of the master must remain at 0°.

Frequency (Hz) can only be set for the whole multi-phase system.

Set parameters for each AC source individually by selecting a connected AC source listed under

the ‘Setting Parameters’ table. The AC source you are currently setting will be highlighted in

blue as shown:

Click ‘Set’ to send the parameters to the selected AC source(s). More than one AC source can be

selected and set at a time by holding the Control (Ctrl) key on your keyboard and selecting AC

sources from the list.

Output

50

Click ‘Output On’ to enable the output of the multi-phase system. Fields will be highlighted in

green when the output is enabled.

The Output Monitor panel displays live Voltage (Vrms), Current (Arms), Power (VA), and Power

(W).

Click ‘Output Off’ to disable the output of the system.

Data Logging

This software is capable of logging time, voltage (Vrms), current (Arms), power (VA), and power

(W) at user-defined sampling intervals for each AC Source. Data is exported as a .CSV file.

To enable data logging, click ‘Setting’ located in the Output Monitoring panel and the following

menu will appear:

51

Check the box to enable data logging and set the desired sampling interval. The sampling

interval is displayed in seconds (s). Data logging will start when the output is enabled.

Output Timer

The output timer is used to disable the output after a certain period of time. The timer can be

set from 1 second to over 277 hours.

To enable output timer, click ‘Setting’ and the following menu will appear:

Check the box under ‘Timer setting’ to enable the timer. Set the desired time in seconds (s)

and click ‘Ok’ to confirm. The timer will start when the output is enabled.

52

Settings

Value

Baud

19200

Data bits

8

Parity

None

Stop bits

1

Flow control

None

Settings

Value

Baud

19200

Data bits

8

Parity

None

Stop bits

1

Flow control

None

The USB interface does not support flow control. The programmer should be

aware of this limitation and pay attention to the Instrument command process

time. If the remote commands are sent too fast the internal buffer may overrun

and cause communication errors. Therefore, it is mandatory to add a delay

between commands so that the Instrument can have sufficient time to process.

12 Remote Interface Operation

The Instrument comes with RS232, USB (USBTMC, and USBVCP), GPIB, LAN and analog

interfaces. Users can program the Instrument using the SCPI (Standard Commands for

Programmable Instruments) commands through any of the remote interfaces. Only one

interface at a time can be enabled and used to control the Instrument.

12.1 Interface Connection

12.1.1 RS232

The RS232 interface can be found on pin 23 (RX) and 11 (TX) of the DB25 port. See the

settings below:

Table 17 - RS232 Settings

Note: RS232 communication is not available in 3-phase mode

12.1.2 USBVCP (virtual COM)

The USB port is a virtual COM port, which can be used for remote communication. See

the settings below:

USBVCP Driver

The USBVCP driver for the SiLabs CP210x used in the unit can be downloaded from the

following link.

https://bkpmedia.s3.amazonaws.com/downloads/software/CP210X_USB_Driver.zip

53

12.1.3 USBTMC

The USB port is USBTMC-compliant and can be used for remote communication and

control. There are no additional settings in the menu system for USB configuration. The

only requirement is that the USBTMC driver be installed. It is included when installing

VISA software on the computer. (We recommend using NI-VISA, which can be

downloaded at http://www.ni.com/visa/).

12.1.4 GPIB

Each device is assigned a GPIB address from 1-30. To communicate via GPIB, connect a

GPIB cable to the GPIB interface on the back of the instrument and configure the

address.

12.1.5 LAN (Ethernet)

There are three ways to control the Instrument via LAN interface: Web server, Telnet

connection, and Socket connection.

12.1.6 Web server

There is an embedded web server GUI (Graphical User Interface) that can access the

Instrument via LAN interface using a web browser. Using a web browser from a

computer connected to the same local area network as the Instrument. The GUI provides

a simple way to set the voltage and current, and to monitor the output. To use this

function, follow the steps below:

Open up a web browser on the computer.

1. Check the IP address of the Instrument through menu tree System →

Information.

2. Enter the IP address of the Instrument in the URL bar of your browser with IP

Address

a. For example 192.100.111.

If correctly configured, the following screen will be shown:

54

Figure 41 - Web Login Page

A password is required to login and access the menu items on the page.

The default admin password is 123456.

The web server menu items are described below:

HOME

This page provides general information about the instrument, Manufacturer, Model

Number, Serial Number, Firmware version, Interface, USBTMC setting, MAC address, and

IP Address.

Figure 42 - Home Page

55

LAN Config

This page provides settings and status of LAN, including IP address, IP subnet, Gateway,

DNS server, Hostname, Domain, mDNS host name, TCP/IP VXI-11 instrument, and TCP/IP

Raw Socket.

Figure 43 - LAN Config

Config

The Config page provides different settings output voltage range, waveform A/B, output

type, inrush current. Limitations can also be set for R.M.S. voltage, +/- Peak voltage,

output R.M.S. current and output power.

Figure 44 - Source Config

56

Control

The Control page provides the general control of the instrument such as output on/off as