Page 1

OPERATING INSTRUCTIONS

®

635

INFRARED THERMOMETER

WITH LASER SIGHTING

INTRODUCTION

This instrument is a portable easy to use 3 digit, compactsized digital infrared thermometer with laser sighting designed for simple one hand operation. Meter comes with

Backlit LCD display, Auto-hold function and auto power

down (15 seconds approx.) after releasing MEAS button to

extend battery life.

SAFETY INFORMATION

It is recommended that you read the safety and operation

instructions before using the infrared thermometer.

DANGER

Pressing the button turns the laser beam on and off.

Exercise extreme care and do not allow the laser beam

to enter your eye or those of any other person or animal.

• Do not look directly into the laser light from the optical

system.

• When measuring the temperature of an object which

has a mirror finish, be careful not to allow the laser

light beam to be reflected off the surface into your eyes

or those of another person.

• Do not allow the laser light beam to impinge upon any

gas which can explode.

• Do not use the unit near any device which generates

strong electromagnetic radiation or near a static

electrical charge, as these may cause errors.

• Do not use the unit where it may be exposed to

corrosive or explosive gases. The unit may be damaged, or explosion may occur.

• Do not keep or use this unit in an environment where

it will be directly illuminated by sunshine, or where it

will be exposed to high temperatures, high humidity or

condensation. If you do, it may be deformed, its

insulation may be damaged, or it may no longer

function according to specification.

• Do not point the lens at the sun or at any other source

of strong light. If you do, the sensor may be damaged.

• Do not contact the lens against the object whose

temperature is to be measured, or get it dirty, allow it

to be scratched, or allow any foreign material to

adhere to it. Doing so may cause errors.

• Do not touch or hold by the front cone. Temperature

reading can be affected by heat from hand.

• Do not place the meter on or around hot objects (70°C/

158°F). It may cause damage to the case.

• If the meter is exposed to significant changes in

ambient temperature (hot to cold or cold to hot). Allow

20 minutes for temperature stabilization, before taking measurement.

• Condensation may form on the lens when going from

a cold to hot environment-wait 10 minutes for conden

sation to dissipate before taking measurements.

• This unit is not constructed to be water proof or

dustproof, so do not use it in a very dusty environment

or in one where it will get wet.

CAUTION

SPECIFICATIONS

GENERAL

Display:

3½ digit liquid crystal display (LCD) with maximum

reading of 1999

Low battery indication: the " " is displayed when the

battery voltage drops below the operating level

Measurement rate: 1 times per second, nominal.

Operating Environment: 32°F to 122°F (0°C to 50°C)

at < 80% relative humidity

Storage Temperature: 40°F to 140°F (-20°C to 60°C) ,

0 to 80% R.H. with battery removed from meter

Auto power off: 15 seconds.

Standby consuming current: <20µA

Battery:

Standard 9V battery (NEDA 1604, IEC 6F22)

Battery Life: 100 hours (continuity) typical with carbon-

zinc battery (Laser marker and Back-Light not illuminated)

Dimensions:

170mm(H) x 65.5mm(W) x 35mm(D)

Weight: 195g (including probe and batteries)

Laser Specifications:

Laser safety classification of Class 2

Wave Lenght: Red (630nm~670nm).

Operating Distance: 2 to 50 feet.

Power out: <1mW , class 2 laser product.

ELECTRICAL

Temperature Range: -4°F to 1022°F / -20°C to 550°C

Display Resolution: 1°F , 0.5°C/1°C(Auto)

Accuracy: ±2% of reading or ±6°F/3°C, whichever is

greater @ 64.4 to 82.4°F (@ 18 to 28°C) ambient

operating temperature.

Temperature Coefficient: ±0.2% of reading or ±0.36°F/

0.2°C, whichever is greater, change in accuracy per °F/

°C change in ambient operating temperature above 82.4°F/

28°C or below 64.4°F/18°C.

Response Time: 1 second

Spectral Response: 6 to 14µm nominal

Emissivity: 0.10 to 1.00 by step of 0.01

Detection Element: Thermopile

Optical Lens: Fresnel Lens

Sighting: 1-beam laser marker <1mW (class 2)

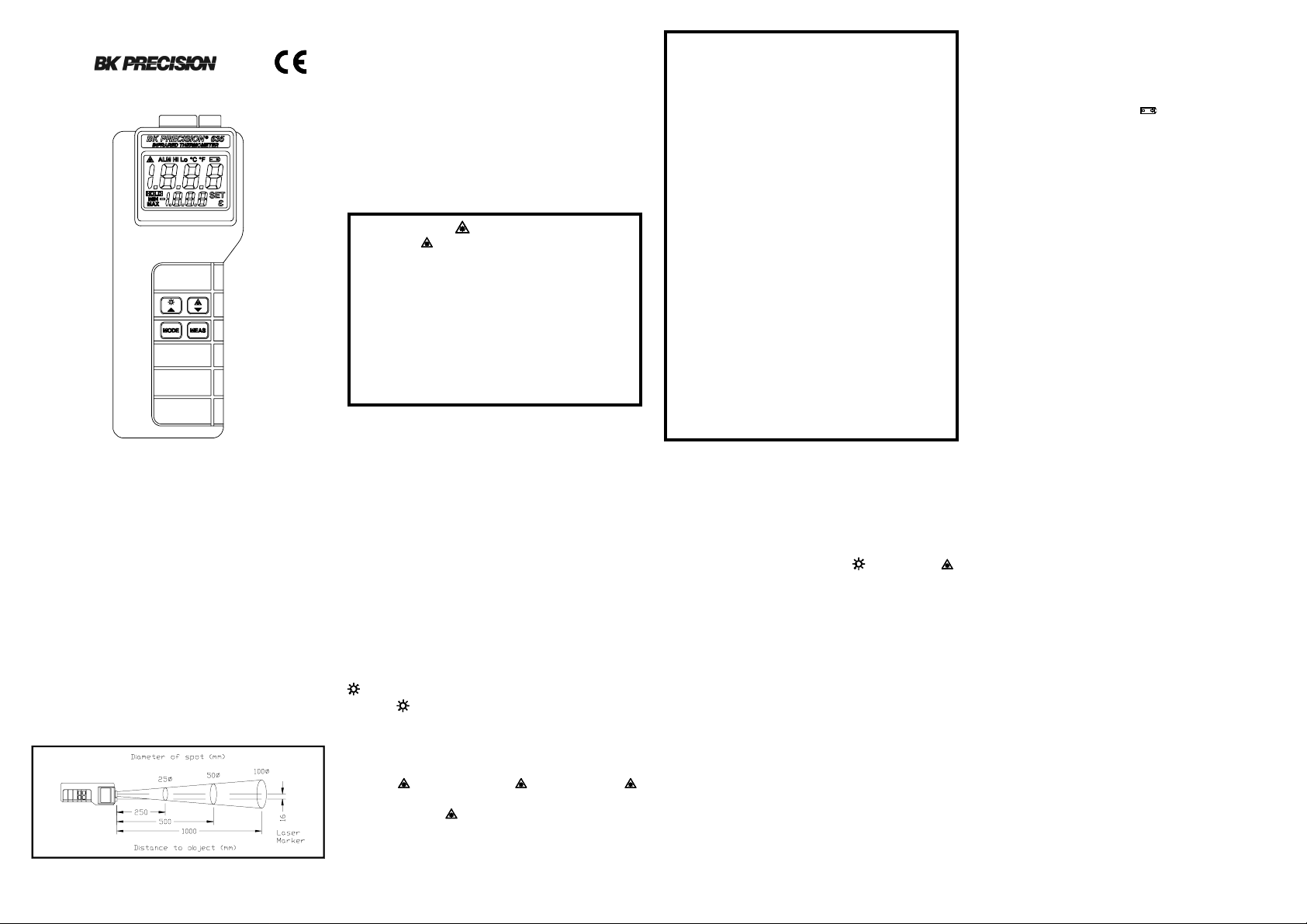

Field of View: 100mmØ at 1000mm (3.9"Ø at 39.0")

Spot size increases with distance from the probe tip as shown

(Spot Diameter measured at 90 % Energy)

OPERATING INSTRUCTIONS

Auto Power-down function

If unused for about 15 seconds, the meter will powerdown automatically. Press MEAS button switches to resume

power-on mode.

Turning the Power on

When the power is down, press MEAS less than 1 sec

button to turn on the meter.

The values and settings on the LCD return to what they

were before the power was last turned off.

When the power is down, press MEAS more than 1 sec,

the last record of MAX/MIN was erased.

Display Back-Light Button

Press " " button to turn on or off the LCD Back-Light

during measurement, or while the display shows HOLD,

MAX or MIN.

Laser Sighting

Press " " button to on the " " annunciator. If " "

annunciator is on, press MEAS button and the laser beam

will turn on and " " annunciator will blink. Releasing

MEAS button turns off the laser beam.

Selecting the Temperature Scale (°C or °F)

Readings are displayed in either degrees Celsius(°C) or

degrees Fahrenheit(°F). When the thermometer is turned

on, it is set to the temperature scale that was in use when the

thermometer was last turned off. To change the temperature

scale, in power down mode hold the " " button (°F) [" "

button (°C)] down, and then press MEAS button until the °F

(°C) annunciator appear.

Continuous Measurement

1. In the power down mode, holding the MODE key down

and then pressing the MEAS key will put the meter into

the continuous measurement mode, if HOLD was show,

please press MEAS button again to into the continuous

measurement.

2. When the MEAS key is pressed again to stop measuring

temperature and automatically hold the display reading,

the meter power down automatically after 15 seconds.

NOTE: During the continuous measurement mode, the

HOLD indication does not appear.

NOTE: During the continuous measurement mode, the laser

sighting is not turned on.

MODE SELECTION AND OPERATION

Press MODE button switches the mode around the cycle ε

→ ALM Hi → ALM Lo → MAX → MIN → HOLD.

HOLD :Releasing MEAS button stops measuring tem-

perature, the HOLD indication appears, and the

measured temperature is held.

ε:The thermal emissivity of the object set using

the ▲ and ▼ keys.

ALM Hi :The upper limit alarm temperature is set using

the ▲ and ▼ keys. When the measured temperature is exceeded the Hi setpoint, the beeper

emits a discontinuous pulse tone and "ALM Hi"

is displayed.

ALM Lo :The lower limit alarm temperature is set using

the ▲ and ▼ keys. When the measured temperature is blew the Lo setpoint, the beeper

emits a continuous pulse tone and "ALM Lo" is

displayed.

MAX :The maximum temperature during measure-

ment is displayed. when measuring and also

pressing the mode key, this will enter MAX/

MIN/Present cycling.

MIN :The minimum temperature during measure-

ment is displayed. when measuringand also

pressing the mode key, this will enter MAX/

MIN/Present cycling.

Page 2

NOTE: when the power is down, press the MEAS key more

than 1 sec the last record of MAX/MIN was erased.

SET MODE & Numeric input key

"SET" annunciator appears when a numerical value can

be set ( during setting of ε, ALM Hi and ALM Lo).

▲ key :The numerical value is increased.

▼ key :The numerical value is reduced.

If either of these numerical value keys is held down, the

numerical value changes rapidly in the appropriate

direction.

The data will store in nonvolatile storage region while

after completing settings will store in volatile storage.

How to specify the thermal emissivity (

1. Stick black body tape on the object whose temperature is

to be measured, or spray it with black body spray.

2. Set the thermal emissivity value (ε) on the LCD to 0.95.

3. Press the MEAS key, so as to measure the temperature

(Treal) of the part on which body tape (or black body spray)

is applied.

4. Measure the temperature (T) of the parts to which body

tape (or black body spray) is not applied.

5. Change the thermal emissivity value (ε).

6. The value of the thermal emissivity (ε) at which T comes

out to be equal to Treal is the correct value for the inherent

thermal emissivity of the body whose temperature is to be

measured.

ε ) ε )

ε )

ε ) ε )

OPERATION

1. When the power is down, pressing MEAS button turns on

the power.

2. Use " " button to select turn on or turn off the display

Back-Light.

3. Use " " button to select turn on or turn off the Laser

beam.

4. Press the MODE button, if necessary to set the thermal

emissivity value (ε).

5. Point the lens at the object whose temperature is to be

measured.

6. Press the MEAS button. Measurement is performed as

long as the MEAS button is kept pressed.

7. Referring to the spot size figure, aim the laser beam at the

object whose temperature is to be measured.

NOTE: Although the field of measurement (or Field of

View) and the spot almost coincide, actually the

field of measurement corresponds to the diameter for 90% optical response. The object whose

temperature is to be measured needs to be larger

than the measurement diameter (spot of size) by

an adequate margin at least 1.5 to 2 times larger.

8. Read the display.

MEASUREMENT CONSIDERATIONS

1. Theory of Measurement

Every object emits infrared energy in accordance with its

temperature. By measuring the amount of this radiant

energy, it is possible to determine the temperature of the

emitting object.

2. About Infrared

Infrared radiation is a form of light (electromagnetic

radiation), and has the property that it passes easily

through air while it is easily absorbed by solid matter.

With an emission thermometer which operates by detecting infrared radiation accurate measurement is possible,

irrespective of the air temperature or the measurement

distance.

3. Emission Thermometer Structure

Infrared radiation which has been emitted from the object

is focused upon an infrared radiation sensor, via an optical

system. This includes a lens which is transparent to

infrared radiation, and 5.3µm cut off filter. The output

signal from the infrared radiation sensor is input to an

electronic circuit along with the output signal from a

standard temperature sensor (Thermopile).

4. Emissivity

All objects emit invisible infrared energy. The amount of

energy emitted is proportional to the object's temperature

and its ability to emit IR energy. This ability, called

emissivity, is based upon the material that the object is

made of and its surface finish. Emissivity values range

from 0.10 for a very reflective object to 1.00 for a black

body. Factory set emissivity value of 0.95, which cover

90% of typical applications.

5. If the surface to the measured is covered by frost or other

material, clean it to expose the surface.

6. If the surface to be measured is highly reflective, apply

masking tape or matt finish black paint to the surface.

7. If the meter seems to be giving incorrect readings check

the front cone. There may be condensation or debris

obstructing the sensor; clean per instructions in the

maintenance section.

MAINTENANCE

Battery Replacement

Power is supplied by a 9 volt "transistor" battery. (NEDA

1604, IEC 6F22). The " " appears on the LCD display

when replacement is needed. To replace the battery, remove

the two screws from the back of the meter and lift off the

battery cover. Remove the battery from battery contacts.

Cleaning

Periodically wipe the case with a damp cloth and detergent, do not use abrasives or solvents.

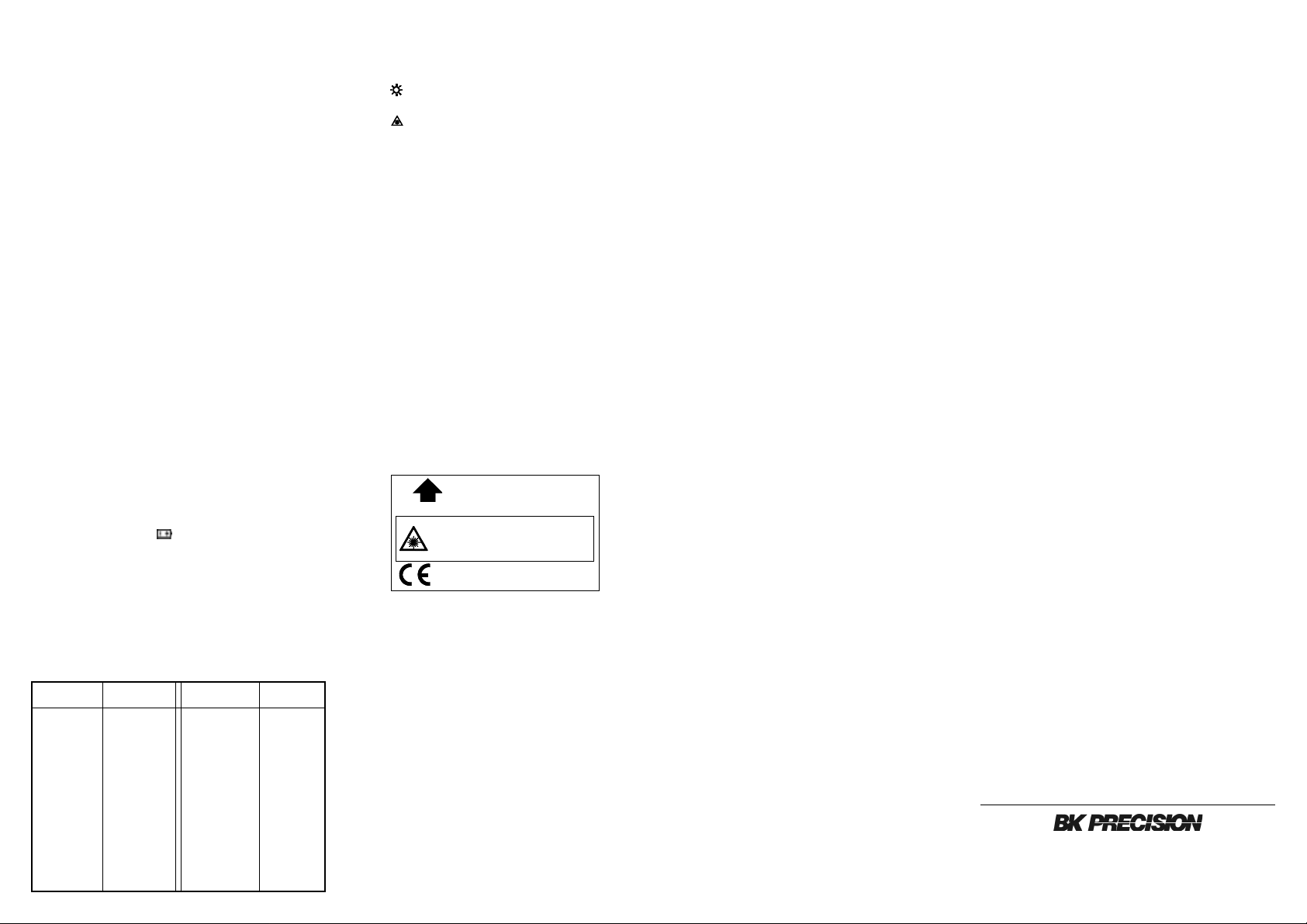

Substance Thermal Substance Thermal

Asphalt 0.90 to 0.98 Cloth (black) 0.98

Concrete 0.94 Human skin 0.98

Cement 0.96 Lather 0.75 to 0.80

Sand 0.90

Earth 0.92 to 0.96 Lacquer 0.80 to 0.95

Water 0.92 to 0.96 Lacquer (matt) 0.97

Ice 0.96 to 0.98 Rubber (black) 0.94

Snow 0.83 Plastic 0.85 to 0.95

Glass 0.90 to 0.95 Timber 0.90

Ceramic 0.90 to 0.94 Paper 0.70 to 0.94

Marble 0.94

Plaster 0.80 to 0.90 Copper oxides 0.78

Mortar 0.89 to 0.91 lron oxides 0.78 to 0.82

Brick (red) 0.93 to 0.96 Textiles 0.90

emissivity emissivity

Charcoal (powder)

chromium oxides

0.96

0.81

CAUTION

Laser radiation is emitted from the APERTURE

AVOID EXPOSURE

LASER RADIA TION DO NO T ST ARE INT O BEAM

SEMICONDUCTOR LASER 630nm - 670nm

MAX. 1mW CLASS 2 LASER PRODUCT

EN 60825-1:1994/A11:1996/A2:2001

MADE IN TAIWAN

LIMITED ONE YEAR WARRANTY

BK PRECISION warrants to the original purchaser that

its product, and the component parts thereof, will be free

from defects in workmanship and materials for a period of

one year from the date of purchase.

BK PRECISION will, without charge, repair or replace,

at its option, defective product or component parts upon

delivery to an authorized BK PRECISION service contractor or to the factory service department, accompanied by

proof of the purchase date in the form of a sales receipt.

Exclusions: This warranty does not apply in the event of

misuse or abuse of the product or as a result of unauthorized

alterations or repairs. It is void if the serial number is altered

, defaced or removed.

BK PRECISION shall not be liable for any consequential

damages, including without limitation damages resulting

from loss of use. Some states do not allow limitation of

incidental or consequential damages, so the above limitation

or exclusion may not apply to you.

This warranty gives you specific rights and you may have

other rights which vary from state-to-state.

For your convenience, we suggest you contact your BK

PRECISION distributor, who may be authorized to make

repairs or can refer you to the nearest service contractor.

If warranty cannot be obtained locally, please send the unit

to BK PRECISION Service Department, 22820 Savi

Ranch Parkway Yorba Linda, CA 92887, properly packaged to avoid damage in shipment.

BK PRECISION Test Instruments only warrants products sold in the U.S.A. and its overseas territories. In other

countries each distributor warrants the BK PRECISION

products which it sells.

CUSTOMER SUPPORT 1-800-462-9832

Precision offers courteous, professional technical support

before and after the sale of their test instruments. The

following services are typical of those available from our

toll-free telephone number:

• Technical advice on the use of your instrument.

• Technical advice on special applications of your

instrument.

• Technical advice on selecting the best instrument for a

given task.

• Instrument for information on optional accessories for

your instrument.

• Information on instrument repair and recalibration

services.

• Replacement parts ordering.

• Information on other BK PRECISION instruments.

• Requests for a new BK PRECISION catalog.

• The name of your nearest BK PRECISION distributor.

Call toll-free 1-800-462-9832

Monday through Friday, 8:00 A.M. to 5:00 P.M.

Pacific Standard Time

®

22820 Savi Ranch Parkway Yorba Linda, CA 92887

© 2000 BK PRECISION

481-310-9-001 Printed in Taiwan

Loading...

Loading...