Page 1

Model: 4075B, 4076B, 4077B, 4078B, 4079B, 4080B

Arbitrary/Function Waveform Generator

USER MANUAL

Page 2

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must be

followed during all phases of operation, service, and repair of this instrument.

Before applying power to this instrument:

Read and understand the safety and operational information in this manual.

Apply all the listed safety precautions.

Verify that the voltage selector at the line power cord input is set to the correct line voltage.

Operating the instrument at an incorrect line voltage will void the warranty.

Make all connections to the instrument before applying power.

Do not operate the instrument in ways not specified by this manual or by B&K Precision.

Failure to comply with these precautions or with warnings elsewhere in this manual violates the

safety standards of design, manufacture, and intended use of the instrument. B&K Precision assumes

no liability for a customer’s failure to comply with these requirements.

Category rating

The IEC 61010 standard defines safety category ratings that specify the amount of electrical energy

available and the voltage impulses that may occur on electrical conductors associated with these

category ratings. The category rating is a Roman numeral of I, II, III, or IV. This rating is also

accompanied by a maximum voltage of the circuit to be tested, which defines the voltage impulses

expected and required insulation clearances. These categories are:

Category I (CAT I): Measurement instruments whose measurement inputs are not intended to be

connected to the mains supply. The voltages in the environment are typically derived from a limitedenergy transformer or a battery.

Category II (CAT II): Measurement instruments whose measurement inputs are meant to be

connected to the mains supply at a standard wall outlet or similar sources. Example measurement

environments are portable tools and household appliances.

Category III (CAT III): Measurement instruments whose measurement inputs are meant to be

connected to the mains installation of a building. Examples are measurements inside a building's

circuit breaker panel or the wiring of permanently-installed motors.

Category IV (CAT IV): Measurement instruments whose measurement inputs are meant to be

connected to the primary power entering a building or other outdoor wiring.

i

Page 3

Do not use this instrument in an electrical environment with a higher category rating than what is

specified in this manual for this instrument.

You must ensure that each accessory you use with this instrument has a category rating equal to or

higher than the instrument's category rating to maintain the instrument's category rating. Failure to

do so will lower the category rating of the measuring system.

Electrical Power

This instrument is intended to be powered from a CATEGORY II mains power environment. The mains

power should be 120 V RMS or 240 V RMS. Use only the power cord supplied with the instrument and

ensure it is appropriate for your country of use.

Ground the Instrument

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical

safety ground. This instrument is grounded through the ground conductor of the supplied, threeconductor AC line power cable. The power cable must be plugged into an approved three-conductor

electrical outlet. The power jack and mating plug of the power cable meet IEC safety standards.

Do not alter or defeat the ground connection. Without the safety ground connection, all accessible

conductive parts (including control knobs) may provide an electric shock. Failure to use a properlygrounded approved outlet and the recommended three-conductor AC line power cable may result in

injury or death.

Unless otherwise stated, a ground connection on the instrument's front or rear panel is for a

reference of potential only and is not to be used as a safety ground.

Do not operate in an explosive or flammable atmosphere

Do not operate the instrument in the presence of flammable gases or vapors, fumes, or finely-divided

ii

Page 4

particulates.

The instrument is designed to be used in office-type indoor environments. Do not operate the

instrument

In the presence of noxious, corrosive, or flammable fumes, gases, vapors, chemicals, or finely-

divided particulates.

In relative humidity conditions outside the instrument's specifications.

In environments where there is a danger of any liquid being spilled on the instrument or

where any liquid can condense on the instrument.

In air temperatures exceeding the specified operating temperatures.

In atmospheric pressures outside the specified altitude limits or where the surrounding gas is

not air.

In environments with restricted cooling air flow, even if the air temperatures are within

specifications.

In direct sunlight.

This instrument is intended to be used in an indoor pollution degree 2 environment. The operating

temperature range is 0 °C to 50 °C and the operating humidity is ≤ 95 % relative humidity at < 30 °C,

with no condensation allowed.

Measurements made by this instrument may be outside specifications if the instrument is used in

non-office-type environments. Such environments may include rapid temperature or humidity

changes, sunlight, vibration and/or mechanical shocks, acoustic noise, electrical noise, strong electric

fields, or strong magnetic fields.

Do not operate instrument if damaged

If the instrument is damaged, appears to be damaged, or if any liquid, chemical, or other material gets

on or inside the instrument, remove the instrument's power cord, remove the instrument from

service, label it as not to be operated, and return the instrument to B&K Precision for repair. Notify

B&K Precision of the nature of any contamination of the instrument.

Clean the instrument only as instructed

iii

Page 5

Do not clean the instrument, its switches, or its terminals with contact cleaners, abrasives, lubricants,

solvents, acids/bases, or other such chemicals. Clean the instrument only with a clean dry lint-free

cloth or as instructed in this manual.

Not for critical applications

This instrument is not authorized for use in contact with the human body or for use as a component

in a life-support device or system.

Do not touch live circuits

Instrument covers must not be removed by operating personnel. Component replacement and

internal adjustments must be made by qualified service-trained maintenance personnel who are

aware of the hazards involved when the instrument's covers and shields are removed. Under certain

conditions, even with the power cord removed, dangerous voltages may exist when the covers are

removed. To avoid injuries, always disconnect the power cord from the instrument, disconnect all

other connections (for example, test leads, computer interface cables, etc.), discharge all circuits, and

verify there are no hazardous voltages present on any conductors by measurements with a properlyoperating voltage-sensing device before touching any internal parts. Verify the voltage-sensing device

is working properly before and after making the measurements by testing with known-operating

voltage sources and test for both DC and AC voltages. Do not attempt any service or adjustment unless

another person capable of rendering first aid and resuscitation is present.

Do not insert any object into an instrument's ventilation openings or other openings.

Hazardous voltages may be present in unexpected locations in circuitry being tested when a fault

condition in the circuit exists.

Fuse replacement

Fuse replacement must be done by qualified service-trained maintenance personnel who are aware

of the instrument's fuse requirements and safe replacement procedures. Disconnect the instrument

from the power line before replacing fuses. Replace fuses only with new fuses of the fuse types,

voltage ratings, and current ratings specified in this manual or on the back of the instrument. Failure

to do so may damage the instrument, lead to a safety hazard, or cause a fire. Failure to use the

iv

Page 6

specified fuses will void the warranty.

Servicing

Do not substitute parts that are not approved by B&K Precision or modify this instrument. Return the

instrument to B&K Precision for service and repair to ensure that safety and performance features are

maintained.

Cooling fans

This instrument contains one or more cooling fans. For continued safe operation of the instrument,

the air inlet and exhaust openings for these fans must not be blocked nor must accumulated dust or

other debris be allowed to reduce air flow. Maintain at least 25 mm clearance around the sides of the

instrument that contain air inlet and exhaust ports. If mounted in a rack, position power devices in

the rack above the instrument to minimize instrument heating while rack mounted. Do not continue

to operate the instrument if you cannot verify the fan is operating (note some fans may have

intermittent duty cycles). Do not insert any object into the fan's inlet or outlet.

For continued safe use of the instrument

Do not place heavy objects on the instrument.

Do not obstruct cooling air flow to the instrument.

Do not place a hot soldering iron on the instrument.

Do not pull the instrument with the power cord, connected probe, or connected test lead.

Do not move the instrument when a probe is connected to a circuit being tested.

v

Page 7

Compliance Statements

This product is subject to Directive 2002/96/EC of the European

Parliament and the Council of the European Union on waste electrical

and electronic equipment (WEEE), and in jurisdictions adopting that

Directive, is marked as being put on the market after August 13, 2005,

and should not be disposed of as unsorted municipal waste. Please

utilize your local WEEE collection facilities in the disposition of this

product and otherwise observe all applicable requirements.

Disposal of Old Electrical & Electronic Equipment (Applicable in the European

Union and other European countries with separate collection systems)

vi

Page 8

CE Declaration of Conformity

This instrument meets the requirements of 2006/95/EC Low Voltage Directive and 2004/108/EC

Electromagnetic Compatibility Directive with the following standards.

Low Voltage Directive

- EN61010-1: 2001

EMC Directive

- EN 61000-3-2: 2006

- EN 61000-3-3: 1995+A1: 2001+A2: 2005

- EN 61000-4-2 / -3 / -4 / -5 / -6 / -11

- EN 61326-1: 2006

vii

Page 9

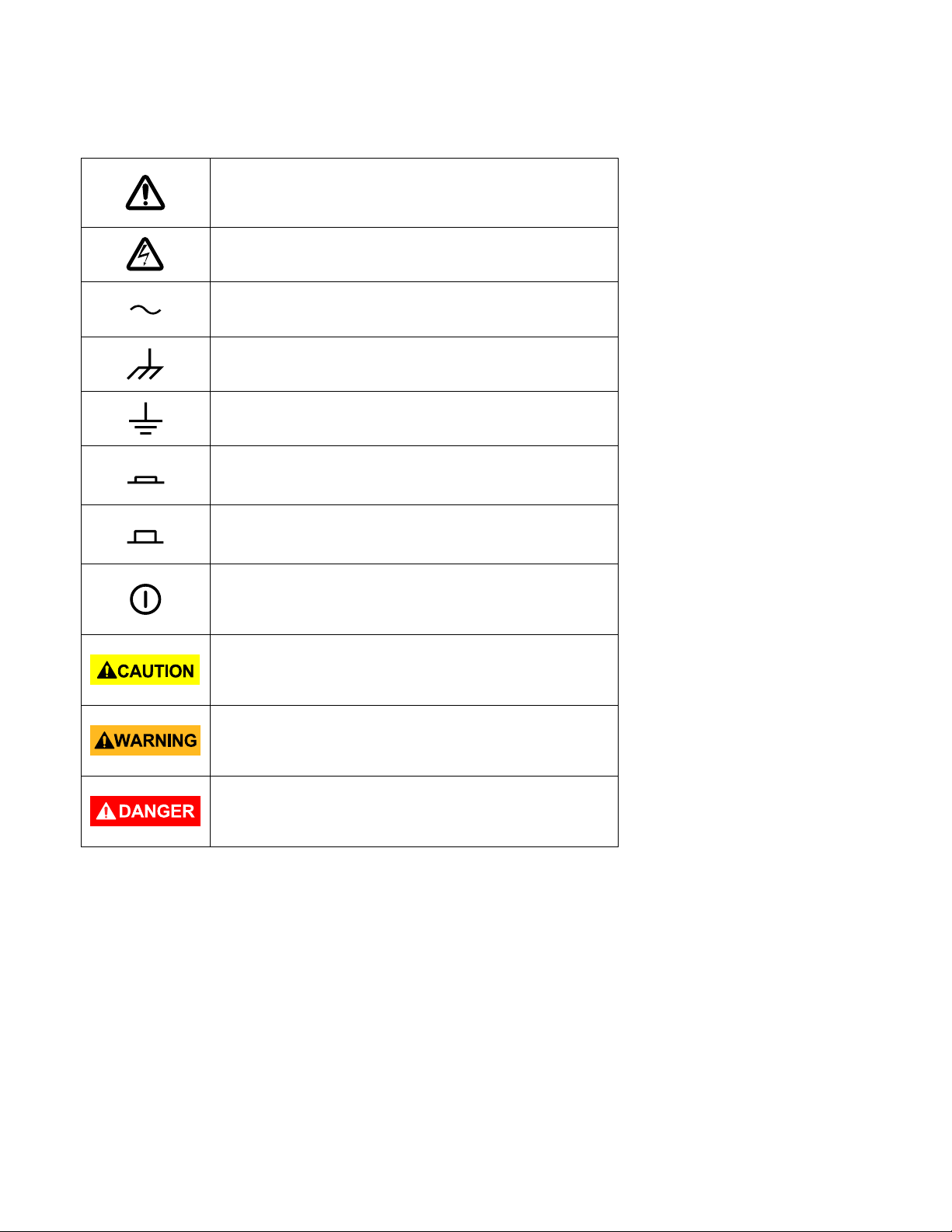

Safety Symbols

Refer to the user manual for warning information

to avoid hazard or personal injury and prevent

damage to instrument.

Electric Shock hazard

Alternating current (AC)

Chassis (earth ground) symbol.

Ground terminal

On (Power). This is the In position of the power

switch when instrument is ON.

Off (Power). This is the Out position of the power

switch when instrument is OFF.

Power Switch (On/Off). This is the power switch

located in front of the instrument.

CAUTION indicates a hazardous situation which, if

not avoided, will result in minor or moderate injury

WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury

DANGER indicates a hazardous situation which, if

not avoided, will result in death or serious injury.

viii

Page 10

Contents

Safety Summary .............................................................................................. i

Compliance Statements ........................................................................................................ vi

Safety Symbols .................................................................................................................... viii

1 General Information ........................................................................... 1

1.1 Product Overview ......................................................................................................... 1

1.2 Package Contents ......................................................................................................... 1

1.3 Front Panel Overview ................................................................................................... 2

Front Panel Description ................................................................................................ 2

1.4 Rear Panel Overview .................................................................................................... 3

Rear Panel Description ................................................................................................. 3

1.5 Display Overview .......................................................................................................... 4

Display Description ....................................................................................................... 4

2 Getting Started ................................................................................... 4

2.1 Input Power Requirements .......................................................................................... 5

Input Power .................................................................................................................. 5

2.2 Output Connections ..................................................................................................... 5

Impedance Matching.................................................................................................... 6

2.3 Preliminary Check ......................................................................................................... 6

Output Check ................................................................................................................ 6

3 Operating Instructions ........................................................................ 7

3.1 Menu Keys .................................................................................................................... 7

Menu Tree..................................................................................................................... 7

PARAMETER Key ......................................................................................................... 10

WAVEFORM Key .......................................................................................................... 12

PULSE Menu ............................................................................................................... 18

MODE Key ................................................................................................................... 18

SWEEP Key .................................................................................................................. 20

MODULATION Key ...................................................................................................... 21

SETUPS Key ................................................................................................................. 23

UTILITY Key ................................................................................................................. 25

3.2 ON Key ........................................................................................................................ 26

ix

Page 11

3.3 Cursor Movement Keys .............................................................................................. 26

3.4 Rotary Input Knob ...................................................................................................... 26

3.5 Power-On Settings ...................................................................................................... 26

3.6 Memory ...................................................................................................................... 27

3.7 Displaying Errors ......................................................................................................... 28

3.8 Creating an Arbitrary Waveform ................................................................................ 29

Entering Individual Data Points .................................................................................. 29

Creating a Complex Arbitrary Waveform ................................................................... 30

Setting the Frequency ................................................................................................. 32

Setting the Amplitude ................................................................................................. 33

Loading an Arbitrary Waveform ................................................................................. 33

3.9 Remote Interface ........................................................................................................ 33

USB Interface .............................................................................................................. 33

GPIB Interface ............................................................................................................. 34

4 Programming .................................................................................... 35

4.1 Overview .................................................................................................................... 35

GPIB ............................................................................................................................ 35

4.2 Device State ................................................................................................................ 35

Local State (LOCS) ....................................................................................................... 35

Local With Lockout State (LWLS) ................................................................................ 35

Remote State (REMS) ................................................................................................. 35

Remote With Lockout State (RWLS) ........................................................................... 35

4.3 Interface Function Subsets ......................................................................................... 35

4.4 Device Address ........................................................................................................... 35

4.5 Message Exchange Protocol ....................................................................................... 36

The Input Buffer .......................................................................................................... 36

The Output Queue ...................................................................................................... 36

Response Messages .................................................................................................... 36

Coupled Commands .................................................................................................... 36

4.6 Block Data ................................................................................................................... 37

4.7 Instrument Identification ........................................................................................... 38

4.8 Instrument Reset ........................................................................................................ 38

4.9 Self-test ...................................................................................................................... 38

4.10 Command Syntax ........................................................................................................ 38

x

Page 12

General Command Structure ...................................................................................... 38

SCPI Command Structure ........................................................................................... 41

4.11 Status Reporting ......................................................................................................... 43

The Status Byte ........................................................................................................... 43

Service Request Enabling ............................................................................................ 43

Standard Event Status Register .................................................................................. 43

The Error Queue ......................................................................................................... 44

Error Codes ................................................................................................................. 44

4.12 Common Commands .................................................................................................. 48

System Data Commands............................................................................................. 48

Internal Operation Commands ................................................................................... 48

Synchronization Commands ....................................................................................... 49

Status and Event Commands ...................................................................................... 49

Device Trigger Commands .......................................................................................... 51

Stored Settings Commands ........................................................................................ 51

4.13 Instrument Control Commands .................................................................................. 52

SOURce Subsystem ..................................................................................................... 52

OUTPut Subsystem ..................................................................................................... 68

Trigger Subsystem ...................................................................................................... 69

Arbitrary Subsystem ................................................................................................... 71

Status Subsystem ........................................................................................................ 80

System Subsystem ...................................................................................................... 84

4.14 IEEE 488.1 Interface Messages ................................................................................... 87

GET - Group Execute Trigger ....................................................................................... 87

DCL - Device Clear ....................................................................................................... 87

SDC - Selected Device Clear ........................................................................................ 87

LLO - Local Lockout ..................................................................................................... 87

4.15 SCPI Command Tree ................................................................................................... 88

Root Node ................................................................................................................... 88

:SOURce Subsystem .................................................................................................... 88

:OUTPut Subsystem .................................................................................................... 88

:TRIGger Subsystem .................................................................................................... 89

:ARBitrary Subsystem ................................................................................................. 89

:STATus Subsystem ...................................................................................................... 90

xi

Page 13

:SYSTem Subsystem ..................................................................................................... 90

4.16 Block Transfer (GPIB only) .......................................................................................... 92

4.17 GPIB Communication Protocol ................................................................................... 94

General ....................................................................................................................... 94

Responses to IEEE-488.1 Interface Messages ............................................................ 94

IEEE 488.2 Interface Function Subsets ........................................................................ 97

5 Troubleshooting Guide ...................................................................... 98

6 Specifications .................................................................................... 99

SERVICE INFORMATION ............................................................................. 103

LIMITED THREE-YEAR WARRANTY .............................................................. 104

xii

Page 14

1 General Information

1.1 Product Overview

The B&K Precision 4075B series are versatile high performance arbitrary/function waveform

generators capable of generating arbitrary waveforms with 14-bit resolution and length up to

16,000,000 points. In addition to the large waveform memory, these generators offer AM, FM, and FSK

modulation along with sweep, burst, and flexible triggering capabilities. The instrument can be

remotely operated via the USBTMC or GPIB (IEEE-488.2) interface supporting SCPI commands. Users

can create arbitrary waveforms directly from the front panel using the generator’s built-in waveform

editing functions or load arbitrary waveforms via the instrument’s remote interfaces.

Features:

14-bit, 200 MSa/s, and up to 16M points arbitrary waveform generator

Generate Sine waveforms up to 80 MHz, Square waveforms up to 60 MHz

Color LCD display

AM, FM, and FSK modulation functions

Fully programmable markers

Store/recall up to 49 different instrument setups

Standard USBTMC and GPIB (50 MHz/80 MHz models only) interfaces

SCPI-compliant command set

1.2 Package Contents

Please inspect the instrument mechanically and electrically upon receiving it. Unpack all items from the

shipping carton, and check for any obvious signs of physical damage that may have occurred during

transportation. Report any damage to the shipping agent immediately. Save the original packing carton

for possible future reshipment. Every instrument is shipped with the following contents:

1 x 4075B, 4076B, 4077B, 4078B, 4079B, or 4080B waveform generator

1 x Full instruction manual on CD

1 x AC power cord

1 x USB type A to type B cable

1 x Certificate of calibration

1 x Test report

Verify that all items above are included in the shipping container. If anything is missing, please contact

B&K Precision.

1

Page 15

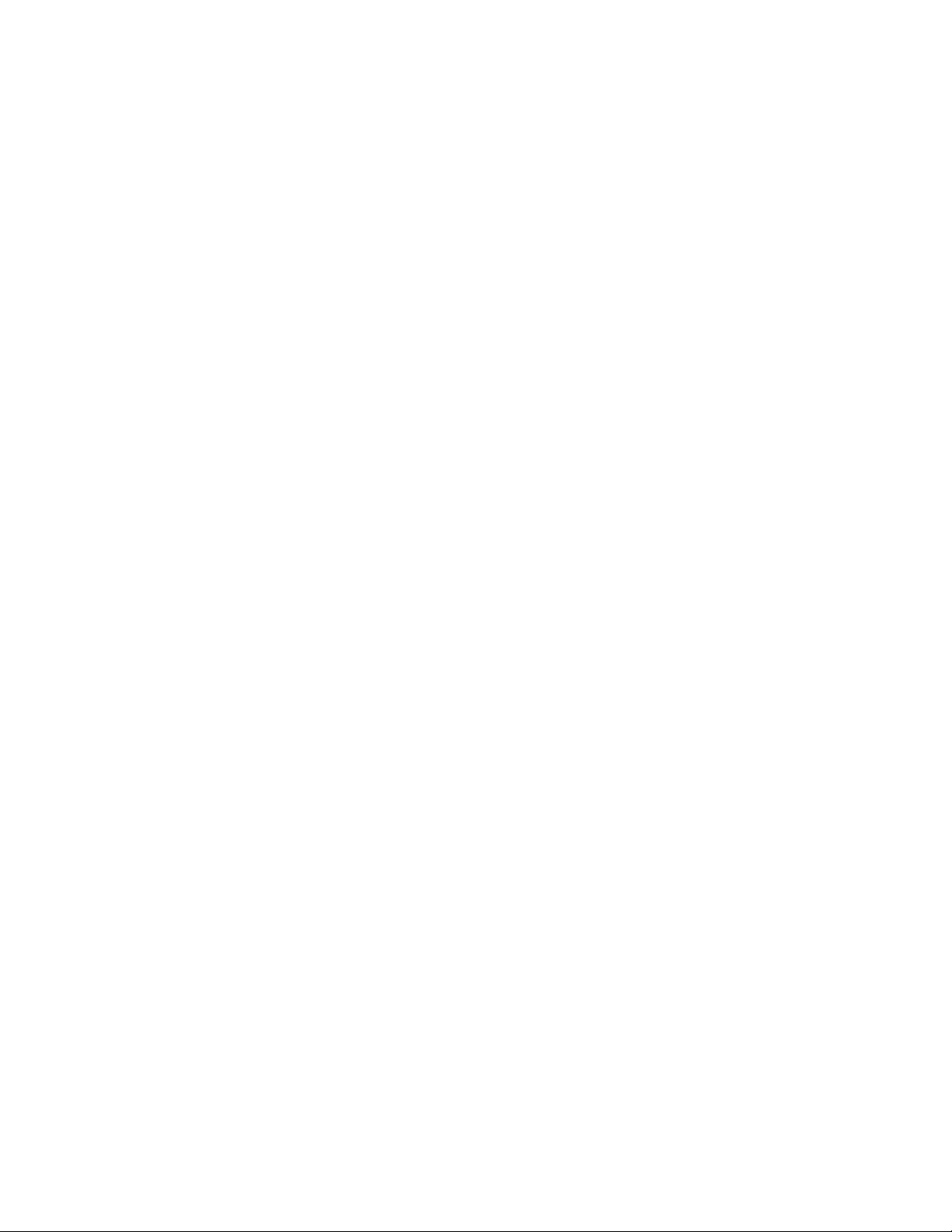

Power On/Off Switch

Function Keys (F1-F5)

UTILITY Key

CHANNEL Key (4078B, 4079B, and 4080B only)

ENTER Key

Channel Output BNC (50 Ω) and Enable

Rotary Knob and Cursor Keys

Unit Setting Keys

Numeric Keypad

Menu Option Keys

Color LCD Display Window

1

2 3 4 5 6

7 8 9

10

11

(For Models

and 4077B)

1

2

3 4 5

7

8

9

11

10

6

1.3 Front Panel Overview

4075B, 4076B,

Front Panel Description

Figure 1.1 – Front Panel Overview

2

Page 16

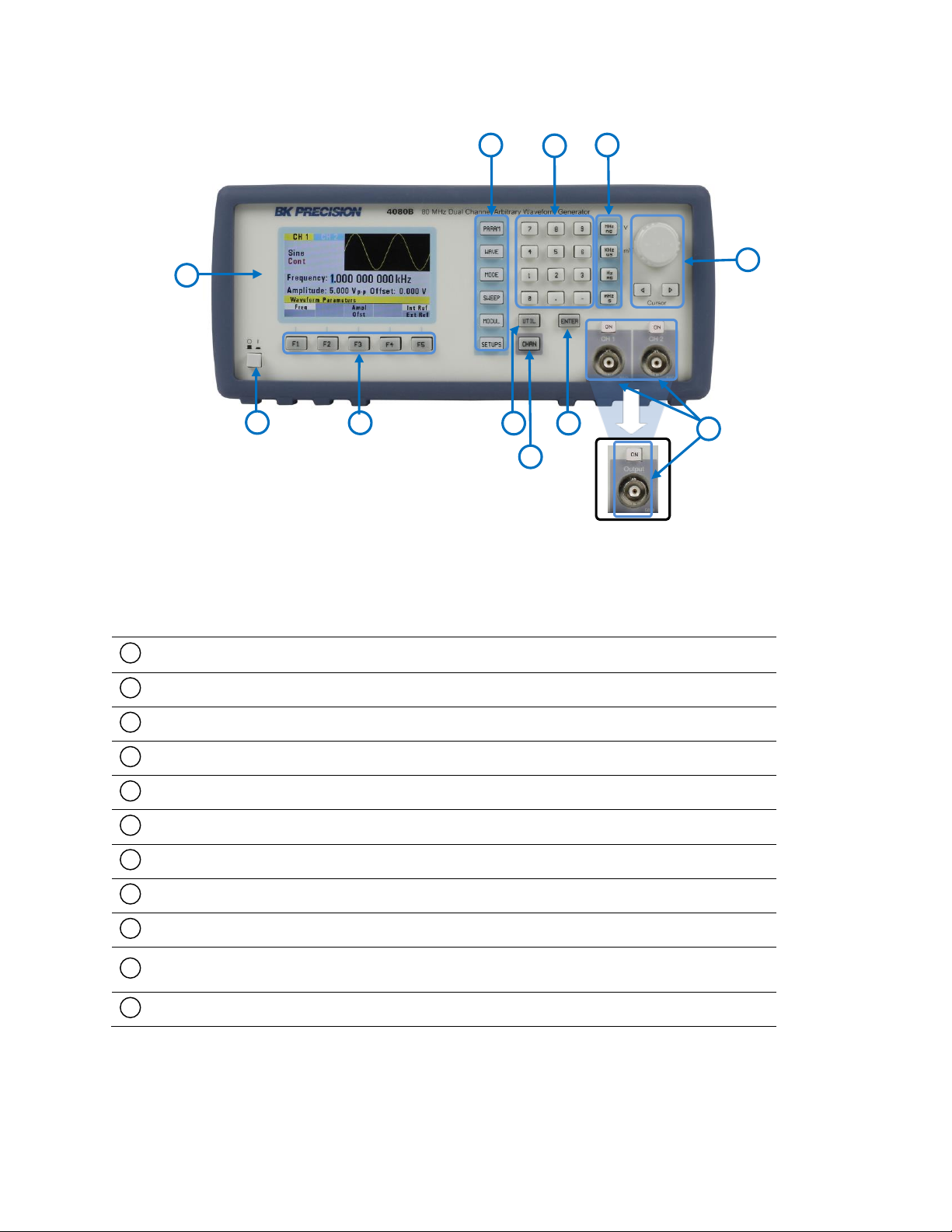

Modulation Input BNC

External Trigger Input BNC

Sync Output BNC

Marker Output BNC

10 MHz Reference Output BNC

10 MHz Reference Input BNC

USBTMC interface

Earth Ground

AC Power Connector and Fuse Box

Rear Cooling Fan

GPIB Port (4076B, 4077B, 4079B, and 4080B only)

Channel 2 I/O (4078B, 4079B, and 4080B only)

Channel 1 I/O

1 2 3

4

5 6 7 8 9

10

11

12

13

1 2 3

4

9

11

5 6 7

8

10

13

12

1.4 Rear Panel Overview

Rear Panel Description

Figure 1.2 – Rear Panel Overview

3

Page 17

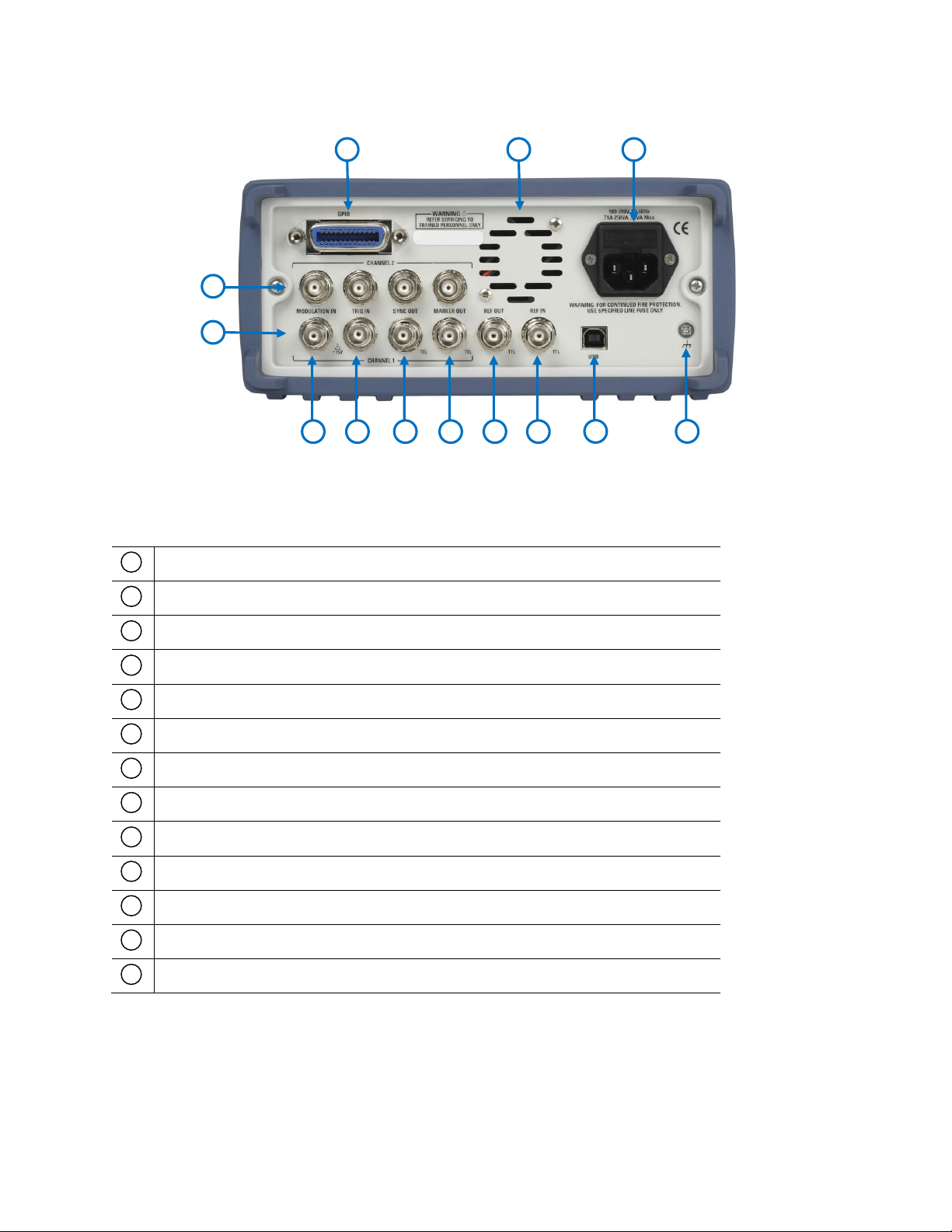

Wave Type

Trigger Mode

Frequency

Menu Parameters Values

Menu Options

Menu Title

General Waveform Display

Channel Selection Indicator

1

2 3 4 5 6

7

8

5

4

8 2 1 3 7

6

1.5 Display Overview

Display Description

2 Getting Started

Figure 1.3 – Display Overview

Before connecting and powering up the instrument, please review and go through the instructions in

this chapter.

4

Page 18

The included AC power cord is safety certified for this

instrument operating in rated range. To change a

cable or add an extension cable, be sure that it can

meet the required power ratings for this instrument.

Any misuse with wrong or unsafe cables will void the

warranty.

2.1 Input Power Requirements

Input Power

The instrument has a universal AC input that accepts line voltage and frequency input within:

100 – 240 V (+/- 10%), 50 – 60 Hz (+/- 5%)

Before connecting to an AC outlet or external power source, be sure that the power switch is in the OFF

position and verify that the AC power cord, including the extension line, is compatible with the rated

voltage/current and that there is sufficient circuit capacity for the power supply. Once verified, connect

the cable firmly.

2.2 Output Connections

The waveform generator output circuits are protected against short circuit or nominal accidental

voltages applied to the main output connector. The output circuits operate as a 50 Ω voltage source

working into a 50 Ω load. At higher frequencies, a non-terminated or improperly terminated output

may cause aberrations on the output waveform. In addition, loads with an impedance less than 50 Ω

will reduce the waveform amplitude, while loads with an impedance greater than 50 Ω will increase

waveform amplitude.

Excessive distortion or aberrations caused by improper termination are less noticeable at lower

frequencies, especially with sine and triangle waveforms. To ensure waveform integrity, follow these

precautions:

1. Use good quality 50 Ω coaxial cable and connectors.

2. Make all connections tight and as short as possible.

3. Use good quality attenuators, if it is necessary to reduce waveform amplitudes applied to sensitive

circuits.

4. Use termination or impedance-matching devices to avoid reflections.

5. Ensure that attenuators and terminations have adequate power handling capabilities.

If there is a DC voltage across the output load, use a coupling capacitor in series with the load. The

time constant of the coupling capacitor and load must be long enough to maintain pulse flatness.

5

Page 19

Impedance Matching

If the waveform generator is driving a high impedance, such as a 1 MΩ input impedance (paralleled by

a stated capacitance) of an oscilloscope vertical input, connect the transmission line to a 50 Ω

attenuator, a 50 Ω termination and to the oscilloscope input. The attenuator isolates the input

capacitance of the device and terminates the waveform generator properly.

2.3 Preliminary Check

Complete the following steps to verify that the generator is ready for use.

1. Verify AC Input Voltage

Verify and check to make sure proper AC voltages are available to power the instrument. The AC

voltage range must meet the acceptable specification as explained in section 2.1.

2. Connect Power

Connect AC power cord to the AC receptacle in the rear panel and press the power switch to the

ON position to turn ON the instrument. The instrument will have a boot screen while loading, after

which the main screen will be displayed.

3. Self Adjust

At power-on, the waveform generator performs a diagnostic self-test procedure to check itself for

errors. If it finds an error, an error code and text will appear in the display window. Other error

codes appear when you enter an invalid front-panel setting. For more information on error codes,

see the Displaying Errors section 3.7. When the waveform generator finishes the diagnostic selftest routine, it enters the local state (LOCS) and assumes power-on default settings.

Output Check

Follow the steps below to do a quick check of the settings and waveform output.

1. Turn on the instrument and set the instrument to default settings. To set to default, press Setups,

press Recall, and select 0 Default Setup. The instrument will set both channels with the following

parameters:

Waveform Shape: Sine

Frequency: 1.000000000 kHz

Amplitude: 5 .000 Vpp

Offset: 0.000 Vdc

Phase: 0.0 °

Output Impedance: 50 OHM

2. Connect the BNC output of CH1 into an oscilloscope.

3. Press the On button on top of CH1 output BNC to turn on the output and observe a sine wave with

the parameters above.

4. Press the Freq option in the menu and use the rotary knob or the numeric keypad to change

frequency. Observe the changes on the oscilloscope display.

6

Page 20

5. Press the Ampl option in the menu and use the rotary knob or the numeric keypad to change the

amplitude. Observe the changes on the oscilloscope display.

6. Press the Offset option in the menu and use the rotary knob or the numeric keypad to change the

DC offset. With the oscilloscope set for DC coupling, observe the changes on the display.

7. Now, connect the BNC output of CH2 into an oscilloscope and follow steps 3 to 6 to check its

output.

3 Operating Instructions

3.1 Menu Keys

These keys select the main menus for displaying or changing a parameter, function or mode. Below is

the hierarchy and selections of the menu tree.

Menu Tree

- PARAM

o FREQ | RATE (Arb Mode Only)

o AMPL| OFST

o UNITS (Only when AMPL is selected, press to toggle display in Vp-p, Vrms, dBm)

o 50 OHM | HI-Z

o INTCLK | EXTCLK

- WAVE

o SINE

o SQR (Duty Cycle)

o TRI (Symmetry)

o PULSE

FREQ | PERIOD

WIDTH

EQUAL EDGE

LEAD | TRAIL

PREV

o ARB

START

LENGTH

MARK

ADDR

LENGTH

ON | OFF

PREV

EDIT

POINT

7

Page 21

o ADRS

o DATA

o PREV

LINE

o FROM

o TO

o EXEC

NO

YES

PREV

o PREV

PREDEF

o TYPE (Predefined Waveform Type)

o FROM | DATA

o LENG

o SCALE (In %)

o EXEC

NO

YES

PREV

o EXEC (When NOISE is selected as TYPE)

ADD

NEW

EXEC

NO

YES

PREV

PREV

MORE

o COPY

FROM

LENG

TO

EXEC

NO

YES

PREV

PREV

o CLEAR

FROM

TO

ALL

EXEC

NO

YES

8

Page 22

PREV

o PROT

FROM

TO

ALL

ON | OFF

PREV

o SHOW WAVE

o PREV

PREV

PREV

- MODE

o CONT

o TRIG

MAN (Manual Trigger)

INT (Internal Trigger Rate)

EXT (External Trigger)

PREV

o GATE

MAN (Manual Gate Trigger)

INT (Internal Gate Trigger Rate)

EXT (External Gate Trigger)

PREV

o BURST

MAN (Manual Burst)

INT (Internal Burst Rate)

EXT (Burst External)

NBRST (Number of Bursts)

PREV

o PHASE (Not available in ARB mode)

PHASE (Set Phase Degree)

SET-ZERO (Set Phase to 0)

SYNC Both Ch

PREV

o SYNC Both Ch (ARB mode only)

- SWEEP ( Not Available in PULSE and ARB mode)

o ON | OFF

o START (Sweep Start Frequency)

o STOP (Sweep Stop Frequency)

o RATE (Sweep Rate)

o LIN | LOG | UP-DOWN (Linear or Logarithmic)

- MODUL

o AM

ON | OFF

% (% of Modulation)

PREV

9

Page 23

- SETUPS

- UTIL

SHAPE (AM Modulation Shape)

MOD FREQ (AM Modulation Frequency)

EXT | INT (External or Internal Modulation)

o FM (Not available in PULSE and ARB mode)

ON | OFF

DEV (FM Deviation Frequency)

SHAPE (FM Modulation Shape)

MOD FREQ (FM Modulation Frequency)

EXT | INT (External or Internal Modulation)

o FSK (Not available in PULSE and ARB mode)

ON | OFF

F-LO (FSK Low Frequency)

F-HI (FSK High Frequency)

RATE (FSK Rate)

EXT | INT (External or Internal modulation)

o RECALL (Recall Setup from Memory)

o LOAD ARB (Loads arbitrary waveform. Available only in ARB mode)

o STORE (Store Setup from Memory)

o SAVE ARB (Saves current arbitrary waveform into memory. Available only in ARB mode)

o GPIB (ACTIVE) (GPIB Address)

o USB (ACTIVE)

o POWER (Power On Setup)

o SN (Serial number information)

PARAMETER Key

This key selects and displays the waveform frequency, amplitude, offset and external reference, and

allows you to adjust the parameters. When Arbitrary Waveform is selected, the display also shows the

point rate.

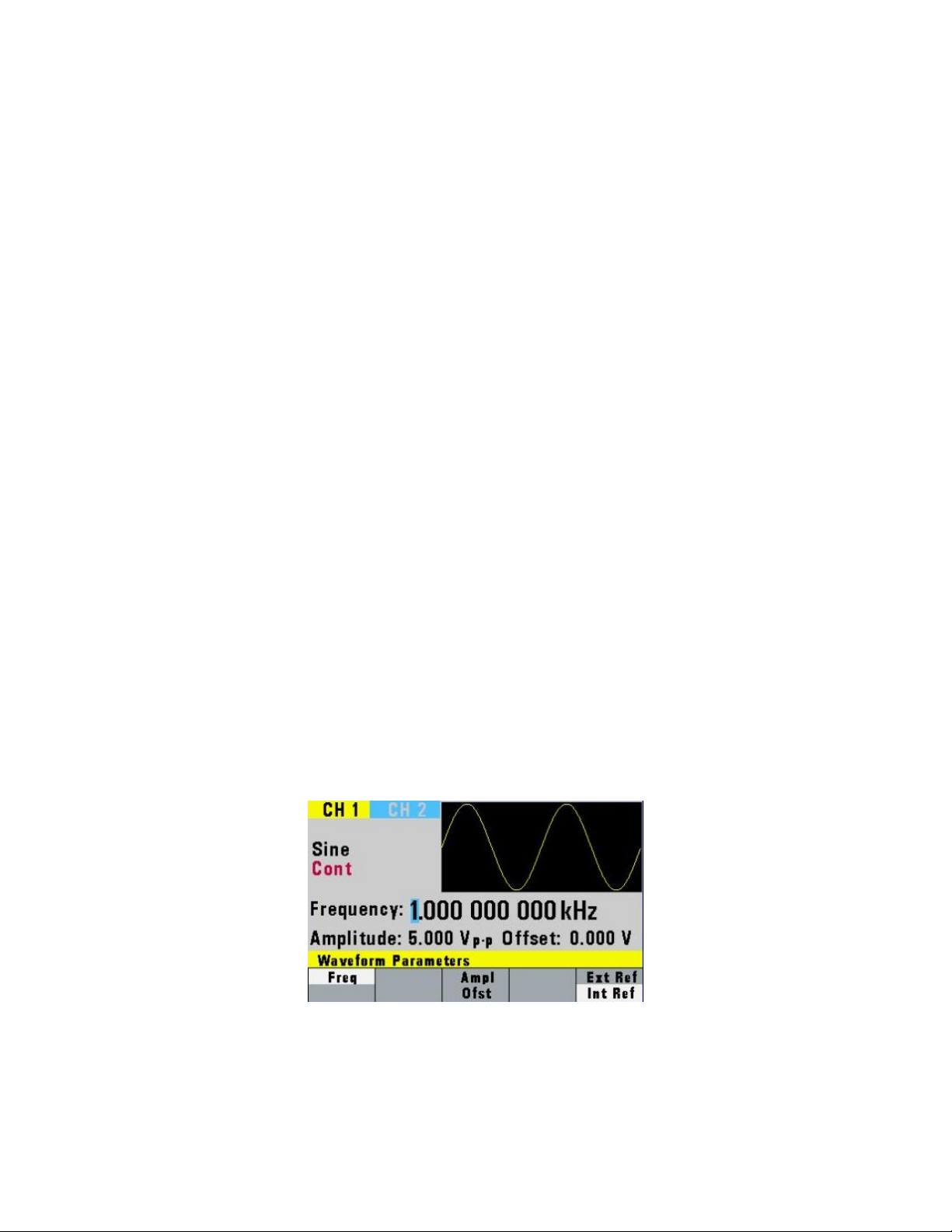

Figure 3.1 - Frequency Menu

F1: Freq/Rate - (Frequency) Selects and displays the frequency. Change the frequency setting using

the cursor keys and rotary knob or numerical keypad. If a certain wavelength can't

produce the waveform at the desired frequency, the waveform generator displays an

“Out of Range” error message.

10

Page 24

Front Panel

Amplitude Setting

Data Point

Value

Relative Output

Amplitude Voltage

5 Vp-p

8191

+2.5 V

5 Vp-p

4095

+1.25 V

5 Vp-p

0

0V (offset voltage)

- (Rate) Selects and displays the Point Rate (for Arbitrary Waveform only). The Rate

parameter governs the rate at which waveform points are executed, and thus the

frequency of the waveform output. When you set this parameter, the waveform

generator will keep that execution rate for all waveform lengths until it is changed.

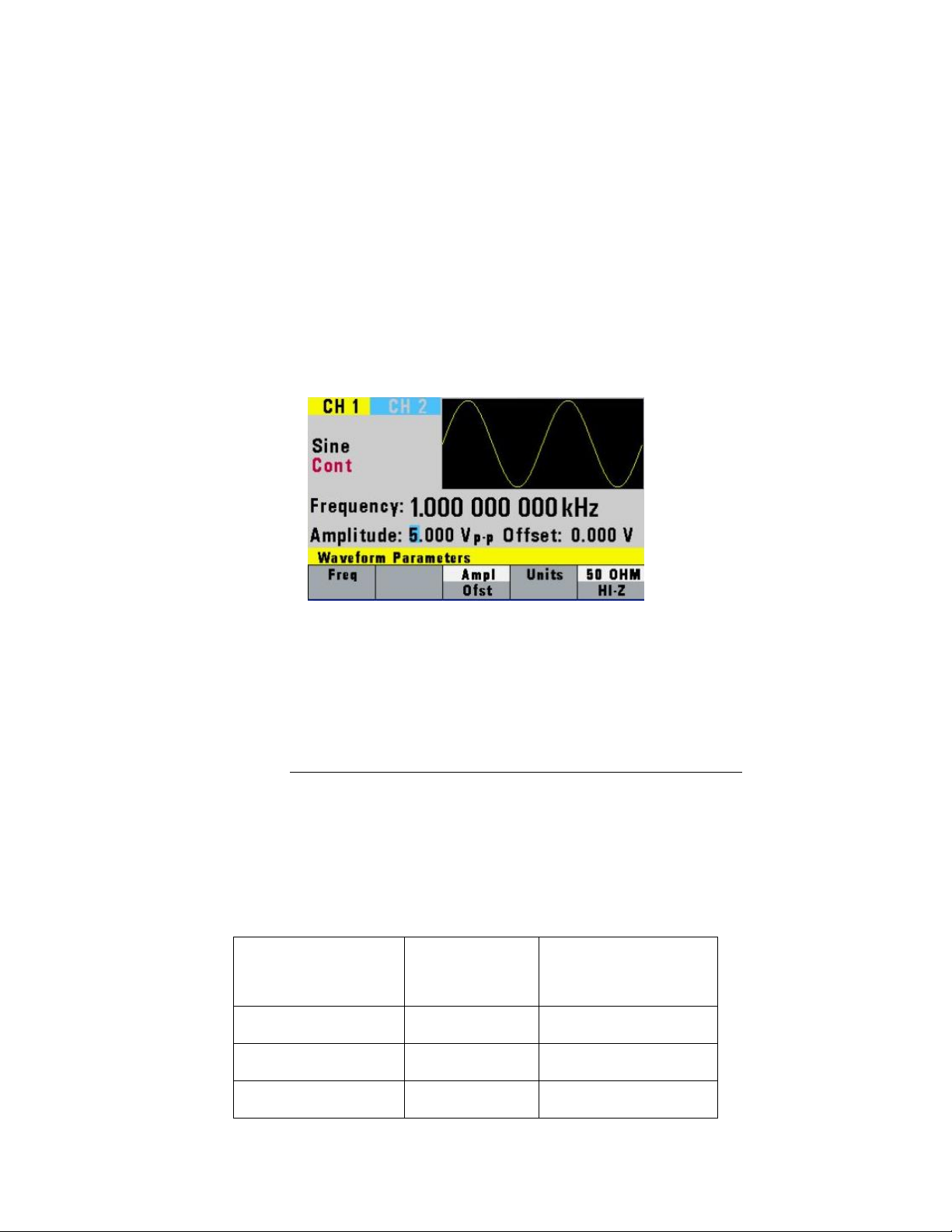

F3: Ampl/Ofst - Selects the Amplitude or the Offset parameters.

- (Offset) Change the offset by using the cursor keys, rotary dial or numerical keypad. If

a certain setting cannot be produced, the waveform generator will display a “Setting

Conflict” message.

In Arbitrary mode, this setting defines the maximum peak-to-peak amplitude of a fullscale waveform. If the waveform does not use the full scale of data (-8191 to +8191),

then its actual amplitude will be smaller.

Figure 3.2 - Amplitude Menu

Setting the Amplitude

The following equation represents the relative output amplitude voltage relationship

between the front-panel amplitude peak-to-peak setting and the data point values in

waveform memory:

𝐴𝑚𝑝𝑙𝑖𝑡𝑢𝑑𝑒 (𝑃𝑒𝑎𝑘 𝑡𝑜 𝑃𝑒𝑎𝑘 𝑠𝑒𝑡𝑡𝑖𝑛𝑔)× 𝑑𝑎𝑡𝑎 𝑝𝑜𝑖𝑛𝑡𝑠 𝑣𝑎𝑙𝑢𝑒

𝑂𝑢𝑡𝑝𝑢𝑡 𝑉𝑜𝑙𝑡𝑎𝑔𝑒 =

+ 𝑜𝑓𝑓𝑠𝑒𝑡

16382

Where 16382 is the total data point value range in waveform memory.

Examples

Table 3.1 - Output Voltage Examples

11

Page 25

9 Vp-p

-4095

-4.5 V

4 Vp-p

-8191

-2 V

F4: Units - Selects the amplitude units: peak-to-peak, RMS or dBm (sine waves only).

Note: This option is shown when Ampl is selected.

F5: 50 OHM/HI-Z - Selects the amplitude voltage value based on the two different impedance

termination (i.e. if connected to oscilloscope with 1MΩ input impedance,

generator will display the correct amplitude value for 1MΩ termination when HIZ is selected).

Note: This option is shown when Ampl/Ofst is selected.

F5: Int Ref/Ext Ref - Selects internal or external reference source (the external reference must be

connected to the rear panel Ref In connector).

Note: This option is shown when Freq is selected.

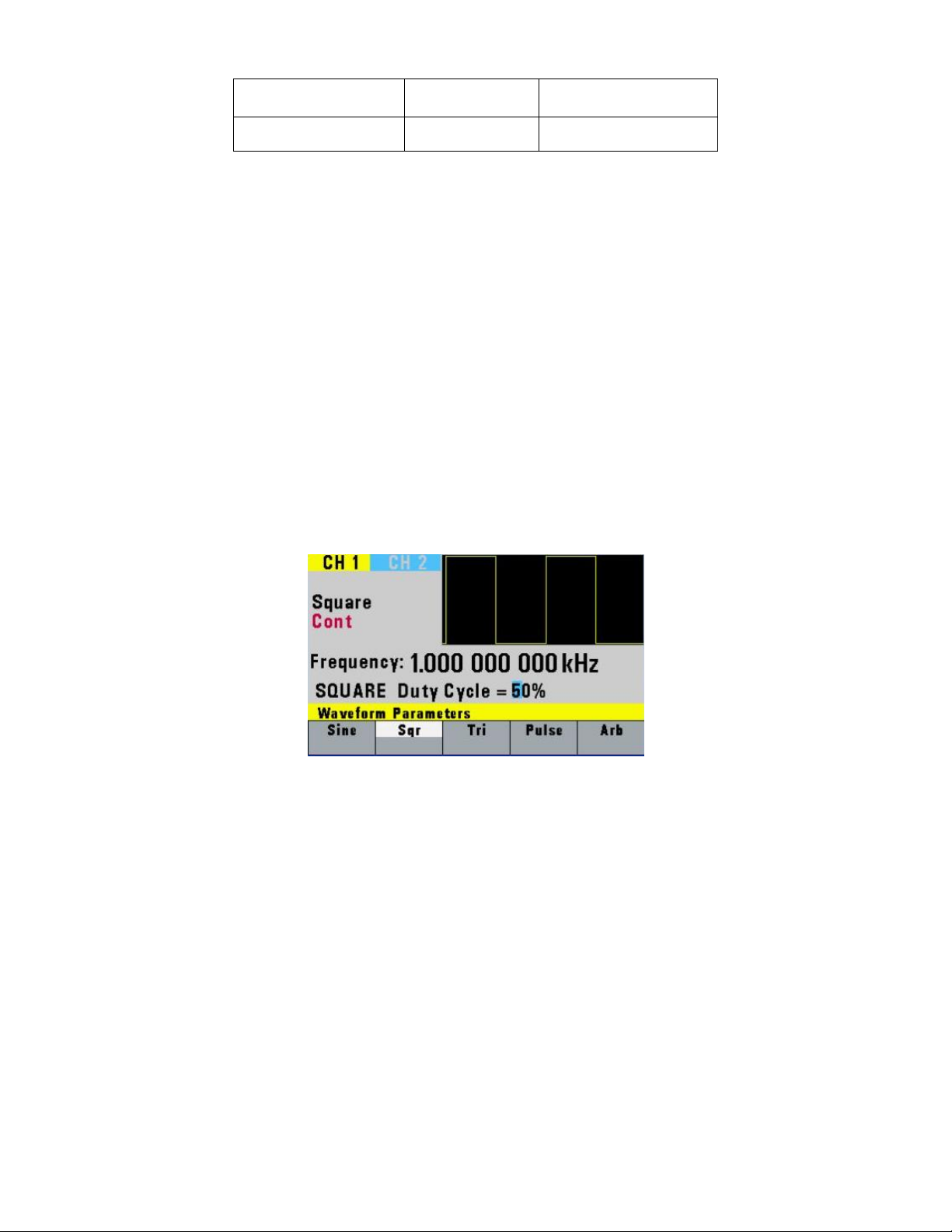

WAVEFORM Key

Displays the waveforms available:

Figure 3.3 - Waveform Menu

F1: Sine - Selects the sine waveform.

F2: Sqr - Selects the square waveform and displays the waveform duty cycle that can be

changed from 20% to 80% up to 10 MHz, 40% to 60% up to 30 MHz.

F3: Tri - Selects the triangle waveform and displays the waveform duty cycle that can be

changed from 0% to 100% up to 500 kHz, 10% to 90% up to 2 MHz, and 50% up to the

max frequency. The triangle maximum frequency is 5 MHz.

F4: Pulse - Selects the Pulse waveform and then displays the pulse menu. Refer to the PULSE

Menu section for details.

F5: ARB - Selects the arbitrary waveform and then displays the Arbitrary menu:

12

Page 26

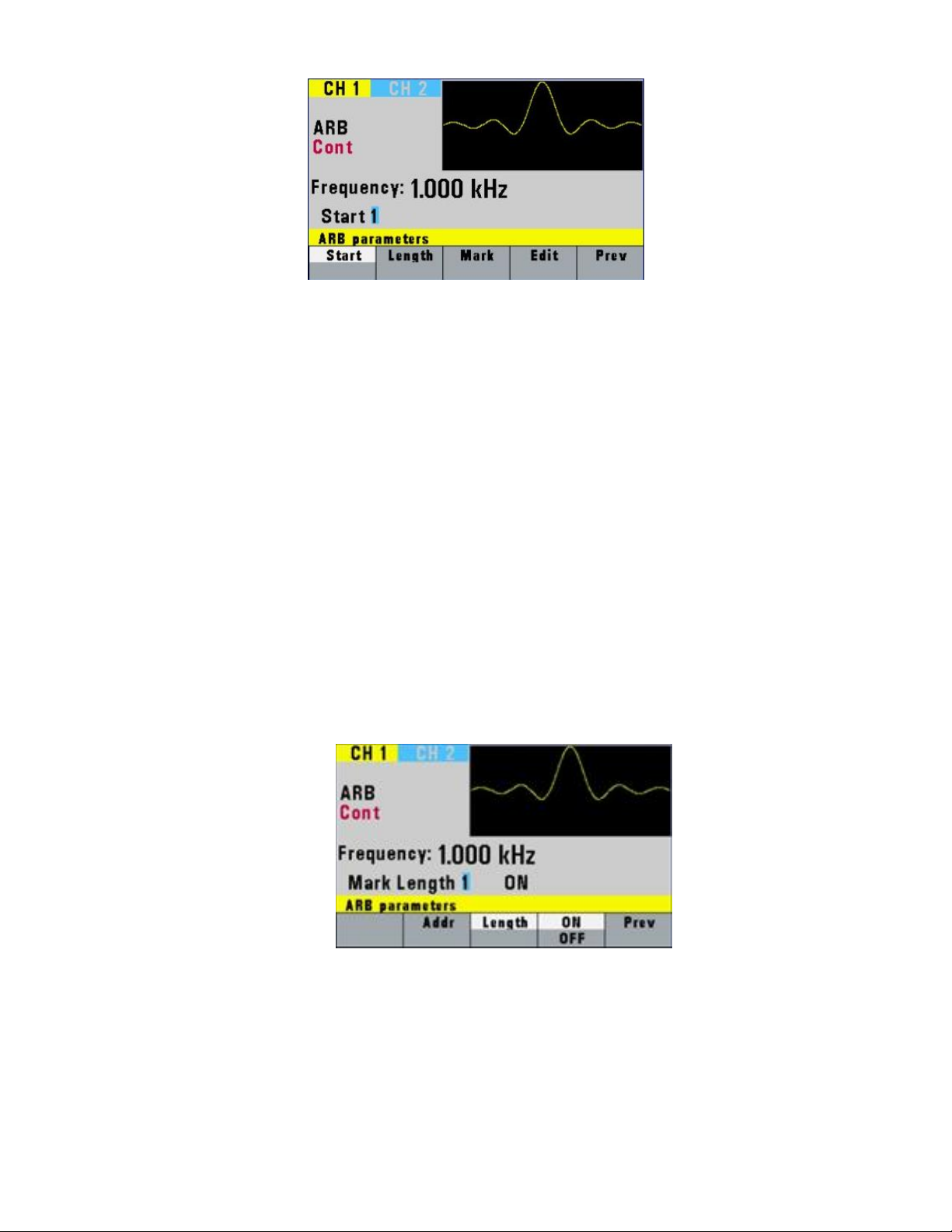

Figure 3.4 - Arbitrary Menu

F1: Start - Selects the starting address of the arbitrary waveform.

F2: Length - Selects the length of the arbitrary waveform. Use the START and LENGTH

menu selection to mark a selection of the waveform memory that will be

executed.

Note: The maximum Length allowed depends on model.

F3: Mark - (Marker Output) Selects the marker output address of the signal to be

available at the Marker Out connector. The F2: ADDR, F3: LENGTH or F4:

ON/OFF can be selected and the Marker output signal can be available at

every 4th location address between the start and stop addresses of the

executed waveform, starting from address 1 (i.e. 1, 5, 9, 13, etc.). This

marker output feature will allow you to generate a positive TTL level

output signal at the points specified by address and length.

Note: The maximum Length allowed to be set for marker is 4000. Marker

Length can be set at every 4th location address starting from 4 (i.e. 4, 8,

12, etc.)

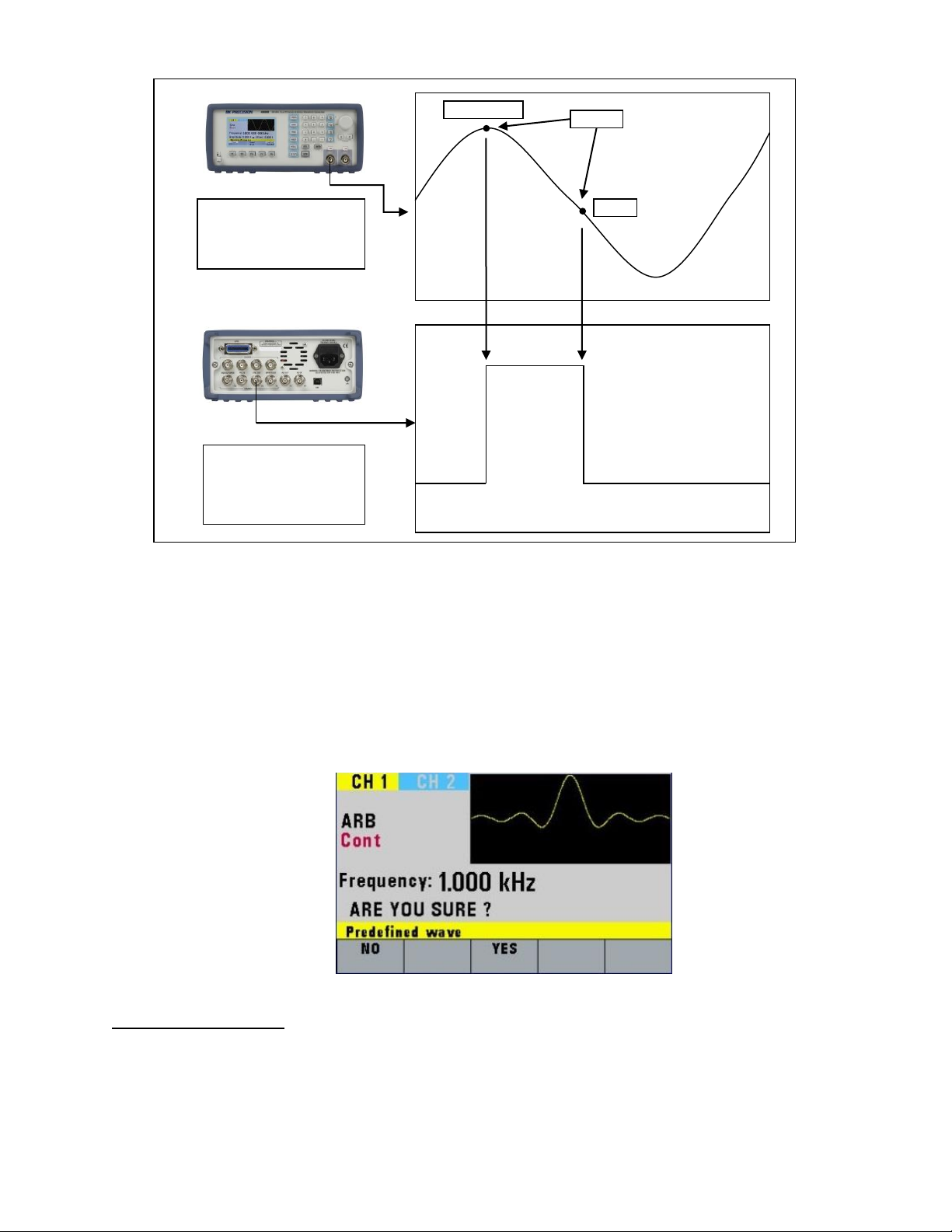

Figure 3.5 - Marker Menu

Below is an illustration of how the marker function works:

13

Page 27

Start Address

Length

Markers

0

5 V

Arbitrary waveform

channel output

5 V TTL signal output

from front panel

from rear Marker Out

connector

F4: Edit - Refer to the Arbitrary EDIT Menu section below for details.

F5: Prev - Back to previous menu.

Note: Changing one of the arbitrary parameters as start and length causes an update of the output

waveform to the new parameters. When exiting the Arbitrary Menu by selecting a different waveform,

a message to save the Arbitrary wave will be displayed. Select YES or NO to save the new waveform.

This save functions the same as the SAVE ARB function.

Figure 3.6 - Arb Saving Menu

Arbitrary EDIT Menu

Enters data for creating arbitrary waveforms. You can enter data one point at a time, as a value at an

address, draw a line from one point (a value at an address) to another point, create a predefined

waveform, or combine these to create complex waveforms. The valid data values range is -8191 to

8191. The valid waveform memory addresses range from 1 to maximum memory length of instrument.

14

Page 28

The data value governs the output amplitude of that point of the waveform, scaled to the instrument

output amplitude. Therefore, a value of 8191 corresponds to positive peak amplitude, 0 corresponds to

the waveform offset, and -8191 corresponds to the negative peak amplitude. The following menu

displayed:

Figure 3.7 - Edit Menu

F1: Point - This menu allows point by point waveform editing. When selected, the following

menu is displayed:

Figure 3.8 - Point Editing Menu

F1: Adrs - Select the current address in the arbitrary waveform memory.

F2: Data - Selects the data point value at the current address. You can change the

point value from -8191 to 8191.

F5: Prev - Returns to the previous menu (Edit menu).

F2: Line - This menu allows a line drawing between two selected points. When selected, the

following menu is displayed:

F1: From - Selects the starting point address.

F2: To - Selects the ending point address.

F4: Prev - Displays the Confirmation menu, F1: NO and F3: YES.

F5: Prev - Returns to the previous menu (Edit menu).

F3: Predef - (Predefined Waveforms) Selects one of the predefined waveforms.

15

Page 29

Wave

Minimum

Length

Divisible by

Sine

16

4

Triangle

16

4

Square

2

2

Noise

16

1

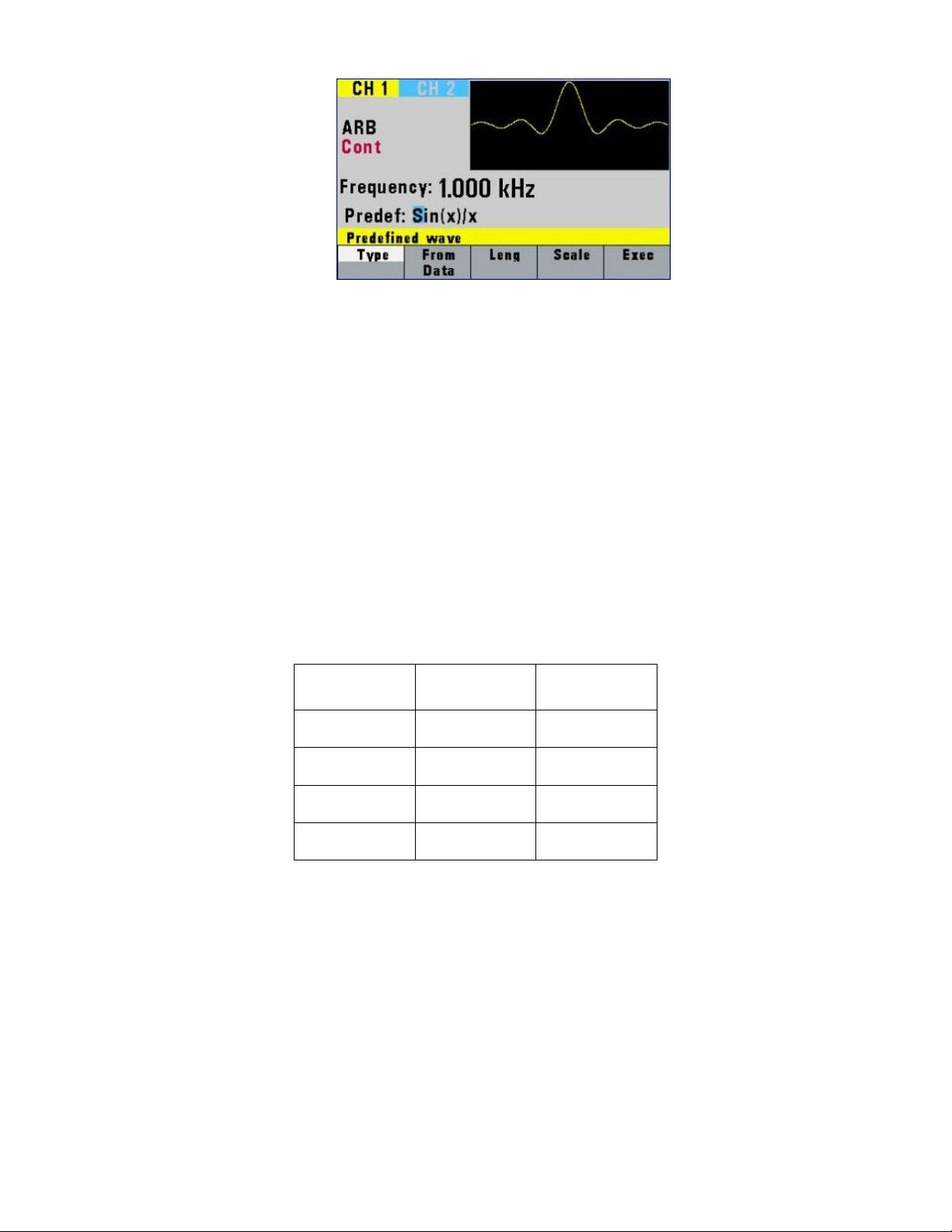

Figure 3.9 - Predefine Waveform Menu

F1: Type - Selects the waveform Sine, Triangle, Square, Noise, Ramp up, Ramp

down, exponential up, exponential down, Sin(x)/x, and Gaussian distribution. If Noise

function is selected, a submenu is displayed when F5: EXEC is pressed to allow adding

the noise to an available waveform or to generate it as a new noise waveform.

F2: From/Data - Selects the starting point of the generated waveform and its data

value.

F3: Leng - Selects the length of the predefined waveform (number of points for a

full wave). The length value must be a number that is divisible by 4 or by

2 in some instances. If not, a pop up message will say “Must divide by 4”

or “Must divide by 2” and entered values will change back to its original.

Different waveforms have different limitations on the length. Refer to

Table 3-2 below.

Table 3.2 - Waveform Length Limits for Predefined Waveforms

F4: Scale - Selects the scale of the waveform. If scale is too high, a message will

display “Scale too high.” 100% means that the waveform spans the full

scale of -8191 to 8191. Scale factors are limited by the point data value of

the starting point and automatically calculated by the unit.

16

Page 30

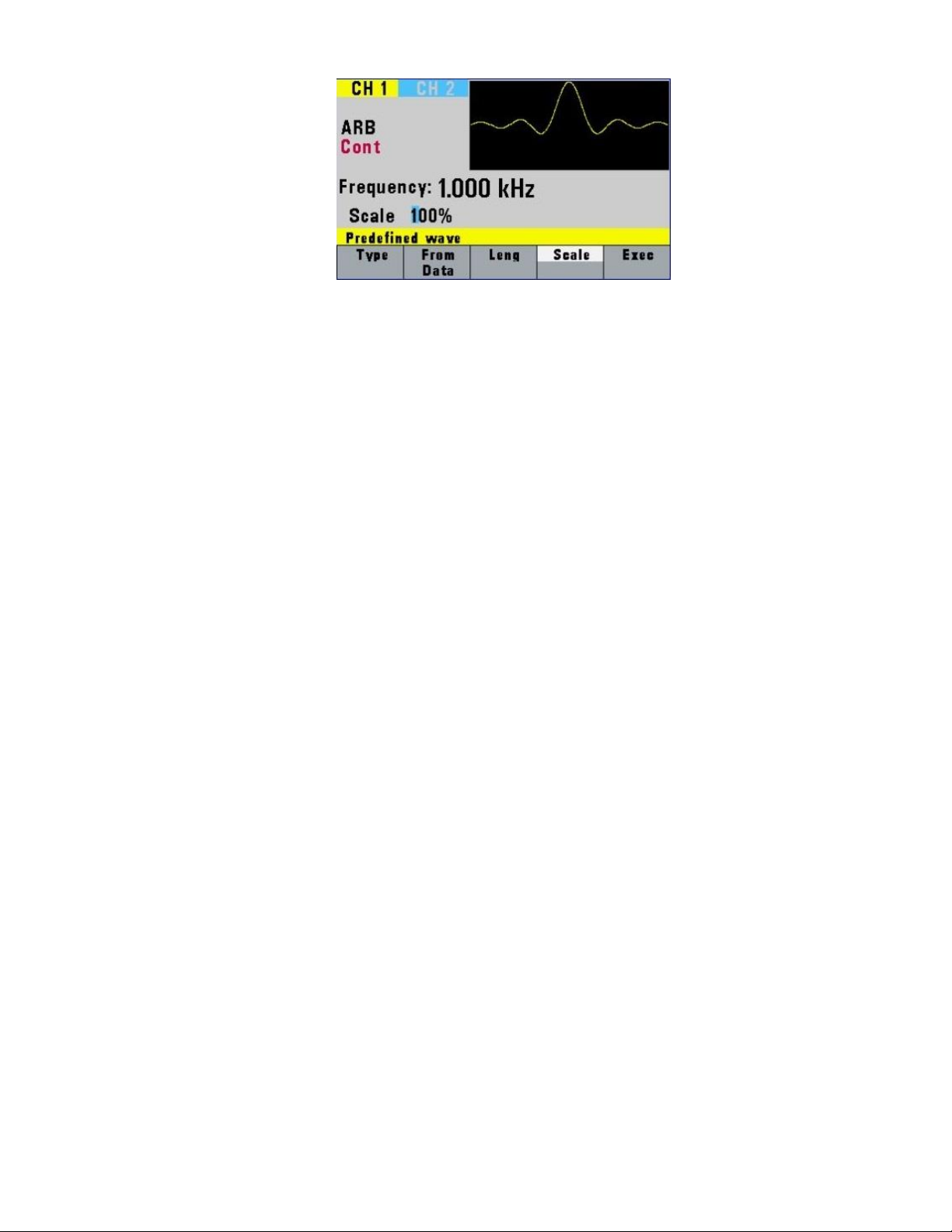

Figure 3.10 - Scale Menu

F5: Exec - Prompts you to confirm whether to execute the selected predefined

waveform. Press NO to abort executing the predefined waveform; press

YES to execute the predefined waveform. On the NOISE function a menu

of ADD and NEW is prompted to select a new noise waveform or to add

noise to the existing waveform.

F4: More - Displays the following Menu:

F1: Copy - Displays the Copy menu (see the Copy Function later in this section).

F2: Clear - Displays the Clear menu (see the Clear Function later in this section).

F3: Prot - Displays the Protect menu (see the Protect Function later in this

section).

F4: Show Wave - Display the Arbitrary waveform in full screen mode on LCD display.

This is only an approximated display for quick viewing. It does not represent the exact

waveform being generated. To return back to the MENU selection, press any button.

F5: Prev - Returns to the previous menu.

Copy Function - Copies an area of waveform memory to another area of waveform memory.

F1: From - Selects the address of the first point to copy.

F2: Leng - Selects the length (number of points) of the waveform to copy.

F3: To - Selects the destination address where the first point is copied.

F4: Exec - Prompts to confirm to copy data. Press NO to abort copying, YES to copy.

F5: Prev - Returns to previous menu.

Clear Function - Clears (sets the data values to zero) either a section of or all of waveform memory.

F1: From - Selects the address of the first point to clear.

F2: To - Selects the address of the last point to clear.

F3: All - Clears the whole waveform memory.

F4: Exec - Prompts to confirm to clear data. Press NO to abort clearing, YES to

clear.

F5: Prev - Returns to previous menu.

17

Page 31

Protect Function - Protects (makes read-only) a section of waveform memory.

Note: Only one segment of waveform memory can be protected at a time.

F1: From - Selects the address of the first point to protect.

F2: To - Selects the address of the last point to protect.

F3: All - Clears the whole waveform memory.

F4: On/Off - Selects the unprotect mode and resets memory protection so that the

whole waveform memory can be written into.

F5: Prev - Returns to previous menu.

PULSE Menu

From the WAVE menu, select F4: Pulse.

Figure 3.11 - Pulse Menu

F1: Freq/Period - Selects the parameter definition of the Pulse repetition period.

F2: Width - Selects the Width of the generated pulse.

F3: Equal Edge - Selects equal Rise (Leading edge) and Fall (Trailing edge) times of the pulse.

F4: Lead/Trail - Selects different Rise and Fall times of the Pulse.

F5: Prev - Returns to previous menu.

MODE Key

Selects the output mode: Cont (Continuous), Trig (Triggered), Gated (Gated), and Burst (Burst).

To select the output mode, press MODE, then press the function key that corresponds to the desired

Mode menu option, as shown:

18

Page 32

Figure 3.12 - Mode Menu

F1: Cont - (Continuous) - Selects continuous output.

F2: Trig - (Triggered) - Triggers one output cycle of the selected waveform for each trigger

event.

F3: Gate - (Gate) - Triggers output cycles as long as the trigger source asserts the gate signal.

F4: Burst - (Burst) - Triggers output N output cycles for each trigger event, where N ranges from

2 to 999999.

F5: Phase - Selects the start phase of the signal in non-continuous modes. The range is from -

180˚ to +180˚, with a 0.1˚ resolution.

When Phase Menu is selected the following screen is displayed:

Figure 3.13 - Phase Menu

F1: Phase - Sets the phase.

F2: SET-Zero - Sets the phase reference to zero.

F3: SYNC Both Ch. - For Dual Channel models, pushing this key synchronizes both

channels in between with a phase shift as in the Phase parameter

entered (or 0 after pushing SET-Zero).

After selecting the TRIG, GATE or BURST menu, the trigger source menu is available:

19

Page 33

Figure 3.14 - Trigger Menu

F1: Man - Selects manual as the trigger source. To trigger the waveform generator, press this

MAN TRIG again.

F2: Int - (Internal) Selects the internal trigger generator as the trigger source. Change the

internal trigger rate displayed with the rotary input knob.

F3: Ext - (External) Selects the external trigger signal as the trigger source. The trigger source

is supplied through the TRIG IN connector.

F4: Nbrst - In BURST mode, the F4 displays Nbrst, the number of burst pulses to be output with

each trigger. The N can be changed from 1 to 999,999.

F5: Prev - (Previous) Returns to the previous Menu selection.

SWEEP Key

Selects the Sweep Mode and allows the entering of sweep parameters: Sweep Start, Sweep Stop, and

Sweep Rate.

To select the sweep mode, press SWEEP and then press the function key that corresponds to the

desired Sweep menu option as shown below.

Figure 3.15 - Sweep Menu

F1: ON/OFF - Operates the sweep function, selecting between Sweep On or Off.

20

Page 34

F2: Start - Defines the Sweep Start frequency.

F3: Stop - Defines the Sweep Stop frequency.

F4: Rate - Defines the Sweep Rate.

F5: Lin/Log - Selects Linear or Logarithmic Sweep.

How to Set up Sweep in Different Modes

By default, turning ON the sweep function will automatically set to a continuous (Cont) sweep. In order

to change to other modes of sweep, do the following:

1. Set sweep to On by pressing F1.

2. Press the MODE button on the front panel.

3. Select between triggered (Trig), burst (Burst) or gated (Gate) mode.

Note: If this is done before turning on sweep, sweep On selection will automatically reset to

default (continuous mode).

MODULATION Key

Selects the modulation mode AM, FM, or FSK.

To select the modulation mode, press MODUL key and then press the function key that corresponds to

the desired menu option.

Figure 3.16 - Modulation Menu

F1: AM - If AM is selected, the following menu is available:

21

Page 35

Figure 3.17 - AM Menu

F1: ON/OFF - Turns the modulation ON or OFF.

F2: % - Defines the AM modulation depth.

F3: Shape - Defines the modulation shape between Sine, Triangle or Square.

F4: Mod/Freq - Selects the modulation frequency, from 0.01 Hz to 20.00 KHz.

F5: Ext/Int - Selects and enables the external modulation by an external signal

applied to the Modulation In connector.

F2: FM - If FM is selected, the following menu is available:

Figure 3.18 - FM Menu

F1: ON/OFF - Turns the modulation ON or OFF.

F2: Dev - Defines the FM deviation frequency.

Note: The deviation is < the frequency. Frequency + deviation is limited to

the unit maximum frequency.

F3: Shape - Defines the modulation shape between Sine, Triangle or Square.

F4: Mod/Freq - Selects the modulation frequency, from 0.01 Hz to 20.00 KHz.

F5: Ext/Int - Selects and enables the external modulation by an external signal

applied to the Modulation In connector.

F3: FSK - If FSK is selected, the following menu is available:

22

Page 36

SINE

SQUARE

TRIANGLE

PULSE

ARBITRARY

AM

Yes

Yes

Yes

Yes

Yes

FM

Yes

Yes

Yes

No

No

FSK

Yes

Yes

Yes

No

No

Figure 3.19 - FSK Menu

F1: ON/OFF - Turns the modulation ON or OFF.

F2: F-LO - Defines the low frequency of the FSK.

F3: F-HI - Defines the high frequency of the FSK.

F4: Rate - Selects the rate of the alternating between the low and high

frequencies.

F5: Ext/Int - Selects and enables the external FSK when the unit frequency is

alternating between the low and high frequencies by an external signal

applied to the Trig In connector.

Modulation Combinations

SETUPS Key

The waveform generator can store the current front-panel settings, called a setup, into one of 50

storage locations. When you recall a setup, the waveform generator restores the front-panel settings to

those that you stored in the selected storage location. All waveform data except for the waveform

memory data is stored in the setup.

Figure 3.20 - Setups Menu

23

Page 37

Stored

Parameters

FREQUENCY

RATE(ARB)

AMPLITUDE

FUNCTION

OFFSET

REPETITION

MODE

N-BURST

START ADRS

WAVELENGTH

TRIG SOURCE

OUTPUT

SWEEP

MODULATION

F1: Recall - Recalls a previously stored front-panel setup from the selected storage location.

Change the storage location number by using the rotary input knob. Valid storage

location numbers are from 0 to 49. Location 0 is a read-only buffer that contains the

power-on settings listed in Table 3.3.

F3: Store - Stores the current front-panel setup to the specified storage location. Change the

storage location number by using the numeric keypad or the rotary input knob. Valid

storage location numbers range from 1 to 49. Below is a list of parameters that can be

stored in each storage location.

Table 3.3 - List of Stored Parameters

When the ARB waveform is selected, the setup menu is as shown:

Figure 3.21 - Setups Menu (with Arbitrary waveform selected)

F2: Load ARB - Selecting this will load the selected Arbitrary waveform data points.

F4: Save ARB - Selecting this will save the current Arbitrary waveform data points so that it can be

recalled when revisiting the ARB menu later on or when power cycling the instrument.

24

Page 38

8 full-length waveforms can be saved per channel. The saving is performed only on the

waveform segment that is defined by the Start and Length parameters defined in the

ARB menu.

Note: Storing a waveform generator setup does not store waveform memory data.

The STORE and RECALL function can be used as a tool to store and locate many arbitrary waveforms.

See Memory section for more information on segmenting arbitrary waveforms.

UTILITY Key

Figure 3.22 - Utility Menu

F1: Gpib - Selects the GPIB remote mode of operation. After selection, the GPIB address can be

set to any value from 1 to 31 using the rotary knob. The value is kept in nonvolatile

memory and used at power-on. The factory default address is 9. Setting the address to

31 puts the device in the off-bus state (it will not respond to messages on the GPIB

bus).

Note: GPIB is only for models 4076B, 4077B, 4079B, and 4080B.

F2: USB - Selects the USB remote mode of operation. If selected, the ACTIVE message is

displayed.

F4: Power - (Power-On default) Selects the power-on default setting. Select a value using the

numeric keypad or the rotary input knob. The selection is effective after a 10 s timeout period. Select zero (0) to have the waveform generator power on with the factory

default settings. Select 50 to have the waveform generator power-on with the settings

it had at the last power-off. Select any other value in the range from 1 to 49 to have

the waveform generator power-on with the settings that you have saved with STORE

(see SETUPS Key section) in the range of 1 to 49.

F5: SN - Selecting this will display the serial number information of the unit.

25

Page 39

Key Functions

Values

Description

FREQUENCY

1.000000000 Hz

Wave frequency

RATE(ARB)

1 µs

Sample time per point

AMPLITUDE

5.00 V

Peak to peak output amplitude

FUNCTION

SINE

Output waveform

OFFSET

0.00 V

Zero offset

REPETITION

10 ms

Internal trigger rate

Figure 3.23 - Serial Number Information

3.2 ON Key

Use this key to control the main output signal. When the output is active, the On button is illuminated

by the built-in LED.

3.3 Cursor Movement Keys

Use these keys to move the cursor (when visible) either left or right. They are used in conjunction with

the rotary input knob to set the step size of the rotary input knob.

3.4 Rotary Input Knob

Use this knob to increase and decrease numeric values or to scroll through a list. The cursor indicates

the low-order position of the displayed value which changes when you rotate the knob (for straight

numeric entries only). For other types of data, the whole value changes when you rotate the knob.

3.5 Power-On Settings

At power-on, the waveform generator performs a diagnostic self-test procedure to check itself for

errors. If it finds an error, an error code and text will appear in the display window. Other error codes

appear when you enter an invalid front-panel setting. For more information on error codes, see the

Displaying Errors section 3.7.

When the waveform generator finishes the diagnostic self-test routine, it enters the local state and

assumes power-on default settings. Table 3.4 below lists the factory default settings. You can also

program the waveform generator for any settings you want at power-on.

Table 3.4 - Power-On Default Settings

26

Page 40

MODE

CONT

Waveform mode

N-BURST

2

Waves per burst

START ADRS

1

Start memory address

WAVELENGTH

1000

Number of points per waveform

TRIG SOURCE

EXT

External trigger source

OUTPUT

OFF

Output disabled

SWEEP

OFF

Sweep execution

MODULATION

OFF

Modulation execution

4075B

4078B

4076B

4079B

4077B

4080B

Channels 1 2 1 2 1 2

Waveform

Memory

Length

2 points to 1,048,576 points

2 points to 4,194,304 points

2 points to 16,777,216 points

3.6 Memory

The waveform generator has two types of memory that can be stored and recalled:

- Waveform Memory (8 waveforms per channel)

- Setup Memory (0-49 buffer storage locations)

Up to 8 full waveforms can be stored, each with up to the maximum waveform memory points

available per channel.

The user can edit arbitrary waveforms in waveform memory and specify any data value in the range

from -8191 to 8191 for any point in waveform memory (14-bit depth). Due to the large memory bank,

users have greater freedom in selecting the size and number of waveforms they desire to generate. The

STORE and RECALL functions can be used to save the starting address and length of up to 49 different

waveforms as reference point setups for quick recall.

Note: The 49 different setups are shared between all 8 arbitrary waveform memory banks. For

instance, if Setup 1 is saved from address 1 to 1000 for ARB Wave 1, then ARB Wave 2 is selected and

Setup 1 is recalled, address 1 to 1000 will be the recalled reference points.

Waveform Memory setup example:

4080B users could segment one 16,777,216-point arbitrary waveform bank to create a waveform with 1

Mpts, another waveform with 5 Mpts, a third waveform with 4 Mpts, and a fourth waveform with 6

Mpts as shown in figure below.

27

Page 41

1. First, create or load 16,777,216 waveform data points into arbitrary waveform memory. For more

information, please see the Creating an Arbitrary Waveform section.

2. Save all 16,777,216 points into ARB Wave 1 using the “Save ARB” key in the SETUPS menu.

3. Reference each waveform in the memory bank according to their starting point and length. Using

the “Store” key in the SETUPS menu, save the parameters for each waveform to separate Setup

memory locations as follows:

Setup 1 ARB parameters: Start address = 1; Length = 1,000,000 points

Setup 2 ARB parameters: Start address = 1,000,001; Length = 5,000,000 points

Setup 3 ARB parameters: Start address = 6,000,002; Length = 4,000,000 points

Setup 4 ARB parameters: Start address = 10,000,003; Length = 6,000,000 points

To save edited arbitrary waveforms into Waveform Memory, the instrument will display a message

"SAVE DATA" after each modification of the arbitrary waveform in the EDIT menu. Please note that any

subsequent saving of data will rewrite the entire arbitrary waveform memory bank. Therefore, in order

to properly segment the entire range of points in Waveform Memory for Setup recall, the full length of

data points should be saved to Waveform Memory first.

Note: Since it is impossible to guarantee 100% of the time against loss of stored data, you should

maintain a record of the data stored in memory so that you can manually restore such data, if

necessary.

3.7 Displaying Errors

At power-on, the waveform generator performs a diagnostic routine to check itself for problems. If the

diagnostic routine finds an error, an error message is displayed. The waveform generator also displays

error messages when front-panel settings are either invalid or may produce unexpected results.

Message Text Cause

Out of range Attempt to set variable out of instrument limits.

Setting conflict Can't have this parameter set with some other.

28

Page 42

Trig rate short Internal trigger rate too short for wave/burst.

Empty location Attempt to restore nonexistent setting.

SCALE too high Attempt to set scale too high for current dot value

Protected RAM Attempt to write to protected RAM range.

RAM error Error in testing RAM.

Save RAM New firmware installed.

Must divide by 4 Predefined wave length must be divisible by 4.

Must divide by 2 Predefined wave length must be divisible by 2.

3.8 Creating an Arbitrary Waveform

You can create an arbitrary waveform using the following methods:

Enter individual data points

Draw lines between data points

Create a predefined waveform

Export a waveform from software

Create data points using SCPI commands

The waveform’s frequency and amplitude are influenced by the number of data points and their value

in the waveform. For further information on how the number of data points influence the frequency

and amplitude of a waveform in execution memory, see Setting the Frequency section (on page 32) and

Setting the Amplitude section (on page 33), respectively.

Entering Individual Data Points

The most basic way to program an arbitrary waveform is to enter data points for the waveform, one

data point at a time. While this can become tedious, the auto-increment function helps this process.

To enter individual data points into waveform memory, follow these steps:

1. Press WAVE main key to display the selection menu.

2. Press F5: ARB to display the arbitrary menu.

3. Press F4: EDIT to display the Edit menu.

4. Press F1: POINT to select the point-by-point programming mode.

5. Press F1: ADRS.

6. Use the rotary knob or the numerical keypad to enter the address.

7. Press F2: DATA.

8. Use the rotary knob or the numerical keypad to enter the value for the data point. Valid

entries range from –8191 to 8191.

9. Repeat steps 5 through 8 for additional points until you finish creating your arbitrary

waveform.

29

Page 43

ACTION

KEYSTROKES

Loads the first 1000 points of waveform

memory.

WAVE

F5: ARB

F1: START

1

F2: LENGTH

1000

F5: PREV

MODE

F1: CONT

OUTPUT ON

ACTION

KEYSTROKES

Step 1: Load a 1000-point, 50% scaled,

predefined sine wave into waveform memory

starting at address 1.

WAVE

F5: ARB

F4: EDIT

F3: PREDEF

F1: TYPE (rotate knob for selection)

SINE

F2:FROM/DATA

1

F3: LENG

1000

F4: SCAL

50

F5: EXEC

Creating a Complex Arbitrary Waveform

To create a complex arbitrary waveform:

Load a predefined sine waveform

Load a scaled sine waveform at the positive peak of the first sine wave

Draw a straight line between two data points in the waveform

Add a pulse/glitch to the waveform

Add a noise signal at the negative peak of the first sine wave

To see the waveform as you build it, connect the waveform generator to an oscilloscope and perform

the following steps:

Note: The user must press ENTER to confirm any input data value (Start address, Length, etc.) when

performing the following steps.

The following steps set up the waveform shown in Figure 3.24.

30

Page 44

F3: YES

Step 2: Load a 5% scaled, 100-point predefined

waveform into waveform memory starting at

address 200.

F3: PREDEF

F1: TYPE

SINE

F2: FROM

200

F3: LENG

100

F4: SCAL

5

F5: EXEC

F3: YES

Step 3: Draw a line between address 251 (the

highest point of the sine wave) and address 501

(where the sine wave crosses the origin).

F2: LINE

F1: FROM

251

F2: TO

501

F4: EXEC

F3: YES

Step 4: Add a negative pulse/glitch (data value -

8191) at addresses 600 through 606.

F1: POINT

F1: ADRS

600

F2: DATA

-8191

(repeat -8191 and ENTER

for addresses 601-606)

F5: PREV

Step 5: Add a 5% noise signal to addresses 700

through 800.

F3:PREDEF

F2:FROM

700

F3:LENG

100

F4:SCAL

5

F1:TYPE

NOISE

F5:EXEC

F1:ADD

F4:EXEC

F3-YES

31

Page 45

ACTION

KEYSTROKES

Step 1. Set the output rate to 1 µs (equivalent to

1000 Hz output frequency)

PARAM

F1: RATE

1

KHz/us

Figure 3.24 - Steps to set up an Arbitrary Waveform

Setting the Frequency

The arbitrary waveform frequency is a function of the number of data points used to run the waveform

(the length parameter in the ARB menu) and the waveform execution point rate. The waveform

execution point rate is the execution time between each point in the waveform. The total time taken to

run one period of the waveform is given by:

𝑇𝑜𝑡𝑎𝑙 𝑡𝑖𝑚𝑒 = # 𝑜𝑓 𝑝𝑜𝑖𝑛𝑡𝑠 ∙ 𝑟𝑎𝑡𝑒

Because the output frequency is a function of the rate and the number of points being executed, the

output frequency is calculated as:

𝑓𝑟𝑒𝑞𝑢𝑒𝑛𝑐𝑦 =

# 𝑜𝑓 𝑝𝑜𝑖𝑛𝑡𝑠 ∙ 𝑟𝑎𝑡𝑒

For example, to set the output frequency to 1000 Hz, given the number of data points used for the

waveform output is 1000, the rate is calculated as:

1

𝑟𝑎𝑡𝑒 =

1000 𝑝𝑡𝑠 ∙ 1000 𝐻𝑧

EXAMPLE: Setting the Output Frequency

To set the output frequency of a 1000-point waveform to 1000 Hz, set the rate to 1 µs:

1

= 1 𝜇𝑠

32

Page 46

Front Panel

Amplitude Setting

Data Point Value

Relative Output

Amplitude Voltage

5 V p-p

8191

2.5 V positive peak

5 V p-p

0

0 V (offset voltage)

10 V p-p

-8191

5 V positive peak

Setting the Amplitude

The following equation represents the relative output amplitude voltage relationship between the

front-panel amplitude peak-to-peak setting and the data point values in waveform memory:

𝑜𝑢𝑡𝑝𝑢𝑡 𝑣𝑜𝑙𝑡𝑎𝑔𝑒 =

Where 16382 is the total data point value range in waveform memory.

Table 3.5 - Relative Amplitude for Waveform Output (Examples)

𝐴𝑚𝑝𝑙𝑖𝑡𝑢𝑑𝑒 𝑝 − 𝑝 𝑠𝑒𝑡𝑡𝑖𝑛𝑔 ∙ 𝑑𝑎𝑡𝑎 𝑝𝑜𝑖𝑛𝑡 𝑣𝑎𝑙𝑢𝑒

+ 𝑜𝑓𝑓𝑠𝑒𝑡

16382

Loading an Arbitrary Waveform

To load a section of arbitrary waveform memory, specify its start address and length in the ARB menu:

1. Select the channel to ON.

2. Press WAVE and select the F5: ARB function.

3. Press F1: START to display the start address and use the rotary input knob or the numerical

keys to enter the address.

4. Press F2: LENGTH to display the length of the waveform and use the rotary input knob or the

numerical keys to enter the length.

Note: The starting address must be an odd number. If an even number is entered, the instrument will

automatically decrement one value to an odd number. For example, if you set start address to 2000

and press ENTER, it will display 1999. The length value must always be an even number. If you input an

odd number length, a message will pop up and say “Even wave length” and then decrement one value

to an even number. For example, if you entered 1001 as the length, the message will pop up for one

second and change the value automatically to 1000.

3.9 Remote Interface

USB Interface

The instrument has a USB interface (USBTMC) on the rear panel for remote communication. From the

UTIL menu, press USB to select the USB interface.

33

Page 47

To communicate with the unit, you must install the USB driver. For Windows® 7 and 8 users, this may

install automatically. For other users, visit www.bkprecision.com to download the driver.

Note: Users who have LabVIEW™ or NI-VISA installed will automatically have this driver in their system.

In this case, driver download is not required.

GPIB Interface

GPIB Address

The instrument has an optional GPIB interface on the rear panel for remote communication. The

optional GPIB interface is shipped with the address set to decimal 9. The address can be changed from

the front panel by using the UTIL menu (refer to UTILITY Key section on page 25).

GPIB Connection

The rear panel GPIB connector connects to a standard IEEE-488 bus cable connector. The GPIB line

screens are not isolated from chassis and signal ground.

Figure 3.25 – Standard GPIB connector

34

Page 48

4 Programming

4.1 Overview

GPIB

This section provides detailed information on programming the 4075B Series generators via IEEE-488

GPIB interface. The command syntax as defined by the IEEE 488.2 and SCPI standards are explained in

this chapter.

4.2 Device State

The device may be in one of the four possible states described below. The transition between states is

defined by IEEE 488.1.

Local State (LOCS)

In LOCS, the device may be operated from the front panel only. Its settings may be queried over the

GPIB, but not changed. Commands that do not affect the signal being output by the instrument are

accepted.

Local With Lockout State (LWLS)

In LWLS, the device may be operated from the front panel only. Its settings may be queried over the

GPIB, but not changed. Commands that do not affect the signal being output by the instrument are

accepted. The difference between the LOCS and the LWLS is that from the LWLS the device may enter

the Remote With Lockout State.

Remote State (REMS)

In REMS, the device may be operated from the GPIB. Actuating any front panel key will cause the

device state to revert to the LOCS.

Remote With Lockout State (RWLS)

In the RWLS the device is operable only from the GPIB. Front panel operation may be returned by

either sending an appropriate IEEE 488.1 command, or by cycling the device power.

4.3 Interface Function Subsets

The following interface function subsets are implemented in the 4075B series:

SH1, AH1, T6, L4, SR1, RL1, PP0, DC1, DT1, E2, C0

4.4 Device Address

The GPIB address of the device may be set to any value from 0 to 31. The address may be changed from

the front panel, using the numeric keypad or the rotary encoder, or via the GPIB itself using the

35

Page 49

command:

:SYSTem:COMMunicate:GPIB:ADDRess

Setting the device to address 31 puts it in the 'off-bus' state. In this state it will not respond to

messages on the GPIB. If the device is in the REMS when set to address 31, an internal 'return-to-local'

command will be given, setting the device to the LOCS. If the device is in the RWLS, the 'return-to-local'

command is ignored, and the device remains in the RWLS. The only way to then re-establish

communication with the device over the GPIB is to cycle the power, and to then change the address to

that required from the front panel.

4.5 Message Exchange Protocol

The device decodes messages using the Message Exchange Protocol (MEP) defined in IEEE 488.2. The

following functions implemented in the MEP must be considered:

The Input Buffer

The device has a 256-byte long cyclic input buffer. Decoding of remote messages begins as soon as the

input buffer is not empty, that is, as soon as the controller has sent at least one byte to the device.

Should the input buffer be filled up by the controller faster than the device can remove the bytes and

decode them, the bus handshake is not completed until room has been made for more bytes in the

buffer. This prevents a fast controller from overrunning the device with data.

If the user has sent part of a Program Message, but not the Program Message Terminator, and he

wishes to abort the message decoding and execution, the Device Clear command may be sent, or front

panel operation resumed (in REMS only).

The Output Queue

The device has a 100-byte long output queue in which it stores response messages for the controller to

read. If at the time a response message is formatted the queue contains previously formatted response

messages, such that there are not enough places in the queue for the new message, the device will put

off putting the message in the queue until there is place for it.

The Status Byte MAV bit, when set, indicates that part or all of a response message is ready to be read.

Response Messages

The device sends a Response Message in response to a valid query. All queries return a single Response

Message Unit. In only one case is the Response Message generated when the response is read (as

opposed to when the response is parsed), and this is when querying Arbitrary Waveform data. All other

queries generate the Response Message when they are parsed.

Coupled Commands

Coupled Commands are either commands whose execution validity depends on the value of other

parameters, or commands whose execution changes the value of another parameter. The execution of

commands designated as being coupled is deferred until all other commands in the same Program

36

Page 50

Message have been executed. The coupled commands are then grouped together according to their

functionality, and executed as a group. These groups of coupled commands are defined in the 4075B

series:

a) The commands to set the amplitude, the offset, and to switch the output on. The output being