Page 1

Model: 4076, 4079

50 MHz Arbitrary Function Generator

USER MANUAL

Page 2

SERVICE INFORMATION

Warranty Service: Please go the support and service section on our website www.bkprecision.com to obtain a RMA #. Return the

product in the original packaging with proof of purchase to the address below. Clearly state on the RMA the performance problem and

return any leads, probes, connectors and accessories that you are using with the device.

Non-Warranty Service: Please go the support and service section on our website www.bkprecision.com to obtain a RMA #. Return the

product in the original packaging to the address below. Clearly state on the RMA the performance problem and return any leads, probes,

connectors and accessories that you are using with the device. Customers not on an open account must include payment in the form of a

money order or credit card. For the most current repair charges please refer to the service and support section on our website.

Return all merchandise to B&K Precision Corp. with pre-paid shipping. The flat-rate repair charge for Non-Warranty Service does not

include return shipping. Return shipping to locations in North America is included for Warranty Service. For overnight shipments and

non-North American shipping fees please contact B&K Precision Corp.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Include with the returned instrument your complete return shipping address, contact name, phone number and description of

problem.

LIMITED THREE-YEAR WARRANTY

B&K Precision Corp. warrants to the original purchaser that its products and the component parts thereof, will be free from defects in

workmanship and materials for a period of three years from date of purchase.

B&K Precision Corp. will, without charge, repair or replace, at its option, defective product or component parts. Returned product must

be accompanied by proof of the purchase date in the form of a sales receipt.

To obtain warranty coverage in the U.S.A., this product must be registered by completing a warranty registration form on our website

www.bkprecision.com

Exclusions: This warranty does not apply in the event of misuse or abuse of the product or as a result of unauthorized alterations

or repairs. The warranty is void if the serial number is altered, defaced or removed.

B&K Precision Corp. shall not be liable for any consequential damages, including without limitation damages resulting from loss of use.

Some states do not allow limitations of incidental or consequential damages. So the above limitation or exclusion may not apply to you.

This warranty gives you specific rights and you may have other rights, which vary from state-to-state.

within fifteen (15) days of purchase.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

2

Page 3

Do not alter the ground connection. Without the protective ground connection, all

accessible conductive parts (including control knobs) can render an electric shock.

The power jack and mating plug of the power cable meet IEC

To avoid electrical shock hazard, disconnect power cord before removing covers.

Refer servicing to qualified personnel.

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must be

observed during all phases of operation, service, and repair of this instrument. Before applying power,

follow the installation instructions and become familiar with the operating instructions for this

instrument.

Failure to comply with these precautions or with specific warnings elsewhere in this manual violates

safety standards of design, manufacture, and intended use of the instrument. B&K PRECISION

assumes no liability for a customer’s failure to comply with these requirements. This is a Safety Class I

instrument.

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical

ground. This instrument is grounded through the ground conductor of the supplied, three-conductor ac

power cable. The power cable must be plugged into an approved three-conductor electrical outlet. Do

not alter the ground connection. Without the protective ground connection, all accessible conductive

parts (including control knobs) can render an electric shock. The power jack and mating plug of the

power cable meet IEC safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes. Operation of any electrical

instrument in such an environment constitutes a definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Instrument covers must not be removed by operating personnel. Component replacement and internal

adjustments must be made by qualified maintenance personnel. Disconnect the power cord before

removing the instrument covers and replacing components. Under certain conditions, even with the

power cable removed, dangerous voltages may exist. To avoid injuries, always disconnect power and

discharge circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt any internal service or adjustment unless another person, capable of rendering first aid

and resuscitation, is present.

DO NOT SUBSTITUTE PARTS OR MODIFY THE INSTRUMENT

Do not install substitute parts or perform any unauthorized modifications to this instrument. Return the

instrument to B&K Precision for service and repair to ensure that safety features are maintained.

WARNINGS AND CAUTIONS

WARNING and CAUTION statements, such as the following examples, denote a hazard and appear

throughout this manual. Follow all instructions contained in these statements.

A WARNING statement calls attention to an operating procedure, practice, or condition, which, if not

followed correctly, could result in injury or death to personnel.

A CAUTION statement calls attention to an operating procedure, practice, or condition, which, if not

followed correctly, could result in damage to or destruction of part or all of the product.

WARNING:

This image cannot currently be displayed.

safety standards.

WARNING:

This image cannot currently be displayed.

3

Page 4

Before connecting the line cord to the AC mains, check the rear panel AC line

voltage indicator. Applying a line voltage other than the indicated voltage can

destroy the AC line fuses. For continued fire protection, replace fuses only with

those of the specified voltage and current ratings.

This product uses components which can

static discharge

(ESD). To avoid damage, be sure to follow proper procedures for handling, storing

and transporting parts and subassemblies which contain ESD-sensitive

components.

CAUTION:

This image cannot currently be displayed.

CAUTION:

This image cannot currently be displayed.

be damaged by electro-

4

Page 5

Table of Contents

Safety Summary .............................................................................................. 3

Section 1 .......................................................................................................... 1

Introduction ........................................................................................................................ 1

1.1 Introduction .............................................................................................................................................. 1

1.2 Description ............................................................................................................................................... 1

1.3 Memory Architecture ............................................................................................................................... 1

1.4 Package Contents ................................................................................................................................... 2

Specifications ..................................................................................................................... 2

Modulation Combinations ................................................................................................. 4

Section 2 .......................................................................................................... 5

Installation .......................................................................................................................... 5

2.1 Introduction .............................................................................................................................................. 5

2.2 Mechanical Inspection ............................................................................................................................. 5

2.3 Initial Inspection ....................................................................................................................................... 5

2.4 Instrument Mounting ................................................................................................................................ 5

2.5 Product Dimensions ................................................................................................................................ 5

2.6 Power Requirements ............................................................................................................................... 6

2.7 Grounding Requirements ........................................................................................................................ 6

2.8 Signal Connections .................................................................................................................................. 6

2.9 RS-232 Connection ................................................................................................................................. 6

2.10 RS-232 Configuration ............................................................................................................................. 7

2.11 GPIB Address ......................................................................................................................................... 8

2.12 GPIB Connections ................................................................................................................................. 8

Section 3 .......................................................................................................... 9

Operating Instructions ...................................................................................................... 9

3.1 General Description ................................................................................................................................. 9

3.2 Display Window .................................................................................................................................... 10

3.3 Front Panel Controls .............................................................................................................................. 11

3.4 Back Panel Controls .............................................................................................................................. 11

3.5 Output connectors ................................................................................................................................. 13

3.6 MENU Keys ........................................................................................................................................... 13

3.7 ON Key .................................................................................................................................................. 28

3.8 Cursor Movement Keys ......................................................................................................................... 28

3.9 Rotary Input Knob .................................................................................................................................. 28

3.10 Power-On Settings .............................................................................................................................. 28

3.11 Memory ................................................................................................................................................ 29

3.12 Displaying Errors ................................................................................................................................. 29

3.13 Using The Model 4076 and 4079 ........................................................................................................ 30

3.14 Examples ............................................................................................................................................. 31

Section 4 ........................................................................................................ 37

Programming .................................................................................................................... 37

4.1 Overview ................................................................................................................................................ 37

4.2 Device State .......................................................................................................................................... 38

4.3 Interface Function Subsets .................................................................................................................... 38

4.4 Device Address...................................................................................................................................... 39

5

Page 6

4.5 Message Exchange Protocol ................................................................................................................. 39

4.6 Block Data (GPIB Only) ......................................................................................................................... 40

4.7 Instrument Identification ........................................................................................................................ 40

4.8 Instrument Reset ................................................................................................................................... 40

4.9 Self Test ................................................................................................................................................. 40

4.10 Command Syntax ................................................................................................................................ 40

4.11 Status Reporting .................................................................................................................................. 44

4.12 Common Commands ........................................................................................................................... 48

4.13 Instrument Control Commands ............................................................................................................ 52

4.14 IEEE 488.1 Interface Messages .......................................................................................................... 80

4.15 SCPI Command Tree .......................................................................................................................... 81

4.16 Block Transfer (GPIB only) .................................................................................................................. 86

4.17 GPIB Communication Protocol ............................................................................................................ 87

Section 5 ........................................................................................................ 91

Performance Check Procedures ..................................................................................... 91

5.1 Introduction ........................................................................................................................................... 91

5.2 Test Equipment..................................................................................................................................... 91

5.3 Performance Tests ............................................................................................................................... 92

6

Page 7

4,000,000

Waveform 1

Waveform …

Waveform 2

Waveform 3

A pts.

B pts.

C pts.

D pts.

A pts. + B pts. + C pts. + D pts. ≤ 4,000,000 pts.

Point

Point

Section 1

Introduction

1.1 Introduction

This manual contains information required to operate, program and test the Model 4076 and 4079 – 50 MHz DDS Arbitrary

Function Generators. This section covers the instrument general description, instrument specifications and characteristics.

1.2 Description

The Model 4076 and 4079 are versatile high performance arbitrary waveform generators. Arbitrary waveforms can be

programmed and generated with 14 bit resolution and up to 4,000,000 points length. Waveforms can be output in continuous,

triggered, gated or burst mode. AM and FM modulation combined with versatile Sweep capabilities make the unit suitable for a

wide range of applications. Editing is flexible and easy including auto increment, line draw and predefined waveform facilities.

The instrument can be remotely operated via the RS232 or GPIB interface and they are SCPI compatible.

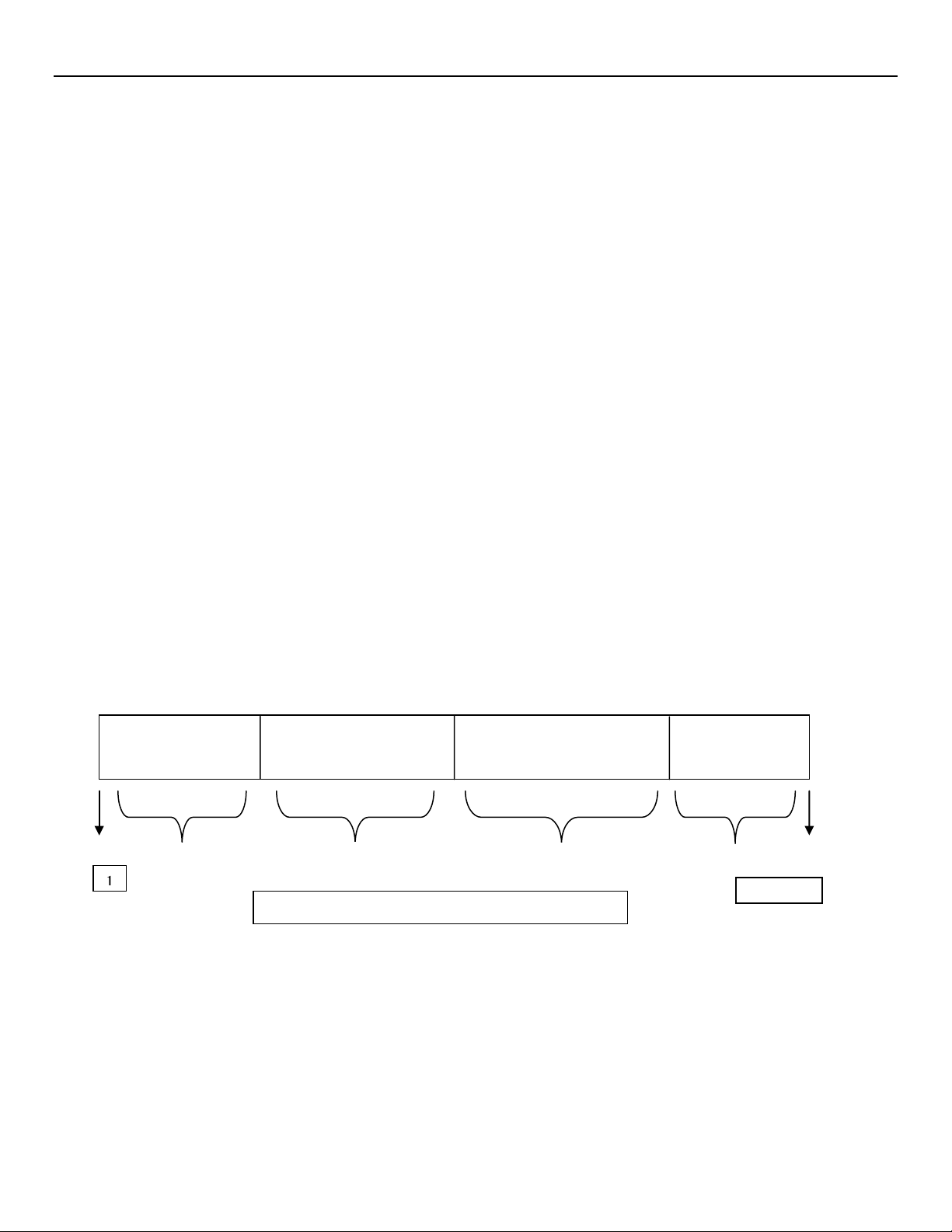

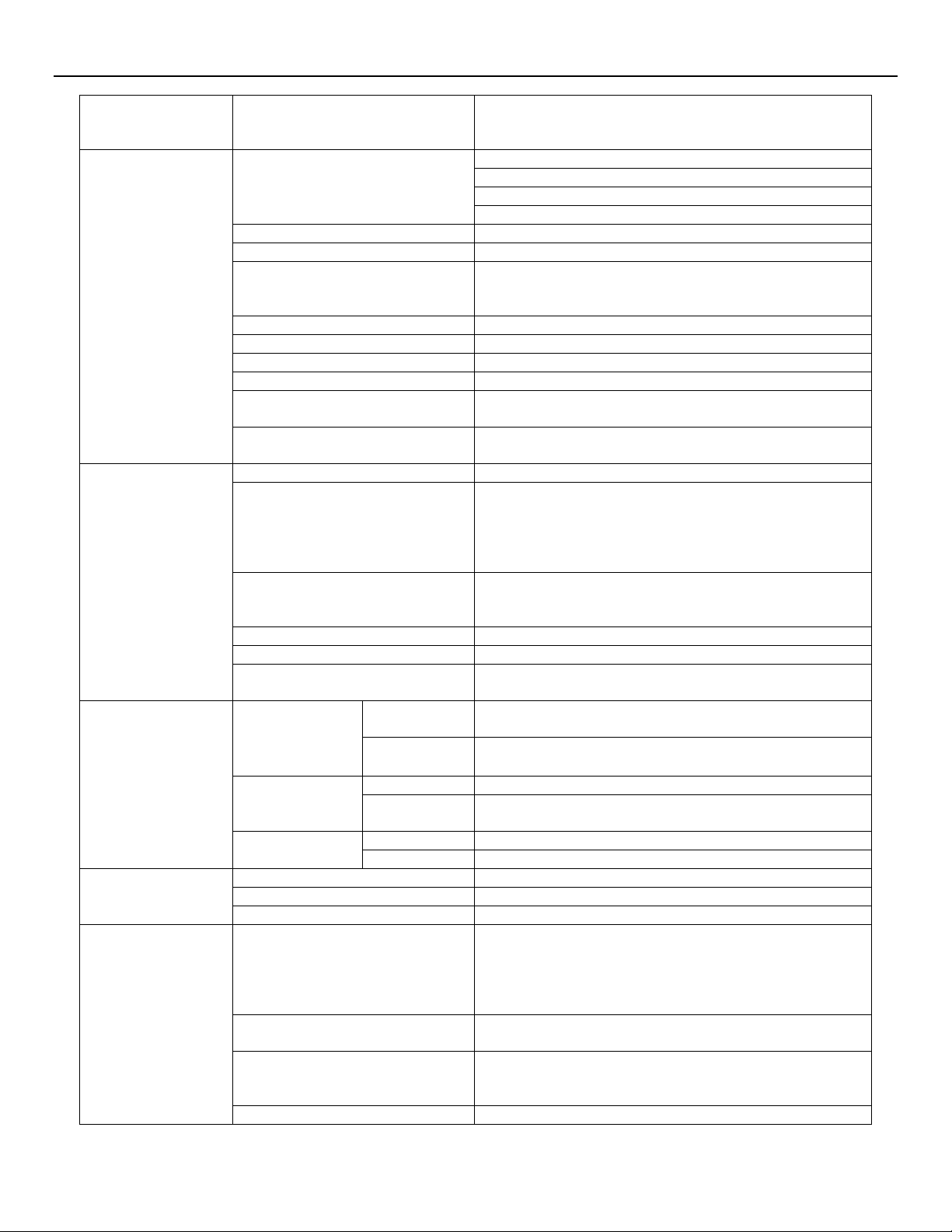

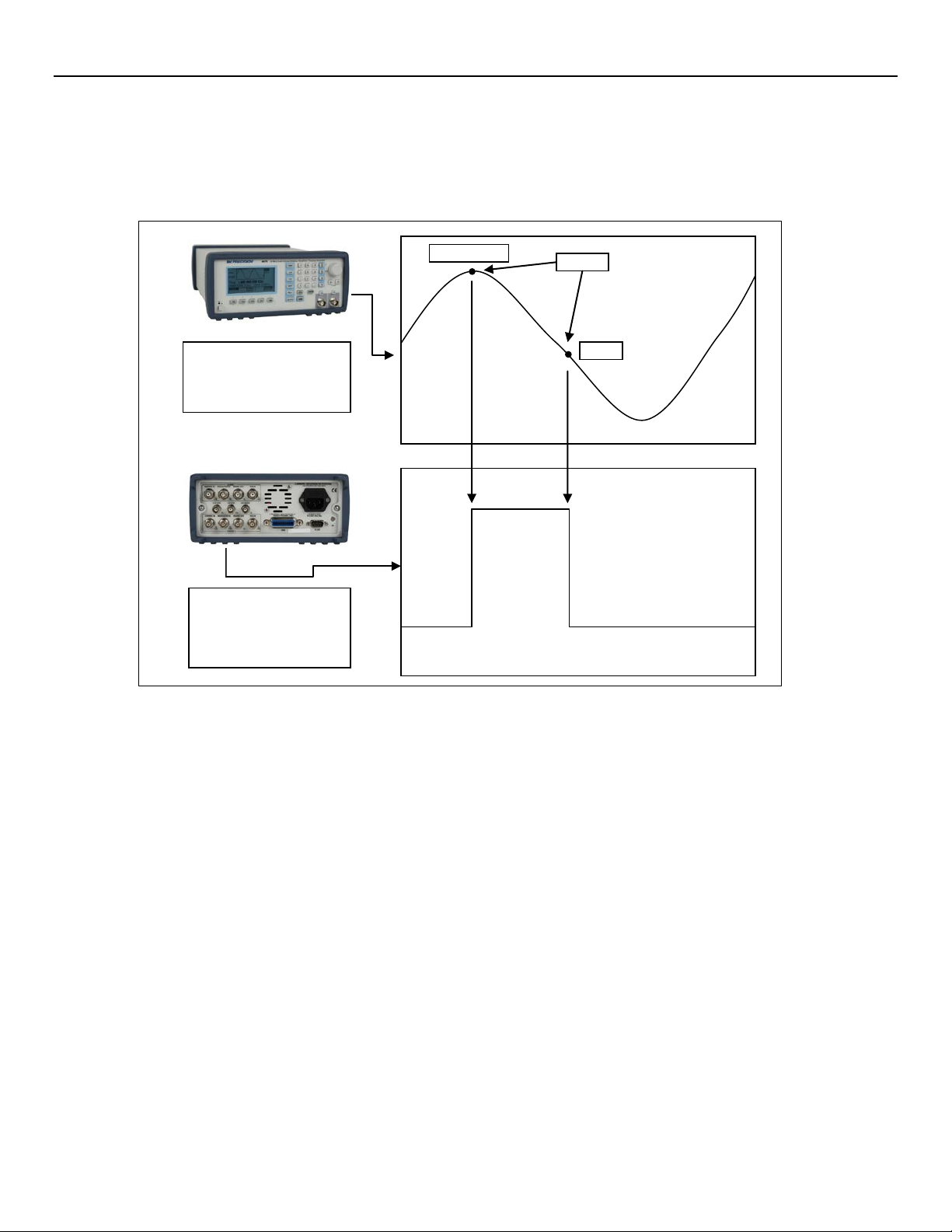

1.3 Memory Architecture

The waveform memory consists of 4,000,000 points. The user can edit arbitrary waveforms in waveform memory and can specify

any data value in the range from -8191 to 8191 for any point in waveform memory (14 bit depth). Due to their large memory

bank, the 4076 and 4079 can essentially give the user greater freedom in selecting the size of their waveforms and the number of

waves they desire to generate, with the limit of 4,000,000 total points when added together.

For example, these generators can create a waveform with 100,000 points, another waveform with 500,000 points, a third

waveform with 400,000 points, and a fourth waveform with 3,000,000 points. These four waveforms total up to 4,000,000 points,

but essentially they can be referenced in the memory bank according to their starting point and their length. There are no

restrictions as to how many different waveforms you can store in the memory, so as long as the sum of the points of all the

waveforms do not exceed 4,000,000 points. To better illustrate this, refer to drawing below:

The following operations can be performed in the waveform memory:

- Insert and scale any of the following predefined waveforms:

o Sine

o Triangle

o Square

o Ramp up

o Ramp down

o Noise

1

Page 8

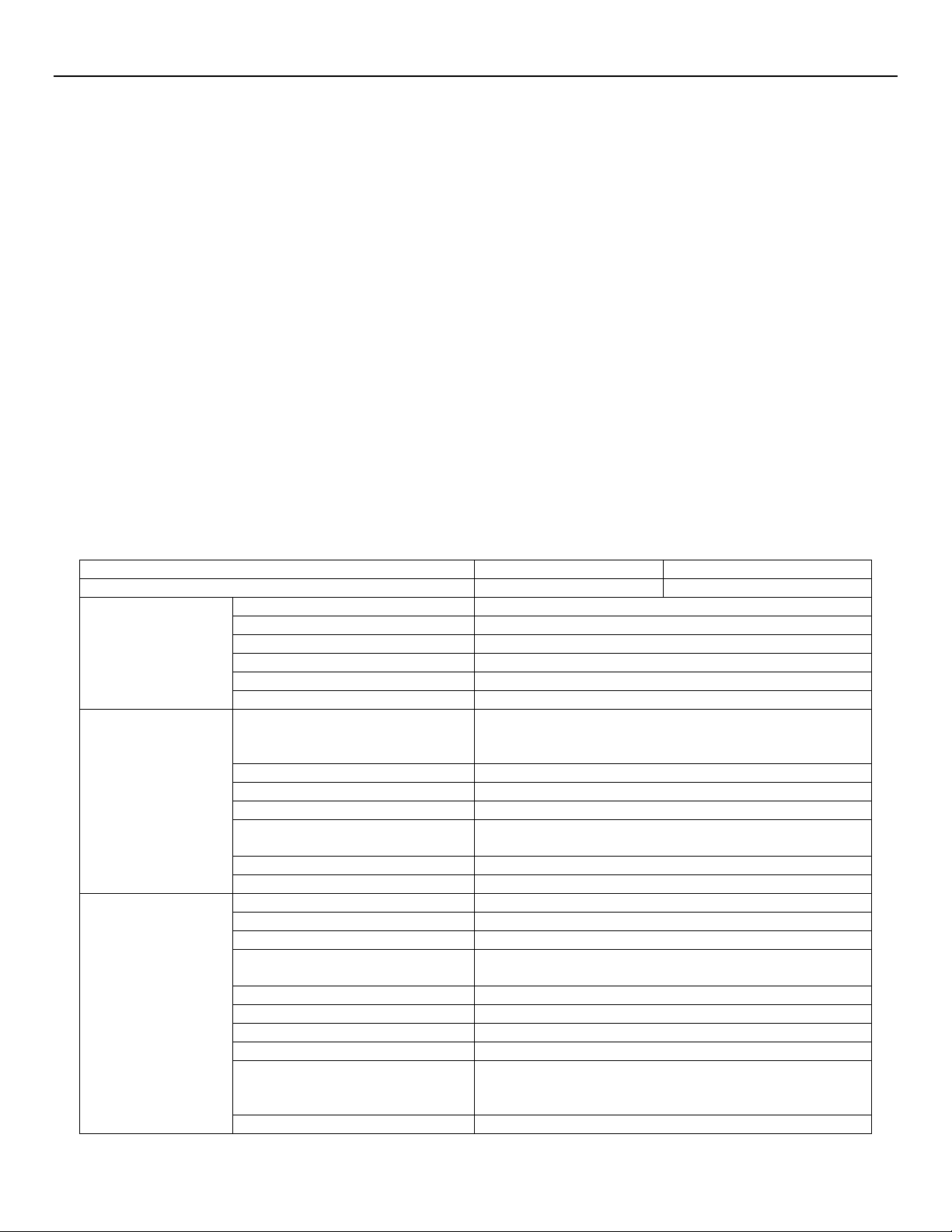

Models

4076

4079

Channels

1 Channel

2 Channels

Sine

1 uHz to 50 MHz

Square

1 µHz to 50 MHz

Triangle, Ramp

1 µHz to 5 MHz

Pulse

0.5 mHz to 25 MHz

Accuracy

0.001 % (10 ppm)

Resolution

12 digits or 1 µHz

Sine, Triangle, Square, Noise, Ramp Up, Ramp Down,

Gaussian

Waveform Length

2 points to 4,000,000 points

Vertical Resolution

14 bits (16,384 levels)

Noise

Add 1% to 100% to output waveform

125 MSa/s, Point execution rate: adjustable from 8 ns

to 100 s

Frequency Accuracy

0.005% (50 ppm)

Frequency Resolution

4 digits or 1 ps

Amplitude Range

10 mV to 10 Vp-p into 50 ohms

Amplitude Resolution

3 digits (1000 counts)

Amplitude Accuracy (at 1 kHz)

± 1% ± 20 mV of programmed output from 1 V – 10 V

± 0.1 dB to 10 MHz

± 1 dB to 50 MHz

Offset Range

± 4.99 V into 50 Ω, depending on the Amplitude setting

Offset Resolution

10 mV with 3 digits resolution

Offset Accuracy

± 1% ± 10 mV into 50 Ω

Output Impedance

50 Ω typical

The instruments output is protected against short

main output connector

Filters

9 pole Elliptic and 5 pole Bessel filters

- Draw a line between any two points

- Clear (set to zero) any set of points or all points

- Protect any set of points or all points from being changed or erased

- Copy any set of points to another area in the memory

- Set individual point values

After specifying a section of waveform memory for execution, the following parameters of the waveform can be configured:

- Point rate (frequency)

- Peak-to-peak amplitude

- Offset voltage

1.4 Package Contents

The following list of items and accessories come in the package:

1. 4076 or 4079 DDS Function Generator

2. AC power cord

3. CD containing user manual and waveform creation software Wave-X

4. RS232 Serial Cable

Frequency

Characteristics

Arbitrary

Characteristics

Built-in Waveforms

Sampling Rate

Flatness (relative to 1 kHz)

Specifications

Sine(X)/X, Exponential Up, Exponential Down,

Output

Characteristics

Output Protection

circuit or nominal accidental voltages applied to the

2

Page 9

Approximately 10 mA can be present at the output

output is off

DC-20 kHz, -65 dBc

20 kHz-100 kHz, -60 dBc

100 kHz-5 MHz, -45 dBc

5 MHz-50 MHz, -35 dBc

Spurious (sine)

DC-1 MHz < -65 dBc

Rise/Fall Time (square, pulse)

< 6 ns (10% to 90%) at full amplitude into 50 Ω

20% to 80% to 10 MHz (square)

50% >30 MHz (square)

Variable Symmetry

10%-90% to 5 MHz (triangle)

Symmetry at 50%

< 0.5 %

Linearity (triangle, ramp)

<0.1 % of peak output (1 µHz to 250 kHz)

Aberrations

< 3 % of p-p amplitude ± 50 mV

Pulse Width (period 10 μs - 0.1

μs)

20 ns to < ( Period -20 ns )

(10 ns resolution)

Variable Edge Time

(period 100 μs - 0.16 μs)

100 ns to Width/0.625 (50 % duty cycle)

10 ns resolution

Continuous

Output continuous at programmed parameters

Output quiescent until triggered by an internal or

10 MHz in DDS mode

Same as triggered mode, except waveform is executed

started is completed

Burst

2-999,999 cycles

Phase

-180 to +180 degrees with 0.1 degree resolution

Trigger source may be internal, external or manual.

Internal trigger rate 0.01 Hz-1 MHz (1 µs – 100 s)

0.01 Hz-20 kHz sine , square or triangle waveform

variable modulation from 0% to 100%

5 Vp-p for 100% modulation, 10 kΩ input impedance

Internal

0.01 Hz-20 kHz sine wave, square or triangle

5 Vp-p for 100% deviation, 10 kΩ input impedance,

0.01 Hz – 50 kHz bandwidth

Internal

0.01 Hz to 1 MHz

External

1 MHz max.

Sweep Shape

Linear and Logarithmic, up or down

Sweep Time

10 ms to 500 s

Sweep Trigger

internal, external, continuous or burst

TTL Compatible

Input Impedance10 kΩ nominal

TTL pulse at programmed frequency, 50ohms source

impedance

5 Vp-p for 100% modulation

DC to >50 kHz minimum bandwidth

Marker Out

Positive TTL pulse user programmable in Arbitrary

Waveform

Characteristics

Output Leakage

Harmonic Distortion (sine)

Variable Duty Cycle

Triggered

BNC connector when unit is powered on and the

40% to 60% to 30 MHz (square)

external trigger, at which time one waveform cycle is

generated to programmed parameters. Frequency of

waveform cycle is limited to 20 MHz in ARB mode and

Operating Modes

Modulation

Characteristics

Sweep

Characteristics

Inputs and Outputs

Gate

Trigger Source

Amplitude

Modulation

Frequency

Modulation

FSK

Trigger IN

Sync OUT

Internal

External

External

for the duration of the gate signal. The last cycle

0.01 Hz – 50 KHz bandwidth

Maximum rate 20 MHz in ARB mode, 3 MHz in DDS

mode

Minimum width 20ns

Modulation IN

10 KΩ input impedance

3

Page 10

waveform, 50 Ω source impedance

10 MHz, TTL compatible, input or output, for external

input

Adds signal from an external source to the main

output. Input impedance is 500 Ω

Repetition

1 ms to 100 s

Resolution

4 digits

Accuracy

+0.002%

Display Resolution

160 x 80 dots LCD

Remote Control Interface

GPIB, RS-232

Store Memory

50 full panel settings at power-off

Dimensions

8.4(213) x 3.5(88) x 11.8(300) inches (mm) (WxHxD)

Weight

Approx. 2.5 kg (5.5lbs)

Power

100-240 VAC ± 10%, < 50 VA max.

Operating

0 ºC to +50 ºC

Nonoperating

Humidity

95 % RH , 0 ºC to 30 ºC

According to EN55011 for radiated and conducted

emissions

Electrical Discharge Immunity

According to EN55082

Safety Specifications

According to EN61010 , CE approved

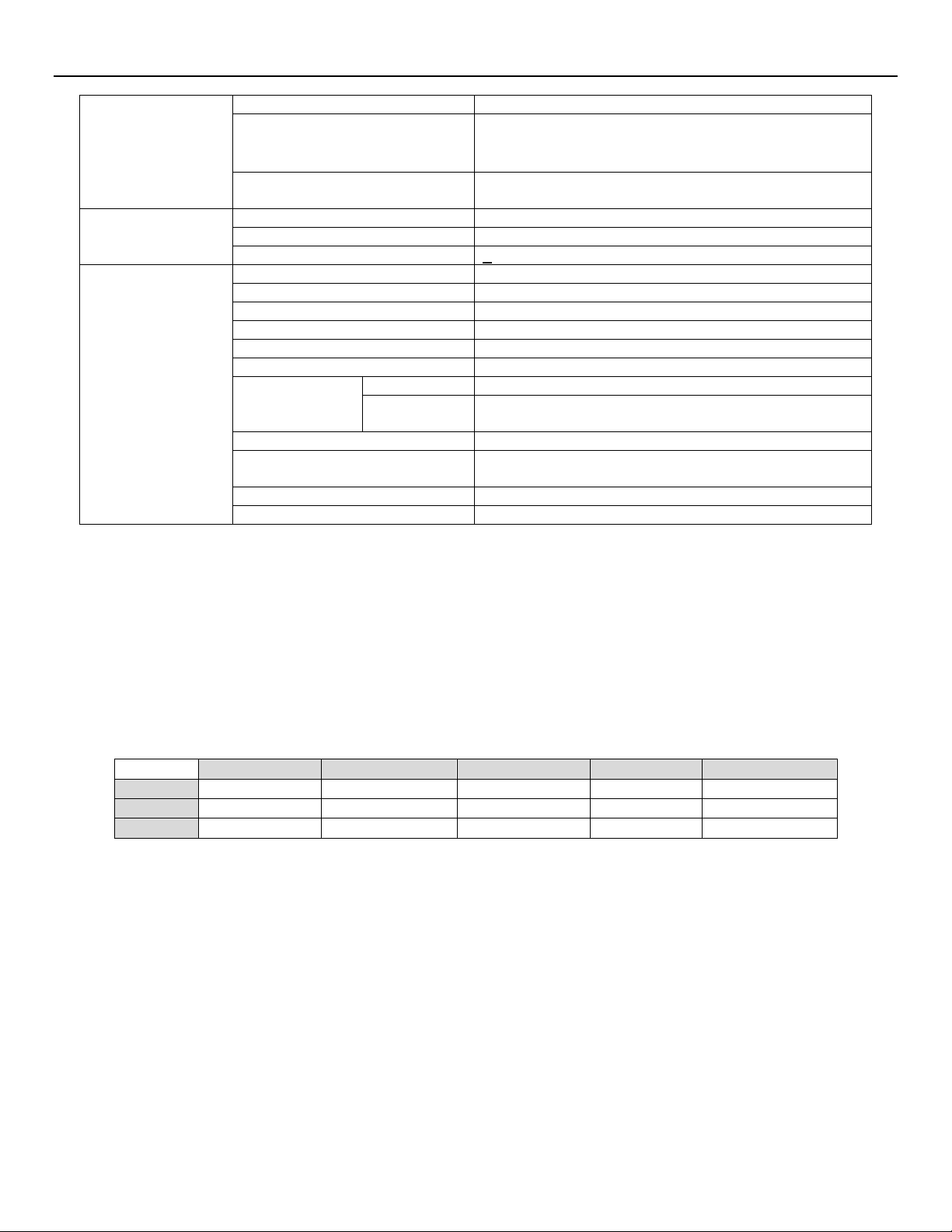

SINE

SQUARE

TRIANGLE

PULSE

ARBITRARY

AM

Yes

Yes

Yes

Yes

Yes

FM

Yes

Yes

Yes

No

No

FSK

Yes

Yes

Yes

No

No

Internal Trigger

General

Reference IN-OUT

Summing IN

Temperature

EMC

unit synchronization 50 Ω output impedance and 1 kΩ

-20 ºC to +70 ºC

NOTE

Specifications listed in manual are applicable after a powered 30 minute warm-up

Specifications are verified according to the performance check procedures.

Specifications not verified in the manual are either explanatory notes or general performance characteristics only.

Specifications and information is subject to change without notice. For the most current and correct data please visit

www.bkprecision.com

Modulation Combinations

4

Page 11

300 mm

213 mm

88 mm

Section 2

Installation

2.1 Introduction

This section contains installation information, power requirements, initial inspection and signal connections for Model 4076

and 4079.

2.2 Mechanical Inspection

This instrument was carefully inspected before shipment. Upon receipt inspect the instrument for damage that might have

occurred in transit. If there is damage due to shipping, file a claim with the carrier who transported the unit. The shipping and

packing material should be saved if reshipment is required. If the original container is not to be used, then use a heavy carton

box. Wrap the unit with plastic and place cardboard strips across the face for protection. Use packing material around all sides

of the container and seal it with tape bands. Mark the box "FRAGILE".

2.3 Initial Inspection

After the mechanical inspection, verify the contents of the shipment (accessories). If the contents are incomplete, or if the

instrument does not pass the specification acceptance tests, notify the local service center.

2.4 Instrument Mounting

The Model 4076 and 4079 - Function Generators are intended for bench use. The instrument includes a front feet tilt

mechanism for optimum panel viewing angle. The instrument does not require special cooling when operated within

conventional temperature limits. The unit can be installed in a closed rack or test station if proper air flow is assured for

removing about 20 W of power dissipation.

2.5 Product Dimensions

5

Page 12

2.6 Power Requirements

The Model 4076 and 4079 can be operated from any source of 100 V to 265 V AC, frequency from 48 Hz to 66 Hz. The

maximum power consumption is 50 VA. Use a slow blow fuse UL/CSA approved of 1 A as indicated on the rear panel of the

instrument.

WARNING

THE LINE POWER VOLTAGE OF THE INSTRUMENT IS NOTED ON THE AC INPUT PLUG. TO

PREVENT DAMAGE TO THE INSTRUMENT, CHECK FOR PROPER MATCH OF LINE VOLTAGE

AND PROPER FUSE TYPE AND RATING.

The instrument power fuse is located in the AC input plug. To access the fuse, first disconnect the power cord and then remove

the fuse cartridge.

2.7 Grounding Requirements

For the safety of operating personnel, the instrument must be grounded. The central pin on the AC plug grounds the instrument

when properly connected to the ground wire and plugged into proper receptacle.

WARNING

TO AVOID PERSONAL INJURY DUE TO SHOCK, THE THIRD WIRE EARTH GROUND MUST BE

CONTINUOUS TO THE POWER OUTLET. BEFORE CONNECTION TO THE POWER OUTLET, EXAMINE ALL

CABLES AND CONNECTIONS BETWEEN THE UNIT AND THE FACILITY POWER FOR A CONTINUOUS

EARTH GROUND PATH.

THE POWER CABLE MUST MEET IEC SAFETY STANDARDS.

2.8 Signal Connections

Use RG58U 50 Ω or equivalent coaxial cables for all input and output signals to and from the instrument.

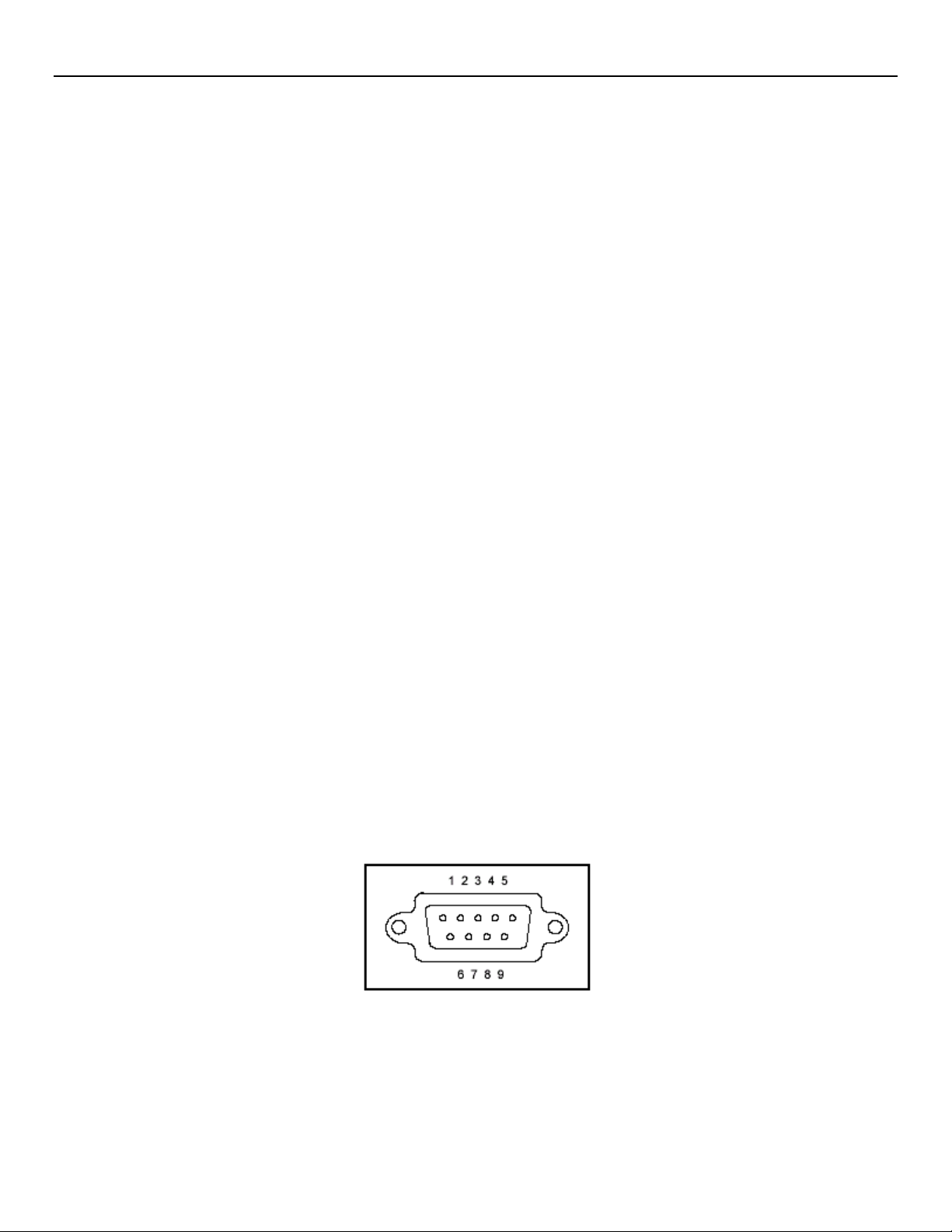

2.9 RS-232 Connection

The rear panel RS-232 connector is a standard DB-9 male connector configured as a DCE. The pin assignments are defined

in the table below:

6

Page 13

DB-9 pin

Name

Note

1

9

-

-

-

-

Number of data pts.

Baudrates (bps)

~30 mins

(receiving)

2

3

4

5

6

7

8

*Note: Use a Null-modem or cross over cable (pin 2 and 3 switched) in order to communicate with instrument. When transmitting

large files via RS232, highest baud rate setting of 38400 is recommended, and number of data points of transfer at any instance

should not exceed 1,000,000 points. If 4,000,000 points are required, multiple transfers are recommended; each time transferring

100,000 points. For optimal speed in transferring large files, GPIB interface is recommended using block transfer (see

Programming Section of this manual).

TXD

RXD

-

GND

RTS

CRS

Transmit Data

Receive Data

-

Signal ground

-

Request to Send

Clear to send

2.9.1 Communication Speed Chart

The 4076 and 4079 have the capabilities of generating large arbitrary waveforms with up to 4,000,000 points. Due to this

nature, the time it takes to transmit these large waveforms may vary depending on the baudrate and cable used for RS232

interface. As a general reference, provided below is a chart that shows the approximate amount of time it takes to download or

send the waveforms of the indicated sizes at the rated baudrate speed.

400,000 points 1,000,000 points

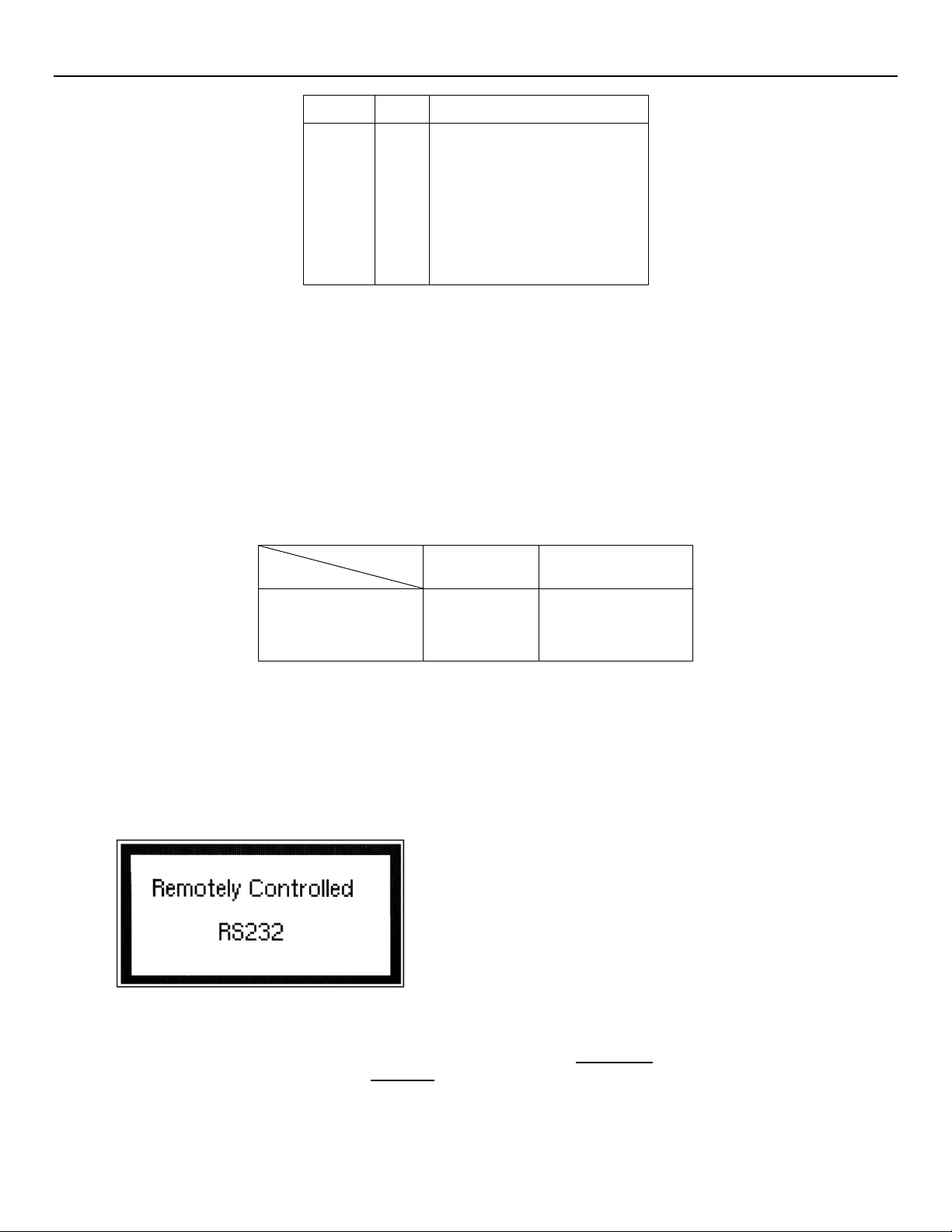

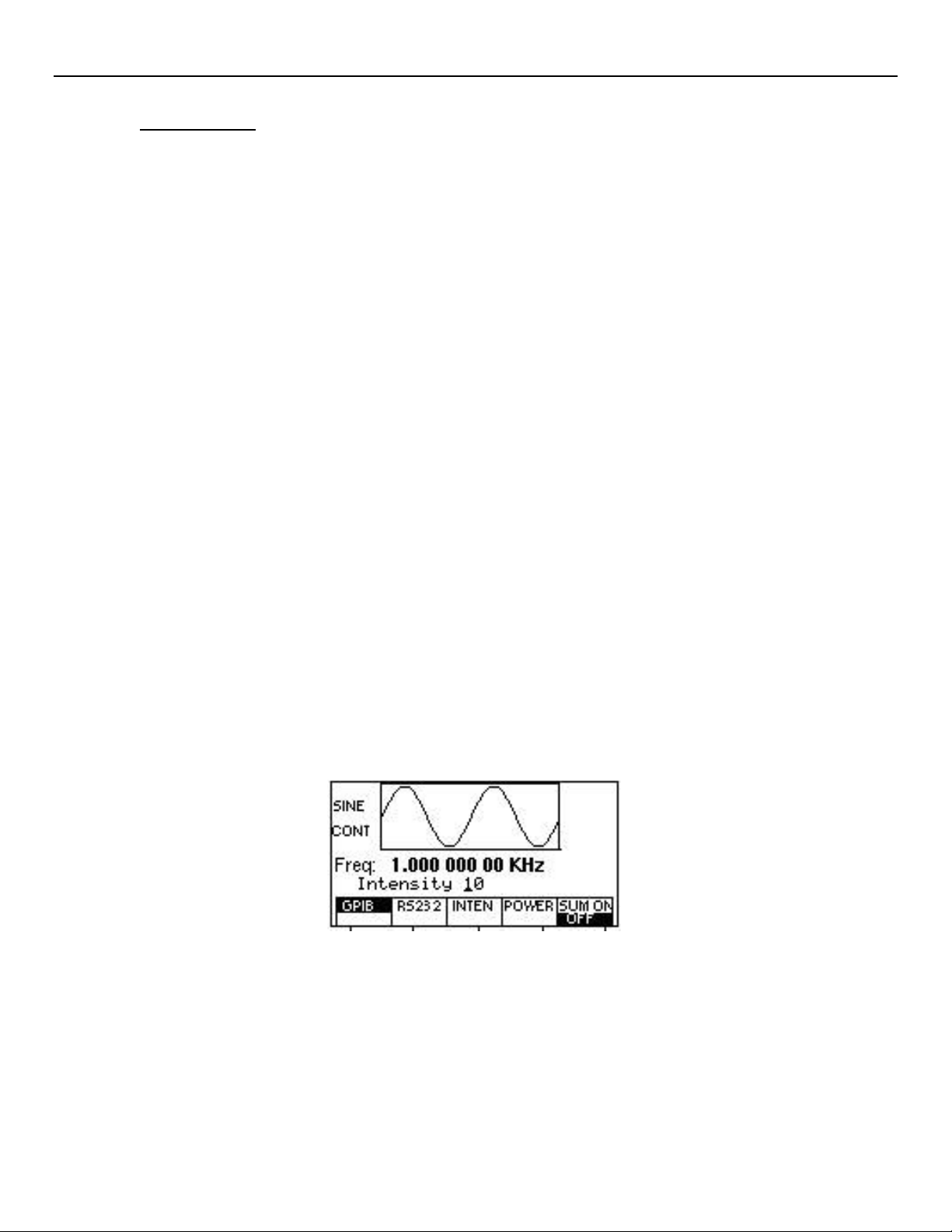

2.10 RS-232 Configuration

The instrument use 8 data bits, 1 stop bit, no parity and baud rate selectable from 2400 to 38.4K (2400, 4800, 9600, 19200,

38400). By default, the instrument is set at 9600-8-N-1.

When the instrument is in remote mode, it will display the following screen:

This screen comes up whenever there is a transmission process, be it sending or receiving. To return to local mode and exit

this screen, simply press any front panel keys. Only do this when nothing is being transmitted or received from a connected

PC. In the case where a large waveform is being transmitted, please allow AT LEAST 15 seconds or more after the PC

software or program has finished sending BEFORE pressing a key to return to local mode. The instrument requires this time

to completely finish generating/transmitting the waveform.

38400

(sending)

~15 mins

~1hr (sending)

~30mins (receiving)

7

Page 14

2.11 GPIB Address

The instrument is shipped with the address set to decimal 9. The address can be changed from the front panel by using the "UTILITY"

menu.

2.11.1 Communication Speed Chart

The 4076 and 4079 have the capabilities of generating large arbitrary waveforms with up to 4,000,000 points. As a general

reference, the GPIB interface can send and receive 1,000,000 points within less than 12 minutes.

Note: When GPIB is used, transferring in blocks of 100,000 points at a time is recommended to avoid any transfer errors.

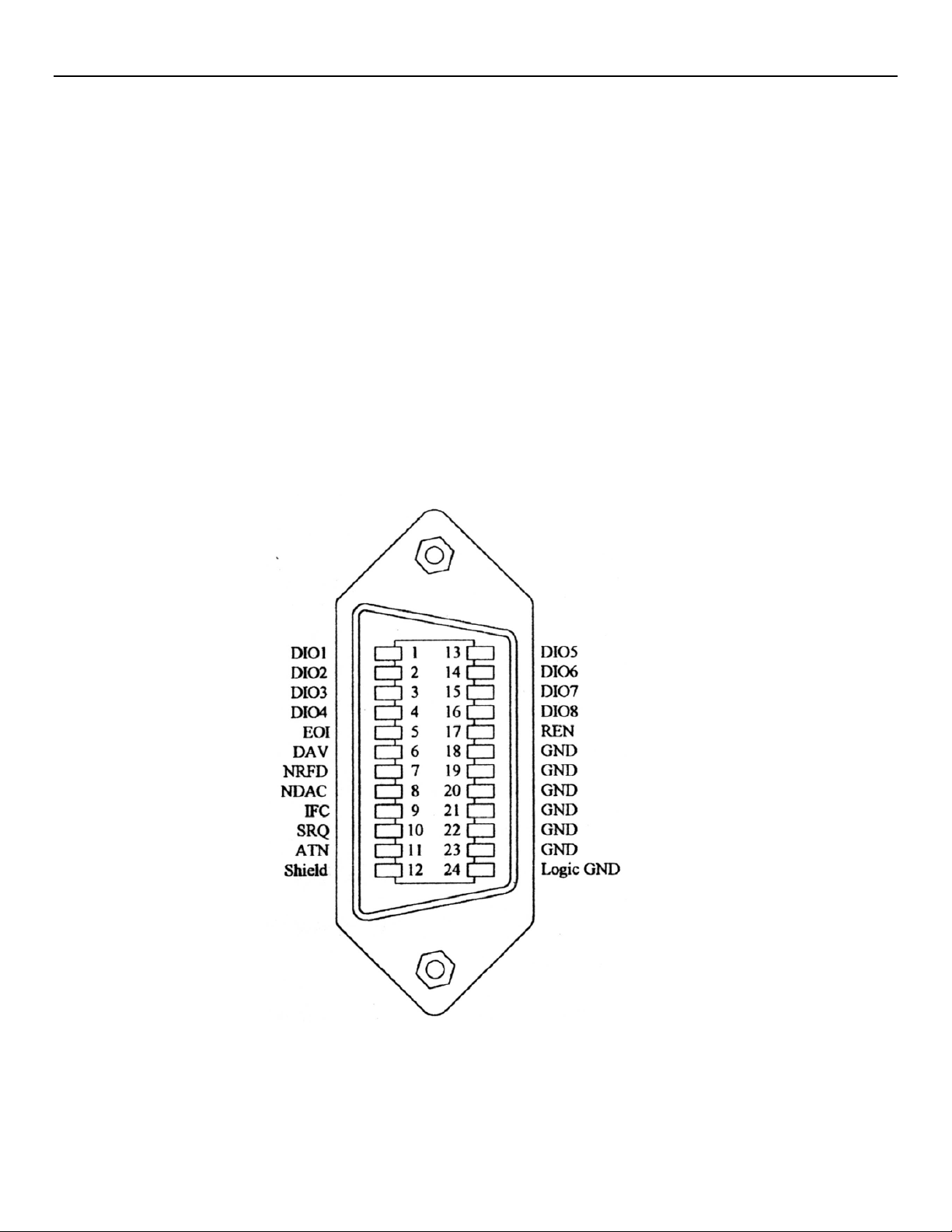

2.12 GPIB Connections

The rear panel GPIB connector is an AMPHENOL 57-10240 or equivalent, and connects to a standard IEEE-488 bus cable

connector. The GPIB line screens are not isolated from chassis and signal ground.

8

Page 15

1 2 3

7

8

9

11

14 5 6

15

16

12

10

4

13

(for Model 4076)

(Model 4079 only)

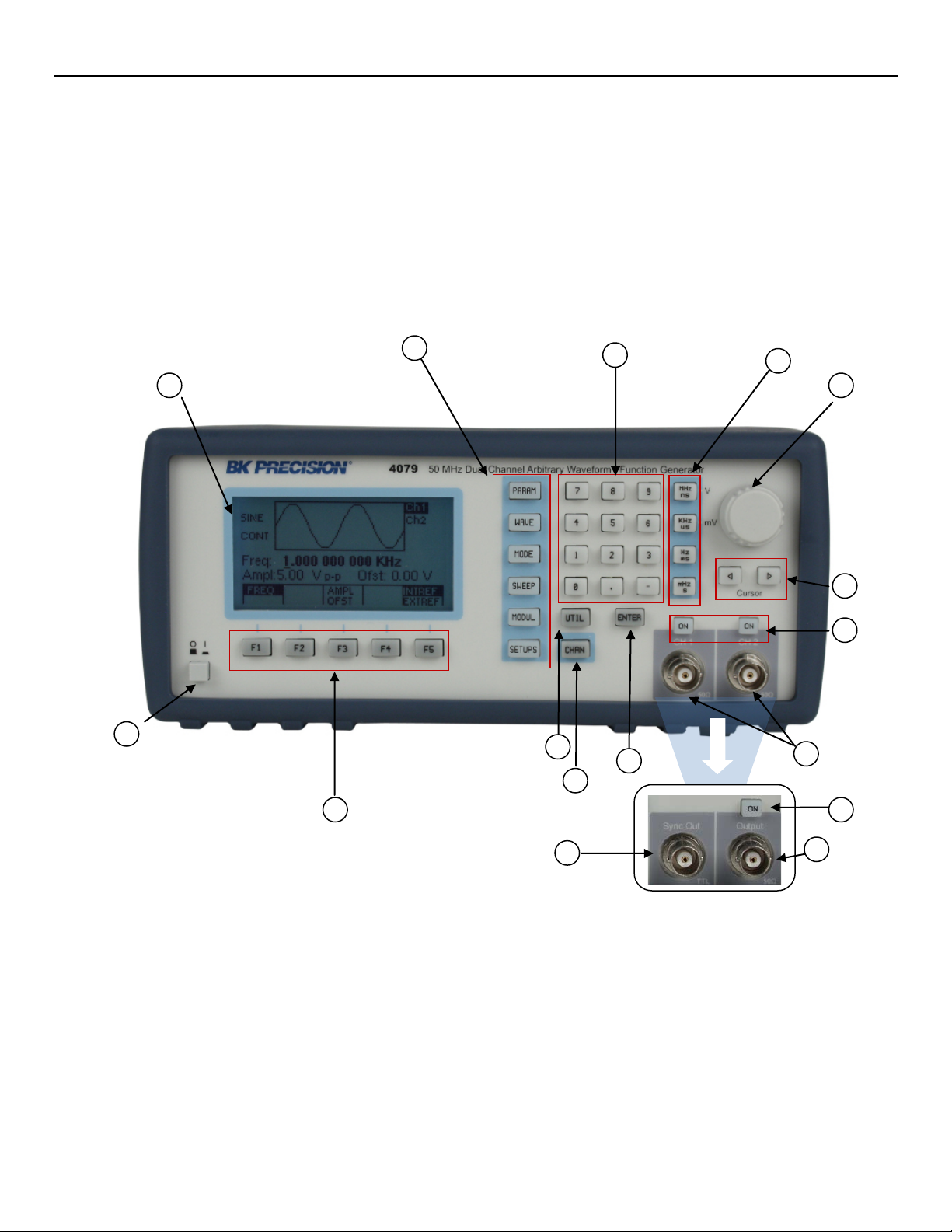

3.1 General Description

This section describes the displays, controls and connectors of the Model 4076 and 4079 - Function Generators.

All controls for the instrument local operation are located on the front panel. The connectors are located on both

front and rear panels.

Section 3

Operating Instructions

Figure 3.1 - Front Panel View

1. Power ON-OFF - Applies and removes AC power to the unit

2. Display Window - Displays all instrument data and settings on a LCD.

3. FI-F5 Keys - Select the menu options that appear on the bottom section of the LCD display.

4. Function Keys - Select menu options for waveform parameters (PARAM), waveform type

(WAVE), mode of generator (MODE), sweep function (SWEEP), modulation function

(MODUL), and setup configurations (SETUPS).

5. Numerical Keypad - Numeric entry keys for entering values for various functions and modes

9

Page 16

1 2 3 4 5 6 7

6. Unit Setting Keys - Quick keys for setting units for frequency, time, and amplitude

7. Rotary Knob - Used to increment/decrement numerical values or to scan through the possible

selections.

8. Cursor Keys - Used to move the cursor (when visible) to either left or right when modifying

values of various parameters.

9. Output ON - Controls the main output signal. The output status is ON when display shows

“Out On” (for model 4076) or “On” (for model 4079).

10. Channel Output - (model 4079 only) Dual BNC channel outputs (50 Ω) of function signals.

11. Output ON - (model 4076) Controls the main output signal. The output status is ON when

illuminated.

12. Channel Output - (model 4076) BNC channel output.

13. Sync Out - (model 4076) Sync output, 50 Ω 5V TTL level

14. CHAN Key - (model 4079 only) Channel select key

15. UTIL Key - Selects remote interface options, LCD intensity, power settings, and summing

input.

16. ENTER Key - Used for confirming parameter adjustments and settings.

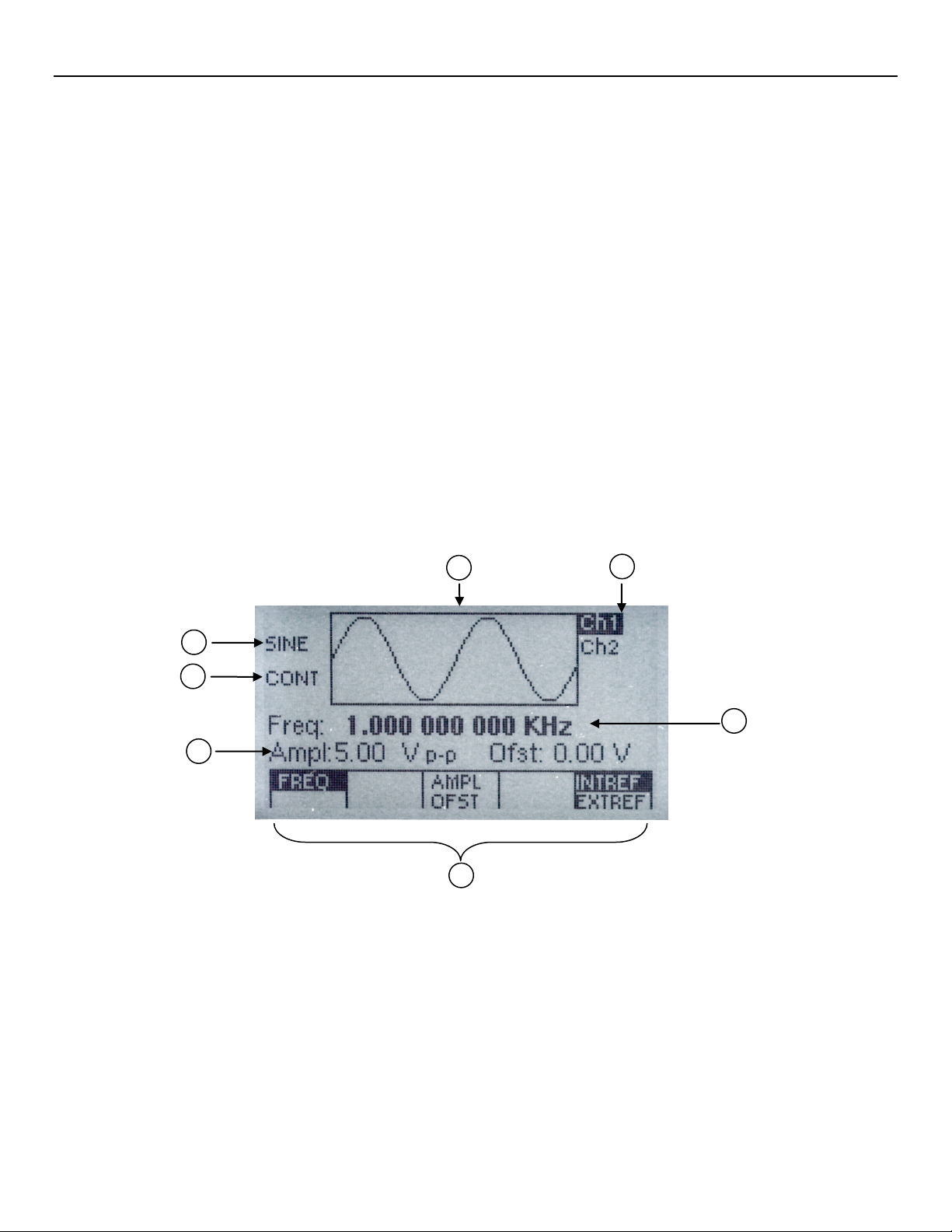

3.2 Display Window

The Model 4076 and 4079 have graphic LCD displays that can display up to 160 x 80 dots. When you power-on the unit a

parameter (Frequency) and its current settings appear in the display

parameter or mode display selected.

. The bottom displays a menu that corresponds to the function,

Figure 3.2 - LCD Display Screen

1. Channel/Output Display - Displays the current selected channel (when highlighted).

(For model 4079 only). Also displays highlighted text “Out On” when

output is ON (For model 4076) or displays a highlighted text “On” next to

“Ch 1” and/or “Ch 2” when either or both channel outputs are ON (For

model 4079).

2. General Waveform Display - Displays the general waveform being generated in the channel.

Note: Waveform shown is approximated and scaled down. It does not

show the exact representation of the waveform at the output.

3. Frequency/ Sweep Mode Display - Displays the frequency values currently set to. In sweep mode,

it displays the sweeping type (Linear or Logarithmic).

10

Page 17

4. Menu Functions Display - Displays the menu options available. Use F1-F5 keys on front

panel to select the options.

5. Menu Parameters Values Display - Displays the values of parameters selected in the menu.

Depending on the options chosen, various parameters will display with a

cursor for adjusting their values.

6. Mode Display - Displays the current mode selected. The can be continuous,

trigger, burst, or gate (displayed as CONT, TRI, BURST, or

GATE respectively). Refer to section 3.6.2 for details.

7. Wave Type Display - Displays the waveform type currently selected. It can be sine

(SINE), Square (SQU), triangle (TRI), pulse (PULSE), or arbitrary (ARB).

3.3 Front Panel Controls

The front-panel controls select, display, and change parameter, function, and mode settings. They also include the keys you use

to program and generate arbitrary waveform output. Refer to Figure 3.1.

Use the rotary input knob and the cursor movement keys to enter data into the waveform generator.

To change a setting:

1. Press PARAM to display options in menu to control parameters.

1. Press any FUNCTION keys (F1 – F5) that lead to a required item.

2. Move cursor using CURSOR keys to the appropriate position in the numeric field (if applicable).

3. Use the rotary input or the numerical KEYPAD to change the value of the displayed item. Changes take effect immediately.

4. In some parameter settings, the ENTER key must be pressed in order to set their numerical/setting values. Otherwise, it may

not save.

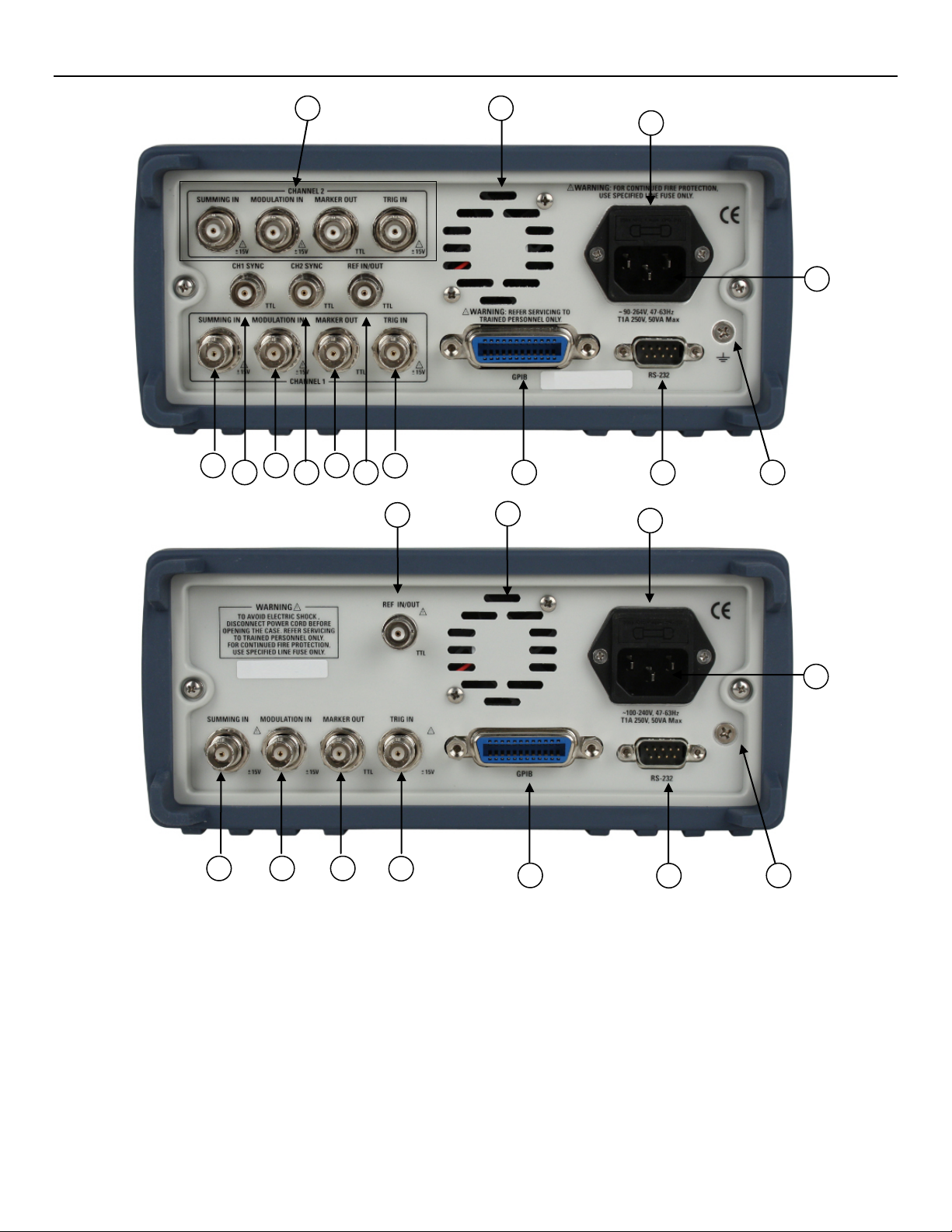

3.4 Back Panel Controls

The function generator has 11 (5 for model 4076) BNC Connectors on the rear panel where you can connect coaxial cables.

These coaxial connectors are labeled accordingly on the back panel for their respective channels and serve as carrier lines for

input and output signals delivered to and from the function generator.

11

Page 18

Model 4076

6

11 9 10

1 3 5

7

13

14

12

Model 4079

8 1 2 3 4 5 6

7

11 9 10

13

14

12

Figure 3.3 - Back Panel View

1. Summing In - For CH 1. Use this input to apply an external analog signal to be added to the output waveform.

A 5 Vp-p signal is required for full scale output. Maximum input is ± 15 V.

2. CH1 Sync - This is the sync output of channel one. For model 4076 the sync output is in the front panel of

the instrument (see Figure 3.1).

3. Modulation In - Modulation input used for external modulation of a signal in AM/FM/FSK mode.

Maximum input is ± 15 V.

4. CH2 Sync - This is the sync output of channel two. For model 4076 the sync output is in the front panel of

the instrument (see Figure 3.1).

5. Marker Out - Use this connector to output a positive TTL pulse in Arbitrary waveform mode. The Marker

12

Page 19

position and width can be programmed at any desired Arbitrary locations. (See section 3.6.3 for details)

6. Ref In/Out - Use this connector to input a 10 MHz TTL signal to be used as a reference clock for the unit

signal generation. A 10MHz TTL level signal is available for synchronization of external units, when not in

External Reference mode.

7. Trig In - Use this connector to apply an external trigger or gate signal, depending on the waveform generator

setting, to the generator. This connector is also used when using an external signal to generate FSK under

modulation menu. Maximum input is ± 15 V. (See section 3.6.8 for details)

8. CH2 I/O - These are the same inputs/outputs as 1, 3, 5, and 7 and are dedicated for channel two only.

9. Rear Fan - Rear fan for internal cooling and ventilation. Do not block this area and be sure to leave enough

room for air to exhaust.

10. Fuse Box - Fuse compartment to check or replace fuse.

11. AC Power Connector - Used to connect power cable to AC line source.

12. Earth GND - This screw is the earth ground that is tied to the chassis.

13. GPIB Port - This is a standard GPIB port for remote interface.

14. RS-232 Port - This is a standard RS-232 port used for remote interface. Null modem or cross serial cable is

required to communicate with a PC via this port.

3.5 Output connectors

The waveform generator output circuits is protected against short circuit or nominal accidental voltages applied to the main

output connector . It operate as a 50 ohm voltage source working into a 50 ohms load. At higher frequencies, non-terminated or

improperly terminated output causes aberrations on the output waveform. In addition, loads less than 50 ohms reduce the

waveform amplitude, while loads more than 50 ohms increase waveform amplitude.

Excessive distortion or aberrations caused by improper termination are less noticeable at lower frequencies, especially with sine

and triangle waveforms. To ensure waveform integrity, follow these precautions:

1. Use good quality 50 ohms coaxial cables and connectors.

2. Make all connections tight and as short as possible.

3. Use good quality attenuators if it is necessary to reduce waveform amplitudes applied to sensitive circuits.

4. Use termination or impedance-matching devices to avoid reflections.

5. Ensure that attenuators and terminations have adequate power handling capabilities.

If there is a DC voltage across the output load, use a coupling capacitor in series with the load. The time constant of the

coupling capacitor and load must be long enough to maintain pulse flatness.

Impedance Matching

If the waveform generator is driving a high impedance, such as the 1 MΩ input impedance (paralleled by a stated

capacitance) of an oscilloscope vertical input, connect the transmission line to a 50 Ω attenuator, a 50 Ω termination and to

the oscilloscope input. The attenuator isolates the input capacitance of the device and terminates the waveform generator

properly.

3.6 MENU Keys

These keys select the main menus for displaying or changing a parameter, function or mode. Below is the hierarchy and

selections of the menu tree.

MENU TREE

- PARAM

o FREQ | RATE

13

Page 20

o AMPL| OFST

o INTCLK | EXTCLK

- WAVE

o SINE

o SQR (Duty Cycle)

o TRI (Symmetry)

o PULSE

o ARB

UNITS (Only when AMPL is selected, press to toggle display in Vp-p, Vrms, dBm)

50 OHM | HI-Z

FREQ | PERIOD

WIDTH

EQUAL EDGE

LEAD | TRAIL

PREV

START

LENGTH

MARK

• ADDR

• LENGTH

• ON | OFF

• PREV

EDIT

• POINT

o ADRS

o DATA

o PREV

• LINE

o FROM

o TO

o EXEC

NO

YES

PREV

o PREV

• PREDEF

o TYPE (Predefined Waveform Type)

o FROM | DATA

o LENG

o SCALE (In %)

o EXEC

NO

YES

PREV

o EXEC (When NOISE is selected as TYPE)

ADD

NEW

EXEC

• NO

• YES

• PREV

PREV

• MORE

o COPY

FROM

LENG

TO

EXEC

• NO

• YES

• PREV

PREV

o CLEAR

FROM

TO

ALL

EXEC

• NO

• YES

• PREV

PREV

14

Page 21

o PROT

o SHOW WAVE

o PREV

• PREV

PREV

- MODE

o CONT

o TRIG

MAN (Manual Trigger)

INT (Internal Trigger Rate)

EXT (External Trigger)

PREV

o GATE

MAN (Manual Gate Trigger)

INT (Internal Gate Trigger Rate)

EXT (External Gate Trigger)

PREV

o BURST

MAN (Manual Burst)

INT (Internal Burst Rate)

EXT (Burst External)

NBRST (Number of Bursts)

PREV

o PHASE (Not available in ARB mode)

PHASE (Set Phase Degree)

SET-ZERO (Set Phase to 0)

PREV

- SWEEP ( Not Available in PULSE and ARB mode)

o ON | OFF

o START (Sweep Start Frequency)

o STOP (Sweep Stop Frequency)

o RATE (Sweep Rate)

o LIN | LOG (Linear or Logarithmic)

- MODUL

o AM

ON | OFF

% (% of Modulation)

SHAPE (AM Modulation Shape)

MOD FREQ (AM Modulation Frequency)

EXT | INT (External or Internal Modulation)

o FM (Not available in PULSE and ARB mode)

ON | OFF

DEV (FM Deviation Frequency)

SHAPE (FM Modulation Shape)

MOD FREQ (FM Modulation Frequency)

EXT | INT (External or Internal Modulation)

o FSK (Not available in PULSE and ARB mode)

ON | OFF

F-LO (FSK Low Frequency)

F-HI (FSK High Frequency)

RATE (FSK Rate)

EXT | INT (External or Internal modulation)

- SETUPS

o RECALL (Recall Setup from Memory)

o STORE (Store Setup from Memory)

o SAVE ARB (Saves current arbitrary waveform into memory. Available only in ARB mode)

- UTIL

o GPIB (ACTIVE) (GPIB Address)

o RS232 (ACTIVE) (Baudrate)

o INTEN

o POWER (Power On Setup)

o SUM ON | OFF

FROM

TO

ALL

ON | OFF

PREV

15

Page 22

offset

valuespodatasettingppAmplitude

voltageoutput +

⋅−

=

16382

int

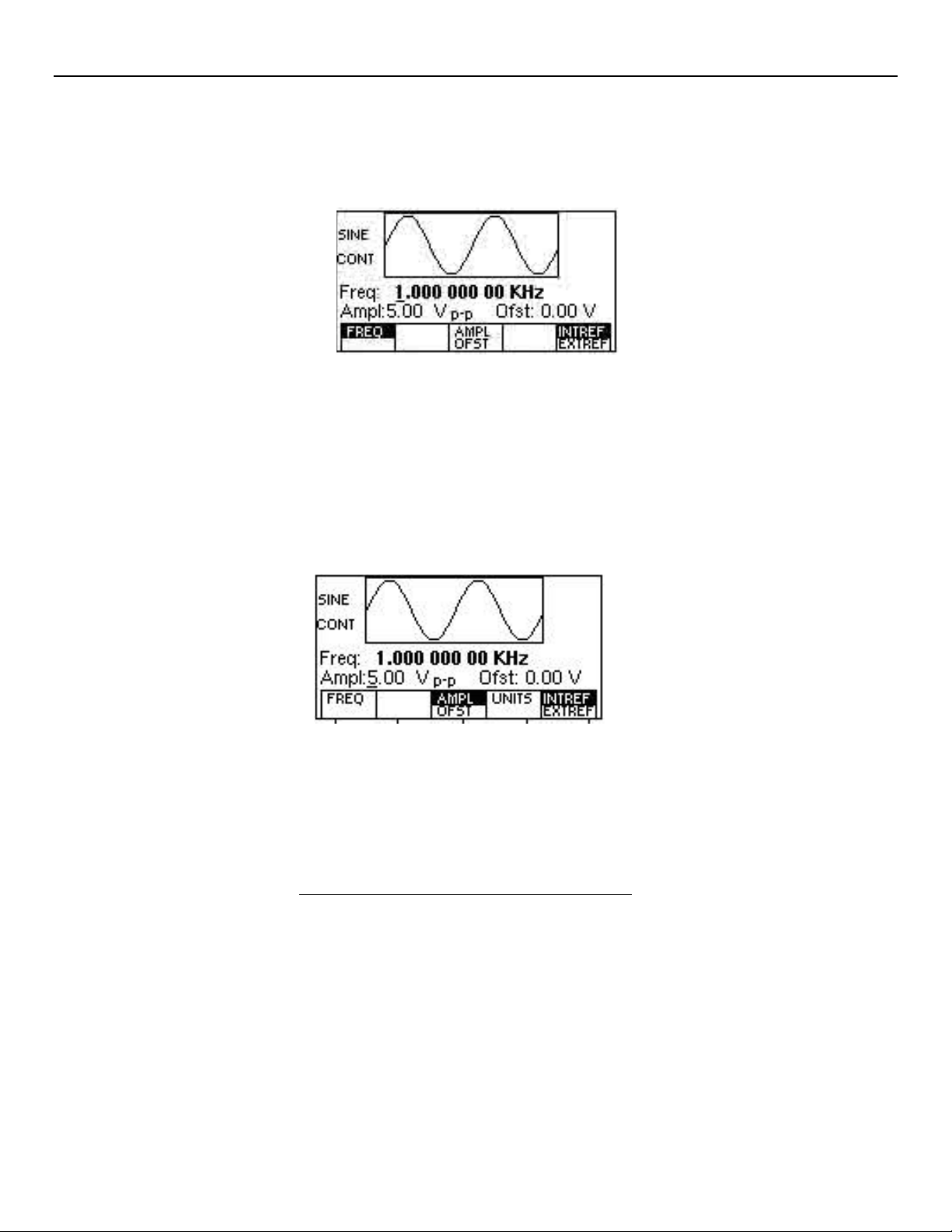

3.6.1 PARAMETER Key

This key selects and displays the waveform frequency, amplitude, offset and external reference and allows changing the parameter

data. When the Arbitrary Waveform is selected, the display shows also the waveform rate.

F1: FREQ - (Frequency) Selects and displays the frequency. Change the frequency setting using the cursor keys and

rotary knob or numerical keypad. If a certain wavelength can't produce the waveform at the desired

frequency, the waveform generator displays an “Out of Range” error message.

F3: AMPL/OFST - Selects the Amplitude or the Offset parameters.

In Arbitrary mode this setting defines the maximum peak-to-peak amplitude of a full-scale waveform. If

the waveform does not use the full scale of data (-8191 to +8191), then its actual amplitude will be smaller.

Amplitude Menu

Setting the Amplitude

The following equation represents the relative output amplitude voltage relationship between the front-

panel amplitude peak-to-peak setting and the data point values in waveform memory:

Frequency Menu

Where 16382 is the total data point value range in waveform memory.

Examples

16

Page 23

+2.5 V

+1.25 V

0V (offset voltage)

-4.5 V

F3:OFST - Selects the Offset parameter. Change the offset by using the cursor keys, rotary dial or numerical keypad.

F5:INTREF/EXTREF - Selects internal or external reference source (the external reference must be connected to the

Front Panel

Amplitude

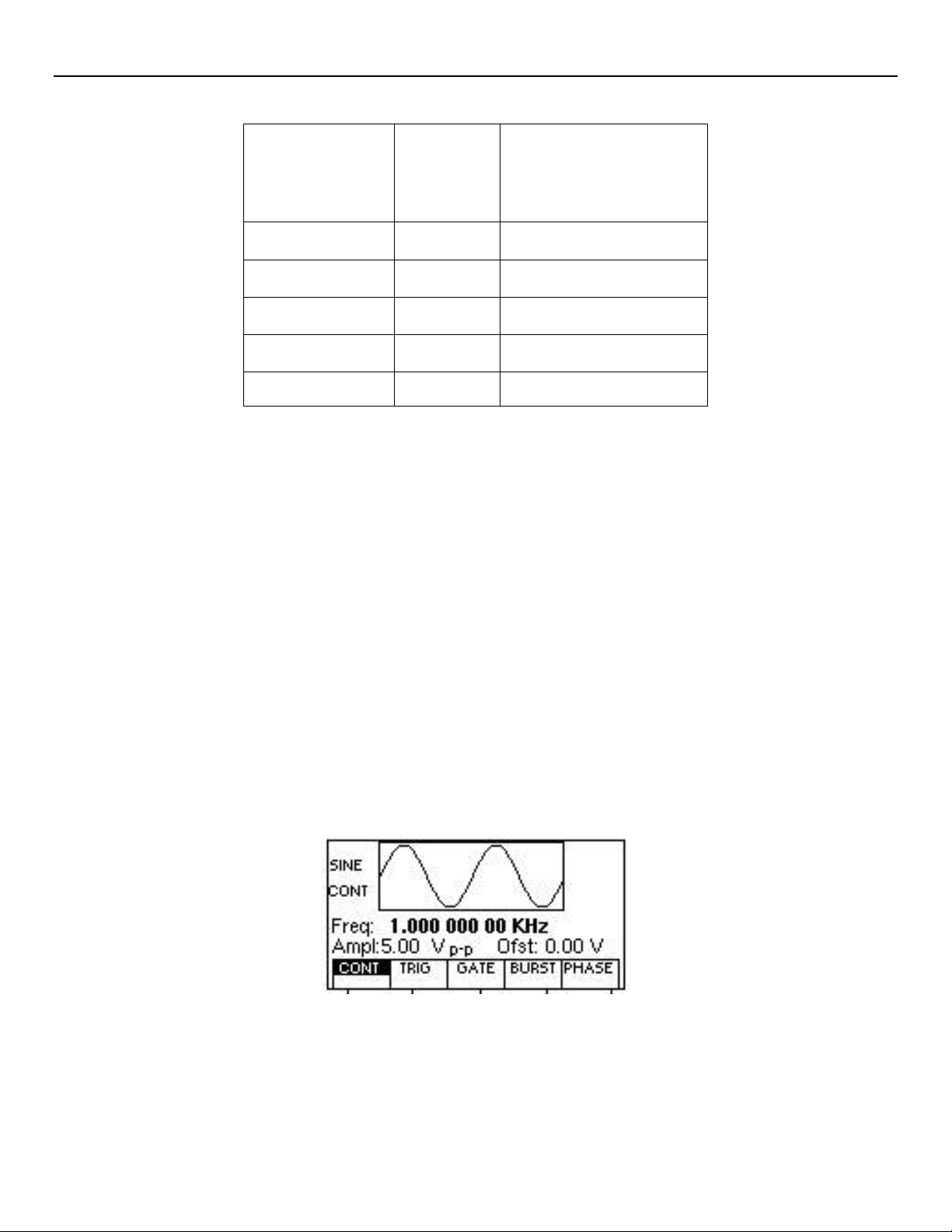

Setting

Data Point

Value

Relative Output

Amplitude Voltage

5 Vp-p 8191

5 Vp-p 4095

5 Vp-p 0

9 Vp-p -4095

4 Vp-p -8191 -2 V

F4:UNITS -

F5:50 OHM/HI-Z - Selects the amplitude voltage value based on the two different impedance termination. (i.e.

Selects the amplitude units: peak-to-peak, RMS or dBm.

if connected to oscilloscope with 1Mohm, generator will display the correct amplitude value

for 1Mohm termination if HI-Z is selected)

If a certain setting cannot be produced, the waveform generator will display a “Setting Conflict” message.

rear panel Ref In connector).

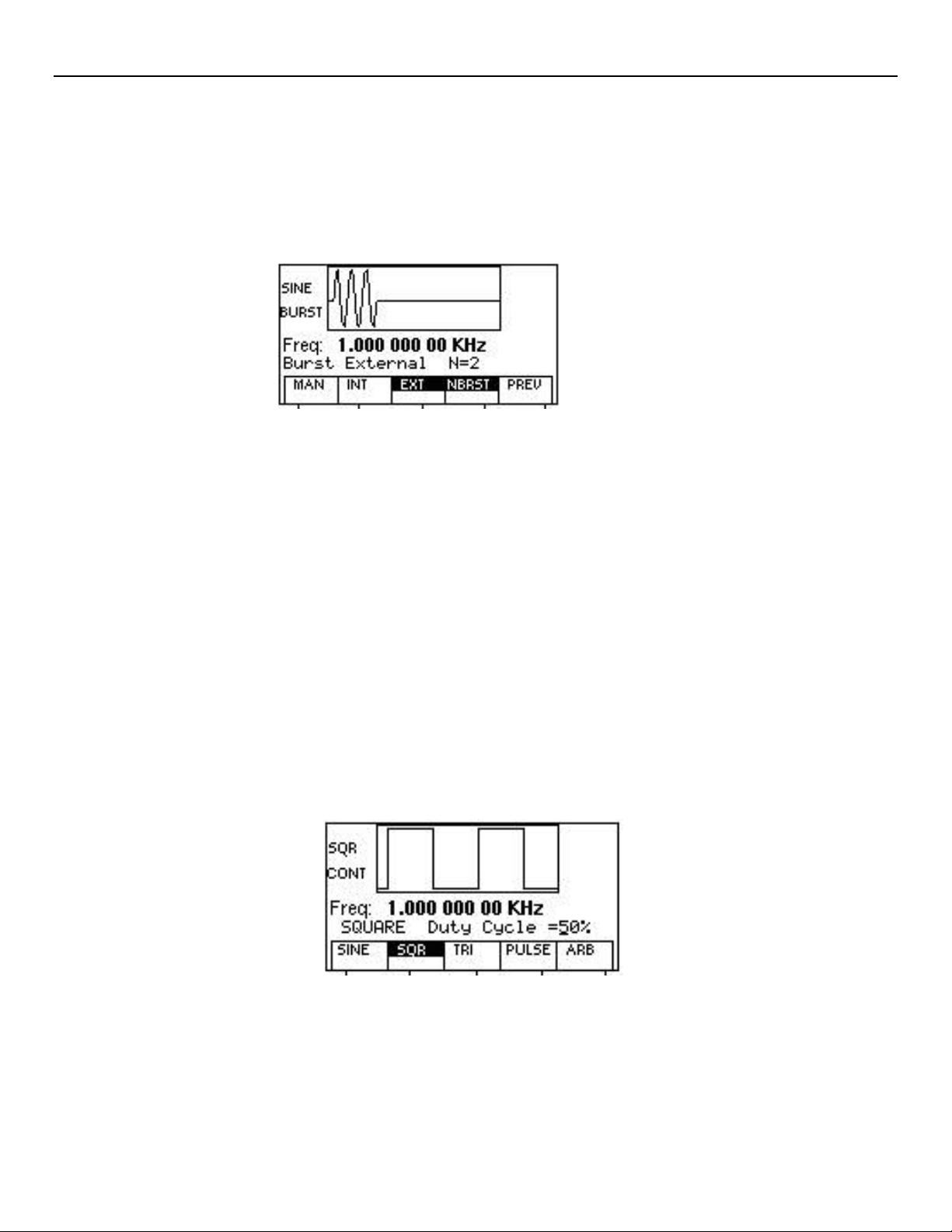

3.6.2 MODE Key

Selects the output mode: CONT (Continuous), TRIG (Triggered), GATE (Gated), and BRST (Burst).

To select the output mode, press MODE, then press the function key that corresponds to the desired Mode menu option, as

shown:

Mode Menu

F1: CONT - (Continuous) - Selects continuous output.

F2: TRIG - (Triggered) - Triggers one output cycle of the selected waveform for each trigger event.

F3: GATE - (Gated) - Triggers output cycles as long as the trigger source asserts the gate signal.

17

Page 24

F4:BURST - (Burst) - Triggers output N cycles for each trigger event, where N ranges from 2 to 999,999.

F5: PHASE - Selects the start phase of the signal in non-continuous modes. The range is from -180˚ to +180˚, with a 0.1˚

resolution. In PHASE mode F2: SET-ZERO sets the phase reference to zero when few instruments are

connected to the same external reference and need to be synchronized with different phase relations.

After selecting the TRIG , GATE or BURST menu, the trigger source menu is available:

Trigger Menu

F1: MAN - Selects manual as the trigger source. To trigger the waveform generator,

press this MAN TRIG again.

F2: INT - Selects the internal trigger generator as the trigger source. Change the

internal trigger rate displayed with the rotary input knob.

F3: EXT - Selects the external trigger signal as the trigger source. The trigger source

is supplied through the TRIG IN connector.

F4: NBRST - Selects the number of burst pulses to be output with each trigger. The N can be changed from 2 to

999,999.

F5:PREV - Goes back to previous menu

3.6.3 WAVEFORM Key

Displays the waveforms available:

F1: SINE - Selects the sine waveform.

F2: SQR - Selects the square waveform and displays the waveform duty cycle that can be changed from 20% to 80% up to 10MHz

and 40% to 60% to 30MHz.

F3: TRI - Selects the triangle waveform and displays the waveform duty cycle that can be changed from

maximum frequency is 5MHz.

Waveform Menu

10% to 90%. The triangle

18

Page 25

F4: PULSE - Selects the Pulse waveform and then displays the pulse menu. Refer to section 3.6.5 for details.

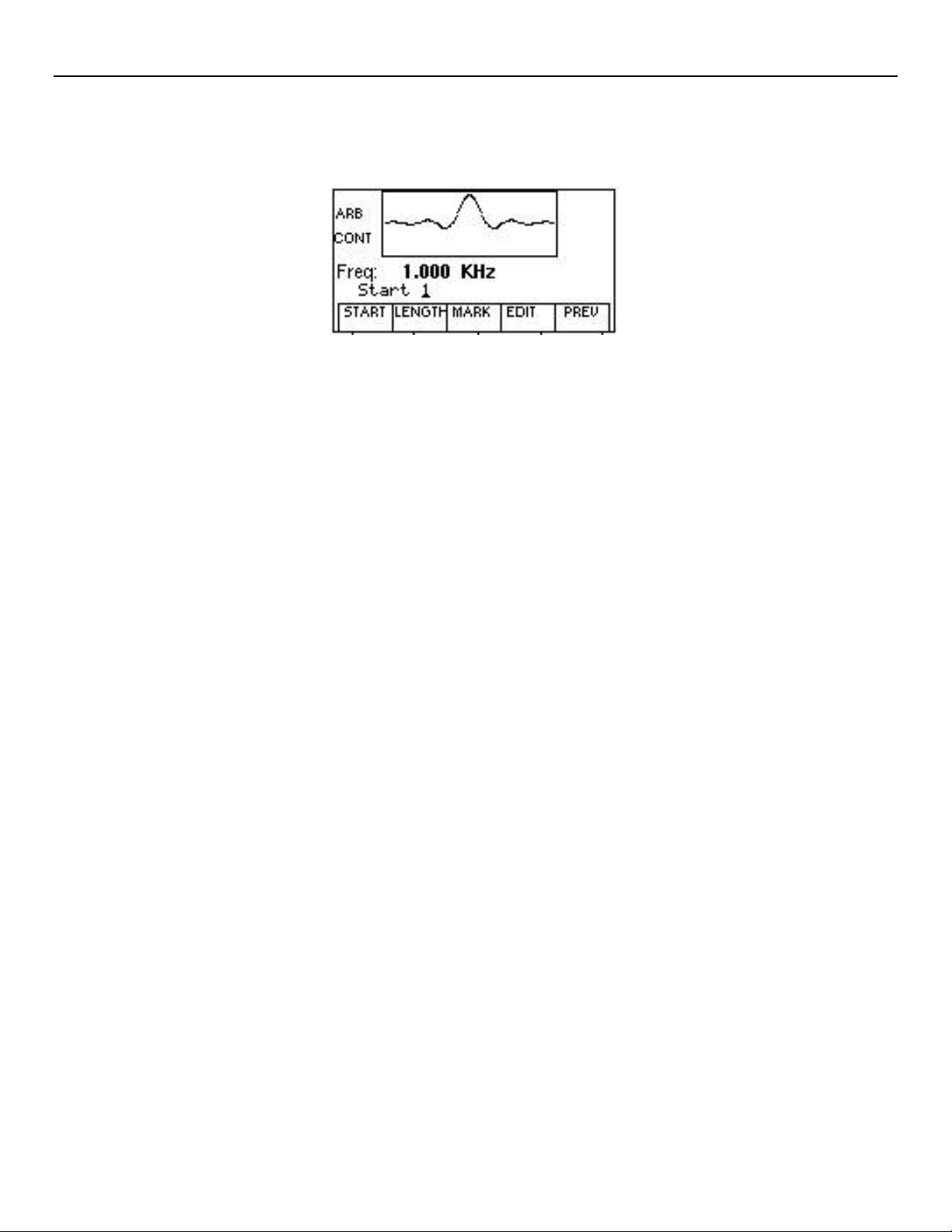

F5: ARB - Selects the arbitrary waveform and then displays the Arbitrary menu:

Arbitrary Menu

F1: START - Selects the starting address of the arbitrary waveform.

Note: The starting address always has to be an odd number. If an even number is entered, it will automatically decrement one value to an odd number. For example, if you set start address to 2000 and press ENTER, it will display 1999.

F2: LENGTH - Selects the length of the arbitrary waveform. Use the START and LENGTH menu selection

to mark a selection of the waveform memory that will be executed.

Note: The length value must always be an even number. If you input an odd number

length, a message will pop up and say “Even wave length” and then decrement one

value to an even number. For example, if you entered 1001 as the length, the message

will pop up for one second and change the value automatically to 1000.

F2: SAVE ARB - Selecting this will save the current Arbitrary waveform data points so that it can be recalled

when revisiting the ARB menu later on or when power cycling the instrument.

Note: The 4076 and 4079 can both save multiple numbers of waveforms because the

instruments have one large memory bank to store up to 4,000,000 points total.

Essentially, the user can store multiple waves with various lengths in different

locations in the memory. This can be done simply by generating each of the waveforms

with different starting addresses. As long as the lengths of each do not overlap, user

can save as much waveforms with different lengths as desired (Total points of all

waveforms cannot exceed 4,000,000 points). If user has multiple waveforms to create

and do not want to remember all the different starting addresses and lengths, there is a

“STORE” and “RECALL” feature explained in section 3.6.6 that will allow you to

store and recall up to 50 settings (Note: Only 49 settings can be restores because 50 is

reserved for restoring last known working state of the instrument). Each setting can

save all the waveform parameters, configurations, modes, starting address, length and

more. (Refer to Table 3-2 in section 3.10 to see entire list of stored parameters) This

way, user can quickly recall back the different waves stored in the memory. Refer to

section 3.6.6 for details.

F3: MARK - (Marker Output) Selects the marker output address of the signal to be available at the Marker

Out connector. The F2:ADDR, F3:LENGTH or F4:ON/OFF can be selected and the Marker

output signal can be available at any desired location address between the start and stop addresses

of the executed waveform. This marker output feature will allow you to generate a positive TTL

19

Page 26

Start Address

Length

Markers

0

5 V

Arbitrary waveform

5 V TTL signal

level output signal at the points specified by address and length.

Note: The maximum LENGTH allowed to be set for marker is 4000.

Below is an example to illustrate how marker function works:

from front panel

channel output

output from rear

Marker Out connector

Marker Function Illustration

F4: EDIT - Refer to section 3.6.4 below for details.

F5: PREV - Back to previous menu

**Changing one of the arbitrary parameters as start and length causes an update of the output waveform to the new

parameters. When exiting the Arbitrary Menu by selecting a different waveform, a message to save the Arbitrary wave will

be displayed. Select YES or NO to save the new waveform. This save functions the same as the SAVE ARB function.

3.6.4 Arbitrary EDIT Menu

Enters data for creating arbitrary waveforms. You can enter data one point at a time, as a value at an address, draw a line

from one point (a value at an address) to another point, create a predefined waveform, or combine these to create complex

waveforms. The valid data values range is -8191 to 8191. The valid waveform memory addresses range from 1 to 4,000,000.

The data value governs the output amplitude of that point of the waveform, scaled to the instrument output

20

Page 27

Wave

Minimum Length

Divisible by

Sine

16

4

Triangle

16

4

Square 2 2

Noise

16

1

amplitude. Therefore, a value of 8191 corresponds to positive peak amplitude, 0 corresponds to the waveform offset, and 8191 corresponds to the negative peak amplitude.

F1: POINT - This menu allows point by point waveform editing. When selected, the following menu is displayed:

F1: ADRS - Select the current address in the arbitrary waveform memory.

F2: DATA - Selects the data point value at the current address. You can change the point

value from -8191 to 8191.

F5: PREV - Goes back to previous menu (Edit menu).

F2: LINE - This menu allows a line drawing between two selected points.

Displays the following menu:

F1: FROM - Selects the starting point address.

F2: TO - Selects the ending point address.

F4: EXEC - Displays the Confirmation menu, F1:NO and F3:YES

F5: PREV - Goes back to previous menu (Edit menu).

F3: PREDEF - (Predefined Waveforms) Selects one of the predefined waveforms

F1: TYPE - Selects the waveform Sine, Triangle, Square, Noise, Ramp up, Ramp down, exponential up,

exponential down, Sin(x)/x, and Gaussian distribution. If Noise function is selected, a submenu is displayed

when F5:EXEC is pressed to allow adding the noise to an available waveform or to generate it as a new

noise waveform.

F2: FROM/DATA - Selects the starting point of the generated waveform and its data value.

F3: LENG - Selects the length of the predefined waveform (number of points for a full wave).

The length value must be a number that is divisible by 4 or by 2 in some instances.

If not, a pop up message will say “Must divide by 4” or “Must divide by 2” and

entered values will change back to its original. Different waveforms have different

limitations on the length. Refer to Table 3-1 below.

F4: SCALE - Selects the scale of the waveform. If scale is too high, a message will display

“Scale too high.” 100% means that the waveform spans the full scale of -8191 to

8191. Scale factors are limited by the point data value of the starting point and

automatically calculated by the unit.

Table 3-1: Waveform Length Limits for Predefined Waveforms

F5: EXEC - Prompts you to confirm whether to execute the selected predefined waveform. Press NO to

21

Page 28

abort executing the predefined waveform; press YES to execute the predefined waveform. On the NOISE

function a menu of ADD and NEW is prompted to select a new noise waveform or to add noise to the

existing waveform.

F4: MORE - Displays the following Menu:

F1: COPY - Displays the Copy menu (see the Copy Function later in this section).

F2: CLEAR - Displays the Clear menu (see the Clear Function later in this section).

F3: PROT - Displays the Protect menu (see the Protect Function later in this section).

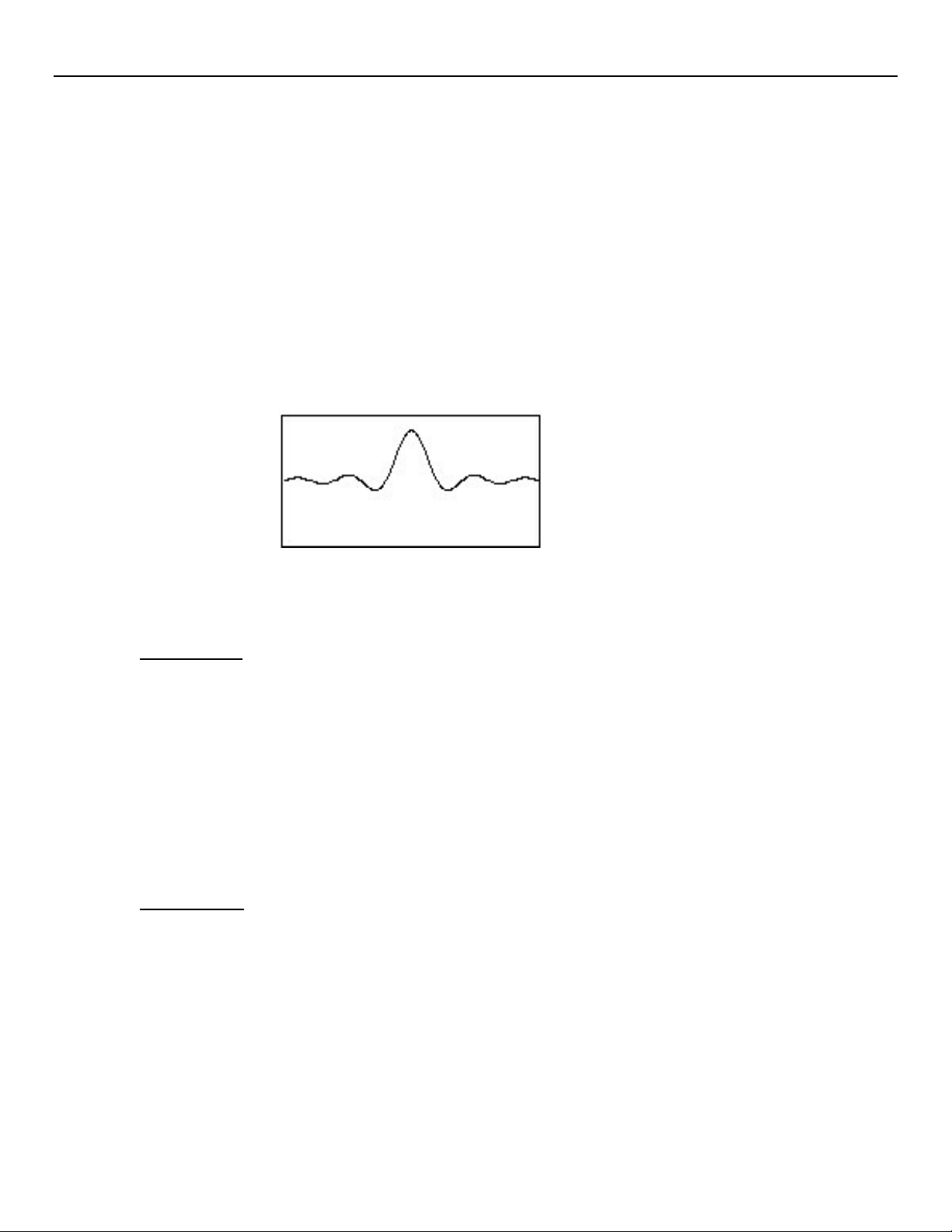

F4: SHOW WAVE - Display the Arbitrary waveform in full screen mode on LCD display. This is only an

approximated display for quick viewing. It does not represent the exact waveform

being generated. To return back to the MENU selection, press any button.

Full Display Example

F5: PREV - Returns to previous menu.

Copy Function. Copies an area of waveform memory to another area of waveform memory.

F1: FROM - Selects the address of the first point to copy.

F2: LENG - Selects the length (number of points) of the waveform to copy.

F3: TO - Selects the destination address where the first point is copied.

F4: EXEC - Prompts you to confirm whether to copy. Press NO to abort copying, YES to copy.

F5: PREV - Returns to previous menu.

Clear Function. Clears (sets the data values to zero) either a section of or all of waveform memory.

F1: FROM - Selects the address of the first point to clear.

F2: TO - Selects the address of the last point to clear.

F3: ALL - Clears the whole waveform memory. Equivalent to selecting from 1 to 4,000,000.

F4: EXEC - Prompts you to confirm whether to clear. Press NO to abort clearing, YES to clear.

F5: PREV - Returns to previous menu.

22

Page 29

Protect Function. Protects (makes read-only) a section of waveform memory.

F1: FROM - Selects the address of the first point to protect.

F2: TO - Selects the address of the last point to protect.

F3: ALL - Protects the whole waveform memory. Equivalent to selecting from 1 to 4,000,000.

Note: You can protect only one segment of waveform memory at a time.

F4: ON/OFF - Selects the unprotect mode and resets memory protection so that the whole waveform

memory can be written into.

F5: PREV - Returns to previous menu.

3.6.5 PULSE Menu

From the WAVE menu, select F4:PULSE.

F1: FREQ/PERIOD - Selects the parameter definition of the Pulse repetition period.

F2: WIDTH - Selects the Width of the generated pulse.

F3: EQUAL EDGE - Selects equal Rise (Leading edge) and Fall (Trailing edge) times of the pulse.

F4: LEAD-TRAIL - Selects different Rise and Fall times of the Pulse.

F5:PREV - Returns to previous menu.

3.6.6 UTILITY Key

Utility Menu

F1: GPIB - Selects the GPIB remote mode of operation. After selection the GPIB address can be set to any value

from 1 to 31 using the rotary knob. The value is kept in a nonvolatile memory and used at power-on. The

factory default address is 9. Setting the address to 31 puts the device in the off-bus state (it will not respond

to messages on the GPIB bus).

F2:RS232 - Selects the RS232 remote control mode. After selection, the baud rate can be selected as 2400, 9600,

19200, and 38400. The RS-232 uses 8 bit data, 1 stop bit and no parity.

23

Page 30

F3:INTEN

F3: POWER - (Power-on default) Selects the power-on default setting. Select a value using the numeric keypad or the

F5: SUM ON/OFF - (Summing On/Off) Selects the external summing mode. An analog signal connected to the

- (Intensity) Selects the intensity of the LCD display. Select a value using the rotary input knob.

Valid numeric values are from 1 to 31. The value is kept in the nonvolatile memory, after a 20

seconds time-out. The lower the value, the dimmer the display.

rotary input knob. The selection is effective after a 10 s time-out period. Select zero (0) to have the

waveform generator power on with the factory default settings. Select 50 to have the waveform generator

power-on with the settings it had at the last power-off. Select any other value in the range from 1 to 49 to

have the waveform generator power-on with the settings that you have saved with STORE(see SETUP key

section 3.6.9) in the range of 1 to 49.

Sum In connector in the rear panel of the unit is added to the output signal. A 5Vp-p input signal will generate a

full amplitude output signal.

3.6.7 SWEEP Key

Selects the Sweep Mode and allows the entering of sweep parameters as Sweep Start, Sweep Stop and Sweep Rate.

To select the sweep mode, press SWEEP, then press the function key that corresponds to the desired Sweep menu option, as

shown:

Sweep Menu

F1: ON/OFF - Operates the sweep function, selecting between Sweep On or Off.

F2: START/STOP - Defines the Sweep Start frequency.

F3: STOP - Defines the Sweep Stop frequency.

F4: RATE - Defines the Sweep Rate.

F5: LIN/LOG - Selects the Sweep Shape, LIN or LOG.

3.6.7.1 How to Setup Sweep in Different Modes

By default, turning ON the sweep function will automatically set to a continuous (CONT) sweep. In order to

change to other modes of sweep, do the following:

1. Set sweep to ON FIRST by pressing F1.

2. Then, press the MODE button on front panel.

24

Page 31

3. Select between triggered (TRIG), burst (BURST) or gated (GATE) mode.

Note: If this is done before turning on sweep, sweep ON selection will automatically reset to default

(which sweeps in continuous mode).

3.6.8 MODULATION Key

Selects the Modulation mode AM, FM or FSK.

To select the output mode, press MODUL key, then press the function key that corresponds to the desired menu option.

F1: AM

If the AM is selected, the following menu is available:

AM Menu

F1: ON/OFF - Selects the Modulation ON or OFF operating mode.

F2: % - Defines the modulation depth (from 0 to 100%)

F3: SHAPE - Defines the modulation shape between SINE, TRIANGLE or SQUARE .

F4: MOD-FREQ - Selects the modulation frequency, from 0.01 Hz to 20.00 KHz.

F5: EXT/INT - Selects and enables the external modulation by an external signal applied to the Modulation

In connector.

F3: FM

If the FM is selected, the following menu is available:

FM Menu

F1: ON/OFF - Selects the Modulation ON or OFF operating mode.

25

Page 32

F2: DEV - Defines the FM deviation frequency.

F3: SHAPE - Defines the modulation shape, between SINE, TRIANGLE or SQUARE.

F4: MOD-FREQ - Selects the modulation frequency, from 0.01 Hz to 20.00 KHz.

F5: EXT/INT - Selects and enables the external modulation by an external signal applied to the

Modulation In connector.

F5: FSK

If the FSK is selected, the following menu is available:

FSK Menu

F1: ON/OFF - Selects the FSK ON or OFF operating mode.

F2: F-HI - Defines the High frequency of the FSK.

F3: F-LO - Defines the Low frequency of the FSK.

F4: RATE - Selects the rate of alternation between the low and high frequencies.

F5: EXT/INT - Selects and enables the external FSK when the unit frequency is alternating between the low and

high frequencies by an external signal applied to the Trig In connector.

3.6.9 SETUPS Key

The waveform generator can store the current front-panel settings, called a setup, into one of 50 storage buffers.

When you recall a setup, the waveform generator restores the front-panel settings to those that you stored in the

selected buffer. All waveform data, except for the waveform memory data, is stored in the setup.

SETUP Menu

F1: RECALL - Recalls a previously stored front-panel setup from the selected buffer. Change the buffer

number by using the rotary input knob. Valid storage buffer numbers are from 0 to 49.

26

Page 33

Stored Parameters

FREQUENCY

RATE(ARB)

AMPLITUDE

FUNCTION

OFFSET

REPETITION

MODE

N-BURST

START ADRS

WAVELENGTH

TRIG SOURCE

OUTPUT

SWEEP

MODULATION

4,000,000

Waveform 1

Waveform 4

Waveform 2

Waveform 3

A pts.

B pts.

C pts.

D pts.

A pts. + B pts. + C pts. + D pts. ≤ 4,000,000 pts.

Point

Point

Buffer 0 is the factory default setup.

F3: STORE - Stores the current front-panel setup to the specified storage buffer. Change the buffer number by using

the numeric keypad or the rotary input knob. Valid storage buffer numbers range from 1 to 49. Below is a

list of parameters that can be stored in each buffer.

Note: Location 50 is for last working setup before power down.

List of Stored Parameters

**The RECALL and STORE function can be used as a tool to store and locate many arbitrary waveforms.

Because the 4076 and 4079 are designed with one large memory bank (up to 4,000,000 points of storage),

users can have the freedom to store as many waveforms of different lengths as they desired in a dynamic

fashion (with the limit of total points not to exceed memory capacity). Then, by using STORE and

RECALL functions to save the starting address and lengths of each created arbitrary waveforms, users can

quickly locate (in the memory) and output each of the different waves. These functions can behave like

reference points, so users can actually save up to 49 different waveform reference points in the memory.

See example illustration below to see how it works:

27

Page 34

Stored Buffer number

Data points of different waveforms

(Start address + length)

1

A pts.

2

B pts.

3

C pts.

4

D pts.

Key Functions

Values

Comments

FREQUENCY

1.000000000 Hz

Wave frequency

RATE(ARB)

1 µs

Sample time per point

AMPLITUDE

5.00 V

Peak to peak output amplitude

FUNCTION

SINE

Output waveform

From the above illustration, all the points of Waveform 1 can be stored and recalled using buffer #1. Likewise,

Waveform 2 can be stored/recalled by buffer #2. Waveform 3 by buffer #3. Waveform 4 by buffer #4.

3.7 ON Key

Use these key to control the main output signal. When the output is active, an Out On message is displayed on the left

upper side of the LCD.

3.8 Cursor Movement Keys

Use these keys to move the cursor (when visible) either left or right. They are used in conjunction with the rotary input knob to

set the step size of the rotary input knob.

3.9 Rotary Input Knob

Use this knob to increase and decrease numeric values or to scroll through a list. The cursor indicates the low-order position of

the displayed value which changes when you rotate the knob (for straight numeric entries only). For other types of data, the

whole value changes when you rotate the knob.

3.10 Power-On Settings

At power-on, the waveform generator performs a diagnostic self-test procedure to check itself for errors. If it finds an error, an

error code and text will appear in the display window. Other error codes appear when you enter an invalid front-panel setting.

For more information on error codes, see the Error Indication section 3.12.

When the waveform generator finishes the diagnostic self-test routine, it enters the local state (LOGS) and assumes power-on

default settings. Table 3-2 lists the factory default settings. You can program the waveform generator for any settings you want

at power on, as described earlier in section 3.6.6.

Table 3-2

Power-on Default Settings

28

Page 35

OFFSET

0.00 V

Zero offset

REPETITION

10 ms

Internal trigger rate

MODE

CONT

Waveform mode

N-BURST

2

Waves per burst

START ADRS

1

Start memory address

WAVELENGTH

1000

Number of points per waveform

TRIG SOURCE

EXT

External trigger source

OUTPUT

OFF

Output disabled

SWEEP

OFF

Sweep execution

MODULATION

OFF

Modulation execution

3.11 Memory

The waveform generator uses a non-volatile FLASH memory for storing arbitrary waveform data and front panel settings. Up

to 4,000,000 points Arbitrary waveform and 50 front panel settings are stored. These front panel settings can be used to store

starting address and lengths of many different waveforms stored in memory as reference points for quick recall.

Because it is impossible to guarantee 100% of the time against loss of stored data, you should maintain a record of the data

stored in memory so that you can manually restore such data, if necessary.

3.11.1 Nonvolatile Flash (Arbitrary Waveform Memory)

The FLASH stores the arbitrary waveform memory at power off, which the waveform generator uses to store the data points

that make up an arbitrary waveform.

The FLASH also stores the settings storage buffer, which the waveform generator uses to store up to 49 front-panel

setups. For more information about the settings storage buffer, see SETUPS key earlier in this section.

Because it is impossible to 100% guarantee against loss of stored data, you should maintain a record of the data stored

in memory so that you can manually restore such data, if necessary.

3.11.2 Dynamic RAM

The DRAM stores waveform output. For arbitrary waveform output, the waveform generator loads the selected

contents of the FLASH (arbitrary waveform memory) into the DRAM. In order to save the arbitrary edited data in the DRAM

memory, the instrument will display a message " SAVE DATA" after each modification of the arbitrary

waveform in the EDIT menu.

3.12 Displaying Errors

At power-on, the waveform generator performs a diagnostic routine to check itself for problems. If the diagnostic routine finds

an error, an error message is displayed. The waveform generator also displays error messages when front-panel settings are

either invalid or may produce unexpected results.

Error messages for Model 4076 and 4079

Message Text Cause

Out of range Attempt to set variable out of instrument limits.

Setting conflict Can't have this parameter set with some other.

29

Page 36

Trig rate short Internal trigger rate too short for wave/burst.

Empty location Attempt to restore non existent setting.

SCALE too high Attempt to set scale too high for current dot value

Protected RAM Attempt to write to protected RAM range.

RAM error Error in testing RAM.

Save RAM New firmware installed.

Must divide by 4 Predefined wave length must be divisible by 4.

Must divide by 2 Predefined wave length must be divisible by 2.

3.13 Using The Model 4076 and 4079

This section explains how to generate various waveforms and modify the output waveforms.

* Generating a standard waveform

* Creating an arbitrary waveform

* Loading a waveform into execution memory

* Generating a waveform output

* Modifying waveform output

* Storing and recalling a waveform generator setup

The waveform generator has two types of memory: waveform memory and execution memory. Waveform memory

consists of 4,000,000 points at which you can specie a value from -8191 to 8191. You can scale these points in execution memory

through the output amplitude setting; that is, data point 8191 is equal to the positive peak of the output amplitude.

3.13.1 Selecting a Standard Waveform

You can select several standard waveforms as: sine, triangle and square. Creating a standard waveform requires selecting

the waveform type, parameters, modes, etc., and their settings that define the waveform.

Generating a standard waveform requires the following:

* Selecting the waveform by pressing WAVE key, then select the wave type from the menu using the function keys.

* Setting the output.

* Setting the output amplitude and offset.

3.13.2 Setting the Output Mode

To set the output mode:

1. Press MODE to display the Mode menu on the display window.

2. Press the function key (Fl to F5) that corresponds to the desired mode. Choose from Continuous, Trigger, Burst, and

Gate mode. You can also adjust the Phase in the same menu.

3.13.3 Setting the Output

To set the output channel, press the Output ON key. An internal LED is illuminated to indicate that the Output is ON.

3.13.4 Setting the Output Amplitude

To set the output amplitude:

30

Page 37

1. Press PARAMETER to display the Parameter menu.

2. Press F3:AMPL to select the Amplitude parameter.

3. Use the rotary knob to set the amplitude.

4. Press F:OFST again to select the Offset parameter.

3.13.5 Setting the Output Frequency

To set the output frequency:

1. Press PARAMETER to select the Frequency parameter.

2. Use the rotary knob to set the frequency.

3.14 Examples

3.14.1 Creating an Arbitrary Waveform

You can create an arbitrary waveform using the following methods:

* Enter individual data points

* Draw lines between data points

* Create a predefined waveform

* Export waveform from software

* Create data points using SCPI commands

* Combine any of these methods

The waveform’s frequency and amplitude are influenced by the number of data points and their value in the waveform. For

further information on how the number of data points influence the frequency and amplitude of a waveform in execution

memory, see Setting the Frequency portion (Section 3.14.3) and Setting the Amplitude portion (Section 3.14.4), respectively.

3.14.2 Entering Individual Data Points

The most basic way to program an arbitrary waveform is to enter data points for the waveform, one data point at a time. While

this can become tedious, the auto-increment function helps this process.

To enter individual data points into waveform memory, follow these steps:

1. Press WAVEFORM main key to display the selection menu.

2. Press F5: ARB to display the arbitrary menu.

3. Press F4:EDIT to display the Edit menu.

4. Press F1:POINT, to select the point by point programming mode.

5. Press F1:ADRS

6. Use the rotary knob or the numerical keypad to enter the address.

7. Press F2:DATA.

8. Use the rotary knob or the numerical keypad to enter the value for the data point. Valid entries range from

–8191 to 8191.

9. Repeat steps 5 through 8 for additional points until you finish creating your arbitrary waveform.

Note: Each time you press ENTER to complete a data point entry in numerical mode, the auto-increment address

advances the "A= value" by one.

31

Page 38

ACTION

KEYSTROKES

Loads the first 1000 points of waveform

WAVEFORM

ACTION

KEYSTROKES

Step 1: Load a 1000 point, 50% scaled, predefined sine wave

WAVEFORM

Step 2: Load a 5% scaled, 100 point predefined waveform

WAVEFORM

F3:YES

Step 3: Draw a line between address 251 (the highest point

of the sine wave) and address 501 (where the sine

WAVEFORM

F5:ARB

3.14.3 Creating an Arbitrary Waveform

To create a complex arbitrary waveform:

* Load a predefined sine waveform

* Load a scaled sine waveform at the positive peak of the first sine wave

* Draw a straight line between two data points in the waveform

* Add a pulse/glitch to the waveform

* Add a noise signal at the negative peak of the first sine wave

To see the waveform as you build it, connect the waveform generator to an oscilloscope and perform the following

steps:

memory into execution memory.

The following steps set up the waveform shown in Figure 3-2.

into waveform memory starting at address 1

F5:ARB

F1:START

1

F2:LENGTH

1000

F5:PREV

MODE

F1:CONT

OUTPUT ON

F5:ARB

F4:EDIT

F3:PREDEF

F1:TYPE (rotate knob for selection)

SINE

F2:FROM/DATA

1

F3:LENG

1000

F4:SCAL

50

F5:EXEC

F3:YES

into waveform memory starting at address 200.

F5:ARB

F4:EDIT

F3:PREDEF

F1:TYPE

SINE

F2:FROM

200

F3:LENG

100

F4:SCAL

5

F5:EXEC

32

Page 39

wave crosses the origin).

F4:EDIT

F3:YES

Step 4: Add a negative pulse/glitch (data value -4095) at

WAVEFORM

for addresses 601-606)

Step 5: Add a 5% noise signal to addresses 700 through 800.

WAVEFORM

F3-YES

F2:LINE

F1:FROM

251

F2:TO

501

F4:EXEC