Page 1

4050B Series

Function/Arbitrary Waveform

Generator

USER MANUAL

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

i

Page 2

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must

be followed during all phases of operation, service, and repair of this instrument.

Before applying power to this instrument:

Read and understand the safety and operational information in this manual.

Apply all the listed safety precautions.

Verify that the voltage selector at the line power cord input is set to the correct line

voltage. Operating the instrument at an incorrect line voltage will void the warranty.

Make all connections to the instrument before applying power.

Do not operate the instrument in ways not specified by this manual or by B&K Precision.

Failure to comply with these precautions or with warnings elsewhere in this manual violates the

safety standards of design, manufacture, and intended use of the instrument. B&K Precision

assumes no liability for a customer’s failure to comply with these requirements.

Category rating

The IEC 61010 standard defines safety category ratings that specify the amount of electrical

energy available and the voltage impulses that may occur on electrical conductors associated

with these category ratings. The category rating is a Roman numeral of I, II, III, or IV. This rating

is also accompanied by a maximum voltage of the circuit to be tested, which defines the voltage

impulses expected and required insulation clearances. These categories are:

Category I (CAT I): Measurement instruments whose measurement inputs are not intended to

be connected to the mains supply. The voltages in the environment are typically derived from a

limited-energy transformer or a battery.

Category II (CAT II): Measurement instruments whose measurement inputs are meant to be

connected to the mains supply at a standard wall outlet or similar sources. Example

measurement environments are portable tools and household appliances.

Category III (CAT III): Measurement instruments whose measurement inputs are meant to be

connected to the mains installation of a building. Examples are measurements inside a

building's circuit breaker panel or the wiring of permanently-installed motors.

i

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Category IV (CAT IV): Measurement instruments whose measurement inputs are meant to be

connected to the primary power entering a building or other outdoor wiring.

Do not use this instrument in an electrical environment with a higher category rating than what

is specified in this manual for this instrument.

You must ensure that each accessory you use with this instrument has a category rating equal

to or higher than the instrument's category rating to maintain the instrument's category rating.

Failure to do so will lower the category rating of the measuring system.

Electrical Power

This instrument is intended to be powered from a CATEGORY II mains power environment. The

mains power should be 120 V RMS or 240 V RMS. Use only the power cord supplied with the

instrument and ensure it is appropriate for your country of use.

Ground the Instrument

To minimize shock hazard, the instrument chassis and cabinet must be connected to an

electrical safety ground. This instrument is grounded through the ground conductor of the

supplied, three-conductor AC line power cable. The power cable must be plugged into an

approved three-conductor electrical outlet. The power jack and mating plug of the power cable

meet IEC safety standards.

Do not alter or defeat the ground connection. Without the safety ground connection, all

accessible conductive parts (including control knobs) may provide an electric shock. Failure to

use a properly-grounded approved outlet and the recommended three-conductor AC line

power cable may result in injury or death.

ii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Unless otherwise stated, a ground connection on the instrument's front or rear panel is for a

reference of potential only and is not to be used as a safety ground.

Do not operate in an explosive or flammable atmosphere

Do not operate the instrument in the presence of flammable gases or vapors, fumes, or finelydivided particulates.

The instrument is designed to be used in office-type indoor environments. Do not operate the

instrument

In the presence of noxious, corrosive, or flammable fumes, gases, vapors, chemicals, or

finely-divided particulates.

In relative humidity conditions outside the instrument's specifications.

In environments where there is a danger of any liquid being spilled on the instrument or

where any liquid can condense on the instrument.

In air temperatures exceeding the specified operating temperatures.

In atmospheric pressures outside the specified altitude limits or where the surrounding

gas is not air.

In environments with restricted cooling air flow, even if the air temperatures are within

specifications.

In direct sunlight.

This instrument is intended to be used in an indoor pollution degree 2 environment. The

operating temperature range is 0 °C to 40 °C and the operating humidity is ≤ 90 % relative

humidity at < 35 °C and ≤ 60 % relative humidity at 35 °C – 40 °C, with no condensation allowed.

iii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Measurements made by this instrument may be outside specifications if the instrument is used

in non-office-type environments. Such environments may include rapid temperature or

humidity changes, sunlight, vibration and/or mechanical shocks, acoustic noise, electrical noise,

strong electric fields, or strong magnetic fields.

Do not operate instrument if damaged

If the instrument is damaged, appears to be damaged, or if any liquid, chemical, or other

material gets on or inside the instrument, remove the instrument's power cord, remove the

instrument from service, label it as not to be operated, and return the instrument to B&K

Precision for repair. Notify B&K Precision of the nature of any contamination of the instrument.

Clean the instrument only as instructed

Do not clean the instrument, its switches, or its terminals with contact cleaners, abrasives,

lubricants, solvents, acids/bases, or other such chemicals. Clean the instrument only with a

clean dry lint-free cloth or as instructed in this manual.

Not for critical applications

This instrument is not authorized for use in contact with the human body or for use as a

component in a life-support device or system.

iv

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

Do not touch live circuits

Instrument covers must not be removed by operating personnel. Component replacement and

internal adjustments must be made by qualified service-trained maintenance personnel who

are aware of the hazards involved when the instrument's covers and shields are removed.

Under certain conditions, even with the power cord removed, dangerous voltages may exist

when the covers are removed. To avoid injuries, always disconnect the power cord from the

instrument, disconnect all other connections (for example, test leads, computer interface

cables, etc.), discharge all circuits, and verify there are no hazardous voltages present on any

conductors by measurements with a properly-operating voltage-sensing device before touching

any internal parts. Verify the voltage-sensing device is working properly before and after

making the measurements by testing with known-operating voltage sources and test for both

DC and AC voltages. Do not attempt any service or adjustment unless another person capable of

rendering first aid and resuscitation is present.

Do not insert any object into an instrument's ventilation openings or other openings.

Hazardous voltages may be present in unexpected locations in circuitry being tested when a

fault condition in the circuit exists.

Servicing

Do not substitute parts that are not approved by B&K Precision or modify this instrument.

Return the instrument to B&K Precision for service and repair to ensure that safety and

performance features are maintained.

v

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

Cooling fans

This instrument contains one or more cooling fans. For continued safe operation of the

instrument, the air inlet and exhaust openings for these fans must not be blocked nor must

accumulated dust or other debris be allowed to reduce air flow. Maintain at least 25 mm

clearance around the sides of the instrument that contain air inlet and exhaust ports. If

mounted in a rack, position power devices in the rack above the instrument to minimize

instrument heating while rack mounted. Do not continue to operate the instrument if you

cannot verify the fan is operating (note some fans may have intermittent duty cycles). Do not

insert any object into the fan's inlet or outlet.

For continued safe use of the instrument

Do not place heavy objects on the instrument.

Do not obstruct cooling air flow to the instrument.

Do not place a hot soldering iron on the instrument.

Do not pull the instrument with the power cord, connected probe, or connected test

lead.

Do not move the instrument when a probe is connected to a circuit being tested.

vi

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

Compliance Statements

This product is subject to Directive 2002/96/EC of the European

Parliament and the Council of the European Union on waste

electrical and electronic equipment (WEEE), and in jurisdictions

adopting that Directive, is marked as being put on the market after

August 13, 2005, and should not be disposed of as unsorted

municipal waste. Please utilize your local WEEE collection facilities

in the disposition of this product and otherwise observe all

applicable requirements.

Disposal of Old Electrical & Electronic Equipment (Applicable in the European

Union and other European countries with separate collection systems)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

vii

Page 9

CE Declaration of Conformity

This instrument meets the requirements of 2006/95/EC Low Voltage Directive and 2004/108/EC

Electromagnetic Compatibility Directive with the following standards.

Low Voltage Directive

o EN61010-1: 2001

EMC Directive

o EN 61000-3-2: 2006

o EN 61000-3-3: 1995+A1: 2001+A2: 2005

o EN 61000-4-2 / -3 / -4 / -5 / -6 / -11

o EN 61326-1: 2006

viii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Safety Symbols

Refer to the user manual for warning information

to avoid hazard or personal injury and prevent

damage to instrument.

Electric Shock hazard

Alternating current (AC)

Chassis (earth ground) symbol.

Ground terminal

On (Power). This is the In position of the power

switch when instrument is ON.

Off (Power). This is the Out position of the power

switch when instrument is OFF.

Power Switch (On/Off). This is the power switch

located in front of the instrument.

CAUTION indicates a hazardous situation which, if

not avoided, will result in minor or moderate

injury.

WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury.

DANGER indicates a hazardous situation which, if

not avoided, will result in death or serious injury.

Notations

TEXT – Denotes a softkey.

TEXT – Denotes a front panel button.

[TEXT] – Denotes a physical connector in the front or rear panel.

ix

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Table of Contents

SAFETY SUMMARY .................................................................................................................................................. I

COMPLIANCE STATEMENTS ............................................................................................................................................ VII

SAFETY SYMBOLS .......................................................................................................................................................... IX

NOTATIONS ................................................................................................................................................................. IX

1 GENERAL INFORMATION .......................................................................................................................... 1

1.1 PRODUCT OVERVIEW ............................................................................................................................................ 1

1.2 PACKAGE CONTENTS ............................................................................................................................................. 1

1.3 FRONT PANEL OVERVIEW ...................................................................................................................................... 3

Front Panel Description ................................................................................................................................... 3

1.4 REAR PANEL OVERVIEW ........................................................................................................................................ 4

Rear Panel Description .................................................................................................................................... 4

1.5 DISPLAY OVERVIEW .............................................................................................................................................. 5

Display Description .......................................................................................................................................... 5

2 GETTING STARTED .................................................................................................................................... 6

2.1 INPUT POWER REQUIREMENTS ............................................................................................................................... 6

Input Power ..................................................................................................................................................... 6

2.2 OUTPUT CONNECTIONS ......................................................................................................................................... 6

Impedance Matching ....................................................................................................................................... 7

2.3 PRELIMINARY CHECK ............................................................................................................................................. 7

Check Model and Firmware Version ................................................................................................................ 8

Output Check ................................................................................................................................................... 9

3 FRONT PANEL OPERATION ..................................................................................................................... 11

3.1 MENU OPTIONS ................................................................................................................................................. 11

3.2 SELECTING A CHANNEL ........................................................................................................................................ 14

3.3 CONFIGURE WAVEFORM OUTPUT ......................................................................................................................... 15

Configure Waveform Shape .......................................................................................................................... 15

Configure Frequency ...................................................................................................................................... 17

Configure Amplitude ...................................................................................................................................... 18

User-Defined High and Low Level ............................................................................................................................. 19

Configure Offset ............................................................................................................................................ 19

Configure Phase ............................................................................................................................................. 20

Configure Duty Cycle: Square Waveform ...................................................................................................... 21

Configure Width and Duty Cycle: Pulse Waveform ....................................................................................... 22

Configure Rise/Fall Edge: Pulse Waveform ................................................................................................... 23

Configure Delay: Pulse Waveform ................................................................................................................. 24

Configure Symmetry: Ramp Waveform ......................................................................................................... 25

Configure Standard Deviation and Mean: Noise Waveform ........................................................................ 26

Configure Offset: DC Waveform .................................................................................................................... 27

Configure Arbitrary Waveforms .................................................................................................................... 28

Generate Predefined Built-in Waveforms ................................................................................................................. 28

Generate User-Defined Waveforms .......................................................................................................................... 36

Configure Harmonic Generator ..................................................................................................................... 38

3.4 CONFIGURE MODULATION OUTPUT ....................................................................................................................... 40

AM Modulation ............................................................................................................................................. 41

x

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

Selecting Modulation Source .................................................................................................................................... 43

To Set Modulation Depth .......................................................................................................................................... 44

To Set Modulation Frequency ................................................................................................................................... 44

DSB-AM Modulation ...................................................................................................................................... 44

FM Modulation .............................................................................................................................................. 46

To Set Frequency Deviation ...................................................................................................................................... 47

PM (Phase Modulation) ................................................................................................................................. 47

To Set Phase Deviation .............................................................................................................................................. 48

FSK Modulation ............................................................................................................................................. 48

To Set Key Frequency ................................................................................................................................................ 49

To Set Hop Frequency ............................................................................................................................................... 50

ASK Modulation ............................................................................................................................................. 50

PSK Modulation ............................................................................................................................................. 51

PWM (Pulse Width Modulation).................................................................................................................... 52

To Set Pulse Width/Duty Deviation ........................................................................................................................... 53

3.5 CONFIGURE SWEEP OUTPUT ................................................................................................................................. 55

Sweep time .................................................................................................................................................... 56

Sweep Frequency ........................................................................................................................................... 56

Sweep Trigger Source .................................................................................................................................... 56

Trig out .......................................................................................................................................................... 57

Sweep Type .................................................................................................................................................... 58

Direction ........................................................................................................................................................ 59

3.6 CONFIGURE BURST ............................................................................................................................................. 59

N-Cycle ........................................................................................................................................................... 60

Cycles ........................................................................................................................................................................ 61

Infinite ....................................................................................................................................................................... 61

Gated ............................................................................................................................................................. 62

Common Settings for NCycle and Gated Burst: ............................................................................................. 63

Start Phase ................................................................................................................................................................ 63

Burst Period .............................................................................................................................................................. 63

Trig Delay .................................................................................................................................................................. 63

Burst Trigger Source .................................................................................................................................................. 64

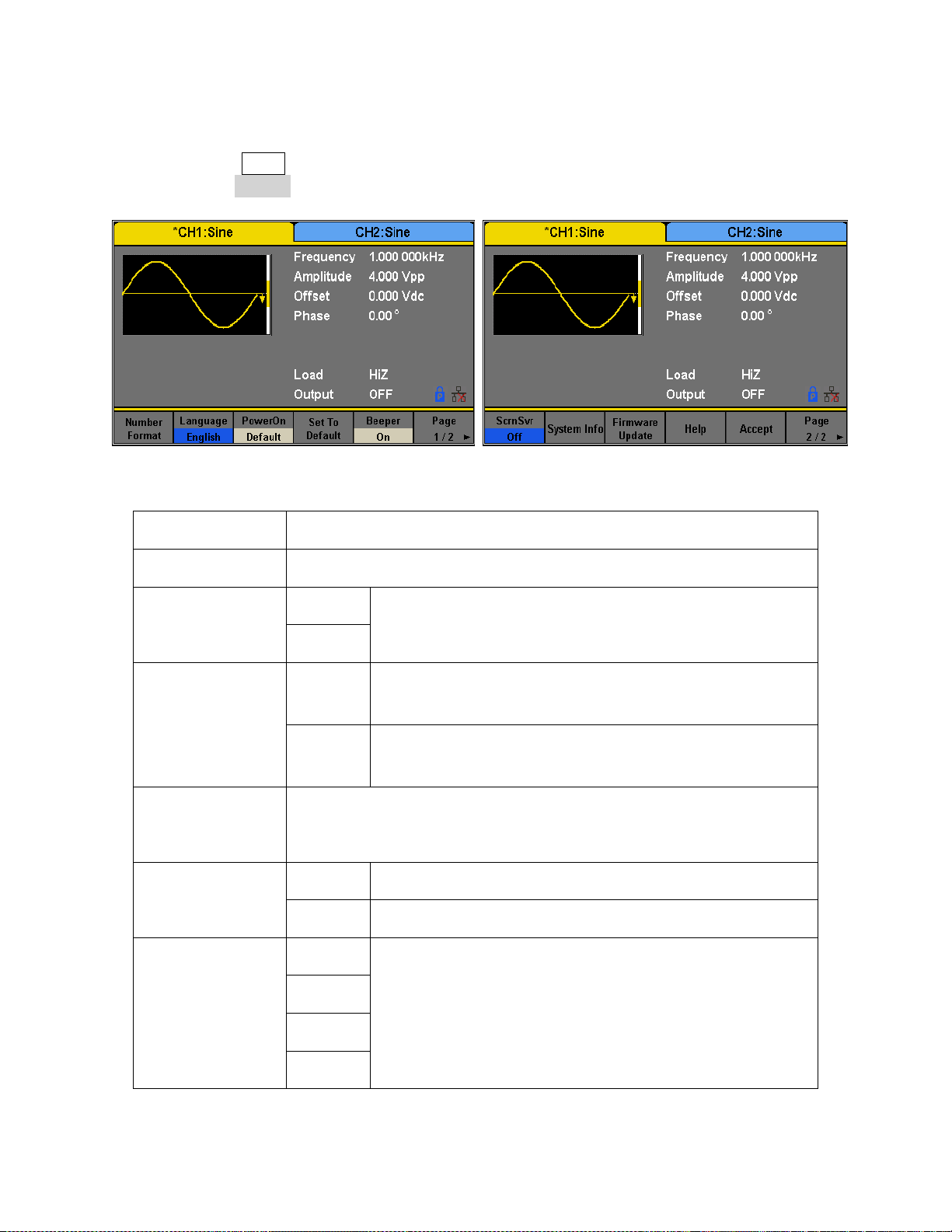

4 UTILITY FUNCTIONS ............................................................................................................................... 65

4.1 SYSTEM SETTINGS............................................................................................................................................... 66

Numerical Format.......................................................................................................................................... 67

Language Setup ............................................................................................................................................. 68

Power On ....................................................................................................................................................... 68

Set to Default ................................................................................................................................................. 69

Key Sound (Beeper)........................................................................................................................................ 70

Screen Saver .................................................................................................................................................. 70

System Info .................................................................................................................................................... 70

Firmware Update........................................................................................................................................... 71

Built-in Help ................................................................................................................................................... 72

4.2 TEST/CAL ......................................................................................................................................................... 73

ScrTest ........................................................................................................................................................... 73

Key Test ......................................................................................................................................................... 74

LED Test ......................................................................................................................................................... 74

Board Test ..................................................................................................................................................... 75

4.3 FREQUENCY COUNTER ......................................................................................................................................... 75

xi

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

4.4 OUTPUT ........................................................................................................................................................... 77

Load ............................................................................................................................................................... 78

Polarity .......................................................................................................................................................... 78

EqPhase ......................................................................................................................................................... 79

Combining Waveforms (Wave Combine) ...................................................................................................... 79

4.5 CH COPY/COUPLING .......................................................................................................................................... 80

Channel Copy ................................................................................................................................................. 80

Channel Coupling ........................................................................................................................................... 81

Frequency Coupling .................................................................................................................................................. 82

Amplitude Coupling .................................................................................................................................................. 82

Phase Coupling .......................................................................................................................................................... 83

Tracking ......................................................................................................................................................... 83

4.6 REMOTE INTERFACE ............................................................................................................................................ 85

USB Interface ................................................................................................................................................. 86

GPIB Interface ................................................................................................................................................ 86

LAN ................................................................................................................................................................ 88

To Set IP Address....................................................................................................................................................... 88

To Set Subnet Mask .................................................................................................................................................. 89

To Set Gateway ......................................................................................................................................................... 89

DHCP Configuration Mode ........................................................................................................................................ 89

4.7 SYNC OUTPUT ................................................................................................................................................... 90

Syncing Signals of Different Waveforms ....................................................................................................... 91

Basic Waveform and Arbitrary Waveform ................................................................................................................ 91

Modulated Waveform ............................................................................................................................................... 91

4.8 REFERENCE CLOCK .............................................................................................................................................. 91

Sync methods for two or more instruments: ................................................................................................. 92

Synchronization between two instruments .............................................................................................................. 92

Synchronization among multiple instruments .......................................................................................................... 92

4.9 MODE .............................................................................................................................................................. 92

4.10 OVER VOLTAGE PROTECTION ................................................................................................................................ 94

5 STORE AND RECALL ................................................................................................................................ 95

5.1 STORAGE SYSTEM ............................................................................................................................................... 96

Local (C:) ........................................................................................................................................................ 96

USB Device (0:) .............................................................................................................................................. 96

Browse ........................................................................................................................................................... 97

5.2 FILE TYPE .......................................................................................................................................................... 97

5.3 SAVE THE INSTRUMENT STATE .............................................................................................................................. 98

5.4 RECALL STATE FILE OR DATA FILE ........................................................................................................................ 100

5.5 DELETE FILE .................................................................................................................................................... 100

5.6 COPY AND PASTE FILE ....................................................................................................................................... 100

6 EXAMPLES ............................................................................................................................................ 102

Example 1: Generate a Sine Waveform ....................................................................................................... 103

Example 2: Generate a Square Waveform .................................................................................................. 104

Example 3: Generate a Ramp Waveform .................................................................................................... 105

Example 4: Generate a Pulse Waveform ..................................................................................................... 106

Example 5: Generate a Noise ...................................................................................................................... 107

Example 6: Generate a DC Waveform ......................................................................................................... 108

Example 7: Generate a Linear Sweep Waveform ........................................................................................ 109

xii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Example 8: Generate a Burst Waveform ..................................................................................................... 110

Example 9: Generate an AM Modulation Waveform .................................................................................. 112

Example 10: Generate an FM Modulation Waveform ................................................................................ 113

Example 11: Generate a PM Modulated Waveform ................................................................................... 114

Example 12: Generate an FSK Modulated Waveform ................................................................................. 115

Example 13: Generate an ASK Modulation Waveform ................................................................................ 116

Example 14: Generate a PSK Modulated Waveform ................................................................................... 117

Example 15: Generate a PWM Modulated Waveform ................................................................................ 118

Example 16: Generate a DSB-AM Modulated Waveform............................................................................ 119

7 TROUBLESHOOTING GUIDE .................................................................................................................. 120

8 SPECIFICATIONS ................................................................................................................................... 121

SERVICE INFORMATION ..................................................................................................................................... 125

LIMITED THREE-YEAR WARRANTY ..................................................................................................................... 126

xiii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

1 General Information

1.1 Product Overview

BK Precision’s 4050B series are dual-channel function/arbitrary waveform generators, capable

of generating sine and square waves of up to 10 MHz, 30 MHz or 60 MHz (depending on

model). They have an informative easy-to-read color display, user-friendly controls and a

numeric keypad which allows users to easily configure waveform properties. These waveform

generators can output square waves with frequencies up to 60 MHz (depending on model) and

less than 300 ps + 0.05 ppm of period of jitter. In addition, they feature non-volatile built-in

memory to create, store, and recall arbitrary waveforms up to 16K points with a 150 MSa/s

sampling rate, and 14-bit vertical resolution. 196 predefined arbitrary waveforms are also

available for output. Having USBTMC, LAN, and GPIB (optional adapter) interfaces, these

generators allow users to easily interface with application software to create and load arbitrary

waveforms into the instrument.

Features:

Dual-channel output with bandwidth up to 10 MHz, 30 MHz or 60 MHz

Amplitude up to 10 Vpp into 50 ohms.

150 MSa/s sampling rate, 14-bit vertical resolution, and 16K points waveform length

Capable of generating low jitter pulse waveforms

Square waves with low jitter and frequencies up to 60 MHz (depending on model)

AM, DSB-AM, FM, PM, FSK, ASK, PSK and PWM modulation functions

Sweep and burst functions

Harmonic waveforms generator

Waveform combining function

High-precision frequency counter

196 built-in arbitrary waveforms

4.3” TFT-LCD display, 480 x 272 resolution

1.2 Package Contents

Please inspect the instrument mechanically and electrically upon receiving it. Unpack all items

from the shipping carton, and check for any obvious signs of physical damage that may have

occurred during transportation. Report any damage to the shipping agent immediately. Save

the original packing carton for possible future reshipment. Every instrument is shipped with the

following contents:

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

1 x 4050B series function/arbitrary waveform generator

1 x Getting started manual (printed)

1 x AC power cord

1 x USB type A to Type B cable

1 x Certificate of calibration

Verify that all items above are included in the shipping container. If anything is missing, please

contact B&K Precision.

An optional USB to GPIB adapter model AK40G is also available.

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

1.3 Front Panel Overview

Power On/Off switch

Menu softkeys

Menu buttons

Channel 1 output terminal

Channel 2 output terminal

Channel 1 and 2 Output On/Off buttons

Arrow keys

Rotary dial knob

Numeric keypad

TFT LCD color display

USB host port/*USB-to-GPIB adapter interface

Accepts USB flash drive to save/recall instrument settings and waveforms.

*This port can be used for connecting the USB-to-GPIB adapter (AK40G)

accessory. It can also be used for connecting an external USB flash drive.

1 2 3 4 5 6 7 8 9

10

11

1

10

2 3 5

6 7 8 9 11

4

Front Panel Description

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

3

Page 18

1.4 Rear Panel Overview

LAN Interface

USB interface

AC Power Input

Chassis ground

10MHz Out BNC connector

Aux In/Out BNC connector

Counter BNC Connector

1 2 3

4

5

6

7

1 2 3

4 6 7

5

Rear Panel Description

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

1.5 Display Overview

Waveform display

Channel status bar

Waveform parameters display

Waveform mode and output impedance indicator

LAN status indicator

Mode phase locked/free running indicator

Menu display

Waveform parameters display

1 2 3 4 5 6 7

8

1 7 3

2

5

4

8

Display Description

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

2 Getting Started

The included AC power cord is safety certified for this instrument operating in rated

range. To change a cable or add an extension cable, be sure that it can meet the

required power ratings for this instrument. Any misuse with wrong or unsafe cables

will void the warranty.

Before connecting and powering up the instrument, please review and go through the

instructions in this chapter.

2.1 Input Power Requirements

Input Power

The supply has a universal AC input that accepts line voltage and frequency input within:

100 – 240 V (+/- 10%), 50 – 60 Hz (+/- 5%)

100 – 127 V, 45 – 440 Hz

Before connecting to an AC outlet or external power source, be sure that the power switch is in

the OFF position and verify that the AC power cord, including the extension line, is compatible

with the rated voltage/current and that there is sufficient circuit capacity for the power supply.

Once verified, connect the cable firmly.

2.2 Output Connections

The waveform generator output circuits operate as a 50 Ω voltage source working into a 50 Ω

load. At higher frequencies, a non-terminated or improperly terminated output may cause

aberrations on the output waveform. In addition, loads with an impedance less than 50 Ω will

reduce the waveform amplitude, while loads with an impedance greater than 50 Ω will increase

waveform amplitude.

Excessive distortion or aberrations caused by improper termination are less noticeable at lower

frequencies, especially with sine and triangle waveforms. To ensure waveform integrity, follow

these precautions:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

6

Page 21

1. Use good quality 50 Ω coaxial cable and connectors.

2. Make all connections tight and as short as possible.

3. Use good quality attenuators, if it is necessary to reduce waveform amplitudes applied

to sensitive circuits.

4. Use termination or impedance-matching devices to avoid reflections.

5. Ensure that attenuators and terminations have adequate power handling capabilities.

If there is a DC voltage across the output load, use a coupling capacitor in series with the load.

The time constant of the coupling capacitor and load must be long enough to maintain pulse

flatness.

Impedance Matching

If the waveform generator is driving a high impedance, such as a 1 MΩ input impedance

(paralleled by a stated capacitance) of an oscilloscope vertical input, connect the transmission

line to a 50 Ω attenuator, a 50 Ω termination and to the oscilloscope input. The attenuator

isolates the input capacitance of the device and terminates the waveform generator properly.

2.3 Preliminary Check

Complete the following steps to verify that the generator is ready for use.

1. Verify AC Input Voltage

Verify and check to make sure proper AC voltages are available to power the

instrument. The AC voltage range must meet the acceptable specification as explained

in section 2.1.

2. Connect Power

Connect AC power cord to the AC receptacle in the rear panel and press the power

switch to the ON position to turn ON the instrument. The instrument will have a boot

screen while loading, after which the main screen will be displayed.

3. Self Test

Press Utility, and select Test/Cal option. Then, select SelfTest option. The instrument

has 4 self-test options: screen test, key test, LED test, and board test.

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

Figure 1 - Preliminary Self-Test

Figure 2 - Self-Test Options

Note: Refer to TEST/CAL section for more information about the Self-Test function.

Check Model and Firmware Version

The model and firmware version can be verified from within the menu system.

Press Utility, press System select and press Page 1/2 from the menu to enter the second menu

page, and select System Info option. The software/firmware version, hardware version, model,

and serial number will be displayed. Press any Menu Softkey key to exit.

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

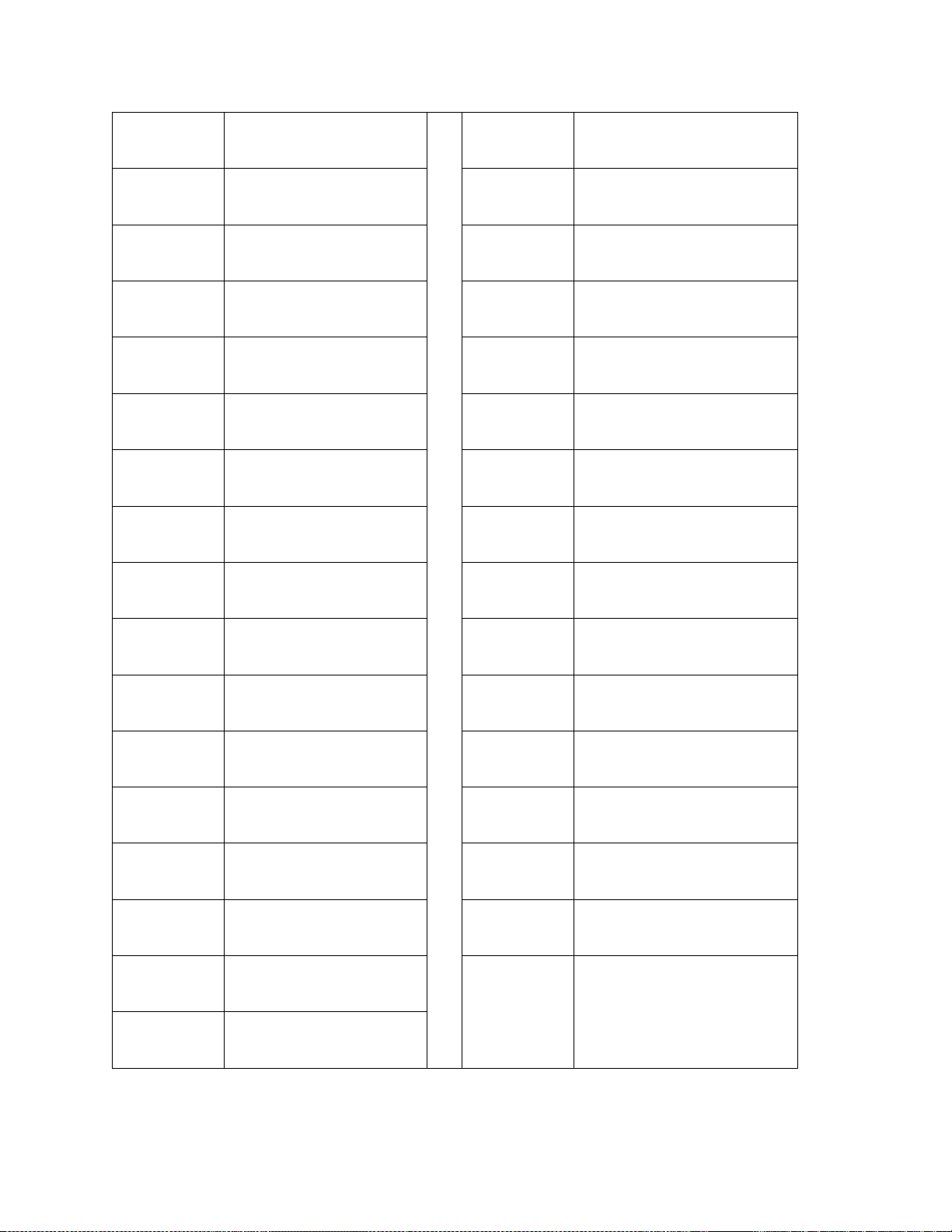

Output Check

Output

Default

Function

Sine Wave

Frequency

1 kHz

Amplitude/Offset

4 Vpp/0 Vdc

Phase

0°

Load

High Z

Modulation

Default

Carrier

1 kHz Sine wave

Modulating

100 Hz Sine wave

AM Depth

100%

FM Deviation

100 Hz

ASK Key Frequency

100 Hz

FSK Key Frequency

100 Hz

FSK Hop Frequency

1 MHz

PSK Key Frequency

10 0Hz

PM Phase Deviation

100°

PWM Width Dev

190 μs

Sweep

Default

Start/Stop Frequency

500 Hz/1.5 kHz

Sweep Time

1 s

Trig Out

Off

Mode

Linear

Direction

↑

Burst

Default

Burst Period

10 ms

Follow the steps below to do a quick check of the settings and waveform output.

1. Turn on the instrument and set the instrument to default settings. To set to default,

press Utility → System → Set To Default to set the system to the default setting. The

instrument will set both channels with the following parameters:

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

Start Phase

0°

Cycles

1 Cycle

Trig Out

Off

Delay

521 ns

Trigger

Default

Source

Internal

Table 1 - Default Settings

1. Connect the BNC output of CH1 (yellow) into an oscilloscope.

2. Press the Output button on top of CH1 output BNC to turn on the output and observe a

sine wave with the parameters above.

3. Press the Parameter button.

4. Press Freq or Period option in the menu and use the rotary knob or the numeric keypad

to change frequency. Observe the changes on the oscilloscope display.

5. Press the Amplitude option in the menu and use the rotary knob or the numeric keypad

to change the amplitude. Observe the changes on the oscilloscope display.

Press the Offset option in the menu and use the rotary knob or the numeric keypad to

change the DC offset. With the oscilloscope set for DC coupling, observe the changes on

the display.

Connect the BNC output of CH2 (blue) into an oscilloscope and follow steps 3 to 6 to

check its output. Use the Ch1/Ch2 to toggle between channels.

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

3 Front Panel Operation

Softkey will toggle

selection between

Frequency or Period.

Softkey will toggle

selection

between

Amplitude or

HighLevel.

Softkey will toggle

selection

between Offset or

LowLevel.

Softkey will select

Phase.

Softkey will enable

or disable the

Harmonic

Generation

Function.

Waveforms

Parameter

Function

Sine

Frequency/Period

Configures the frequency or period of the waveform.

Amplitude/HighLevel

Configures the amplitude or the high level of the

waveform.

Offset/LowLevel

Configures the DC offset or the low level of the waveform.

Phase

Configures the phase relative to the other channel.

Harmonic/Off

Turns Harmonics Generator on or off. See Harmonics

Generator section.

Square

Frequency/Period

Configures the frequency or period of the waveform.

Amplitude/HighLevel

Configures the amplitude or the high level of the

waveform.

Table 2 - Menu Options Softkeys

3.1 Menu Options

All settings and parameters can be configured from the menu system of the instrument. The

channel specific menu options are the same for both channel 1 and channel 2. Use the

Ch1/Ch2 button keys to toggle the channel selection. The selected option will be highlighted in

blue. Some settings are common for most waveforms (i.e. frequency, amplitude, offset, etc.)

and some are specific to each type of waveform (i.e. Duty cycle only available for square and

pulse waveforms). Section 3.3 provides instructions on how to configure these settings.

Many options are grouped in pairs and can be selected by toggling their corresponding menu

function keys. For example:

The menu system is organized as follows:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

11

Page 26

Offset/LowLevel

Configures the DC offset or the low level of the waveform.

Phase

Configures the phase relative to the other channel.

DutyCycle

Configures the duty cycle of the waveform.

Ramp

Frequency/Period

Configures the frequency or period of the waveform.

Amplitude/HighLevel

Configures the amplitude or the high level of the

waveform.

Offset/LowLevel

Configures the DC offset or the low level of the waveform.

Phase

Configures the phase relative to the other channel.

Symmetry

Configures the symmetry of the waveform.

Pulse

Frequency/Period

Configures the frequency or period of the waveform.

Amplitude/HighLevel

Configures the amplitude or the high level of the

waveform.

Offset/LowLevel

Configures the DC offset or the low level of the waveform.

PulWidth/DutyCycle

Configures the pulse width or the duty cycle of the pulse.

Rise/Fall

Configures the rise or fall time of the pulse.

Delay

Configures the delay of the pulse waveform.

Noise

Stdev

Configures the standard deviation of the noise waveform.

Mean

Configures the mean value of the noise waveform.

DC

DC Offset

Configures the DC offset of the DC waveform.

Arb

Frequency/Period

Configures the frequency or period of the waveform.

Amplitude/HighLevel

Configures the amplitude or the high level of the

waveform.

Offset/LowLevel

Configures the DC offset or the low level of the waveform.

Phase

Configures the phase relative to the other channel.

Arb Type

Access selectable built-in arbitrary waveforms and userdefined arbitrary waveform stored in the generator.

Mod

Type

Configures the type of modulation. Configures parameters

for AM, FM, PM, ASK, FSK, DSB-AM, or PWM modulation.

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

Source

Selects modulating source.

AM Depth

Set the modulation depth.

Shape

Configures the modulating waveform shape.

AM Freq

Set the modulating waveform frequency. Frequency range:

1 mHz to 20 kHz (internal source only).

Sweep

Sweep Time

Configures the sweep time for sweep output.

StartFreq/CenterFReq

Configures the sweep start frequency or the center

frequency.

StopFreq/FreqSpan

Configures the sweep stop frequency or the frequency

span of the sweep output.

Source

Selects the sweep source: Internal, external or manual.

Trig Out

Enable/disable trigger out.

Type

Selects between linear or logarithmic sweep operations.

Direction

Selects the sweep direction.

Burst

Ncycle/Gated

Selects burst by number of cycles or selects external gated

burst.

Cycles/Infinite

Configures number of cycles for burst or infinite burst

(external source only).

Start Phase

Configures the start phase of the burst output.

Burst Period

Configures the burst period.

Source

Selects trigger source: Internal, External, Manual.

Trig Delay

Configures the delay of each burst.

Trig Out

Configures signal triggering on rising or falling edge.

Utility

System

Access system settings.

Test/Cal

Configure synchronization output with respect to either

channel 1 or 2.

Counter

Selects built-in counter function.

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

Output Setup

Set the output parameters of CH1 and CH2.

CH Copy Coupling

Set the track, channel coupling or channel copy function.

Interface

Select and set parameters of remote communication.

Clock

Choose the system clock source: internal or external.

Mode

Choose Phase-locked or independent mode.

OverVoltage Protection

Turn on/off the overvoltage protection function.

CHCopy

Copy channel settings between channels.

Table 3 - Menu System Organization

Figure 3 – Channel 1 Selected

3.2 Selecting a Channel

The 4050B series function/arbitrary waveform generators have dual channel outputs. They can

be operated independently or in sync with each other. To select between channel 1 and 2 and

view/change their parameters, press the Ch1/Ch2 key.

When Channel 1 is selected, the display will look like the following:

When Channel 2 is selected, the display will look like the following:

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

Waveforms

Sine

Square

Ramp

Pulse

Noise

DC

Arbitrary

Figure 4 - Channel 2 Selected

Table 4 - Waveforms

3.3 Configure Waveform Output

Configure Waveform Shape

The instrument can generate many standard as well as arbitrary waveforms. There is a

dedicated waveform key on the front panel that will allow the user to select between different

waveform shapes to output, as listed in Table 4.

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

Press Waveforms to select a waveform. Menu options relevant to the selected waveform

Sine Waveform

Square Waveform

Ramp Waveform

Pulse Waveform

Noise Waveform

DC Waveform

Arbitrary Waveform

shape will display at the bottom of the screen. The screenshots below illustrates the menu

options for each of the waveform types.

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

Table 5 - Waveforms

Figure 5 - Frequency

Configure Frequency

This section does not apply to noise or DC waveforms.

Press the Frequency/Period softkey to toggle between the Frequency and Period settings. The

option selected will be highlighted in blue. The current value for the waveform’s frequency or

period is now highlighted on the Waveform Parameters display section of the screen.

The adjustable frequency range is different for each model and for each type of waveforms.

See the specifications sheet section for the adjustable ranges.

Follow the steps below to configure the frequency or period of the output:

1. After selecting the waveform shape, press the Frequency/Period menu option.

2. The cursor position will now highlight the first digit of the frequency parameter display.

3. Use the rotary knob or the numeric keypad to change the frequency. If numeric keypad

is used, the following screen will be displayed after entering a numeric value:

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

4. Use the menu function keys to select the unit. Available units are: MHz, kHz, Hz, mHz,

Note: When using the numeric keyboard to enter the value, the left arrow key can be used to move the

cursor backward and delete the previous digit.

Figure 6 - Amplitude

and uHz.

Configure Amplitude

This section does not apply for noise or DC waveform. The amplitude setting range is limited by

the load and frequency, as shown below:

2 mVpp – 10 Vpp into 50 Ω (4 mVpp – 20 Vpp into open circuit), ≤ 10 MHz

2 mVpp – 5 Vpp into 50 Ω (4 mVpp – 10 Vpp into open circuit), > 10 MHz

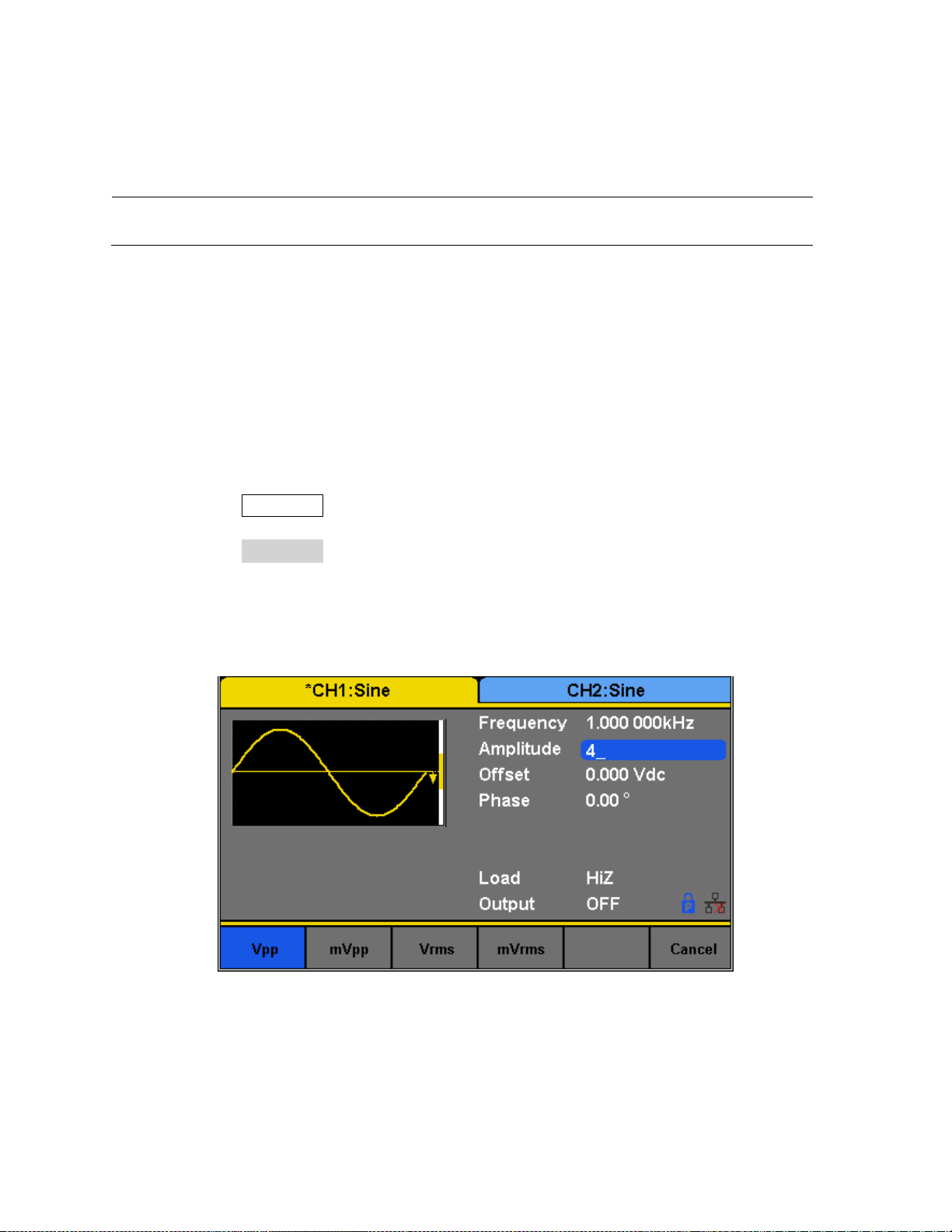

Follow the steps below to configure the amplitude of the output:

1. Press the Waveforms button.

2. Select a waveform from the menu.

3. Press the Amplitude softkey. The cursor position now highlights the first digit of the

amplitude parameter display.

4. Use the rotary knob or the numeric keypad to change the amplitude.

a. If numeric keypad is used, the following screen will be displayed after entering a

number:

5. Use the menu function keys to select the unit. Available units are: Vpp, mVpp, Vrms,

and mVrms.

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

Figure 7 - Amplitude: High and Low Level

Note: DC offset settings will be automatically adjusted if the high and low levels reflect a DC offset.

User-Defined High and Low Level

The user has the option to adjust the high and low level of the waveform. To do this, toggle the

menu function key from Amplitude to HighLevel and the LowLevel option will be available as

well.

Configure Offset

This section does not apply to noise waveform.The offset setting range is limited by the “Load”

and “Amplitude/HighLevel” settings. The range is: ± 5 V into 50 Ω (± 10 V into open circuit). The

default value is 0 Vdc.

Follow the steps below to configure the DC offset of the output:

1. Press the Waveforms button.

2. Select a waveform from the menu.

3. Press the Offset softkey.

4. The cursor position now highlights the first digit of the offset parameter display.

5. Use the rotary knob or the numeric keypad to change the offset. If numeric keypad is

used, the following screen will be displayed after entering a number:

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

Figure 8 - Offset

6. Use the menu function keys to select the unit. Available units are: Vdc and mVdc.

Configure Phase

This section does not apply for pulse, noise, or DC waveforms.

The Phase setting is useful for adjusting the phase relationship between channels 1 and 2,

between a channel and its sync signal, and synchronizing multiple instruments. This setting is

different from the Start Phase in Burst mode.

Follow the steps below to configure the phase of the output:

1. Press the Waveforms button.

2. Select a waveform from the menu.

3. Press the Phase softkey.

4. The cursor position now highlights the first digit of the phase parameter display.

5. Use the rotary knob or the numeric keypad to change the phase. If numeric keypad is

used, the following screen will be displayed after entering a number:

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

Figure 9 - Phase

Note: When the IndependentMode is enabled, the phase parameter cannot be modified (i.e., the phase

can only be set when there is a reference clock waveform provided on the back panel).

Figure 10 - Duty Cycle

6. Use the menu function keys to select the degree (°) unit.

Configure Duty Cycle: Square Waveform

The duty cycle setting range is limited by the “Frequency/Period” setting. The default value is

50%.

Follow the steps below to configure the phase of the output:

1. Press the Waveforms button and select the Square waveform.

2. Press the DutyCycle softkey and input the desired duty cycle.

3. Use the rotary knob or the numeric keypad to change the duty cycle. If numeric keypad

is used, the following screen will be displayed after entering a number:

21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

Note: The instrument allows for adjusting pulse width to a minimum of 32.6 ns, depending on frequency.

Figure 11 - Duty Cycle of a Square Waveform

Figure 12 - Pulse Width and Period

4. Use the menu function keys to select the degree (°) unit.

Configure Width and Duty Cycle: Pulse Waveform

The pulse width and duty cycle parameters are related to each other and both control the

length of the “On Time” of a pulse. Users have the option to specify the pulse width in units of

seconds or the duty cycle as a percentage. Pulse duty cycle and pulse width are dependent—

changing one of the parameters will automatically change the other.

22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

Follow the steps below to configure the pulse width or duty cycle.

Figure 13 - Pulse Width or Duty Cycle

Figure 14 - Pulse Width

1. Press the Waveforms button.

2. Press the Pulse softkey.

3. Select PulWidth softkey for pulse width adjustment or DutyCycle for duty cycle

adjustment.

4. The cursor position will now highlight the first digit of the width or duty parameter

display.

5. Use the rotary knob or the numeric keypad to change the width or the duty.

After entering the numeric value, use the menu function keys to select s, ms, us, or ns

for pulse width or select percent (%) unit for duty cycle.

Configure Rise/Fall Edge: Pulse Waveform

Follow the below steps to setup rise and fall time.

1. Press the Waveforms button.

2. Press the Pulse softkey.

23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

3. Toggle the Rise/Fall softkey to set the rise or fall edge.

Figure 15 - Rise Edge of a Pulse

The Rise/Fall softkey lets the user toggle between the Rise and Fall Edge settings. The selected

setting will be highlighted in blue.

Use the numeric keyboard to input the parameter value directly and press the corresponding

key to select the parameter unit. Alternatively, use the arrow keys to select the digit and use

the knob to change its value.

Configure Delay: Pulse Waveform

Follow the steps below to configure the pulse delay.

1. Set the instrument for pulse.

2. From the menu, select Delay.

3. The cursor position will now highlight the first digit of the delay parameter display.

24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

Figure 16 - Pulse Delay

Figure 17 - Symmetry

4. Use the rotary knob or the numeric keypad to change the pulse delay.

After entering the numeric value, use the menu function keys to select s, ms, us, or ns.

Configure Symmetry: Ramp Waveform

A ramp waveform with 50% of symmetry is a triangular waveform. A sawtooth waveform is a

ramp waveform with either 0 or 100 percent.

Follow the steps below to configure the symmetry of a ramp/triangle waveform.

1. Press the Waveforms button.

2. Select and press the Ramp waveform softkey from the menu.

3. The cursor position will now highlight the first digit of the symmetry parameter display.

25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

Figure 18 - Ramp Symmetry

4. Use the rotary knob or the numeric keypad to change the symmetry.

5. Once the value has been entered, press the “%” softkey from the menu to set the value.

Configure Standard Deviation and Mean: Noise Waveform

There are two parameters that can be adjusted of the noise waveform: Standard deviation and

mean. Noise is a non-periodic random signal which has no frequency or period.

Follow the steps below to configure these parameters.

1. Press the Waveforms button.

2. Select and press the Noise waveform softkey from the menu.

3. From the menu, select Stdev for the standard deviation adjustment or Mean for the

mean adjustment.

4. The cursor position will now highlight the first digit of the standard deviation or mean

parameter display.

26

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

Figure 19 - Noise Standard Deviation

Figure 20 - Noise Mean

5. Use the rotary knob or the numeric keypad to change the two parameters. Both

parameters can be specified in V or mV units.

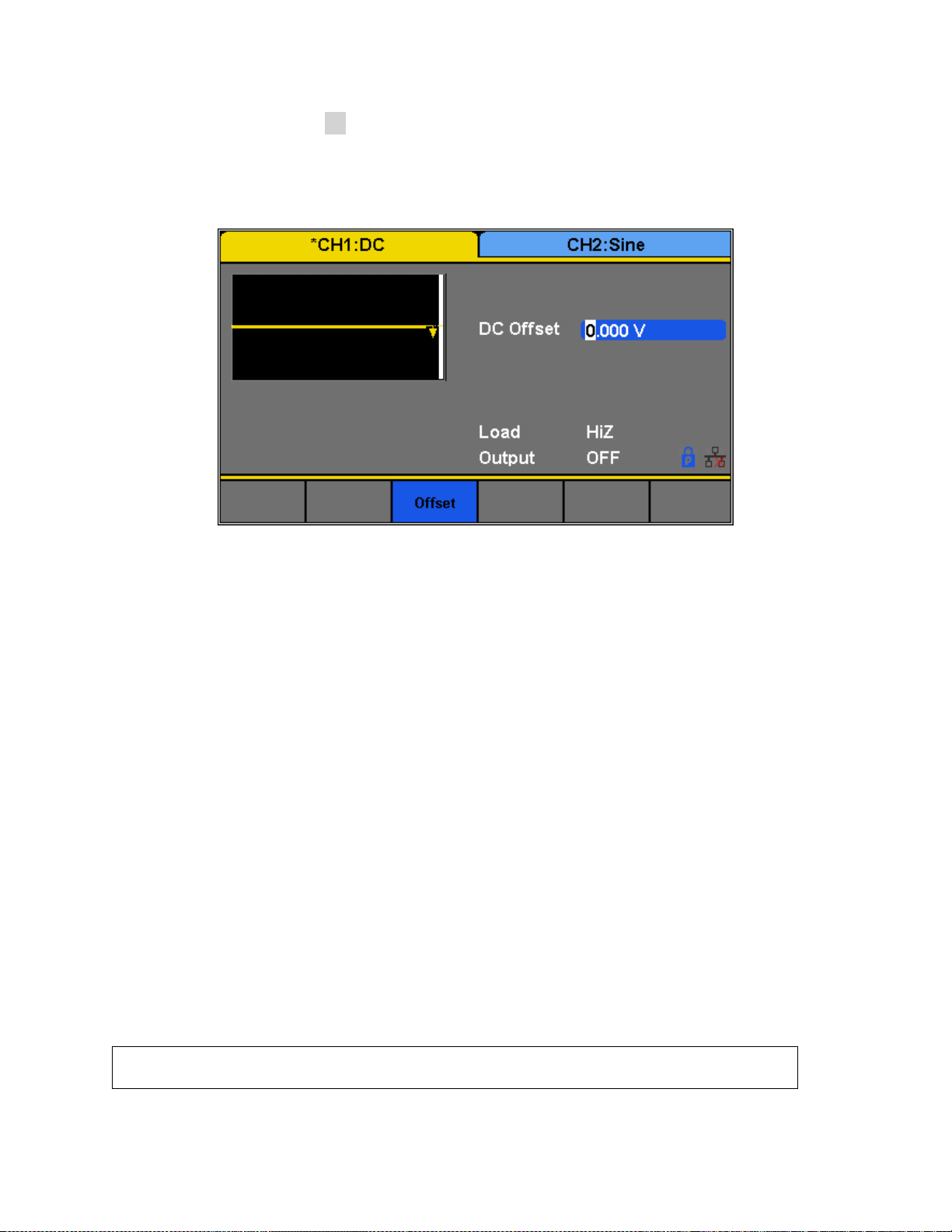

Configure Offset: DC Waveform

The instrument can output a DC waveform output at a range of voltage levels (-12 Vdc – 12

Vdc).

There is only one parameter, DC Offset, to configure a DC output waveform.

Follow the steps below to configure the parameter.

1. Press the Waveforms button.

27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

2. Select and press the DC waveform softkey from the menu.

Arbitrary Waveform: Common

Figure 21 - DC Offset

3. The cursor position will now be highlighted the first digit of the DC offset parameter

display.

4. Use the rotary knob or the numeric keypad to change the two parameters. Both

parameters can be specified in Vdc or mVdc units.

Configure Arbitrary Waveforms

There are two ways to generate arbitrary waveforms. Users can output a predefined arbitrary

waveform that is built-in, or create and output a user-defined waveform by specifying point by

point arbitrary data using the EasyWave software. Waveforms can be stored in the internal

non-volatile memory. The methods of setting the parameters of an arbitrary waveform signal

are similar to those of the sine waveform function.

Generate Predefined Built-in Waveforms

There are a total of 196 predefined built-in arbitrary waveforms that can output from the

generator. They are divided in the following categories:

28

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

Waveform

Function

Waveform

Function

StairUp

Stair-up waveform

Npulse

Negative pulse

StairDn

Stair-down waveform

UpRamp

UpRamp waveform

StairUD

Stair-up and down

waveform

DnRamp

DnRamp waveform

Trapezia

Trapezia waveform

SineTra

Sine-Tra waveform

Ppulse

Positive pulse

SineVer

Sine-Ver waveform

Arbitrary Waveform: Math

Waveform

Function

Waveform

Function

ExpFall

ExpFall function

Legend

5-times Legend polynomial

ExpRise

ExpRise function

Versiera

Versiera

LogFall

LogFall function

Sinc

Sinc function

LogRise

LogRise function

Gaussian

Gaussian function

Sqrt

Sqrt function

Dlorentz

Dlorentz function

Root3

Root3 function

Haversine

Haversine function

X^2

X2 function

Lorentz

Lorentz function

X^3

X3 function

Gauspuls

Gauspuls signal

Airy

Airy function

Gmonopuls

Gmonopuls signal

Besselj

Bessel I function

Tripuls

Tripuls signal

Bessely

Bessel II function

Weibull

Weibull distribution

Dirichlet

Dirichlet function

LogNormal

LogNormal Gaussian

distribution

Erf

Error function

Laplace

Laplace distribution

Erfc

Complementary error

function

Maxwell

Maxwell distribution

ErfcInv

Inverted complementary

error function

Rayleigh

Rayleigh distribution

ErfInv

Inverted error function

Cauchy

Cauchy distribution

Laguerre

4-times Laguerre

polynomial

29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

Arbitrary Waveform: Engine

Waveform

Function

Waveform

Function

Cardiac

Cardiac signal

SCR

SCR firing profile

Quake

Analog quake waveform

TV

TV signal

Chirp

Chirp signal

Voice

Voice signal

TwoTone

TwoTone signal

Surge

Surge signal

SNR

SNR signal

Radar

Analog radar signal

AmpALT

Gain oscillation curve

Ripple

Ripple wave of battery

AttALT

Attenuation oscillation

curve

Gamma

Gamma signal

RoundHalf

RoundHalf Waveform

StepResp

Step-response signal

RoundsPM

RoundsPM Waveform

BandLimited

Bandwidth-limited signal

BlaseiWave

Time-velocity curve of

explosive oscillation

CPulse

C-Pulse

DampedOsc

Time-displacement curve of

damped oscillation

CWPulse

CW pulse

SwingOsc

Kinetic energy – time curve

of swing oscillation

GateVibr

Gate self-oscillation signal

Discharge

Discharge curve of NI-MH

battery

LFMPulse

Linear FM pulse

Pahcur

Current waveform of DC

brushless motor

MCNoise

Mechanical construction noise

Combin

Combination function

Arbitrary Waveform: Window

Waveform

Function

Waveform

Function

Hamming

Hamming window

Bartlett

Bartlett window

Hanning

Hanning window

BarthannWin

Modified Bartlett-Hann

window

30

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

Kaiser

Kaiser window

BohmanWin

BohmanWin window

Blackman

Blackman window

ChebWin

ChebWin window

GaussiWin

GaussiWin window

FlattopWin

Flat top weighted window

Triangle

Triangle window (Fejer

window)

ParzenWin

ParzenWin window

BlackmanH

BlackmanH window

TaylorWin

TaylorWin window

Bartlett-Hann

Bartlett-Hann window

TukeyWin

TukeyWin (tapered cosine)

window

Arbitrary Waveform: Trigonometric (Trigo)

Waveform

Function

Waveform

Function

Tan

Tangent

Csch

Hyperbolic cosecant

Cot

Cotangent

SecH

Hyperbolic secant

Sec

Secant

SinH

Hyperbolic sine

Csc

Cosecant

SinInt

Integral sine

Asin

Arc sine

TanH

Hyperbolic tangent

Acos

Arc cosine

ACosH

Arc hyperbolic cosine

Atan

Arc tangent

ASecH

Arc hyperbolic secant

ACot

Arc cotangent

ASinH

Arc hyperbolic sine

CosH

Hyperbolic cosine

ATanH

Arc hyperbolic tangent

CosInt

Integral cosine

ACsch

Arc hyperbolic cosecant

Coth

Hyperbolic cotangent

ACoth

Arc hyperbolic cotangent

Arbitrary Waveform: Square 1

Waveform

Function

Waveform

Function

SquareDuty01

Square waveform with 1%

duty

SquareDuty36

Square waveform with 36%

duty

31

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

SquareDuty02

Square waveform with 2%

duty

SquareDuty38

Square waveform with 38%

duty

SquareDuty04

Square waveform with 4%

duty

SquareDuty40

Square waveform with 40%

duty

SquareDuty06

Square waveform with 6%

duty

SquareDuty42

Square waveform with 42%

duty

SquareDuty08

Square waveform with 8%

duty

SquareDuty44

Square waveform with 44%

duty

SquareDuty10

Square waveform with 10%

duty

SquareDuty46

Square waveform with 46%

duty

SquareDuty12

Square waveform with 12%

duty

SquareDuty48

Square waveform with 48%

duty

SquareDuty14

Square waveform with 14%

duty

SquareDuty50

Square waveform with 50%

duty

SquareDuty16

Square waveform with 16%

duty

SquareDuty52

Square waveform with 52%

duty

SquareDuty18

Square waveform with 18%

duty

SquareDuty54

Square waveform with 54%

duty

SquareDuty20

Square waveform with 20%

duty

SquareDuty56

Square waveform with 56%

duty

SquareDuty22

Square waveform with 22%

duty

SquareDuty58

Square waveform with 58%

duty

SquareDuty24

Square waveform with 24%

duty

SquareDuty60

Square waveform with 60%

duty

SquareDuty26

Square waveform with 26%

duty

SquareDuty62

Square waveform with 62%

duty

SquareDuty28

Square waveform with 28%

duty

SquareDuty64

Square waveform with 64%

duty

SquareDuty30

Square waveform with 30%

duty

SquareDuty66

Square waveform with 66%

duty

SquareDuty32

Square waveform with 32%

duty

SquareDuty68

Square waveform with 68%

duty

SquareDuty34

Square waveform with 34%

duty

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

32

Page 47

Arbitrary Waveform: Square 2

Waveform

Function

Waveform

Function

SquareDuty70

Square waveform with 70%

duty

SquareDuty86

Square waveform with 86%

duty

SquareDuty72

Square waveform with 72%

duty

SquareDuty88

Square waveform with 88%

duty

SquareDuty74

Square waveform with 74%

duty

SquareDuty90

Square waveform with 90%

duty

SquareDuty76

Square waveform with 76%

duty

SquareDuty92

Square waveform with 92%

duty

SquareDuty78

Square waveform with 78%

duty

SquareDuty94

Square waveform with 94%

duty

SquareDuty80

Square waveform with 80%

duty

SquareDuty96

Square waveform with 96%

duty

SquareDuty82

Square waveform with 82%

duty

SquareDuty98

Square waveform with 98%

duty

SquareDuty84

Square waveform with 84%

duty

SquareDuty99

Square waveform with 99%

duty

Arbitrary Waveform: Medical

Waveform

Function

Waveform

Function

EOG

Electro-Oculogram

ECG8

Electrocardiogram 8

EEG

Electroencephalogram

ECG9

Electrocardiogram 9

EMG

Electromyogram

ECG10

Electrocardiogram 10

Pulseilogram

Pulseilogram

ECG11

Electrocardiogram 11

ResSpeed

Speed curve of the

respiration

ECG12