Page 1

Y

OU'RE HEARD, LOUD AND CLEAR.

Installation and Operation Manual for

T-Pass® Transmit Multicouplers

73-67-11 Series and

73-67-25/25 (High Power) Series

Manual Part Number

7-9120

8625 Industrial Parkway, Angola, NY 14006 Tel: 716-549-4700 Fax: 716-549-4772 sales@birdrf.com www.bird-technologies.com

Page 2

Warranty

This warranty applies for five years from shipping date.

TX RX Systems Inc. warrants its products to be free from defect in material and workmanship at the time of shipment.

Our obligation under warranty is limited to replacement or repair, at our option, of any such products that shall have

been defective at the time of manufacture. TX RX Systems Inc. reserves the right to replace with merchandise of

equal performance although not identical in every way to that originally sold. TX RX Systems Inc. is not liable for dam-

age caused by lightning or other natural disasters. No product will be accepted for repair or replacement without our

prior written approval. The purchaser must prepay all shipping charges on returned products. TX RX Systems Inc.

shall in no event be liable for consequential damages, installation costs or expense of any nature resulting from the

purchase or use of products, whether or not they are used in accordance with instructions. This warranty is in lieu of all

other warranties, either expressed or implied, including any implied warranty or merchantability of fitness. No representative is authorized to assume for TX RX Systems Inc. any other liability or warranty than set forth above in connection with our products or services.

TERMS AND CONDITIONS OF SALE

PRICES AND TERMS:

Prices are FOB seller’s plant in Angola, NY domestic packaging only, and are subject to change without notice. Federal, State and local sales or excise taxes are not included in prices. When Net 30 terms are applicable, payment is

due within 30 days of invoice date. All orders are subject to a $100.00 net minimum.

QUOTATIONS:

Only written quotations are valid.

ACCEPTANCE OF ORDERS:

Acceptance of orders is valid only when so acknowledged in writing by the seller.

SHIPPING:

Unless otherwise agreed at the time the order is placed, seller reserves the right to make partial shipments for which

payment shall be made in accordance with seller’s stated terms. Shipments are made with transportation charges collect unless otherwise specified by the buyer. Seller’s best judgement will be used in routing, except that buyer’s routing

is used where practicable. The seller is not responsible for selection of most economical or timeliest routing.

CLAIMS:

All claims for damage or loss in transit must be made promptly by the buyer against the carrier. All claims for shortages

must be made within 30 days after date of shipment of material from the seller’s plant.

SPECIFICATION CHANGES OR MODIFICATIONS:

All designs and specifications of seller’s products are subject to change without notice provided the changes or modifications do not affect performance.

RETURN MATERIAL:

Product or material may be returned for credit only after written authorization from the seller, as to which seller shall

have sole discretion. In the event of such authorization, credit given shall not exceed 80 percent of the original purchase. In no case will Seller authorize return of material more than 90 days after shipment from Seller’s plant. Credit

for returned material is issued by the Seller only to the original purchaser.

ORDER CANCELLATION OR ALTERATION:

Cancellation or alteration of acknowledged orders by the buyer will be accepted only on terms that protect the seller

against loss.

NON WARRANTY REPAIRS AND RETURN WORK:

Consult seller’s plant for pricing. Buyer must prepay all transportation charges to seller’s plant. Standard shipping policy set forth above shall apply with respect to return shipment from TX RX Systems Inc. to buyer.

DISCLAIMER

Product part numbering in photographs and drawings is accurate at time of printing. Part number labels on TX RX

products supersede part numbers given within this manual. Information is subject to change without notice.

Bird Technologies Group TX RX Systems Inc.

Page 3

Manual Part Number 7-9120

Copyright © 2010 TX RX Systems, Inc.

First Printing: January 1994

Version Number Version Date

1 04/01/94

2 08/02/94

3 03/27/96

4 11/30/06

5 07/26/10

Symbols Commonly Used

WARNING

CAUTION or ATTENTION

High Voltage

Heavy Lifting

ESD Electrostatic Discharge

Hot Surface

Electrical Shock Hazard

NOTE

Important Information

Bird Technologies Group TX RX Systems Inc.

Page 4

Changes to this Manual

We have made every effort to ensure this manual is accurate. If you discover any

errors, or if you have suggestions for improving this manual, please send your

comments to our Angola, New York facility to the attention of the Technical Publications

Department. This manual may be periodically updated. When inquiring about updates to

this manual refer to the manual part number and revision number on the revision page

following the front cover.

Contact Information

Sales Support at 716-217-3113

Customer Service at 716-217-3144

Technical Publications at 716-549-4700 extension 5019

Bird Technologies Group TX RX Systems Inc.

Page 5

Table of Contents

General Description ........................................................................................... 1

Unpacking ............................................................................................................ 4

Installation Overview........................................................................................... 5

RF Cables and Connectors ................................................................................. 5

Intermodulation Considerations........................................................................... 5

General Installation Procedure ............................................................................ 6

Transmitter Combiner Checkout........................................................................ 7

Required Equipment ............................................................................................ 7

Procedure .......................................................................................................... 7

Measurement Accuracy..................................................................................... 7

General Tuning Information ............................................................................... 7

Tuning Specifics .................................................................................................. 8

Fine Cavity Tuning............................................................................................. 8

Procedure ........................................................................................................ 8

Cavity Tuning Tip............................................................................................. 9

Coarse Cavity Tuning ........................................................................................ 9

Procedure ...................................................................................................... 10

Retuning System to all new Frequencies .......................................................... 10

Combiner Expansion .........................................................................................11

Typical Expansion Channel Installation ............................................................. 11

Peg Rack Procedure (6.625” and 10” Cavities) ............................................... 11

Relay Rack Procedure (10” Cavities) .............................................................. 12

Relay Rack Procedure (6.625” Cavities) ......................................................... 13

Setting Cavity Insertion Loss ............................................................................. 14

Cavity Loss Setting Procedure 1 ....................................................................... 15

Required Test Equipment................................................................................ 15

Procedure for T-Pass Loop ............................................................................. 16

Procedure for BandPass Loop ........................................................................ 17

Cavity Loss Setting Procedure 2 ....................................................................... 18

Required Test Equipment................................................................................ 18

Procedure for T-Pass Loop ............................................................................. 18

Procedure for BandPass Loop ........................................................................ 20

Maintenance ....................................................................................................... 21

Isolators.............................................................................................................. 21

Table of Contents Manual 7-9120-5 07/26/10

Page 6

Figures and Tables

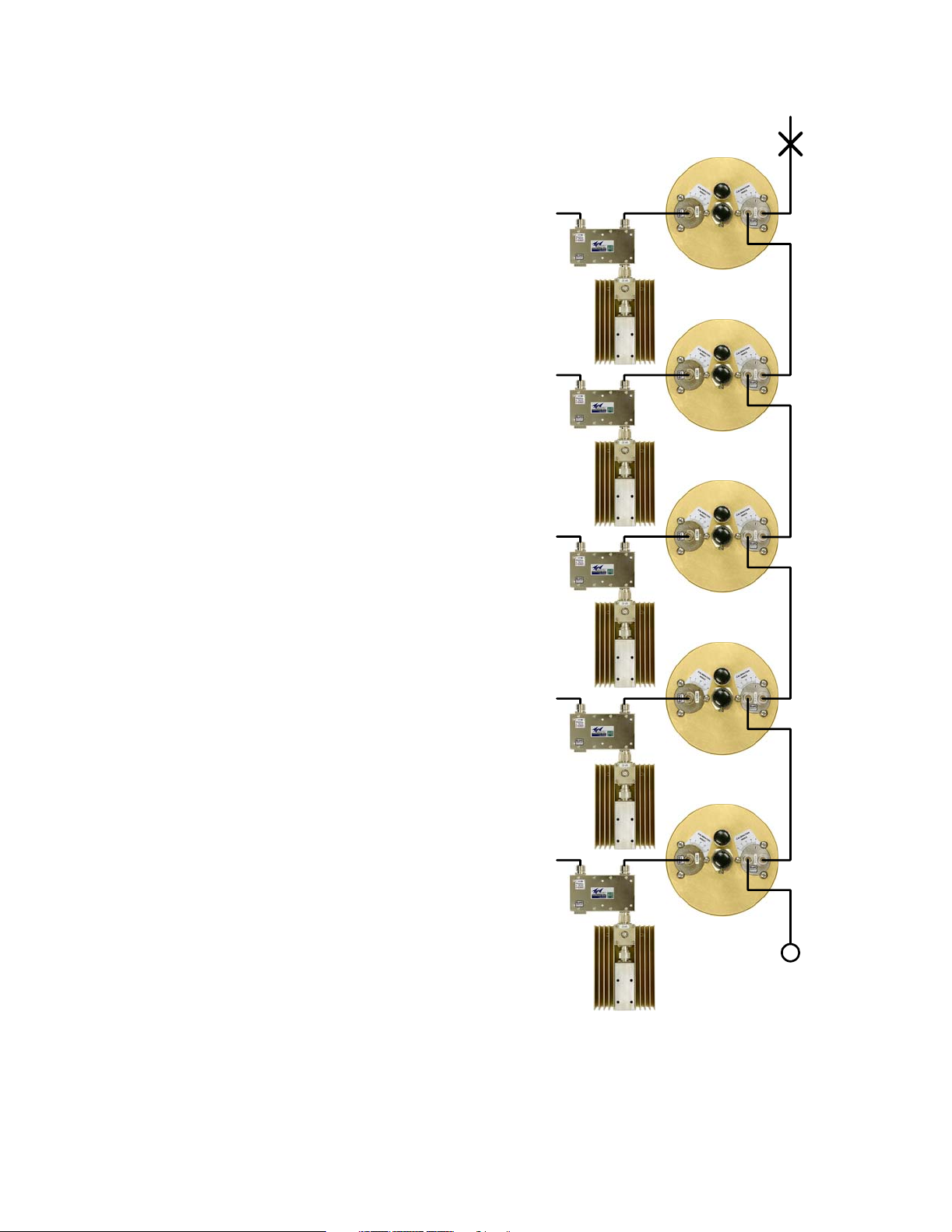

Figure 1: Block diagram of typical system ............................................................ 1

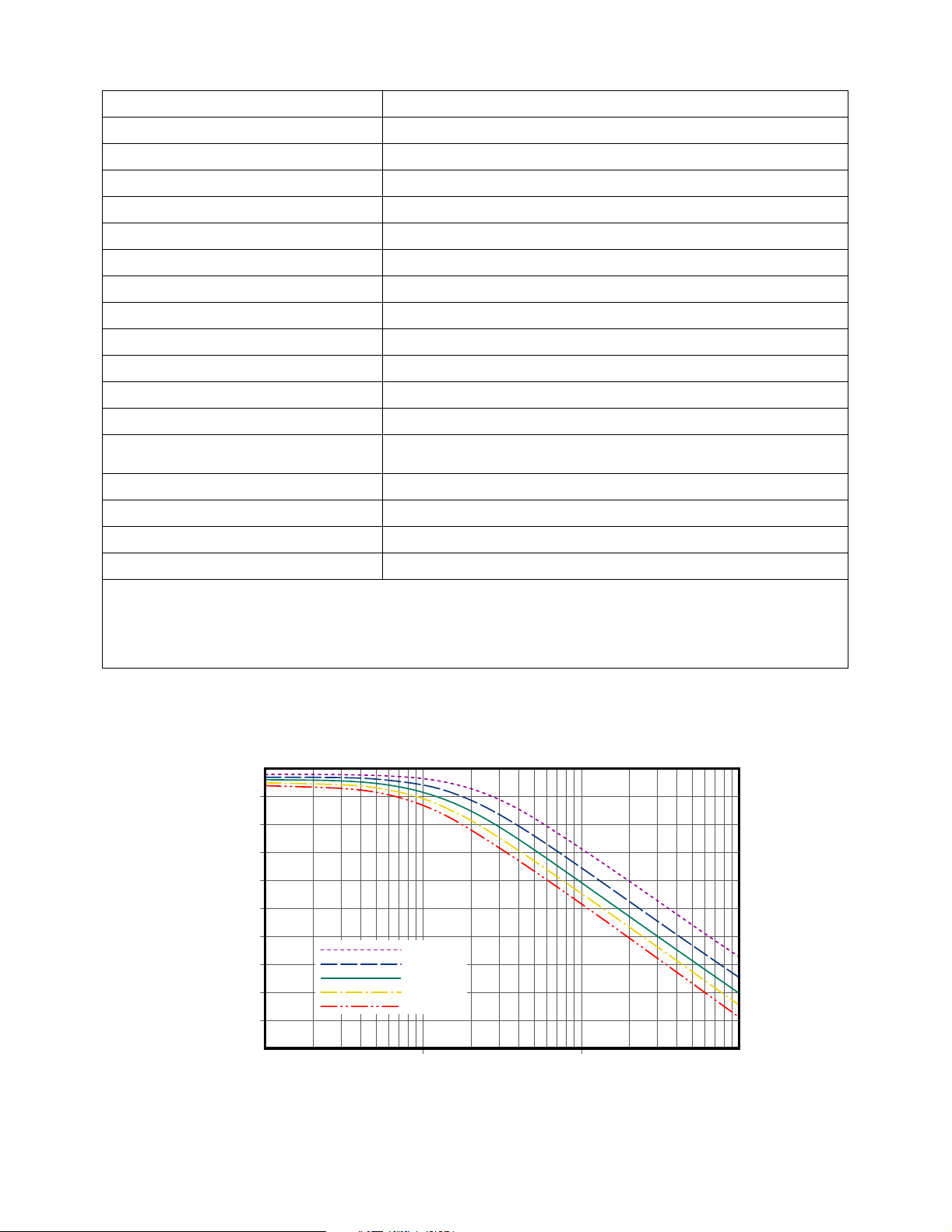

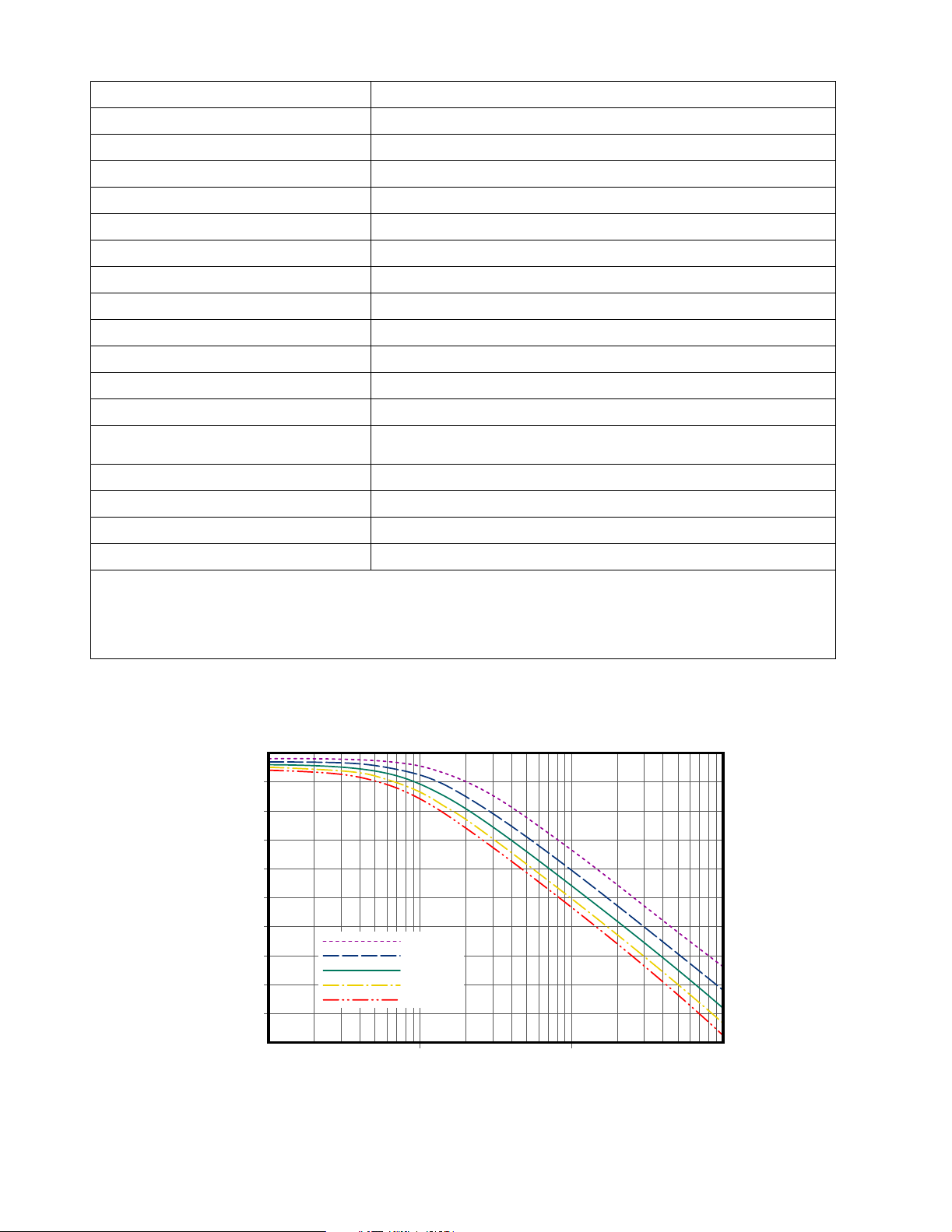

Figure 2: Noise suppression graph for 6.625” cavities .......................................... 2

Figure 3: Noise suppression graph for 10” cavities ............................................... 3

Figure 4: Typical Peg rack model .......................................................................... 4

Figure 5: Typical 19” Relay rack model ................................................................. 4

Figure 6: Typical combiner installation .................................................................. 5

Figure 7: Measuring T-Pass channel performance ............................................... 6

Figure 8: T-Pass cavity fine tuning ........................................................................ 8

Figure 9: T-Pass cavity tuning controls .................................................................9

Figure 10: Coarse tuning a T-Pass cavity ........................................................... 10

Figure 11: Peg rack mounting details .................................................................. 12

Figure 12: Relay rack mounting details ............................................................... 13

Figure 13: Top view of T-Pass cavity .................................................................. 14

Figure 14: Setting loop adjustment reference...................................................... 16

Figure 15: Setting T-Pass loop using step attenuators........................................ 17

Figure 16: Setting BandPass loop using step attenuators................................... 18

Figure 17: Setting T-Pass loop insertion loss ...................................................... 19

Figure 18: Setting Bandpass loop insertion loss .................................................20

Table 1: General specifications 6.625” cavity systems.......................................... 2

Table 2: General specifications for 10” cavity systems ......................................... 3

Table 3: Cavity insertion loss reference loop settings ......................................... 15

Appendix A

UHF Isolators (Compact style)

General Description .......................................................................................... 22

Installation.......................................................................................................... 22

Verifying Isolator Functionality ........................................................................ 22

Recommended Test Equipment ...................................................................... 22

Measuring Reverse Isolation (S12) ................................................................... 22

Measuring Insertion loss (S21) .......................................................................... 23

Figure A1: Verifying Reverse Isolation ...............................................................23

Figure A2: Verifying Insertion Loss .................................................................... 23

Figure A3: Typical Reverse Isolation Waveform ................................................ 24

Figure A4: Typical Insertion Loss Waveform...................................................... 24

Table A1: Specifications .................................................................................... 25

Table of Contents Manual 7-9120-5 07/26/10

Page 7

GENERAL DESCRIPTION

T

T

T

T

T

The model 73-67-11/25-XX-NN Series T-Pass

Transmit Combiners are designed to connect multiple transmitters to a common antenna. They use

three-port bandpass filters (called T-Pass cavities)

and ferrite isolators to provide low channel insertion loss, high isolation between transmitters, high

antenna-to-transmitter isolation, high intermodulation suppression, and excellent transmitter noise

suppression. T-Pass transmit combiners are

broadband and easily adaptable to the most difficult duplex system design requirements.

Transmitter Combiner (T-Pass)

X5

The block diagram of a typical transmit combiner is

shown in Figure 1. The T-Pass filter passes one

X4

narrow band of frequencies and attenuates all others with increasing attenuation above and below

the pass frequency. The T-Pass filter has a “dualport” output loop plate which allows the filter to be

easily connected to other T-Pass filters. Connections between the filters are made with a “thru-line”

cable that behaves like a low loss 50 Ohm transmission line. The thru-line cables are individually

optimized to their own channel frequency. No com-

X3

promises are necessary to accommodate other

channel frequencies. Each channel can therefore

be anywhere in a very broad frequency range.

An isolator is added at the input to each T-pass

channel to increase channel isolation. The ferrite

isolators will isolate the transmitter from unwanted

signals that enter the system via the antenna. The

X2

transmitter sees an excellent impedance match on

its output, because the isolator absorbs reflected

power that would otherwise enter the transmitters

output stage. This improves the stability, spectral

purity and long-term reliability of the transmitter.

The model 73-67-11/25-XX-NN Series T-Pass

transmit combiners are available with either 6.625”

or 10” cavities. TX combiners constructed with

X1

6.625” cavities are ideal for operation at channel

separations of 115 KHz or more, with 110 to 150

Watt transmitters. These models are suitable for

19” relay rack mounting or TX RX peg rack mounting. TX combiners constructed with high perfor-

S

mance 10” diameter cavities, which have higher

selectivity and power handling capabilities, allow

operation at 75 KHz minimum separation with 125

to 150 Watt transmitters. In addition, High power

10” diameter models are also available which contain 250 Watt dual isolators with 100 or 250 Watt

loads.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 1

Figure 1: Block diagram of a typical TX T-Pass

combiner. Typical five channel system shown as

an example.

Page 8

Frequency Range (MHz) 406 - 512 MHz

Cavity Type and Diameter 3/4 wave, 6.625” (168 mm)

Maximum Continuous Transmit Power 150 Watts

Isolator Load Power (Continuous) 73-67-11-2B-nn: 5W/25W [Note 3] ; 73-67-11-2D-nn: 5W/100W

Minimum TX-TX Separation at Cavity Loss 215 KHz @ -1.5 dB ; 115 KHz @ -2.5 dB

Typical TX-TX Isolation at Minimum Separation (dB) 80 dB

Typical Antenna - TX Isolation (dB) 70 dB

Typical TX Noise Suppression depends on cavity loss

Nominal Impedance (Ohms) 50

Maximum Input Return Loss (VSWR) -20 dB (1.22:1)

Temperature Range (°C) -30 to +60

Connectors, Input and Antenna N

Mounting Peg Rack ®

Mounting Options

Maximum Channels / Rack 15 [Note 4]

Dimensions 65.25” x 24” x 36” (H x W x D) [Note 6] ; (1659 x 610 x 914 mm)

Weight - Basic - Single Channel [lb (Kg)] 73-67-11-2B-nn: 36 (16.3) ; 73-67-11-2D-nn: 37 (16.7)

Weight - Expansion Channel Assembly [lb (Kg)] 73-67-11-2B-nn: 15 (6.8) ; 73-67-11-2D-nn: 16 (7.2)

Note 1: -nn in model number represents the number of channels.

Note 3: Models available with 5W/60W loads. same specifications as 25W and 100W models, except load power.

Note 4: -MC option reduces maximum number of channels to ten 10-inch or twelve 6.625-inch channels per rack.

Note 5: -LR systems are tuned and tested on customer frequencies, then disassembled for shipping.

Note 6: Rack depth with cavity tuning rods at maximum frequency. Rod travel is approximately 5.1” (130 mm).

Note 2: These specifications are applicable to 406 - 512 MHz models.

MC: 19” rackmount adapter plates, 17.5” high

LR: System supplied without Peg Rack ® [Notes 4,5]

Tab l e 1 : General specifications for 6.625” cavity system.

73-67-11-Series Systems

0

-5

-10

-15

-20

6.625" Diameter 3/4-Wave, Fo = 460 MHz

-25

-30

Attenuation (dB)

-35

IL = 1.0 dB

IL = 1.5 dB

IL = 2.0 dB

-40

IL = 2.5 dB

IL = 3.0 dB

-45

-50

0.01 0.1 1

10

Offset from Fo (MHz)

Figure 2: Typical transmitter noise suppression using 6.625” cavities.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 2

Page 9

Frequency Range (MHz) 406 - 512 MHz

Cavity Type and Diameter 3/4-wave, 10” (254 mm)

Maximum Continuous Transmit Power 150 Watt

Isolator Load Power (Continuous) 5W/25W [Note 3]

Minimum TX-TX Separation at Cavity Loss 150 KHz @ -1.5 dB ; 75 KHz @ -2.5 dB

Typical TX-TX Isolation at Minimum Separation (dB) 80 dB

Typical Antenna - TX Isolation (dB) 70 dB

Typical TX Noise Suppression Depends on cavity loss

Nominal Impedance (Ohms) 50

Maximum Input Return Loss (VSWR) -20 dB (1.22 : 1)

Temperature Range (°C) -30 to +60

Connectors, Input and Antenna N

Mounting Peg Rack ®

Mounting Options

Maximum Channels / Rack 12 [Note 4]

Dimensions 79.5” x 24” x 36” (H x W x D) [Note 6] ; (2019 x 610 x 914 mm)

Weight - Basic Single-Channel [lb (Kg)] 14 (18.6)

MC: 19” rackmount adapter plates, 17.5 “ high

LR: System supplied without Peg Rack ® [Notes 4,5]

Weight - Expansion Channel Assembly [lb (Kg)] 19 (8.6)

Note 1: -nn in model number represents the number of channels.

Note 3: Models available with 5W/60W loads. same specifications as 25W and 100W models, except load power.

Note 4: -MC option reduces maximum number of channels to ten 10-inch or twelve 6.625-inch channels per rack.

Note 5: -LR systems are tuned and tested on customer frequencies, then disassembled for shipping.

Note 6: Rack depth with cavity tuning rods at maximum frequency. Rod travel is approximately 5.1” (130 mm).

Note 2: These specifications are applicable to 406 - 512 MHz models.

Table 2 : General specifications for 10” cavity systems.

73-67-25-Series Systems

0

-5

-10

-15

-20

-25

-30

Attenuation (dB)

-35

-40

-45

10" Diameter 3/4-Wave, Fo = 460 MHz

IL = 1.0 dB

IL = 1.5 dB

IL = 2.0 dB

IL = 2.5 dB

IL = 3.0 dB

-50

0.01 0.1 1

10

Offset from Fo (MHz)

Figure 3: Typical transmitter noise suppression using 10” cavities.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 3

Page 10

The TX combiners can be expanded one channel

at a time with factory-tuned, easy-to-install expansion channel assemblies. Expansion is usually

accomplished without modifications to the existing

system, and usually amounts to nothing more than

placing a new channel assembly, or several, on top

of the existing system. New channel frequencies

can be above, below, or between existing channel

frequencies.

The number of channels in the combiner is indicated by the last two digits of the model number in

place of the NN designation. All of the information

for both installation and expansion is included in

this manual. The combiner is easy to install and

has been factory tuned in most cases so that no

adjustments are necessary. The specifications for

the 73-67-11/25-XX-NN family of T-Pass combiners are listed in Tables 1 and 2 for the 6.625” and

10” cavities respectively. The curves shown in Fig-

ures 2 and 3 show the typical transmit noise suppression for the 6.625” and 10” cavity systems

respectively. Noise suppression depends on the

cavity’s loss setting. Figure 4 shows a typical Peg

rack model and Figure 5 shows a typical 19” rack

mount model.

UNPACKING

It is important to visually inspect the system components for any shipping damages as soon as possible after taking delivery. It is the customers

responsibility to file any necessary damage claims

with the carrier.

Figure 4: Example of typical Peg-rack model

using 10” cavities.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 4

Figure 5: Example of typical Relay-rack model

using 10” cavities.

Page 11

The transmit combiner is a very rugged device and

is well packed for damage-free shipping to any

place in the world. However, a high impact during

shipping can have a detrimental affect. A damaged

shipping container is a sure sign of rough handling.

The most easily damaged parts of the combiner

are the tuning rods. These rods are marked where

they exit from the locking nut with a dab of red varnish or other color/type of paint. If this seal appears

to be broken it may indicate that the system has

been detuned in transit.

INSTALLATION OVERVIEW

The combiner should be located in a dry and level

area, indoors. It is best if all transmitters are as

equal in distance as possible from the combiner so

that cable losses are the same for all channels.

Figure 6 shows a suggested orientation for the

equipment. Two points are important. First, a work

area space should be left as illustrated so that the

tuning controls are easy to access. This will facilitate tuning when channel frequencies are

changed. Secondly, space is needed when adding

expansion channels. If there is a lack of space to

access the side of the combiner, then plan to allow

the rack to be moved into the indicated work area

to facilitate adding channels. This will require some

slack in the cables that connect to the station transmitters. Each transmitter connects to its respective

channel through an ‘N style’ female connector on

the isolator. We recommend using a high quality

double shielded or semi flexible cable.

This system is designed for use with separate

transmit and receive antennas. For best operation,

the transmit and receive antennas should be separated vertically by 20 feet with little or no horizontal

offset between antennas. Lesser separations can

be used but with an increased risk of harmful interference between radio systems. In most cases, it

will be desirable to mount the receive antenna

higher than the transmit antenna to maximize the

talk-back range of low power portable radios.

RF Cables and Connectors

All connections to and from the combiner system

should be made with double-shielded or semi-rigid

heliax cable. High quality 'N' connectors that use

either silver or gold plated contacts should be

used.

Intermodulation Considerations

Following the previously mentioned antenna spacing recommendations will go a long way toward

minimizing or eliminating intermodulation (IM)

interference. IM is the result of a frequency mixing

process that occurs when two or more RF signals

are present simultaneously in the same circuitry

where nonlinearities occur. Product frequencies

generated have frequencies that are determined by

relatively simple mathematical relationships such

as F(im) = 2F1-F2 and are normally determined by

doing a computer intermodulation analysis for the

antenna site. These products can be generated in

a corroded tower joint, metal-roofing, transmitter

final amplifier or the receiver front-end.

T-Pass

Transmitter

Combiner

Radio

Cabinet

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 5

Radio

Cabinet

Work

Area

Figure 6: Typical combiner installation.

Radio

Cabinet

Radio

Cabinet

Page 12

Both cavity filters and ferrite isolators isolate the

transmitters connected to the combiner from oneanother thus reducing intermodulation interference.

However in all transmitter combiners, intermodulation products are reduced in strength but never

completely eliminated. They have to be reduced by

an amount to meet the federal Communications

Commission,

43 + 10 Log(Power Out)

rule for spurious output reduction. Because of the limitations

imposed by the tension and friction joints in connectors, IM products will be down 100 to 120 dB

below carrier so they are still strong enough to

cause problems if they fall on a near-by receiver

frequency.

Transmitter

To avoid transmitter generated IM problems, do

not put two channels on the same combiner that

your IM software predicts will cause interference by

generating either 3rd or 5th order IM products.

Having at least two transmitter combiners allows

maximum flexibility in dealing with transmitter generated IM.

General Installation Procedure

1) Install the peg rack or relay rack in the radio

equipment room.

2) Connect the transmitters and the transmitting

antenna to the appropriate connectors on the

cavities.

Wattmeter 2

T-Pass

Cavity Filter

50 Ohm

Load

Transmitter

Wattmeter 1

UG57

Male-Male

Transmitter

Single

or Dual

Section

Isolators

Single

or Dual

Section

Isolators

Single

or Dual

Section

Isolators

Channel 3

Channel 2

Channel 1

UG27 Elbow Connector

& UG57 Male-Male

Adaptor

This T-Pass Loop

requires a 3-1268

short circuit

connector

Figure 7: Equipment hookup for measuring T-Pass channel performance.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 6

Page 13

3) Verify proper operation of each channel by

measuring the power output for each individual

channel.

TRANSMITTER COMBINER CHECKOUT

It is recommended that the performance of the

transmitter combiner be checked initially and data

recorded for future reference. This is done by measuring the input and output power of each channel

and recording the data. Figure 7 shows the equipment hook up.

Required Equipment

If a power monitoring system is not installed along

with the combiner, two Bird Model 43 thruline wattmeters or equivalent can be used. They should be

equipped with elements for the frequency band of

interest and rated for the expected transmitter

power output. The use of two wattmeters eliminates errors that can occur from changing cable

lengths. The measurements should only be done

one channel at a time because most wattmeters

cannot accurately measure the total power of two

or more transmitters simultaneously. A pocket calculator with Log functions makes for easy calculation of power loss in dB using this measured data.

PROCEDURE

Start with channel 1 and proceed to the next higher

channels. The two wattmeters should be connected to the equipment as shown in figure 7. Note

that the use of the elbow and/or male-male connectors allows the shortest connections and negligible hook up loss. Longer cable lengths will tend

to increase measurement error.

It is important that the same wattmeters and wattmeter elements be used in the same position

throughout the tests. The serial numbers of the

wattmeters should be recorded for future reference. Wattmeter elements may not have serial

numbers so they need to be labeled or otherwise

keyed to a specific wattmeter to assure repeatability of the measurements.

MEASUREMENT ACCURACY

The Bird thruline wattmeter has a measurement

accuracy of +/- 5% of full scale. When using a 100

watt element in this meter, the measurement error

can be as great as + or - 5 watts.

As an example of the actual dB loss readings that

might be produced using the wattmeter method,

consider a T-Pass channel that has a factory mea-

sured loss of 3.0 dB. We would expect that a 100

watt transmitter would produce 50 watts out of this

channel but the actual wattmeter reading for the

input power could measure as low as 95 watts to

as high as 105 watts. The measured output power

could run from 45 to 55 watts. It is possible that the

output reading may be 5 watts low while the input

reading is 5 watts high or just the opposite. These

two extremes would yield the following dB loss values:

For a Power Out (PO) of 45 watts and a Power

Input (PI) of 105 watts:

Loss (dB) = 10 Log10 (45/105)

Loss (dB) = -3.7

For a PO of 55 watts and PI of 95 watts:

Loss (dB) = 10 Log10 (55/95)

Loss (dB) = -2.4

So the calculated loss for this channel can run from

-2.4 to -3.7dB and be acceptable considering the

measurement error factor. The actual error could

be much greater if a 250 watt element was

used; the measured values could vary by as much

as +/- 12.5 watts so using a wattmeter element with

the smallest possible rating is important for accuracy. Use of between series adapters or UHF type

connectors for making connections to the wattmeters, device under test or loads could make this

error even worse due to the additional impedance

mismatch that these connectors can cause.

GENERAL TUNING INFORMATION

T-Pass transmitter combiners are pre-tuned at the

factory and usually require no adjustment. T-Pass

expansion channels are also pretuned but may

require fine tuning after being installed in an existing system. Channels that are close in frequency

(adjacent channels in the multicoupler) to the

expansion channel may also benefit from fine tuning due to the slight interaction that occurs with the

new channel. The procedures that follow may be

used at any time to verify that any or all channels

are properly tuned or to correct any misalignments.

It is interesting to note that T-Pass filters, bandpass

filters and cavity filters in general can act as impedance transformers as well as filters. It is for this

reason that many field service personnel claim that

they can always tune a filter or duplexer better than

the factory. What isn't generally realized is that

their tuning efforts are usually producing better

impedance matching between transmitter and

antenna which can be improved by the transform-

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 7

Page 14

ing action of filters. Since the filters are usually

r

s

r

s

tuned using laboratory grade 50 ohm loads, the

tuning adjustment that produces this improved

match will be slightly different than the factory

adjustment. While this tuning may produce slightly

greater power output readings, it will rarely produce any discernible change in system performance and may detune any notching circuitry

contained in the cavities.

It is our recommendation that channel tuning only

be attempted under the previously mentioned conditions or when it is suspected that the combiner

has been tampered with or subjected to extreme

shock in shipping or installation. This condition is

indicated when the channel loss is in excess of that

expected from actual measurement of power input

and output.

Tuning Specifics

Tuning of the combiner consists of tuning the individual T-Pass channels. T-Pass channel tuning

involves cavity filter tuning. The isolators are

broad band and do not require adjustments.

The procedures for tuning cavities follows.

FINE CAVITY TUNING

Figure 8 shows hookups which are suitable for fine

tuning any channel under power while installed in

the combiner. The term fine tuning here refers to

cavities that have already been tuned to frequency

and may only require adjustment of the fine tuning

control (+/- 50 KHz). The transmitter is used as a

signal source and the cavity is adjusted for minimum reflected power.

Procedure

With the transmitter keyed, the cavity fine tuning

control is adjusted (pushed in or out) to obtain a

minimum meter reading. See Figure 9 for a detail

of the cavity tuning controls. If a minimum meter

reading is obtained with the fine tuning rod fully in

or completely out, do the following:

1) Set the fine tuning rod so that about 1/2 of its

length is inserted into the cavity.

2) Loosen the coarse tuning rod locking screw (5/

32”/4mm Allen/Hex-key wrench required) and

move the rod in or out slightly to obtain minimum meter reading. Small movements of the

coarse tuning rod are facilitated by tapping the

rod with the handle end of a screw driver while

gently pushing or pulling the main tuning rod.

Tighten the coarse tuning locking screw.

3) Adjust the fine tuning control for a minimum

meter reading.

Fine

Tuning

Two Single Section

or One Dual Isolators

Transmitter

Input

50 Ohm

Termination

Figure 8: Using a wattmeter for T-Pass cavity fine tuning.

Output

Coarse

Tuning

Wattmeter

Output

Section

Termination

T-Pass

Cavity Filter

To Othe

Channel

To Othe

Channel

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 8

Page 15

Coarse Tuning Rod

Fine Tuning Rod

Coarse Tuning Lock

10-32 Cap Screw

Cavity Resonator

Input/Output Port

Loop Plate

Hold Down Screws

Loop Plate Assembly

Calibration Index

Figure 9: T-Pass cavity tuning controls details.

4) Tighten the fine tuning locking mechanism.

CAVITY TUNING TIP

When tuning a cavity that has been in service for

some time it is not unusual to find the main tuning

rod hard to move in or out. This occurs because TX

RX uses techniques borrowed from microwave

technology to provide large area contact surfaces

on our tuning plungers. These silver plated surfaces actually form a pressure weld that maintains

excellent conductivity. This pressure weld develops over time and must be broken to move the

main tuning rod. This is easily accomplished by

gently tapping the tuning rod with a plastic screwdriver handle or small hammer so that it moves into

the cavity. The weld will be broken with no damage

to the cavity.

When adjusting the coarse tuning rod, it is easy to

put the cavity far off resonance and cause most of

the transmitter power to be reflected back into the

isolator output section load. This load should be

capable of dissipating this power or damage could

result. If in doubt about the loads capability, follow

the coarse tuning procedure outlined below. It is

based on the use of a tracking generator which

avoids the need to consider power levels.

Input/Output Port

Loop Plate Assembly

Calibration Mark

Calibration Index

Fine Tuning Lock

Knurled Thumb Nut

COARSE CAVITY TUNING

When a T-Pass cavity frequency has to be

changed by over 100 KHz, adjustment of the main

tuning rod is required. Large frequency changes

are more easily observed when using a tracking

generator and a return loss bridge to give a swept

display of the return loss curve. The return loss

curve is a very precise indicator of T-Pass cavity

tuning. The test equipment hookup for doing this is

illustrated in Figure 10 and uses the following

equipment or its equivalent;

1) Spectrum Analyzer that covers the frequencies

of interest such as the Bird Technologies “Signal Hawk ™”.

2) Signal generator capable of producing the frequencies of interest.

3) Eagle Return Loss Bridge (35 dB directivity).

Model RLB150N3A.

4) Double shielded coaxial cable test leads

(RG142 B\U or RG223/U).

5) 50 Ohm load with at least -35 dB return loss

(1.10:1 VSWR).

6) 3-1268 short circuit connector.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 9

Page 16

Spectrum Analyzer

Bird SignalHawk

Signal Generator

RLB - 150 Bridge

LOAD

PROCEDURE

1) Set the spectrum analyzer for the desired center frequency (display center) and vertical scale

of 10 dB/div. Set the signal generator for the

desired center frequency.

2) Connect the return loss bridge to the spectrum

analyzer and signal generator as shown in figure 10 but do not connect it to the cavity. Leave

the test port (called the load port) on the bridge

open.

3) Set up a 0 dB return loss reference display on

the spectrum analyzer. Then connect the return

loss bridge.

4) Loosen the fine tuning rod locking nut and set

the fine tuning rod so that 1/2 its length is

inserted into the cavity.

5) Loosen the main tuning rod locking screw and

move the main tuning rod in or out to obtain

maximum return loss at the desired frequency.

Small movements of the main tuning rod are

facilitated by tapping the rod with the handle

end of a screw driver while gently pushing or

pulling the main tuning rod.

6) Lock the Main and Fine tuning rods and reconnect the cavity into the system. Use the previously outlined fine tuning procedure to verify

proper tuning under power.

Retuning System To All New Frequencies

50 Ohm Load

T-Pass

Cavity Filter

When retuning the combiner to all new frequencies

perform the following procedure in a step-by-step

fashion;

1) Determine new thruline cable lengths for the

new channels and the specific stacking order in

the rack. TX RX Systems Sales engineers will

assist by making the calculations using their

design software. Due to variations in coaxial

cable characteristics and assembly techniques,

factory supplied cables are recommended.

2) Use the coarse tuning procedure to tune each

3-1268

Short Circuit

Connector

cavity channel to the new transmitter frequencies.

3) Connect the channels according to the new

thru-line cable chart.

Figure 10: Coarse tuning a T-Pass cavity.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 10

Page 17

4) Fine tune each channel using the fine tuning

procedure starting with channel 1 and proceeding to the next higher channel. After tuning all

channels, repeat this step a second time to verify that their is no more channel interaction.

(1) Cavity and isolator mounting hardware.

(1) T-Pass thru-line cable.

(1) T-Pass thruline chart.

5) Verify channel losses if desired using the

checkout procedure outlined previously.

Combiner Expansion

Expansion channels for your combiner may be

ordered directly from TX RX Systems or its authorized representative. If you wish, a TX RX Systems

engineer will help you select the right model and

any required options.

The expansion channel and options are shipped

with mounting instructions and a new T-Pass

Thruline cable sheet which shows the exact mounting location of the new channel in the existing system. In most cases, this channel will be added

directly to the next topmost position in the rack and

the antenna connection will then move to this cavity. A new thruline cable will connect this channel to

the existing cavities.

The system engineer may also advise that the cavity insertion loss on some of the existing channels

needs to be changed in order to accommodate a

new channel. This can be necessary when the new

channel is much closer in frequency separation to

existing channels than was previously encountered. This usually means increasing the cavity

loss for all close spaced channels which provides

the increased selectivity required. Cavity insertion

loss values are shown on the T-Pass Thruline

cable sheet.

Typical Expansion Channel installation

The following text is a procedure for adding expansion channel components to a typical T-Pass

Transmit Combiner system. Please keep in mind

that if instructions are shipped with the expansion

components they would supersede these procedures.

Typical Parts Included: (Quantity and Description)

(1) T-Pass Cavity Assembly.

(1) Dual or single isolator with load(s).

PEG RACK PROCEDURE

(6.625” AND 10” CAVITIES)

1) Determine the location of the Expansion Channel in the rack by consulting the new

THRULINE cable chart.

2) Mount the cavity in the peg rack using two (2)

stainless band clamps, refer to Figure 11.

3) Rotate the cavity body so that the connectors

are oriented the same as those on the other

cavities and that no cavity-end cap screws are

preventing a flush fit with a mounting peg.

4) Tighten the cavity mounting clamps.

5) Attach the isolator mounting plate to the cavity

using two (2) band clamps. Clamp screws

should be positioned as shown in figure 11. Do

not tighten the clamps.

6) Rotate the isolator mounting bracket so that the

isolator is in the vertical plane as illustrated,

forming a smooth line in relation to the other

channels in the rack.

7) Due to the limited space, tightening may require

the use of a 5/16" open end wrench. Tighten

both clamps securely.

8) Connect the black isolator-to-cavity cable using

a pair of cable pliers to tighten-up the connectors.

9) Connect the new channel to the combiner using

the proper length T-Pass Thruline cable. Use a

pair of cable pliers to tighten these connections.

The required length thruline cable and

NOTE

new cabling chart has either been factory supplied or is to be determined

and fabricated by the customer as

determined at the time of order. Use

T-Pass thruline design sheets supplied by the factory.

(1) Isolator to cavity interconnect cable.

10) If necessary, reset the cavity insertion loss of

adjacent channels as noted on the Thru-line

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 11

Page 18

Figure 11: Peg-rack mounting details.

cable sheet. Follow the procedure outlined

below under Setting Cavity Insertion Loss.

11) Fine tune the T-Pass cavity of the expansion

channel according to the fine tuning procedure

outlined earlier.

RELAY RACK PROCEDURE

(10” CAVITIES)

Because of their width, 10” cavities

NOTE

are mounted in relay racks with a vertical orientation as shown in Figure

12.

1) Install the expansion cavities to the rack above

existing channels using four mounting screws.

Make sure you leave sufficient space between

the upper and lower cavity groups so that the

tuning rods and interconnect cables do not

interfere.

2) Connect the black isolator-to-cavity cable using

a pair of cable pliers to tighten-up the connectors.

3) Connect the new channel to the combiner

using the proper length T-Pass Thruline cable.

Use a pair of cable pliers to tighten these connections.

The required length thruline cable and

NOTE

new cabling chart has either been factory supplied or is to be determined

and fabricated by the customer as

determined at the time of order. Use

T-Pass thruline design sheets supplied by the factory.

4) If necessary, reset the cavity insertion loss of

adjacent channels as noted on the Thru-line

cable sheet. Follow the procedure outlined

below under Setting Cavity Insertion Loss

.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 12

Page 19

Screw

Screw

Screw

Screw

Figure 12: Relay rack mounting details. Ten-inch cavities shown as an example.

5) Fine tune the T-Pass cavity of the expansion

channel according to the fine tuning procedure

outlined earlier.

RELAY RACK PROCEDURE

(6.625” CAVITIES)

Because of their width, 6.625” cavities

NOTE

are mounted on relay racks in a hori-

1) Determine the location of the expansion channel in the rack by consulting the new

THRULINE cable chart.

2) If necessary install an empty cavity deck in the

rack using 4 Phillips screws. If there is room on

an already existing cavity deck then skip this

step of the procedure.

zontal orientation on cavity deck

plates.

3) Mount the cavity on the deck by laying the cavity onto the “V shaped” cavity bracket.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 13

Page 20

4) Rotate the cavity body so that the connectors

are oriented the same as those on the other

cavities in the system. Secure the new cavity to

the brackets using (2) stainless band clamps.

5) Tighten the cavity mounting band clamps.

6) Connect the black isolator-to-cavity cable using

a pair of cable pliers to tighten-up the connectors.

7) Connect the new channel to the combiner

using the proper length T-Pass Thruline cable.

Use a pair of cable pliers to tighten these connections.

The required length thruline cable and

NOTE

new cabling chart has either been factory supplied or is to be determined

and fabricated by the customer as

determined at the time of order. Use

T-Pass thruline design sheets supplied by the factory.

8) If necessary, reset the cavity insertion loss of

adjacent channels as noted on the Thru-line

cable sheet. Follow the procedure outlined

below under Setting Cavity Insertion Loss

.

9) Fine tune the T-Pass cavity of the expansion

channel according to the fine tuning procedure

outlined earlier.

Setting Cavity Insertion Loss

It is sometimes necessary to reset the insertion

loss of a T-Pass cavity filter in order to change its

selectivity. Increasing the loss will increase the

cavity selectivity which may be necessary to

accommodate more closely spaced channels.

observed across the tee. The depth of the rejection

notch is directly related to the loop's coefficient of

coupling.

The first procedure uses precision rotary attenuators, a signal generator and a RF millivolt meter to

provide very accurate results. The actual loss setting obtained when this procedure is carefully followed will be within one tenth of a dB of the desired

value and the return loss will be 20 dB (1.25:1) or

better.

The second procedure uses a spectrum analyzer

and a signal generator and produces slightly less

accurate results. When this procedure is carefully

followed, the loss settings will be within two tenths

of a dB of the desired value and the return loss will

usually be -15 dB (1.5:1 VSWR) or better. The

advantage of this procedure is that it is much faster

to do, does not require precision attenuators and

will yield acceptable results in most cases.

Table 3 is a reference chart for setting T-Pass cavity loss with either procedure. The chart shows the

desired cavity loss settings and the reference setting for both the T-Pass and bandpass loop assembly. The reference notch depth for a given loss is

that which can be observed across a tee connector

connected to either loop assembly.

Calibration

Mark

Loop Locking

Screws (6 places)

Changing the loss is accomplished by rotating the

coupling loops to change the coefficient of coupling. Both loops are normally adjusted for a given

insertion loss setting. Most T-Pass cavities have a

calibration index label beside both loops that gives

a relative indication of their settings, see Figure

13. In actual practice, these marks are not accurate

enough for setting different loss values consistently.

Two procedures are offered for setting the cavity

Bandpass

Loop

T-Pass

Loop

loss. Both procedures take advantage of the fact

that when a tee connector is placed on a single

Figure 13: Top view of T-Pass cavity.

bandpass or T-Pass loop, a rejection notch can be

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 14

Page 21

Cavity Loss (dB) Coupling Loop Type TXRX Part # Reference Notch Depth

1.0

1.5

2.0

2.5

3.0

T-Pass 3-3724 -9.2

Bandpass 2-0675 -12

T-Pass 3-3724 -7.4

Bandpass 2-0675 -10.2

T-Pass 3-3724 -5.6

Bandpass 2-0675 -8.8

T-Pass 3-3724 -4.4

Bandpass 2-0675 -8.0

T-Pass 3-3724 -3.6

Bandpass 2-0675 -7.2

Table 3: Cavity insertion loss reference loop settings.

Cavity Loss Setting Procedure 1

This procedure uses precision rotary attenuators, a

signal generator and an RF millivolt meter.

REQUIRED TEST EQUIPMENT

1) Signal generator capable of producing a CW

signal level of at least -10 dBm with variable

output level capability at the frequency of interest.

2) An RF voltmeter with a 0.001 V (-50 dBm)

scale and a 50 ohm input adapter. Helper

Instruments RF millivolter used for this example.

3) Rotary Attenuators, 1@ 0-1 dB in 0.1 dB increments. 1@ 0-10 dB in 1.0 dB increments. 1@

0-70 dB in 10 dB increments. JFW Industries

model 50BR-017.

4) Two 10 dB fixed attenuator pads with BNC

connectors. JFW Industries model 50F-010.

5) UG-914/U, BNC(F) to BNC(F) union.

TX RX Systems' part # 8-5805.

6) UG-28A/U, N(F), N(F), N(F) tee.

7) UG-57B/U, N(M)-N(M) coupling.

8) Two, UG-201A/U BNC(F)-N(M) adapter.

TX RX Systems' part # 8-5814.

9) 50 ohm coaxial cable test leads with BNC male

connectors (high quality cable).

A spectrum analyzer may be used in place of the

RF voltmeter. However, the personnel doing the

work should fully understand the procedure and

understand the use of the analyzer for this application.

We have found it convenient to use test cables with

BNC connectors. They allow for more convenient

connection to test equipment and to small attenua-

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 15

Page 22

Modulated

Signal Source RF Voltmeter

2

0 0 000 0 00

All cables are 50 Ohm

ZERO

SET

coaxial. Double shielded

cables preferred.

1

4567

3

50 Ohm Adaptor

3

8

9

10

ZERO

SET

UG914/U

0.1 dB/Div. 1.0 dB/Div. 10 dB/Div.

Female-Female

Connector

10 dB Attenuator Pads

Figure 14: Setting loop adjustment reference level.

tor pads. UG-201 BNC to N adapters are used

when connections to N connectors are needed.

PROCEDURE FOR T-PASS LOOP

1) Set the signal generator at the desired frequency (within 1 MHz of operating frequency)

and an output level of approximately -10 dBm.

Set the rotary attenuators for the Reference

Notch Depth Value shown in table 3 for the

desired insertion loss.

2) Connect the test leads together through the

female union, as shown in Figure 14, and

adjust the range switch and the zero set on the

voltmeter for a convenient reference level (

level of 2 on the 0 to 3 scale for example

) on the

meter. The generator output level may also be

adjusted slightly if necessary.

3) Remove the bandpass loop from the cavity and

reinsert it, connector end first, back into the cavity and tighten all 3 screws securely. See Fig-

ure 15.

4) Set all three attenuators for 0 dB but leave them

in the circuit.

5) Connect a UG-28A/U Tee connector and UG57B/U coupling to the T-Pass loop as shown in

figure 15. Then connect the test leads as

Rotary Attenuators

Set to Loop Reference Settings

shown. Make sure to install the 3-1268 short circuit connector from the top of the T-Pass rack.

6) Loosen the main tuning rod locking screw and

slowly slide the tuning rod in or out to obtain a

dip (minimum voltage) in the meter reading

which indicates cavity resonance. Use the fine

tuning control to maximize the dip (the fine tuning rod should not be full in or out which would

indicate that slight adjustment of the main tuning rod is necessary). Note the meter reading.

7) If the meter reading is greater or less than the

reference level from step 2, the T-Pass loop

A

rotation will have to be adjusted. If the meter

reading is greater than the reference level, the

loop will have to be rotated so that the calibration mark on the loop points to a slightly higher

number on the calibration index label. Conversely, if the meter reading is less than the reference, the loop will have to be rotated so that

the index mark points to a slightly lower number

on the calibration index. Loosen the three loop

locking screws and rotate the loop so that the

index mark is moved to the next higher or lower

calibration tag number as needed and tighten

the 3 locking screws. Note that tight screws are

necessary for accuracy.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 16

Page 23

Modulated

Signal Source RF Voltmeter

Short Circuit Connector

3-1268 from top of rack

10 dB Pad 10 dB Pad

Figure 15: Setting the T-Pass loop using step attenuators.

UG-28A/U

UG-57B/U

T-Pass

Loop

50 Ohm Adaptor

0.1 dB/Div. 1.0 dB/Div. 10 dB/Div.

Rotary Attenuators

Set to Loop Reference Settings

Bandpass Loop turned upside down

with connector inserted into cavity.

Loop visible and screws tight.

8) Repeat steps 6 and 7 until the minimum meter

reading is equal to the reference level from step

2. Rotation of loops will change the cavity frequency slightly.

9) The Bandpass loop should be reinstalled with

the connector facing upward and the ground

point circle oriented toward the center of the

cavity as shown in Figure 16.

10) Remove the short circuit connector from the T-

Pass loop.

PROCEDURE FOR BANDPASS LOOP

1) Maintain the previous signal generator settings

and set the rotary attenuators for the proper setting as shown in table 3 for the Bandpass Loop.

2) Connect the test leads together through the

female union and adjust the range switch and

the zero set on the voltmeter for a reference

level (

A level of 2 on the 0 to 3 scale is conve-

nient

) on the meter. See figure 14. The generator output level may also be adjusted slightly if

convenient.

3) Set all three attenuators for 0 dB but leave them

in the circuit.

4) Connect a UG-107 Tee and the UG-57B/U to

the Bandpass loop as shown on figure 16. Then

connect the test leads as shown. Make sure the

short circuit connector has been removed from

the T-Pass loop.

5) Loosen the main tuning rod locking screw and

slowly slide tuning rod in or out to obtain a dip

(minimum voltage) in the meter reading which

indicates cavity resonance. Use the fine tuning

control to maximize the dip (the fine tuning rod

should not be full in or out which would indicate

that slight adjustment of the main tuning is necessary). Note the meter reading.

6) If the meter reading is greater or less than the

reference level from step 2, the bandpass loop

rotation will have to be adjusted. If the meter

reading is greater than the reference level, the

loop will have to be rotated so that the calibration mark on the loop, points to a slightly higher

number on the calibration index label. Conversely, if the meter reading is less than the ref

erence, the loop will have to be rotated so that

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 17

Page 24

Modulated

Signal Source RF Voltmeter

UG-28A/U

UG-57B/U

Bandpass

Loop

50 Ohm Adaptor

10 dB Pad 10 dB Pad

Figure 16: Setting the bandpass loop using step attenuators.

the index mark points to a slightly lower number

on the calibration index. Loosen the three loop

locking screws and rotate the loop so that the

index mark is moved to the next higher or lower

calibration tag number as needed and tighten

the 3 locking screws. Note that tight screws are

necessary for accuracy.

7) Repeat steps 5 and 6 until the minimum meter

reading is equal to the reference level from step

2. Rotation of loops will change the cavity frequency slightly.

0.1 dB/Div. 1.0 dB/Div. 10 dB/Div.

Rotary Attenuators

Set to Loop Reference Settings

Small Circle on Bandpass Loop indicates

ground end of loop and should be

oriented as shown.

Previously calibrated T-Pass Loop 3-1268

short circuit removed.

3) UG-914/U, BNC(F) to BNC(F) union.

TX RX Systems' part # 8-5805.

4) UG-28A/U, N(F), N(F), N(F) tee.

5) UG-57B/U, N(M)-N(M) coupling.

6) Two, UG-201A/U BNC(F)-N(M) adapter.

TX RX Systems' part # 8-5814.

7) 50 ohm coaxial cable test leads with BNC male

connectors (high quality cable).

8) Make sure that all the loop locking screws are

tight. The cavity loops are now set and the cavity should now be tuned to the desired frequency.

We have found it convenient to use test cables with

BNC connectors. They allow for a more convenient

connection to test equipment and small attenuator

pads. UG-201 BNC to N adapters are used when

connections to N connectors are needed.

Cavity Loss Setting Procedure 2

This procedure uses a spectrum analyzer and signal generator.

PROCEDURE FOR T-PASS LOOP

1) Remove the screws that hold in the bandpass

loop assembly; remove the assembly; invert it

REQUIRED TEST EQUIPMENT

1) Spectrum Analyzer and a signal generator.

and place it back into the cavity (see Figure

17). The coupling loop will be visible. Install and

tighten the three locking screws.

2) Two 10 dB fixed attenuator pads with BNC

connectors. JFW Industries model 50F-010.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 18

Page 25

UG-28A/U

n

UG-57B/U

T-Pass

Loop

Connector 3-1268

Spectrum Analyzer

Bird SignalHawk

Signal Generator

10 dB Pad10 dB Pad

Short Circuit

from top of rack

Bandpass Loop

turned upside dow

with connector

inserted into cavity.

Loop visible and

screws tight.

Figure 17: Setting a T-Pass loop for specific cavity insertion loss.

2) Connect the test leads to the spectrum analyzer; turn it on and let it warm up for at least 30

minutes.

3) Connect the 10 dB attenuator pads to the test

leads. They will remain connected for all subsequent measurements.

4) Note the Reference Notch Depth value for the

T-Pass loop assembly to be adjusted from table

3.

5) Set the spectrum analyzer for the frequency of

the channel of interest (within 1 MHz of actual

operating frequency).

6) If the Reference Notch Depth is 8 dB or less

then set the display for a vertical range of 2dB/

div otherwise set it for 10dB/div.

7) Temporarily connect the test leads from the

spectrum analyzer together through a UG-914

BNC union to set the zero reference.

8) Connect a UG-28 tee and a UG-57 coupling to

the T-Pass loop as shown in figure 17.

9) Connect the test leads from the spectrum analyzer to the tee connector as shown in figure 17.

10) Adjust the cavities main tuning rod so that a

rejection notch appears in the center of the display.

11) Loosen the three loop locking screws and

rotate the loop to obtain the reference notch

depth from step 4. Tighten the T-Pass loop

locking screws only. Note that the tightness of

the locking screws affects the depth of the

rejection notch slightly. It is usually necessary

to rotate the loop for a notch depth that is

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 19

Page 26

slightly less than the reference. The Notch

.

d

depth will tend to increase slightly as all three

locking screws are tightened.

5) If the Reference Notch Depth is 8 dB or less

then set the display for a vertical range of 2dB/

div otherwise set it for 10dB/div.

12) Remove the bandpass loop and place it back

into the cavity with the connector-end up.

PROCEDURE FOR BANDPASS LOOP

1) The Bandpass loop should be installed with the

connector up and the ground point circle oriented toward the center of the cavity as shown

in Figure 18.

2) Connect the test leads, with 10 dB pads

attached, to the spectrum analyzer; turn it on

and let it warm up for at least 30 minutes if this

has not been done.

3) Note the Reference Notch Depth value for the

Bandpass loop assembly to be adjusted from

table 3.

4) Set The spectrum analyzer for the frequency of

the channel of interest (within 5 MHz of actual

operating frequency).

UG-28A/U

6) Temporarily connect the test leads from the

spectrum analyzer together through a UG-914

BNC union to set the zero reference. Make sure

to use the 10 dB pads which should remain on

the test cables for all measurements.

7) Connect a UG-28 tee and a UG-57 coupling to

the bandpass loop as shown in figure 18.

8) Connect the test leads from the spectrum analyzer to the tee connector as shown in figure 18.

9) Adjust the cavities main tuning rod so that a

rejection notch appears in the center of the display.

10) Loosen the three loop locking screws and

rotate the loop assembly to obtain the reference notch depth from step 3. Note that the

tightness of the locking screws affects the

depth of the rejection notch slightly, it is usually

Signal Generator

UG-57B/U

Bandpass

Loop

Spectrum Analyzer

Bird SignalHawk

Figure 18: Setting a bandpass loop for specific cavity insertion loss.

10 dB Pad 10 dB Pad

Small Circle on

Bandpass Loop

indicates ground

end of loop and

should be oriente

as shown.

Previously calibrated

T-Pass Loop 3-1268

short circuit removed

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 20

Page 27

necessary to rotate the loop for a notch depth

that is slightly less than the reference. The

Notch depth will tend to increase slightly as all

three locking screws are tightened.

11) Tighten all loop locking screws. The cavity loss

is now set. The cavity will have to be tuned to

its operating frequency following the procedures outlined earlier in this manual.

MAINTENANCE

Because T-Pass transmit combiners are composed of passive components, they will continue to

operate without any maintenance for years and

there is no recommended maintenance period.

However, we do feel that it is wise to check combiner performance by measuring channel loss periodically and this may be done at any convenient

time along with other radio system maintenance.

ISOLATORS

Isolators perform two important functions. Their primary function is to keep unwanted RF frequencies

out of the transmitter so that intermodulation products cannot be generated. Isolators have a sub-

stantial amount of reverse isolation. They also

ensure that the transmitter never sees any significant reflected power so it will always operate with

maximum stability at full-power output. Isolators

prevent energy from getting into the transmitters

output by dumping any RF energy entering the output of the isolator into a dummy load. The model

73-67-11/25-XX-NN series of T-pass transmit combiners will use either single section or dual section

isolators at the input to each T-pass channel.

Single-section isolators have one load port. A properly sized load capable of dissipating the maximum

expected reflected power that might be encountered should be used. Dual section isolators have

two load ports, one for each section. Although

loads of equal power rating may be used for both

ports, it is customary to use an output load capable

of dissipating the maximum expected reflected

power that might be encountered. A small load (5

watts) is usually factory installed on the first section

of the isolator where high reflected power is not a

factor. Refer to Appendix A for a further discussion of isolators.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 21

Page 28

Appendix A

UHF Isolators (Compact Style)

GENERAL DESCRIPTION

Isolators perform two important functions. Their primary function is to keep other RF frequencies out

of the transmitter so that intermodulation products

cannot be generated. Isolators have a substantial

amount of reverse isolation. They also insure that

the transmitter never sees any significant reflected

power so it will always operate with maximum stability at full-power output. Isolators prevent energy

from getting into the transmitters output stage by

dumping reflected RF energy entering the output of

the isolator into a dummy load.

The UHF (compact style) isolators available from

TXRX Systems are broad-band and do not require

tuning. The isolators are available as either single

section or dual section models. Dual section models consist of two single sections mounted in the

same case with a load permanently attached to the

load port of the first section. Ta b l e A 1 lists the UHF

isolators available from TX RX Systems along with

their performance specifications.

INSTALLATION

The isolators can be mounted on most types of

surfaces but should not be physically located

where they will be exposed to moisture or very high

humidity. TXRX Systems isolators are well

shielded magnetically and may be mounted on

steel cabinets or panels.

The isolators can get quite hot

during operation. This can occur

when an antenna system component fails causing high reflected

power which is then dissipated by

the isolator load. These loads can

get hot enough to burn skin so

use caution when servicing these

systems.

VERIFYING ISOLATOR FUNCTIONALITY

If you suspect there may be a problem with an isolator you can verify the functionality of the device

by measuring its reverse isolation and insertion

loss. It is important to electrically remove the isolator from the system before testing. This is easily

accomplished by disconnecting the input and output cables.

WARNING: Do not make or break

cable connections to the isolator

while the circuit is under transmit

power. Shut down the transmitter

before servicing.

RECOMMENDED TEST EQUIPMENT

The following equipment or it’s equivalent is recommended when verifying isolator functionality.

1) Spectrum Analyzer. Bird Technologies Signal

Hawk.

2) A pair of double shielded coaxial cable test

leads (RG142 B/U or RG223/U).

3) 50 Ohm load with at least -35 dB return loss

(1.10 : 1) VSWR.

Measuring Reverse Isolation (S12)

The reverse isolation of your isolator can be verified by performing the following procedure in a

step-by-step fashion.

1) Make sure the transmitter associated with the

isolator is turned off.

2) Disconnect the input and output cable to the

isolator.

3) Connect a spectrum analyzer and tracking generator to the input and output ports of the isolator respectively, as shown in Figure A1.

4) Make sure that a 50 Ohm load is connected to

the load port of the isolator. If you are testing

the isolator on the bench make sure you connect a load. If you are testing the isolator while it

is still mounted on the system rack/cabinet

leave the existing load connected.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 22

Page 29

5) Inject a test signal (-10 dBm) from the tracking

generator into the output port of the isolator.

The test signal should sweep across the operating bandwidth of the isolator.

Measuring Insertion Loss (S21)

The insertion loss of your isolator can be verified

by performing the following procedure in a step-bystep fashion.

6) Compare your displayed waveform against the

example shown in Figure A3 as well as the

specification listed in table A1.

Spectrum Analyzer

Bird SignalHawk

Tracking Generator

1) Make sure the transmitter associated with the

isolator is turned off.

Spectrum Analyzer

Bird SignalHawk

Tracking Generator

50 Ω Load

Figure A1: Verifying Reverse Isolation.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 23

Figure A2: Verifying Insertion Loss.

50 Ω Load

Page 30

2) Disconnect the input and output cable to the

isolator.

3) Connect a tracking generator and spectrum

analyzer to the input and output ports of the isolator respectively, as shown in Figure A2.

4) Make sure that a 50 Ohm load is connected to

the load port of the isolator. If you are testing

the isolator on the bench make sure you connect a load. If you are testing the isolator while it

is still mounted on the system rack/cabinet

leave the existing load connected.

5) Inject a test signal into the input of the isolator

from the tracking generator which will sweep

across the operating bandwidth of the isolator.

The strength of the test signal should be -10

dBm.

6) Compare your displayed waveform against the

example shown in Figure A4 and the specification listed in table A1.

Figure A3: Typical reverse isolation waveform.

Figure A4: Typical insertion loss waveform.

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 24

Page 31

TXRX

Systems

Part #

3-8195P 295 - 400 18 0.60

3-23018P 390 - 420 25 0.25

3-23269P 380 - 400 25 0.25

3-8191P 406 - 430 25 0.35

3-22401P 430 - 450 25 0.35

3-8192P 450 - 470 25 0.35

3-8193P 470 - 490 25 0.35

3-8194P 490 - 512 25 0.35

3-8195-1P 510 - 530 25 0.35

3-8195PA 295 - 400 18 0.50

3-8191PA 406 - 430 25 0.25

3-22401PA 430 - 450 25 0.25

3-8192PA 450 - 470 25 0.25

3-8193PA 470 - 490 25 0.25

3-8194PA 490 - 512 25 0.25

3-8195-1PA 510 - 530 25 0.25

3-8195PB 295 - 400 18 0.60

3-8191PB 406 - 430 25 0.35

3-22401PB 430 - 450 25 0.35

3-8192PB 450 - 470 25 0.35

3-8193PB 470 - 490 25 0.35

3-8194PB 490 - 512 25 0.35

3-8195-1PB 510 - 530 25 0.35

3-20721P 300 - 350 46 0.44

3-10010P 350 - 400 46 0.44

3-23425P 380 - 400 50 0.44

3-8196P 406 - 430 50 0.44

3-8201P 430 - 450 50 0.44

3-8197P 450 - 470 50 0.44

3-8198P 470 - 490 50 0.44

3-8199P 490 - 512 50 0.44

3-8200P 512 - 530 50 0.44

Freq

Range

(MHz)

Isolation

(dB) (min)

Insertion

Loss

(dB) (max)

TXRX

Systems

Part #

3-20721PL 300 - 350 23 0.22

3-10010PL 350 - 400 23 0.22

3-23425PL 380 - 400 25 0.22

3-8196PL 406 - 430 25 0.22

3-8201PL 430 - 450 25 0.22

3-8197PL 450 - 470 25 0.22

3-8198PL 470 - 490 25 0.22

3-8199PL 490 - 512 25 0.22

3-8200PL 512 - 530 25 0.22

3-20721PLA 300 - 350 23 0.22

3-10010PLA 350 - 400 23 0.22

3-8196PLA 406 - 430 25 0.22

3-8201PLA 430 - 450 25 0.22

3-8197PLA 450 - 470 25 0.22

3-8198PLA 470 - 490 25 0.22

3-8199PLA 490 - 512 25 0.22

3-8200PLA 512 - 530 25 0.22

3-20721PLB 300 - 350 23 0.22

3-10010PLB 350 - 400 23 0.22

3-8196PLB 406 - 430 25 0.22

3-8201PLB 430 - 450 25 0.22

3-8197PLB 450 - 470 25 0.22

3-8198PLB 470 - 490 25 0.22

3-8199PLB 490 - 512 25 0.22

3-8200PLB 512 - 530 25 0.22

3-20721PLC 300 - 350 46 0.44

3-10010PLC 350 - 400 46 0.44

3-8196PLC 406 - 430 50 0.44

3-8201PLC 430 - 450 50 0.44

3-8197PLC 450 - 470 50 0.44

3-8198PLC 470 - 490 50 0.44

3-8199PLC 490 - 512 50 0.44

Freq

Range

(MHz)

Isolation

(dB) (min)

Insertion

Loss

(dB) (max)

3-8200PLC 512 - 530 50 0.44

Tabl e A 1: Specification for UHF Isolators (Compact Style).

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 25

Page 32

TX RX Systems Inc. Manual 7-9120-5 07/26/10 Page 26

8625 Industrial Parkway, Angola, NY 14006 Tel: 716-549-4700 Fax: 716-549-4772 sales@birdrf.com www.bird-technologies.com

Loading...

Loading...