Page 1

Part No

.

YOU'RE HEARD, LOUD AND CLEAR.

Installation and Operation Manual

for the Two-Way Signal Booster System

Model Number 61-89A-50-XXX-XX

Copyright © 2005 TX RX Systems Inc.

First Printing: March 2004

7-9362-2

Version Number Version Date

1 03/30/04

1.2 04/15/04

2 10/19/05

8625 Industrial Parkway, Angola, NY 14006 Tel: 716-549-4700 Fax: 716-549-4772 sales@birdrf.com www.bird-technologies.com

Page 2

Warranty

This warranty applies for one year from shipping date.

TX RX Systems Inc. warrants its products to be free from defect in material and workman-

ship at the time of shipment. Our obligation under warranty is limited to replacement or

repair, at our option, of any such products that shall have been defective at the time of

manufacture.

TX RX Systems Inc. reserves the right to replace with merchandise of equal performance

although not identical in every way to that originally sold.

TX RX Systems Inc. is not liable for damage caused by lightning or other natural disasters.

No product will be accepted for repair or replacement without our prior written approval.

The purchaser must prepay all shipping charges on returned products. TX RX Systems

Inc. shall in no event be liable for consequential damages, installation costs or expense of

any nature resulting from the purchase or use of products, whether or not they are used in

accordance with instructions. This warranty is in lieu of all other warranties, either expressed or implied, including any implied warranty or merchantability of fitness. No representative is authorized to assume for TX RX Systems Inc. any other liability or warranty

than set forth above in connection with our products or services.

Terms and Conditions of Sale

Symbols

Commonly Used

WARNING

CAUTION or

ATTENTION

High Voltage

PRICES AND TERMS: Prices are FOB seller’s plant in Angola, NY domestic packaging

only, and are subject to change without notice. Federal, State and local sales or excise

taxes are not included in prices. When Net 30 terms are applicable, payment is due

within 30 days of invoice date. All orders are subject to a $100.00 net minimum.

QUOTATIONS: Only written quotations are valid.

ACCEPTANCE OF ORDERS: Acceptance of orders is valid only when so acknowledged

in writing by the seller.

SHIPPING: Unless otherwise agreed at the time the order is placed, seller reserves the

right to make partial shipments for which payment shall be made in accordance with

seller’s stated terms. Shipments are made with transportation charges collect unless

otherwise specified by the buyer. Seller’s best judgement will be used in routing, except

that buyer’s routing is used where practicable. The seller is not responsible for selection

of most economical or timeliest routing.

CLAIMS: All claims for damage or loss in transit must be made promptly by the buyer

against the carrier. All claims for shortages must be made within 30 days after date of

shipment of material from the seller’s plant.

SPECIFICATION CHANGES OR MODIFICATIONS: All designs and specifications of

seller’s products are subject to change without notice provided the changes or modifications do not affect performance.

RETURN MATERIAL: Product or material may be returned for credit only after written

authorization from the seller, as to which seller shall have sole discretion. In the event

of such authorization, credit given shall not exceed 80 percent of the original purchase.

In no case will Seller authorize return of material more than 90 days after shipment from

Seller’s plant. Credit for returned material is issued by the Seller only to the original

purchaser.

ORDER CANCELLATION OR ALTERATION: Cancellation or alteration of acknowledged

orders by the buyer will be accepted only on terms that protect the seller against loss.

NON WARRANTY REPAIRS AND RETURN WORK: Consult seller’s plant for pricing.

Buyer must prepay all transportation charges to seller’s plant. Standard shipping policy

set forth above shall apply with respect to return shipment from TX RX Systems Inc. to

buyer.

NOTE

Use Safety

Glasses

ESD

Electrostatic

Discharge

Hot Surface

Electrical Shock

Hazard

Important

Information

Disclaimer

Product part numbering in photographs and drawings is accurate at time of printing.

Part number labels on TX RX products supercede part numbers given within this manual.

Information is subject to change without notice.

Page 3

WARNING

For Class A Unintentional Radiators

WARNING

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Changes or modifications not expressly approved by TX

RX System Inc. could void the user’s authority to operate

the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference and

(2) this device must accept any interference received, including interference

that may cause undesired operation.

To satisfy FCC RF exposure requirements for mobile transmitting devices, a separation distance of 1.0 Meters or more

should be maintained between the UPLINK antenna of this

device and persons during device operation. To satisfy FCC

RF exposure requirements for mobile transmitting devices, a

separation distance of 0.2 Meters or more should be maintained between the DOWNLINK antenna of this device and

persons during device operation. To ensure compliance,

operations at closer than these distances is not recommended.

The antenna used for this transmitter must not be co-located

in conjunction with any other antenna or transmitter.

Page 4

Antenna System Installation

The antenna or signal distribution system consists of two branches. An uplink

branch typically uses an outdoor mounted, unidirectional gain antenna such

as a yagi and a downlink signal radiating system consisting of a network of

zero-gain whip antennas or lengths of radiating cable usually mounted inside

of the structure.

Even though the antenna system may not be supplied or installed by TX RX

Systems. The following points need to be observed because both the safety

of the user and proper system performance depend on them.

1) Antenna system installation should only be performed by qualified technical personnel.

2) The following instructions for your safety describe antenna installation

guidelines based on FCC Maximum RF Exposure Compliance requirements.

3) The uplink antenna is usually mounted outside and exchanges signals

with the repeater base station or donor site. It is typically mounted permanently-attached to the building wall or roof. The gain of this antenna should

NOT exceed 10 dB. Only qualified personnel should have access to the

antenna and under normal operating conditions, no one should be able to

touch or approach it within 1 meter (40 inches).

4) The downlink or in-building signal distribution system is connected to the

downlink booster port using coaxial cable. The distribution system may

use radiating coaxial cable or a network 1/4 wave whip antennas whose

gain does not exceed 0 dB for any radiator. These antennas should be

installed so that the user cannot approach any closer than 0.2 meters (8

inches) from the antenna.

Page 5

Table of Contents

General Description .............................................................................................. 1

Unpacking .......................................................................................................1

Installation .......................................................................................................1

Location .......................................................................................................1

Mounting .......................................................................................................2

Connections .......................................................................................................4

AC Line .......................................................................................................4

Backup DC Power.................................................................................................. 4

Alarm Terminals (Form-C Contacts) ...................................................................... 4

RF Connections ..................................................................................................... 5

Pre-RF Connection Tests......................................................................................5

Test Equipment ...................................................................................................... 5

Antenna Isolation ................................................................................................... 5

Procedure for Measuring Antenna Isolation .......................................................... 5

Increase isolation or decrease gain?..................................................................... 6

Normal Operation .................................................................................................. 6

LED Status Indicators ............................................................................................ 7

Front Panel LED’s ................................................................................................ 7

Module LED’s ...................................................................................................... 7

OLC Light Bars .................................................................................................... 7

Front Panel Controls & the LCD Display................................................................7

LCD Screen ....................................................................................................... 7

Configuration Settings ........................................................................................... 9

Restore Original Configuration ........................................................................... 9

Calibrate Currents .............................................................................................. 9

Set Gain .......................................................................................................9

Set Output Level ................................................................................................. 9

Change Gain Configuration ................................................................................9

Detailed Status Screens ........................................................................................ 10

Amplifiers .......................................................................................................10

Power Supply...................................................................................................... 10

OLC .......................................................................................................10

OLC Datalog ....................................................................................................... 10

Alarms .......................................................................................................10

LED Indicators ....................................................................................................... 10

Form-C contacts .................................................................................................... 11

Performance Survey..............................................................................................11

Maintenance and Repair ....................................................................................... 12

Power Amplifier Replacement................................................................................ 14

Module Replacement.............................................................................................14

Display/User Interface Replacement .....................................................................15

Power Supply Replacement................................................................................... 16

Duplexer / Filter Replacement ...............................................................................16

Card Cage Replacement ....................................................................................... 16

Recommended Spares .......................................................................................... 16

Table of Contents

Manual 7-9362-2 10/19/05

Page 6

Figures and Tables

Figure 1 Cabinet mounting hole layout 2

Figure 2 Front internal cabinet view 3

Figure 3 AC power entry 4

Figure 4 Measuring antenna isolation 6

Figure 5 Boot-up display 6

Figure 6 Operational status display 7

Figure 7 Menu System 8

Figure 8 Measuring Booster Gain 11

Figure 9 Performance Survey 12

Figure 10 Removing the Power Amplifier (1 of 3) 13

Figure 11 Removing the Power Amplifier (2 of 3) 13

Figure 12 Removing the Power Amplifier (3 of 3) 14

Figure 13 Disconnecting Display/User Interface 15

Table 1 Model Number Designations 1

Specifications 17

Block Diagram High Gain (1 of 4) 18

Block Diagram Med Gain (2 of 4) 19

Block Diagram Low Gain (3 of 4) 20

Block Diagram (4 of 4) 21

Celsius to Fahrenheit Conversions 22

Table of Contents

Manual 7-9362-2 10/19/05

Page 7

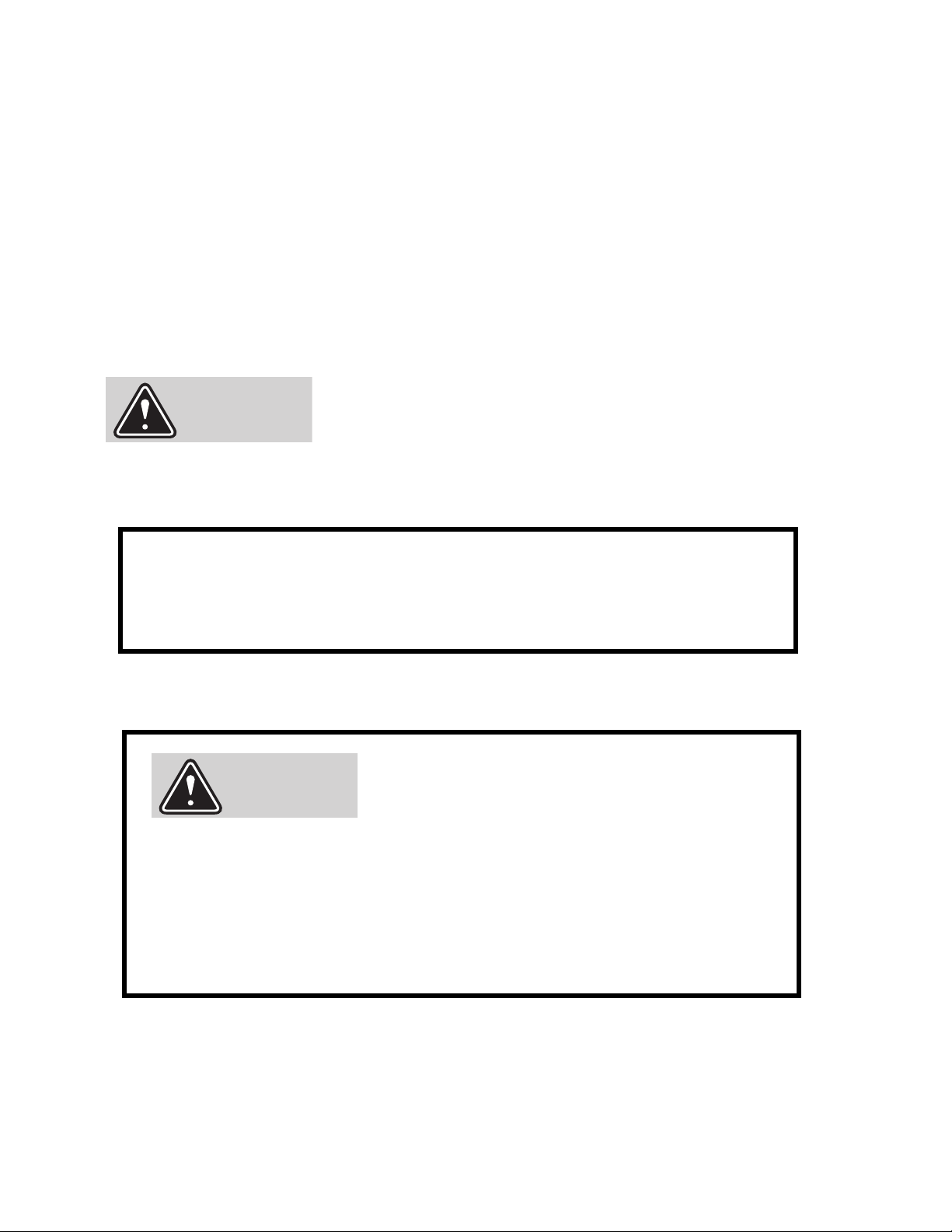

GENERAL DESCRIPTION

61 - 89A - 50 - A18 - G1

(Example)

FAMILY FREQUENCY

BAND

MODEL COARSE

GAIN

BANDWIDTH ENCLOSURE

TYPE

60 =

61 =

612 =

1 Way

2 Way

2 Way

w/Fiber

Interface

89A = 806 - 824

851 - 869

50 = Signal

Booster II

A =

B =

C =

80 dB

60 dB

45 dB

18 = 18 MHz

15 = 15 MHz

10 = 10 MHz

05 = 5 MHz

03 = 3 MHz (NPSPAC)

G1 =

G2 =

RM =

Painted, Nema4

Stainless, Nema4X

Rack Mount

Table 1: Model number designations. Model 61-89A-50-A18-G1 shown as example.

*

*

Note: Gain of 80 dB model set to 50 dB at factory. Please measure antenna isolation before resetting.

GAI

GAIN

Signal boosters extend radio coverage into areas

where abrupt propagation losses prevent reliable

communication. No frequency translation (conversion) occurs with this device. Signal Booster II (SB

II) is a broadband, bi-directional signal booster

available in a variety of configurations as shown in

Table 1. The product model number is used to

describe each configuration available. This manual

details the installation and operation of the 61-89A50-XXX-XX series of boosters.

The system can be ordered in one of three maximum gain configurations including Full Gain (+80

dB gain max), Medium Gain (+60 dB gain max),

and Low Gain (+45 dB max gain). The maximum

gain of the system is determined by the exact type

of cards plugged into the low and mid level slots as

shown in the block diagrams at the back of this

manual. The maximum gain of the uplink or downlink branch is adjustable and can be setup independently. In addition, the gain of each branch can

be reduced up to 30 dB in 0.5 dB increments via

software interface.

The bandwidth of the system is determined by the

passband of the input/output filtering. The filters

passband is determined by its physical construction so must be determined at the time of order. As

shown in table 1 the system may be ordered in any

of five different bandwidths including 18, 15, 10, 5,

and 3 MHz.

Three cabinet styles are available. The G1 suffix

denotes a NEMA-4 style cabinet which is suitable

for indoor or outdoor use. The G2 suffix denotes a

stainless steel NEMA-4X style cabinet suitable for

corrosive environments such as salt air and the RM

suffix a rack mount version which is intended for

indoor mounting only.

UNPACKING

It is important to report any visible damage to the

carrier immediately. It is the customer's responsibility to file damage claims with the carrier within a

short period of time after delivery (1 to 5 days).

Care should be taken when removing the unit from

the packing box to avoid damage to external heatsink fins. Use caution because the heatsink fins

can have somewhat sharp corners. Signal Booster

II (SB II) weighs about 85 lbs. so use enough people when lifting the unit.

INSTALLATION

The following sections discuss general considerations for installing the booster. All work should be

performed by qualified personal in accordance with

local codes.

Location

The layout of the signal distribution system will be

the prime factor in determining the mounting location of Signal Booster II. However, safety and serviceability are also key considerations. The unit

should be located where it cannot be tampered

with by the general public, yet is easily accessible

to service personnel. Also consider the weight of

Manual 7-9362-2 Page 1TX RX Systems Inc. 10/19/05

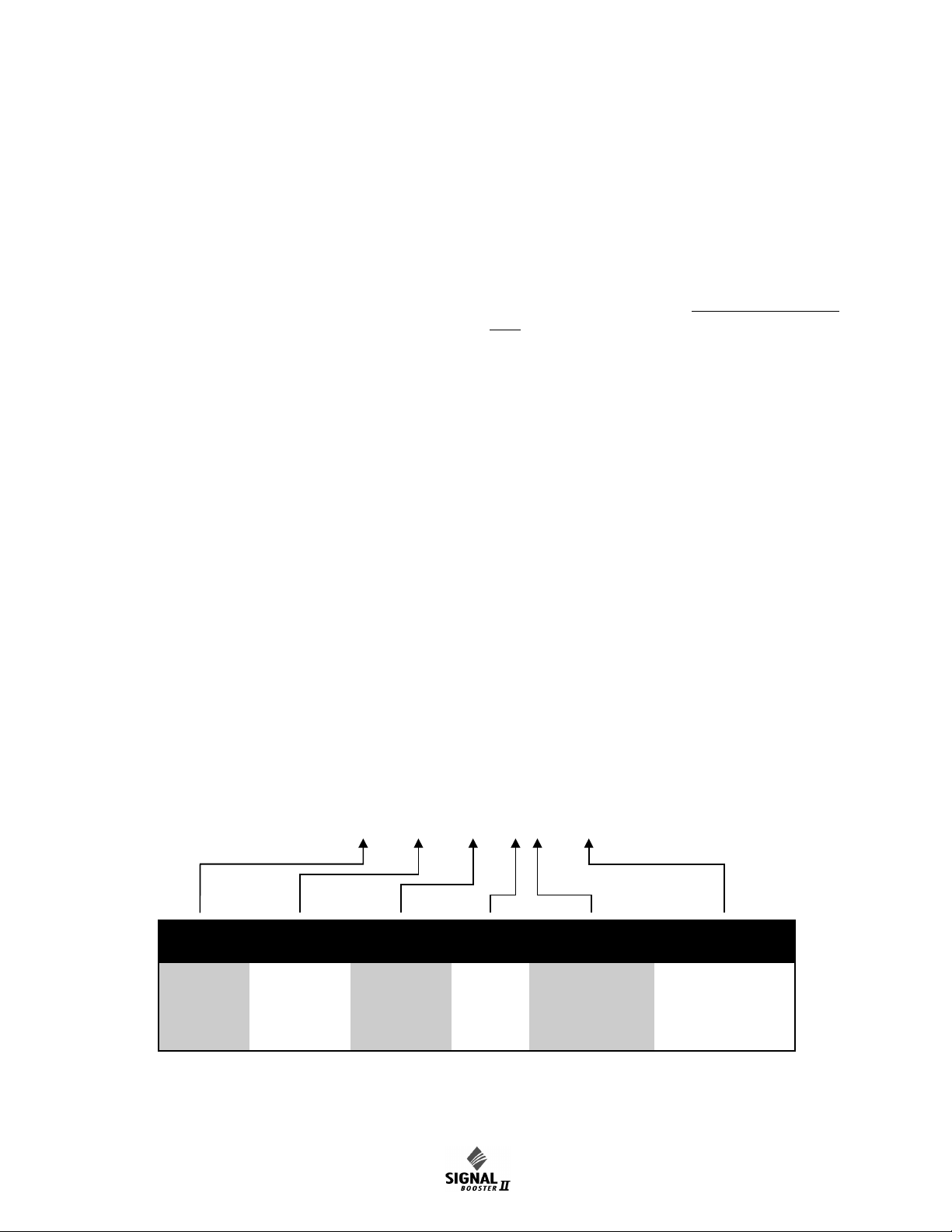

Page 8

the unit and the possibility for injur y if the unit

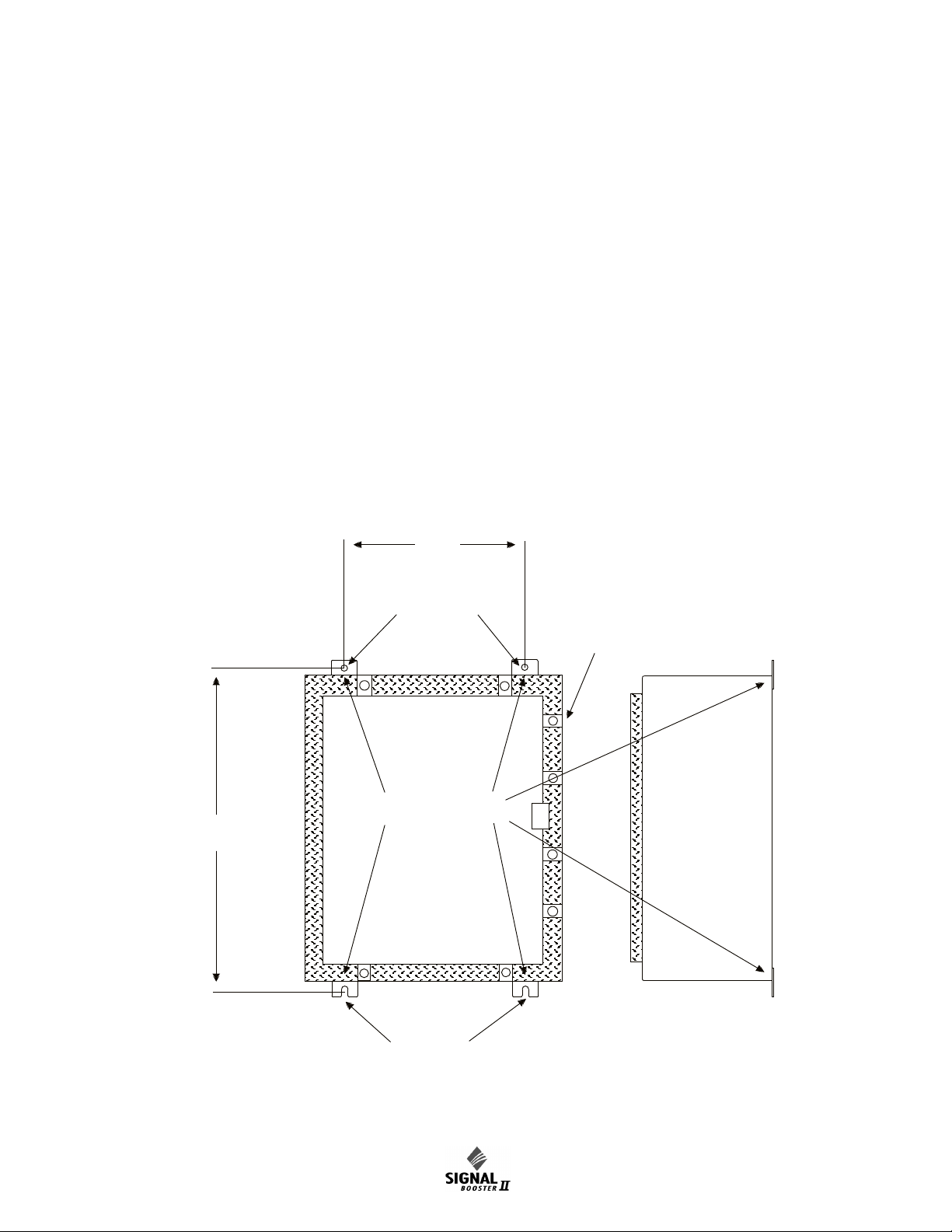

MOUNTING TA BS

DOOR

CLAMPS

0.438" DIA.

(12mm)

0.438" DIA.

(12mm)

SIDE VIEW

18"

(457mm)

25.25"

(641mm)

Figure 1: SB II cabinet mounting hole layout.

should become detached from its mounting surfaces for any reason.

Although signal boosters can operate for years

without being attended to, the unit will need to be

accessed by service personnel with troubleshooting equipment, such as digital multimeters and

spectrum analyzer or a laptop computer from time

to time. The location of the power source will also

have a bearing on the mounting location. SB II

uses external heat sinks and needs to be mounted

where there can be an unobstructed air flow over

the heat sinks fins. The SB II cabinet will stay warm

during normal operation so in the interest of equipme nt lon gevity, avoid locatio ns tha t carr y ho t

exhaust air or are continually hot.

Mounting

Figure 1 shows mounting hole dimensions and

layout for the cabinet. Mount the cabinet using 3/8”

(10 mm) diameter steel bolts (not supplied). We

recommend flat washers on both ends and a lock

washer under the nut. Nut and bolt mounting is

preferred to the use of lag bolts. Use backer blocks

where necessary to spread the force over a larger

surface area. In areas of known seismic activity,

additional devices such as tether lines may be necessary.

Because TX RX Systems, Inc. cannot anticipate all

the possible mounting locations and struc ture

types where these devices will be located, we recommend consulting local building inspectors, engineering consultants or architects for advice on how

to properly mount objects of this type, size and

weight in your particular situation.

Manual 7-9362-2 Page 2TX RX Systems Inc. 10/19/05

Page 9

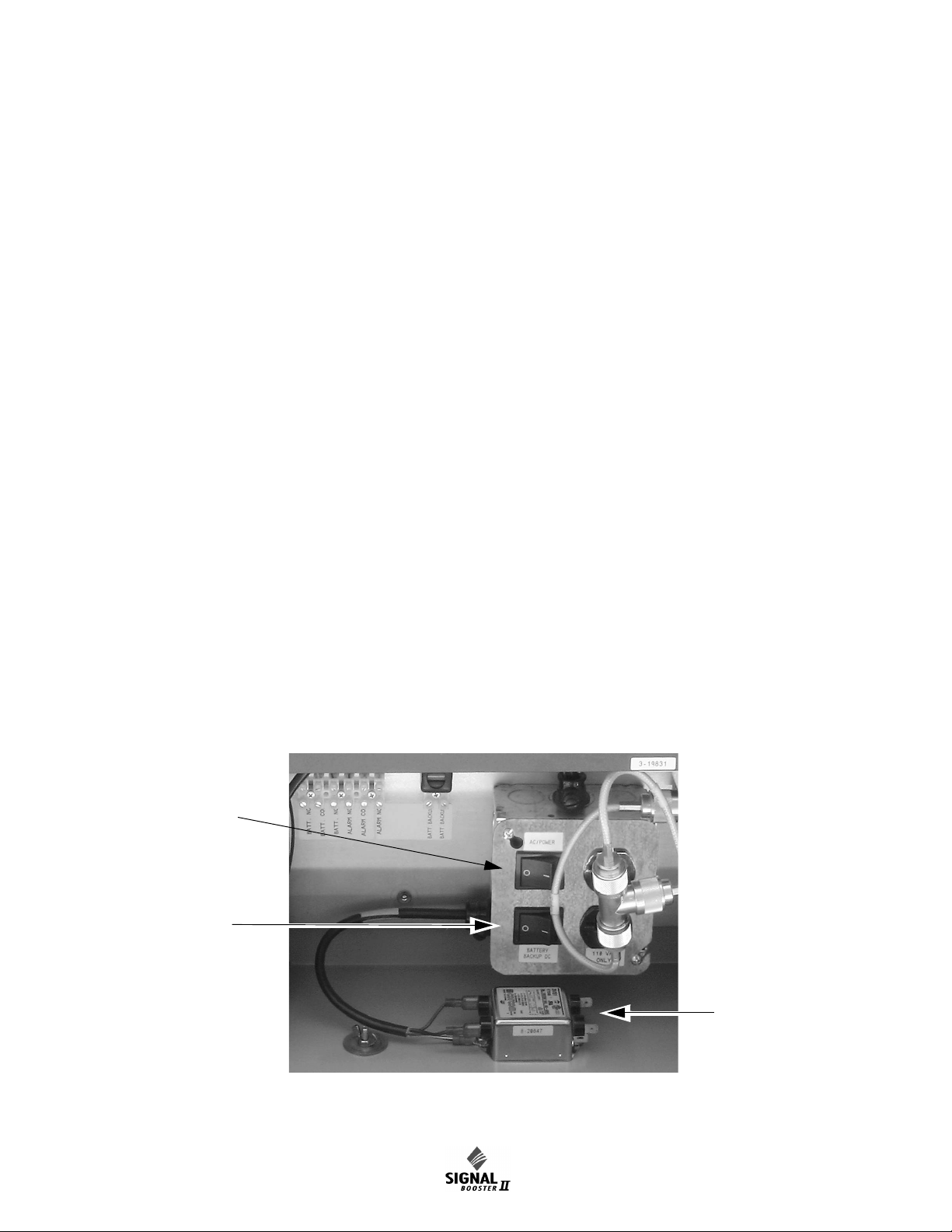

Power Supply

AC Power

Switch

Battery

Backup

Switch

Form-C

Contacts

Connect Backup

Battery here

Uplink

Power

Duplexer

Downlink Power

Amplifier

Duplexer

Menu

Select

Buttons

Uplink M/L Card

(for Full Gain Model)

Uplink M/L Card

(for Mid Gain Model)

Uplink Low Gain Card

(for Low Gain Model)

Uplink L/L Card

(for Full Gain Model)

Attenuator Card

(for Mid Gain Model)

Attenuator Card

(for Low Gain Model)

Uplink

Power

Distribution

Downlink M/L Card

(for Full Gain Model)

Downlink M/L Card

(for Mid Gain Model)

Downlink Low Gain Card

(for Low Gain System)

Downlink L/L Card

(for Full Gain Model)

Attenuator Card

(for Mid Gain Model)

Attenuator Card

(for Low Gain Model)

Downlink

Power

Distribution

Controller

Downlink In

Uplink Out

to Donor

Antenna

Uplink Out

Downlink In

to In-building

Distribution

AC Power

Entry

Comm-Card

(Optional)

Spare

(unused slot)

OLC Light

Bars

Status LEDs

Isolator

Test Port

Isolator

Test Port

Figure 2: Front view of SB II. Model 61-89A-50-A18-G1 two-way signal booster shown as an example.

Manual 7-9362-2 Page 3TX RX Systems Inc. 10/19/05

Page 10

It is the customer’s responsibility to make sure

Figure 3: Wiring of AC line entry.

Connect

incoming AC

here

AC Power

Switch

Battery

Backup

Switch

these devices are mounted safely and in compliance with local building codes.

CONNECTIONS

All cabling connections to the booster should be

made and checked for correctness prior to powering up the system.

AC Line

Signal Booster II is designed to be hard-wired to

110 single phase AC lines at 50 - 60 Hz (see Fig-

ures 2 and 3). An AC line filter is provided for this

purpose. There is a hole provided in the cabinet

bottom-wall for bringing in the AC line. Fasten

quick connect plugs to the incoming AC line, then

connect the ground wire, neutral wire, and hot wire

to the respective pins on the top of the AC line filter. Refer to the photo shown in Figure 3 below.

The output of the AC line filter is wired into the

switch box which also contains a dual convenience

outlet for running test equipment. Use conduit for

running the wiring into SB II and #14 gauge or

larger conductors.

Backup DC Power

SB II may be run on a DC power source that can

supply 24 to 27 volts DC at 2.5 amps. Screw terminals are provided for this purpose (see figure 2).

This line should be equipped with a fast-acting 3

Amp fuse. Use #16 or #18 gauge wire for this connection.

The power system in SB II automatically switches

to this backup DC input when the AC supply fails

for any reason including a power outage or intentional disconnection.

It is not necessary that this connection be made for

normal operation on the AC line.

Alarm Terminals (Form-C contacts)

Two sets of contacts are provided to monitor the

gen e ral operat i n g c ondition of SB II and are

intended for connection to a supervisory system.

See figure 2.

One set changes state when the AC power supply

shuts down for any reason and the unit switches to

operation on the backup DC power system.

The other set of contacts changes state when any

of a number of fault conditions arises within the

electronics such as current drain outside of the

expected operating range in some module.

A six-terminal strip is provided for the interface and

uses screw terminals for ease of connection. Route

the alarm wires through one of the access holes in

the bottom of the box, strip about 3/16” of insulation from each end, loosen the screw terminal,

insert and retighten. Use #20 or #22 gauge insulated wire.

Manual 7-9362-2 Page 4TX RX Systems Inc. 10/19/05

Page 11

Use of these terminals is optional. SB II also has a

NOTE

number of status LEDs built-in to individual modules to indicate a fault condition.

RF Connections

N(F) bulkhead connectors are provided on the bottom of the cabinet for connection to the signal distribution system. Be sure that the correct branch of

the distribution system is connected to its corresponding Uplink/Downlink connector or the system

will not work properly. Using high-quality connectors with gold center pin s is a dvised. Flexible

jumper cables made of high-quality coax are also

acceptable for connecting to rigid cable sections.

CAUTION: The maximum RF input

power level for the SBII is -15 dBm.

Stronger input signals will cause the

unit to exceed it’s IM specifications.

Input signals stronger than 0 dBm

will physically damage the unit.

Antenna Isolation

Just like the feedback squeal that can occur when

the microphone and speaker get too close to each

other in a public address system, a signal booster

can start to self oscillate. This can occur when the

is olation b etween th e inp ut antenn a or signal

source and the output distribution system does not

exceed the signal boosters gain by at least 15 dB.

Oscillation will reduce the effectiveness of the system and may possibly damage the power amplifier

stages.

In general, if one or both antenna ports are connected to sections of radiating coaxial cable (lossy

cable) the isolation will be more than adequate

because of the high coupling loss values that are

encountered with this type of cable. When a network of antennas are used for the input and output,

this problem is much more likely. Isolation values

are relatively easy to measure with a spectrum

analyzer and signal generator.

PRE-RF CONNECTION TESTS

Antenna isolation between the uplink and downlink

branches should be measured before connecting

the signal booster to the antenna system. This step

is necessary to insure that no conditions exist that

could possibly damage the signal booster and

should not be skipped for even the most thoroughly

designed system.

Note: The 80 dB gain models are factory preset to 50 dB gain and should

only be reset to a higher value after

determining the safe maximum gain

based on antenna isolation

Test Equipment

The following equipment is required in order to perform the pre-installation measurements.

1) Signal generator for the frequencies of interest

capable of a 0 dBm output level. Modulation is

not necessary.

2) Spectrum analyzer that covers the frequencies

of interest and is capable of observing signal

levels down to -100 dBm or better.

3) Double shielded coaxial test cables made from

RG142, RG55 or RG223 coaxial cable.

Procedure for Measuring Antenna Isolation

1) Set the signal generator for a 0 dBm output

level at the center frequency of one of the signal

boosters passbands (815 or 860 MHz)

2) Set the spectrum analyzer for the same center

frequency and a sweep width equal to or just

slightly greater than the passband (18 MHz)

chosen in step one.

3) Connect the test leads of the signal generator

and the spectrum analyzer together using a

female barrel connector, see Figure 4. Observe

the signal on the analyzer and adjust the input

attenuator of the spectrum analyzer for a signal

level that just reaches the 0 dBm level at the top

of the graticule.

4) Referring to figure 4, connect the generator test

lead to one side of the signal distribution system

(external antenna) and the spectrum analyzer

lead to the other (internal distribution system)

and observe the signal level. The difference

between this observed level and 0 dBm is the

isolation between the sections. If the signal is

too weak to observe, the spectrum analyzer's

bandwidth may have to be narrowed and its

input attenuation reduced. Record the isolation

value. The isolation value measured should

exceed the signal booster’s gain figure by at

least 15 dB.

Manual 7-9362-2 Page 5TX RX Systems Inc. 10/19/05

Page 12

It is wise to repeat the procedure listed above for

INTERNAL

SIGNAL DISTRIBUTION

SYSTEM

SPECTRUM

ANALYZER

EXTERNAL

ANTENNA

SIGNAL

GENERATOR

ZERO LOSS

REFERENCE

ISOLATION (dB)

Figure 4: Typical test equipment interconnection for measuring antenna isolation.

Figure 5: Software version is displayed briefly

during the boot-up sequence.

measuring antenna isolation with the signal generator set to frequencies at the passbands edges in

order to see if the isolation is remaining relatively

constant over the complete width of the passband.

determined in step 1. A detailed explanation of

how to negotiate the menu system is given on

page 8.

3) Repeat step 2 for the downlink path.

Repeat the isolation measurements at the other

passband in bi-directional systems and use the

lesser of the two values to determine the maximum

gain setting.

Increase Isolation or decrease gain?

Modification of the signal distribution system is

required to increase isolation between the up and

downlink path. This will require significant changes

that may or may not be practical from a cost or

logistical standpoint. Gain reduction may be the

only alternative but this is easy to achieve with Signal Booster II. Gain for both the uplink and downlink path can be set from 50 to 80 dB. Here are the

steps to follow.

1) Subtract 15 dB from the measured isolation

between uplink and downlink branches of the

antenna/signal distribution system. This is the

maximum usable gain level for both the uplink

and downlink path.

2) Accessing the user menu through the front

panel, set the gain of the uplink path to the level

NORMAL OPERATION

Power is applied to the signal booster by turning on

the AC power switch located on the junction box

inside the cabinet, refer to figure 2. The following

startup sequence occurs.

1) At turn-on, the four status LEDs on the front

panel glow red for about 5 seconds as the result

of entering a self-check mode.

Manual 7-9362-2 Page 6TX RX Systems Inc. 10/19/05

Page 13

2) The two green OLC light bars will be fully lit

WARNING

Figure 6: Normal Operational LCD Display.

along their length for approximately 5 seconds.

12V: Green indicates the 12 volt DC power system

is operating properly.

3) The LCD display shows the firmware revision

screen for about 5 seconds (see Figure 5).

4) After the self check is complete, the four status

lights should turn green and the light bars

should be dark unless a signal is activating OLC

action in either the uplink or downlink.

If the OLC light-bar segments on both the Uplink

and Downlink display light-up and pulse on and off

every 1 to 3 seconds simultaneously, SHUT OFF

THE POWER IMMEDIATELY! The booster may

be oscillating. Disconnect the uplink and downlink

antenna connections and measure the isolation

between the two branches to insure there is sufficient isolation. Reset the booster gain as needed.

5) The LCD display should appear similar to Fig-

ure 6 after the self check is complete.

LED Status indicators

The SB II front panel has 4 status LEDs that glow

green or red to indicate the general health of 4 sub-

UL PA: Gre en indicates that the uplink power

amplifier is drawing current within the expected

operating range and at a safe temperature.

DL PA: Green indicates that the downlink power

amplifier is drawing current within the expected

operating range and at a safe temperature.

Module LEDS;

Mid-Level, Low-Level, Low Gain Module: Green

indicates current or device temperature within the

expected operating range. Orange indicates current or temperature slightly out of the expected

range but the overall booster operation may still

appear normal. Red indicates a large departure

from normal current or device temperature and

booster operation is likely to be affected. See page

9 for more details about alarm operation.

Attenuator Module: Green only indicating DC

power is applied to the card.

OLC LIGHT BARS

Ideally, there should be little or no light bar activity.

Each light bar segment represents an average 3

dB of OLC gain reduction. OLC (output level control) is meant to reduce gain for transient episodes

of very strong signals. However, when OLC is

active, gain is reduced for all signals being processed by that booster branch and that reduction

may compromise communications for weaker signals in the booster’s passband.

systems from a DC perspective. Additionally, the

plug-in, Low-Level and Mid-Level amplifier cards

have tri-color (green-orange-red) status LEDs visible when the cabinet door is open.

FRONT PANEL LEDS:

24V: Green indicates the 24 volt DC Power system

is operating properly.

If more than 2 or 3 light-bar segments are lit up

more than occasionally, it is advised that the gain

of that branch be reduced. See the SET GAIN

paragraph on page 9 for details.

Front Panel Controls & the LCD Display

SB II is software directed so control of the system

is accomplished via user interface with the control

panel using the LCD display screen and the menu

select buttons, see figure 2. A flow chart showing

all of the possible user menu selections is shown in

Figure 7.

LCD Screen

Once the boot-up sequence is completed (after

several seconds) the LCD screen will switch to the

main status display as shown in figure 6. This is the

normal display for the signal booster. The system

Manual 7-9362-2 Page 7TX RX Systems Inc. 10/19/05

Page 14

GAIN

## dB

## dB

OUT LVL

## dBm

## dBm

UL:

DL:

SBII Status OK

Calibrate Currents

Set Gain

Set Output Level

Change Gain Config

Restore Orig Config

Uplink Low Level Amp

Uplink Mid Level Amp

Uplink Power Amp

Downlink Low Amp

Downlink Mid Amp

Downlink Power Amp

Power Supply

Current OLC Status

OLC Historical Info

OLC Historical Info

Avg

# dB

# %

Day

# dB

# %

UL

Current OLC Status

Uplink

# dB

# %

Downlink

# dB

# %

Name of Amp

Current # Temp #

Amp Status Message

Power Supply Status

24v ### 12v ###

Set Desired Gain

Uplink

## dB

Downlink

## dB

Done

Save Changes?

Yes No

Uplink

## dBm

Downlink

## dBm

Done

Set Output Levels

UL >

DL >

_ _ _ _ Gain ## dB

_ _ _ _ Gain ## dB

Done

Change Gain Config

Are you sure

you want to restore

the Factory Presets?

Yes No

Press Enter to

Calibrate Currents

Calibrating . . .

Done Calibrating

Press Enter to Save

Press ENTER key

KEY

61-89A-50 USER MENU 1 (8-20460A)

Press Item Select arrow key

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

E

Detailed Status

Configuration

NOTE:

Press ENTER

to see Downlink

NOTE:

Button press required

to exit this display

NOTE:

Pressing CANCEL always returns

you to the previous menu without

saving changes

NOTE:

If no button is pressed within

2 minutes, system returns to

Main Status Display Screen

NOTE:

This menu screen will also give you

the option to place an amplifier into

Bypass or take one out of Bypass.

Figure 7: Signal Booster II Menu System.

Manual 7-9362-2 Page 8TX RX Systems Inc. 10/19/05

Page 15

will return to this display from any other display if

NOTE

NOTE

none of the menu interface buttons are pressed

within 2 minutes. The exception is the OLC status

display which does require a button press to exit.

The main status d isplay shows the uplink and

downlink gain in dB as well as the uplink and downlink output level in dBm.

The last line of the main status display gives a

summary status message for the entire signal

booster. In this example “Status OK” is being displayed. Pressing the “ENTER” button will move

you from the main status display into the menu

selections and will permit interaction with the system. There are two main functions available within

the software menus including configuration settings and detailed status displays.

Configuration Settings

In most cases, the factory default settings are the

optimum values for adjustable parameters. The

most common setting to be changed by the system’s technician is the gain setting. This is normally

done to compensate for varying values of antenna

isolation as outlined earlier in this manual or to

reduce excessive OLC action resulting from excessive gain.

Please thoroughly study this section before making

any adjustments to the configuration values. Each

configured item is discussed in detail.

Note: Changes to configuration settings do not take affect until the Main

Sta t us s creen is re-e n abled. T h is

occurs automatically after 2 minutes

without button input or manually by

pressing the Enter/Done/Cancel buttons to return

to the status screen.

RESTORE ORIG CONFIG

This command will restore all configured settings to

their original factory default values. SB II ships

from the factory preset to the lowest gain possible.

CALIBRATE CURRENTS

Use this command when replacing an RF amplifier.

This function automatically calibrates the current

alarm “trip” point of each amplifier in the system.

Due to manufacturing tolerances there are small

differen ces in current d raw between a mplifier

assemblies. This software function matches the

alarm sensing circuit to the respective amplifier

assembly and should be repeated whenever an

amplifier assembly is replaced.

SET GAIN

This function allows the user to electronically set

the gain of the booster in 0.5 dB increments over a

range of 30 dB. Gain can be adjusted independently for both the uplink and downlink channels

but in most cases both uplink and downlink should

be set to the same gain value.

Know your antenna isolation before making this

adjustment. We recommend that you temporarily

disconnect both the uplink and downlink antennas

when setting the gain to avoid the possibility of

causing the unit to oscillate. After changing the setting, power the unit down, reconnect the antennas

and power-up the booster.

Note: A reduction in system gain will

also result in an equal reduction in the

OLC dynamic range, refer to the section titled “OLC” on page 10.

SET OUTPUT LEVEL

Allows the output power for the uplink and downlink

channels to be independently adjusted in.5 dB

increments up to +31 dBm. Note that the OLC circuitry will maintain the systems output level at the

values you have selected in this menu.

Use this function ONLY if your system is causing

some form of interference to another radio system.

You can only reduce the booster’s output power

with this command.

CHANGE GAIN CONFIGURATION

Insures proper gain readings when changing basic

booster gain by changing the type of plug-in card

assemblies.

Use of this menu is ONLY needed when converting

your stock SB II to a different gain level by changing the low level, mid-level plug-in amplifier card or

the addition of an attenuator card. It actually is a

change to the characteristics of another model.

Don’t confuse this with simple amplifier bypassing

to reduce gain. Uplink and down link can be set

independently. Choices for gain are Full, Mid or

Low and the Enter key toggles the gain setting.

The corresponding gain level is displayed. Select

Manual 7-9362-2 Page 9TX RX Systems Inc. 10/19/05

Page 16

Done using the a rrow keys and press en ter to

NOTE

NOTE

NOTE

return to the menu. Use the Cancel button to return

to the Status Display.

briefly lit. Constant light bar activity means the

booster gain needs to be reduced for optimum performance.

Detailed Status Screens

These items allow a detailed examination of system components including; all amplifiers (current

draw and temperature), the power supply (voltage

level), and the OLC function (present status and

historical archive). Each item is discussed below in

detail.

AMPLIFIERS

A separate status screen is available for each

am plifi er in th e syste m. When a n amplifier i s

selected this function will display the present current draw of that amp as well as its present operating temperature in degrees Celsius. In addition, a

status message will indicate if the amplifier is connected and whether the amplifier is bypassed or

not bypassed. This menu selection also provides

the option of placing an amplifier in bypass or taking an amplifier out of bypass.

The current draw will be blank if an amplifier is not

connected, wil l display BYP if the am plif ier is

bypassed, and will display ATTEN if an attenuator

card is being used in place of the amplifier card.

The power amplifier currents will nor-

mally fluctuate up to 850 ma when sig-

nals are present.

POWER SUPPLY

This function displays the real time power supply

voltages for both 24 volt and 12 volt supplies.

OLC

This screen shows the amount of attenuation presently being used by the OLC for both the uplink

and downlink channels. In addition, the percentage

of OLC presently being used is also shown.

The amount of OLC currently being

used in either the uplink or downlink

channels is also indicated by LED bar

graph displays located on the display

panel. Each segment represents 2 to

4 dB of attenuation depending on the gain setting

of the booster. The OLC bars should only be active

occasionally and no more than 3 or 4 segments

Th e s y st e m ha s 6 0 dB of O L C

dy n a m i c ra n g e . Ho w e v e r , th e

dynamic range of the OLC is reduced

when t h e u s e r selec t a ble gain i s

re duced. T he reduc tion wil l be an

equal amount. For instance, if the user selectable

gain is reduced by 20 dB then the OLC dynamic

range will also be reduced by 20 dB.

OLC DATALOG

This screen displays an OLC Datalog which is the

OLC data over the past 100 days for both uplink

and downlink branches of the system. This is a rolling 100 day log with day 101 overlapping day 1

and so forth. Day zero represents the current day

while day one represents yesterday and so on. The

logged data is stored in non-volatile memory and

will not be erased when the unit is powered down.

The average OLC attenuation used when the OLC

was active is given both for individual days and

over the entire past 100 days. The percentage of

time the OLC was active is also given for both individual d ays and over th e past 1 00 days. This

archived information will permit the creation of a

user signal profile to facilitate optimum system configuration and performance.

This archive feature will allow you to see if the gain

of the unit is set too high or if there are transient

episodes of strong signals perhaps desensing

other channels being amplified by the booster.

Alarms

The system continuously monitors the current draw

and operating temperature of each amplifier as

well as the voltage level of the +12 and +24 VDC

supplies. If any of these parameters exceed normal

operating levels by a factory preset percentage the

system enters an alarm condition. Notification of an

alarm condition is provided by LED indicators and

Form-C contacts available via the alarm terminal

screws.

LED INDICATORS

There are LED indicators for each amplifier in the

system as well as the +12 and +24 VDC power

supply voltages. The LED indicators for the low,

mid, and low gain amplifiers are located on the

Manual 7-9362-2 Page 10TX RX Systems Inc. 10/19/05

Page 17

individual plug-in module. These are tri-color LED’s

Signal

Generator

Zero

Reference

Spectrum

Analyzer

Gain

Sample

Sample

T

est Po

rt

Test Port

Figure 8: Measuring signal booster gain.

wit h green re p resent i ng NORMAL ope ration ,

orange representing a WARNING condition, and

red indicating a FAU LT. A war ning condition

occurs when the current draw of the amplifier

exceeds nominal by +/- 20%. Fault conditions

occur when the current draw exceeds +/- 30% or

the amplifiers operating temperature exceeds 80°

Celsius. The LED for the attenuator card is green

only and indicates DC power applied to the card.

The LED indicators for the power amplifiers are

located on t he display panel next to t he menu

select buttons and are dual color LED’s. Green

represents NORMAL operation while red indicates

a FAULT condition. Fault conditions occur when

the current draw exceeds 900 ma or falls below

200 ma. Also, whenever the amplifiers operating

temperature exceed s 95° Celsius. The power

amplifiers do not have a warning state.

The power supply LED indicators are located on

display panel next to the menu selection buttons

and are also dual color. Green representing normal

operation and red a fault condition. A fault condition for the +24 VDC supply occurs whenever the

volta ge pot enti al drops below +1 6 VDC (3 0%

below nominal). Likewise, a fault for the +12 VDC

supply occurs when the potential is below +8 VDC

(30% below nominal).

FORM-C CONTACTS

Form-C contacts are available inside the cabinet

next to the power supply assembly, see figure 2.

These screw terminals are intended for connection

to the customers supervisory alarm or data acquisition system. One set of terminals supplies notification of any alarm condition occurring and the

second set of contacts indicate the system is operating on battery backup power.

PERFORMANCE SURVEY

It is a good idea to document the performance of

the system after installation so that a reference

exists for future comparisons. This information can

make troubleshooting an interference problem or

investigation of a complaint about system performance much easier. If there are coverage problems with a system, this survey will usually reveal

them allowing corrective measures to be taken

before the system is put into routine use. The fol-

Manual 7-9362-2 Page 11TX RX Systems Inc. 10/19/05

Page 18

lowing is an outline of how to do such a survey.

To Donor

Signal

Signal Distribution System

Spectrum

Analyzer

10 dB Pad

S

ampl

e

S

ampl

e

Test Port

Test Port

Figure 9: Methodology for doing a performance survey of the signal distribution system.

Because the nature of each installation can be

quite different, only a broad outline is given.

1) Measure the gain of the signal booster being

careful not to exceed the maximum input level.

The recommended maximum RF Input power

for the SBII is -15 dBm. Stronger input signals

will cause the unit to exceed its maximum IM

specifications. Input signals which are stronger

than 0 dBm will physically damage the unit. Fig-

ure 8 shows this being done using a signal generator and spectrum analyzer. Record the

measured values for each passband. We recommend that a 50 ohm load be connected to

the unused RF port on the bottom of the cabinet

during the gain test.

2) The spectrum analyzer is connected to the -30

dB signal sampler port following the final output

amp. This port will allow the observation of the

amplifier output at a considerably reduced output level. This decoupling value (-30 dB) needs

to be added to any measured signal value in

order to arrive at the actual signal level.

3) With a spectrum analyzer connected to the sig-

nal sampler port (see Figure 9), have personnel with handheld radios move to several

predetermined points and key their radios.

Record the level of these signals as observed

on the analyzer and also record the location of

the person transmitting. In this way, a map of

the systems performance can be generated.

4) For signals coming from a fixed antenna or station, record the level of all the desired incoming

signals for future reference.

MAINTENANCE AND REPAIR

Signal boosters manufactured by TX RX Systems,

Inc. can perform for years with little maintenance

and repair. However, if the amplifiers are subjected

to excessively high signal levels, power surges or

lightning strikes, failures may occur. The following

procedures may be followed for detecting a malfunctioning unit or as part of a periodic maintenance program.

1) The heatsink area should be cleared of dust

and debris.

Manual 7-9362-2 Page 12TX RX Systems Inc. 10/19/05

Page 19

Figure 10: Remove 14 mounting screws to detach amplifier assembly from cabinet.

Remove Screws

Remove Screws

Remove

Screws

Remove

Screws

Figure 11: Slide amplifier towards bottom of cabinet to remove upper cable.

2) Inspect the unit to see that the two power supply LED DC indicators are lit (remove any dust

or debris that may obscure the LEDs). This will

verify that DC power is flowing properly. Check

all hardware for tightness.

3) Compare system performance to initial performance levels measured when the system was

first installed. The lack of signal can be traced

to a malfunctioning amplifier by progressive signal monitoring from the output (far end) to the

input end of the system noting the area where

the signal returns to normal level. The next

amplifier toward the output end of the system

will probably be the one that failed.

or

Measure the gain at any convenient frequency

in the working frequency band to verify that the

performance is still within specifications.

Manual 7-9362-2 Page 13TX RX Systems Inc. 10/19/05

Page 20

squeeze the top and bottom of the connector

NOTE

NOTE

Figure 12: Slide amplifier towards top of cabinet to

remove lower cables.

together to release a hold down tab. When

properly squeezed the grey cable will disconnect easily from the amplifier. Refer to Figure

12.

4) To replace the amplifier assembly repeat steps

1 through 3 in reverse order. When replacing

the RF cables do not overtighten the SMA connectors. They should be tightened just slightly

more than hand tight or to the specification of 7

in/lbs. The replacement amplifier comes with an

attached gasket which must press up against

the outside of the cabinet firmly and squarely in

order to provide a correct moisture seal.

Module Replacement

The SB II modules are field replaceable. Follow the

steps listed below in sequential order. The required

tools are a #1 Phillips screwdriver. Two thum b

screws hold each module into place.

Power Amplifier Replacement

The SB II power amplifiers are field replaceable.

Follow the steps listed below in sequential order.

The required tools are a #1 Phillips screwdriver

and a 5/16” open-ended wrench.

Note: Power to the SB II cabinet must

be t u rn e d O F F d u r ing the power

amplifier replacement process.

1) Remove the Phillips screws which hold the

amplifier into place, refer to Figure 10. The nuts

holding the screws are pressed into the cabinet

and will remain in place when the screws are

removed.

2) Slide the amplifier towards the bottom of the

cabinet as far as it will go. This will allow the top

RF connector to clear the opening. Tilt the top

of the amplifier outwards and remove the top

RF cable at the SMA connector using the 5/16”

wrench. See Figure 11.

3) Slide the amplifier assembly towards the top of

the cabinet as far as it will go. This will allow the

bottom RF connector and grey control cable to

clear the opening. Tilt the bottom of the amplifier outwards and remove the bottom RF cable

at the SMA connector and the grey control

cable. To remove the grey cable from the

socket on the amplifier it is necessary to

Note: Power to the SB II cabinet must

be t u r n ed OFF dur ing t he module

replacement process except for the

amplifier modules which are “HOT”

switchable.

1) Loosen the two thumb screws which hold the

module into place. Phillips screws are incorporated into the thumbscrews and they made

need to be loosened first.

2) Grasping the two loosened thumb screws pull

the module straight out of the card cage.

3) To install the replacement module place the

module into the guide-rails of the slot and press

down firmly into place. Each type of module is

keyed uniquely to fit in only one slot within the

card cage. Once the card is seated into place

properly tighten the thumb screws.

The SB II low level and mid level amplifier stages

are field replaceable by simply removing the module and plugging in a replacement. These modules

are HOT switchable meaning they can be swapped

without powering down the system. RF cables

attached to the modules must be removed (5/16”

wrench) prior to swapping the modules and must

be re-attached after the new module is in place.

when replacing the RF cables do not overtighten

Manual 7-9362-2 Page 14TX RX Systems Inc. 10/19/05

Page 21

the SMA connectors. They should be tightened just

NOTE

NOTE

Figure 13: Disconnecting the display/user interface assembly from the card cage.

Disconnect

ribbon cable

here

slightly more than hand tight or to the specification

of 7 in/lbs.

Modules can be swapped between the uplink and

downlink branches for troubleshooting purposes. If

a problem exists in one branch and the problem

moves to the ot her b ranch when mo dules ar e

swapped around this indicates a defective module.

Note: After an amplifier m odule is

replaced use the Calibrate Currents

software function to properly set the

amplifiers alarm trip point, see page 9.

Due to slight differences in component

tolerances the trip point must be reset for any new

amplifier assemblies introduced into the system.

Display/User Interface Assembly Replacement

The SB II Display/User Interface assembly is field

re p laceable. Follow t h e steps lis ted belo w in

sequential order. No tools are required.

Note: Power to the SB II cabinet must

be turned OFF during the display/user

interface replacement process.

1) Loosen the two thumb-nuts which hold the display/user interface assembly to the card cage.

2) Gently tilt only the top of the assembly up from

the card cage. Keep the bottom of the assembly

in place. The bottom mounting plate (part of the

card cage) has an overhang on it to support the

display/user interface board. If the assembly is

lifted straight out the overhang it could possibly

damage the interface circuit board.

3) With the display/user interface board standing

up straight gently move it upwards while lifting it

out about an inch or two. This should allow the

overhang to clear the interface circuit board

without damage.

Manual 7-9362-2 Page 15TX RX Systems Inc. 10/19/05

Page 22

4) Remove the ribbon cable that connects the dis-

NOTE

NOTE

play/user interface assembly to the card cage,

see Figure 13.

5) To replace the display/user interface assembly

repeat steps 1 through 4 in reverse order.

Card Cage Replacement

To replace the card cage follow the steps listed

below in sequential order. The required tools are a

#1 Phillips screwdriver with an extended shaft to

reach down far enough into the unit to loosen the

mounting screws.

Power Supply Replacement

The SB II power supply assembly is field replaceable. Follow the steps listed below in sequential

order. The required tools are a #1 Phillips screwdriver.

1) Turn off AC power at the junction box.

2) Disconnect the 3 conductor cable that brings

AC power to the supply from the junction box.

3) Disconnect the red and black leads from the

power supply that connect to the card cage.

4) Remove the Phillips screws that hold the power

supply mount bracket to the back plate and

remove the assembly from the cabinet.

5) Reverse steps 4 through 2 to install the replacement power supply.

Duplexer / Filter Replacement

The filter assemblies are field replaceable. Follow

the steps listed below in sequential order. The

required tools are a #1 Phillips screwdriver with an

extended shaft to reach down far enough into the

unit to loosen the mounting screws.

Note: Power to the SB II cabinet must

be t u r n e d O F F d ur i n g t he fi l t e r

replacement process.

Note: Power to the SB II cabinet must

be turned OFF during the card cage

replacement process.

1) Disconnect the display/user interface assembly.

2) Disconnect 4 cables at the backplane of the

card cage which are assessable with the display/user interface board out of the way.

3) Remove the row of Phillips screws which hold

the card cage to the back plate. There is a row

of screws at the top and bottom of the cage.

4) To install a replacement cage perform steps 3

through 1 in reverse order.

RECOMMENDED SPARES

It is recommended that one spare of each of the

following assemblies be kept on hand for emergency repair purposes; Power Supply 8-19938,

Uplink Power Amplifier 3-19787, Downlink Power

Amplifier 3-20028, Mid Level Amplifier Card 319576, Low Level Amplifier Card 3-19575, Low

Gain Amplifier Card 3-20294, Attenuator Card 320208, Power Distribution Card 3-19833, Controller Card 3-19832, and the Display/User Interface

Assembly 3-19831.

1) All RF cables attached to the assembly must be

removed (5/16” wrench).

2) Remove the Phillips screws that hold the

assembly mount brackets to the back plate and

remove the assembly from the cabinet.

3) Reverse steps 2 and 1 to install the replacement filter. When replacing the RF cables do

not overtighten the SMA connectors. They

should be tightened just slightly more than hand

tight or to the specification of 7 in/lbs.

Manual 7-9362-2 Page 16TX RX Systems Inc. 10/19/05

Page 23

Low Gain Model Mid Gain Model High Gain Model

Maximum Gain: +45 dB +60 dB +80 dB

Gain Adjustment:

Programmable attenuation,

0-30 dB, 0.5 dB steps

Programmable attenuation,

0-30 dB, 0.5 dB steps

Programmable attenuation,

0-60 dB, 0.5 dB steps

3rd Order Output Intercept Point:

+55 dBm minimum,

with no attenuation

+55 dBm minimum,

with no attenuation

+55dBm minimum,

with no attenuation

RF Sampler: PA Output sampler ports PA Output sampler ports PA Output sampler ports

Noise Figure (without attenuation): 6.5 dB maximum 6.5 dB maximum 3.5 dB maximum,

Operating Temperature Range: -30°C to +50° C -30°C to +50° C -30°C to +50° C

Nominal Impedance: 50 ohms, <1.5:1 VSWR 50 ohms, <1.5:1 VSWR 50 ohms, <1.5:1 VSWR

Input/Output Connectors: N female N female N female

RF Sampler Connectors: BNC female BNC female BNC female

AC Power Input: 100-240 VAC; 50-60 Hz 100-240 VAC; 50-60 Hz 100-240 VAC; 50-60 Hz

DC Input Voltage: +24 to +27 VDC +24 to +27 VDC +24 to +27 VDC

Unit Power Consumption (AC/DC): <100 VA <100 VA <100 VA

Housing:

NEMA 4, NEMA 4X

Rack Mount

NEMA 4, NEMA 4X

Rack Mount

NEMA 4, NEMA 4X

Rack Mount

Nominal Size: 24" x 24" x 8" 24" x 24" x 8" 24" x 24" x 8”

Net Weight: < 85 lbs. < 85 lbs. < 85 lbs.

Manual 7-9362-2 Page 17TX RX Systems Inc. 10/19/05

Page 24

Driver PA

DET

Temp

Sense

+5

5 Volt

Regulator

Analog

Temp Out

Analog

OLC Out

To Display

Panel LED

RF Bypass

OLC

Relay

Control

+5

VDC

+5 VDC

from

Current

Monitor

Controller

(Bypass)

I C from Controller

2

+12 VDC from Backplane

+12 VDC from Current Monitor

+24 VDC Current Monitor

Amp Amp

OLC &

Temp

Sense

RF Bypass

OLC

Relay

Control

+5

VDC

+5 VDC

from

Current

Monitor

Controller

(Bypass)

I C from Controller

2

Amp Amp

OLC

& Temp

Sense

RF Bypass

OLC

Relay

Control

+5

VDC

+5 VDC

from

Current

Monitor

Controller

(Bypass)

I C from Controller

2

+12 VDC from

Current Monitor

+12 VDC from

Current Monitor

Amp Amp

OLC

& Temp

Sense

RF Bypass

OLC

Relay

Control

+5

VDC

+5 VDC

from

Current

Monitor

Controller

(Bypass)

I C from Controller

2

+12 VDC from Current Monitor

Amp Amp

OLC &

Temp

Sense

DL3

UL3

DL1

UL1

DL2

UL2

Test Port

Test Port

Low Level

Amplifier Card

Mid Level

Amplifier Card

Mid Level

Amplifier Card

Low Level

Amplifier Card

Power

Amplifier

Assembly

DriverPA

DET

Temp

Sense

+5

5 Volt

Regulator

Analog

Temp Out

Analog

OLC Out

+12 VDC from Backplane

+24 VDC Current Monitor

Power

Amplifier Assy

To Display

Panel LED

High Gain Model Block Diagram (Part 1 of 2)

Sample

Sample

Duplexer

Assembly

3-19575

3-19787

3-19576

3-19576

3-20028

3-19575

Duplexer

Assembly

Manual 7-9362-2 Page 18TX RX Systems Inc. 10/19/05

Page 25

Driver PA

DET

Temp

Sense

+5

5 Volt

Regulator

Analog

Temp Out

Analog

OLC Out

To Display

Panel LED

RF Bypass

OLC

Relay

Control

+5

VDC

+5 VDC

from

Current

Monitor

Controller

(Bypass)

I C from Controller

2

+12 VDC from Backplane

+12 VDC from Current Monitor

+24 VDC Current Monitor

Amp Amp

OLC &

T

emp

Sense

RF Bypass

OLC

+5

VDC

+5 VDC

from

Current

Monitor

I C from Controller

2

OLC

RF Bypass

OLC

Relay

Control

+5

VDC

+5 VDC

from

Current

Monitor

Controller

(Bypass)

I C from Controller

2

+12 VDC from

Current Monitor

Amp Amp

OL

C

& Temp

Sense

RF Bypass

OLC

+5

VDC

+5 VDC

from

Current

Monitor

I C from Controller

2

OLC

DL3

UL3

DL1

UL1

DL2

UL2

Test Port

Test Port

Mid Level

Amplifier Card Attenuator Card

Attenuator Card

Mid Level

Amplifier Card

Power

Amplifier

Assembly

DriverPA

DET

Temp

Sense

+5

5 Volt

Regulator

Analog

Temp Out

Analog

OLC Out

+12 VDC from Backplane

+24 VDC Current Monitor

Power

Amplifier Assy

To Display

Panel LED

Mid Gain Model Block Diagram (Part 1 of 2)

Sample

Sample

3-19576

3-19787

3-20208

3-20208

3-20028

3-19576

Duplexer

Assembly

Duplexer

Assembly

Manual 7-9362-2 Page 19TX RX Systems Inc. 10/19/05

Page 26

Driver PA

DET

Temp

Sense

+5

5 Volt

Regulator

Analog

Temp Out

Analog

OLC Out

To Display

Panel LED

RF Bypass

OLC

Relay

Control

+5

VDC

+5 VDC

from

Current

Monitor

Controller

(Bypass)

I C from Controller

2

+12 VDC from Backplane

+12 VDC from Current Monitor

+24 VDC Current Monitor

Amp

OLC & Temp

Sense

RF Bypass

OLC

+5

VDC

+5 VDC

from

Current

Monitor

I C from Controller

2

O

LC

RF Bypass

OLC

Relay

Control

+5

VDC

+5 VDC

from

Current

Monitor

Controller

(Bypass)

I C from Controller

2

+12 VDC from

Current Monitor

Amp

OLC

&

Te

mp

Sense

RF Bypass

OLC

+5

VDC

+5 VDC

from

Current

Monitor

I C from Controller

2

OLC

DL3

UL3

DL1

UL1

DL2

UL2

Test Port

Test Port

Low Gain

Amplifier Card Attenuator Card

Attenuator Card

Low Gain

Amplifier Card

Power

Amplifier

Assembly

DriverPA

DET

Temp

Sense

+5

5 Volt

Regulator

Analog

Temp Out

Analog

OLC Out

+12 VDC from Backplane

+24 VDC Current Monitor

Power

Amplifier Assy

To Display

Panel LED

Low Gain Model Block Diagram (Part 1 of 2)

Sample

Sample

3-20294

3-19787

3-20208

3-20208

3-20028

3-20294

Duplexer

Assembly

Duplexer

Assembly

Manual 7-9362-2 Page 20TX RX Systems Inc. 10/19/05

Page 27

High, Mid, and Low Gain Model Block Diagram (Part 2 of 2)

Communications

Card

TCPIP

RS232

+5 V +5 V

+5 V

DL3 UL3 DL1 UL1 DL2 UL2

OLC

Temp

OLC

OLC/Temp

Temp

Bypass

OLC/Temp

Bypass

OLC/Temp

Bypass

OLC/Temp

Bypass

PS

110/240 VAC

24/27 VDC

+24

VDC

10 Base T

RS232

Operations

Alarm

Backup

Power

ON

+24 UL3

+12 UL1

+5 UL2

+12 UL2

+5 UL1

+24 DL3

+12 DL1

+12 DL2

+5 DL2

+5 DL1

Converter

Converter

+12

+12

+5

UL

Power

Distribution

Card

3-19833

DL

Power

Distribution

Card

3-19833

Backplane

Controller Card

NO

CommonNCNO

Common

NC

Display and User Interface

3-19832

3-19831

3-19940Junction Box 3-19833

3-19833

A/C

On-Off

Switch

A/C

Duplex

Outlet

Battery

Backup

On-Off

Switch

SYSTEMS

INC.

Enter Cancel

24v 12v UL PA DL PA

UPLINK OLC

DOWNLINK OLC

Manual 7-9362-2 Page 21TX RX Systems Inc. 10/19/05

Page 28

CELCIUS FARENHEIT

105 221.0

104 219.2

103 217.4

102 215.6

101 213.8

100 212.0

99 210.2

98 208.4

97 206.6

96 204.8

95 203.0

94 201.2

93 199.4

92 197.6

91 195.8

90 194.0

89 192.2

88 190.4

87 188.6

86 186.8

85 185.0

84 183.2

83 181.4

82 179.6

81 177.8

80 176.0

79 174.2

78 172.4

77 170.6

76 168.8

75 167.0

74 165.2

73 163.4

72 161.6

71 159.8

70 158.0

69 156.2

68 154.4

67 152.6

66 150.8

65 149.0

64 147.2

63 145.4

62 143.6

61 141.8

60 140.0

59 138.2

58 136.4

57 134.6

56 132.8

55 131.0

54 129.2

53 127.4

52 125.6

51 123.8

50 122.0

49 120.2

48 118.4

47 116.6

46 114.8

45 113.0

44 111.2

43 109.4

42 107.6

41 105.8

40 104.0

39 102.2

38 100.4

37 98.6

36 96.8

35 95.0

34 93.2

33 91.4

32 89.6

31 87.8

30 86.0

29 84.2

28 82.4

CELCIUS FARENHEIT

27 80.6

26 78.8

25 77.0

24 75.2

23 73.4

22 71.6

21 69.8

20 68.0

19 66.2

18 64.4

17 62.6

16 60.8

15 59.0

14 57.2

13 55.4

12 53.6

11 51.8

10 50.0

9 48.2

846.4

7 44.6

642.8

5 41.0

439.2

3 37.4

235.6

1 33.8

032.0

-1 30.2

-2 28.4

-3 26.6

-4 24.8

-5 23.0

-6 21.2

-7 19.4

-8 17.6

-9 15.8

-10 14.0

-11 12.2

CELCIUS FARENHEIT

-12 10.4

-13 8.6

-14 6.8

-15 5.0

-16 3.2

-17 1.4

-18 -0.4

-19 -2.2

-20 -4.0

-21 -5.8

-22 -7.6

-23 -9.4

-24 -11.2

-25 -13.0

-26 -14.8

-27 -16.6

-28 -18.4

-29 -20.2

-30 -22.0

-31 -23.8

-32 -25.6

-33 -27.4

-34 -29.2

-35 -31.0

-36 -32.8

-37 -34.6

-38 -36.4

-39 -38.2

-40 -40.0

-41 -41.8

-42 -43.6

-43 -45.4

-44 -47.2

-45 -49.0

-46 -50.8

-47 -52.6

-48 -54.4

-49 -56.2

-50 -58.0

CELCIUS FARENHEIT

CELSIUS TO FAHRENHEIT CONVERSION TABLE

Manual 7-9362-2 Page 22TX RX Systems Inc. 10/19/05

Page 29

500

400

300

200

100

50

40

30

20

POWER FWD./REV.

VS

VSWR

V

S

W

R

1.1:1

1.15:1

1.2:1

10

FORWARD POWER (Watts)

5.0

4.0

3.0

2.0

1.0

0.5

40

20

10

8.0 6.0

4.0

2.0

REFLECTED POWER (Watts)

FOR OTHER POWER LEVELS

MULTIPLY BOTH SCALES

BY THE SAME MULTIPLIER

1.0 0.8

0.6

0.4

1.25:1

1.3:1

1.4:1

1.5:1

1.6:1

1.8:1

2.0:1

2.5:1

3.0:1

0.2

Bird Technologies Group TX RX Systems Inc.

Page 30

POWER IN/OUT

VS

INSERTION LOSS

The graph below offers a convenient means of determining the insertion loss of filters, duplexers,

multicouplers and related products. The graph on the back page will allow you to quickly determine

VSWR. It should be remembered that the field accuracy of wattmeter readings is subject to

considerable variance due to RF connector VSWR and basic wattmeter accuracy, particularly at low

end scale readings. However, allowing for these variances, these graphs should prove to be a useful

reference.

INSERTION LOSS (dB)

500

400

300

250

200

150

125

INPUT POWER (Watts)

100

7.0

6.5

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

.50

.25

75

50

50

75 100

125 150 200

250

300

400

500

OUTPUT POWER (Watts)

FOR LOWER POWER LEVELS

DIVIDE BOTH SCALES

BY 10 (5 TO 50 WATTS)

Bird Technologies Group TX RX Systems Inc.

Page 31

Bird Technologies Group TX RX Systems Inc.

Return Loss vs. VSWR

Return Loss VSWR

30 1.06

25 1.11

20 1.20

19 1.25

18 1.28

17 1.33

16 1.37

15 1.43

14 1.50

13 1.57

12 1.67

11 1.78

10 1.92

9 2.10

Watts to dBm

Watts dBm

300 54.8

250 54.0

200 53.0

150 51.8

100 50.0

75 48.8

50 47.0

25 44.0

20 43.0

15 41.8

10 40.0

5 37.0

4 36.0

3 34.8

2 33.0

1 30.0

dBm = 10log P/1mW

Where P = power (Watt)

Insertion Loss

Input Power (Watts)

50 75 100 125 150 200 250 300

3 25 38 50 63 75 100 125 150

2.5 28 42 56 70 84 112 141 169

2 32 47 63 79 95 126 158 189

1.5 35 53 71 88 106 142 177 212

1 40 60 79 99 119 159 199 238

.5 45 67 89 111 134 178 223 267

Output Power (Watts)

Insertion Loss

Free Space Loss

Distance (miles)

.25 .50 .75 1 2 5 10 15

150 68 74 78 80 86 94 100 104

220 71 77 81 83 89 97 103 107

460 78 84 87 90 96 104 110 113

860 83 89 93 95 101 109 115 119

940 84 90 94 96 102 110 116 120

1920 90 96 100 102 108 116 122 126

Free Space Loss (dB)

Free space loss = 36.6 + 20log D + 20log F

Where D = distance in miles and F = frequency in MHz

Frequency (MHz)

Page 32

8625 Industrial Parkway, Angola, NY 14006 Tel: 716-549-4700 Fax: 716-549-4772 sales@birdrf.com www.bird-technologies.com

Loading...

Loading...