Page 1

DIGITAL POWER METER

MODEL 5000-XT

OPERATING INSTRUCTIONS

©Copyright 2012 by Bird Electronic Corporation

Instruction Book P/N 920-5000-XT Rev. E

Thruline is a Registered Trademark of

Bird Electronic Corporation

Windows 95 is a registered trademark

of the Microsoft Corporation

SeaLatch is a registered trademark of

Sealevel Systems, Inc.

Page 2

ii

Page 3

Safety Precautions

The following are general safety precautions that are not necessarily related to

any specific part or procedure, and do not necessarily appear elsewhere in this

publication. These precautions must be thoroughly understood and apply to all

phases of operation and maintenance.

WARNING

Keep Away From Live Circuits

Operating Personnel must at all times observe general safety precautions. Do

not replace components or make adjustments to the inside of the test

equipment with the high voltage supply turned on. To avoid casualties,

always remove power.

WARNING

Shock Hazard

Do not attempt to remove the RF transmission line while RF power is present.

WARNING

Do Not Service Or Adjust Alone

Under no circumstances should any person reach into an enclosure for the

purpose of service or adjustment of equipment except in the presence of

someone who is capable of rendering aid.

WARNING

Safety Earth Ground

An uniterruptible earth safety ground must be supplied from the main power

source to test instruments. Grounding one conductor of a two conductor

power cable is not sufficient protection. Serious injury or death can occur if

this grounding is not properly supplied.

WARNING

Resuscitation

Personnel working with or near high voltages should be familiar with modern

methods of resuscitation.

WARNING

Remove Power

Observe general safety precautions. Do not open the instrument with the

power on.

WARNING

Chemical Hazard

Dry cleaning solvents for cleaning parts may be potentially dangerous. Avoid

inhalation of fumes or prolonged contact with skin.

iii

Page 4

Safety Symbols

WARNING

Warning notes call attention to a procedure, which if not correctly

performed, could result in personal injury.

CAUTION

Caution notes call attention to a procedure, which if not correctly performed,

could result in damage to the instrument.

The caution symbol appears on the equipment indicating there is

important information in the instruction manual regarding that particular area

Note: Calls at ten tion to supplemen t al information.

Warning Statements

The following safety warnings appear in the text where there is danger to operating and maintenance personnel, and are repeated here for emphasis.

WARNING

Never attempt to connect or disconnect RF equipment from the transmission

line while RF power is being applied.

Leaking RF energy is a potential health hazard.

See page 7.

WARNING

RF voltage may be present in RF element socket. Keep element in socket

during operation.

See page 8 and 14.

WARNING

Do not interrupt the calibration.

See page 15.

WARNING

Disconnect from external power before any disassembly. The potential for

electric shock exists.

See page 47.

iv

Page 5

Caution Statements

The following equipment cautions appear in the text and are repeated here for

emphasis.

CAUTION

When connecting the TPS or the TPS-EF, only turn the connector nut. Damage

may occur if torque is applied to the sensor body.

See page 9.

CAUTION

Discharge all static potentials before connecting the TPS(-EF). Electrostatic

shock could damage the sensor.

See page 9.

CAUTION

Do not exceed 2 W average or 125 W peak power for 5 μs when using the TPS

or the TPS-EF. Doing so will render the sensor inoperative.

See page 10 and 14.

CAUTION

Do not use harsh or abrasive detergents for cleaning.

See page 45.

v

Page 6

Safety Statements

USAGE

ANY USE OF THIS INSTRUMENT IN A MANNER NOT

SPECIFIED BY THE MANUFACTURER MAY IMPAIR THE

INSTRUMENT’S SAFETY PROTECTION.

USO

EL USO DE ESTE INSTRUMENTO DE MANERA NO

ESPECIFICADA POR EL FABRICANTE, PUEDE ANULAR LA

PROTECCIÓN DE SEGURIDAD DEL INSTRUMENTO.

BENUTZUNG

WIRD DAS GERÄT AUF ANDERE WEISE VERWENDET ALS VOM

HERSTELLER BESCHRIEBEN, KANN DIE GERÄTESICHERHEIT

BEEINTRÄCHTIGT WERDEN.

UTILISATION

TOUTE UTILISATION DE CET INSTRUMENT QUI N’EST PAS

EXPLICITEMENT PRÉVUE PAR LE FABRICANT PEUT

ENDOMMAGER LE DISPOSITIF DE PROTECTION DE

L’INSTRUMENT.

IMPIEGO

QUALORA QUESTO STRUMENTO VENISSE UTILIZZATO IN

MODO DIVERSO DA COME SPECIFICATO DAL PRODUTTORE

LA PROZIONE DI SICUREZZA POTREBBE VENIRNE

COMPROMESSA.

vi

Page 7

SERVICE

SERVICING INSTRUCTIONS ARE FOR USE BY SERVICE TRAINED PERSONNEL ONLY. TO AVOID DANGEROUS

ELECTRIC SHOCK, DO NOT PERFORM ANY SERVICING

UNLESS QUALIFIED TO DO SO.

SERVICIO

LAS INSTRUCCIONES DE SERVICIO SON PARA USO

EXCLUSIVO DEL PERSONAL DE SERVICIO CAPACITADO. PARA

EVITAR EL PELIGRO DE DESCARGAS ELÉCTRICAS, NO

REALICE NINGÚN SERVICIO A MENOS QUE ESTÉ

CAPACITADO PARA HACERIO.

WARTUNG

ANWEISUNGEN FÜR DIE WARTUNG DES GERÄTES GELTEN

NUR FÜR GESCHULTES FACHPERSONAL. ZUR VERMEIDUNG

GEFÄHRLICHE, ELEKTRISCHE SCHOCKS, SIND

WARTUNGSARBEITEN AUSSCHLIEßLICH VON

QUALIFIZIERTEM SERVICEPERSONAL DURCHZUFÜHREN.

ENTRENTIEN

L’EMPLOI DES INSTRUCTIONS D’ENTRETIEN DOIT ÊTRE

RÉSERVÉ AU PERSONNEL FORMÉ AUX OPÉRATIONS

D’ENTRETIEN. POUR PRÉVENIR UN CHOC ÉLECTRIQUE

DANGEREUX, NE PAS EFFECTUER D’ENTRETIEN SI L’ON N’A

PAS ÉTÉ QUALIFIÉ POUR CE FAIRE.

ASSISTENZA TECNICA

LE ISTRUZIONI RELATIVE ALL’ASSISTENZA SONO PREVISTE

ESCLUSIVAMENTE PER IL PERSONALE OPPORTUNAMENTE

ADDESTRATO. PER EVITARE PERICOLOSE SCOSSE

ELETTRICHE NON EFFETTUARRE ALCUNA RIPARAZIONE A

MENO CHE QUALIFICATI A FARLA.

vii

Page 8

RF VOLTAGE MAY BE PRESENT IN RF ELEMENT SOCKET - KEEP

ELEMENT IN SOCKET DURING OPERATION.

DE LA TENSION H.F. PEAT ÊTRE PRÉSENTE DANS LA PRISE DE

L'ÉLÉMENT H.F. - CONSERVER L'ÉLÉMENT DANS LA PRISE LORS

DE L'EMPLOI.

HF-SPANNUNG KANN IN DER HF-ELEMENT-BUCHSE ANSTEHEN ELEMENT WÄHREND DES BETRIEBS EINGESTÖPSELT LASSEN.

PUEDE HABER VOLTAJE RF EN EL ENCHUFE DEL ELEMENTO RF MANTENGA EL ELEMENTO EN EL ENCHUFE DURANTE LA

OPERACION.

IL PORTAELEMENTO RF PUÒ PRESENTARE VOLTAGGIO RF TENERE L'ELEMENTO NELLA PRESA DURANTE IL

FUNZIONAMENTO.

viii

Page 9

About This Manual

This manual covers the operating and maintenance instructions for the following models:

5000-XT

Changes to this Manual

We have made every effort to ensure this manual is accurate. If you discover

any errors, or if you have suggestions for improving this manual, please send

your comments to our Solon, Ohio factory. This manual may be periodically

updated. When inquiring about updates to this manual refer to the part number

and revision on the title page.

Terminology

There are some unique terms used throughout this literature. They are defined

here to clarify any misunderstanding.

Hard Keys — A specific function which is indicated on the key. The key names

for hard keys are set in bold typeface, e.g. Press the ON key.

Chapter Layout

Introduction —Identifies the parts of the DPM, describes the functions of the

various keys, and explains the meaning of the indicators which may be displayed. Also lists the items supplied and optional equipment available.

Insallation —Gives directions for connecting the DPM, and discusses the vari-

ous power sources.

Operation —Explains how to make measurements with the DPM, and the spe-

cial functions used with specific sensors.

Software Interfaces —Explains software interfaces.

Maintenance —Lists routine maintenance tasks for the Digital Power Meter,

and troubleshooting tips for common problems. Specifications and battery

information are also included.

ix

Page 10

x

Page 11

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Warning Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Caution Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Changes to this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Introduction1

Items Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Directional Power Sensor (DPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Terminating Power Sensors (TPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Wideband Power Sensor (WPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Attenuators & Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Soft Carry Case (P/N 5A5000-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Component Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Display Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Display Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Battery Level Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Duty Cycle Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Analog Bar Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Offset Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5000-XT Initial User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Startup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5000-XT Main Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation7

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

AC Mains Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Automobile Cigarette Lighter Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Resetting the 5000-XT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Upgrading the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

xi

Page 12

Chapter 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Operation13

Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Shutting Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Performing a Screen Shot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Directional Power Sensor (DPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Terminating Power Sensor (TPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Zeroing Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wideband Power Sensor (WPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Zeroing Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Video Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Average Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Peak Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Crest Factor Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CCDF Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Software Interfaces17

Wideband Power Sensor Attached . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Forward Avg Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Reflected Avg Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Match Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Forward Peak Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Forward Burst Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Crest Factor Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

CCDF Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Main Menu Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Zero/Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Filter Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CCDF Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

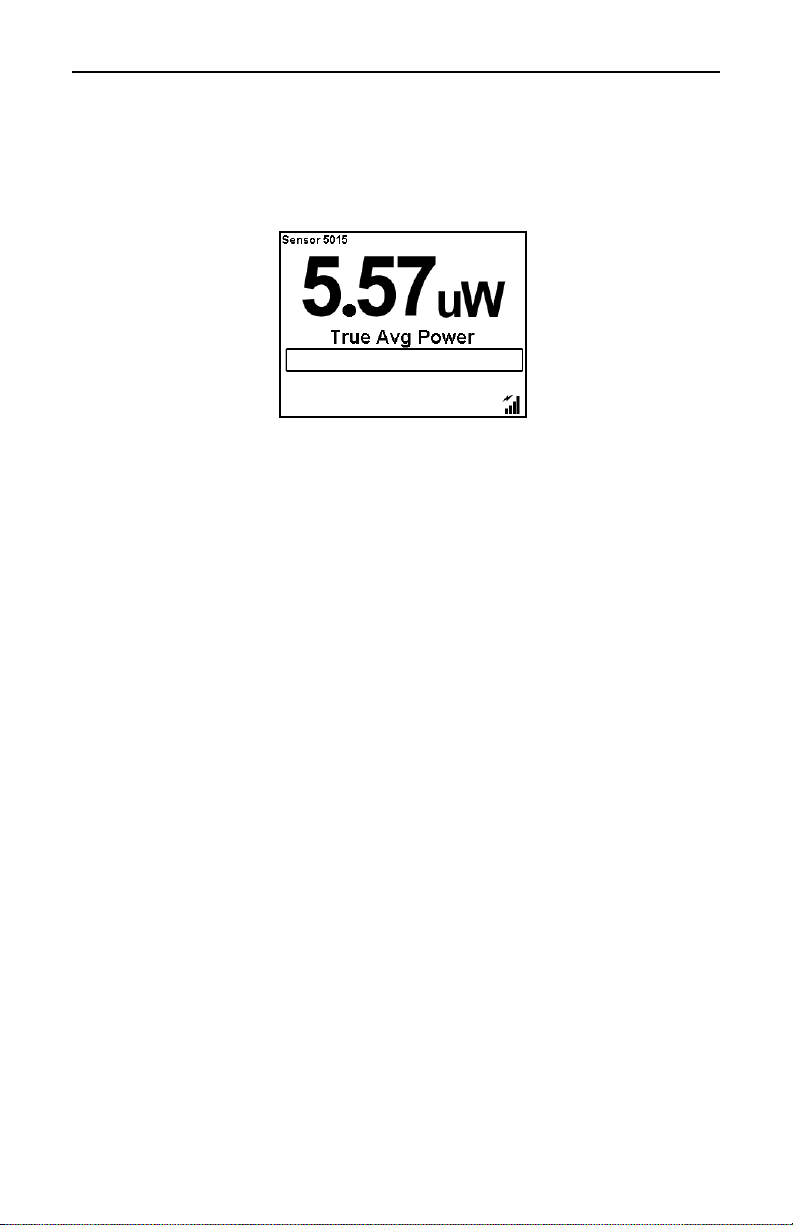

Terminating Power Sensor Attached . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

True Avg Power Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Directional Power Sensor (Legacy) Attached . . . . . . . . . . . . . . . . . . . . . . . . 26

Forward Avg Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Reflected Avg Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Match Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Directional Power Sensor Attached . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Forward Avg Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Reflected Avg Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Match Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

xii

Page 13

Forward Peak Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Forward Avg Peak Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Main Menu Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Scale Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Element Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

TSTPM Sensor Attached . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

TPS Calibration Standard Power Interface . . . . . . . . . . . . . . . . . . . . . . . 35

5000XT Main Menu, No Sensor Attached . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Smoothing Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Date/Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Backlight Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

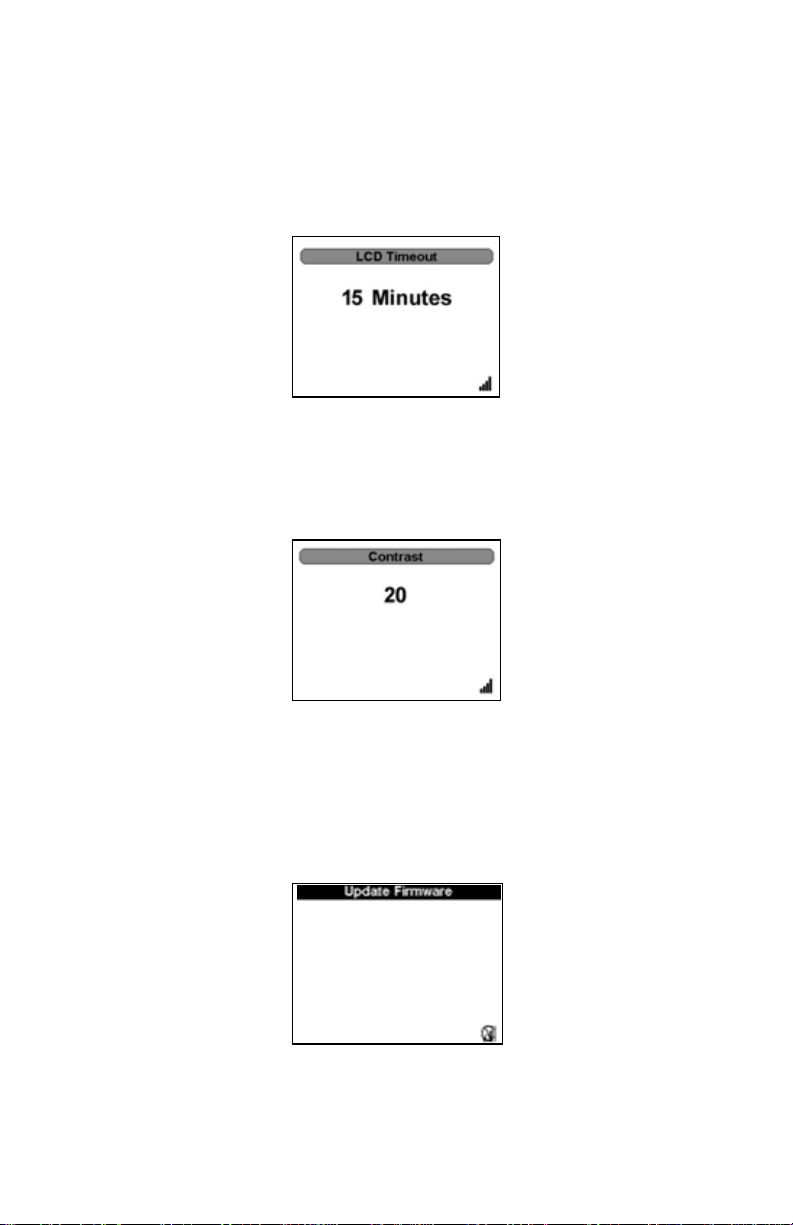

LCD Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Update Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Main Menu, Sensor Attached . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Filter Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

CCDF Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Language Selection Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Logging Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Logging Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Logging Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Logging Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Logging Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Maintenance45

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Charging Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Prolonging Battery Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

xiii

Page 14

Conserving Battery Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Conserving power during operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Storing a battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Managing Low-Battery Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Identifying Low-Battery Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Resolving Low-Battery Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Calibrating the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Attenuators & Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Bird 5000-XT Digital Power Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Bird 5010, 5010B, 5010T, & 5014 Directional Power Sensors . . . . . . . . 54

Bird 5011, 5015, 5011-EF and 5015-EF Terminating Sensors . . . . . . . . 56

Bird 5012B, 5016B, 5017B, 5018B, and 5019B

Wideband Power Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Sensor Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Average Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Match Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Peak Envelope Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Match Measurement Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Maximum Peak Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Burst Average Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Crest Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Complementatry Cumulative Distribution Function (CCDF) . . . . . . . . 61

Physical and Environmental Specifications . . . . . . . . . . . . . . . . . . . . . 61

ROHS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

xiv

Page 15

Chapter 1 Introduction

Items Supplied

1. Bird Digital Power Meter (DPM)

2. Battery

Note: To install the battery see “Cust omer Service” on page 50 or

refer to the Quick Start Guide.

3. Power Supply

Note: Includes Brick, Cord, 3 In tl Adaptors, and cigare tt e adaptor

4. USB SeaLatch® Cable, 6’

5. DB9 Cable, 10’

6. Soft Case

7. Accessory Pack

8. Carabiner

9. Tri-Lingual Instruction Book on CD

10. Quick Start Guide

1

Page 16

Optional Equipment

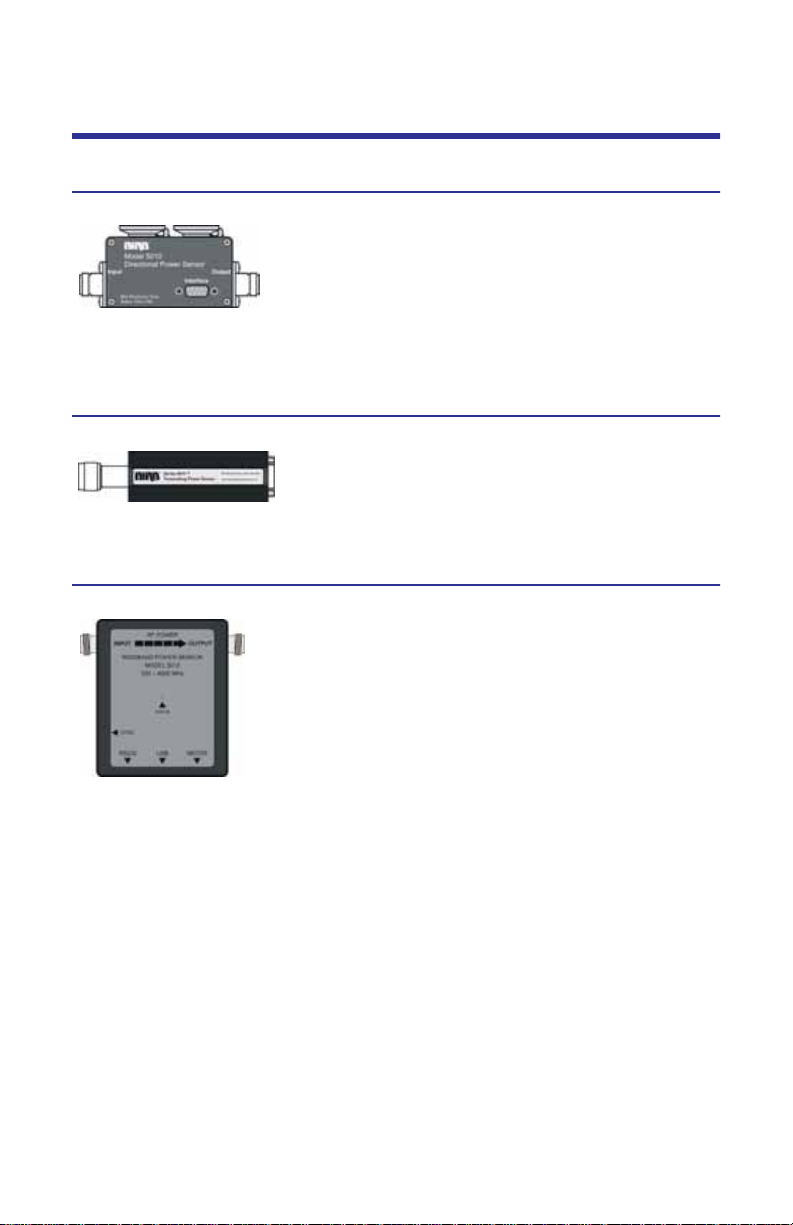

Directional Power Sensor (DPS)

The Bird 5010B and 5014 Thruline® Sensors require

two 43 or APM/DPM elements. The DPS measures both

forward and reverse power, so VSWR and other match

measurements can be calculated and displayed.

Note: The 5010B replaces the Bird 5010. The 5010 was

only compatible with APM/DPM elements, and lacked peak-reading

capability. The 5000-XT will s till recogniz e the 5010.

Terminating Power Sensors (TPS)

The Bird 5011and 5015 series terminating power sensors do not require elements. The Bird 5011 and 5015

have a frequency range of 40 MHz – 4 GHz. The 5011EF and 5015-EF sensors have a frequency range of 40

MHz – 12 GHz.

Wideband Power Sensor (WPS)

The Bird 5012B, 5016B, 5017B, 5018B, and 5019B Thruline Sensors do not require elements. The WPS can measure average, peak, or burst power, VSWR, crest factor,

and Complementary Cumulative Distribution Function

(CCDF).

Attenuators & Accessories

A variety of attenuators and connectors for measuring

large powers with the TPS. For a complete list, see

page 51.

Soft Carry Case (P/N 5A5000-1)

Convenient and protective. Cutouts allow operation while in the case.

2

Page 17

Component Description

Figure 1 Component Description

1. Period Key Input numeric values.

2. OK/Power Key Turns the DPM on or off.

3. +/- Key Toggles between positive and negative

numbers.

4. Log Key Brings up the Logging Menu.

5. Menu Key Brings up the Main Menu.

6. Arrow Keys Scrolls through menu items.

7. Numeric Keys Input numeric values.

8. USB Sensor Port Connection for power sensors.

9. COM Sensor Port Connection for power sensors.

10. USB Port Connection for computer.

11. LCD Display Backlit liquid crystal display.

12. External DC

Connector

Connect either the AC adapter or the cigarette

lighter adapter. External supplies power the

unit and charge the internal battery.

USB

Port

USB Sensor

Port

COM

Sensor Port

DC

Connector

3

Page 18

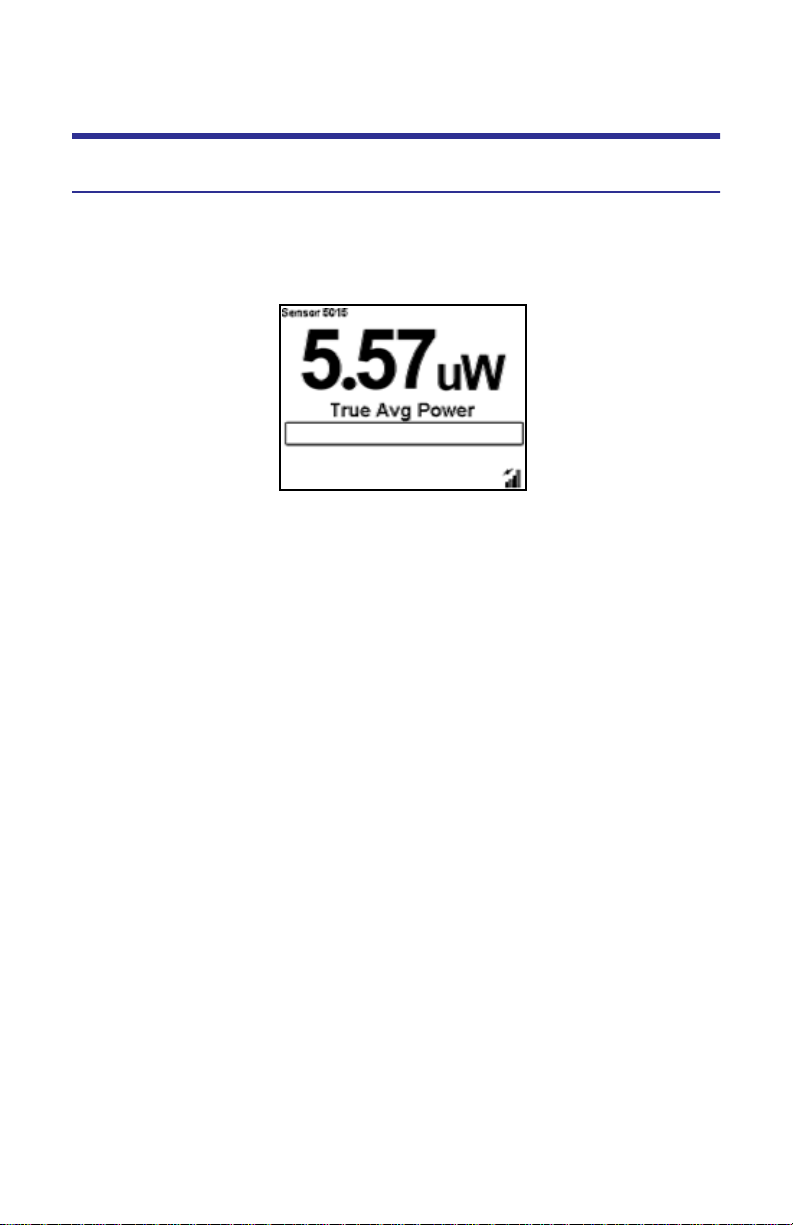

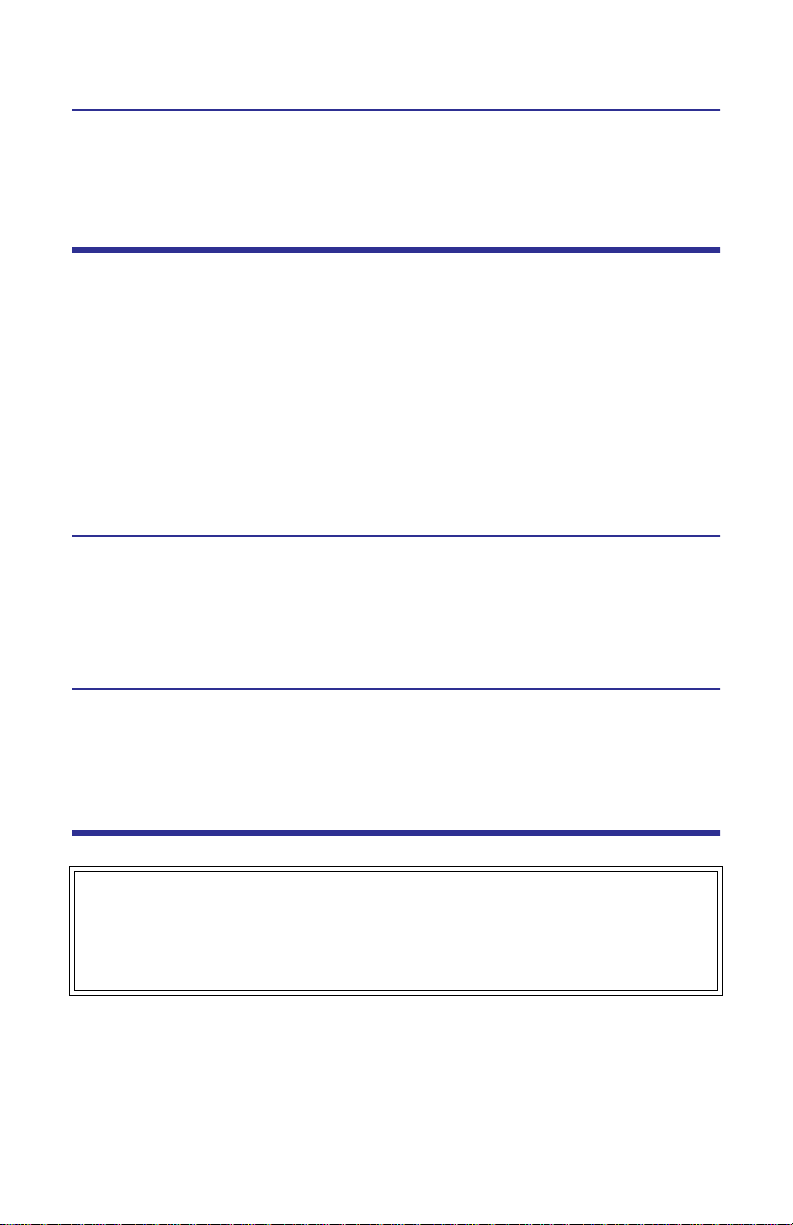

Display Description

Display Units

Shows the measurement mode and units for the display directly above.

Figure 2 Display

Battery Level Indicator

When the external adapter is connected, a lightening bolt icon will indicate the

battery is charging. The battery operates off of the external power supply unless

it is not present.

When using the internal batteries, the indicator is on continuously. When the

battery level indicator is blank, the battery needs to be recharged. If the unit is

logging when the battery becomes too low, a notification that logging is being

stopped will appear,

Duty Cycle Indicator

For burst power measurements, shows the signal’s duty cycle.

Analog Bar Graph

Displays the dynamic range of the sensor attached. Minimum and maximum

depend on sensor.

Offset Indicator

On when an offset is in use.

Power Indicator

If the power exceeds 100% of full scale, “Over” will be displayed.

The numbers in the main measurement will flash.

4

Page 19

5000-XT Initial User Interface

Startup Screen

Upon initial startup, when from complete shutdown, the splash screen will display for 5 seconds while the file system is being initialized, then it will display

the language selection screen.

Note: If this is the firs t st artup, the unit should ask f or the language

to be used.

5000-XT Main Display Elements

5

Page 20

6

Page 21

Chapter 2 Installation

Power Supply

The DPM uses a rechargeable Lithium Ion battery pack. Charge life is about 20

hours with the Bird WPS, 50 hours with other sensors.

The DPM can use an external power source. Using the DPM with the AC adapter

or the 12V cigarette lighter adapter will also charge the battery. Charging time

from full discharge is 5 hours using the AC adapter. When using the cigarette

lighter adapter, charge time will depend on the car battery charge. When the

external adapter is connected, a lightening bolt icon will indicate the battery is

charging. The battery operates off of the external power supply unless it is not

present.

AC Mains Adapter

1. Insert the adapter’s barrel connector into the DPM’s external DC connector

(See Figure 1 on page 3).

2. Insert the adapter plug into a wall receptacle.

Automobile Cigarette Lighter Adapter

1. Insert the adapter’s barrel connector into the DPM’s external DC connector.

2. Insert the adapter plug into a cigarette lighter jack.

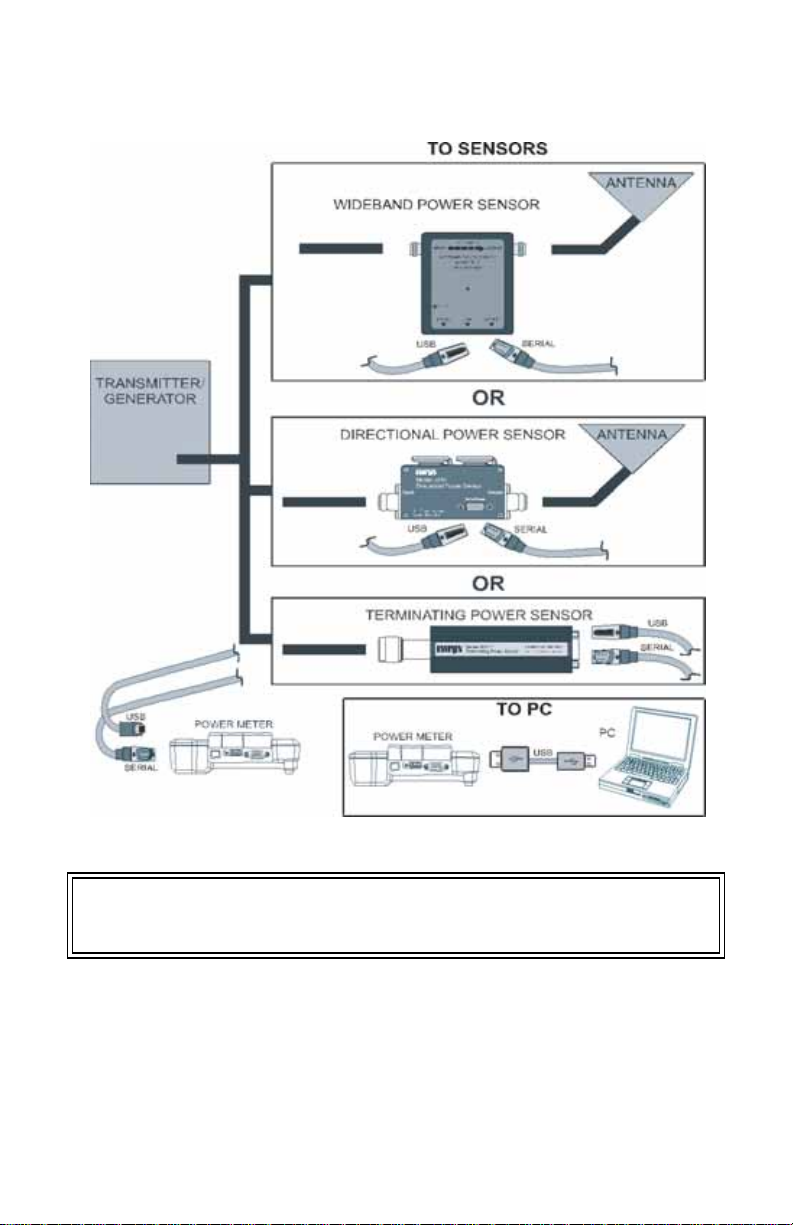

Connections

WARNING

Never attempt to connect or disconnect RF equipment from the transmission

line while RF power is being applied.

Leaking RF energy is a potential health hazard.

Note: If the 5000-XT is connect ed to a PC when s tarting or res t arting

the PC, it may cause the boot process to lock up.

Disconnect the 5000-XT before starting or rest arting the PC.

7

Page 22

Figure 3 DPM Connections

Connecting the Directional Power Sensor (DPS)

WARNING

RF voltage may be present in RF element socket. Keep element in socket during

operation.

1. Do one of the following:

For Models 5010, 5010B, 5011, 5012, 5012A, 5012B, 5016, 5016B,

5017, 5017B, 5018, 5018B, 5019, and 5019B:

Connect the Bird DPS to the “Sensor” serial port on the DPM using the

sensor cable provided.

8

Page 23

For Models 5014:

Connect the Bird DPS to the “Sensor” USB port on the DPM using the

sensor cable provided.

2. Connect the DPS to the RF line so that the arrow on the sensor points

towards the load.

Note: The arrow on the f orward element should poin t t owards the

load.

Note: The arrow on the reflect ed element should poin t t owards the

source.

Note: Both elements mus t be either APM/DPM or 43 types, do not

mix elements.

3. Set the power on the DPM to the forward element’s power rating.

Figure 4 DPS Element Orientation

Connecting the Wideband Power Sensor (WPS)

1. Do one of the following:

Connect the DPM port on the Bird WPS to the “Sensor” serial port on

the DPM using the sensor cable provided.

Connect the DPM port on the Bird WPS to the “Sensor” USB port on the

DPM using the sensor cable provided.

2. Connect the WPS to the RF line so that the arrow on the sensor points

towards the load.

Connecting the Terminating Power Sensor (TPS)

CAUTION

Discharge all static potentials before connecting the TPS(-EF). Electrostatic

shock could damage the sensor.

CAUTION

When connecting the TPS or the TPS-EF, only turn the connector nut. Damage

may occur if torque is applied to the sensor body.

9

Page 24

CAUTION

Do not exceed 2 W average or 125 W peak power for 5 μs when using the TPS

or the TPS-EF. Doing so will render the sensor inoperative.

Note: Connections are the same f or the Bird 5011 and 5011-EF.

1. Do one of the following:

Connect the DPM port on the Bird TPS to the “Sensor” serial port on

the DPM using the sensor cable provided.

Connect the DPM port on the Bird TPS to the “Sensor” USB port on the

DPM using the sensor cable provided.

Note: An att enuat or or directional coupler should be used with the

TPS in most applications.

Example - For an RF source with output between 0.1 and

50 W, use a 40 dB, 50 W attenuator.

2. Connect the TPS RF input to the source (using an attenuator, if appropriate).

Note: Only connect the TPS directly t o a sourc e if the RF power will

be less than 10 mW.

Resetting the 5000-XT

Pressing and holding down the 5 button for two seconds will reset the unit.

The unit will return to default settings and pop-up the language selection menu.

Upgrading the Firmware

Note: Bef ore performing this proc edure, sign on to the in ternet and

go to:

www.bird-technologies.c om/products/ software/5000-xt/

1. Power on the 5000-XT

2. Connect the USB from the 5000-XT to the PC and wait for the drive to appear.

Note: This could t ake 30 seconds

3. Create a folder named “FIRMWARE”.

Note: The f older name is case sensitive. If there is already a f older,

use the existing folder, but delete any firmware versions already in

that folder.

4. Place the updated firmware file into the folder.

Note: This file can be named an ything as long as the file extension is

.bin.

10

Page 25

5. Eject and disconnect the 5000-XT from the PC.

6. Press the Menu key.

7. Select Setup on the Main Menu.

8. Select Update Firmware on the Setup Menu. The Update Firmware file list

will display.

9. Select the newly downloaded firmware file from the list.

10. Select ACCEPT when asked “Update System Firmware?”

Note: The file will be checked. If file is corrupt, it will notify as such.

11. The following screens will be displayed:

a. “Loading” screen

b. “Erasing Flash” screen with a progress bar

c. “Writing Flash” screen with a progress bar.

d. “Update Success” screen.

12. Select OK when prompted after this message: “The system will now

power down.”.

11

Page 26

12

Page 27

Chapter 3 Operation

The Bird Digital Power Meter is very easy to operate. Once a sensor is connected, turn the DPM on and take a reading. Additional commands are available, depending on the sensor used.

Setting Up

1. Connect the sensor.

2. Turn on the DPM.

3. Set the measurement and measurement units.

Note: R ef er to the sections f ollo wing for ins tructions specific t o each

sensor .

4. Zero the sensor (WPS and TPS only).

5. Perform the following if the system loss is known or if using an attenuator:

a. Add the losses (in dB) of all components in the system.

Note: Use the loss at the measured frequency.

b. Press OFFSET and enter the total loss in dB.

Note: This will allow the user t o read the actual line power. The

DPM accepts offsets from –10 to 100 dB, depending on the sensor.

6. Turn on the RF source.

7. Take a reading.

Note: The analog bar graph will respond immediat ely to changes in

the RF power. The major and minor displays will respond after a delay

of 1 to 13 seconds, depending on the level of smoothing.

Shutting Down

Press and Hold the “OK” key for 2 seconds. This will put the unit into

Sleep mode. It will stop logging in this mode.

Press and hold the “OK” key until the “OK” key illuminates, approxi-

mately 8 seconds. Release the key after it illuminates. This will shut the

unit down completely.

Performing a Screen Shot

1. Press and hold <.> for two seconds will perform a screen shot of the current

screen on the DPM.

2. Select OK to confirm the screen shot.

Note: The image file name will be displayed.

13

Page 28

Directional Power Sensor (DPS)

WARNING

RF voltage may be present in RF element socket. Keep element in socket

during operation.

Setting Scale

Note: The Bird DPS uses Bird Plug-In Elemen ts. These are labeled

with a max power and a frequency range.

Note: The transmitt er frequency should be within the

element range.

Note: Forward and Reflected full scale power must be entered

manually.

1. Press Scale.

2. Select the power units (W, mW or kW) with up and down arrow keys.

3. Enter the maximum power of the element in the forward element socket

using the numeric keypad and <.> key.

Note: The element’s max power is listed on the element nameplate.

4. Press OK.

Terminating Power Sensor (TPS)

CAUTION

Do not exceed 2 W average or 125 W peak power for 5 μs when using the TPS

or the TPS-EF. Doing so will render the sensor inoperative.

Zeroing Sensor

Over time, the sensor’s “zero value” (reading with no applied RF power) can

drift due to environmental factors (temperature, humidity, etc.) This can make

the readings performed by this sensor less accurate by the drift value. If the drift

would be a significant error, re zero the sensor.

1. Ensure the sensor has been connected to the DPM.

2. Press and hold “0” for two seconds to begin zero calibration.

Note: “Z ero/Cal” will be displayed and calibration will begin.

14

Page 29

Note: Z eroing the sensor takes 60 sec onds. The bar graph will display

calibration progress.

Note: When comple te, “PASS” should be displayed.

3. Press Enter to return to normal operation when zeroing is complete.

Note: If “FAIL” is displayed, mak e sure no RF power is applied t o the

sensor and perform the procedure again.

TPS-EF

The Bird TPS-EF uses frequency correction factors to allow more accurate measurements. Look at the label on the side of the sensor and find the correction

factor for the frequency being measured. Add the correction factor to the other

attenuation or coupling factors and enter this as an offset.

Wideband Power Sensor (WPS)

A status LED on the front lights when the WPS is powered, and blinks when the

WPS is connected to the DPM.

Zeroing Sensor

Over time, the sensor’s “zero value” (reading with no applied RF power) can

drift due to environmental factors (temperature, humidity, etc.) This can make

the readings performed by this sensor less accurate by the drift value. If the drift

would be a significant error, re zero the sensor.

1. Make sure the sensor has reached a stable operating temperature.

2. Make sure no RF power is applied to the sensor.

3. Press and hold “0” for two seconds to begin zero calibration.

WARNING

Do not interrupt the calibration.

Note: “Z ero/Cal” will be displayed and calibration will begin.

Note: Z eroing the sensor takes 60 sec onds. The bar graph will display

calibration progress.

Note: When comple te, “PASS” should be displayed.

4. Press Enter to return to normal operation when zeroing is complete.

Note: c.If “FAIL” is displayed, make sure no RF power is applied to

the sensor and perform the procedure again.

15

Page 30

Video Filter

Except for average power and VSWR measurements, all measurements use a

variable video filter to improve accuracy. This filter can be set to either 4.5 kHz,

400 kHz, or Full bandwidth.

Note: It should be as narrow as possible while s till being larger than

the demodulated signal bandwidth (video bandwidth). Narrowing the

filter limits the noise contribution from interf ering signals.

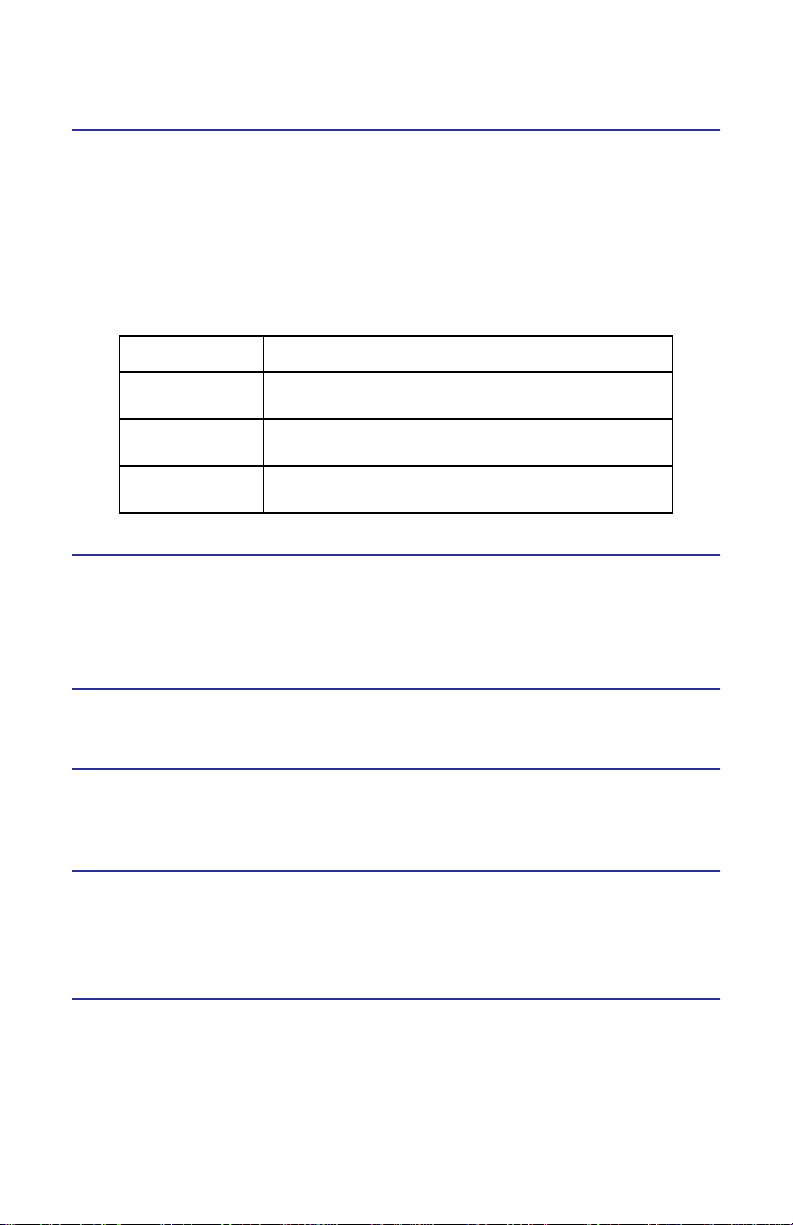

Listed below are some common modulation schemes and the appropriate video filter.

Video Filter Modulation Type

4.5 kHz CW Burst (Burst width > 150 s), Voice Band

AM, FM, Phase Modulation, Tetra

400 kHz CW Burst (b.w. > 3 s), GSM, 50 kHz AM,

DQPSK (¼, symbol rate < 24 k/s)

Full Bandwidth CW Burst (b.w. > 200 ns), CDMA, WCDMA,

DQPSK (¼, symbol rate < 200 k/s), DAB/DVB-T

Average Mode

This mode displays the average forward and reflected power.

Note: In average mode, the VS WR or sys tem match can be displayed

instead of the reflected power.

Peak Mode

This mode displays the peak envelope power.

Burst Mode

This mode displays the average power in a burst. The burst’s duty cycle is measured by the DPM.

Crest Factor Mode

The crest factor is the ratio of the forward peak power and the forward average

power. It is measured in dB.

Note: There are no additional c ontrols in this mode.

CCDF Mode

The CCDF measures the percentage of time the power level is above a threshold. To set the power threshold:

1. Press menu.

2. Select CCDF Limit from the Main Menu.

3. Enter new value.

16

Page 31

Chapter 4 Software Interfaces

Wideband Power Sensor Attached

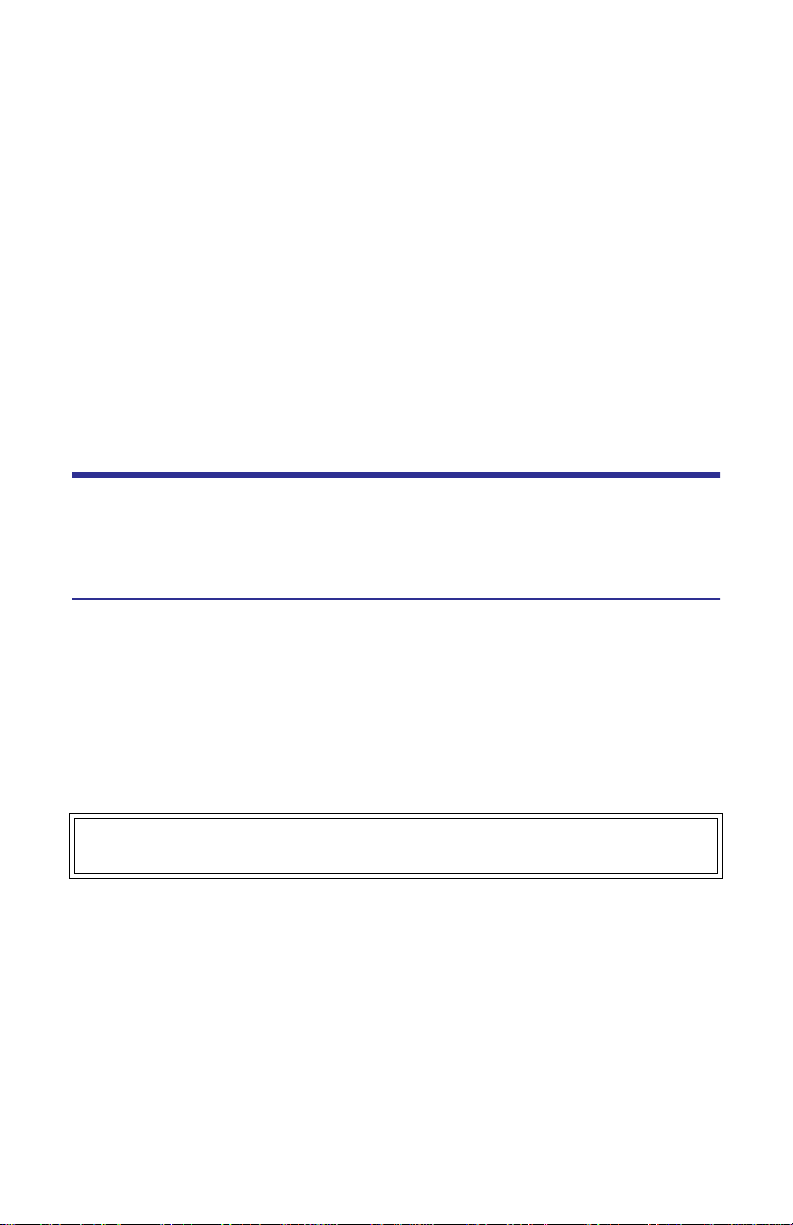

Forward Avg Interface

Small Display

\

Large Display

Key Button Action

Right Arrow Changes the Main Measurement to Reflected Avg

Left Arrow Changes the Main Measurement to the CCDF

Up Arrow Toggles Fwd Avg units from W to dBm

Down Arrow Toggles Fwd Avg units from W to dBm

OK Button Initiates Shutdown. See “Shutting Down” on page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) Zero/Cal Unit/Sensor

8 (2 Sec) Turn On/Off Smoothing

Menu & Log (2 sec) Language Selection Screen

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

17

Page 32

Reflected Avg Interface

Small Display

Large Display

Key Button Action

Right Arrow Changes the Main Measurement to Match

Left Arrow Changes the Main Measurement to Forward Avg

Up Arrow Toggles Rfl Avg units from W to dBm

Down Arrow Toggles Rfl Avg units from W to dBm

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) Zero/Cal Unit/Sensor

8 (2 Sec) Turn On/Off Smoothing

Menu & Log (2 sec) Language Selection Screen

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

18

Page 33

Match Interface

Small Display

Large Display

Key Button Action

Right Arrow Changes the Main Measurement to Forward Peak

Left Arrow Changes the Main Measurement to Reflected Avg

Up Arrow Switch Match (VSWR, Rtn Loss, Match Eff%)

Down Arrow Switch Fwd/Rfl Avg (W, dBm)

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) Zero/Cal Unit/Sensor

8 (2 Sec) Turn On/Off Smoothing (*for Fwd/Rfl Power)

Menu & Log (2 sec) Language Selection Screen

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

19

Page 34

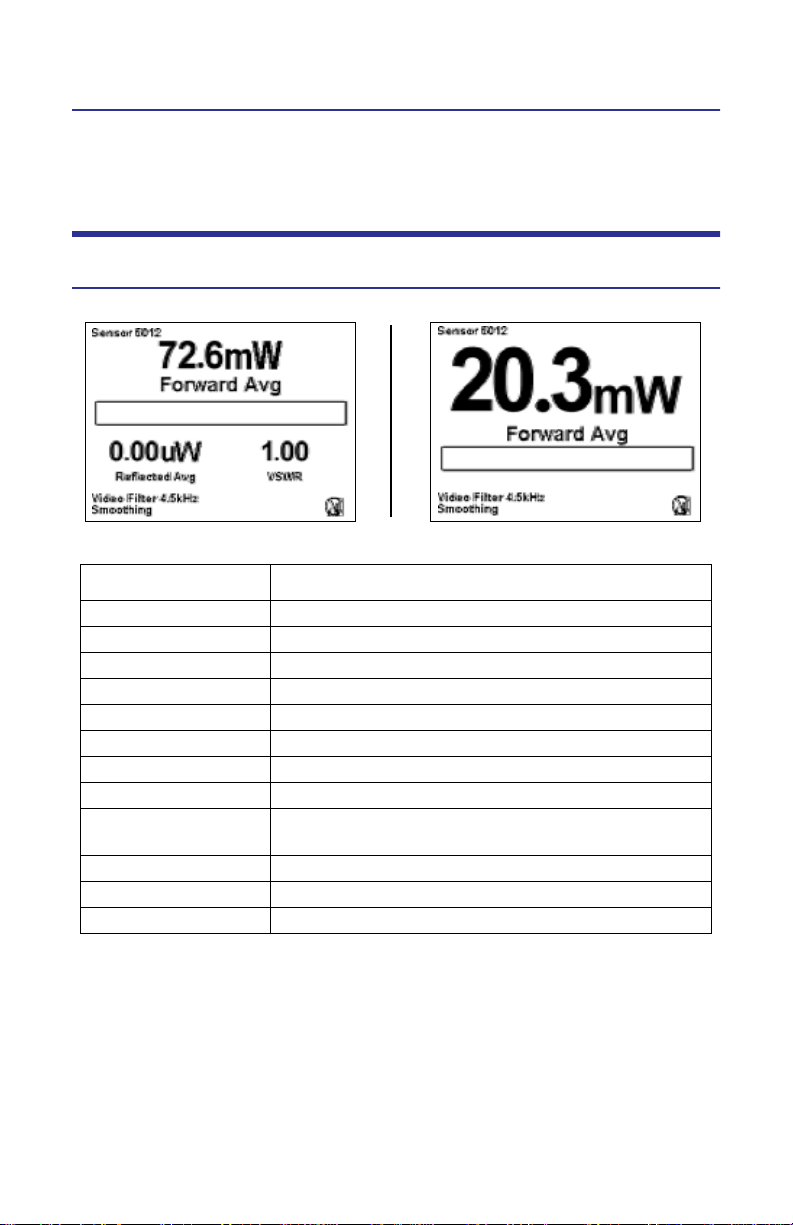

Forward Peak Interface

Small Display

Large Display

Key Button Action

Right Arrow Changes the Main Measurement to Forward Burst

Left Arrow Changes the Main Measurement to Match

Up Arrow Switch Fwd Peak (W, uW, mW, kW, dBm)

Down Arrow Switch Fwd Avg Power (W, uW, mW, kW, dBm

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) Zero/Cal Unit/Sensor

8 (2 Sec) Turn On/Off Smoothing (*for Fwd Avg)

Menu & Log (2 sec) Language Selection Screen

* - ‘This mode displays the peak envelope power.

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

20

Page 35

Forward Burst Interface

Small Display Large Display

Key Button Action

Right Arrow Changes the Main Measurement to Crest Factor

Left Arrow Changes the Main Measurement to Forward Peak

Up Arrow Switch Burst Power (W, uW, mW, kW, dBm)

Down Arrow Switch Fwd Avg Power (W, uW, mW, kW, dBm)

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) Zero/Cal Unit/Sensor

8 (2 Sec) Turn On/Off Smoothing* (for Fwd Avg)

Menu & Log (2 sec) Language Selection Screen

* - Burs t mode displays the A verage po wer in a burst. The burs t’ s duty

cycle is measured burst width/period.

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

21

Page 36

Crest Factor Interface

Small Display

Large Display

Key Button Action

Right Arrow Changes the Main Measurement to CCDF

Left Arrow Changes the Main Measurement to Forward Burst

Up Arrow Switch Fwd Ave (W, uW, mW, kW, dBm)

Down Arrow Switch Rfl Ave (W, uW, mW, kW, dBm)

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) Zero/Cal Unit/Sensor

8 (2 Sec) Turn On/Off Smoothing (*for Fwd Avg)

Menu & Log (2 sec) Language Selection Screen

* - Cres t Fact or is the ratio of the f orward peak power and the forward

Average power. It is measured in dB.

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

22

Page 37

CCDF Interface

Small Display

Large Display

Key Button Action

Right Arrow Changes the Main Measurement to Forward Avg

Left Arrow Changes the Main Measurement to Crest Factor

Up Arrow Switch between Forward Peak/Forward Average

Down Arrow Switch Fwd Peak/Ave (W, uW, mW, kW, dBm)

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) Zero/Cal Unit/Sensor

8 (2 Sec) Turn On/Off Smoothing

Menu & Log (2 sec) Language Selection Screen

* - CCDF measures the percen t age of time the power level is abo ve a

threshold.

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

23

Page 38

Main Menu Interface

Note: To reach this screen, press the Menu button.

Zero/Cal

Begins a zero calibration on the sensor.

Offset

Sets the Offset for the measurement.

Filter Menu

Sets the filter tolerance level.

CCDF Limit

Sets the CCDF limit.

24

Page 39

Logging

See “Log Files” on page 36.

Smoothing

See “Smoothing Menu” on page 36.

Setup

See “Setup Menu” on page 37.

Terminating Power Sensor Attached

Note: Includes the Ext ended Frequency versions.

True Avg Power Interface

Key Button Action

Right Arrow No effect

Left Arrow No effect

Up Arrow Toggles Fwd Avg units from W to dBm

Down Arrow Toggles Fwd Avg units from W to dBm

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

0 (2 Sec) Zero/Cal Unit/Sensor

8 (2 Sec) Turn On/Off Smoothing

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

Menu & Log (2 sec) Language Selection Screen

25

Page 40

Directional Power Sensor (Legacy) Attached

Forward Avg Interface

Small Display

Large Display

Key Button Action

Right Arrow Changes the Main Measurement to Reflected Avg

Left Arrow Changes the Main Measurement to Match

Up Arrow Switch True Avg (W, uW, mW, kW, dBm)

Down Arrow Switch True Avg (W, uW, mW, kW, dBm)

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) No effect

8 (2 Sec) Turn On/Off Smoothing

Menu & Log (2 sec) Language Selection Screen

* - 5010 only supports APM/DPM Elemen ts – No Element Type Select on

Menu.

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

26

Page 41

Reflected Avg Interface

Small Display

Large Display

Key Button Action

Right Arrow Changes the Main Measurement to Match

Left Arrow Changes the Main Measurement to Forward Avg.

Up Arrow Switch True Avg (W, uW, mW, kW, dBm)

Down Arrow Switch True Avg (W, uW, mW, kW, dBm)

OK Button Initiates Shutdown. See “Shutting Down” on

page 13.

Menu Button Goes to Main Menu.

Log Button Goes to Logging submenu.

+/- Toggles between “Small” and “Large” Display.

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13.

0 (2 Sec) No effect

8 (2 Sec) Turn On/Off Smoothing

Menu & Log (2 sec) Language Selection Screen

* - 5010 only supports APM/DPM Elemen ts – No Element Type Select on

Menu.

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

27

Page 42

Match Interface

Small Display

Large Display

Key Button Action

Right Arrow Goes to Forward Avg measurement

Left Arrow Goes to Reflected Avg measurement

Up Arrow Switch Match (VSWR, Rtn Loss, Match Eff%)

Down Arrow Switch Fwd/Rfl Avg (W, dBm)

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) No effect

8 (2 Sec) Turn On/Off Smoothing

Menu & Log (2 sec) Language Selection Screen

* - 5010 only supports APM/DPM Elemen ts – No Element Type Select on

Menu.

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

28

Page 43

Directional Power Sensor Attached

Forward Avg Interface

Small Display

Large Display

Key Button Action

Right Arrow Changes the Main Measurement to Forward Avg Peak

Left Arrow Changes the Main Measurement to Reflected Avg

Up Arrow Switch True Avg (W, uW, mW, kW, dBm)

Down Arrow Switch True Avg (W, uW, mW, kW, dBm)

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) No effect

8 (2 Sec) Turn On/Off Smoothing

Menu & Log (2 sec) Language Selection Screen

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

29

Page 44

Reflected Avg Interface

Small Display

Large Display

Key Button Action

Right Arrow Changes the Main Measurement to Forward Avg

Left Arrow Changes the Main Measurement to Match

Up Arrow Switch True Avg (W, uW, mW, kW, dBm)

Down Arrow Switch True Avg (W, uW, mW, kW, dBm)

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu.

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) No effect

8 (2 Sec) Turn On/Off Smoothing

Menu & Log (2 sec) Language Selection Screen

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

30

Page 45

Match Interface

Small Display

Large Display

Key Button Action

Right Arrow Changes the Main Measurement to Forward Peak

Left Arrow Changes the Main Measurement to Reflected Avg

Up Arrow Switch Match (VSWR, Rtn Loss, Match Eff%)

Down Arrow Switch Fwd/Rfl Avg (W, dBm)

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) No effect

8 (2 Sec) Turn On/Off Smoothing

Menu & Log (2 sec) Language Selection Screen

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

31

Page 46

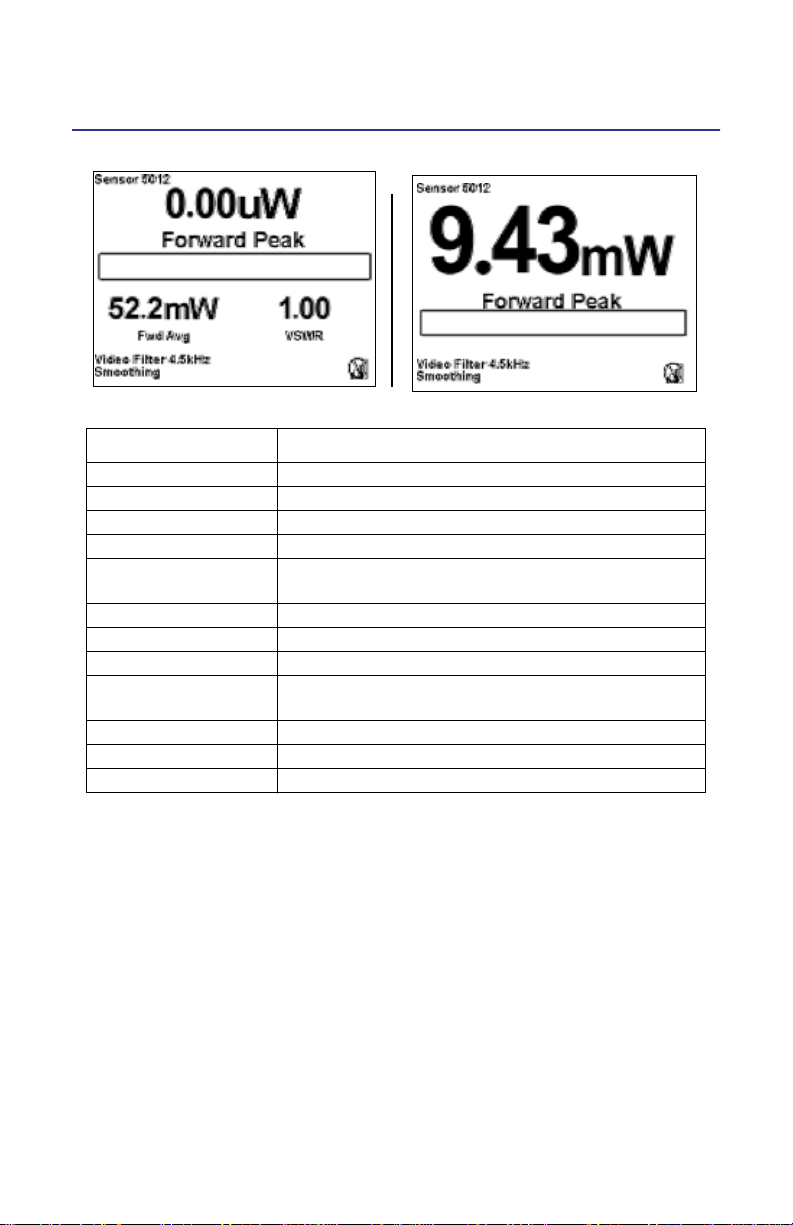

Forward Peak Interface

Key Button Action

Right Arrow Changes the Main Measurement to Forward Avg

Peak

Left Arrow Changes the Main Measurement to Match

Up Arrow Switch True Avg (W, uW, mW, kW, dBm)

Down Arrow Switch True Avg (W, uW, mW, kW, dBm)

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) No effect

8 (2 Sec) Turn On/Off Smoothing

Menu & Log (2 sec) Language Selection Screen

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

32

Page 47

Forward Avg Peak Interface

Key Button Action

Right Arrow Changes the Main Measurement to Forward Avg

Left Arrow Changes the Main Measurement to Forward Peak

Up Arrow Switch True Avg (W, uW, mW, kW, dBm)

Down Arrow Switch True Avg (W, uW, mW, kW, dBm)

OK Button Initiates Shutdown. See “Shutting Down” on

page 13

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

+/- Toggles between “Small” and “Large” Display

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) No effect

8 (2 Sec) Turn On/Off Smoothing

Menu & Log (2 sec) Language Selection Screen

Note: The main measuremen t is in the larger display located

above the graph bar. The two smaller, secondary measurements

are located below the graph bar. All of these measurements vary

depending on the main measurement displayed.

33

Page 48

Main Menu Interface

Note: To reach this screen, press the Menu button.

Offset

Sets the Offset for the measurement.

Scale Menu

Sets the scale.

Element Type

Toggle between 43 and APM/DPM Element types.

34

Page 49

Logging

See “Log Files” on page 36.

Smoothing

See “Smoothing Menu” on page 36.

Setup

See “Setup Menu” on page 37.

TSTPM Sensor Attached

TPS Calibration Standard Power Interface

Key Button Action

Right Arrow No effect

Left Arrow No effect

Up Arrow Switch True Avg (W, uW, mW, kW, dBm)

Down Arrow Switch True Avg (W, uW, mW, kW, dBm)

Ok Button Selects language and change all screens to reflect

the language selected

Menu Button Goes to Main Menu

Log Button Goes to Logging submenu

OK (2 Sec) Initiates Shutdown. See “Shutting Down” on

page 13

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13

0 (2 Sec) Zero/Cal Unit/Sensor

8 (2 Sec) Turn On/Off Smoothing

Menu & Log (2 sec) Language Selection Screen

Note: The main measuremen t is in the larger display locat ed above

the graph bar . The two smaller, secondary measurements are located

below the graph bar. All of these measurements vary depending on

the main measurement displayed.

35

Page 50

5000XT Main Menu, No Sensor Attached

Key Button Action

Right Arrow No effect.

Left Arrow Return to Start Screen.

Up Arrow Up through menu

Down Arrow Down through menu

OK Button Select highlighted.

Menu Button No effect.

Log Button No effect.

. (2 Sec) Performs a screen shot. See “Performing a Screen Shot”

on page 13.

Ok (2 Sec) Initiates Shutdown. See “Shutting Down” on page 13.

Log Files

Lists the stored log files. Pressing the “OK” button will delete the selected file.

Logfiles are named using date/time YYYYMMDDHHMMSS.XML

Smoothing Menu

Sets smoothing feature.

36

Page 51

Setup Menu

Controls all the preferences of the DPM.

Date/Time

Sets the date and time.

The Up and Down arrows control the settings.

The “OK” button locks the settings.

Language

See “Language Selection Menu” on page 41.

System Information

Lists the information regarding firmware, serial number of the unit, as well as

battery and drive capacities.

Backlight Timeout

Sets the amount of time before the backlight shuts down.

The Up and Down arrows control the settings.

The “OK” button locks the settings.

37

Page 52

LCD Timeout

Sets the amount of time before the LCD shuts down.

The Up and Down arrows control the settings.

The “OK” button locks the settings.

Contrast

Sets the contrast of the display.

The Up and Down arrows control the settings.

The “OK” button locks the settings.

Update Firmware

Updates the firmware of the DPM.

Note: A connection t o a PC must be made bef ore updating can be

done. Disconnect from the PC, though, before file operations, such as

logging, are done. If logging when connected to a PC, the logging is

automatically stopped.

38

Page 53

Main Menu, Sensor Attached

Key Button Action

Right Arrow No effect.

Left Arrow Return to Start Screen.

Up Arrow Up through menu

Down Arrow Down through menu

OK Button Select highlighted.

Menu Button No effect.

Log Button No effect.

. (2 Sec) Performs a screen shot. See “Performing a Screen Shot”

on page 13.

Ok (2 Sec) Initiates Shutdown. See “Shutting Down” on page 13.

Offset

Sets offset.

Filter Menu

Controls the filter.

39

Page 54

CCDF Limit

Sets the CCDF Limit.

Log Files

Opens access to the log files.

Smoothing

Sets the Smoothing.

Setup Menu

Controls all the preferences of the DPM.

40

Page 55

Language Selection Menu

Note:

This screen appears

either when the unit is

turned on for the first

time or when the unit

has been reset (see

“Resetting the 5000-XT”

on page 10).

Key Button Action

Right Arrow No effect.

Left Arrow Return to Main Menu

Up Arrow Up through menu

Down Arrow Down through menu

Ok Button Select language and change all screens to reflect

the language selected

Menu Button No effect.

Log Button No effect.

. (2 Sec) Performs a screen shot. See “Performing a Screen

Shot” on page 13.

OK (2 Sec) Initiates Shutdown. See “Shutting Down” on

page 13.

41

Page 56

Logging Menu

Logging Date

Key Button Action

Right Arrow Cycles through onscreen fields

Left Arrow Cycles through onscreen fields

Up Arrow Adjusts Date and Time setting

Down Arrow Adjusts Date and Time setting

OK Button Confirms the setting and moves to the next screen.

Numeric Keypad Directly inputs date and time.

Logging Rate

Key Button Action

Right Arrow

Left Arrow

Up Arrow Cycles through onscreen fields

Down Arrow Cycles through onscreen fields

OK Button Confirms the setting and moves to the next screen.

Numeric Keypad

42

Page 57

Logging Duration

Key Button Action

Right Arrow

Left Arrow

Up Arrow Cycles through onscreen fields

Down Arrow Cycles through onscreen fields

OK Button Confirms the setting and moves to the next screen.

Numeric Keypad

Logging Start

Key Button Action

Right Arrow Cycles through onscreen fields

Left Arrow Cycles through onscreen fields

Up Arrow

Down Arrow

OK Button Confirms the setting and moves to the next screen.

Numeric Keypad

Note: The “OK” but t on will blink when logging.

Log Files

See “Log Files” on page 36.

43

Page 58

44

Page 59

Chapter 5 Maintenance

Cleaning

CAUTION

Do not use harsh or abrasive detergents for cleaning.

Clean the Bird Digital Power Meter and its display with a soft cloth dampened

with mild detergent and water only. Clean sensors with a dry cleaning solvent

that leaves no residue.

Battery Maintenance

Charging Batteries

Fully charged batteries provide about 20 hours of continuous operation with the

Bird WPS, 50 hours with other sensors. Charging time is typically 5 hours using the

AC adapter. The batteries charge whenever the DPM is connected to AC or DC

power sources, using either the AC Mains adapter or the automobile cigarette

lighter adapter. When the external adapter is connected, the battery level indicator will blink until the battery is fully charged. When using the internal batteries,

the indicator will be on continuously and the black bar will show the battery

change remaining. The unit will charge with its power turned either on or off.

Note: F or optimum bat tery lif e, only charge the batt eries after the

battery level indicator empties complet ely and begins to blink.

Prolonging Battery Life

To prolong battery life and optimize the accuracy of battery charge displays:

Charge the battery while the DPM is plugged into external power

through the AC adapter.

Charge it fully before turning on.

The battery charges whether the DPM is off or in use, but the battery

charges faster while the DPM is off.

Charging may be delayed if a battery is new, has been unused for 2

weeks or more, or is much warmer or cooler than room temperature.

45

Page 60

Conserving Battery Power

Conserving power during operation

Disconnect external devices that you are not using that are not plugged

into an external power source.

Stop, disable, or remove any sensors that you are not using.

If left alone, initiate Sleep mode or shut down completely.

Storing a battery

CAUTION

To prevent damage to a battery pack, do not expose it to high temperatures

for extended periods of time.

If the 5000-XT will be unused and unplugged from external power for

more than 2 weeks, remove the battery and store it separately.

To prolong the charge of a stored battery pack, place it in a cool, dry

place.

Calibrate a battery pack before using it if it has been stored for one

month or more.

Managing Low-Battery Conditions

The information in this section describes the alerts and system responses set at

the factory.

Identifying Low-Battery Conditions

The battery power indicator shows the battery power level is low.

Resolving Low-Battery Conditions

When External Power is Available - To resolve a low-battery condition

when external power is available, connect one of the following:

AC adapter

Optional expansion product

Optional power adapter

When a Charged Battery is Available - To resolve a low-battery condition

when a charged battery is available:

1. Shut down the 5000-XT. See “Shutting Down” on page 13.

2. Insert a charged battery pack.

3. Turn on the the 5000-XT.

46

Page 61

When No Power Source is Available - To resolve a low-battery condition

when no power source is available:

Initiate sleep mode. See “Shutting Down” on page 13.

Log trace (see “Logging Menu” on page 42)and turn off the 5000-XT

(see “Shutting Down” on page 13).

When the 5000-XT Cannot Restore from Sleep Mode - To resolve a low-

battery condition when the DPM lacks the power to restore from sleep mode:

1. Do one of the following:

Insert a charged battery (see “Battery Replacement” on page 47).

Plug the computer into an external power source (see “Charging Bat-

teries” on page 45).

2. Restore from hibernation by pressing the power button.

Calibrating the Battery

Note: E ven if a bat tery pack is heavily used, it should not be neces-

sary to calibrate it more than once a month.

Note: It is not necessary t o calibrat e a new bat tery pack.

Note: Calibrat e a battery pack under the f ollowing conditions:

When battery charge displays seem inaccurate

When there is a significant change in battery run time

When the battery has been unused for one month or more

1. Charge the battery. See “Charging Batteries” on page 45.

2. Discharge the battery fully through normal use.

3. Recharge the battery. See “Charging Batteries” on page 45.

Battery Replacement

The Lithium Ion (Li18S) batteries do not normally need to be replaced. If necessary, however, follow these instructions (see Figure 5).

WARNING

Disconnect from external power before any disassembly.

The potential for electric shock exists.

47

Page 62

Figure 5 Back Cover Removal

Back

Cover

Battery

Strap

Battery

1. Lay the DPM, display side down, on a clean surface.

2. Remove the two mounting screws from the back cover.

3. Remove the back cover.

Note: Take care to not disconnect the bat tery c onnector.

4. Pull the battery strap and remove the old battery.

5. Install the new battery.

Note: Check the orien tation of the positive and negative t erminals.

6. Replace the back cover.

7. Secure the back cover with the mounting screws.

Mounting

Screws

48

Page 63

Troubleshooting

PROBLEM POSSIBLE CAUSE REMEDY

Nothing

shown on

display

Display shows

Start Screen

when sensor

is attached.

Display shows

dashes and

“Overrange”;

bar scale is full

WPS Status

LED is not on

Erratic power

readings

Unit is off Press and hold the OK key unitl

the key is illuminated blue.

Batteries are drained Use external power source (see

“Power Supply” on page 7)

Replace the batteries (see

“Customer Service” on page 50)

Sensor communication

has failed

Unit is overrange Use higher power elements (if

WPS not powered Check connection to DPM

Element contact out of

alignment (DPS)

Check connection to DPM.

Use a different cable.

Use a different sensor.

applicable), or reduce RF power.

Connect WPS to a power supply

using the AC adapter

Align the contact. It must be far

enough out to make good

contact with the element, but

must not restrict entry of the

element body.

PC locks when

booting with

the 5000-XT

connected.

Damaged element

(DPS)

Sensor has lost its zero

(TPS)

Sensor is damaged Replace sensor.

Incorrect BIOS settings

on PC.

Replace element.

Rezero sensor.

Disconnect the unit from the PC

then reboot.

49

Page 64

Customer Service

Any maintenance or service procedure beyond the scope of those in this chapter should be referred to a qualified service center.

If you need to return the unit for any reason, request an RMA through the Bird

Technologies website (link shown below). All instruments returned must be

shipped prepaid and to the attention of the RMA number.

Bird Service Center

30303 Aurora Road

Cleveland (Solon), Ohio 44139-2794

Fax: (440) 248-5426

E-mail: bsc@bird-technologies.com

For the location of the Sales Office nearest you, visit our website at:

http://www.bird-technologies.com

50

Page 65

Parts List

Part Name Part Number

Digital Power Meter 5000-XT

Battery, Installed 5A5001-1

Power Supply, Includes Brick, Cord, 3

Intl Adaptors 5A5002-1

Cigarette Lighter Adapter 5A2238-4

Directional Power Sensor 5010, 5010B & 5014

DPM Elements

See P/N 871-DPM-019-901,

the DPM Element Guide,

for a complete list of elements

Terminating Power Sensor

40 MHz – 4 GHz

40 MHz – 12 GHz

Wideband Power Sensor 5012, 5012A, 5012B,

Soft Carry Case 5A5000-1

Lanyard 5A5000-2

Carabiner 5A5000-3

Hard Carry Case 5000-035

PC Interface

Virtual Power Meter (WPS) VPM

Serial to USB Adapter DC-DB9-U

Instruction manual 920-5000-XT

Quick Start Guide 920-5000-XT-QSG

Attenuators & Accessories

Various

5011 & 5015

5011-EF & 5015-EF

5016, 5016B, 5017,

5017B, 5018, 5018B,

5019, & 5019B

N(F) – N(M) Attenuators (RF power range with TPS)

30 dB (10 mW – 10 W)

40 dB (100 mW – 50 W)

DC Block 5011A035–1

N(F) – N(M) Test Cable, 1.5 m TC–MNFN–1.5–G

N(F) – N(M) Armored, Phase Stable Test Cable

1.5 m

3.0 m

Calibration Data 5011–CALDATA

Recommended for attenuators, test cables, DC block,

and right angle adapter

8353A030–10

8353A040–50

TC–MNFN–1.5

TC–MNFN–3.0

Adapters

N(F) – N(F) 4240-500-1 N(F) – N(M)

Right Angle

N(F) –SMA(F) 4240-500-4 N(F) –SMA(M) 4240-500-5

N(F) – 7/16 DIN(F) PA-FNFE N(F) – 7/16 DIN(M) PA-FNME

4240-500-3

51

Page 66

Specifications

Bird 5000-XT Digital Power Meter

General Specifications

Display Monochrome VGA Display with backlight.

Indoor/Outdoor viewable

Backlight When in backlight mode (key has been selected) the unit

should be backlit when any key is pressed on the unit for

a system selectable (Off/15/30/60) seconds from the last

key pressed. The backlight timeout will be based on a

system setup menu option.

General Display Requirements:

Measurement Modes Determined by the sensor

Numerical 1 Channel numerical display (Fwd & Rfl simultaneously)

Units

Battery Condition

Trends

Compatible Sensors 5010 Directional Power Sensor, Legacy

5010B Directional Power Sensor, DB9

5010T Directional Power Sensor, TETRA

5011Terminating Power Sensor, 4 GHz, DB9

5011-EF Terminating Power Sensor, 12 GHz, DB9

5012 Wideband Power Sensor, Legacy

5012A Wideband Power Sensor, Legacy

5012B Wideband Power Sensor

5014 Directional Power Sensor, USB

5015 Terminating Power Sensor, 4 GHz, USB

5015-EF Terminating Power Sensor, 12 GHz, DB9

5016 Wideband Power Sensor, Legacy

5016B Wideband Power Sensor, Low Power

5017 Wideband Power Sensor, Legacy

5017B Wideband Power Sensor, Low Frequency

5018 Wideband Power Sensor, Legacy

5018B Wideband Power Sensor, High Frequency

5019 Wideband Power Sensor, Legacy

5019B Wideband Power Sensor, High Power

TSTPM Test Set

Primary Functions VSWR

Peak Power

True Average Power

Crest Factor

CCDF (Complimentary Cumulative Distributive

Function)

Burst Power

Data Logging

Sensor Detection Automatic

52

Page 67

Operating Power Internal Battery

AC Adapter/Charger

Internal Battery Rechargeable, field replaceable, Lithium Ion battery pack

Battery Life 20 hours continuos usage with WPS series sensors.

60 hours continuos usage with all other sensors.

AC Adapter/Charger 115/230 VAC, 50/60 Hz

Charge Indicator Icon on display

Upgradability Field firmware updateable via USB port.

Calibration Interval No calibration required

Languages English

Mandarin

Spanish

Physical Specifications

Housing PC/ABS housing and shock-

mounted hardware.

Keypad Single-piece integrated unit is

sealed to protect against water. Also

protects against impacts to display.

Dimensions 6.5” x 4” x 1.7”

(165 mm x 102 mm x 43 mm)

Interconnects / Interfaces:

Sensor DB9

USB 2.0 Sealatch Type A

PC USB 2.0 Sealatch Type B

Weight with Battery 1.4 lbs Max

Environmental Specifications

Temperature:

Operating

Storage

Altitude, Max. 4600m (15.091.9 ft.) above sea level

Humidity, Max. 95% non-condensing

Safety & EMC

Standards

0° to 50 °C (32° to 122°F)

(MIL-PRF-28800F, Class 3)

–20° to +50 °C (-4° to +122°F)

(MIL-PRF-28800F, Class 2)

(MIL-PRF-28800F, Class 2)

RoHS

CE

(Applicable standards include EMC

89/336/EEC, EMC EN 61326-1, 73/

23/EEC with amendment 93/68/EEC,

and EN 61010-1)

53

Page 68

Drop Tested 1 meter drop in most severe

position per EN 61010-1

Additional Transit Drop Per MIL-

STD-810F

Transit Drop 10 drops on corners and faces per

MIL-PRF-28800F, Class 2

Bench Handling 4 drops on each face per MIL-PRF-

28800F, Class 2

Vibration Random 10 to 500 Hz per MIL-PRF-

28800F, Class 2