Page 1

OPERATING INSTRUCTIONS

DIGITAL POWER METER

MODEL 5000

Page 2

Page 3

INSTRUCTION BOOK

DIGITAL POWER METER

MODEL 5000

AND POWER SENSORS

MODELS 5010, 5011,

AND 5011-EF

©Copyright 2003 by Bird Electronic Corporation

Instruction Book P/N 920-5000S Rev. E.

®

is a Registered Trademark of

Bird Electronic Corporation

of the Microsoft Corporation

Microsoft

THRULINE

®

and Windows® are registered trademarks

Page 4

I am not blank

Page 5

Safety Precautions

The following are general safety precautions that are

not necessarily related to any specific part or

procedure, and do not necessarily appear elsewhere in

this publication. These precautions must be

thoroughly understood and apply to all phases of

operation and maintenance.

Keep Away From Live Circuits

Operating personnel must at all times observe normal

safety regulations. Do not replace components or make

adjustments inside the equipment with high voltage

turned on. To avoid casualties, always remove power.

Shock Hazard

Do not attempt to remove the RF transmission line

while RF power is present. Radiated RF power is a

potential health hazard.

Do Not Service or Adjust Alone

Under no circumstances should any person reach into

an enclosure for the purpose of service or adjustment

of equipment except in the presence of someone who is

capable of rendering aid.

Chemical Hazard

Dry cleaning solvents for cleaning parts may be

potentially dangerous. Avoid inhalation of fumes or

prolonged contact with skin.

i

Page 6

Bird Model 5000 Digital Power Meter

Safety Earth Ground

An uninterruptible earth safety ground must be

supplied from the main power source to test

instruments. Grounding one conductor of a two

conductor power cable is not sufficient protection.

Serious injury or death can occur if this grounding is

not properly supplied.

Resuscitation

Personnel working with or near high voltages should

be familiar with modern methods of resuscitation.

Safety Symbols

WARNING

Warning notes call attention to a procedure which,

if not correctly performed, could result in

personal injury.

CAUTION

Caution notes call attention to a procedure which,

if not correctly performed, could result in damage to

the instrument.

The caution symbol appears on the

equipment indicating there is important

information in the instruction manual

regarding that particular area.

NOTE: Calls attention to supplemental

information

ii

Page 7

Warning Statements

The following safety warnings appear in the text

where there is danger to operating and maintenance

personnel, and are repeated here for emphasis.

WARNING

Never attempt to connect or disconnect RF

equipment from the transmission line while RF

power is being applied.

Leaking RF energy is a potential health hazard.

WARNING

Disconnect from external power before any

disassembly. The potential for electric shock exists.

Caution Statements

The following equipment cautions appear in the text

whenever the equipment is in danger of damage, and

are repeated here for emphasis.

CAUTION

When connecting the TPS, only turn the connector

nut. Damage may occur if torque is applied to the

sensor body.

CAUTION

Ground all instruments before connecting the TPS.

Electric shock could damage the sensor.

CAUTION

Use a Bird adapter only and do not use the adapter

with the batteries removed.

iii

Page 8

Bird Model 5000 Digital Power Meter

CAUTION

Do not exceed 2 W average or 125 W peak power for

5 µs when using the TPS or TPS-EF.

Doing so will render the sensor inoperative.

CAUTION

Harsh or abrasive detergents and some solvents

can damage the display unit and

information on the labels.

CAUTION

Always turn off the DPM before connecting or

disconnecting a sensor.

CAUTION

Replace only with Ni-MH rechargeable A batteries.

Nominal Voltage 1.2V; Capacity 2700mAhr.

Safety Statements

USAGE

ANY USE OF THIS INSTRUMENT IN A

MANNER NOT SPECIFIED BY THE

MANUFACTURER MAY IMPAIR THE

INSTRUMENT’S SAFETY PROTECTION.

USO

EL USO DE ESTE INSTRUMENTO DE MANERA

NO ESPECIFICADA POR EL FABRICANTE, PUEDE

ANULAR LA PROTECCIÓN DE SEGURIDAD DEL

INSTRUMENTO.

iv

Page 9

BENUTZUNG

WIRD DAS GERÄT AUF ANDERE WEISE

VERWENDET ALS VOM HERSTELLER

BESCHRIEBEN, KANN DIE GERÄTESICHERHEIT

BEEINTRÄCHTIGT WERDEN.

UTILISATION

TOUTE UTILISATION DE CET INSTRUMENT QUI

N’EST PAS EXPLICITEMENT PRÉVUE PAR LE

FABRICANT PEUT ENDOMMAGER LE

DISPOSITIF DE PROTECTION DE

L’INSTRUMENT.

IMPIEGO

QUALORA QUESTO STRUMENTO VENISSE

UTILIZZATO IN MODO DIVERSO DA COME

SPECIFICATO DAL PRODUTTORE LA PROZIONE

DI SICUREZZA POTREBBE VENIRNE

COMPROMESSA.

SERVICE

SERVICING INSTRUCTIONS ARE FOR

USE BY SERVICE - TRAINED

PERSONNEL ONLY. TO AVOID DANGEROUS

ELECTRIC SHOCK, DO NOT PERFORM ANY

SERVICING UNLESS QUALIFIED TO DO SO.

SERVICIO

LAS INSTRUCCIONES DE SERVICIO SON PARA

USO EXCLUSIVO DEL PERSONAL DE SERVICIO

CAPACITADO. PARA EVITAR EL PELIGRO DE

DESCARGAS ELÉCTRICAS, NO REALICE NINGÚN

SERVICIO A MENOS QUE ESTÉ CAPACITADO

PARA HACERIO.

v

Page 10

Bird Model 5000 Digital Power Meter

WARTUNG

ANWEISUNGEN FÜR DIE WARTUNG DES

GERÄTES GELTEN NUR FÜR GESCHULTES

FACHPERSONAL.

ZUR VERMEIDUNG GEFÄHRLICHE,

ELEKTRISCHE SCHOCKS, SIND

WARTUNGSARBEITEN AUSSCHLIEßLICH VON

QUALIFIZIERTEM SERVICEPERSONAL

DURCHZUFÜHREN.

ENTRENTIEN

L’EMPLOI DES INSTRUCTIONS D’ENTRETIEN

DOIT ÊTRE RÉSERVÉ AU PERSONNEL FORMÉ

AUX OPÉRATIONS D’ENTRETIEN. POUR

PRÉVENIR UN CHOC ÉLECTRIQUE DANGEREUX,

NE PAS EFFECTUER D’ENTRETIEN SI L’ON N’A

PAS ÉTÉ QUALIFIÉ POUR CE FAIRE.

RF VOLTAGE MAY BE PRESENT IN RF

ELEMENT SOCKET - KEEP ELEMENT IN

SOCKET DURING OPERATION.

DE LA TENSION H.F. PEAT ÊTRE PRÉSENTE

DANS LA PRISE DE L’ÉLÉMENT H.F. CONSERVER L’ÉLÉMENT DANS LA PRISE LORS

DE L’EMPLOI.

HF-SPANNUNG KANN IN DER HF-ELEMENTBUCHSE ANSTEHEN - ELEMENT WÄHREND DES

BETRIEBS EINGESTÖPSELT LASSEN.

PUEDE HABER VOLTAJE RF EN EL ENCHUFE

DEL ELEMENTO RF - MANTENGA EL ELEMENTO

EN EL ENCHUFE DURANTE LA OPERACION.

IL PORTAELEMENTO RF PUÒ PRESENTARE

VOLTAGGIO RF - TENERE L’ELEMENTO NELLA

PRESA DURANTE IL FUNZIONAMENTO.

vi

Page 11

About This Manual

This instruction manual guides users through the

operation and maintenance of the Bird 5000 Digital

Power Meter (DPM), as well as the Bird 5010

Directional Power Sensor (DPS) and Bird 5011 and

5011-EF Terminating Power Sensors (TPS).

Typography

There are two types of keys on the DPM. A hard key

has a specific function which is indicated on the key.

The key names for hard keys are set in bold typeface,

e.g. Press the ON key.

Speed keys, which appear under the display, have a

different label depending upon the function selected.

The names appear at the bottom of the display,

directly above the corresponding key. The key names

for speed keys are set in bold italic typeface, e.g. Press

the SCALE Key. In this manual, speed keys will also

be referred to by number, with speed key 1 being the

key on the left. Figure 2 on page 2 shows these speed

key numbers.

Chapter Layout

Introduction — Identifies the parts of the DPM,

describes the functions of the various keys, and

explains the meaning of the indicators which may be

displayed. Also lists the items supplied and optional

equipment available.

Installation — Gives directions for connecting the

DPM, and discusses the various power sources.

vii

Page 12

Bird Model 5000 Digital Power Meter

Operation — Explains how to make measurements

with the DPM, and the special functions used with

specific sensors.

Maintenance — Lists routine maintenance tasks for

the Digital Power Meter, and troubleshooting tips for

common problems. Specifications and battery

information are also included.

Changes to this Manual

We have made every effort to ensure this manual is

accurate at the time of publication. If you should

discover any errors or if you have suggestions for

improving this manual, please send your comments to

our factory. This manual may be periodically updated,

when inquiring about updates to this manual refer to

the part number and revision level on the title page.

viii

Page 13

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Items Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Component Description . . . . . . . . . . . . . . . . . . . . . . 2

Display Description . . . . . . . . . . . . . . . . . . . . . . . . . 4

Speed Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DPM Connection . . . . . . . . . . . . . . . . . . . . . . . . . . 11

RF Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Directional Power Sensor (DPS) . . . . . . . . . . . 11

Terminating Power Sensor (TPS) . . . . . . . . . . 12

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . 13

Loading Setups . . . . . . . . . . . . . . . . . . . . . . . . 14

Directional Power Sensor . . . . . . . . . . . . . . . . . . . 14

Setting Forward Scale . . . . . . . . . . . . . . . . . . . 14

Terminating Power Sensor . . . . . . . . . . . . . . . . . . 15

Zeroing Sensor . . . . . . . . . . . . . . . . . . . . . . . . 15

TPS-EF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Charging Batteries . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ix

Page 14

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . 20

Customer Service. . . . . . . . . . . . . . . . . . . . . . . . . . 21

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Attenuators & Accessories . . . . . . . . . . . . . . . . . . . 23

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

x

Page 15

Chapter 1 Introduction

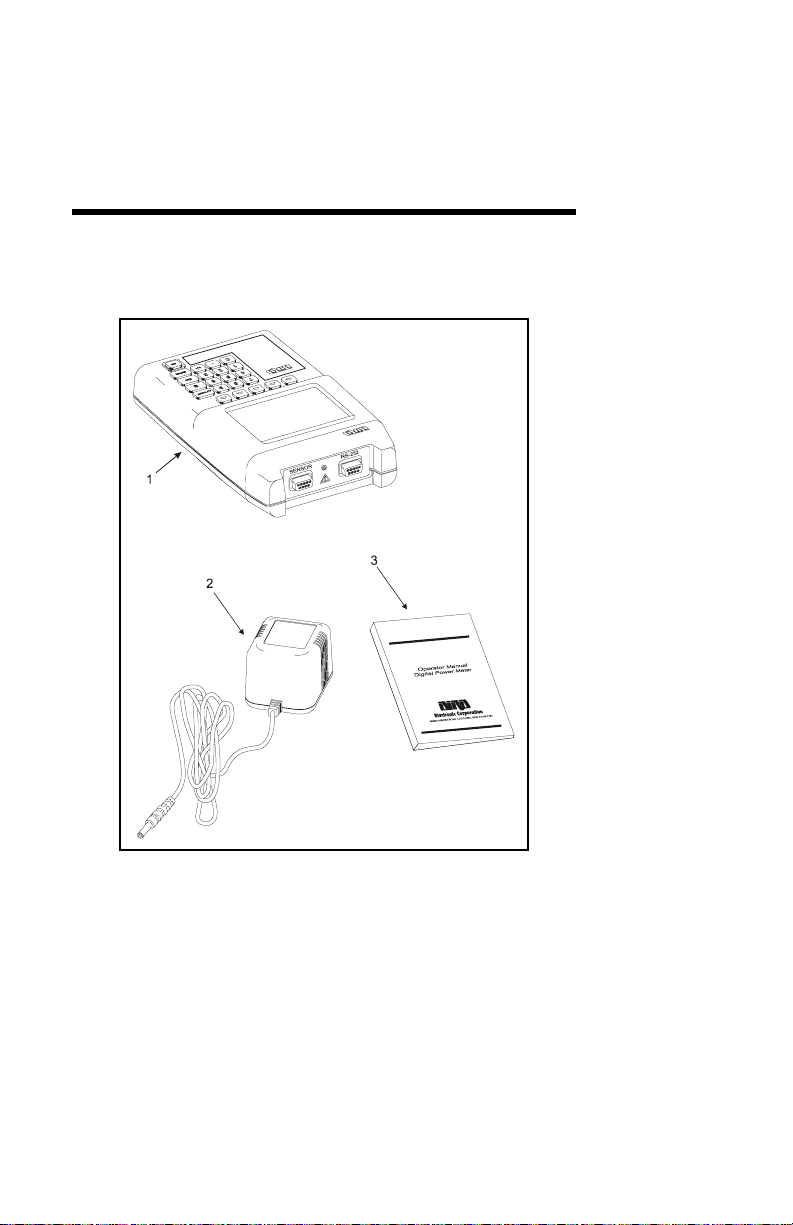

Items Supplied

Figure 1 Supplied Items

1. Bird Digital Power Meter (DPM)

2. AC Mains Adapter

3. Instruction Book

1

Page 16

Bird Model 5000 Digital Power Meter

8

Component Description

11

12

910

12

1

Model

5000

3

Digital Power Meter

Figure 2 Component Description

5

4

7

6

5

4

3

2

2

Page 17

Introduction

1. Speed Keys Activates the command displayed

above it.

2. On Key Turns the DPM on or off.

3. +/- Key Toggles between positive and

negative numbers.

4. Enter Key Completes data entry.

5. Escape Key Aborts data entry without accepting

changes.

6. Backlight Key Turns the backlight on momentarily.

7. Offset Key Enter offset values in dB.

8. Numeric Keys Input numeric values.

9. Sensor Port Connection for power sensors.

10. RS-232 Port Connection for an optional PC 9-pin

RS-232 (DB9) connector, compatible

with PC serial port. 9600 baud, 8

data bits, 1 stop bit, and no parity.

11. LCD Display Backlit liquid crystal display.

12. External DC

Connector

Connect either the ac adapter or the

cigarette lighter adapter. External

supplies power the unit and charge

the internal battery.

3

Page 18

Bird Model 5000 Digital Power Meter

011

Display Description

1

2

3

4

5

6

7

True Avg Power

MAX

Fwd

MIN

Match Eff% Rho VSWR dBr RL dBm W mW KW

Dpm

Rfl

Sens

Match Eff% Rho VSWR dBr RL dBm W mW KW

µ

µ

Overrange

Low Bat

8

Scale

Fwd

Units

Rfl

Units

Figure 3 Display Description

1. Field Indicator Indicates the type of power

being measured.

2. Major Display Displays forward power or

match efficiency, rho, VSWR, or

return loss.

3. Major Display

Annunciator

Indicates function being

measured.

4. Major Display Unit Unit of measure for the major

display.

5. Minor Display Displays reflected power or

match efficiency, rho, VSWR, or

return loss.

9

1

6. Minor Display

Annunciator

Indicates function being

measured.

7. Minor Display Unit Unit of measure for the minor

display.

4

Page 19

Introduction

8. Analog Bar Graph Proportional to the major

display. Minimum at 0 W or –20

dBm. Max at full scale power.

9. Overrange

Indicator

10. Low battery

Indicator

11. Menu Speed Key

Labels

Turns on when the forward

power exceeds 100% of scale or

the reflected power exceeds

120% of scale.

Turns on when the batteries

need charged. Refer to

“Charging Batteries” on

page 17.

Defines the function of the

speed keys.

Speed Keys

Scale — For element-based sensors, sets the forward

full scale power. This is listed on the forward element’s

nameplate. Reflected full scale power is automatically

set to 10 dB below the forward full scale. This speed

key is disabled for non-element-based sensors.

Fwd Units — Selects the units for the major display.

Rfl Units — Selects the units for the minor display.

This speed key is disabled for terminating sensors.

Recall Setup (Speed Key 4) — This speed key is only

enabled for the Directional Power Sensor, although

the label is never displayed. Enter a setup number to

load a stored setup. 0 returns to the default setups.

Setups are stored in the DPM using the optional

PCTool software. For more information, refer to the

help files in the PCTool Software.

5

Page 20

Bird Model 5000 Digital Power Meter

Indicators

Dashes — When no sensor is connected or if

communication with the sensor fails the display will

show a line of dashes and the bar scale will be blank.

Overrange Indicator — If the forward power exceeds

100% of full scale, “Overrange” will be displayed. If

forward or reflected power exceeds 120% of full scale,

the display will show a line of dashes and the bar scale

will be filled.

Low Battery Indicator — “Low Bat” is displayed when

the battery needs recharging. Refer to “Charging

Batteries” on page 17 for more information. The

display will change to “Bat Error” when a Terminating

Power Sensor is connected and the battery is very low.

Offset Indicator — “Fwd” will blink when an offset has

been applied.

Features

Compatibility — The DPM is compatible with Bird

Thruline or Terminating Power Sensors, and with

Bird VSWR Alarm and Broadcast Power Monitor

products with the use of an accessory adapter.

Serial Communication Link — Built-in serial port and

optional software let you download data to a personal

computer for analysis and storage.

Forward and Reflected Power at a Glance — Forward

and reflected power are easily read on the major and

minor display.

6

Page 21

Introduction

Optional Equipment

Directional Power Sensor (DPS) — Bird 5010,

requires two DPM Elements. As a Thruline Sensor,

the DPS measures both forward and reverse power,

enabling the DPM to display VSWR and other match

measurements. Includes interface cable.

Terminating Power Sensors (TPS)— Highly accurate

terminating sensors; do not require elements.

The Bird 5011 frequency range is 40 MHz – 4 GHz.

The 5011-EF frequency range is 40 MHz – 12 GHz.

Includes interface cable.

Automobile Cigarette Lighter Adapter —

(P/N 5A2238-1) Connects the DPM to a standard 12V

automotive cigarette lighter jack.

Soft Carry Case — (P/N 5000-030) Convenient and

protective. Cutouts allow for operation without

removal from the case.

Hard Carry Case — (P/N 5000-035) Protective case

holds DPM, sensor, and accessories.

Attenuators & Accessories — A variety of

attenuators and connectors for measuring large

powers with the TPS. For a complete list, see page 23.

7

Page 22

Bird Model 5000 Digital Power Meter

Interface Software — (P/N 4397A040) PC software

with real time display of DPM measurements. Can

also log data for analysis, printing, or storage.

System requirements: IBM PC or equivalent; Windows

95 or later, 2 MB free hard disk space; VGA monitor,

open Com port. Includes interface cable.

Serial to USB Adapter— (P/N DC-DB9-U) Converts

the serial cable to USB. Lets the DPM be connected to

a PC’s USB port if the serial port is unavailable.

8

Page 23

Chapter 2 Installation

Power Supply

The DPM uses a rechargeable Nickel-Metal Hydride

battery pack. Charge life is a minimum of 100 hours

continuous usage. “Low Bat” is displayed when the

batteries require charging.

NOTE: For optimum battery life, charge the

batteries only after “Low Bat” is displayed.

The DPM can use an external power source. Using the

DPM with the ac adapter or the 12V cigarette lighter

adapter will also charge the battery. Charging time

from full discharge is 8 hours using the ac adapter.

When using the cigarette lighter adapter, charge time

will depend on the car battery charge.

CAUTION

Use a Bird adapter only and do not use the adapter

with the batteries removed.

y AC Mains Adapter — To use the ac adapter. insert

the adapter’s barrel connector into the DPM’s

external dc connector (See Figure 2 on page 2).

Insert the adapter plug into a wall receptacle.

y Automobile Cigarette Lighter Adapter — Insert the

adapter’s barrel connector into the DPM’s external

dc connector. Insert the adapter plug into a

cigarette lighter jack.

9

Page 24

Bird Model 5000 Digital Power Meter

10

Figure 4 DPM Connections

Page 25

Installation

DPM Connection

CAUTION

Always turn off the DPM before connecting or

disconnecting a sensor.

Although unlikely, it is possible to corrupt the power

sensor firmware by connecting it to the DPM while the

DPM is on. To prevent this, always turn the DPM off

before connecting or disconnecting a sensor.

Connect the power sensor to the “Sensor” port on the

DPM using the sensor cable provided. If you are using

the optional PCTool software, connect the PC’s serial

port to the “RS-232” port on the DPM.

RF Connections

WARNING

Never attempt to connect or disconnect RF

equipment from the transmission line while RF

power is being applied.

Leaking RF energy is a potential health hazard.

Directional Power Sensor (DPS)

Connect the DPS to the RF line so that the arrow on

the DPS points towards the load. The element in the

forward socket should be inserted with its arrow

pointing in the direction of forward power, as shown

below. The reflected element should point in the

direction of reverse power. The forward element’s

power rating must be 10x the reverse element’s rating.

11

Page 26

Bird Model 5000 Digital Power Meter

Figure 5 DPS Element Orientation

Terminating Power Sensor (TPS)

CAUTION

Ground all instruments before connecting the

TPS(-EF). Electric shock could damage the sensor.

CAUTION

When connecting the TPS or the TPS-EF, only turn

the connector nut. Damage may occur if torque is

applied to the sensor body.

CAUTION

Do not exceed 2 W average or 125 W peak power for

5 µs when using the TPS or the TPS-EF.

Doing so will render the sensor inoperative.

RF connections are the same for the TPS-EF and the

TPS. In most cases, the TPS should be connected to an

attenuator or a directional coupler. For example, to

measure a transmitter with power output between 0.1

and 50 Watts, use a 40 dB, 50 Watt attenuator. Insert

the attenuator between the TPS and the RF source.

Only connect the TPS directly to the source if the RF

power will be less than 10 mW.

12

Page 27

Chapter 3 Operation

The Bird Digital Power Meter is very easy to operate.

Once a sensor is connected, turn the DPM on and take

a reading. Additional commands are available,

depending on the sensor used.

Normal Operation

y Connect the sensor.

y Turn on the DPM.

y Set the measurement units by pressing FWD Units

and RFL Units.

y If you know the system loss or are using an

attenuator, add the losses (in dB) of all components

in the system. For attenuators and other frequencydependent components, use the loss at the measured

frequency. Then, press OFFSET and enter the total

loss in dB. This will allow you to read the actual line

power. The DPM accepts offsets from 0 to 100 dB.

y Turn on the RF source.

y Read the power level on the display.

NOTE: The analog bar graph will respond immedi-

ately to changes in the RF power. The major and

minor displays will respond after a delay of 1 to 13

seconds, depending on the power level.

13

Page 28

Bird Model 5000 Digital Power Meter

Loading Setups

When used with the optional PCTool software, setups

can be stored in the DPM. Loading a setup will set the

forward scale (for the DPS only) and the offset (for

both the DPS and the TPS).

y Press Speed Key 4.

y Enter the number of the setup you want to load.

NOTE: Entering 0 returns the DPM to its default

scale and offset.

Directional Power Sensor

The Directional Power Sensor (DPS) uses Bird Plug-In

Elements. These are labeled with a max power and a

frequency range. The transmitter frequency should be

within the element range, and the forward element

power should be 10x the reverse element power.

Setting Forward Scale

For the DPS, the forward full scale power must be

entered manually. The reflected full scale power is

automatically set to 1/10 of the forward full scale.

y Press SCALE.

y Change the units with the FWD Units key until the

DPM units match the units on the forward element.

y Use the numeric keypad to enter the maximum

power of the element in the forward element socket.

NOTE: The element’s max power is listed on the

element nameplate.

y Press ENTER.

14

Page 29

Operation

Terminating Power Sensor

CAUTION

Do not exceed 2 W average or 125 W peak power for

5 µs when using the TPS or the TPS-EF.

Doing so will render the sensor inoperative.

Zeroing Sensor

Over time, the sensor’s “zero value” (reading with no

applied RF power) can drift, making all readings

inaccurate by this value. For example, if the zero value

is –2 µW, measuring a 5 mW signal will give a reading

of 4.998 mW, a 0.04% error. Measuring a 50 µW signal

will give a reading of 48 µW, a 4% error. If the drift

would be a significant error, rezero the sensor:

y Make sure the sensor has been connected to the

DPM and the DPM turned on for at least 5 minutes.

y Make sure no RF power is applied to the sensor.

y Press and hold 0 for at least three seconds. “CAL 0”

will be displayed and calibration will begin.

y Zeroing the sensor takes 60 seconds. The bar graph

will display calibration progress. When complete,

“0 CAL PASS” should be displayed. Press ENTER to

return to normal operation. If “0 CAL FAIL” is

displayed, make sure no RF power is applied to the

sensor, press ENTER and zero the sensor again.

TPS-EF

The Bird 5011-EF uses frequency correction factors to

provide more accurate measurements. To use these,

look at the label on the side of the sensor and find the

correction factor for the frequency being measured.

Add the correction factor to the other attenuation or

coupling factors and enter this as an offset.

15

Page 30

Bird Model 5000 Digital Power Meter

16

Page 31

Chapter 4 Maintenance

Cleaning

CAUTION

Harsh or abrasive detergents and some solvents

can damage the display unit and

information on the labels.

Clean the Bird Digital Power Meter and its display

with a soft cloth dampened with mild detergent and

water only. Clean sensors with a dry cleaning solvent

that leaves no residue.

Charging Batteries

Fully charged batteries provide a minimum of 100

hours of continuous operation. Charging time is

typically 8 hours using the ac adapter. The batteries

charge whenever the DPM is connected to either ac or

dc power sources, using either the ac Mains adapter or

the automobile cigarette lighter adapter. The unit will

charge with its power turned either on or off.

NOTE: For optimum battery life, charge the

batteries only after “Low Bat” is displayed.

17

Page 32

Bird Model 5000 Digital Power Meter

Troubleshooting

PROBLEM POSSIBLE

CAUSE

Nothing shown

on display

Display shows

dashes; bar

scale is blank

Display shows

“Bat Error”

or dashes and

“Low Bat”; bar

scale is blank

Unit is off Momentarily press the

Batteries are

drained

DPM firmware

corrupted

No sensor

connected

Sensor

communication

has failed

Sensor calibration corrupted

Batteries are

drained

REMEDY

ON key.

Use external power

source. (page 9)

Replace the batteries.

(page 20)

Update firmware.

Connect a sensor.

Use a different cable.

Use a different sensor.

Return sensor to Bird

for recalibration.

Turn off the DPM

before connecting or

disconnecting a sensor.

Use external power

source. (page 9)

Display shows

dashes and

“Overrange”;

bar scale is full

18

Unit is

overrange

Use higher power

elements (if applicable),

or reduce RF power.

Page 33

Maintenance

PROBLEM POSSIBLE

CAUSE

Erratic power

readings

Element

contact out of

alignment

(DPS)

Damaged

element (DPS)

Sensor has lost

its zero (TPS)

Sensor is

damaged

Sensor calibration corrupted

REMEDY

Align the contact. It

must be far enough out

to make good contact

with the element, but

must not restrict entry

of the element body.

Replace element.

Rezero sensor.

Replace sensor.

Return sensor to Bird

for recalibration.

Turn off the DPM

before connecting or

disconnecting a sensor.

19

Page 34

Bird Model 5000 Digital Power Meter

Battery Replacement

The Nickel-Metal Hydride (Ni-MH) batteries do not

normally need to be replaced. If necessary, however,

follow these instructions (see Figure 6).

WARNING

Disconnect from external power before any

disassembly. The potential for electric shock exists.

CAUTION

Replace only with Ni-MH rechargeable A batteries.

Nominal Voltage 1.2V; Capacity 2700mAhr.

20

Battery Connector

Figure 6 Back Cover Removal

Page 35

Maintenance

y Lay the DPM, display side down, on a clean surface.

y Use a small screwdriver to remove all six screws

from the back cover.

y Taking care to not disconnect the battery connector,

lift the back cover off, flip it over, and lay it, battery

side up, next to the front cover.

y Remove the old batteries.

y Install the new batteries checking the orientation of

the positive and negative terminals.

y Make sure the battery connector is connected.

y Taking care to not pinch the connector wires, put

the covers back together and screw into place.

Customer Service

Any maintenance or service procedure beyond the

scope of those in this chapter should be referred to a

qualified service center.

If you need to return the unit for any reason, contact

the Bird Service Center for a return authorization. All

instruments returned must be shipped prepaid and to

the attention of Bird Service Center.

Bird Service Center

30303 Aurora Road

Cleveland (Solon), Ohio 44139-2794

Phone: (440) 519-2298

Fax: (440) 519-2326

E-mail: bsc@bird-technologies.com

For the location of the Sales Office nearest you, give us

a call or visit our Web site at:

http://www.bird-electronic.com

21

Page 36

Bird Model 5000 Digital Power Meter

Parts List

Part Name Part Number

Digital Power Meter 5000

AC adapter

120V ac

230V ac

Cigarette Lighter Adapter 5A2238-1

Directional Power Sensor 5010

5A2229

5A2226

DPM Elements

See P/N 871-DPM-019-901,

the DPM Element Guide,

for a complete list of elements

Terminating Power Sensor

40 MHz – 4 GHz

40 MHz – 12 GHz

Soft Carry Case 5000-030

Hard Carry Case 5000-035

PC Interface Software 4397A040

Serial to USB Adapter DC-DB9-U

Instruction manual 920-5000S

Various

5011

5011-EF

22

Page 37

Maintenance

Attenuators & Accessories

N(F) – N(M) Attenuators (RF power range with TPS)

30 dB (10 mW – 10 W)

40 db (100 mW – 50 W)

DC Block 5011A035–1

N(F) – N(M) Test Cable, 1.5 m TC–MNFN–1.5–G

N(F) – N(M) Armored, Phase Stable Test Cable

1.5 m

3.0 m

Calibration Data 5011–CALDATA

Recommended for attenuators, test cables, dc block,

and right angle adapter

Adapters

8353A030–10

8353A040–50

TC–MNFN–1.5

TC–MNFN–3.0

N(F)–N(F) 4240-500-1 N(F) –N(M)

Right Angle

N(F)–SMA(F) 4240-500-4 N(F)–SMA(M) 4240-500-5

N(F)–7/16

DIN(F)

PA-FNFE N(F)–7/16

DIN(M)

4240-500-3

PA-FNME

23

Page 38

Bird Model 5000 Digital Power Meter

Specifications

Bird 5000 Digital Power Meter

Display Backlit LCD with major and

minor displays and analog bar

graph

Major Display 5 digits, 5/16” High

Minor Display 5 digits, 1/4” High

Analog Bar Graph 20 segment, horizontal

orientation. Tracks the major

digital display

Measurement Modes Average power, true average

power, or peak power as

determined by the element or

sensor.

Sensor Interface 9-pin D-shell RS-232 serial

connector. Sensor is powered from

the DPM.

PC Interface 9-pin RS-232 serial port

Dimensions 8.0”H x 4.625”W x 2.0”D

(203 x118 x 51 mm)

Weight 2 lbs. (0.9 kg) nominal

Power Supply Rechargeable Nickel-Metal

Hydride (NiMH) battery. Meter

may be operated from ac mains

using supplied adapter.

Battery Life 100 hours, minimum, per charge.

Battery Charge Time 8 hours for full charge.

Operating Temp. 32 to 122 ° F (0 to +50 °C)

24

Page 39

Maintenance

Storage Temp. –4 to 122 ° F (–20 to +50 °C)

Humidity 95% ± 5% max. (non-condensing)

Altitude 15,000 ft. (4572 m) operating

EMC Complies with directive 92/31/

EEC with exceptions noted:

Emissions: EN-55011:1991,

Class B

EN-61000-3-2:1995

EN-61000-3-3:1995

Immunity: EN-50082-2:1997

Safety Complies with EN-61010, IAW

Council Directives 73/23/EEC and

93/68/EEC

Mechanical Shock MIL-T-28800D Class 3

Vibration MIL-T-28800D Class 3

25

Page 40

Bird Model 5000 Digital Power Meter

Bird 5010 Sensor

Sensor Type /

Elements

*

Bird Thruline directional dualelement line section. Uses two

Bird DPM Elements.

†

Power

Frequency Range

0.1 to 1,000 W

†

2 MHz to 3600 MHz

Accuracy With DPM Elements:

±5% of reading 15 to 35 °C RSS

±7% of reading –10 to 50 °C RSS

Peak / Average 10 dB maximum with DPM

Elements.

Settling Time < 2.5 seconds

Connectors QC Type, Female N normally

supplied

Insertion VSWR 1.05:1 up to 1 GHz (with N

connectors).

Dimensions 2.5”H x 5.0”W x 2.0”D

(58 x 127 x 51 mm)

Weight 1.25 lb. (0.57 kg) nominal with

elements.

* RFL element power must be 1/10 of FWD power.

† Power and frequency range based on selected elements.

26

Page 41

Maintenance

Bird 5011 and 5011-EF Sensors

Sensor Type Diode based terminated true

average power measurement

Power

Maximum Power 2 W avg.

Frequency Range

5011

5011-EF

Accuracy ±(5% of reading

Peak / Average 12 dB max

Input Connector

5011

5011-EF

Output Connector Male DB-9 to host instrument

Input Impedance 50 Ohms (nominal)

Input VSWR:

5011

Typical

Maximum

5011-EF

Typical

Maximum

10

µW to 10 mW

(–20 dBm to +10 dBm)

125 W peak for 5 µs

40 MHz to 4 GHz

40 MHz to 12 GHz

*

+ 1.0 µW)

(excluding mismatch uncertainty)

(with correction factors for

5011-EF)

N Male

Precision N Male

1.03 (36.6 dB return loss)

1.20 (20.8 dB return loss)

1.05 (32.0 dB return loss)

1.25 (19.1 dB return loss)

27

Page 42

Bird Model 5000 Digital Power Meter

Power Supply From host instrument via cable

connection

Operating Temp. –10 to +50 °C (+14 to +122 °F)

Storage Temp. –40 to +80 °C (–40 to +176 °F)

Humidity 95% max. (non-condensing)

Altitude 15,000 ft operating

Size 6” long max . (including

connectors) 1.5” diameter nominal

Weight 3/4 lb. (0.35 kg) max.

Recommended Cali-

12 Months

bration Interval

* 5011: Above 40 °C, when making measurements at

frequencies between 40 and 100 MHz, add 1%.

5011-EF: Above 40 °C or below 10 °C, add 1%.

28

Page 43

Limited Warranty

All products manufactured by Seller are warranted to be free from

defects in material and workmanship for a period of one (1) year,

unless otherwise specified, from date of shipment and to conform to

applicable specifications, drawings, blueprints and/or samples.

Seller’s sole obligation under these warranties shall be to issue credit,

repair or replace any item or part thereof which is proved to be other

than as warranted; no allowance shall be made for any labor charges

of Buyer for replacement of parts, adjustment or repairs, or any other

work, unless such charges are authorized in advance by Seller.

If Seller’s products are claimed to be defective in material or

workmanship or not to conform to specifications, drawings,

blueprints and/or samples, Seller shall, upon prompt notice thereof,

either examine the products where they are located or issue shipping

instructions for return to Seller (transportation charges prepaid by

Buyer). In the event any of our products are proved to be other than

as warranted, transportation costs (cheapest way) to and from

Seller’s plant, will be borne by Seller and reimbursement or credit

will be made for amounts so expended by Buyer. Every such claim for

breach of these warranties shall be deemed to be waived by Buyer

unless made in writing within ten (10) days from the date of

discovery of the defect.

The above warranties shall not extend to any products or parts

thereof which have been subjected to any misuse or neglect, damaged

by accident, rendered defective by reason of improper installation or

by the performance of repairs or alterations outside of our plant, and

shall not apply to any goods or parts thereof furnished by Buyer or

acquired from others at Buyer’s request and/or to Buyer’s

specifications. Routine (regularly required) calibration is not covered

under this limited warranty. In addition, Seller’s warranties do not

extend to the failure of tubes, transistors, fuses and batteries, or to

other equipment and parts manufactured by others except to the

extent of the original manufacturer’s warranty to Seller.

The obligations under the foregoing warranties are limited to the

precise terms thereof. These warranties provide exclusive remedies,

expressly in lieu of all other remedies including claims for special or

consequential damages. SELLER NEITHER MAKES NOR

ASSUMES ANY OTHER WARRANTY WHATSOEVER, WHETHER

EXPRESS, STATUTORY, OR IMPLIED, INCLUDING

WARRANTIES OF MERCHANTABILITY AND FITNESS, AND NO

PERSON IS AUTHORIZED TO ASSUME FOR SELLER ANY

OBLIGATION OR LIABILITY NOT STRICTLY IN ACCORDANCE

WITH THE FOREGOING.

Page 44

DECLARATION OF CONFORMITY

Manufacturer: Bird Electronic Corporation

30303 Aurora Road

Cleveland, Ohio 44139-2794

Product: Digital Power Meter and Power Sensor

Models: 5000 5010

The undersigned hereby declares, on behalf of Bird

Electronic Corporation of Cleveland, Ohio, that the abovereferenced product, to which this declaration relates, is in

conformity with the provisions of the following standards

with exceptions noted;

European Standard EN 55011:1991 - Emissions: Class B

•

• European Standard EN 61000-3-2:1995 - Emissions

• European Standard EN 61000-3-3:1995 - Emissions

• European Standard EN 50082-2:1997 - Immunity

These standards are in accordance with Council Directive

89/336/EEC, on Electromagnetic Compatibility, as amended

by Council Directive 92/31/EEC.

• European Standard EN 61010-1:1993 - Safety, Group II

Including Amendment 2: 1995

This standard is in accordance with Council Directive 73/23/

EEC and 93/68/EEC.

The technical documentation file required by this directive is

maintained at the corporate headquarters of Bird Electronic

Corporation, 30303 Aurora Road, Cleveland, Ohio 44139.

Bob Gardiner

Director of Quality

Bird Electronic Corporation

Page 45

DECLARATION OF CONFORMITY

Manufacturer: Bird Electronic Corporation

30303 Aurora Road

Cleveland, Ohio 44139-2794

Product: Terminating Power Sensor

Models: 5011

The undersigned hereby declares, on behalf of Bird

Electronic Corporation of Cleveland, Ohio, that the abovereferenced product, to which this declaration relates, is in

conformity with the provisions of the following standards

with exceptions noted;

European Standard EN 55011:1998 - Radiated Emissions

•

• European Standard EN 61000-4-2:1995 - ESD Immunity

• European Standard EN 61000-4-3:1995 - Radiated RF /

EMF Immunity

• European Standard EN 61000-4-4:1995 - Fast Transient /

Burst Immunity

• European Standard EN 61000-4-6:1995 - Conducted

Immunity

These standards are in accordance with EMC Directive (89/

336/EEC). Electrical equipment for measurement, control

and laboratory use, EN 61326-1, 1997 edition.

European Standard EN 61010-1:1993 - Part 1: General

•

Requirements Including Amendment 2: 1995

This standard is in accordance with Low Voltage Directive

(73/23/EEC), 1973

The technical documentation file required by this directive is

maintained at the corporate headquarters of Bird Electronic

Corporation, 30303 Aurora Road, Cleveland, Ohio 44139.

Bob Gardiner

Director of Quality

Bird Electronic Corporation

Page 46

DECLARATION OF CONFORMITY

Manufacturer: Bird Electronic Corporation

30303 Aurora Road

Cleveland, Ohio 44139-2794

Product: Terminating Power Sensor

Models: 5011-EF

The undersigned hereby declares, on behalf of Bird

Electronic Corporation of Cleveland, Ohio, that the above

referenced product, to which this declaration relates, is in

conformity with the provisions of the following standards;

European Standard EN 61326-1:1997 - Electronic

•

Equipment for Measurement, Control and Laboratory Use EMC Requirements

• European Standard EN 55011:1998 - Radiated Emissions

• European Standard EN 61000-4-2:1995 - ESD Immunity

• European Standard EN 61000-4-3:1995 - Radiated RF /

EMF Immunity

• European Standard EN 61000-4-4:1995 - Fast Transient /

Burst Immunity

• European Standard EN 61000-4-6:1995 - Conducted

Immunity

These standards are in accordance with EMC Directive (89/

336/EEC).

• European Standard EN 61010-1:1993 - Part 1: General

Requirements Including Amendment 2: 1995

This standard is in accordance with Low Voltage Directive

(73/23/EEC), 1973

The technical documentation supporting compliance with

these directives is maintained at Bird Electronic

Corporation, 30303 Aurora Road, Cleveland, Ohio 44139.

Bob Gardiner

Director of Quality

Bird Electronic Corporation

Page 47

Page 48

QUALITY INSTRUMENTS

FOR RF POWER MEASUREMENTS

From 2 to 4000 MHz and from 25 milliwatts

to 250 kilowatts in 50 ohm coaxial line systems

TERMALINE

ABSORPTION

WATTMETERS

LOAD RESISTORS

CALORIMETERS

THRULINE

DIRECTIONAL

MONITORING

WATTMETERS

TENULINE

ATTENUATORS

COAXWITCH

SELECTOR

SWITCHES

COAXIAL RF FILTERS

®

®

®

®

SENTRILINE

FILTER-COUPLERS

ELECTRONIC CORPORATION

30303 Aurora Road Cleveland, (Solon) Ohio 44139-2794

®

Loading...

Loading...