Page 1

YOU'RE HEARD, LOUD AND CLEAR.

Installation and Operation Manual for

Compact Tower-Top Amplifier System

Models 429-83H-01-M/T

and 429-83H-01-M-48

Manual Part Number

7-9439

8625 Industrial Parkway, Angola, NY 14006 Tel: 716-549-4700 Fax: 716-549-4772 sales@birdrf.com www.bird-technologies.com

Page 2

Warranty

This warranty applies for one year from shipping date.

TX RX Systems Inc. warrants its products to be free from defect in material and workmanship at the time of shipment.

Our obligation under warranty is limited to replacement or repair, at our option, of any such products that shall have

been defective at the time of manufacture. TX RX Systems Inc. reserves the right to replace with merchandise of

equal performance although not identical in every way to that originally sold. TX RX Systems Inc. is not liable for dam-

age caused by lightning or other natural disasters. No product will be accepted for repair or replacement without our

prior written approval. The purchaser must prepay all shipping charges on returned products. TX RX Systems Inc.

shall in no event be liable for consequential damages, installation costs or expense of any nature resulting from the

purchase or use of products, whether or not they are used in accordance with instructions. This warranty is in lieu of all

other warranties, either expressed or implied, including any implied warranty or merchantability of fitness. No representative is authorized to assume for TX RX Systems Inc. any other liability or warranty than set forth above in connection with our products or services.

TERMS AND CONDITIONS OF SALE

PRICES AND TERMS:

Prices are FOB seller’s plant in Angola, NY domestic packaging only, and are subject to change without notice. Federal, State and local sales or excise taxes are not included in prices. When Net 30 terms are applicable, payment is

due within 30 days of invoice date. All orders are subject to a $100.00 net minimum.

QUOTATIONS:

Only written quotations are valid.

ACCEPTANCE OF ORDERS:

Acceptance of orders is valid only when so acknowledged in writing by the seller.

SHIPPING:

Unless otherwise agreed at the time the order is placed, seller reserves the right to make partial shipments for which

payment shall be made in accordance with seller’s stated terms. Shipments are made with transportation charges collect unless otherwise specified by the buyer. Seller’s best judgement will be used in routing, except that buyer’s routing

is used where practicable. The seller is not responsible for selection of most economical or timeliest routing.

CLAIMS:

All claims for damage or loss in transit must be made promptly by the buyer against the carrier. All claims for shortages

must be made within 30 days after date of shipment of material from the seller’s plant.

SPECIFICATION CHANGES OR MODIFICATIONS:

All designs and specifications of seller’s products are subject to change without notice provided the changes or modifications do not affect performance.

RETURN MATERIAL:

Product or material may be returned for credit only after written authorization from the seller, as to which seller shall

have sole discretion. In the event of such authorization, credit given shall not exceed 80 percent of the original purchase. In no case will Seller authorize return of material more than 90 days after shipment from Seller’s plant. Credit

for returned material is issued by the Seller only to the original purchaser.

ORDER CANCELLATION OR ALTERATION:

Cancellation or alteration of acknowledged orders by the buyer will be accepted only on terms that protect the seller

against loss.

NON WARRANTY REPAIRS AND RETURN WORK:

Consult seller’s plant for pricing. Buyer must prepay all transportation charges to seller’s plant. Standard shipping policy set forth above shall apply with respect to return shipment from TX RX Systems Inc. to buyer.

DISCLAIMER

Product part numbering in photographs and drawings is accurate at time of printing. Part number labels on TX RX

products supersede part numbers given within this manual. Information is subject to change without notice.

Bird Technologies Group TX RX Systems Inc.

Page 3

Symbols Commonly Used

WARNING

ESD Electrostatic Discharge

Hot Surface

Electrical Shock Hazard

Important Information

CAUTION or ATTENTION

High Voltage

Heavy Lifting

Bird Technologies Group TX RX Systems Inc.

NOTE

Manual Part Number 7-9439

Copyright © 2009 TX RX Systems, Inc.

First Printing: June 2007

Version Number Version Date

1 06/08/07

2 08/17/07

3 10/10/07

4 02/08/08

5 10/24/08

6 09/03/09

Page 4

Changes to this Manual

We have made every effort to ensure this manual is accurate. If you discover any

errors, or if you have suggestions for improving this manual, please send your

comments to our Angola, New York facility to the attention of the Technical Publications

Department. This manual may be periodically updated. When inquiring about updates to

this manual refer to the manual part number and revision number on the revision page

following the front cover.

Contact Information

Sales Support at 716-217-3113

Customer Service at 716-217-3144

Technical Publications at 716-549-4700 extension 5019

Bird Technologies Group TX RX Systems Inc.

Page 5

Table of Contents

General Description ............................................................................................ 1

Unpacking ............................................................................................................ 4

Pre-Installation Checkout ................................................................................... 4

Mechanical Inspection ....................................................................................... 4

Initial Power-up Test ........................................................................................... 5

Bench Testing ..................................................................................................... 6

Installation............................................................................................................ 8

Base to Tower-Top Communications ................................................................. 8

Test Transmission Line ...................................................................................... 9

Installing the System .......................................................................................... 9

Installing the Tower-Top Box ............................................................................. 9

In-building Lightning Arresters ............................................................................ 9

Installing the MCU ............................................................................................12

Interference and IM Considerations.................................................................. 14

Feedline Data ..................................................................................................... 14

Optimizing The System ..................................................................................... 15

Attenuation Settings ......................................................................................... 15

TTA Net Gain.....................................................................................................15

Receiver Multicoupler Distribution ..................................................................... 15

Setting the TTA NET GAIN Attenuation ............................................................ 16

Determining Needed Attenuation .................................................................... 16

Setting Distribution Attenuation ......................................................................... 17

Spectrum Analysis ............................................................................................ 17

Procedure for Spectral Analysis......................................................................19

Operational Tests (Sensitivity and Degradation) ........................................... 19

Front Panel Test Port ........................................................................................ 19

Tower Top Amplifier Inputs................................................................................ 19

Static System Sensitivity ................................................................................... 19

Measuring Static Sensitivity (Load Connected) ................................................. 19

Effective System Sensitivity............................................................................... 21

Measuring Effective Sensitivity (Antenna Connected)....................................... 22

Degradation ....................................................................................................... 23

Routine Operation ............................................................................................. 23

Amplifier Monitoring ........................................................................................... 23

LCD Display.......................................................................................................23

Current Draw ................................................................................................... 23

Test Cable Connection .................................................................................... 23

TTA Temperature ............................................................................................ 23

Software Version ............................................................................................. 23

Front Panel LEDs .............................................................................................. 24

Form-C Contacts ............................................................................................... 24

Alarms ................................................................................................................ 24

The Test Mode ................................................................................................... 24

Set LNA X Active ............................................................................................... 24

Terminate LNA X ............................................................................................... 25

Un-Terminate LNA X ......................................................................................... 25

System Troubleshooting .................................................................................. 25

Performance Degradation ................................................................................ 25

Hardware Problems .......................................................................................... 25

Lightning and Lightning Arresters ................................................................... 26

Vandalism ....................................................................................................... 26

AC Line Fuse (Model 429-83H-01-M) ...............................................................26

Table of Contents Manual 7-9439-6 09/03/09

Page 6

Disconnected Cables ........................................................................................ 26

Periodic Maintenance........................................................................................27

Recommended Spare Parts.............................................................................. 27

Optional Equipment .......................................................................................... 27

Narrowband Filter .............................................................................................. 27

Multicoupler Expansion Deck ............................................................................ 28

Figures and Tables

Figure 1: Front view of the tower-top box ............................................................ 1

Figure 2A: Top view of the multicoupler unit (MCU) ............................................ 2

Figure 2B: Front view of the MCU ....................................................................... 2

Figure 2C: Back view of the MCU ....................................................................... 2

Figure 3: Cable connections for system components .......................................... 4

Figure 4: Initial power-up test ............................................................................... 5

Figure 5: Boot-up sequence ................................................................................. 6

Figure 6: Default display ....................................................................................... 6

Figure 7: Menu selections .................................................................................... 7

Figure 8: Test equipment interconnection for “bench testing” ............................. 8

Figure 9A: System installation guidelines .......................................................... 10

Figure 9B: System installation guideline notes................................................... 11

Figure 10: Tower-top box mechanical details ...................................................... 9

Figure 11: Application of rubber splicing tape ................................................... 12

Figure 12: Lightning Arrester .............................................................................. 12

Figure 13: Optional Data Network Protector....................................................... 13

Figure 14: Alarm terminals ................................................................................ 14

Figure 15: Testing the output spectrum ............................................................. 18

Figure 16: Maximum signal level mask ............................................................. 18

Figure 17: Calculating actual sensitivity ............................................................. 20

Figure 18: Measuring sensitivity through the test port ....................................... 21

Figure 19: Optional filter interconnect diagram .................................................. 28

Figure 20: Optional multicoupler expansion deck .............................................. 28

Table 1: System Specifications ............................................................................. 1

Table 2: Tower Box Specifications......................................................................... 3

Table 3: Multicoupling Unit Specifications............................................................. 3

Table 4: Bench Test Results.................................................................................. 6

Table 5: Optimum Total TTA NET GAIN .............................................................. 16

Table 6: Distribution Attenuation Settings ........................................................... 17

Table 7: Amplifier Status Troubleshooting Guide ................................................ 22

Table 8: Typical Current Readings ...................................................................... 23

Table 9: Loss of Sensitivity Troubleshooting Guide ............................................ 26

Table 10: Disconnected Cables .......................................................................... 27

Table 11: Optional Narrowband Filters................................................................27

Table of Contents Manual 7-9439-6 09/03/09

Page 7

Appendixes

Appendix A: Front Panel Ethernet Connectivity ................................................. 29

Ethernet Connectivity .......................................................................................... 29

Direct Connection .............................................................................................. 29

Required Equipment ........................................................................................ 29

Procedure ........................................................................................................ 29

Networked Connection ...................................................................................... 30

Required Equipment ........................................................................................ 32

Procedure ........................................................................................................ 32

TTA Network Port Security ................................................................................ 34

Data Encryption ............................................................................................... 34

SNMP Support Disabled..................................................................................34

Telnet Security ................................................................................................. 34

Changing the Telnet Port Password................................................................... 35

Appendix B: Changing your Service Computer IP Address............................... 36

Table of Contents Manual 7-9439-6 09/03/09

Page 8

Table of Contents Manual 7-9439-6 09/03/09

Page 9

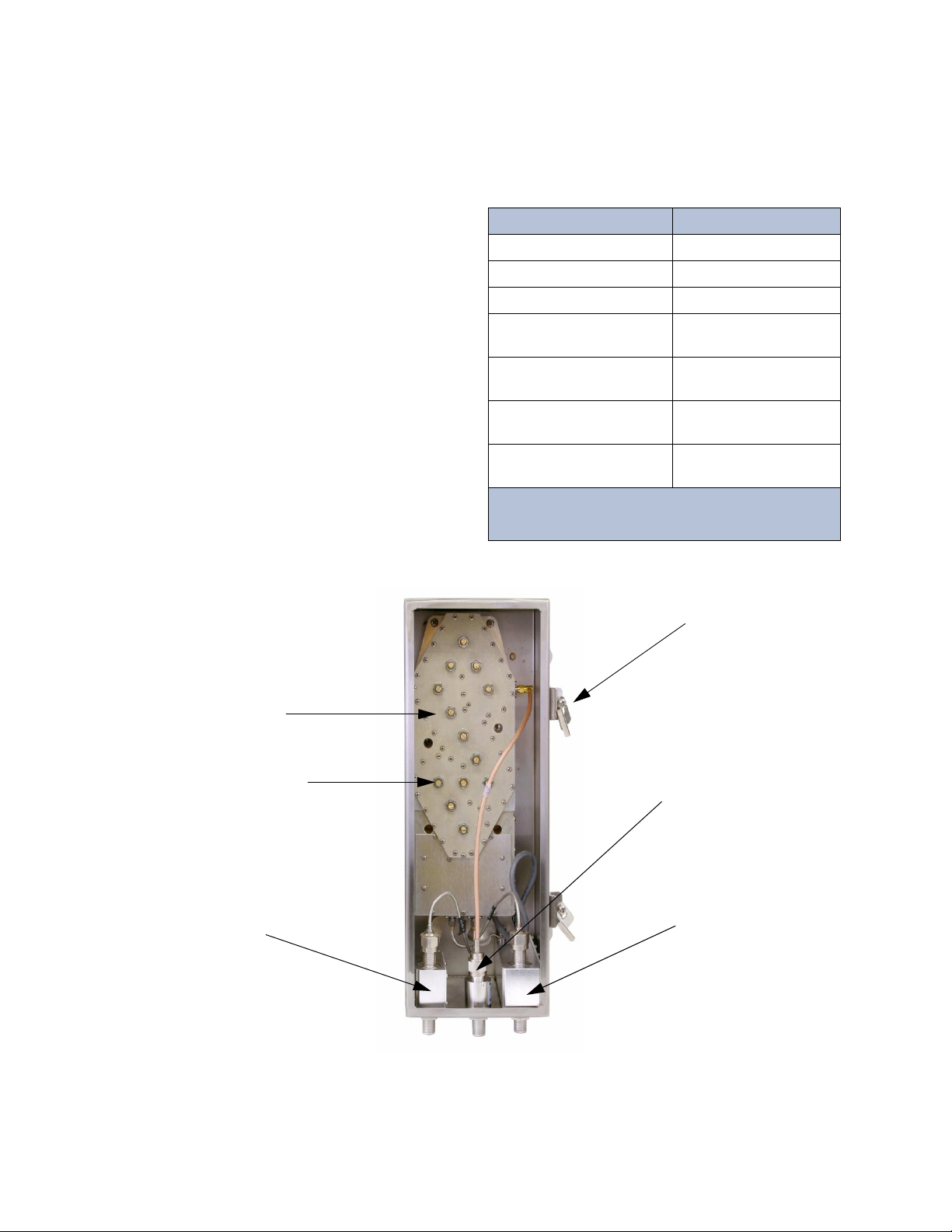

GENERAL DESCRIPTION

Figure 1: Front view of the tower-top box (door removed for clarity).

Amplifier / Filter

Assembly

3-21548

Surge

Suppressor

8-21514

Door

Clamp

Surge

Suppressor

8-21183

Surge

Suppressor

8-21549

Tuning Screw

DO NOT ADJUST

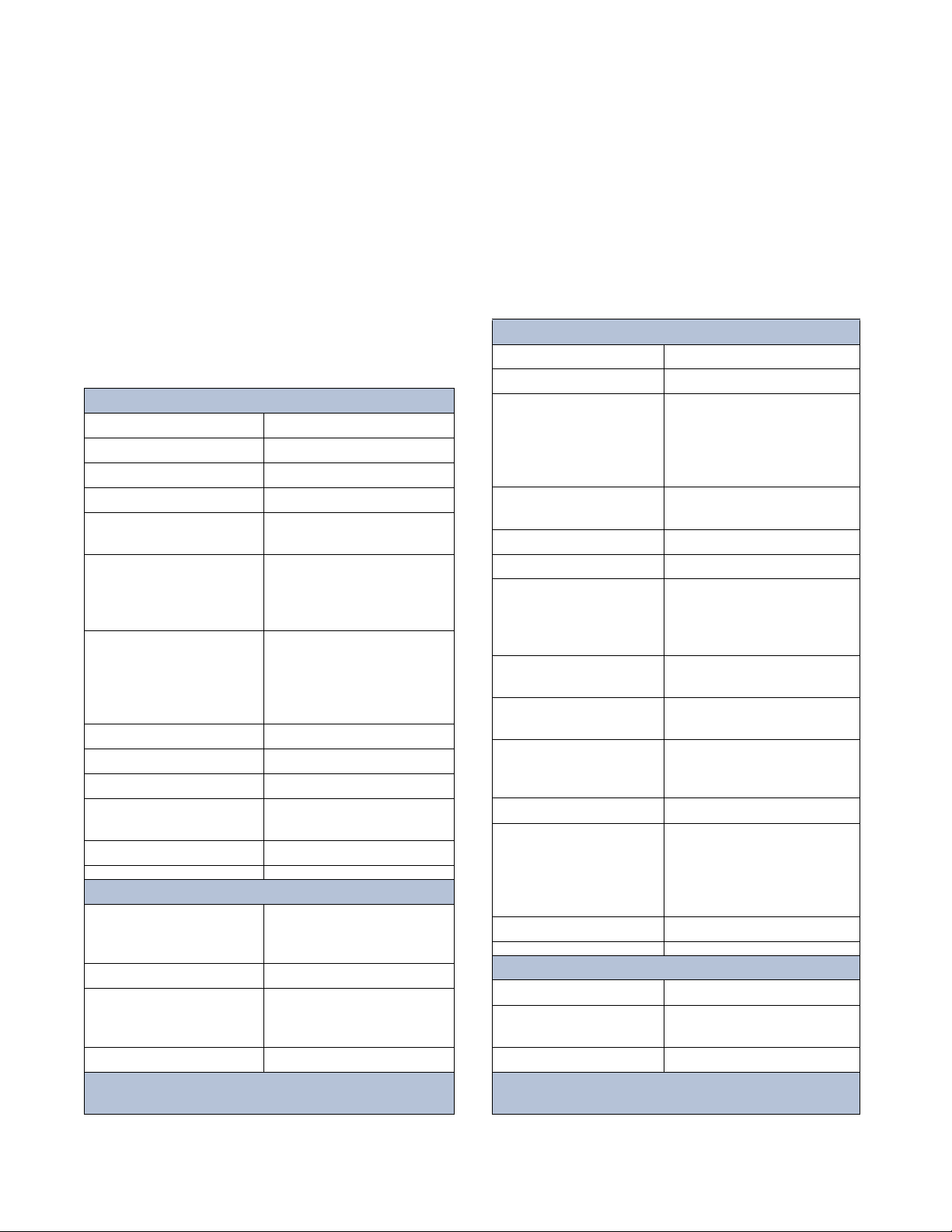

Parameter Specification

Bandwidth 792 - 824 MHz

Noise Figure 2.9 dB typ, 3.5 dB max

3rd order IIP > 15.0 dBm

TTA Net Gain Fully settable by

electronic attenuator

Rejection 110 dB Min, 120 db Nom

@776 and 851 MHz

AC Current

(model 429-83H-01-M) 340 mA (typ) @120 VAC

DC Current

(model 429-83H-01-M-48) 780 mA (typ) @ 48 VDC

Table 1: System specifications.

13 dB TTA Net Gain and

maximum 6 dB transmission line loss assumed

Your TXRX Systems Inc. Tower Top Amplifier System provides the highest degree of reliability available in a Tower Top Amplifier (TTA). The system

uses quadrature-coupled amplifiers (also called

balanced amplifiers) to create a redundant amplifier configuration in both the tower box and the

receiver multicoupling unit (MCU). Each quadamplifier provides two simultaneously used, essentially parallel paths of amplification. Failure of one

of these paths of amplification results in an overall

gain reduction of only 6 dB.

The system also supplies automatic backup-amplifier switching in the tower top box. Fault detection

circuitry continuously monitors the DC power operation of the primary quad-amplifier and automatically switches to the identical secondary quadamplifier if conditions indicate a primary malfunction. If the secondary quad-amplifier malfunctions,

operation switches to whichever quad-amplifier is

still providing some gain due to operation of one of

its amplification paths. Fault detection circuitry also

provides at-a-glance status reporting, with frontpanel LED ’s a nd an LCD displ ay. The sy stem

specifications for the tower top amplifier are listed

in Table 1.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 1

Page 10

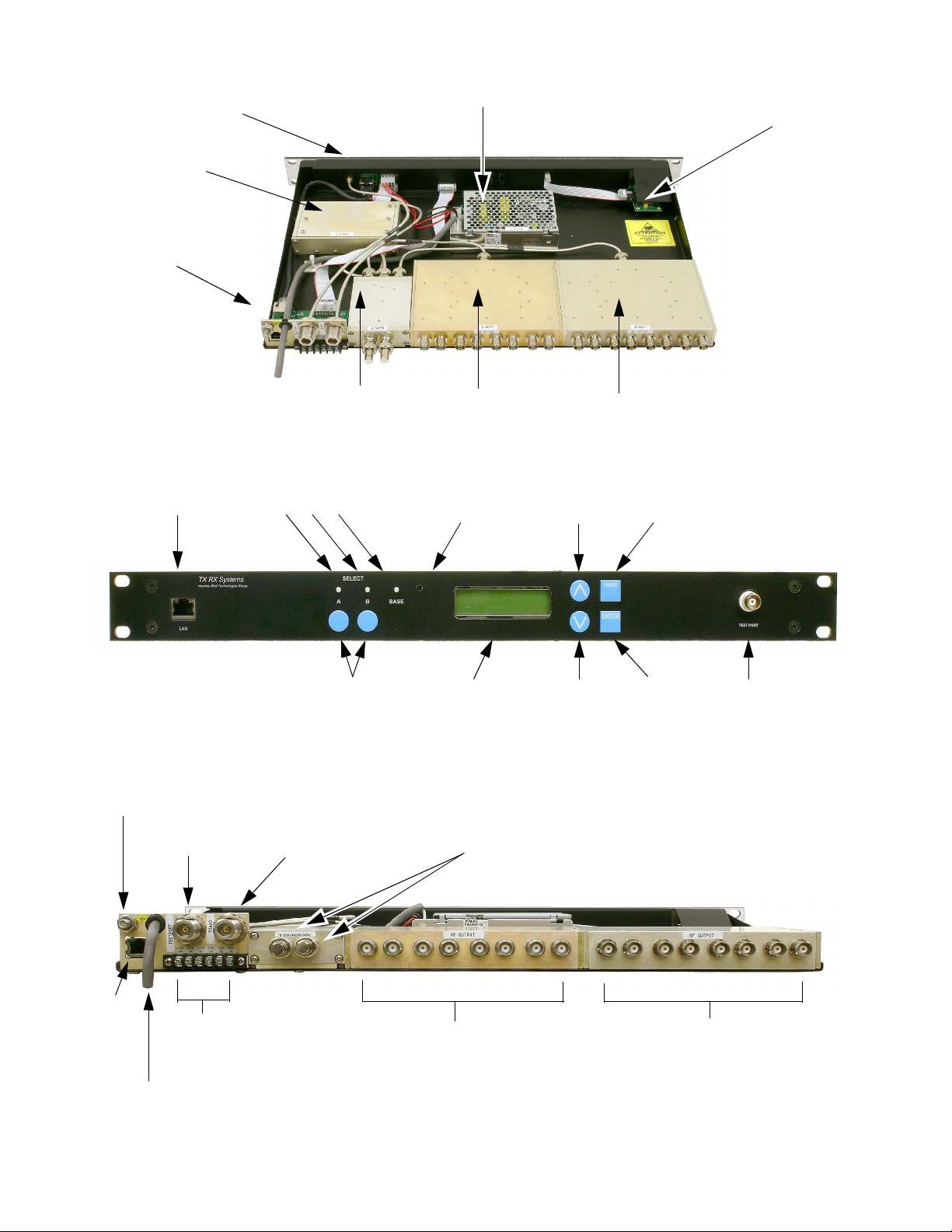

Figure 2C: Back view of the MCU. Model 429-83H-01-M shown.

Ground

Test

cable

Transmission

cable

To additional 8-way dividers

on optional expansion deck.

Terminate when unused.

CAT-5

Cable

here

AC or DC Cord

(model dependent)

Alarm

Terminals

To station receivers

Unused ports do not

require termination

To station receivers

Unused ports do not

require termination

Figure 2B: Front view of the MCU. Model 429-83H-01-M shown.

LAN Port

Status LED’s

Contrast

Adjust

Up

Button

Cancel

Button

Amplifier Select

Buttons

Down

Button

Enter

Button

Test

Port

Display

Figure 2A: Top view of the Multicoupling Unit (MCU). Model 429-83H-01-M shown.

8-21515 Power Supply

(model 429-83H-01-M

)

3-21516 DC-DC Converter

(model 429-83H-01-M-48)

3-21476

Front Ethernet Board

(under shroud)

3-21453

Front Panel Board

(under shroud)

3-21450

Distribution Amp

3-21496

Rear Panel

Board

3-18173

4-Way Divider

3-18171

8-Way Divider

3-18171

8-Way Divider

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 2

Page 11

The quad-amplifier in the tower top box amplifies

Electrical Specifications

Frequency Range 792 to 824 MHz

Net Gain 23 dB

Noise Figure (typ /max) 2.7 / 3.0 dB

Backup Amplifier Switching Solid State RF Switch

Integrated Test Port

Isolation

45 dB

Preselector Type

Loss

Rejection

7-pole TEM Bandpass

with cross-couplings

<0.8 dB

>60 dB @ 776 and 851 MHz

LNA Type

Gain

Noise Figure

3rd Order Input IP

2-stage Quadrature

integrated into filter

26 dB

1.2 dB

18 dBm

Impedance 50 Ohms

Antenna Port VSWR 2 : 1

Power Requirements 12 VDC @ 1.25 A

Lightning Protection Impulse Suppressor on all

external connectors

Operating Temp Range -30° C to +60° C

Mechanical Specifications

Enclosure Modified NEMA 4x:

Stainless steel

weather resistant

Connectors N -female

Dimensions (HWD)

not including mounting tabs

and connectors

18” x 6” x 6”

(457 x 152 x 152 mm)

Net Weight 20 lbs (9.1 kg)

Table 2: Tower box specifications. Values are typical unless

noted otherwise.

Electrical Specifications

Frequency Range 792 to 824 MHz

Multicoupler Net Gain +1 dB typ; 0 dB min

Distribution Amp Type

Gain

Noise Figure

1 dB compression point

3rd Order Output IP

Quad-Coupled dual stage

23 dB

4 dB

27 dBm

46 dBm

Number of Outputs

Split Loss

16 or 32

18 dB

Impedance 50 Ohms

VSWR <2 : 1

Connectors

to TTA

to BTS

Test Port input

N - Female

BNC - Female

BNC - Female

TTA NET GAIN

electronic attenuator

0 to 15.5 dB

in 0.5 dB steps

DISTRIBUTION

electronic attenuator

0 to 3 db

in 0.5 dB steps

Alarm / Warning Contacts Two Form-C Contacts

Nominal 2A @ 30 VDC

or 0.5A @125 VAC

I/O Ethernet

Power Requirements

Model 429-83H-01-M

Model 429-83H-01-M-48

90 - 240 Vac @ 50/60 Hz

-48VDC

Operating Temp Range 0° C to + 50° C

Mechanical Specifications

Enclosure Standard EIA 19” Rack Mount

Dimensions (HWD) 1 RU x 19” x 14”

(38 x 483 x 356 mm)

Net Weight 10.5 lbs (4.8 kg)

Table 3: Multicoupling Unit specifications. Values are

typical unless noted otherwise.

the weak received signal before the signal enters a

long and lossy transmission line, thus preventing

the line loss from degrading the signal-to-noise

ratio. The quadrature amplifiers have a separate

power circuit for each half of the amplifier which

provides component redundancy as well as unsurpassed IM performance. Microprocessor controlled

fault detection circuitry in the tower top box provides continuous monitoring and switching of each

quad amplifier while sending operational data to

the base unit front panel for at-a-glance status

reporting and form-C contact switching for alarm

integration. Included in the tower top box is a pre-

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 3

selector fil ter, amplifi er “A” and ampli fier “B,”

switching circuitry, control board and PolyPhaser

surge suppressors (see Figure 1). The specifications for the tower box are listed in Table 2.

The ground-mounted MCU shown in Figures 2A

through 2C is intended for 19-inch rack mounting.

It houses amplifier and signal distribution assemblies, alarm indicators, a power supply or DC-DC

Page 12

conver ter, and a display panel to provide visual

NOTE

Test

Port Trans

To

Station ReceiversToStation Receivers

To

120

VAC

CAT-5e Cable

Test

Port

Main

Transmission

Main

Main

Test

Antenna

MCU

Tower Top Box

Lightning Arrester

TX RX part no.8-21550

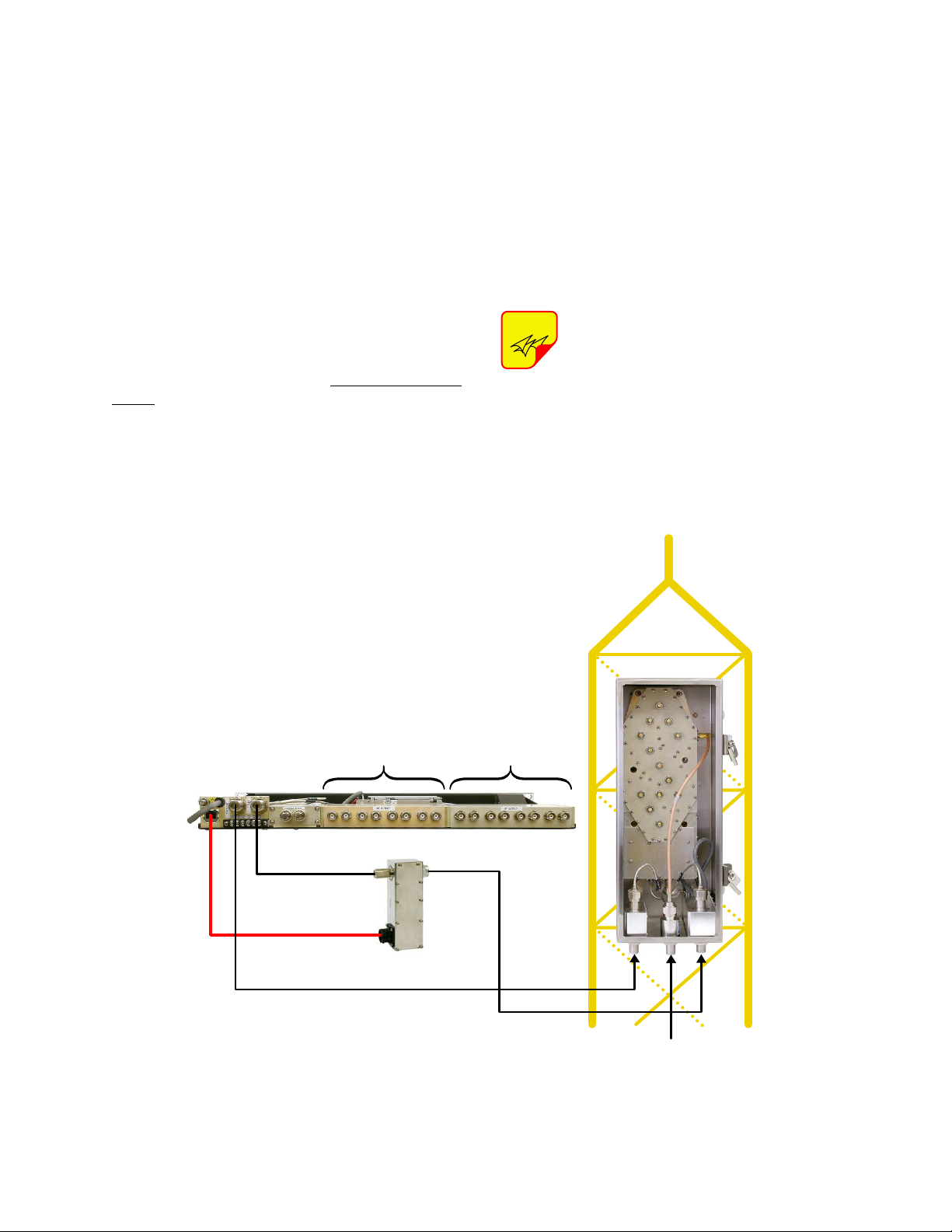

Figure 3: Cable connections for system components. Model 429-83H-01-M shown.

feedback on the system’s operating status. The

specifications for the MCU are listed in Table 3.

Also included in the system is a webpage user

interface for controlling and monitoring of amplifier

currents, alarms, and attenuators. The webpage

user interface is accessed through the front panel

LAN connector. Refer to Appendix A for instructions on accessing this feature.

PRE-INSTALLATION CHECKOUT

The following pre-installation tests should be performed after unpacking the system to verify nothing

has loosened during transit. Additionally, the system should be made operational on the bench with

all components at ground level to verify proper

electrical performance. Figure 3 illustrates all of

the cable connection points for both the tower top

box and the MCU.

UNPACKING

Each major component of the TTA system is individually packaged and shipped via motor freight or

UPS. It is important to report any visible damage to

the carrier immediately. It is the customer's responsibility to file damage claims with the carrier within

a short period of time after delivery (1 to 5 days).

The tower top box should NOT be

installed on the tower until all of the

pre-installation tests are successfully

completed.

Mechanical Inspection

Open the tower top box by loosening all the doorclamp locking screws and rotating the clamps to

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 4

Page 13

release the door. Make sure that all of the connec-

Tower Top Box

MCU

Lightning Arrester

TX RX part no. 8-21550

CAT-5e

Cable

Front

Panel

Test

Port

Test Ant Main

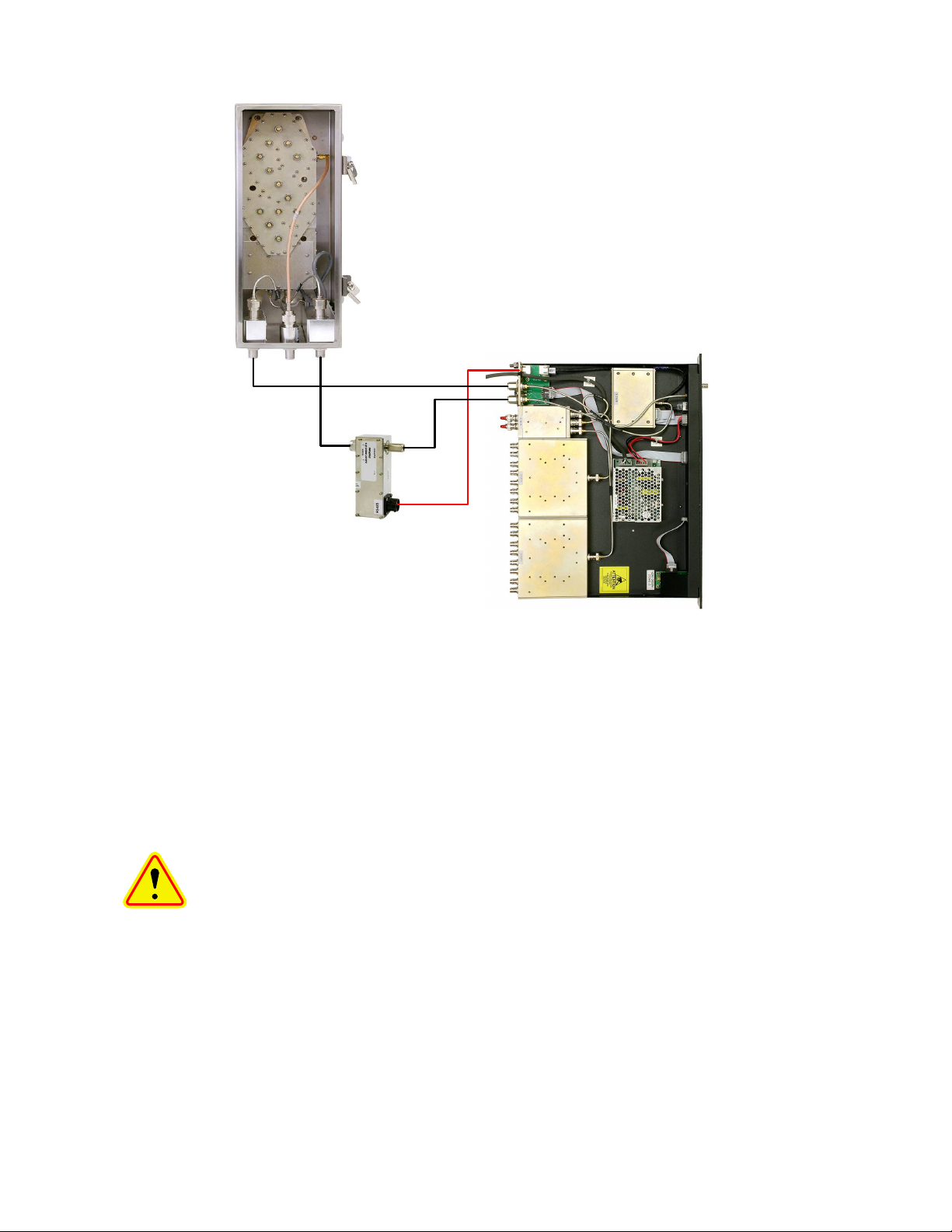

Figure 4: Initial power-up test.

tors are tight. In addition, it is advisable to check

the tightness of the hold-down screws for the various assemblies to insure nothing loosened during

shipment. Likewise, check all of the cable connections on the MCU to insure they are all properly

mated to their associated plugs.

Initial Power-Up Test

To perform the initial power-up test the system

should be temporarily interconnected at ground

level using short cables. Figure 4 shows the tem-

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 5

CAUTION: The wide band filter in

the tower top box is factory tuned

and must not be field adjusted. Field

tuning of this filter is not required. Do

not adjust the tuning sl ugs o f the

amplifier/filter assembly.

porary equipment hookup for initial power-up testing.

Once the equipment is temporarily interconnected

then power is applied to the system by plugging the

MCU’s AC cord into a suitable AC outlet (model

429-83H-01-M) or connecting the DC power cable

to a suitable -48 VDC supply (model 429-83H-01M-48). The following start-up sequence occurs.

1) At turn-on, the three front panel status LED’s

will all glow a steady red while the display panel

shows a row of solid boxes on the top display

line. This will last for about 10 seconds while

the systems micro-controllers boot-up.

2) During the next 5 seconds the base unit (MCU)

will establish communications with the tower

box. The front panel status LED’s will occasionally flash green. The display panel will present

the message “Connecting to Tower Controller”

and then will briefly flash the MCU’s current

software version. See Figure 5.

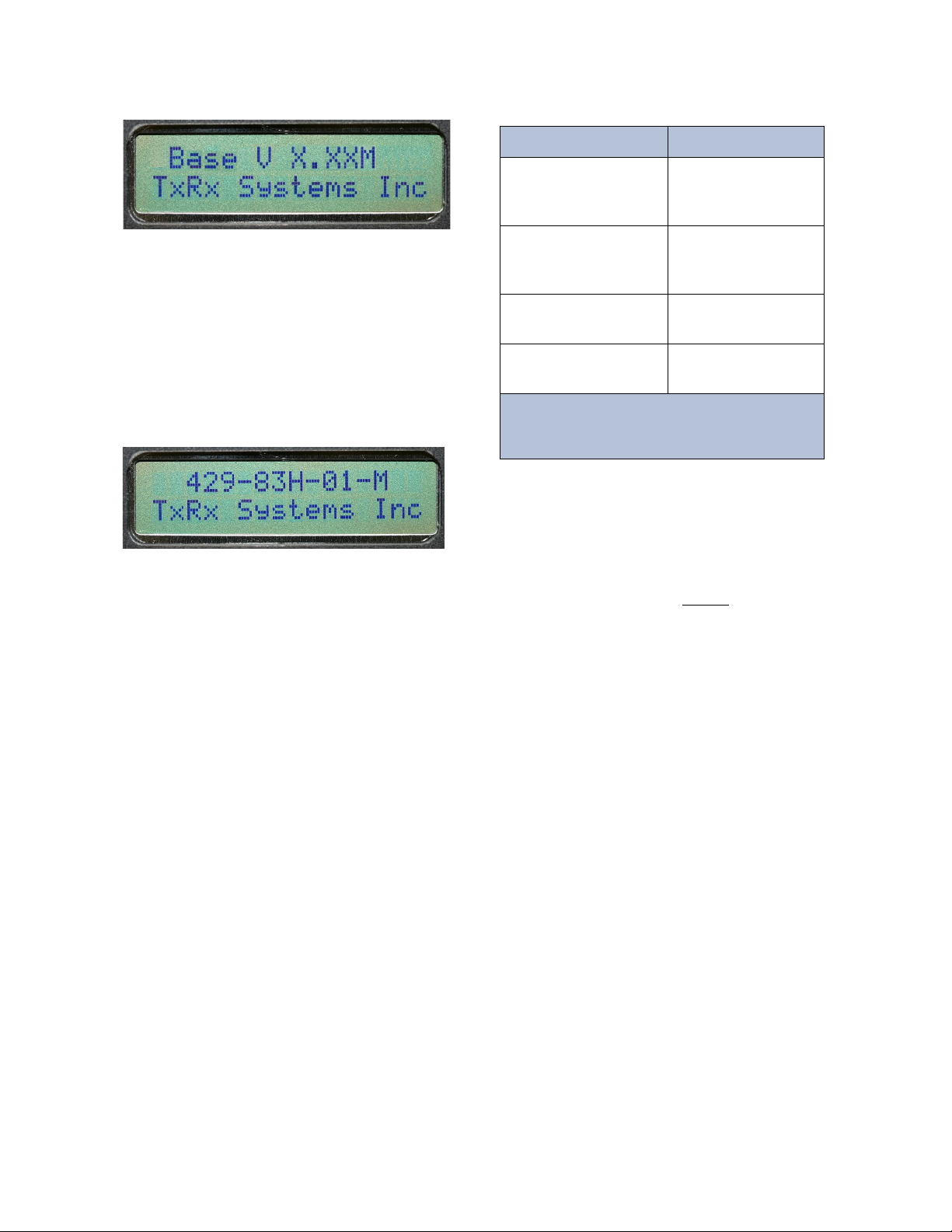

Page 14

3) After the power-up sequencing is complete the

Test Performed Result

Stand Alone

Receiver

Sensitivity

dBm

* Bench Test

Static

Sensitivity dBm

Model Number

(Tower Top Box)

Serial Number

(Tower Top Box)

Table 4: Bench Test Results.

* Default “TTA NET GAIN“ Attenuation (3.0 dB)

* Default “DISTRIBUTION” Attenuation (1.0 dB)

Figure 6: Default display.

Figure 5: MCU software version is displayed briefly

during the boot-up sequence.

screen should show the default display as

shown in Figure 6. The status LED for each

active amplifier will glow a steady green and the

status LED for the inactive (stand-by) LNA will

be dark.

The tower top amplifier system is software directed

so control of the system is accomplished via user

interface with the front panel using the display

screen and the four menu selection buttons. A flow

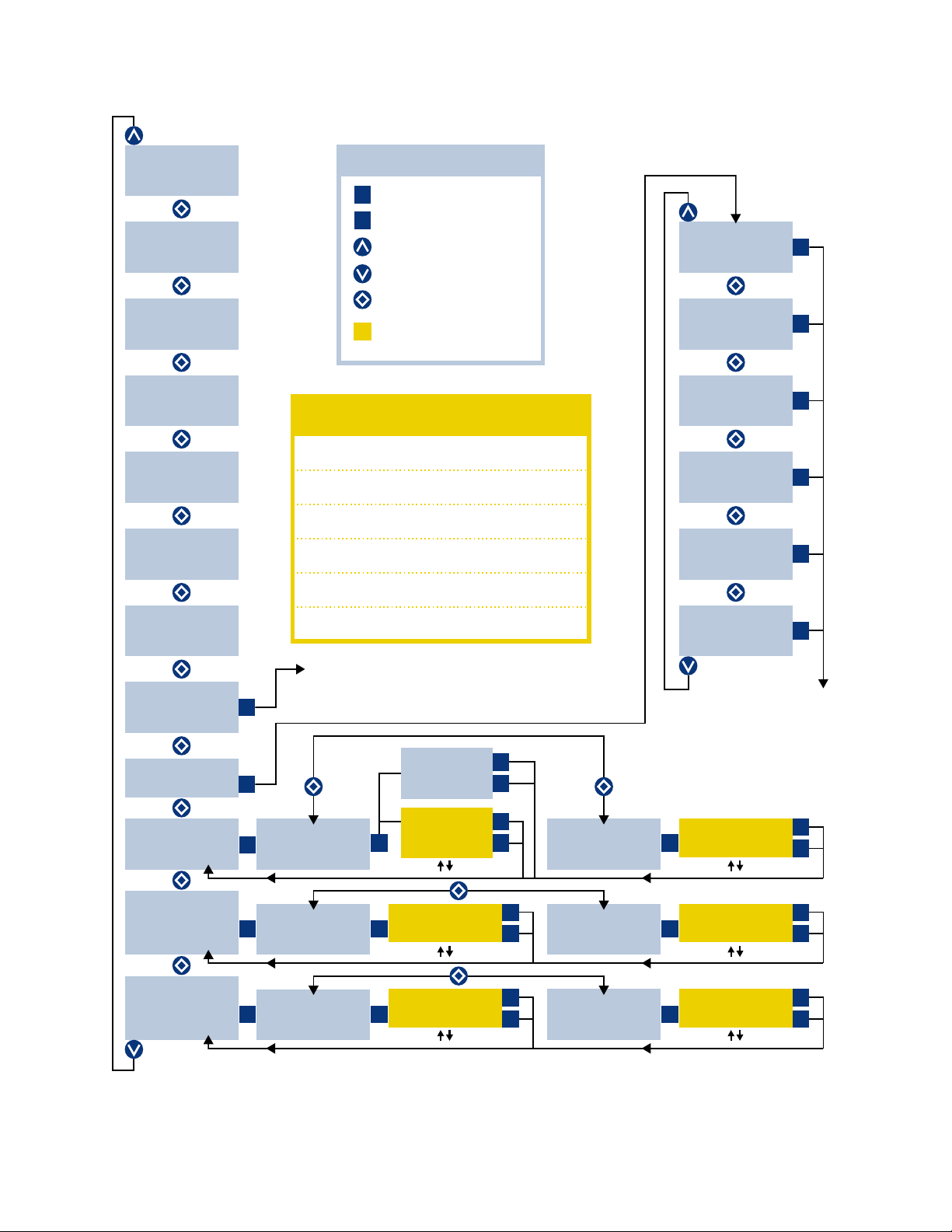

chart showing all of the possible user menu selections is shown in Figure 7.

Bench Testing

The purpose of the bench test is to verify that all of

the system components are working correctly and

to measure the systems sensitivity before climbing

the tower to mount the tower top box. One station

receiver is selected and the test is performed at

this frequency. Short temporary cables are used to

interconnect all components. A SINAD meter is

used for the test (or a bit e r r o r rate m et e r if

required) along with a signal generator.

1) The stand-alone receiver sensitivity is measured and recorded first. Record the value in

Table 4.

2) Connect the equipment as shown in Figure 8.

Be sure that the signal generator is setup for a 3

KHz deviation with a 1000 Hz tone (analog) or

proper pattern for BER testing.

3) Measure and record the systems bench test

static sensitivity in table 4. The sensitivity value

will vary depending on the amount of internal

programmable attenuation selected via software interface. The bench test measurement

should be taken with the default values selected

for “TTA NET GAIN” attenuation (3.0 dB) and

“DISTRIBUTION” attenuation (1.0 dB). These

are the factory default settings that are programmed into your system when you first turn it

on.

4) Select the other tower top amplifier and check

that the bench test static sensitivity value

remains nearly the same. This will insure that

both amplifiers in the tower top box are functioning properly. To select an alternate towertop amplifier press the associated amplifier

select button on the front panel, the status LED

will begin to flash, then press the ENTER button

to finalize the selection.

5) If the tower box door is opened during the

installation it is important to re-tighten the doorclamp locking screws uniformly so that the door

gasket seal is maintained. Tighten each clamp

about half-way, then start back at the first clamp

and fully tighten each one in the same order.

Tighten with a hand tool only. Insure that the

moisture vent holes at the bottom of the box are

unobstructed.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 6

Page 15

TTA NET GAIN

DISTRIBUTION

MAIN LINE LOSS

TEST LINE LOSS

STATIC W/LOAD

REFERENCE W/ANT

AS AN EASY REFERENCE

RECORD VALUES HERE

NOTE: Use arrow to adjust

NOTE: Use arrow to adjust

NOTE: Use arrow to adjust

NOTE: Use arrow to adjust

NOTE: Use arrow to adjust

NOTE: Use arrow to adjust

429-83H-01-M

TX RX SYSTEMS INC

DEFAULT

DISPLAY

PRESS CANCEL KEY

LNA X ACTIVE

A CURRENT XXXmA

B CURRENT XXXmA

BASE CURRENT

XXXX mA

TEST CABLE

CONNECTED

NOT CONNECTED

TTA TEMPERATURE

+/- XX DEGREES C

BASE V X.XX

TOWER V X.XX

INITIALIZE

ENTER TO RESTART

TEST

ENTER TO SELECT

ATTENUATORS

ENTER TO SELECT

FEEDLINE DATA

ENTER TO SELECT

SENSITIVITY

ENTER TO SELECT

TTA NET GAIN

ENTER TO ADJUST

MAIN LINE LOSS

ENTER TO ADJUST

STATIC W/LOAD

ENTER TO ADJUST

Manual Mode

TTA NET GAIN

X.X dB

Automatic Mode

TTA NET GAIN

AUTO MODE

MAIN LINE LOSS

X.X dB

STATIC W/LOAD

-XX.X dB

DISTRIBUTION

ENTER TO ADJUST

TEST LINE LOSS

ENTER TO ADJUST

REFERENCE W/ANT

ENTER TO ADJUST

DISTRIBUTION

X.X dB

TEST LINE LOSS

XX.X dB

REFERENCE W/ANT

-XX.X dB

SET LNA A ACTIVE

ENTER TO CONFIRM

SET LNA B ACTIVE

ENTER TO CONFIRM

TERMINATE LNA A

ENTER TO CONFIRM

TERMINATE LNA B

ENTER TO CONFIRM

UNTERM LNA A

ENTER TO CONFIRM

UNTERM LNA B

ENTER TO CONFIRM

Return to

Default

Display

NOTE:

After pressing the ENTER Button the MCU

will re-boot, then return to the

Default Display.

PRESS ENTER KEY

PRESS UP-ARROW KEY

PRESS DOWN-ARROW KEY

PRESS EITHER ARROW KEY

YELLOW INDICATES

RECORDABLE VALUE

KEY

429-83H-01-M Menu System

C

E

E

E E

E E

E

E

E

E

C

E

C

E

C

C

C

C

C

C

C

E

C

E

C

E

E

E

E

C

E

C

Figure 7: 429-83H-01-M menu selections.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 7

Page 16

Minimum length cables

Best possible sensitivity

Default "TTA NET GAIN" Attenuation (3.0 dB)

Default Distribution Attenuation (1.0 dB)

Signal Generator

MCU

Front

Panel

Test

Port

Tower Top Box

Lightning Arrester

TX RX part no. 8-21550

12 dB SINAD Receiver

CAT-5e

Cable

Diagnostic Cable

Test Ant Main

Figure 8: Test equipment interconnection for “bench testing” of system components.

Connection to an appropriate power source is assumed.

The following sub-sections of the manual discuss

general considerations for installing the system. All

work should be performed by qualified personal.

TXRX Systems provides the base MCU, tower top

amplifier box, and the mainline lightning arrester.

All additional parts required for installation must be

supplied by the customer. Before mounting the

tower top box we recommend that you record the

model number and serial number of the unit for

future reference (table 4 is a convenient place to

record them). The numbers are located on a tag

attache d to the inside of t h e door and maybe

required in the future if you call the factory for customer support.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 8

INSTALLATION

Base to Tower-Top Communications

A special lightning arrester (TXRX part # 8-21550)

is provided with this TTA for installation at the main

transmission line entry bulkhead/grounding plate.

This unit not only passes the DC current required

to operate the TTA, but also generates the low frequency subcarrier used for the standard AISG/EIA485 data communications between the base unit

and the tower top box. A standard CAT-5e data

cable (double shielded) must be installed between

the base unit (MCU) and the lightning arrester for

carriage of the EIA-485 data. The TTA will operate

normally with all backup functionality intact if this

data cable is not installed, is damaged or removed,

but status and alarms will not be available at the

base.

Page 17

Test Transmission Line

NOTE

Mounting Tabs

.312 Dia Thru

Mount Holes

4 Places

6.69"

12.00"

Figure 10: Tower-top box mechanical details.

Prope r installati on of this system requires t he

installation of a test transmission line in addition to

the main transmission line for system testing and

diagnostics. The system will operate normally if the

test transmission line is not installed or becomes

damaged, except the base status LED will continuously display an alarm (red) condition. In addition,

one of th e display sub-menu’s will show a test

cable not connected message.

Installing the System

Installation of the TTA system should follow the

installation standards listed in Figure 9A and 9B

on pages 10 and 11. Lightning arresters are incorporated throughout the system; refer to items 6, 7,

and 11 listed in figure 9. In addition, surge suppression is also provided for all cable connections

within the tower top box. Proper grounding techniques MUST BE obser ved for these devices to

perform properly. See the following sections for

specific installation instructions.

Installing the Tower Top Box

Figure 10 shows some of the mechanical features

of t h e t ower to p b ox. Four mounting tabs are

welded to the back of the box to allow for fastening

to the tower. Because of the varied tower types,

the customer must fabricate the interface brackets

between the tower frame and the box. To install the

tower top box perform the following steps.

1) Mount a receiving antenna on the tower.

2) Run the main transmission cable as well as the

test transmission cable up the tower.

3) Mount the tower top box on the tower and connect the antenna feedline, main transmission

line and test line to the box.

4) Connect the tower top box ground lug to a good

solid ground on the tower.

To insure stability, it is important to

fasten the box to the tower using all

moun t i ng t a bs. T h e b ox must be

moun ted with the conne c tors and

moisture openings facing downward

to prevent water entry. After connecting the main

transmission line, test line, and the antenna feedline, we recommend that the connections be tightly

wrapped with rubber splicing tape (see Figure 11).

This will help prevent water entry into the cables.

Start the wraps on the cable several inches away

from the connector and wrap towards the connector, this will prevent water from seeping in between

the wraps of tape. Cover the conne ctors co mpletely with tape.

5) If the tower box door is opened during the

installation it is important to re-tighten the doorclamp locking screws uniformly so that the door

gasket seal is maintained. Tighten each clamp

about half-way, then start back at the first clamp

and fully tighten each one in the same order.

Tighten with a hand tool only. Insure that the

moisture vent holes at the bottom of the box are

unobstructed.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 9

In-building Lightning Arresters

Two lightning surge suppressors must be installed

in the equipment room one each for the main and

test transmission lines, refer to Figure 9. The following steps are required for proper installation.

1) For the test line install a lightning arrester.

PolyPhaser part # DC50LNZ15MA (N-M/N-F

connectors) or DC50LNZ15 (N-F/N-F connectors). The chassis of the lightning arrester

should be connected to the master ground bus

with a pigtail.

2) For the main transmission line install a lightning

arrester TXRX part # 8-21550. This device is

Page 18

Lightning Arresters 7 and 11 must be grounded

to the Master Ground Buss.

MCU ground stud must be connected to the

Equipment Rack Master Ground Bar.

Building entry-point ground plate and

Equipment Rack Master Ground Bar

must be grounded to Master Ground Buss.

GROUNDING REQUIREMENTSGROUNDING REQUIREMENTS

WARNING

Failure to ground the TTA System properly can result

in equipment failure caused by electrical surges.

1

1

1

1

1

1

6

11

7

5

13

Optional

BNC

Test

Port

To

Base

Station

Building

Entry-Point

Ground

Plate

Copper

Ground

Strap

From

Repeaters

10

5

12

1

8

1

2

2

2

2

2 2

2

4

4

4

2

Transmit

Combiner

MCU

Master Ground Buss

Internal Perimeter Ground (Halo)

Tower Top

Amplifier

Test MainAnt

RX TX

Entry-Point

Ground Buss

To Electrical

Service Ground

Equipment Rack

Master Ground Bar

NOTE

*

**

*

*

**

Figure 9A: System installation guidelines.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 10

Page 19

Main transmission and test line grounded at top, base, shelter entrance and every 75 feet.

All external cable connections weatherproofed.

Hoisting grips used every 200 feet per mainline.

1/2" LDF 10 foot jumper cable from each antenna to its mainline and tower top amplifier.

1/2" Superflex for all internal RF runs.

Lightning Arrester on TX lines.

Lightning Arrester on test port line.

Polyphaser part number DC50LNZ15MA (N-M / N-F ).

Polyphaser part number DC50LNZ15 (N-F / N-F ).

3/8" LDF test port mainline.

We recommend that you follow a good industry standard as a guideline for communications

site installations such as Motorola's R56 Standard. This standard depicts grounding methods

which will help to ensure expected system performance, reliability and longevity.

1/4" Superflex, N male to N male.

Lightning Arrester with RS485 communication interface.

TX RX part number 8-21550.

Data Cable - CAT-5e patch cord (Double Shielded).

L-Com part number TRD855DSZ-XX or equivalent.

Additional Protection (Optional):

If additional protection of the data communication line is desired, a data network protector can

be installed. For this, use Polyphaser Model NX3-05.

This data network protector must be located as close as possible to

the MCU rear data port and grounded to the Equipment Rack Master

Ground Bar. Refer to Figure 13.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

INSTALLATION STANDARDS

SYSTEM ENGINEER RESPONSIBLE FOR

All mounting hardware

Wall feed-through hardware

TX RX Systems Inc. 8625 Industrial Parkway, Angola, NY 14006

716- 549-4700 bird -technol ogies.com sales@birdrf.com

Figure 9B: System installation guideline notes.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 11

Page 20

Figure 11: Application of rubber splicing tape. Note: Additional waterproofing protection can be realized by

covering the rubber tape with either “Scotch Kote” or Vinyl Plastic Electrical Tape (“Scotch” brand 33+).

Test

Line

Antenna

Feedline

Main

Transmission

Line

Ground Lug

Moisture

Vent

Figure 12: Lightning arrester TXRX part # 8-21550.

This device must be connected to the master ground

buss with a pigtail.

RF In

from

Tower Top

RF Out

to MCU

CAT-5e

Cable

Here

shipped from the factory along with the

tower top box. Refer to Figure 12. The chas-

sis of the lightning arrester should be connected

to the master ground bus with a pigtail.

Installing the MCU

The MCU is designed for indoor mounting in a

common 19-inch relay rack or cabinet. The following steps are required for proper installation.

1) Install the MCU into the rack or cabinet with four

mounting screws from the hardware kit (part #

3-16509) which is included with your shipment.

Make sure you use a nylon washer under the

head of the screws in order to protect the front

panel. Torque the mounting screws to no more

than 15 in/lbs. Over tightening the mounting

screws may damage the front panel.

2) Connect the MCU ground lug to the Equipment

Rack Master Ground Bar with a pigtail.

3) Connect the main and test transmission cables

to the appropriate connectors at the back of the

unit.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 12

Page 21

4) Connect a double-shielded CAT-5e cable from

Master Ground Buss

Equipment Rack

Master Ground Bar

Internal Perimeter Ground (Halo)

MCU Rear Panel

ground stud

Ground Wire

Keep as short

as possible

RJ45

RJ45

RJ45

RJ45

Short CAT 5e

patch cable

(double shielded)

N

X

3-0

5

L

oca

t

e D

a

t

a

N

etw

o

rk

P

rotec

tor

as

c

los

e

to M

C

U

Dat

a

Po

r

t as

pos

s

ibl

e

Lightning Arrester

TX RX part number 8-21550

RS 485 Data Line

CAT 5e patch cable

(double shielded)

Figure 13: For optional additional protection install the data network protector.

the RJ45 plug on the rear panel of the MCU to

the RJ45 connector on the lightning arrester at

the building entry ground plate. We recommend

using a pre-built cable from L-Com (part #

TRD855DSZ-XX). The -XX suffix represents

the cables length in feet. An equivalent cable

from another manufacturer is acceptable.

5) If optional additional protection of the data communications line is desired a Data Network Protector can be installed. Use PolyPhaser part #

NX3-05. The data network protector must be

grounded to the equipment rack master ground

bar. Keep this ground wire as short as possible.

See Figure 13.

6) Connect the optional data network protector to

the lightning arrester with the cable from step 4.

Then connect the rear panel MCU data port to

the data network protector with a short length of

double-shielded CAT-5e cable. We recommend

using a pre-built cable from L-Com (part #

TRD855DSZ-XX). An equivalent cable from

another manufacturer is acceptable.

7) If you have a supervisory alarm system, connect its wiring harness to the terminal screws at

the back of the MCU. Refer to Figure 14.

8) Connect the station receivers and optional 16port receiver multicoupler expansion deck to the

output ports on the back of the MCU with highquality 50-ohm coaxial cable such as 1/4-inch

superflexible transmission line. Some flexibility

in the jumper cables will prevent strain and possible damage to the connections. We also recommend the use of quality BNC connectors.

Unused receiver outputs need not be terminated. However, unused expansion ports (the 2

left-most ports) should be terminated with 50

ohms until connected to an expansion panel

(refer to Figure 2C).

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 13

Page 22

Interference and IM Considerations

Figure 14: Alarm terminals. Normally open or normally closed screw terminals are available.

Model 429-83H-01-M-48 shown.

DC Power Cord used in model 429-83H-01-M-48

(Red is -48 Volts and Black is common)

AC Cord used in model 429-83H-01-M

Test Cable

connects here

Main Cable

connects here

Ground

(double-shielded)

CAT-5e Cable

connects here

Alarm Terminals

T h e g ro u n d l ug

must be connected

to t h e eq u i p ment

rack master ground

bar with a pigtail.

Although TX RX Systems, Inc. TTA systems are

design ed for maxi mum interference im munity,

there are many factors that can lead to har mful

interference when using a tower-mounted amplifier. It is highly recommended that the receiving

and transmitting antennas be vertically separated

to maximize antenna isolation.

FEEDLINE DATA

As part of the installation process you will need to

determine the cable losses for your main and test

transmission lines. These loss values can be determined by sweepin g the cable s or they can b e

looked up from the cable manufactures specifications. For your system these values will be fixed

once the cable type is chosen and cut to length.

Although most 700/800 MHz transmitters are connected to their antenna through a combiner, it is

quite likely that t h e combiner d o e s not have

enough transmitter noise filtering to prevent desensitization of the receivers unless there is significant

antenna space isolation. Large values of antenna

isolation are most easily realized when the antennas are separated vertically. This antenna isolation

also helps reduce the possibility of intermodulation

interference in the receiving system.

One other important factor that can strongly contribute to interference problems is excessive gain,

ahead of the receiver. Excessive gain can cause

overdrive to the station receivers when strong signals are present, making them more prone to intermodulation or carrier desensitization problems.

Rec e ive r p r eam p li f ier s s hou l d n ot b e u s ed

because the receiver multicoupler, which is incorporated in the MCU, serves this purpose.

Once you have determined the main and test line

cable loss for your system this information can be

recorded in system memory for future reference in

the Feedline Data menu selection. To save the

cable loss values in memory perform the following

steps.

1) From the default display press the DOWN

ARROW button on the front panel to scroll

through the menu choices until you reach the

FEEDLINE DATA menu.

2) With the FEEDLINE DATA menu displayed

press the ENTER button to step down to the

MAIN LINE LOSS sub-menu.

3) Use the UP and DOWN ARROW buttons to set

the main line loss to the desired value. This

storage register works in a forward loop fashion, starting at 0.0 and increasing to 9.9. A button press after 9.9 returns the setting back to 0.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 14

Page 23

4) After setting the main line loss value press the

ENTER button to return back to the FEEDLINE

DATA menu. This will save your setting choice.

5) With the FEEDLINE DATA menu displayed

press the ENTER button to step down to the

MAIN LINE LOSS sub-menu. Press the UP

ARROW button to move to the TEST LINE

LOSS sub-menu.

6) Use the UP and DOWN ARROW buttons to set

the test line loss to the desired value. This storage register works in a forward loop fashion,

starting at 0.0 and increasing to 9.9. A button

press after 9.9 returns the setting back to 0.

7) After setting the test line loss value press the

ENTER button to return back to the FEEDLINE

DATA menu. This will save your setting choice.

Then pressing the CANCEL button while at the

FEEDLINE DATA menu will return you to the

default display.

OPTIMIZING THE SYSTEM

In the TTA system the first stage of amplification is

in the tower top box which is used to overcome the

main line loss, develop the noise figure, and the

TTA Net Gain. The second amplifier, located on

the multicoupler deck (base unit), is used to overcome the losses associated with distribution.

sensitivity and degradation may appear out of tolerance.

ATTENUATION SETTINGS

The system contains programmable attenuators for

optimizing both the TTA Net Gain and receiver

multicoupler distribution. Both of these attenuators

must be adjusted as part of the system installation.

The attenuation adjustments allow the system to

maintain maximum protection of the receivers,

while obtaining the best sensitivity possible.

TTA Net Gain

TTA Net Gain is defined as the net gain between

the input of the tower top LNA and the input of the

base LNA. The amount of programmable attenuation that your system requires in order to reach an

ideal amount of TTA Net Gain will vary depending

on the length of your main transmission line.

The va lue o f the TTA Net Gain programmable

attenuator can be adjusted either manually by the

customer or automatically by the microprocessor in

the MCU. The choice of manual or automatic is

deter mined by a menu choice in the Webpage

User Interface which is accessible via the MCU’s

LAN connector using a separate PC. For a complete description of the Webpage User Interface

software refer to the TXRX Systems Inc. technical

manual 7-9440.

When the tower top amplifier system is installed

there are detailed adjustments and test procedures

which must be followed in order to insure optimum

performance of the system. The process includes:

Attenuation Settings

Spectrum Analysis

Operational Tests

Sensitivity with Load Connected

Sensitivity with Antenna Connected

Operational testing must be performed in a

methodical manner to provide the correct performance evaluation and ensure that the information

obtained is correct. For each procedure it is important that the data be recorded accurately and is

available anytime assistance is required or when

performance is in question. Before a receive system problem is suspected, the appropriate operational tests must be performed. Before operational

tests for sensitivity can be verified, the programmable attenuation settings and spectrum analysis

must be performed. If these are not correct, the

When automatic has been selected the message

“AUTO MODE” will be shown on the MCU front

panel d ispl ay w hen you scroll down the me nu

choices to the TTA Net Gain value, refer to the

menu selections chart shown in figure 7. Manual

changes to the attenuator value using the front

panel ARROW buttons are not allowed when in the

automatic mode.

Receiver Multicoupler Distribution

Receiver Multicoupler Distribution is defined as the

gain between the input of the base LNA and the

input of the station receiver. The receiver multicoupler distribution adjustment allows for proper compensation of the MCU to receiver cable/distribution

losses and should ideally be se t to unity. The

amount of attenuation that your system will require

in order to reach an ideal amount of receiver multicoupler distribution will vary depending on the

length of the cables from the multicoupler outputs

at the rear of the MCU to your receivers. Distribution attenuation is always adjusted manually using

the front panel ARROW buttons. There is no auto-

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 15

Page 24

matic mode for dist ribution a ttenuation adjust-

Type of Signal The optimum total

amount of TTA NET GAIN

FM Voice 13 dB

Digital 10 dB

Table 5: Optimum total TTA NET GAIN.

ments.

The factory default setting for TTA Net Gain is 3.0

dB of attenuation and the factory default setting for

receiver multicoupler Distribution is 1.0 dB of attenuation. These are the initial settings that are programmed into your system when you first turn it on.

You will need to adjust these values to optimize

your system. This is done through software interface via the menu select keys. Your settings will be

stored in system memory until you change them

again even if the equipment is powered down.

Setting the TTA NET GAIN Attenuation

The total amount of TTA Net Gain attenuation for

your system is composed of two parts, the main

line cable loss (which is fixed, based on cable type

and length) as well as the TTA Net Gain attenuation setting (which is variable, depending on software selection). This is illustrated in the formula

below.

Main Line Loss + Software Setting = Total

It has been found in practice that different levels of

total TTA Net Gain attenuation are required for different types of modulated signals to obtain the best

performance. Table 5 lists the optimum total TTA

Net Gain attenuation value for various signal types.

necessary when the main transmission line loss is

low; that is, when line loss does not reduce the

TTA gain enough to obtain the desired total TTA

Net Gain attenuation level.

DETERMINING NEEDED ATTENUATION

To calculate how much attenuation is needed to

optimize the TTA Net Gain of your system use the

following formula;

TTA Net Gain(dB) = Gain TTA(dB) - Line loss(dB)

For example, if the TTA gain is 24 dB and the main

transmission line loss is 3 dB:

TTA Net Gain = 24 dB - 3 dB = 21 dB

If your system uses FM Voice, you would like a

TTA Net Gain as close to 13 dB as possible. The

amount of TTA Net Gain attenuation required is

calculated with the following formula;

Attenuation(dB) = Actual(dB) - Desired(dB)

Attenuation = 21 - 13 = 8 dB

So in this example the TTA Net Gain attenuation

setting should be 8 dB. If the sign of the calculated

attenuation had been negative it would indicate

that we could actually use more gain! No attenuation would be required.

It should be kept in mind that these values are not

extremely critical. Systems that depart from these

values can still give reasonably good performance,

but may degrade somewhat when extremely strong

and very weak signals are present, as compared

with an optimized system.

The TTA Net Gain attenuation is programmable

and needs to be adjusted to optimum levels for the

type of signals being processed. The default factory setting is 3 dB. Further reduction may only be

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 16

The programmable attenuation for optimizing your

TTA Net Gain attenuation is adjustable from 0 to

15.5 dB in 0.5 dB increments. To adjust the value

perform the following steps.

1) Press the DOWN ARROW button on the front

panel to scroll through the menu choices until

you reach the ATTENUATORS menu.

2) With the ATTENUATORS menu displayed

press the ENTER button to step down to the

TTA Net Gain sub-menu.

3) Press the ENTER button again to advance to

the TTA Net Gain adjustment screen. The current TTA Net Gain setting will now be displayed.

Use the UP and DOWN ARROW buttons to set

the TTA Net Gain to the desired value. The

attenuation setting works in a forward loop fashion, starting at 0 and increasing to 15.5, a button press after 15.5 returns the setting back to

0.

Page 25

4) After setting the TTA Net Gain press the

Set DISTRIBUTION

attenuation to

for cable / distribu-

tion losses of

3 dB 1 dB

2 dB 2 dB

1 dB * 3 dB

0 dB more than 3 dB

* factory default setting

Table 6: Distribution attenuation settings.

ENTER button to return back to the ATTENUATORS menu. This will save your setting choice.

Then pressing the CANCEL button while at the

ATTENUATORS menu will return you to the

default display.

Setting Distribution Attenuation

The MCU to receiver cable loss can be determined

from the cable manufacturers specifications. For

your system these values will be fixed once the

cable type is chosen and cut to length. Typically 2

to 3 dB o f Distribu t ion a t t e nuation is us u a l l y

required to achieve unity gain. Use the attenuation

values shown in Table 6 to set the Distribution

attenuation to the correct value.

setting works in a forward loop fashion, starting

at 0.0 and increasing to 15.5, a button press

after 15.5 returns the setting back to 0.

5) After setting the distribution value press the

ENTER button to return back to the ATTENUATORS menu. This will save your setting choice.

Then pressing the CANCEL button while at the

ATTENUATORS menu will return you to the

default display.

SPECTRUM ANALYSIS

Obtaining good sensitivity requires an understanding of the levels applied to the receiver. A receiver,

like any electronic device, has a dynamic range of

operation. As long as this dynamic range is maintained, the specifications of the receiver are maintained. When the levels applied to the receiver

exceed this range, the sensitivity, intermodulation

rejection, as well as the adjacent channel selectivity will deteriorate. To properly perform a Spectrum

Analysis, a spectrum analyzer must be connected

to the output of the multicoupler as if it were a

receiver, essentially monitoring what the receiver

sees.

The DISTRIBUTION attenuation is adjustable from

0.0 to 15.5 dB in 0.5 dB increments. To adjust the

multicouple r attenuation perform the following

steps.

1) Press the DOWN ARROW button on the front

panel to scroll through the menu choices until

you reach the ATTENUATORS menu.

2) With the ATTENUATORS menu displayed

press the ENTER button to step down to the

TTA Net Gain sub-menu.

3) Press the UP ARROW button to move to the

Distribution sub-menu.

4) Press the ENTER button again to advance to

the Distribution adjustment screen. The current

distribution value will now be displayed. Use the

UP and DOWN ARROW buttons to set the distribution to the desired value. The attenuation

Figure 15 shows the equipment interconnection for

this measurement while Figure 16 is a graph which

indicates the maximum desired measured-signal

levels both inside and outside of the transmit and

receive bands. TTA filter selectivity and antenna

space isolation are the dominant factors that determin e t he signal level s o bserved. E x cessively

strong receive signals indicate the need for additional attenuation in the MCU. The re are three

areas of the spectrum that must be evaluated:

1) Receive Band - The spectrum where the

receive frequencies reside must not have carriers above -35 dBm. These are the carriers that

are intended to enter the receiver. If subscribers

or control stations are near the infrastructure

the levels can be very high. If the levels are

above -35 dBm, the gain of the system must be

reduced or the source of the high level carrier

must be reduced.

2) Transmit Band - The highest carrier that the

receive system will consistently see is its own

transmitter. The preselector of the receive system must adequately remove these carriers to

prevent over-drive. The goal of the preselector

is to reduce all transmit carriers below -55 dBm.

If the level of a transmitter is above -55 dBm the

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 17

Page 26

-30

-35

-40

-45

-50

-55

-60

-65

-70

-75

-80

dBm

Receive Band

Less than -35 dBm

Transmit Band

Less than -55 dBm

Remaining Spectrum

Less than -75 dBm

Transmit BandReceive Band

Frequency (MHz)

Maximum Signal Level Mask

Figure 16: Maximum permissible signal levels at receiver output of TTA MCU.

MCU

Front

Panel

Test

Port

Tower Top Box

Lightning Arrester

TX RX part no. 8-21550

CAT-5e

Cable

Test Ant

Antenna

Main

Spectrum Analyzer

Bird SignalHawk

Figure 15: Testing the output spectrum of the TTA system.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 18

Page 27

preselector is not adequately performing its job

and must be changed.

noise. The difference between the two is the system degradation.

3) All Other Frequencies - The receiver is

designed to monitor very low signals and there

must be a minimum amount of undesired

energy exposure. The preselector has very

sharp selectivity and must reduce all carriers

outside the bandwidth below -75 dBm except as

indicated above.

Procedure for Spectral Analysis

Spectral analysis will verify the signals arriving at

the receiver as well as validate the TTA Net Gain

adjustment. To perform a spectral analysis of the

site follow the steps listed below.

1) Make sure programmable attenuators are properly adjusted.

2) Connect the spectrum analyzer to one of the

output ports of the multicoupler.

3) Setup the spectrum analyzer as follows;

Span = 700 to 800 MHz

Resolution = 50 KHz

RF Attenuation = 0 dBm

Reference Level = -20 dBm

Peak (Max) Hold = ON

4) Monitor the spectrum for 5 minutes (during

peak hours).

OPERATIONAL TESTS

(SENSITIVITY AND DEGRADATION)

Before sensitivity and degradation can be verified,

attenuation adjustments and spectrum analysis

must be performed. If these are not correct, the

sensitivity and degradation may appear out of tolerance.

The sensitivity tests will measure the full range of

performance from the maximum achievable to realworld performance in the presence of RF noise.

These tests are absolutely necessary, not only to

insure proper performance, but also to serve as a

bench mark for future evaluations and troubleshooting.

Front Panel Test Port

The front panel BNC test port is connected to the

tower box through the test line allowing signals

generated at ground level to be injected into an isolated 45 dB por t at the input of each tower top

amplifier circuit board. The test port feature provides a convenient means of performing static sensitivity tests of the system.

Tower Top Amplifier Inputs

Under normal operating conditions RF signals pass

from the antenna to the inputs of the tower top

amplifier. In addition, the input of each tower top

amplifier can also be switched to an internal 50

Ohm load for testing purposes. The front panel test

port remains connected (through its isolated 45 dB

input) to the tower top amplifiers regardless of

whether the amplifiers input is connected to the

antenna or the internal load. This allows system

sensitivity testing to be done with and without site

noise being coupled into the system through the

antenna.

Static System Sensitivity

Static sensitivity is the maximum sensitivity achievable because any possible interfering signals are

blocked from entering the LNA while static sensitivity is measured. To determine the Static system

sensitivity the signal level into the first amplifier

must be known. The easiest way to achieve this is

to inject a test signal into the Test Port (located on

the front panel of the base unit) and measure the

BER or SINAD of the test receiver. The static system sensitivity can only be measured while the

active tower-top LNA is connected to the internal

load. Once you have made the measurement the

actual static system sensitivity can be calculated.

Figure 17 shows the formula for calculating the

actual static system sensitivity as well as a worked

through example.

Measuring Static Sensitivity

(Load Connected)

To test the static system sensitivity through the test

port with the internal load connected to the amplifier perform the following steps;

Two types of sensitivity measurements will need to

be made, Static and Effective. Static sensitivity is

measured without the presence of site noise while

the Effective sensitivity measurement includes site

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 19

Page 28

Caution: During this test on-air sig-

NOTE

NOTE

Actual Sensitivity is calculated using the following formula:

Actual Sensitivity (dBm) = IS (dBm) + TC (dB) + TP (dB)

Where:

is the Injected Signal Level

is the Test Cable Loss

is the Test Port Loss

IS

TC

TP

LEV

LO

LO

Example:

If the Test Cable for the system is 200 ft. long with a loss of 3.6 dB per 100 ft., then the Test

Cable Loss will be 7.2 dB. The Test Port Loss is Fixed at 45 dB. If the Injected Signal acquires

BER or SINAD at a level of -71.8 dBm, then the Actual Sensitivity would be -124 dBm.

LEV LO LO

Figure 17: Calculating actual sensitivity (both static and effective).

nals will NOT pass through to the

station receivers.

1) The signal generator and SINAD meter (or bit

error rate meter if appropriate) should be connected to the system as shown in Figure 18.

2) Be sure the signal generator is setup for a 3

KHz deviation with a 1000 Hz tone (analog) or

proper pattern for BER testing.

5) Adjust the signal strength from the signal generator until the 12 dB SINAD or required BER

point is acquired. This determines the systems

static sensitivity without the presence of site

noise. This value should be recorded in the

MCU’s memory for future use.

It is very important that sensitivity

always be measured to a recognized benchmark such as bit rate

error (BER) or SINAD. Do not use

your ear or other subjective techniques.

3) From the default display, use the ARROW buttons to scroll to the TEST menu choice then

press the ENTER button to bring up the test sub

menu’s.

4) Use the ARROW buttons to scroll over to the

TERMINATE LNA “A (or) B” menu choice

(depending on which amplifier is currently

active) and press the ENTER button to switch

the amplifiers input from the antenna to the

load. The “TEST TTA OFFLINE” message will

appear. The RF signal path through the tower

top box will be interrupted and on-air signals will

not be passed to the station receivers.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 20

6) Press the front panel CANCEL button. This will

switch the amplifier input back to the antenna

and will return you to the default display.

If left unattended, after about 9

minutes the input of the active

amplifier will automatically switch

back to the antenna and on-air signals will again pass through to the

station receivers.

7) From the default display, use the ARROW buttons to scroll to the SENSITIVITY menu choice

then press the ENTER button.

Page 29

NOTE

Signal Generator

MCU

Front

Panel

Test

Port

Tower Top Box

Lightning Arrester

TX RX part no. 8-21550

12 dB SINAD Receiver

CAT-5e

Cable

Diagnostic

Cable

Test Ant

Antenna

Main

Figure 18: Using the test port to measure sensitivity of the TTA system.

8) Use the ARROW buttons to scroll over to the

STATIC W/LOAD menu choice and press the

ENTER button.

9) Use the ARROW buttons to dial in the static

sensitivity value (from the signal generator) and

press the ENTER button to save the information

in memory. By storing the sensitivity value at

the time of installation it can be compared with

future tests and used as an indication of system

degradation or failure. In general, the sensitivity

measured with the antenna will be less than

that measured with the load unless site noise is

at a minimum.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 21

The sensitivity value measured in

step 5 is less (45 dB plus Test Line

loss) than the actual sensitivity

value.

Effective System Sensitivity

The Effective System Sensitivity is the sensitivity

as seen by the subscriber. This represents the

Talk-in coverage component of the infrastructure.

To determine the Effective System Sensitivity the

signal level into the first amplifier must be known.

The easiest way to achieve this is to inject a test

signal into the Test Port (located on the front panel

of the base unit) and measure the BER or SINAD

of the test receiver. The effective system sensitivity

can only be measured while the active tower-top

LNA is connected to the antenna. Once you have

made the measurement the actual effective system

sensitivity can be calculated. Figure 17 shows the

formula for calculating the actual effective system

sensitivity as well as a worked through example.

Page 30

Measuring Effective Sensitivity

NOTE

Status LED Possible Amplifier Status Form-C Contact Status

Tower top Amplifier A

Green Selected; normal current Normal

Off Not selected; normal current Normal

Red Failure: Very abnormal current; can only be selected if amplifier B is

also in Alarm

Alarm contacts change state

Red Failure: Extremely abnormal current; cannot be selected Alarm contacts change state

Tower top Amplifier B

Green Selected: normal current Normal

Off Not selected; normal current Normal

Red Failure: Very abnormal current; can only be selected if amplifier A is

also in Alarm

Alarm contacts change state

Red Failure: Extremely abnormal current; cannot be selected Alarm contacts change state

Base (Distribution) Amplifier

Green Normal current Normal

Red Failure: Very abnormal current Alarm contacts change state

Table 7: Amplifier status troubleshooting guide.

(Antenna Connected)

The Effective system sensitivity should be taken

under normal conditions as well as with all transmitters producing full power. All transmitters keyed

will show the worse case situation. To test the systems effective sensitivity through the test port with

the antenna connected to the amplifiers perform

the following steps;

1) The signal generator and SINAD meter (or bit

error rate meter if appropriate) should be connected to the system as shown in Figure 18.

2) Under normal conditions the antenna is connected to the amplifiers so no software interactions are required. Be sure the signal generator

is setup for a 3 KHz deviation with a 1000 Hz

tone (analog) or proper pattern for BER testing.

3) Adjust the signal strength from the signal generator until the 12 dB SINAD or required BER

point is acquired. This determines the systems

sensitivity in the presence of site noise. Record

this value in the MCU’s memory for future use.

4) From the default display, use the ARROW buttons to scroll to the SENSITIVITY menu choice

then press the ENTER button.

5) Use the ARROW buttons to scroll over to the

REFERENCE W/ANT menu choice and press

the ENTER button.

6) Use the ARROW buttons to dial in the effective

sensitivity value and press the ENTER button to

save the information in memory. By storing the

sensitivity value at the time of installation it can

be compared with future tests and used as an

indication of system degradation or failure.

The sensitivity value measured in

step 3 is less (45 dB plus the Test

Line loss) than the actual sensitivity value.

TX RX Systems Inc. Manual 7-9439-6 09/03/09 Page 22

Page 31

Degradation

NOTE

Amplifier Displayed Value

TTA Amp A ~ 600 ma

TTA Amp B ~ 600 ma

Base Amp ~ 850 ma

Table 8: Typical current readings.

The difference between the static sensitivity (loadconnected) and the effective sensitivity (antennaconnected) is the system degradation which can

be caused by noise or interference (such as a user

on an active channel). At 800 MHz it is unusual to

have degradation greater than 2 dB (and even this

is rare). The degradation value should be recorded

for future reference. Degradation levels in excess

of 1 to 2 dB should be investigated, as this will

decrease the range and performance of the system.

During normal operation only one of the two tower

top amplifiers (“A” or “B”), along with the MCU