Page 1

Wattcher® monitor/alarm

Models 3170B

©

Copyright 2011

Instruction Book Part Number 920-3170AS Rev. D

by Bird Electronic Corporation

Wattcher is a registered trademark

of Bird Electronic Corporation

Page 2

Page 3

Safety Precautions

The following are general safety precautions that are not necessarily related to any specific

part or procedure, and do not necessarily appear elsewhere in this publication. These precautions must be thoroughly understood and apply to all phases of operation and maintenance.

WARNING

Keep Away From Live Circuits

Operating Personnel must at all times observe general safety precautions. Do not replace

components or make adjustments to the inside of the test equipment with the high voltage

supply turned on. To avoid casualties, always remove power.

WARNING

Shock Hazard

Do not attempt to remove the RF transmission line while RF power is present.

WARNING

Do Not Service Or Adjust Alone

Under no circumstances should any person reach into an enclosure for the purpose of

service or adjustment of equipment except in the presence of someone who is capable of

rendering aid.

WARNING

Safety Earth Ground

An uniterruptible earth safety ground must be supplied from the main power source to test

instruments. Grounding one conductor of a two conductor power cable is not sufficient

protection. Serious injury or death can occur if this grounding is not properly supplied.

WARNING

Resuscitation

Personnel working with or near high voltages should be familiar with modern methods of

resuscitation.

WARNI NG

Remove Power

Observe general safety precautions. Do not open the instrument with the power on.

Safety Symbols

WARNING

Warning notes call attention to a procedure, which if not correctly performed could result in

personal injury.

CAUTION

Caution notes call attention to a procedure, which if not correctly performed could result in

damage to the instrument.

Note: Calls attention to supplemental information.

i

Page 4

Warning Statements

The following safety warnings appear in the text where there is danger to operating and maintenance personnel and are repeated here for emphasis.

WARNING

Do not use electrically conductive tools for calibration when the front panel is removed.

Damage to the unit and or the possibility of electrical shock exists.

See page 10.

WARNING

Become thoroughly familiar with modern methods of resuscitation before working near

high voltage sources.

See page 15.

WARNING

Shock hazard. Always turn off AC power before removing any equipment panels.

See page 15.

WARNING

Disconnect this unit from ac power source before any disassembly for cleaning, repair or

replacement procedures. The potential for electrical shock exists.

See pages 15 and 20.

WARNING

When using dry cleaning solvents, provide adequate ventilation and observe normal safety

precautions. Many dry cleaning agents emit toxic fumes that may be harmful to your health

if inhaled.

See page 15.

ii

Page 5

Caution Statements

The following equipment cautions appear in the text whenever the equipment is in danger of

damage and are repeated here for emphasis.

CAUTION

Be sure the 115/230 voltage selector switch on the rear panel is set to the proper line

voltage before AC power is applied.

See page 9.

CAUTION

Do not bend this contact finger when cleaning. The position of this contact is some what

critical. If it is out too far the element will not enter the socket and if it is in too far, it will not

make contact with the button on the element. For contact adjustments, refer to "Adjusting

the Element Wiper Contact" on page 18.

See page 15.

CAUTION

If the element cannot be fully inserted into the socket, do not force it. You might

damage the element wiper contact.

See page 18.

CAUTION

Be careful not to bend element wiper contact out too far as to interfere with insertion

of the elements.

See page 18.

iii

Page 6

Safety Statements

USAGE

ANY USE OF THIS INSTRUMENT IN A MANNER NOT SPECIFIED BY THE

MANUFACTURER MAY IMPAIR THE INSTRUMENT’S SAFETY PROTECTION.

USO

EL USO DE ESTE INSTRUMENTO DE MANERA NO ESPECIFICADA POR EL

FABRICANTE, PUEDE ANULAR LA PROTECCIÓN DE SEGURIDAD DEL

INSTRUMENTO.

BENUTZUNG

WIRD DAS GERÄT AUF ANDERE WEISE VERWENDET ALS VOM HERSTELLER

BESCHRIEBEN, KANN DIE GERÄTESICHERHEIT BEEINTRÄCHTIGT WERDEN.

UTILISATION

TOUTE UTILISATION DE CET INSTRUMENT QUI N’EST PAS EXPLICITEMENT

PRÉVUE PAR LE FABRICANT PEUT ENDOMMAGER LE DISPOSITIF DE

PROTECTION DE L’INSTRUMENT.

IMPIEGO

QUALORA QUESTO STRUMENTO VENISSE UTILIZZATO IN MODO DIVERSO DA

COME SPECIFICATO DAL PRODUTTORE LA PROZIONE DI SICUREZZA

POTREBBE VENIRNE COMPROMESSA.

iv

Page 7

SERVICE

SERVICING INSTRUCTIONS ARE FOR USE BY SERVICE - TRAINED

PERSONNEL ONLY. TO AVOID DANGEROUS ELECTRIC SHOCK, DO NOT

PERFORM ANY SERVICING UNLESS QUALIFIED TO DO SO.

SERVICIO

LAS INSTRUCCIONES DE SERVICIO SON PARA USO EXCLUSIVO DEL

PERSONAL DE SERVICIO CAPACITADO. PARA EVITAR EL PELIGRO DE

DESCARGAS ELÉCTRICAS, NO REALICE NINGÚN SERVICIO A MENOS QUE

ESTÉ CAPACITADO PARA HACERIO.

WARTUNG

ANWEISUNGEN FÜR DIE WARTUNG DES GERÄTES GELTEN NUR FÜR

GESCHULTES FACHPERSONAL.

ZUR VERMEIDUNG GEFÄHRLICHE, ELEKTRISCHE SCHOCKS, SIND

WARTUNGSARBEITEN AUSSCHLIEßLICH VON QUALIFIZIERTEM

SERVICEPERSONAL DURCHZUFÜHREN.

ENTRENTIEN

L’EMPLOI DES INSTRUCTIONS D’ENTRETIEN DOIT ÊTRE RÉSERVÉ AU

PERSONNEL FORMÉ AUX OPÉRATIONS D’ENTRETIEN. POUR PRÉVENIR UN

CHOC ÉLECTRIQUE DANGEREUX, NE PAS EFFECTUER D’ENTRETIEN SI L’ON

N’A PAS ÉTÉ QUALIFIÉ POUR CE FAIRE.

ASSISTENZA TECNICA

LE ISTRUZIONI RELATIVE ALL’ASSISTENZA SONO PREVISTE ESCLUSIVAMENTE

PER IL PERSONALE OPPORTUNAMENTE ADDESTRATO. PER EVITARE

PERICOLOSE SCOSSE ELETTRICHE NON EFFETTUARRE ALCUNA RIPARAZIONE

A MENO CHE QUALIFICATI A FARLA.

v

Page 8

CONNECT INTERLOCK TO TRANSMITTER BEFORE OPERATING.

BRANCHER LE VERROUILLAGE À L'ÉMETTEUR AVANT EMPLOI.

CONECTE EL INTERBLOQUEO AL TRANSMISOR ANTES DE LA OPERACION.

VOR INBETRIEBNAHME VERRIEGELUNG AM SENDER ANSCHLIESSEN.

PRIMA DI METTERE IN FUNZIONE L'APPARECCHIO, COLLEGARE IL

DISPOSITIVO DI BLOCCO AL TRASMETTITORE.

vi

Page 9

About This Manual

This manual covers the operating and maintenance instructions for the following models:

3170B 3170B400

3171B 3171B020

Changes to this Manual

We have made every effort to ensure this manual is accurate. If you discover any errors, or if you

have suggestions for improving this manual, please send your comments to our Solon, Ohio factory. This manual may be periodically updated. When inquiring about updates to this manual

refer to the part number and revision on the title page.

Terminology

There are some unique terms used throughout this literature. They are defined here to clarify

any misunderstanding.

Introduction — Describes the features, lists equipment supplied and optional equipment, and

provides power-up instructions.

Theory of Operation — Describes how the load resistor works.

Installation — Describes the power supply and load connection instructions.

Operating Instructions — Describes the base level operation instructions.

Maintenance — Lists routine maintenance tasks as well as troubleshooting for common prob-

lems. Specifications and parts information are also included.

vii

Page 10

viii

Page 11

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Warning Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Caution Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Changes to this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Items Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Items Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Purpose and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 3 Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Models 3170B and 3170B400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Models 3171B and 3171B020 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Checking the LED Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Removing the Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Adjust Set-Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Active Forward Monitor Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Dip Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 4 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

RF Power Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Line Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

. . . . . . . . . . . 17

Page 12

Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adjusting the Element Wiper Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fuse Drawer/Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Changing Fuse Drawer for 230V Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Replacing Blown Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Replacing Fuse for External DC Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Meter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Repackaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Line Section Cable Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Meter Cable Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Element Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7/8" Line Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Line Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Appendix 1 Difference Data Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Appendix 1 User Applications and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Connector Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Active Forward Monitor (AFM) Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dry Contact Closure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Logic “1" Closure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Confirm Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Relay Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Reset Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Remote Contact Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Remote Metering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

DC Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

ix

Page 13

Chapter 1 Introduction

General

This publication refers to the Model 3170B which is a member of the Bird Model 3170B Series of High Speed Wattcher RF Monitors. Models included in the series are listed in Table 1-1. All models will generally be referred to as a

Wattcher unit through out this manual.

The information in this instruction book pertains to all models except noted differences referred to in the text and in

the "Difference Data Sheet" on page 29.

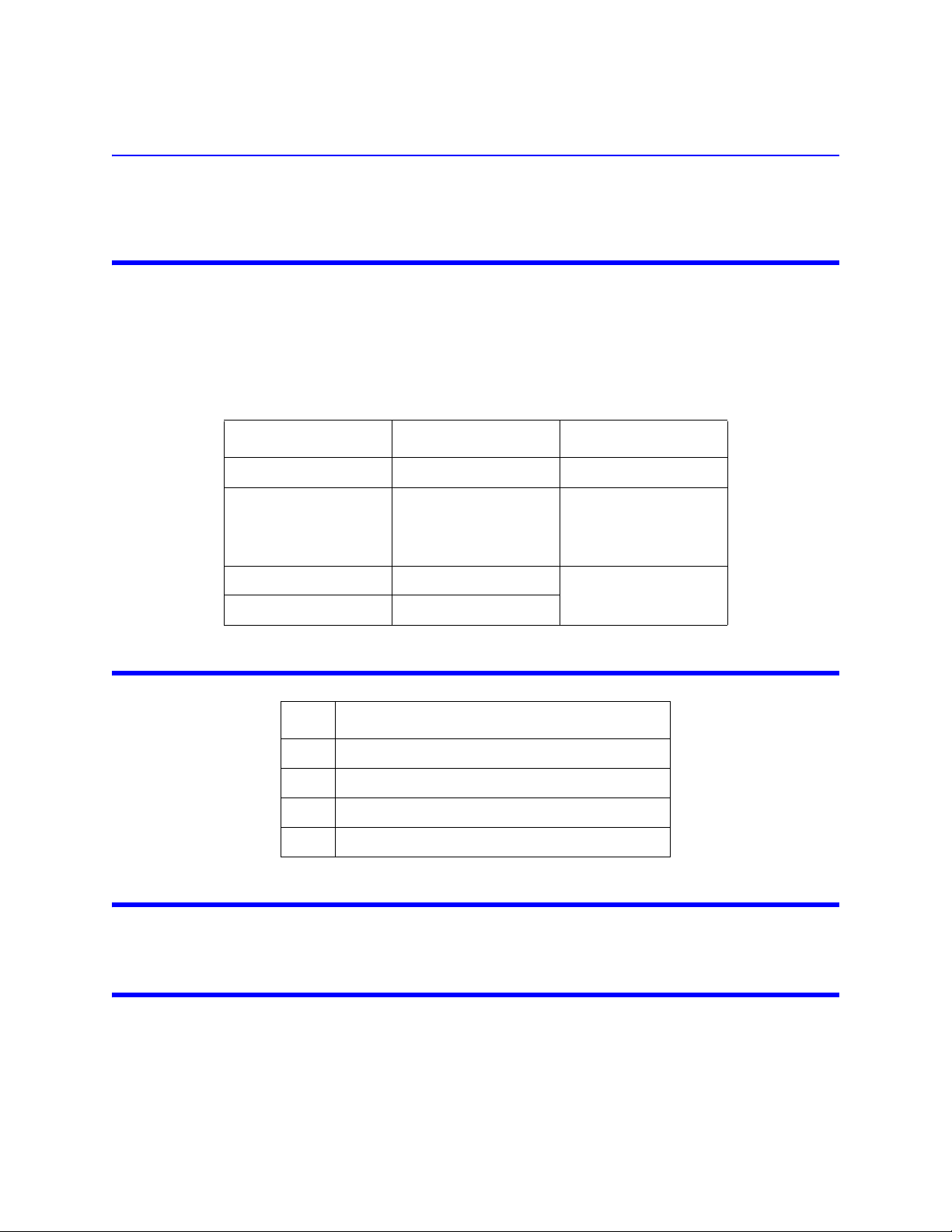

Table 1-1 Various Models

Model Number Power Range Comments

3170B 100 mW - 10 kW Built in Line Section

3170B400 100 mW - 10 kW Built in Line Section.

No reset or audible

alarm function,

Extended AFM timing.

3171B 250 W - 100 kW Uses External Line

3171B020 300 W - 60 kW

Section

Items Supplied

2

Qty Description

1 3170B Series High Speed Wattcher

1 AC Power Cord

1 Fuse drawer for 230V operation

2 Fuses for 230 V operation

Items Required

For power monitoring each port must contain a plug-in element. The determination of elements required is based

on line section size, frequency band of use and RF power level range. Refer to "Element Tables" on page 24.

Optional Accessories

Bird offers a larger number of cable assembly lengths for remote line sections and meters. For different power or

frequency requirements see “Element Table Selection” on page 24.

1

Page 14

Purpose and Function

The Model 3170B Series High Speed Wattcher unit is a two channel power monitoring system for use in 50 ohm

coaxial transmission lines. Adjustable set points allow user to preset maximum reflected and minimum forward

power trip points.

Activated audible/visual alarms indicate an erroneous condition present on the transmission line. Corrective action

can then be followed to either protect transmission equipment or restore transmission line to operational characteristics. This power monitoring capability is accomplished through the use of a dual port 50 ohm insertion type line

section. Each port must contain a standard Bird Electronic Corporation plug-in element. Usually elements with a ten

to one ratio is recommended for the forward and reverse power levels.

The Wattcher monitoring system also provides additional terminal connections for user specific applications. For

details and wiring information, see “User Applications and Wiring” on page 31.

2

Page 15

Functional Description

3

4

2

1

Enclosures

The Wattcher Monitor’s internal circuitry is enclosed in an aluminum housing. This housing is mounted to a standard

19-inch panel for rack mount applications.

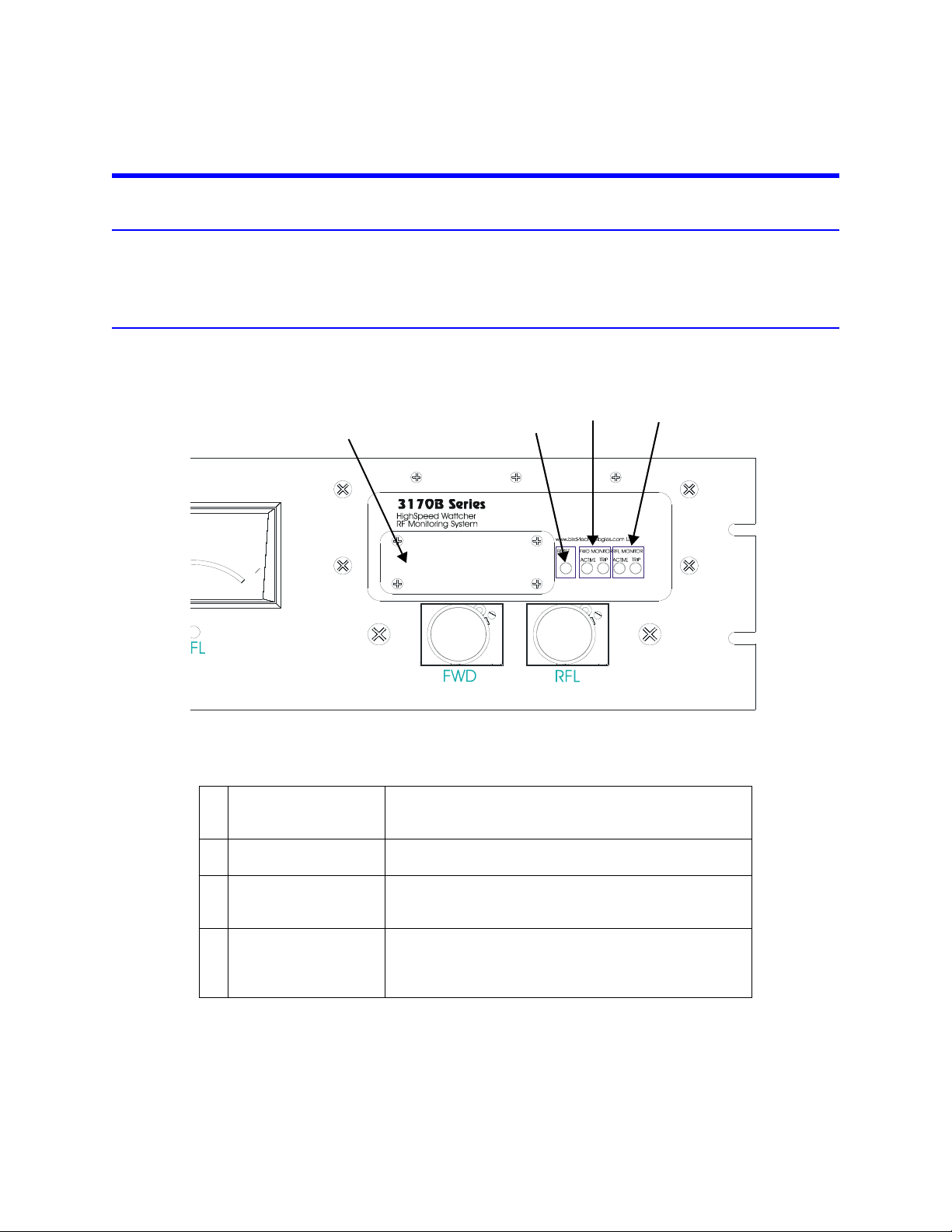

Front Panel

Figure 1 Front Panel

Table 1-2 Front Panel

1 Alarm/Setpoint

Faceplate

2 Reset This push button resets the monitoring system to normal

3 Forward Monitor Active LED—Indicates forward power is being monitored

4 Reflected Monitor Active LED—Indicates reflected power is being

If forward or reflected power set points are exceeded an

audible alarm is sounded. The alarm works in conjuction

with error status indicator reflecting failure conditions.

operation after an error condition has been corrected.

and an error condition will be indicated upon failure.

Trip LED—Indicates error condition has occurred.

monitored and an error condition will be indicated upon

failure.

Trip LED—Indicates error condition has occurred.

3

Page 16

Figure 2 Rear Panel

1

3

2

5

6

7

4

Table 1-3 Rear Panel

1 AC Receptacle Provides a means of supplying AC line power to

Wattcher control unit.

2 AC Line Fuse Slow-blow fuse, provides circuit protection from

excessive surge inline power or in the event of

component failure.

3 Line Voltage Selector

Switch

4 Power/Alarm/Remote

Terminal Strip

5 Remote Meter

Connections

6RF Power Input

Connections

(from line section)

7 Meter Connections Connectors for front panel main meters. Can also be

Determines line voltage operation (115 or 230VAC).

Provides connection for external DC supply, auxiliary

alarm input and output, reset input and output, remote

confirm output and auxiliary 5V output. See “User

Applications and Wiring” on page 31.

Extra meter connections for remote meters. For details

on connecting remote meters see “User Applications

and Wiring” on page 31. Levels: 1.038V full scale. Use

33.2k resistor in series with standard Bird 30mA meters.

Female BNC connectors, provide means of connecting

sampled RF power. Forward and Reflected power

connectors are labeled as such. Levels: 30μA full scale

into 1400Ω (42mV). May be overranged to 100mV.

used to connect remote meters. Levels: 30mA full scale

into 1400 ohm (42mV).

4

Page 17

Line Section

AC Receptacle

RF Input

Connector

RF Output

Connector

1/4”

(6mm)

18-5/32”

(461mm)

19”

(483mm)

2-1/4”

(57mm)

1-31/64”

(38mm)

5-7/32”

(133mm)

Meters

6-7/16”

(164mm)

Figure 3 Models 3170B and 3170B400

5

Page 18

Remote Line Section

AC Receptacle

RF Output

Connector

RF Input

Connector

1/4”

(6mm)

18-5/32”

(461mm)

19”

(483mm)

2-1/4”

(57mm)

1-31/64”

(38mm)

5-7/32”

(133mm)

~

6-7/16”

(164mm)

RFL FWD

Meters

Figure 4 Models 3171B and 3171B020

6

Page 19

Chapter 2 Theory of Operation

Input Signal

Direct current signals representing operating power levels are brought into the RF monitor from the sensing elements through the rear panel jacks labeled RF Power Input Forward and Reflected. These currents are shunted to

ground through 1400 ohm resistors. The voltage developed across these resistors is amplified by a pair of operational amplifiers to approximately one volt (meter full scale).

The drive current to the main indicating meters is taken from the amplifier outputs through series resistors of 33.2k

ohm each. The drive voltage for remote meters also comes from the amplifier outputs and is buffered by a pair of

op-amps configured for unity gain. This protects the 3170B/71B circuitry against accidental shorting of the remote

meter line.

Adjustment

The calibrate/operate switch and the two reference potentiometer allow the user to substitute an adjustable current in place of the signals from the sensing elements to facilitate adjustment of the set-points.

The three set-point potentiometer (forward, reflected, and confirm) provide DC voltages which are compared to the

amplifier outputs by three comparators.

The LED to the left of each potentiometer indicates whether the incoming signal is higher (LED ON) or lower (LED OFF)

than the set-point of the potentiometer.

Operations

The output of the confirm comparator goes directly to the confirm output drive transistors. The output of the

reflected comparator goes directly to the alarm circuitry and to the reflector monitor tripped LED latch. The output

of the forward comparator is gated by the activate forward monitor signal AFM before going to the alarm circuitry

and LED latch.

In other words, the signal is blocked if the activate forward monitor signal is not present. The AFM signal passes

through a delay circuit before reaching the gate. The purpose of the delay is to allow for any delays in the user’s equipment between the initial excitation of the carrier ON signal and the presence of power on the transmission line.

Reset

The reset signal clears the horn latch and the two trip LED latches. This signal can come from three sources: the push

button switch on the front panel, the rear panel input/output, or from the power-up reset capacitor when the

device is first turned on or after a power interruption.

7

Page 20

8

Page 21

Chapter 3 Preparation for Use

General

The series 3170B High-Speed Wattcher RF Monitoring System was designed for indoor use. This section contains

information on unpacking and inspection; and preparing the Wattcher Unit for use.

Unpacking and Inspection

1. Carefully inspect shipping container for signs of damage. If damage is noticed, do not

unpack the unit. Immediately notify the shipping carrier and Bird Electronic Corporation.

2. If container is not damaged, unpack the unit. Save shipping materials for repackaging.

3. Inspect unit for visual signs of damage. Immediately notify the shipping carrier and

Bird Electronic Corporation of equipment damage.

Installation

Mounting

The Model 3170B Series High Speed Wattcher System is intended for rack panel mounting. The panels are designed to fit

ASA standard 19 inch size “C” racks.

The Models 3170B and 3170B400 are fully self-contained units with the RF line section mounted on the panel. The

Models 3171B and 3171B020, however, utilize remotely mounted line sections.

CAUTION

Be sure the 115/230 voltage selector switch on the rear panel is set to the proper line

voltage before AC power is applied.

Note: For installation of Models 3170B and 3170B400 refer to Figure 3 on page 5. For installation of Models 3171B and 3171B020, refer to Figure 4 on page 6.

Models 3170B and 3170B400

Note: If the back of the unit is not accessible from the rear of the rack mount, any connections to the unit

must be made before the panel is secured in place.

1. Connect the RF coaxial transmission line to the line section.

2. Ensure the 115/230 line voltage switch is in the proper position for the voltage supplied.

Note: 3170B series Wattcher is shipped with a fuse and fuse drawer set for

115V operations. For 230V operations, see “Changing Fuse Drawer for 230V

Operation” on page 19.

3. Connect the AC power cord from the Wattcher unit to an appropriate source.

Note: Make DC power connections if needed.

4. Secure the panel to the rack with appropriate fasteners.

9

Page 22

Models 3171B and 3171B020

Remove

these

screws

1. Insert the line section in the coaxial RF coaxial transmission line.

2. Connect the DC cable to the line section.

3. Run the DC cable to the rack console unit.

4. Ensure that the 115/230 line voltage switch is in the correct position for the voltage

supplied.

5. Connect the AC power cord from the Wattcher unit to an appropriate source.

6. Secure the panel to the rack mount using appropriate fasteners.

Initial Setup

Preparation

Do not use electrically conductive tools for calibration when the front panel is

Damage to the unit and or the possibility of electrical shock exists.

Note: If the back of the unit is not accessible from the rear of the rack mount,

all connections to the unit must be made before the panel is secured in place.

Note: 3170B series Wattcher is shipped with a fuse and fuse drawer set for

115V operations. For 230V operations, see “Changing Fuse Drawer for 230V

Operation” on page 19..

Note: Make DC power connections if needed.

WARNING

removed.

Checking the LED Light

When either AC or DC power is applied to the unit, the yellow reflected monitor active LED should light. If this light

does not come on, disconnect the power cord and refer to Chapter 5, Maintenance. With the yellow reflected monitor active LED lit, signifying power is ON and the unit is operational, proceed with the initial setup be low.

Removing the Faceplate

1. Remove the four screws found in the corners of the faceplate.

Note: This exposes the circuit board on which the calibration controls are

located.

2. Set the CALIBRATE/OPERATE switch to the calibrate position (to the left).

Figure 5 Face Plate Removal

10

Page 23

Figure 6 Controls and Indicators

1

2

3

4

5

6

7

LED’s

Calibrate

Operate

Switch

1 Calibrate/Operate Switch

2 Forward Reference Adjustment Potentiometer

3 Reflected Reference Adjustment Potentiometer

4 Forward Set Point Potentiometer

5 Reflected Set Point Potentiometer

6 Confirm Set Point Potentiometer

7 Forward Monitor Active Delay Dip Switch

Adjust Set-Points

1. Set the CALIBRATE/OPERATE switch to the CALIBRATE position (to the left).

2. Do one or more of the following:

• Set the Forward Power Level Alarm Trip Point

a. Adjust the forward reference potentiometer to set the meter to indicate the

power level at which the forward alarm is to be tripped.

b. Adjust the forward set-point potentiometer until the miniature LED to the left

of the potentiometer is just at the transition from off to on.

Note: Turning the potentiometer clockwise will raise the set-point and turn the

light off.

• Set the Reflected Power Level Alarm Trip Point

a. Set the reflected trip point, on the reflected potentiometers, in a similar

manner to the forward trip point. See “Set the Forward Power Level Alarm

Trip Point” on page 11.

Note: The alarm will trip during this operation. It can be reset when completed.

• Set the Confirm Set-Point

a. Adjust the forward reference potentiometer to set the trip point level.

b. Adjust the confirm set-point potentiometer until the miniature LED to the left of

the potentiometer is just at the transition from off to on.

Note: If the confirm output is not used, it is not necessary to adjust the confirm

set-point potentiometer.

3. Return the CALIBRATE/OPERATE switch to the OPERATE position (to the right).

11

Page 24

Active Forward Monitor Setup

Note: Internal circuitry sets Active Forward Monitor (AFM) input to a high state. This inhibits monitoring of

forward power on transmission line. To monitor forward power, follow the steps below.

1. Connect AFM input to ground by hardwiring terminal strip position 10 (AFM input) to

position 7 (ground).

2. Select the appropriate delay (see Table 1-4).

Note: This delay allows transmitting equipment to reach acceptable power

output before being monitored by forward channel for low power condition.

3. Do one of the following:

• If the delay in the user’s equipment is known: the AFM should be set to the

same delay plus a minimum of 25 percent safety factor.

• If the delay in the user’s equipment is unknown:

a. Set the AFM to progressively shorter delays until switching on the carrier

causes the FWD monitor to trip when the user’s equipment is known to be

working properly.

b. Add a 25 percent safety factor to the delay indicated by the switch setting

and set the delay to that setting.

Note: That the disabling of the forward monitor is virtually instantaneous

when the AFM signal is removed and is unaffected by the switch settings.

Dip Switch Settings

Dip Switch bank SW2 is used to select AFM delay time. Refer to Figure 7 for correct on/off position. Ensure the

switches or set fully on or off.

In Table 1-4 the delay times are listed in the appropriate row & column for the switch set tings.

Figure 7 SO2 Dip Switch

12

Table 1-4 Setting AFM Delay

SW6 ON

SW5 OFF

SW4 OFF

SW1 SW2 SW3 3170B400 All

models

ON ON ON 7.1ms 71μs 71ms 710μs 710ms 7.1ms

OFF ON ON 8.3ms 83μs 83ms 830μs 830ms 8.3ms

ON OFF ON 10.0ms 100μs 100ms 1ms 1s 10.0ms

OFF OFF ON 12.1ms 121μs 121ms 1.21ms 1.21s 12.1ms

ON ON OFF 16.7ms 167μs 167ms 1.67ms 1.67s 16.7ms

OFF ON OFF 25.0ms 250μs 250ms 2.5ms 2.5s 25ms

ON OFF OFF 50.0ms 500μs 500ms 5.0ms 5.0s 50ms

SW6 OFF

SW5 ON

SW4 OFF

3170B400 All other

models

SW6 OFF

SW5 OFF

SW4 ON

3170B400 All other

models

Page 25

Chapter 4 Operating Instructions

General

When the unit is installed and connected to a transmitter for remote monitoring, metering, or external alarms and functions as your installation requires, operator attention is not required. The equipment will completely monitor a transmitter’s operation. The only time operating personnel will be necessary is to reset the unit if it has not been wired for

automatic or remote reset. Refer to "User Applications and Wiring" on page 31 for different applications in which the

Wattcher monitor can be used.

RF Power Measurement

RF power measurements are made by the insertion of the detector elements into the line section. The elements are

selected for the frequency range and power level used.

Forward and reflected power is indicated when the arrow on the element plate points in the direction of power

flow. The forward power flows from the transmitter to the load or antenna and the reflected power flows from the

load or antenna to the transmitter.

When the detecting element is placed in the line section, be sure it is fully seated and fully rotated to the stop for

the appropriate indicating position. Also be sure the element catch on the element socket face of the line section is

in place on the shoulder of the element. This will as sure good contact be tween the element and line section body.

Elements are selected for the power and frequency range required. Since the reflected power is generally much less

than the forward power, it may be beneficial to select an element of lower power value for the reflected side. This

will allow better reading resolution. Generally elements of a ten to one ratio are used.

13

Page 26

14

Page 27

Chapter 5 Maintenance

Safety Considerations

WARNING

Become thoroughly familiar with modern methods of resuscitation before working

near high voltage sources.

WARNING

Shock hazard. Always turn off AC power before removing any equipment panels.

Preventive Maintenance

Note: Preventive maintenance is limited to cleaning the unit and connectors.

WARNING

Disconnect this unit from AC power source before any disassembly for cleaning, repair

or replacement procedures. The potential for electrical shock exists.

Cleaning

WARNING

When using dry cleaning solvents, provide adequate ventilation and observe normal

safety precautions. Many dry cleaning agents emit toxic fumes that may be harmful to

your health if inhaled.

Front Panel

Clean the front panel face and meters with a soft cloth dampened with a mild detergent solution. Do not use an

excessive amount of water that would enter the unit and damage electrical components.

Line Section

Clean the line section connectors and elements with a dry cleaning solvent. Use a clean cloth to clean the mating

surfaces of the larger line sections and a cotton swab stick for the smaller connectors, elements, and line section element socket. Clean all mating surfaces thoroughly, especially the bottom shoulder of the element socket and the

spring contact finger.

CAUTION

Do not bend this contact finger when cleaning. The position of this contact is some what

critical. If it is out too far the element will not enter the socket and if it is in too far, it will not

make contact with the button on the element. For contact adjustments, refer to "Adjusting

the Element Wiper Contact" on page 18.

15

Page 28

Customer Service

Any maintenance or service procedure beyond the scope of those in this chapter should be referred to a qualified

service center.

If the unit needs to be returned for any reason, request an RMA through the Bird Technologies website. All instruments returned must be shipped prepaid and to the attention of the RMA number.

Bird Service Center

30303 Aurora Road

Cleveland (Solon), Ohio 44139-2794

Fax: (440) 248-5426

E-mail: bsc@bird-technologies.com

For the location of the Sales Office nearest you, visit our Web site at:

http://www.bird-technologies.com

16

Page 29

Troubleshooting

Locate the problem, review the possible cause, and perform the corrective action listed.

Note: Only those functions within the scope of normal maintenance are listed. This manual can not list all

malfunctions that may occur, or corrective actions. If a malfunction is not listed or not corrected by the listed

corrective actions, notify a qualified service center.

Table 1-5 Troubleshooting

PROBLEM CAUSE AREAS TO CHECK / CORRECTION

Active LED does

not Illuminate

No meter indication No RF power Check RF source.

No Line Power Check power source, restore

Defective line cord.

Fuses Opened Check fuses, replace if needed. See

“Fuse Drawer/Fuse Replacement” on

page 19.

Defective monitor

circuitry.

Line voltage selector

switch in wrong

position.

Arrow on plug-in

element pointing in

wrong direction

No pickup from DC

wiper contact

Open or short circuit

in DC meter cable

Open or short circuit

in line section circuit

in cable.

Return Wattcher, line section, and

elements to the factory. See “Customer

Service” on page 16.

Set switch to proper operating voltage.

Change position of element.

Adjust wiper contact. See “Adjusting the

Element Wiper Contact” on page 18.

Replace defective DC meter cable.

Replace defective cable.

Intermittent or

inconsistent meter

readings

Meter burned out or

damaged

Defective monitor

circuitry.

Faulty transmission

line

Dirty DC contact on

elements

Sticky or defective

meter

Replace defective meter. See “Meter

Replacement” on page 21.

Return Wattcher, line section, and

elements to the factory. See “Customer

Service” on page 16.

Inspect line connectors. Replace

defective connector.

Clean DC contacts. See “Cleaning” on

page 15.

Replace defective meter. See “Meter

Replacement” on page 21.

17

Page 30

PROBLEM CAUSE AREAS TO CHECK / CORRECTION

Reflected meter

pointer max out

with RF power

applied.

High VSWR or

reflected power

Remote meter

pointer is maxed out.

Unit does not

operate from

external DC source.

Meter/Line section

cables reversed.

Bad load or poor

connectors.

Shorted or open

transmission line.

Foreign material in

the line section or in

RF connector bodies.

Series resistor not

installed.

Fuse opened. Replace fuse, but check maximum

Maintenance Procedures

Adjusting the Element Wiper Contact

Connect reflected cable to proper BNC

connector on rear panel.

Replace load or connectors.

Have transmission line serviced.

Remove foreign material. See “Cleaning”

on page 15.

Series resistor of 33.2 K are required for

each remote meter.

voltage of DC source. See “Replacing

Fuse for External DC Input Voltage” on

page 20.

WARNING

Never attempt to adjust wider contact with RF power applied to the transmission line.

CAUTION

If the element cannot be fully inserted into the socket, do not force it. You might

damage the element wiper contact.

CAUTION

Be careful not to bend element wiper contact out too far as to interfere with insertion

of the elements.

Note: Continuous insertion or rotation of the element might cause a slight change in the position of the

contact spring in the element socket. If the contact spring changes position, erratic power readings may be

experienced.

Note: For this procedure, use a small flat head screwdriver.

1. Place the flat side of the screwdriver behind the contact bar. See Figure 8 on page 19.

2. Bend the contact bar so that the contact rests in the center of the slot adjacent to

the element socket.

3. Bend the contact bar slightly toward the center of the element socket bore.

18

Page 31

4. Ensure the profile of the element contact is visible when viewing the element socket

Adjust element contact up and down Adjust element contact in and out

AC Receptacle

Fuse Drawer Release Tab

Fuse Drawer

from the top of the socket bore.

Note: If the contact is accidently moved too far into the element bore, the element will not slide into the socket. Move the contact back into the recessed area

and repeat the process.

Figure 8 Adjust Element Contact Up and Down

Fuse Drawer/Fuse Replacement

Changing Fuse Drawer for 230V Operation

Note: 3170B series Wattcher is shipped with fuse and fuse drawer set per 115V operation.

WARNING

Disconnect this unit from AC power source before any disassembly for cleaning, repair

or replacement procedures. The potential for electrical shock exists.

1. Depress the release tabs on both sides of the fuse drawer.

2. Pull out from AC receptacle housing.

Note: Note the orientation of the fuse drawer and the fuse contained within.

Also note that for 115V operation there is a shorting bar insert in the neutral

side of the AC line.

3. Insert optional fuse drawer with two 315 mA fuse install.

4. Push fuse drawer in housing cavity until release tabs snap into place.

Figure 9 Changing the Fuse Drawer

19

Page 32

Replacing Blown Fuse

230V Fuse Drawer

115V Fuse Drawer with

Shorting Bar

Fuse, 5x20mm SLO-BLO, T315mA

Fuse, 5x20mm SLO-BLO, T315mA

Shorting Bar

Note: For either 115 or 230 Volt Operation.

1. Depress the release tabs on both sides of the fuse drawer.

2. Replace blown fuse.

Operating

Voltage

115 V 5A2257-14 5x20 mm, Slo-Blo, T630 mA

230 V 5A2257-11 5x20 mm, Slo-Blo, T315 mA

Bird PN Type

3. Insert fuse drawer into housing cavity.

4. Push until release tabs snap into place.

Figure 10 Fuses

Replacing Fuse for External DC Input Voltage

Fuse

20

WARNING

Disconnect this unit from AC power source before any disassembly for cleaning, repair

or replacement procedures. The potential for electrical shock exists.

1. Remove the five 4-40 screws from the cover top.

2. Remove the six 4-40 screws from the cover sides.

Note: Three screws from each side.

3. Remove the cover from lower housing to expose internal circuit.

4. Locate fuse on PC board assembly near the AC input receptacle.

5. Remove the fuse.

6. Replace with 3 AG type fast-acting rated at .5 amp.

7. Replace cover and screws.

Page 33

Figure 11 Replacing Fuse for External DC Input Voltage

4-40x3/16

Phillips Pan

Head Screws

Cover

4-40x3/16

Phillips Pan

Head Screws

Fuse 3AG Fast Acting .5 A

Meter Replacement

If the meters should become defective and require replacement, proceed as outlined in the following steps:

1. Observe the connections of the meter leads.

2. Disconnect the leads.

Note: This will insure the correct polarity in reassembly.

3. Loosen the clamp screw on the sides of the meter until the clamp is released.

4. Withdraw the meter through the front panel.

5. Reverse the above steps to install the new meter.

Storing

If the unit is not to be used for an extended period of time, store in a cool dry place where it will be free from rough

treatment, dust, and dampness.

Repackaging

Should you need to return the Wattcher unit, use the original shipping package if possible. If the original package is

not available, use a heavy duty corrugated box with shock-absorbing material around all sides of the unit to provide

firm cushion and to prevent movement in container. Container should be properly sealed.

21

Page 34

Replacement Parts List

Qty Description Part Number

AC power fuse

1

2

1 DC power fuse, 3 AG, 1/2 A 5-721-2

1 Power cord, 115/230 VAC 4421-055

2 Cable assembly (Line Section) 3170-058-1

2 Meter cable assembly 3170B110

2 Meter

1 Line section assembly

(Model 3170B and 3170B400 only) 4522-002-7

2 Bezel kit

(for all meters) 2150A015-2

Line Section Cable Assemblies

115V, 5x20 mm, Slo-Blo, T630 mA

230V, 5x20 mm, Slo-Blo, T315 mA

Models 3170B, 3170B400

Model 3171B

Model 3171B020

Length Part Number

14” 3170-058-1

6’ 3170-058-6

15’ 3170-058-2

*

25’

25’ 3170-058-3

40’ 3170-058-4

50’ 3170-058-5

80’ 3170-058-7

90’ 3170-058-8

100’ 3170-058-9

* Use if line section is 6-1/8”

3171-010

5A2257-14

5A2257-11

2150A015-1

2150A086-1

2150A093-1

Meter Cable Assemblies

Note: Cables are terminated with ring terminals that fit 1/4” meter studs.

22

Length Part Number

2’ 3170B110

6’ 3170B110-6

15’ 3170B110-15

25’ 3170B110-25

50’ 3170B110-50

Page 35

Specifications

Impedance 50 Ohms nominal

Power Range

Models 3170B, 3170B400

Model 3171B

Model 3171B020.

Indicated Power Accuracy 5% of full scale

Alarm Accuracy 5% of full scale

Response Time 25 μsec maximum

Activate Forward Monitor

(Adjustable Delay)

Models 3170B, 3171B, & 3171B020

3170B400

Activate Forward Monitor (Signal Levels)

Models 3170B, 3171B, 3171B020,

and 3170B400

Inputs and Outputs Will interface directly to TTL

100 mW to 10 kW full scale

250 W to 100 kW full scale

300 W to 60 kW full scale

71 μsec to 50 ms nominal

7.1 ms to 5 seconds nominal

Active state: 0 to 1 V Off state:

held to 5 V internally

Output Drive Capability

for Alarm and Confirm only

5 Volt Supply Output Will source 360 mA, regulated

Insertion VSWR 1.05 maximum dc to 1 GHz

Power Requirements

AC Power Requirements

DC Power Requirements

Overall Dimensions 7-23/32"D x 19"W x 5-7/32"H

Weight

Models 3170B, 3170B400

Models 3171B, 3171B020

* Depth dimensions does not include additional depth alotted to

cable assemblies.

Will sink 1.5A mA

115/230 VAC 50/60 Hz @ 56

mA maximum

12.7 VDC to 16.0 VDC @ 400

mA maximum

(237 x 483 x 133 mm)

6 lb. (2.5 kg)

4.2 lb. (1.9 kg)

*

23

Page 36

Element Tables

The following tables are used to determine the part numbers of elements required based on line section, power, and

frequency ranges.

Table 1-6 should be used to determine which element table to use, based on the model.

Note: Table 1-7 through Table 1-18, page 27 are numbered consecutively for convenience. The table heading corresponds to the table heading in the Bird catalog which is the common reference for element tables.

Table 1-6 Element Table Selection

Model

3170B

3170B400

3171B

3171B020

7/8" Line Section

Note: The following tables are used to select elements for 7/8" line sections.

Power

Range

(Watts)

5 -- 5A5B5C5D5E

10 -- 10A 10B 10C 10D 10E

25 -- 25A 25B 25C 25D 25E

50 50H 50A 50B 50C 50D 50E

100 100H 100A 100B 100C 100D 100E

250 250H 250A 250B 250C 250D 250E

500 500H 500A 500B 500C 500D 500E

1000 1000H 1000A 1000B 1000C 1000D 1000E

2500 2500H

5000 5000H

Line Section

Mount

Front

Panel

External Watts kilowatts

25/50/100 5/10/25 15/30/60 Element Table (2-)

Meter Scale

Line Section in

Inches

7/8

1 5/8 3 1/8 6 1/8

7 to 12

3 to 8

13 15 17

14 16 18

Table 1-7 Selection Table

Frequency

2 - 30 25- 60 50 - 125 100 - 250 200 - 500 400 - 1000

24

Table 1-8 High Frequency Milliwatt Elements - Entire Table (8% FS)

Power

Range

(milliwatts)

100 430-82 430-209 430-210 430-178 430-211 430-182 -250 -- -- -- 430-1 430-239 430-240 430-241

500 -- 430-259 -- 430-95 -- 430-159 --

950 1260

1250 1500

1500 1700

Frequency

17002200

2300 2400

2400 2500

2500 2600

Page 37

Table 1-9 Low Frequency Elements

Power Range

(Watts)

1000 1000P

2500 2500P

5000 5000P

10000 10000P

Frequency

Bands (Mhz)

.45 - 2.5

Table 1-10 Low Power Elements

100 mW

Frequency

Cat. No

Band (MHz)

45-50 430-266 45-50 430-267 45-54 430-242

50-60 430-191 50-60 430-212 54-60 430-243

60-66 430-192 60-66 430-213 60-66 430-244

66-72 430-193 66-72 430-214 66-72 430-245

72-76 430-2 72-76 430-22 72-76 430-33

76-82 430-194 76-82 430-215 76-88 430-246

82-88 430-195 82-88 430-216 88-108 430-247

88-97 430-170 88-108 430-217 105-120 430-26

97-108 430-171 105-120 430-20 120-136 430-248

108-136 430-57 116-126 430-48 136-150 430-249

135-175 430-86 125-136 430-218 150-170 430-53

170-190 430-62 130-150 430-13 170-190 430-250

190-210 430-63 150-180 430-15 190-216 430-251

210-216 430-176 170-190 430-64 216-240 430-252

216-230 430-196 190-210 430-65 240-290 430-27

230-240 430-197 210-220 430-184 290-340 430-253

240-250 430-198 216-230 430-219 340-360 430-157

250-260 430-199 230-240 430-220 350-400 430-254

260-270 430-200 240-250 430-221 400-450 430-255

270-280 430-201 250-260 430-222 450-500 430-256

280-290 430-202 260-270 430-223 500-600 430-257

290-300 430-203 270-280 430-224 600-800 430-258

300-320 430-204 280-290 430-225 800-1000 430-265

320-340 430-205 290-300 430-226

340-360 430-164 300 -320 430-227

360-380 430-206 320-340 430-228

380-400 430-207 340-360 430-229

400-420 430-7 360-380 430-230

420-450 430-208 375-400 430-231

450-470 430-8 400-450 430-232

470-500 430-179 450-470 430-61

500-600 430-168 470-500 430-233

600-800 430-169 500-600 430-234

800-1000 430-263 600-800 430-235

250 mW

Frequency

Cat. No

Band (MHz)

800-1000 430-264

500 mW

Frequency

Band

Cat. No

25

Page 38

Table 1-11 Low Frequency Elements

Line Section

Note: The following tables are used to select elements for 1-5/8" line sections.

Power

Range

2 - 30 25- 60 50 - 125 100 - 250 200 - 500 400 - 1000

Frequency

(Watts)

100 W -- 100A12 100B12 100C12 100D12 100E12

250 W -- 250A12 250B12 250C12 250D12 250E12

500 W 500H12 500A12 500B12 500C12 500D12 500E12

Table 1-12 High Frequency Elements Entire Table (8% FS) -

Milliwatt Elements

Power

Range

(Watts)

1 1 J 1 K 1 L 1 M 431 - 17 431 - 20 431 - 23 431 -

2.5 2.5 J 2.5 K 2.5 L 2.5 M 431 -

5 5 J 5 K 5 L 5 M 432-15 432-28 432-2 432-12

905 1260

1100 1800

Frequency Bands (Mhz)

1700 2200

2200 2300

2300 2400

110

2400 2500

431 107

2500 2600

431 108

2600 2700

120

431 -

117

Table 1-13 1-5/8” AA Standard Elements 30mA

Power

Range

100 W -- 100B12 100C12 100E12

250 W -- 250B12 250C12 250E12

500 W 500H12 500B12 500C12 500E12

1000 W 1000H12 1000B12 1000C12 1000E12

2500 W 2500H12 2500B12 2500C12 2500E12

5000 W 5000H12 5000B12 5000C12 5000E12

10 kW 10KH12 10KB12 -- -25 kW 25KH12 25KB12 -- --

2 - 30 50 - 125 100 - 250 400 - 1000

Frequency

Table 1-14 1-5/8” BB Standard Elements 30mA

\

Power

Range

600 W 600H12 600B12 600C12 600E12

1500 W 1500H12 1500B12 1500C12 1500E12

3000 W 3000H12 3000B12 3000C12 3000E12

6000 W 6000H12 6000B12 6000C12 6000E12

15 kW 15KH12 15KB12 -- --

2 - 30 50 - 125 100 - 250 400 - 1000

Frequency

26

Page 39

Table 1-15 3-1/8” AA Standard Elements 30μA

Power

Range

100 W -- 100B32 100C32 100E32

250 W -- 250B32 250C32 250E32

500 W 500H32 500B32 500C32 500E32

1000 W 1000H32 1000B32 1000C32 1000E32

2500 W 2500H32 2500B32 2500C32 2500E32

5000 W 5000H32 5000B32 5000C32 5000E32

10 kW 10KH32 10KB32 10KC32 10KE32

25 kW 25KH32 25KB32 25KC32 25KE32

50 kW 50KH32 50KB32 50KC32 -100 kW 100KH32 -- -- --

2 - 30 50 - 125 100 - 250 400 - 1000

Frequency

Table 1-16 3-1/8” BB Standard Elements 30μA

Power

Range

600 W 600B32 600C32 600E32

1500 W 1500B32 1500C32 1500E32

3000 W 3000B32 3000C32 3000E32

6000 W 6000B32 6000C32 6000E32

15 kW 15KB32 15KC32 15KE32

30 kW 30KB32 30KC32 30KE32

50 - 125 100 - 250 400 - 1000

Frequency

Table 1-17 6-1/8” AA Standard Elements 30μA

Power

Range

2 - 30 50 - 125 100 - 250 400 - 1000

Frequency

(Watts)

250 W -- -- 250C62 250E62

500 W -- 500B62 500C62 500E62

1000 W 1000H62 1000B62 1000C62 1000E62

2500 W 2500H62 2500B62 2500C62 2500E62

5000 W -- 5000B62 5000C62 5000E62

10 kW 10KH62 10KB62 10KC62 10KE62

25 kW -- 25KB62 25KC62 25KE62

50 kW 50KH62 50KB62 50KC62 50KE62

100 kW 100KH62 100KB62 100KC62 --

Table 1-18 6-1/8” BB Standard Elements 30μA

Power

Range

3000 W 3000B32 3000C32 3000E32

6000 W 6000B32 6000C32 6000E32

15 kW 15KB32 15KC32 15KE32

30 kW 30KB32 30KC32 30KE32

60 kW 60KB32 60KC32 60KE32

50 - 125 100 - 250 400 - 1000

Frequency

27

Page 40

28

Page 41

Appendix 1 Difference Data Sheet

Note: Table A-1 is used to outline the differences between various models.

Table 1-19 Differences Between Models

Model

3170B

3170B400

3171B

3171B020

Line Section

Mount

Front

Panel

External Watts kilowatts 71 μs

25/50/100 5/10/25 15/30/60

Meter Scale

AFM Delay

Adjustment Range

7.1 ms

to

50 ms

to

5 seconds

29

Page 42

30

Page 43

Appendix 3 User Applications and Wiring

This section is a collection of user specific applications and the wiring information required to activate them.

Connector Assignment

Table 1-20 BNC Jacks

Connection Description Function Levels

RF Power Input

Forward/Reflected

Main Meter

Forward/Reflected

Remote Meters

Forward/Reflected

Table 1-21 Terminal Strip

Connection Description Function Levels

TB1(+),

TB2(-)

TB3,4 Auxiliary Alarm Inputs Signals to trip alarms

TB5 5V Output Regulated 5V out put Can supply 360mA max.

TB6 Alarm Output Low when alarm is

TB7 Ground Chassis ground Reference for signals.

TB8 Reset Input /Output Input to reset Wattcher

TB9 Confirm Output Low when forward

TB10 Active Forward

DC Input Forward &

Reflected

DC Main Meter Drive

Output

DC Remote Meter

Drive Output

External 12V Supply Used to allow mobile

Monitor Input

(Carrier On)

Detected RF signals

from sensors

Current to drive

indicating meters

Voltage to drive

remote indicating

meters

operation

from external sources

sounding, returned

high by reset

from external source.

May be used as an

output to reset other

equipment when

Wattcher is reset by the

front panel switch.

power exceeds the

users confirm set point

Indicates to the

Wattcher that the RF

is on and that forward

power should be

monitored for a low

condition. There is an

adjustable internal

delay on the leading

edge of this signal.

30μA full scale into

1400Ω (42mV). May be

overranged to 100mV

30mA full scale into

1400W (42mV)

1.038V full scale (use

33.2k resistor in

series with standard

Bird 30mA meters

See Figure 18 on

page 35 for connection

information

TTL levels, active low.

Pulled up to 5V by

4.7k internally.

Shunted to ground by

0.1μF capacitor.

Active low. Pulled up to

5V by 4.7k. Will sink

1.5A and source 1mA.

TTL levels, active low.

Pulled up to 5V by

4.7k internally.

Shunted to ground by

10μF capacitor.

Active low. Pulled up to

5V by 4.7k. Will sink

1.5A and source 1mA.

TTL levels, active low.

Pulled up to 5V by

4.7k.

31

Page 44

Active Forward Monitor (AFM) Input

Wiring concept examples for activating the AFM circuit are shown below. These can be used for remote onsite or

offsite manual or automatic activation.

Dry Contact Closure

Closure will be from terminal 10 to case ground, terminal 7, in any convenient form, e.g. by an extra set of manual

contacts on the transmitter keying relay or a separate remote switch.

Figure 12 Dry Contact Closure

Logic “1" Closure

Closure circuit shown is a simplified means of interfacing a logic “1" as required from TTL driving positive signal, indicating transmitter is on.

Figure 13 Logic “1" Closure

32

Page 45

Confirm Output

270

Ohm

L.E.D.

For visual confirmation of transmitter “ON” see circuit below.

Relay Control

Relay control for greater current requirements. Connect the external relay coil, noting the polarity to terminal 5 for

+5V output and to terminal 9. Confirm output.

Figure 14 Confirm Output Relay Control

LED Indicator

Simple local or remote light emitting diode indicator, that requires no more than 1.5A. Resistors value may vary based on

current requirements of chosen LED.

Figure 15 Confirm Output LED Indicator

33

Page 46

Reset Input

Reflected

M

M

Remote

Off Site

Meters

Remote

Off Site

Meters

M

M

Forward

Shield

Ground

Shield

Ground

Remote

Off Site

Meters

Remote

Off Site

Meters

+

-

+

-

+

-

+

-

A remote reset could be used in case of false alarm or a brief disturbance has tripped the Wattcher Monitor but left

the transmission intact.

Remote Contact Reset

This option allows reset onsite, but remote from the Wattcher unit. Terminal 8, Reset, is active low and will cause a

reset when the switch is closed, making a connection to terminal 7, ground.

One or several momentary contact, normally open, switches can be connected in series for reset from various locations.

Figure 16 Reset Input

Remote Metering

Any number of meter pairs can be driven by the meter amplifiers up to 1mA into a total load of 470 to 1400 ohms,

with out effecting scale shape. Long line losses are compensated by adjusting amplifier gain and full scale meter current after network is balanced and amplifier zero setting. Usually RFI prevention by shielding, using chokes and bypass capacitors, is necessary only near the Wattcher unit.

Figure 17 Remote Monitors and Meters

34

Page 47

DC Power Supply Connections

External

DC Power

Source

+

-

A DC power supply can be connected to allow for mobile operation of the Wattcher unit.

The positive terminal of the DC power supply must be connected to Terminal 1. The negative terminal must be con-

nected to terminal 2. The minimum DC voltage required for operation is +12.7Vdc. The maximum DC voltage allowable is +16Vdc. The maximum current draw for this range is 400mA.

Figure 18 DC Power Supply

35

Page 48

36

Page 49

Limited Warranty

All products manufactured by Seller are warranted to be free from defects in material and workmanship

for a period of one (1) year, unless otherwise specified, from date of shipment and to conform to applicable specifications, drawings, blueprints and/or samples. Seller’s sole obligation under these warranties

shall be to issue credit, repair or replace any item or part thereof which is proved to be other than as warranted; no allowance shall be made for any labor charges of Buyer for replacement of parts, adjustment

or repairs, or any other work, unless such charges are authorized in advance by Seller.

If Seller’s products are claimed to be defective in material or workmanship or not to conform to specifications, drawings, blueprints and/or samples, Seller shall, upon prompt notice thereof, either examine the products where they are located or issue shipping instructions for return to Seller

(transportation-charges prepaid by Buyer). In the event any of our products are proved to be other

than as warranted, transportation costs (cheapest way) to and from Seller’s plant, will be borne by

Seller and reimbursement or credit will be made for amounts so expended by Buyer. Every such claim

for breach of these warranties shall be deemed to be waived by Buyer unless made in writing within

ten (10) days from the date of discovery of the defect.

The above warranties shall not extend to any products or parts thereof which have been subjected to

any misuse or neglect, damaged by accident, rendered defective by reason of improper installation or

by the performance of repairs or alterations outside of our plant, and shall not apply to any goods or

parts thereof furnished by Buyer or acquired from others at Buyer’s request and/or to Buyer’s specifications. Routine (regularly required) calibration is not covered under this limited warranty. In addition,

Seller’s warranties do not extend to the failure of tubes, transistors, fuses and batteries, or to other

equipment and parts manufactured by others except to the extent of the original manufacturer’s warranty to Seller.

The obligations under the foregoing warranties are limited to the precise terms thereof. These warranties provide exclusive remedies, expressly in lieu of all other remedies including claims for special or

consequential damages. SELLER NEITHER MAKES NOR ASSUMES ANY OTHER WARRANTY WHATSOEVER, WHETHER EXPRESS, STATUTORY, OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS, AND NO PERSON IS AUTHORIZED TO ASSUME FOR SELLER ANY OBLIGATION OR LIABILITY NOT STRICTLY IN ACCORDANCE WITH THE FOREGOING.

Loading...

Loading...