SERVICE MANUAL

MS330IA031203

II

INDEX

1. INTRODUCTION 1-1

2. FUNCTIONAL PARTS DESCRIPTION 2-1

2.1. Optical system 2-1

2.1.1. Constitutive parts 2-1

2.1.2. System description 2-1

2.1.3. Physical description 2-2

2.1.4. Signal conditioning 2-2

2.1.5. Adjustment 2-7

2.1.6. Precautions and maintenance 2-7

2.2. Aspiration system 2-7

2.2.1. Components 2-7

2.2.2. System description 2-7

2.2.3. Physical description 2-8

2.2.4. Programmable parameters 2-8

2.2.5. Programming 2-8

2.2.6. Adjustment 2-8

2.2.7. Precautions and maintenance 2-9

2.3. Thermostatization system 2-9

2.3.1. Components 2-9

2.3.2. System description 2-9

2.3.3. Physical description 2-14

2.3.4. Programming 2-14

2.3.5. Adjustment 2-14

2.3.6. Precautions and maintenance 2-14

2.4. Communications system 2-15

2.4.1. Channel type 2-15

2.4.2. Channel characteristics 2-15

2.4.3. Information transmitted 2-15

2.4.4. Programming 2-16

2.5. Block diagram 2-18

2.5.1. Logarithmic amplifier 2-18

2.5.2. Analogic/Digital converter 2-18

2.5.3. Lamp control 2-18

2.5.4. Filters wheel detector 2-18

2.5.5. Filters wheel motor control 2-18

2.5.6. Temperature sensor amplifier 2-18

2.5.7. Peltier cell control 2-18

2.5.8. Pump motor control 2-19

2.5.9. Keyboard circuit 2-19

2.5.10. Printer control 2-19

2.5.11. Display circuit 2-19

2.5.12. RS-232 channel circuit 2-19

2.5.13. Fan control 2-19

2.5.14. Microcontroller 2-19

I

2.5.15. Power supply 2-20

2.5.16. Reset and battery-backup supervisory circuit 2-20

2.6. Electronic circuit description 2-20

2.6.1. Logarithmic amplifier 2-20

2.6.2. Analog to digital converter 2-22

2.6.3. Lamp control 2-22

2.6.4. Filter wheel detector 2-22

2.6.5. Filters wheel motor control 2-23

2.6.6. Temperature sensor amplifier 2-23

2.6.7. Peltier Cell control 2-23

2.6.8. Pump motor control 2-24

2.6.9. Keyboard circuit 2-24

2.6.10. Printer control 2-25

2.6.11. Display circuit 2-25

2.6.12. RS-232 channel circuit 2-26

2.6.13. Fan control 2-26

2.6.14. Microcontroller 2-26

2.6.15. Power supply 2-27

2.6.16. Microcontroll e r supervisory and reset circuit 2-27

3. CHECKS AND ADJUSTMENTS 3-1

3.1. Service menu 3-1

3.1.1. Option TEST 3-1

3.1.2. Option ADJUSTMENTS 3-2

3.1.3. Option UNLOCK/LOCK TESTS 3-2

3.1.4. Option UNLOCK/LOCK instrument 3-2

3.2. ADJUSTMENTS 3-2

3.2.1. Photometric adjustment 3-2

3.2.1.1. Materials needed 3-3

3.2.1.2. General remarks 3-3

3.2.1.3. Procedure 3-3

3.2.2. Thermostatic system adjustement 3-4

3.2.2.1. Materials needed 3-4

3.2.2.2. General remarks 3-4

3.2.2.3. Procedure 3-4

3.2.2.4. Explanation of the list parameters 3-5

3.2.2.4. Check 3-5

3.2.3. Filters wheel adjustment 3-5

3.2.3.1. Materials needed 3-6

3.2.3.2. General remarks 3-6

3.2.3.3. Manual mode 3-6

3.2.3.4. Automatic mode 3-7

3.2.4. Peristaltic pump adjustment 3-8

3.2.4.1. Materials needed 3-9

3.2.4.2. General remarks 3-9

3.2.4.3. Check method 3-9

3.2.4.4. Manual mode 3-9

II

3.2.4.5. Automatic mode 3-10

3.3. Transformer and power supply checking 3-11

3.4. Fan checking 3-12

3.5. Optical system checking 3-12

3.6. Check of the sensitivity with flow cuvette 3-13

4. CHECK TESTS 4-1

4.1. Activation of a test 4-1

4.2. Screen 4-1

4.3. Buzzer 4-1

4.4. Keyboard 4-1

4.5. Printer 4-1

4.6. Serial Port RS-232 4-1

4.7. Motors 4-2

4.7.1. Loss of steps of the peristaltic pump 4-2

4.7.2. Loss of steps of the filters wheel 4-2

4.8. Cuvette temperature 4-2

4.9. Carry Over 4-3

4.10. Photometry 4-3

4.10.1. Filter sensitivity 4-3

4.10.2. Electric noise 4-3

4.10.3. Stability of the readings 4-4

4.10.4. Precision 4-4

4.10.5. Accuracy 4-5

4.11. Unlock / Lock QC techniques 4-5

5. MAINTENANCE 5-1

5.1. Case replacement 5-1

5.2. Main board replacement 5-3

5.3. Change of the display board 5-3

5.4. Printer replacement 5-7

5.5. Keyboard replacement 5-7

5.6. Transformer replacement 5-9

5.7. Cuvette holder tray removal 5-9

5.8. Filters wheel replacement 5-10

5.9. Filters wheel motor replacement 5-10

5.10. Peristaltic pump replacement 5-11

5.11. Peltier cell replacement 5-11

5.12. Change of the photodiode 5-12

5.13. Fan replacement 5-14

5.14. Temperature sensor replacement 5-14

5.15. Lamp replacement 5-15

5.16. Filters replacement 5-17

5.17. Lenses replacement 5-17

5.18. General care 5-18

III

5.19. Cleaning of the optical components 5-20

5.20. Cleaning the filters 5-23

5.21. Cleaning the lenses 5-23

5.22. Cleaning the photodiode 5-23

5.23. Cleaning the aspiration system 5-23

5.24. Cleaning the flow-cuvette 5-24

5.25. General cleaning of the instrument 5-24

APPENDIX I. TECHNICAL SPECIFICATIONS I-1

I.1. Optical system I-1

I.2. Thermostatic control I-1

I.3. Printer I-1

I.4. Display I-1

I.5. Electronics I-2

I.6. Communications I-2

I.7. Installation I-2

I.8. Dimensions and weight I-2

I.9. Cuvette systems I-2

I.10. Flow system I-3

I.11.- Environmental conditions I-3

APPENDIX II. CALIBRATION TOLERANCES TABLES II-1

II.1. Photometric adjustment Tolerances II-1

II.2. Filters Wheel Adjustment II-1

II.3. AC Voltage of the Transformer Secondaries II-1

II.4. Filters sensitivity without flow cuvette II-2

II.5. Electric Noise II-2

II.6. Filters sensitivity with flow cuvette II-2

II.7. Fan Voltage Control II-3

II.8. Zero-Currents for the Sensitivity Test II-3

II.9. Heating Adjustment II-3

II.10. Peristaltic Pump Adjustment II-3

APPENDIX III. DEFAULT PARAMETERS III-1

APPENDIX IV. MAINTENANCE PLAN IV-1

IV.1. Cleaning

IV-1

IV.2.Change IV-1

IV.3. Review IV-1

IV.4.Check IV-1

IV

APPENDIX V. SPARE PARTS AND ACCESSORIES V-1

V.1.Accessories V-1

V.2.Authorized Spare Parts V-2

APPENDIX VI. PASSWORD VI-1

APENDIX VII. SOFTWARE VERSIONS VII-1

APENDIX VIII. COMPATIBILITY TABLE TO UPDATE SOFTWARE VIII-1

VERSIONS

ESQUEMAS

Shematic distribution E33000A

Monocard (1-4) E33001A

Monocard (2-4) E33001A

Monocard (3-4) E33001A

Monocard (4-4) E33001A

Display / Printer (1-2) E33003A

Display / Printer (2-2) E33003A

Keyboard-330 E33005A

Photodetector E33009A

MODIFICATIONS

1 Modification

- This is to make compatible in U7 the integrated circuits MAX691

(Maxim) or ADM691 (Analog Devices). 1-1

- Schemes 1-2

2 Modification

- This is to all devices to be only one monocard 2-1

- Schemes 2-2

3 Modification

- The problem is the transform of inverter circuit fails 3-1

- Photos 3-2

- Schemes 3-5

V

4 Modification

- Modification for recode the components to improve their description 4-1

5 Modification

- Modification for change the display circuit board version 5-1

-Schemes 5-2

VI

1. INTRODUCTION

This instrument instrument, due to its compact design and the reduced number

of components, is a simple, easy-to-maintain one. The computer design has

allowed to study the tolerance of all the optical block’s components, making

unnecessary any mechanical adjustment. Most of its parts are aluminum or

plastic-injected and so a maximum simplicity with reduced maintenance

requirements has been achieved.

Electronic adjustments are also avoided because of the modern, highintegrated circuits used. A powerful software allows the adjustment of most of

the parameters used. Corrections are made via software, using reference tool s

or calibrators.

All the electronic parts are located in two printed circuit boards (PCB’s), and

the software has a lot of check programs to make easy the search and

diagnosis of fail u res.

This manual is not only a guide for maintenance but a document for Technical

Assistance Service staff’s training. The running principles as well as the

electronic circuits are explained in order to get a global vi ew of the instrument.

Note: Throughout this manual, the Absorbance Unit is abbreviated as "Abs"

instead of "A", in order to avoid confusion with the electric current unit, the

Ampere, represented as "A".

1-1

1-2

2. FUNCTIONAL PARTS DESCRIPTION

This instrument is composed of the following functional parts:

a) An optical system to carry out the readings.

b) An aspiration system based on a peristaltic pump, to introduce the sample

in the flow cuvette.

c) A thermostatic system to carry out reactions into the cuvettes at a constant

temperature, when needed.

d) A communications interface, allowing the connection to a host computer by

means of a proper software.

e) A microcontroller-based system, wich controls most of funtional parts.

The next sections describe each one of the functional parts.

2.1. Optical system

2.1.1. Constitutive parts

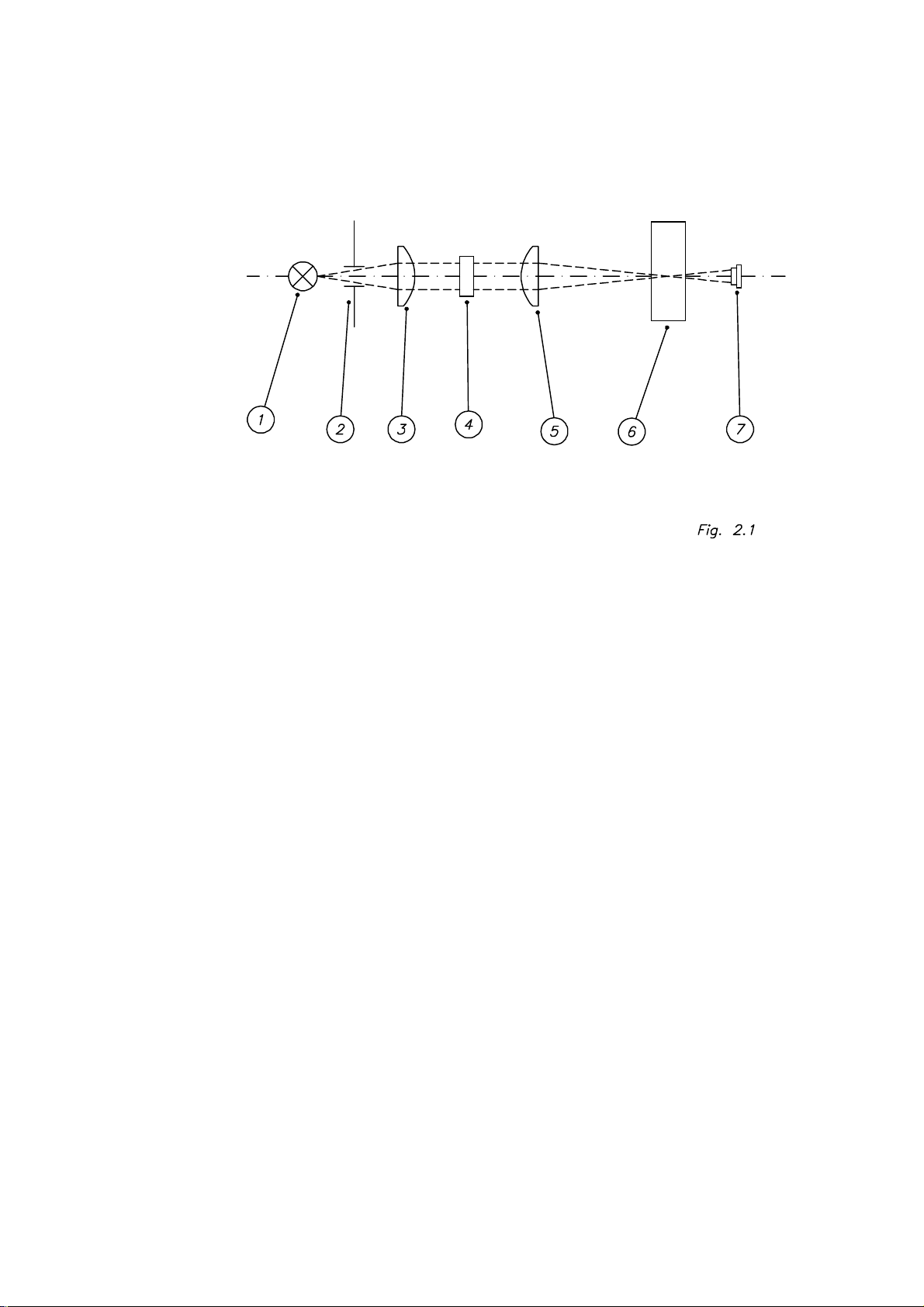

Figure 2.1. shows the optical system. It consists in:

a) An halogen lamp (1)

b) A diaphragm (2)

c) A first plano-convex lens (3)

d) An interference filter (4)

e) A second plano-convex lens (5)

f) A cuvette (6)

g) A silicon photodiode (7)

2.1.2. System description

The first component is the light source: one halogen lamp (1). The di aphragm

(2) delimits a light solid angl e that is collected by the first lens (3). It sends a

parallel beam to an interference filter (4). Thi s is one of the nine possibl e ones

located in the wheel. One stepper motor drives this wheel and, controlled by

the program, place the proper filter in the opti cal axis, in front of the l i ght beam.

Each filter monochromes one wavelength with the characteristics described in

section I.1.

A second lens (5) focuses the monochromatic beam in the cuvette center (6). In

case of flow cuvettes, the light path hole itself behaves as a diaphragm,

decreasing the sensitivity, that it is lower than in the common cuvettes. The

2-1

light beam goes through the cuvette as far as a light sensor (7), that converts

the light beam into electric current.

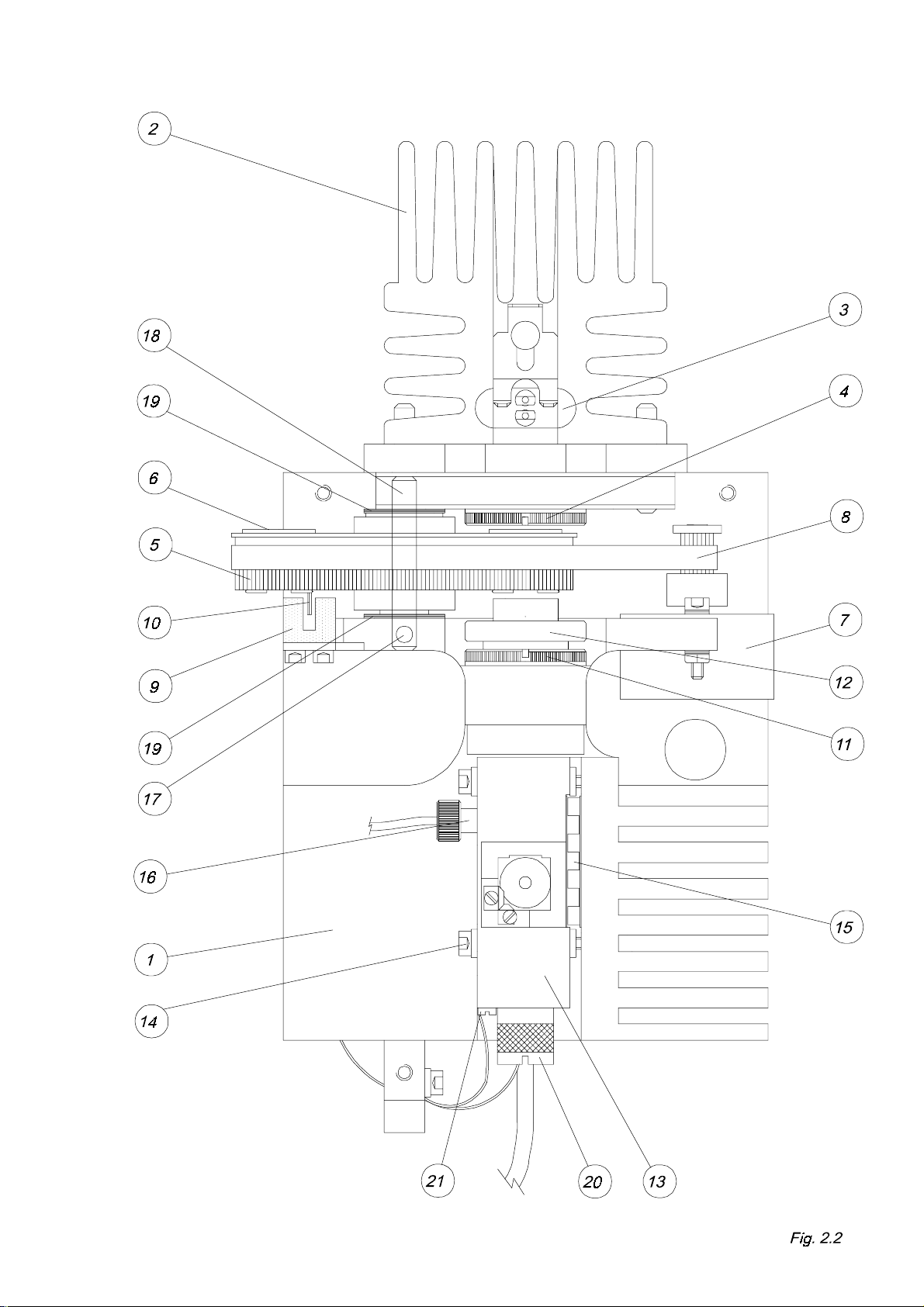

2.1.3. Physical description

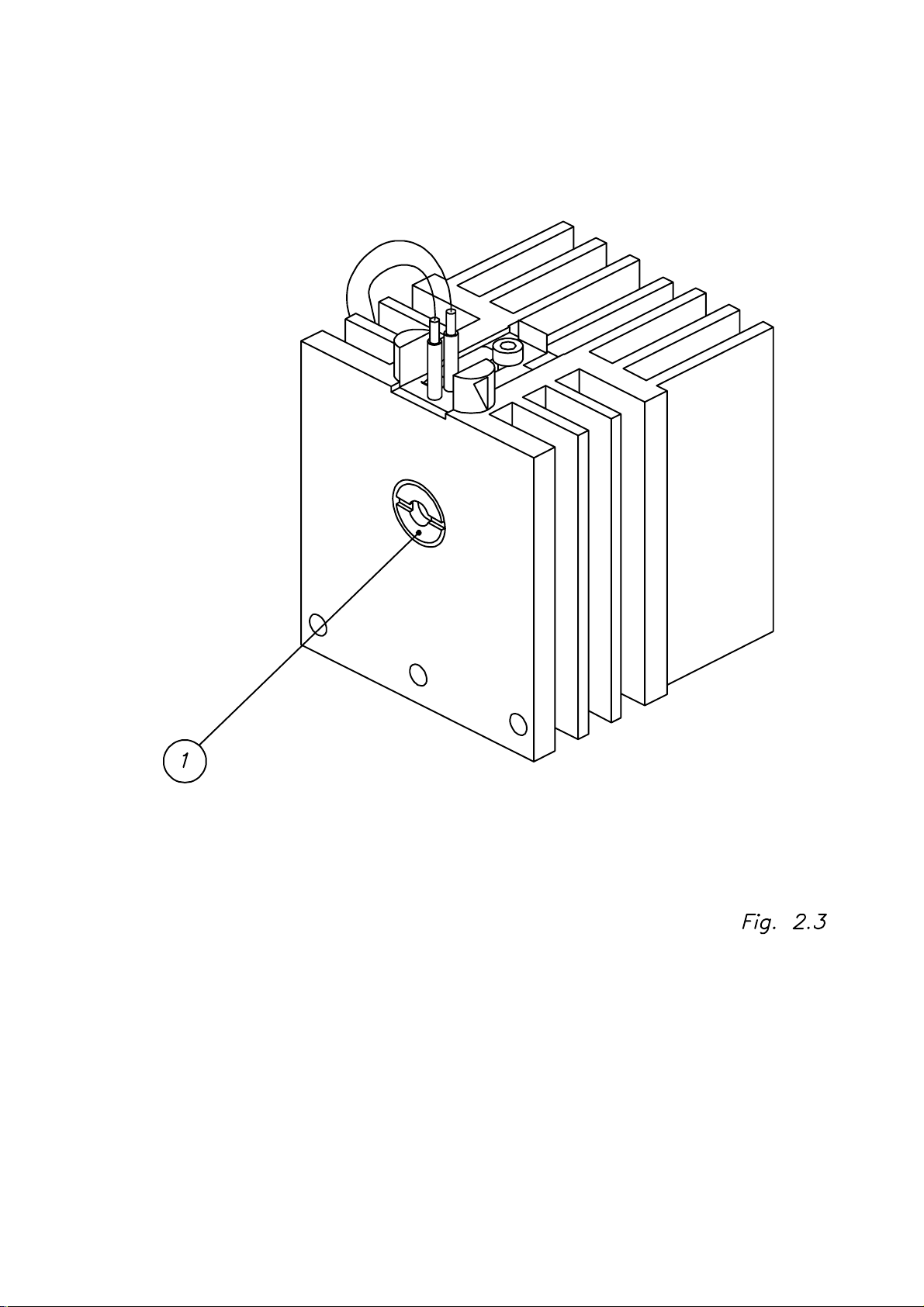

The optical system (figure 2.2) consists in an injected-aluminum holder (1)

where there are mounted the following components:

- A heat sink shape aluminium block (2) containing a lamp-holder (3). That

block includes a diaphragm (figure 2.3 (1)) that delimits the a light solid angle.

- A lens holder (4) that contains the first lens.

- A filters wheel (5), with capacity for 9 filters. This fil ters must be mounted in

special holders (6). Thi s wheel is moved through a belt (8) by a stepper motor

(7). A photointerrupter (9) allows the detection of a stem (10) that indicates the

filters wheel home position.

- A lens holder (11) that contains the second lens.

- A light protector (12), fitted together the second lens holder, avoids the

parasite light in terference.

- A cuvette-holder (13) holds both the cuvette and the photodiode detector. The

thermostatic system is fitted together (see section 2.3.).

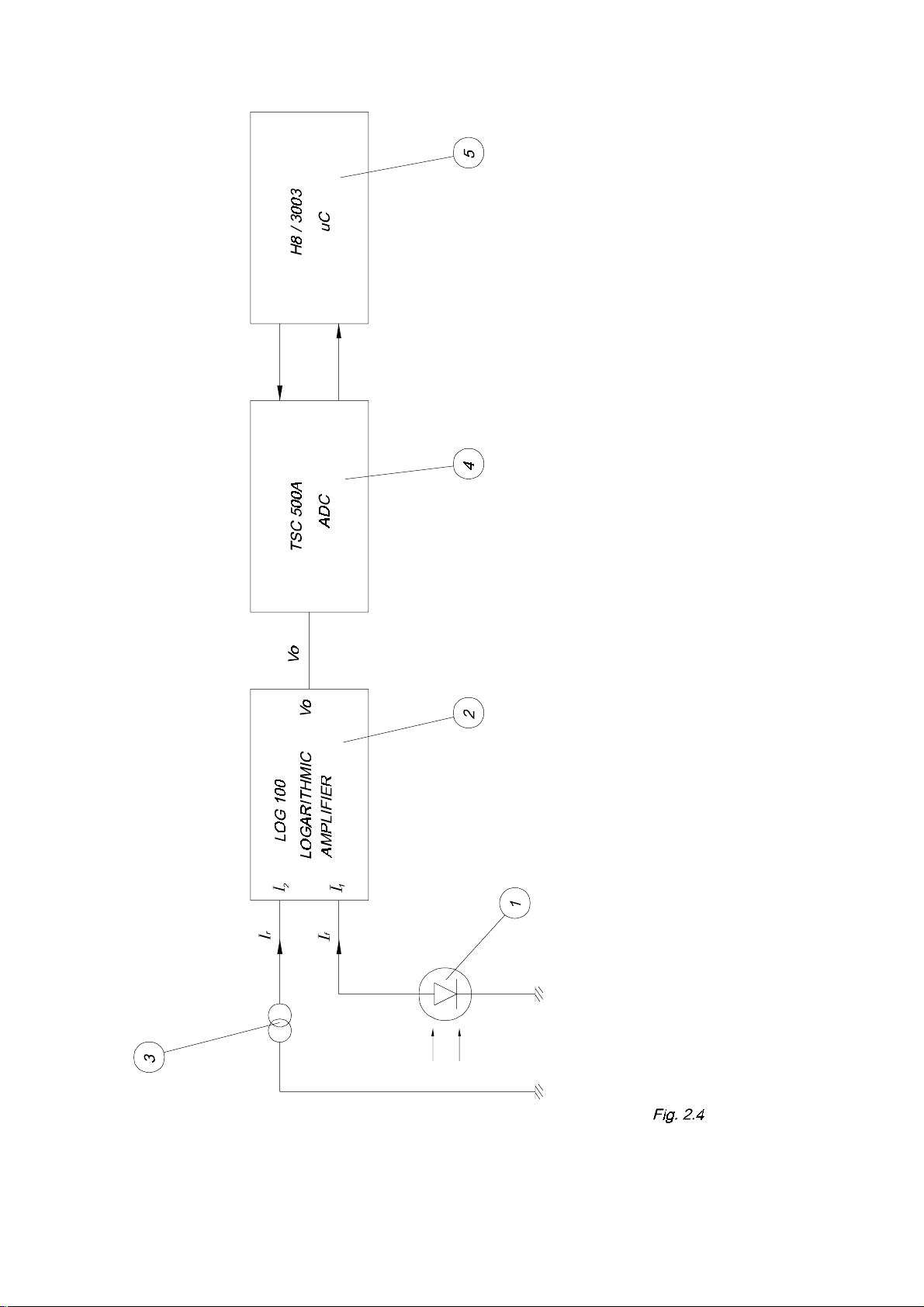

2.1.4. Signal conditioning

(See figure 2.4) The photodiode (1) gives an electric current (If) directly

proportional to the received light. Thi s current goes to the input I

100 logarithmic amplifier (2). A reference current I

introduced by input I

I

. The output voltage of LOG-100 is:

2

f

(3) (nominal 100 nA) is

r

of the LOG-

1

V0 = k x log ---------- I

r

In this case, k=1 and V0 = 1 volt/Abs.

2-2

2-3

2-4

2-5

2-6

V

is digitali zed by the double-ramp converter TSC500A (4) with a resolution of

0

10,000 counts per volt. The conversion time depends on the absorbance value

and increases together with it; for instance, 2 Abs time is 0.15 sec. This

converter is controlled by the microcontroller (5).

2.1.5. Adjustment

The global system (optical system, amplifier and converter) is not stri ctly l inear

due to the components tolerance, so that it is necessary to do some

adjustments to compensate the inherent deviations of the system.

The photometric adjustment is performed in ranges; between 0 and 2 Abs.

Several value ranges are determined and different correction factors are

applied depending on the range. As deviation also depends on the wavelength,

it is necessary to adjust with different filters. Adjustment process is described in

section 3.2.

2.1.6. Precautions and maintenance

Maintenance of the optical system should be carried out according to the

instructions given in section 5.20.

2.2. Aspiration system

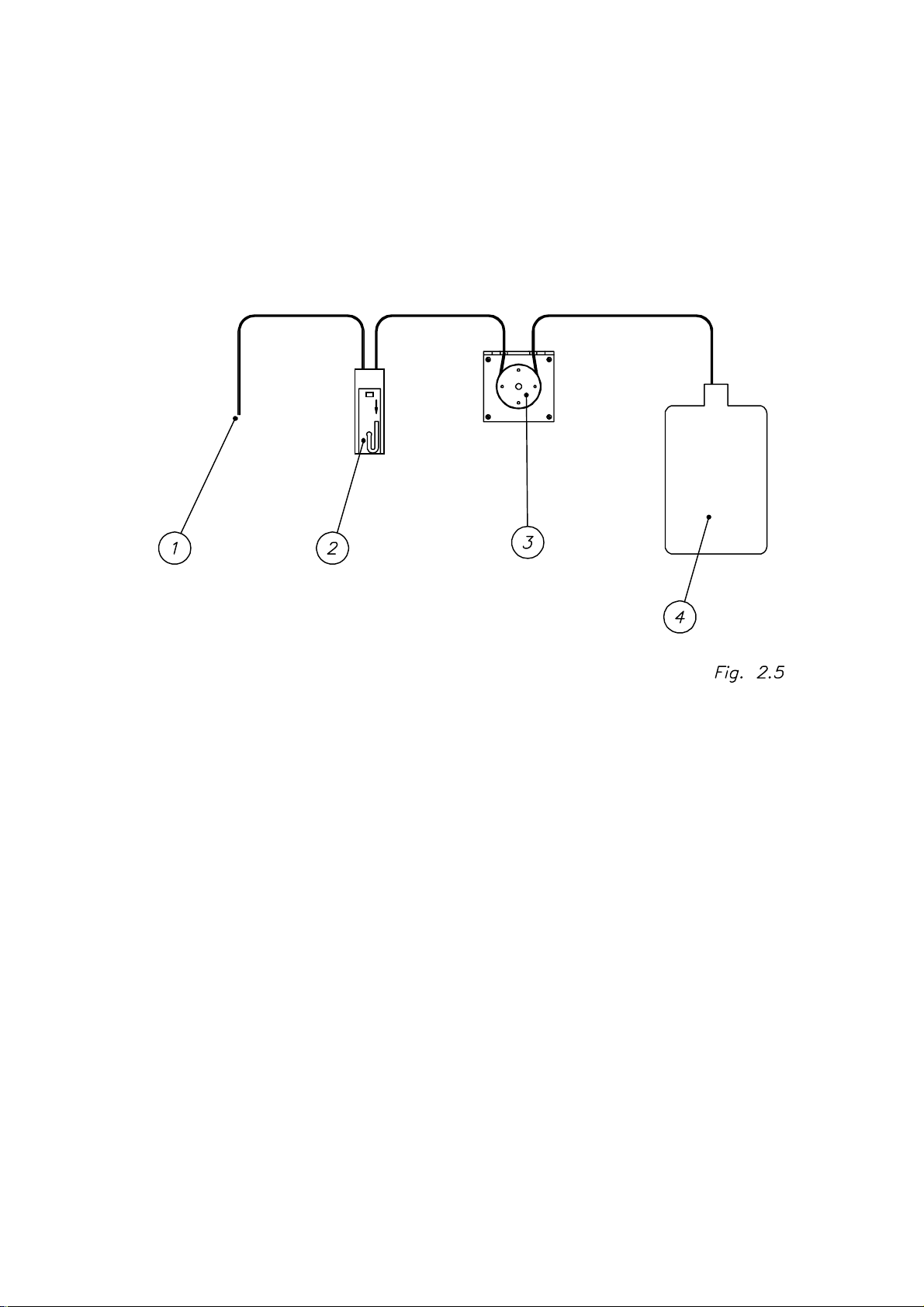

2.2.1. Components

The aspiration system is composed of the following parts (figure 2.5):

a) Sipping tubing (1)

b) Flow cuvette (2)

c) Peristaltic pump (3)

d) Waste bottle (4)

2.2.2. System description

The sample is sipped by the sipping tubing (1). This tubing, Teflon made, has a

standard length and the system is adjusted in accordance with it. The sipped

sample enters into the flow cuvette (2), where readings take place. Sipping is

performed through a silicone tube by means of a peristaltic pump (3), made up

of a four-rollered rotor that is contolled by a stepper motor. Finally, the sample

ends into the waste bottle (4).

2-7

2.2.3. Physical description

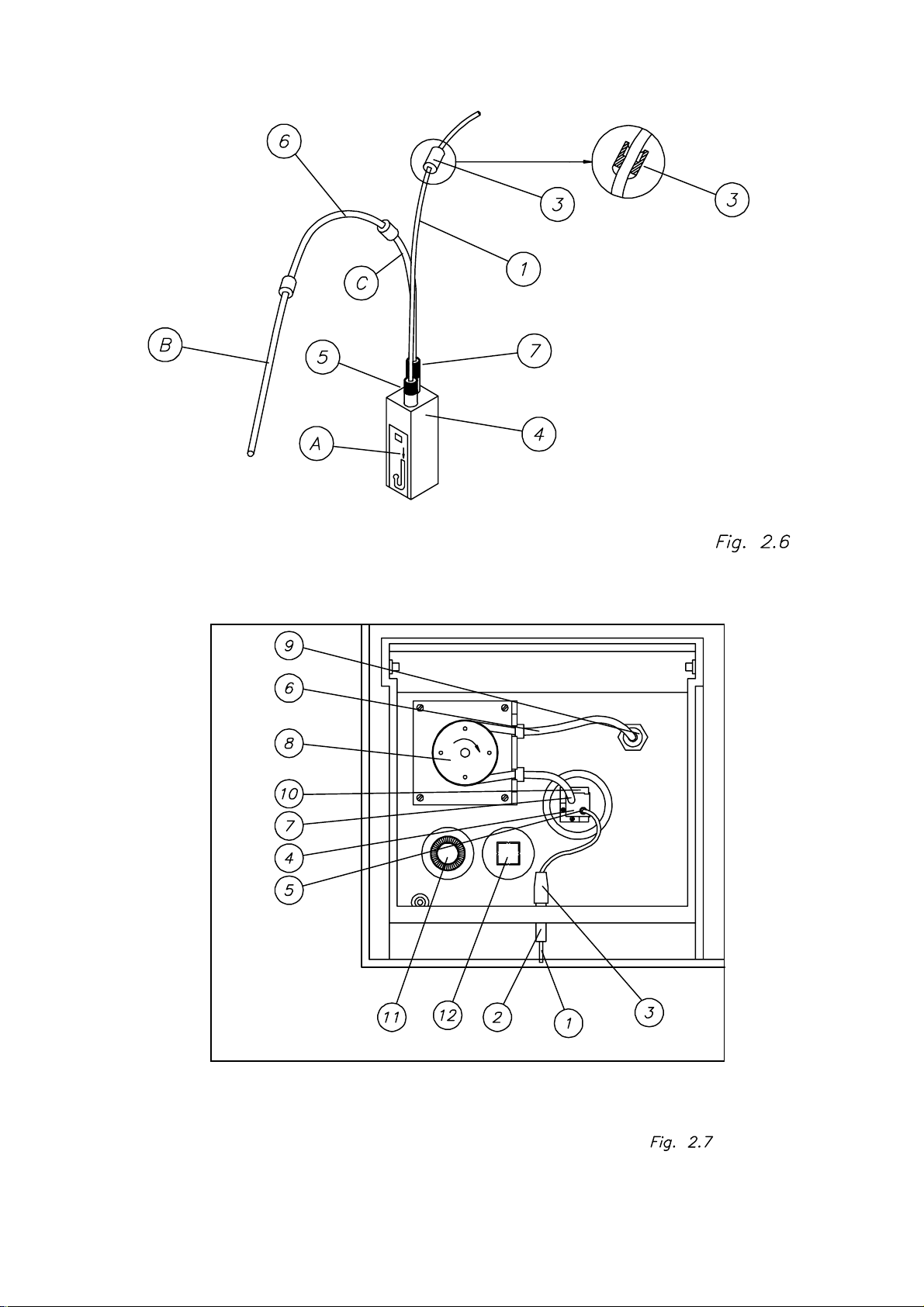

The sipping tubing (figures 2.6 and 2.7) is placed on the cuvette-holder tray.

The silicone tube (1), that crosses the case through a steel guiding tube (2), is

fixed to this guiding tube by means of a silicone connector (3) and to the

cuvette (4) by means of an inlet adapter (5). The teflon tube (6) is connected to

the cuvette by an outlet adapter (7), placed in the peristaltic pump (8) and

finally connected to the waste outlet (9).

The waste bottle (1) (figure 2.8) is connected to the outlet (2) in the back of the

instrument by means of a silicone tube (3).

2.2.4. Programmable parameters

Three parameters control the sipper functioning and they must be programmed

to obtain the expected performance characteristics. Their programming is

explained in the user’s manual.

a) SAMPLE VOLUME. It is a number that indicates the volume of sample to be

sipped, in

P

l.

b) PUMP DELAY. It is the number of seconds the pump will wait since the

sipping finishes till the pump is activated again to position the sample into the

flow cuvette.

c) POSITIONING. It is the number of steps that the peristaltic pump’s motor

gives to set the sample into the flow cuvette, ensuring that it is suitably

positioned in order to be read.

2.2.5. Programming

The aspiration system’s programming must be performed in order to indicate

the instrument the volume, in microlitres, to be sipped.

2.2.6. Adjustment

The pump’s nominal flow is 110 PL/revolution, nevertheless, the accuracy of

this figure depends on the tolerances in length and diameter of the sipping

tube, that may be affected by the aging of the tube itself; this is why this value

should be adjusted from time to time. The adjustment process is explained in

section 3.5. As it can be also done by the user, it i s also explai ned in the user's

manual.

2-8

2.2.7. Precautions and maintenance

The general rules for the aspiration system’s maintenance are the same as the

ones given in section 5.24.

Weekly adjustment of the aspiration system is strongly recommended.

2.3. Thermostatization system

2.3.1. Components

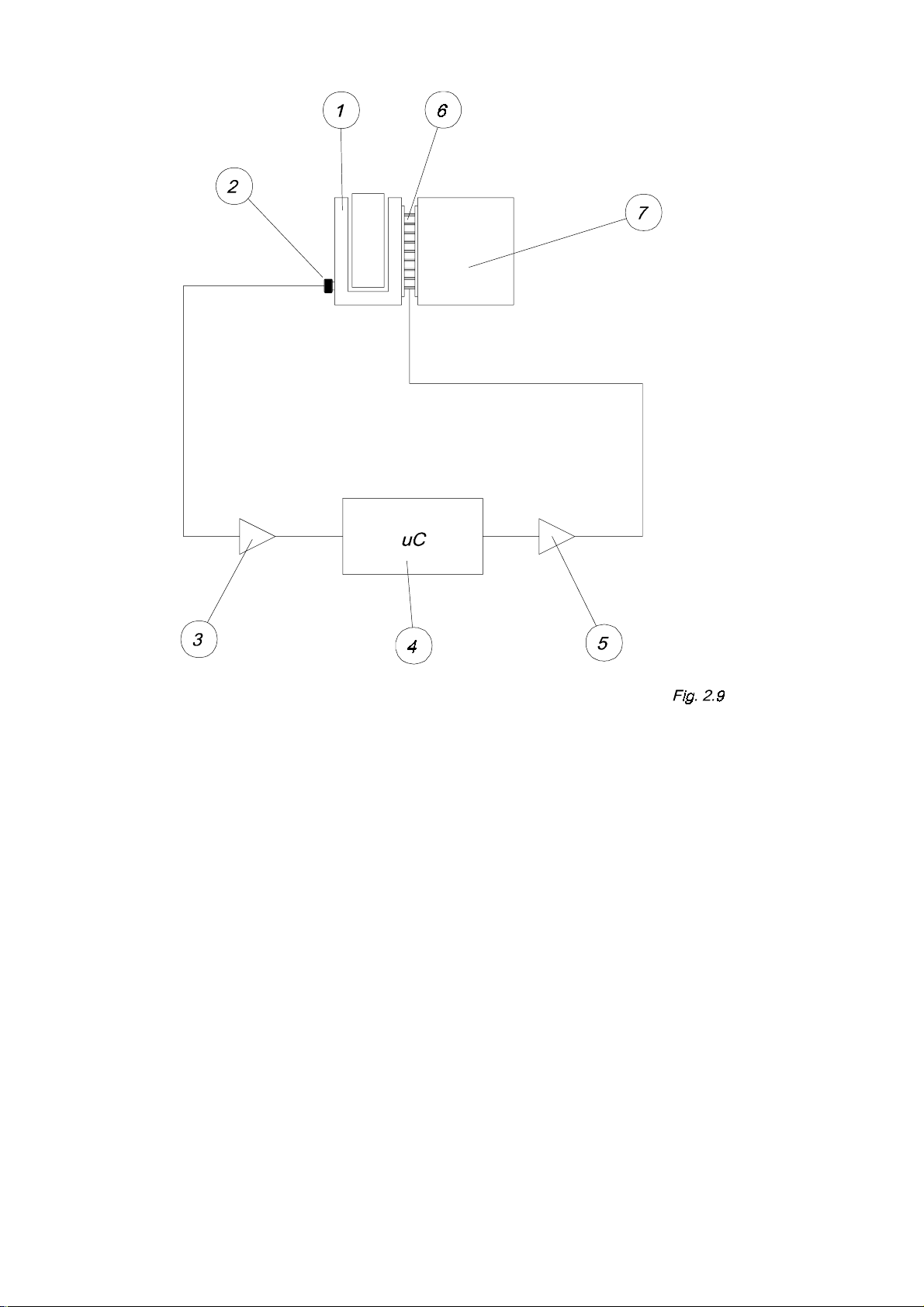

Figure 2.9 shows an schema of the thermostatization system, that is composed

by the following parts:

a) A cuvette-holder (1)

b) A temperature sensor (2)

c) An amplifier of the temperature sensor (3)

d) The microcontrollers’ A/D converter (4).

e) A Peltier Cell’s in-circuit power driver(5).

f) A Peltier Cell (6)

g) A heat sink block (optical system holder) (7).

2.3.2. System description

The cuvette with the reaction mixture to be thermostatized is placed in its

holder (1). Thermal contact is settled between the cuvette and the holder.

The cuvette-holder is isolated from the optical system holder (7) and contacts

one of the Peltier Cell’s faces (6). The other cell ’s face is in contact with the

optical system holder.

The Peltier Cell pumps heat from one face to the other, depending on the

current sense. The power control circuit (5) is in charge of making that current

circulate in the adequate sense inside the Cell, in order to heat or cool

depending on the microcontroller’s instructions.

When heating, heat is pumped from the environment (taken from the optical

system holder) to the cuvette-holder and when cooling the opposite is done.

The optical system holder has a heat sink block to cool the heat coming from

the cuvette-holder. A temperature sensor (2) gives a small voltage, directly

proportional to the cuvette-holder’s temperature, that is conditioned by one

amplifier (3) and read by the microcontroller’s A/D converter (4). The

microcontroller’s thermostatization program, depending on the programmed

temperature and the read value, activates the power control (5) heating or

cooling as required.

2-9

2-10

2-11

Fig 2.8

2-12

2-13

2.3.3. Physical description

The cuvette-holder (13) (figure 2.2) is fixed to the optical system holder (1) by

means of four screws (14) thermally isolated. The Peltier Cell (15) is located

between the cuvette-holder (13) and the optical system holder (1). The

temperature sensor, located in a plastic holder (16) is fixed to the cuvetteholder by a thread.

2.3.4. Programming

Programming the thermostatization system consists in indicating the i nstrument

which temperature is desired for the reaction mixture. This value may

introduced in several program’s points.

2.3.5. Adjustment

Components’ tolerance produce a deviation between the programmed

temperature and the real one, so it is necessary an adjustment procedure to

compensate such deviations. The thermostatization adjustment procedure is

described in section 3.3.

2.3.6. Precautions and maintenance

The thermostatization system has two critical poi nts: the good thermal contact

between both faces of the Peltier Cell with the optical system holder and the

cuvette-holder, and the good thermal contact between the temperature sensor

and the cuvette-holder.

To ensure proper conditions in both points, the following cautions should be

taken into account:

a) A thin, uniform layer of silicone must be placed in each face of the Peltier

Cell, covering the whole surface.

b) The silicone layer should neither go beyond the surface of the Cell, nor go

inside between its two faces; it would result in a thermal short-crossing that

would reduce the system’s performance.

c) The temperature sensor should have a silicone layer in order to make a

good thermal contact with the bottom of its lodging.

For assembling these components, follow the procedures described in secti ons

5.11. (changing the Peltier Cell) and 5.14. (changing the temperature sensor).

2-14

2.4. Communications system

This instrument is equipped with a communication channel all owing connection

with computers. The operation of this communication channel depends on the

program release and the computer’s applicati on software.

2.4.1. Channel type

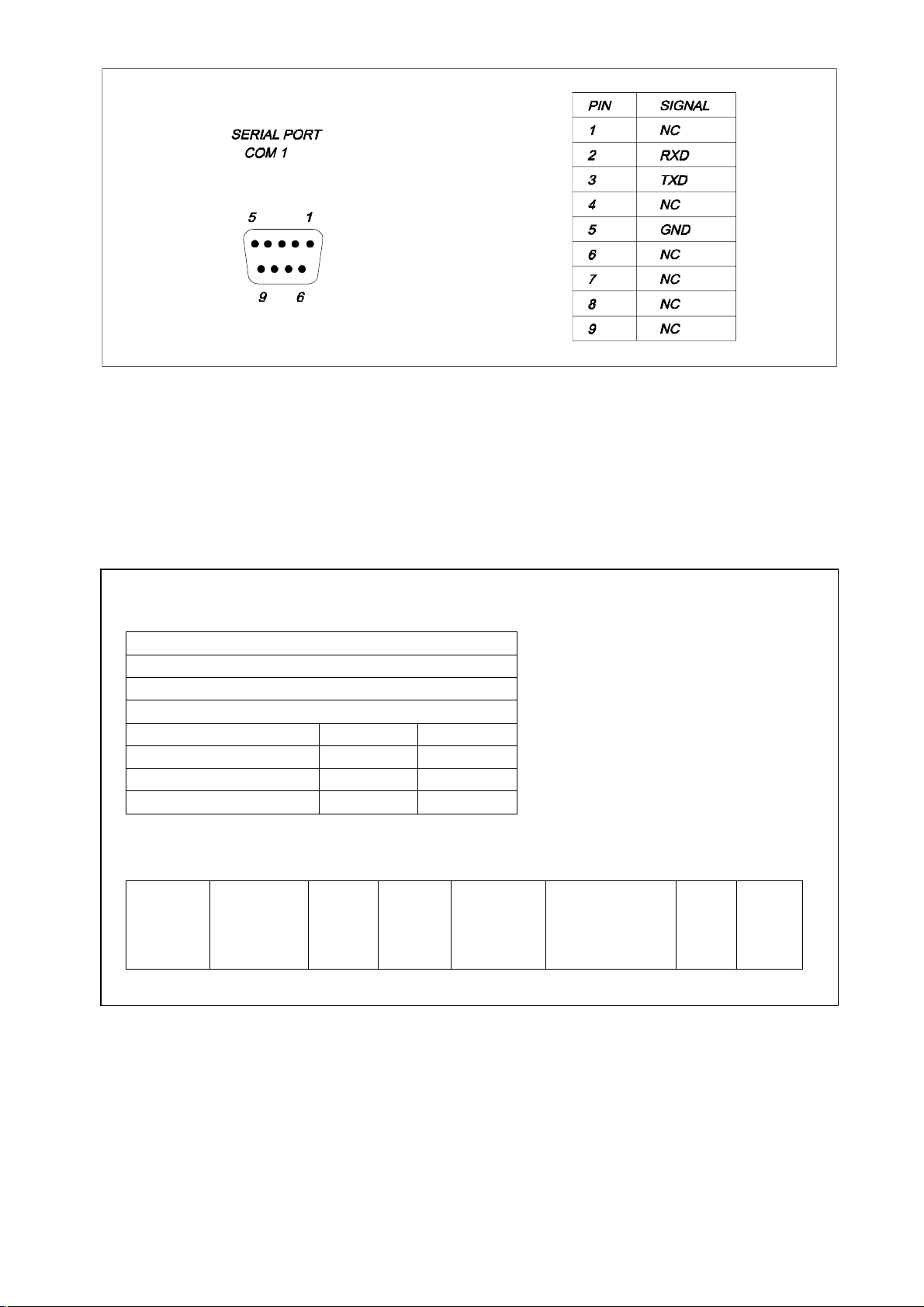

The communication channel is a RS-232, and uses the following connection

lines:

RxD: Receiver Data

TxD: Transmitter Data

GND: Ground (0 volts)

The connector is located in the instrument’s back side, rounded by a box

labeled COM 1. The signals’ electric level meets the E.I.A. RS-232 standard.

Figure 2.10 describes the connector’s signals.

2.4.2. Channel characteristics

The serial channel is pre-programmed by the manufacturer with next default

parameters:

Baud rate: 9600

Timeout:: 0

Terminal number: 0

2.4.3. Information transmitted

The communications procedure uses a ‘sending & waiting’ protocol . Every time

the transmitter sends a message, it waits for an ‘ok’ from the receiver. If the ‘ok’

message is not received, after a programmable timeout period the message is

sended again. The CRC-16 error-detection code is used to check the received

messages.

The communications procedure works using a

MASTER-SLAV

E method, so it

is possible to communicate several instruments at one time. To achieve this,

every instrument has to be configured with a different identification terminal

number. This parameter is configured in the CONFIGURATION /

COMMUNICATIONS menu.

Communications are always started by the

SLAVE

when it is required by the

(the instrument) is in a ‘hearing’ mode, and only sends information

MASTER

.

2-15

MASTER

(the computer). The

The instrument can send the information below:

- Quality control val ues

- Concentration values

In order to get the communication between the computer and the i nstrument, a

proper computer-running software is needed. This program save the data

received from the instrument into the computer hard disk. These data are

stored in an

EXCEL

compatible format.

The file format used is showed in figure 2.11.

2.4.4. Programming

In order to get a suitable communication with a computer through the serial

channel, it is necessary to fit the configuration parameters with the computer

ones. If the computer parameters are not known, refer to its manual. Usually

they are likewise programmable, in most cases from the application programs

themselves.

The instrument can be programmed with the next parameters: transmission

speed (bauds), timeout and terminal number. In the user’s manual is explained

how to program these parameters.

2-16

- Quality control values:

Test’s name

Control 1 or Control 2

Control’s name

Control’s lot

Concentration Date Alarm

Concentration 1 Date 1 Alarm 1

Concentration 2 Date 2 Alarm 2

Concentration n Date n Alarm n

Concentration values:

Test’s

name

Sample’s

number or

patient’s

code

Blank Factor Control-1,

Control-2

or sample

id.

2-17

Concentration Units Date

Fig.2.11

2.5. Block diagram

The block diagram (figure 2.12) is intended to give a general overview of the

the electronic circuit’s different parts.

2.5.1. Logarithmic amplifier

It converts the electric current coming from the photodiode in a voltage equal to

its logarithm (section 2.1.4.).

2.5.2. Analog to digital converter

It digitalizes the voltage coming from the logarithmic amplifier for its further

treatment by the microcontroller.

2.5.3. Lamp control

It supplies the regulated 12V that the lamp needs to work properly.

2.5.4. Filters wheel detector

It is a photointerrupter to detect the filters wheel home position. Allows the

microcontroller to know the location of each filter thus being able to position

them in front of the light beam.

2.5.5. Filters wheel motor control

This is a circuit that, by means of the microcontroller’s logic control, supplies

power to the stepper motor that moves the filters wheel.

2.5.6. Temperature sensor amplifier

This is a circuit to make the signal conditioning for the temperature sensor’s

voltage level in order to be measured by the microcontroll er’s 10-bits analog to

digital converter, with a resolution enough to adjust the system.

2.5.7. Peltier cell control

This is a microcontroller-controlled power circuit that supplies the Peltier cell

the adequate current to heat or cool the cell-holder.

2-18

2.5.8. Pump motor control

This is a circuit that, by means of the microcontroller’s logic control, supplies

the needed power to the stepper motor that moves the peristaltic pump.

2.5.9. Keyboard circuit

This circuit basi cally consists in the keyboard itself and some protection diodes.

2.5.10. Printer control

It consists in the power circuits that allow the orders coming from the

microcontroller to act on the printer, either moving the motors or heating the

thermal head points.

2.5.11. Display circuit

This circuit consists in the display itself, the control and supply lines, one

inverter circuit for the CFL backlight and one circuit to control the LCD contrast

adjustment.

2.5.12. RS-232 channel circuit

It is formed by the circuits needed to make the signal conditioning from TTL

voltage level to the RS-232 standard. The ACIA is integrated in the

microcontroller itself.

2.5.13. Fan control

This is a circuit that measures the temperature in the power supply’s heat sink

and changes the fan’s speed according to the cooling necessi ty. A more silent

working conditions are thus achieved.

2.5.14. Microcontroller

By means of its program, it is in charge of li nking and control ling almost all the

instrument systems. Only the fan’s circuit and the lamp’s one are not controlled

by the microcontroller.

2-19

2.5.15. Power supply

It is in charge of supplying the needed voltages to the different instrument

parts.

2.5.16. Reset and battery-backup supervisory circuit

When the instrument is turned on, this circuit is in charge of keeping the

microcontroller and other chips (like memories) in a ‘reset state’ until the suppl y

voltage reaches the proper working level, avoidi ng undesired effects when the

instrument is powered on, as well as protecting the RAM against erroneous

writings during the on / off voltage transitions.

Also, this circuit provi des a batery backup switchover every ti me the i nstrument

is switched ON/OFF

2.6. Electronic circuit description

This section describes the different electronic parts, following the functional

structure given in section 2.5.

2.6.1. Logarithmic amplifier

(See schema E33001A, sheet 1)

The logarithmic amplifier is formed by the hybrid circuit LOG-100 (U16). Its

supply voltage is

r

15 V. C90, C91, C96 and C97 are bypass capacitors that

store electrical charge that is released to the power line whenever a transient

voltage spike occurs. The photodiode is connected between ground and the

input I1 (1/U16). A reference current (section 2.1.4.) is generated i n the 2.5 V

voltage regulator TL431CD (U15) and the T-circuit formed by R45, R51 and

R52. Its nominal value is 100 nA. The LOG-100 has the output OUT (7/U16)

connected to the pin K1 (3/U16), thus being the logarithmic conversion

constant (K) equal to 1. The capacitor C92 is for circuit stability.

2-20

2-21

2.6.2. Analog to digital converter

(See schema E33001A, sheet n. 1)

The logarithmic amplifier’s output voltage (7/U16) is applied to the A/D

converter’s input VIN(+) (11/U19) through a RC net formed by R56 and C93.

This converter takes as a reference the U15 2.5 V voltage and is supplied at r5

V. The voltages are reached from r15 V by means of the D16 and D17 zeners

and bypassed using the capacitors C80, C81, C83 and C84. The capacitors

C99, C100, C101 and the resistor R60 belong to the converter circuit. This

capacitors must be of polypropylene type in order to have very low leakage

currents.

As the voltage in 7/U16 can vary in the r15 V range while the input voltage of

11/U19 cannot exceed the U19 supply voltage (5 V), the circui t formed by D8,

D9, D10, D12, R43 and R44 protect it against overvoltages.

2.6.3. Lamp control

(See schema E33001A, sheet n. 2)

The lamp’s power supply is done through the circuit formed by the RG1

regulator. It receives the non-regulated voltage from the 0-15 Vac transformer’s

coiling. Thi s voltage is rectified by the bridge D2 and fil tered by C14 and C15

(C17 is the bypass capacitor). The 12V output voltage is given by the resi stors

R19 and R20.

2.6.4. Filter wheel detector

(See schemes E33009A and E33001A, sheet n. 1)

The wheel detector consists in the photointerrupter MCT-81 according to the

schema E33009A and it is mounted on the printed circuit reference 1363. The

schema E33001A shows the resistor R46 connected to the emitter photodiode’s

anode, as a power supply, and the resistor R41 connected to the collector, as a

load. From this point the logic signal is taken and read by the microcontroller

pin PC4 (15/U13).

Under normal conditions, the photodiode’s infra-red light reaches the

phototransistor, which starts to work in saturation mode and the signal in its

collector is a logic "0". When the filters wheel turns and the detection stem

interrupts the light from the photodiode, the transistor stops conducing and the

signal in its collector is a logic "1".

2-22

2.6.5. Filters wheel motor control

(See schema E33001A, sheet n. 2)

The filters wheel stepper motor control is achieved by two integrated circuits

PBL3717A (U5 and U6). These circuits are constant current stepper motor

drivers. Each one supplies the current to one of the motor coils. This current

depends of the reference voltage applied in the REF pins (11/U5 and 11/U6).

This voltage is generated by the 12 V zener D3, the resistors R23 (i n U5) and

R24 (in U6) and the internal voltage dividers of these ci rcuits. C13 and C36 are

bypass capacitors for the +5 V supply voltage of these circuits. The other

connected components complete its operation.

2.6.6. Temperature sensor amplifier

(See schema E33001A, sheet n. 1)

The temperature sensor generates a voltage proportional to the temperature

expressed in Kelvin degrees (Celsius + 273), equal to 0.01 V/

q

K. So, for

instance,

at 25qC VT = (25+273) x 0.01 = 2.98 V

at 37qC VT = (37+273) x 0.01 = 3.10 V

The U20 amplifier and its associated circui t make these voltages adequate to

be read with the maximum resolution by the 10-bit A/D converter of the Hitachi

H8/3003 microcontroller. The adequate voltage exits by 6/U20 and it is applied

to the microcontroller’s input AN0 (86/U13) through the resistor R47.

As the voltage coming from 6/U20 can vary in the range r15 V and the input

voltage of 86/U13 cannot exceed the converter reference voltage applied to

AVCC (84/U13) (5 V), the circuit formed by D11, D13, D14, D15 and R50 is in

charge of keeping this input between this value and ground.

2.6.7. Peltier Cell control

(See schema E33001A, sheets n. 1 and 2)

A low-voltage, full-wave rectified voltage is applied to the Peltier Cell, in the

sense adequate for heating or cooling. Although the use of this current l owers

the performance of the cell, its use is justified by the simplicity of the circuit.

The full-wave rectification in both senses is achieved using two triacs and a

center-tapped coiling. Each triac can l et a positive or negative hal f-wave pass,

when convenient. The circuit formed by the amplifier TL072CD (U3A), that

works as a comparator, and the transistor BC548 (T5), that makes the output

2-23

1/U3A (r15 V) adequate to logic level (0 at +5 V), form a polarity detector for

the alternating voltage that suppl ies the power control circuit.

This signal is appli ed to the microcontroller by the pin P71 (87/U13) in order to

know which triac and when should be activated. The microcontroll er activates

the triacs by means of two signals leaving by pins PA6 (111/U13) and PA7

(112/U13) and that, together with the polarity detection signal (col l ector T5) are

applied to the programmable logic circuit XC9572-PC84 (U9) to generate the

two triacs‘ control signals (77/U9 and 6/U9) and avoid a simultaneous

activation caused by a program error. Circuits 2/U1A, 4/U1B and the transistors

T1 and T3 form the triacs’ activation circuit. Should it occur, the fuses F3 and

F4 in the common coil protect the transformer.

The result of this procedure is that each triac supplies the Peltier Cell a halfwave, in the same sense, depending on the heating or cooling requirements.

2.6.8. Pump motor control

(See schema E33001A, sheet n. 2)

This circuit, formed by the integrated circui ts U2 and U4, is similar to the one

used for the filters wheel control; the only difference between them is the R8

and R10 resistor values, because the current in this motor is different. Thus

refer to section 2.6.5. for its description.

2.6.9. Keyboard circuit

(See schemes E33005A, E33003A and E33001A, sheet n. 1)

The membrane-type keyboard forms a contact matrix and detects the pressed

key by scanning (schema E33005A). The keyboard is connected to the printed

circuit I33004 by J10. The lines of this connector pass di rectly to the connector

J5 (schema E33003A) that carries them to the printed circuit I33002.

The scanning is generated in the li nes referenced KBD[0..9] (pins 65, 63, 62,

61, 58, 57, 56, 55, 54 and 53) of U9 (XC9572-PC84) by the microcontroller,

that sends control commands to U9 using the data bus (DB[0..7] and the

address bus (ADD[0..23]). The line quiescent mode is the logic 1. Onl y one of

them is activated by the logic 0 at one time. The keyboard status is read by

means of the lines KBD0 a KBD4 (65, 63, 62 and 61 of U9). If there is no key

pressed, the status is the logic hi gh level because of the pull- up resistor array

AR2. When a key is pressed, i t is produced a contact with one of the scanni ng

lines and logic low level is leaded to the associated read line. The

microcontroller detects the pressed keys by means of U9 using the data bus.

2-24

Diodes D4 to D8 prevent from undesired short circuits between one scan li ne at

"0" and other at "1" when pressing two keys at the same reading line

simultaneously.

2.6.10. Printer control

(See schemes E33003A and E33001A, sheet n. 1)

The thermal printer is controlled by means of its two own unipolar stepper

motors. One moves the head and the other the paper feed.

Eight thermal points form the printer head and a micro-switch detects the

head’s initial position (HOME). This micro-switch has a pull-up resistor (AR1)

and the signal is read by the microcontroller pin P60 (66/U13).

Both motors and thermal points are controlled by the microcontroller by means

of U9 (eschema E33001A). The motors are controlled using the bus MTR[0..7]

and the thermal points through the bus PRT[0..7]. These logic signals are

powered by the drivers ULN2803A (U1 and U3). The capacitors C12, C13,

C15, C17, C24 and C25 are the bypass ones.

2.6.11. Display circuit

(See schema E33003A and E33001A sheet n. 1)

As a screen, it is used a graphic l iqui d crystal di spl ay (Hitachi LMG7520RPFC)

with a CFL backlight. Its resoluti on is 320 x 240 dots. The LCD is connected to

J2 in the printed circui t I33004A. Both control signals and data are sent to the

display by U9, according microcontroller control commands.

The J2’s pin 4 (VDD) is directly connected to +5V (Vcc) supply voltage. The

capacitors C7 and C9 are for bypassing.

The LCD contrast is controlled by means of a negative adjustable voltage from

0 to –22V through the VEE (P6/J2) line. This adjustable voltage Vee is

generated by the switching regulator LT1111 (U2). The switching regulator

output voltage is controlled by the duty cycle of the PWM signal sent by the

microcontroller (P4/U13):

PWM : 1-3 KHz

0% Duty Cycle: 0V

100% Duty Cycle: -25V

The LCD backlight supply voltage is connected to J8. The backlight supply

voltage is generated from Vpm (+5V) by the inverter circuit (see the block in

wich the TRF1 transformer is).

2-25

Look out: The backlight supply voltage (J8) is up to 300Vrms, 85 KHz

and 6mArms. The lamp start voltage is 1000V minimum.

2.6.12. RS-232 channel circuit

(See schema E33001A, sheet nº 1)

The serial communication is achieved by one of the two ACIA integrated in the

microcontroller. It supplies all the necessary functi ons and the communication

uses two lines, TxD2(transmitter data, 20/U13) and RxD (receiver data

22/U13).

The lines’ logic level is TTL. The signal conditioning to the RS-232-C E.I.A.

standard is made by the integrated circuit MAX202CSE (U17) and a set of

associated capacitors. They generate the needed positive and negative

voltages. The communication lines enter and exit through the J15 connector

(Figure 2.10).

2.6.13. Fan control

(See schema E33001A, sheet n. 2 and 3)

The fan’s power supply is done by an independent circuit, formed by the 24 V

transformer coili ng, the rectifi er bridge D6 and the capaci tors C38 and C52 that

generate a non-regulated voltage. The voltage to apply to the fan i s controlled

by the regulator RG6. The output voltage is given by the voltage divider formed

by R29 and NTC1, wich is in contact whith the power supply heat sink and

makes the voltage increase when it becomes hot. In this way, the higher i s the

load or the external temperature, the faster is the fan’s operation, thus

achieving a more silent function under normal conditions.

2.6.14. Microcontroller

(See schema E33001A, sheet n. 1)

The microcontroller circuit is formed by the H8/3003 Hitachi microcontroller

(U13). It is a last-generation microcontroller, i ncorporating peripherics such as

I/O lines, counters, ACIA's, and a 10-bit A/D converter with eight analog

channels, among others, thus minimizing circuitry.

The microcontroller has internal memory and control signals to connect

external memories.

Both code and data are stored in the 2 Mbytes FLASH memory (U11). A 512

Kbytes RAM (U12) is also used. This RAM is provided with a battery powered

supply voltage (Vbat).

2-26

The chip select signals ared decoded in the CPLD (U9).

U10 is intended to connect a EPROM 27C4001. If the jumper JP2 is closed, the

microcontroller seeks for the code in the EPROM (U10) instead of in the

FLASH (U11).

Usually U10 is used only by the manufacturer to load the monitor program in

U11 the first time. Afterwards, it is no longer usefull at all.

2.6.15. Power supply

(See schema E33001A, sheet n. 2)

The power supply is in charge of supplying the voltages and currents needed in

the different parts of the circuit. The l amp supply has been described in secti on

2.6.3. and the fan supply in section 2.6.13.

Besides these power supplies, there is the r15 V one, formed by the regulators

RG2 and RG3 with their associated circuits, and the +5 V one. This power

supply departs from a 0 to 9 V transformer coiling. The alternate voltage is

rectified by the bridge D4, fil tered by C39 and C40 and the hi gh-frequency is

bypassed by C50. The regulated voltage obtained in this way is applied to

three regulators. RG4 generates the +5 V to supply the thermal head of the

printer, RG5 supplies its motors and RG7 generates the +5 V for the logic

circuits.

2.6.16. Microcontroller supervisory and reset circuit

(See schema E33001A, sheet n. 1 y 3)

The microcontroller supervisory and reset circuit is formed by the integrated

circuit MAX691A (U7). This chip measures the supply voltage and when it is

below a certain reset-threshold voltage, the signal s /RESET y CCE are acti ve.

The /RESET signal makes the microcontroller start agai n and the CCE signal

joined to the U8A gate protect the RAM against undesired writings during the

powering transitions.

This chip provides also a backup-battery switchover. P2/U7 is the Vout pin.

When Vcc is greater than Vbatt and above the reset threshold, Vout connects

to Vcc. When Vcc falls below Vbatt and is below the reset-threshold, Vout

connects to Vbatt.

When the instrument is powered, the battery is always charging through R30.

When mains supply fal ls, Vbatt supplies a backup-voltage to the RAM and to

the timekeeper chip U14.

2-27

2-28

3. CHECKS AND ADJUSTMENTS

In order to simplify the failure’s diagnosis and adjustments, there is included a

set of test programs that allow the checking and adjustment of most of the

functional parts.

With the only exception of the peristaltic pump adjustment, accessible to the

user, the access to these programs is done through the menu

UTILITIES/SERVICE. Then, a password is required:

PASSWORD ... =

Input the password (Appendix VII). The display shows asterisks while typping.

In case of mistake, press “C” to repeat.

3.1. Service menu

When selecting this option, the following is displayed:

SERVICE 03/03/99 17:07:00

0.TEST

1 ADJUSTMENTS

2 UNLOCK/LOCK TEST

3 UNLOCK/LOCK INSTRUMENT

EXIT

3.1.1. Option TEST

By selecting this option, one can access to the diverse tests available for failure

diagnosis, that appear in the fol lowing list. Its function is described in Section 4.

SCREEN

-

BUZZER

-

KEYBOARD

-

3-1

PRINTER

-

SERIAL PORT

-

MOTORS

-

PUMP STEPS LOSS

-

FILTER STEPS LOSS

-

CUVETTE TEMPERATURE

-

CARRY OVER

-

PHOTOMETRIC

-

FILTERS SENSITIVITY

-

ELECTRONIC NOISE READINGS STABILITY

-

PRECISION

-

ACCURACY

-

UNLOCK/LOCK QC TESTS

-

3.1.2. Option ADJUSTMENTS

By selecting this option, one can access to the utility programs to perform the

adjustments of the photometry, temperature control, filter wheel and peristaltic

pump.

The diverse adjustment programs are described in Section 3.2.

3.1.3. Option UNLOCK/LOCK TESTS

This option allows opening and closing the diverse tests, by selecting them

either individually or all together.

The closed tests are not available to the user.

3.1.4. Option UNLOCK/LOCK instrument

This option allows opening or closing the instrument’s programming. When

activated, the option PROGRAMMING disappears from the main menu, thus

making impossible for the user to modify the test and the units. When the

instrument is re-opened, the options allowing modification of tests and units are

available agai n.

3.2. ADJUSTMENTS

3.2.1. Photometric adjustment

The aim of this procedure is to correct the absorbance values in the range 0 –

3 A, with neutral filters previously cali brated, i n order to obtain resul ts the same

as with a reference spectrophotometer. The final target is to obtain results

within the tolerance range between 340 and 900 nm in the previously

mentioned range of absorbances.

3-2

3.2.1.1. Materials needed

Verified calibration neutral filters.

-

Rubber bulb.

-

Cotton ear picks.

-

Alcohol + ether (50/50) solution.

-

3.2.1.2. General remarks

Switch the instrument on 20 minutes before beginning the adjustment.

-

Before beginning, take dust away from the neutral filters using the rubber

-

bulb.

3.2.1.3. Procedure

- Enter in the UTILITIES / SERVICE (Password...) / ADJUSTMENTS /

PHOTOMETRIC menu

Program the values requested in the first display.

-

Press the function key CHECK VALUES

-

Press the function key EDIT VALUES and then input all the standard val ues

-

for each filter. When the last value for each filter is input, the display

automatically changes to the next filter. When the last filter is completed,

the program exits the Edit mode (the Edit mode can be left at any time by

pressing the key EXIT). In case of mistake while entering the val ues, press

C to delete the value and key it in again.

Proceed as follows to correct previously validated values:

Exit the Edit mode by the function key EXIT (taking care of previously validating

with ENTER the last value).

Enter again in the Edit mode if the erroneous value is still on the screen.

Otherwise, use the cursor –up and –down keys until the desi red values appear

on the screen.

Press ENTER until the cursor is located on the standard to be edi ted. (Another

option is to enter in the Edit mode with the first standard of the first filter and to

press repeatedly ENTER until the cursor is located on the standard to be

edited).

Press the function key ADJUST. The program will request the standard values

to be introduced. Once the standards read, an automatic printing process

starts, in which the following data appear for each wavelength and standard:

the absorbance read, the expected absorbance, the relative and absolute

errors. The tolerances appear in Table II.1 of Appendix II.

Press the function key EXIT. The program asks if the adjustment is to be saved.

Answer YES if the relative errors obtained are within the tolerance ranges.

3-3

If there is no accomplishment with the tolerance ranges, repeat the procedure

in order to discard a mistake due to factors l ike errors during the procedure, in

the calibrators and/or instability of the electric supply.

Once all these external factors discarded, if the instrument does not accomplish

the ranges and presents abnormal values in the upper part or the absorbance

range, check the photodiode wire and the welding in the analog part of the

printed circuit board.

3.2.2. Thermostatic system adjustment

This procedure describes the way to adjust the thermostatic circuit of the

cuvette-holder. Both the cuvette-holder temperature sensor and i ts associated

electronic circui t have some tolerances that must be compensated in order to

have the cuvette temperature as programmed. The adjustment allows, using a

thermometer, the calculation of the correction coefficients needed to perform

this compensation.

3.2.2.1. Materials needed

Calibrated digital thermometer and temperature probe.

3.2.2.2. General remarks

Switch the instrument on at least 20 minutes before beginning the

-

adjustment.

It is very important to take into account the corrections indicated in the

-

digital thermometer when registering the temperatures.

3.2.2.3. Procedure

- Enter in the UTILITIES / SERVICE (Password...) / ADJUSTMENTS /

HEATING menu

Press the function key ADJUSTMENTS. The message “Insert the temp.

-

probe and press ENTER” is displayed.

Insert the calibrated digital thermometer’s temperature probe into the

-

cuvette-holder and press ENTER. The message “Heating” is displ ayed with

a time counter going down.

When the time reaches zero, the message “Input cuvette temperature at

-

25ºC” appears. Input the temperature measured by the thermometer

(corrected) and press ENTER. The message “Heating” with a time counter

going down is displayed again.

When the time reaches zero, the message “Input cuvette temperature at

-

37ºC” appears. Input the temperature measured by the thermometer

(corrected) and press ENTER.

3-4

Press the function key EXIT. The program asks if the adjustment is to be saved.

Answer YES if the results obtained are within the tolerance ranges.

3.2.2.4. Explanation of the list parameters

STEP: Each of the adjustment phases.

-

READ TEMPERATURE: Theoretical temperature that is read before

-

applying the correction factors.

CURRENT TEMPERATURE: Temperature indicated by the thermometer,

-

that must be typped by means of the keyboard.

ABSOLUTE ERROR: Difference in degrees between the read and real

-

temperatures.

E = T

RELATIVE ERROR: Percentage of deviation of the real temperature with

-

real

– T

read

regards to the temperature read.

T

E

= ------------------------

relative

T

OFFSET: Additive correction factor.

-

SLOPE: Multiplicative correction factor.

-

real

– T

read

read

3.2.2.4. Option CHECK

Allows the accuracy’s checking at a given temperature. To select this option,

press the function key CHECK in the UTILITIES / SERVICE (Password...) /

ADJUSTMENTS / HEATING menu. The cursor appears in the line:

TEMPERATURE TO CHECK: ____

Insert the calibrated digi tal thermometer’s temperature probe into the cuvette-

holder, Input the temperature to be checked and press ENTER. The message

“Heating” is displayed with a time counter going down.

After the five minutes, the screen’s prompt asks for a new temperature. Check

the reached temperature in the external thermometer.

3.2.3. Filters wheel adjustment

This procedure describes the way to adjust the optimal position of the fil ters in

the optical path of the reading group. The theoretical posi tion is establi shed by

the wheel reference photodetector but, because of the mechanical tolerances,

a further correction is necessary to optimize centering.

3-5

3.2.3.1. Materials needed

Soft paper WYPALL LITE (56 g/cm2) (SCOTT).

-

Washing solution (Code 20103).

-

Alcohol + Ether (50/50) solution.

-

Assay tubes.

-

Distilled water.

-

Closed circuit flow-thru cuvette.

-

3.2.3.2. General remarks

Switch the instrument on at least 20 minutes before beginning the

-

adjustment.

This procedure can be performer either automatic or manually. The

-

automatic procedure is recommended.

The adjustment is performed with the filter in the position nº 1 (340 nm).

-

Clean the outer faces of the cuvette with the ethanol/ether solution, and dry

-

with the WYPALL LITE paper.

Insert the cuvette in to its holder.

-

Wash the inside of the cuvette by performing a washing with 1 mL washing

-

solution and then abundant distilled water with the key “WASH”.

Check the absence of air bubbles in the inside of the cuvette, by taking if

-

out of its lodging and l ooking through.

3.2.3.3. Manual mode

When entering in this menu (UTILITIES / SERVICE (Password...) /

ADJUSTMENTS / FILTERS WHEEL), the display shows the programmed

values. Their meaning is as follows:

SENSITIVITY : indicates the current reading of the photometric sensitivity in

the current filter position.

STEP: indicates the number of steps that the wheel has done from the

reference photodetector until the current position of the fi l ter nº 1. The increase

or decrease regarding to the number without correction is indicated between

brackets.

Press the function key MANUAL and, using the up- and down- cursor keys

-

increase or decrease the steps until the maximum sensitivity position. If

several consecutive steps give the same sensitivity, leave i t in the center of

the range.

Validation criteria: Check that the increase or decrease in steps in within the

-

range indicated in Table II.2 in Appendix II. Otherwise, repeat the

procedure.

3-6

Once the adjustment completed, press the function key EXIT and answer

-

YES to the question “Save values ?”. To exit the process without saving,

thus keeping the former values, answer NO or press ESC instead of EXIT.

Press the function key EXIT again. Select the sensitivity test, by the

-

following path: UTILITIES / SERVICE (Password) / TESTS /

PHOTOMETRIC / FILTERS SENSITI VITY.

WARNING: Check that the test is performed with the cover closed.

The reading process for each filter begins. A list of the sensitivity (nA)

-

obtained for each filter is pri nted. The ori entative ranges appear i n tabl e II.6

of Appendix II. In the case the results are considered not valid, verify the

following points:

The cuvette model is adequate, and the distance between the light path

-

hole and the base of the cuvette is Z = 8,5 mm.

The in side and outside of the cuvette is clean.

-

There are no bubbles inside the cuvette.

-

The connections of tubing and adaptors are tight.

-

The teflon tubing is not strangled.

-

The filters wheel is properly positioned.

-

Press the function key EXIT, wash with distilled water and air the flow-thru

cuvette, by pressing the key WASH, put it in the stand-by position and l oosen

the peristaltic pump silicone tubing.

3.2.3.4. Automatic mode

When entering in this menu (UTILITIES / SERVICE (Password...) /

ADJUSTMENTS / FILTERS WHEEL), the display shows the programmed

values. Their meaning is as follows:

SENSITIVITY : indicates the current reading of the photometric sensitivity in

the current filter position.

STEP: indicates the number of steps that the wheel has done from the

reference photodetector until the current position of the fi l ter nº 1. The increase

or decrease regarding to the number without correction is indicated between

brackets.

Press the function key AUTOMATIC. The instrument with look for the

-

position with maximum sensitivity.

3-7

Validation criteria: Check that the increase or decrease in steps in within the

-

range indicated in Table II.2 in Appendix II. Otherwise, repeat the

procedure.

Once the adjustment completed, press the function key EXIT and answer

-

YES to the question “Save values ?”. To exit the process without saving,

thus keeping the former values, answer NO or press ESC instead of EXIT.

Press the function key EXIT again. Select the sensitivity test, by the

-

following path: UTILITIES / SERVICE (Password) / TESTS /

PHOTOMETRIC / FILTERS SENSITI VITY.

WARNING: Check that the test is performed with the cover closed.

The reading process for each filter begins. A list of the sensitivity (nA)

-

obtained for each filter is pri nted. The ori entative ranges appear i n tabl e II.6

of Appendix II. In the case the results are considered not valid, verify the

following points:

The cuvette model is adequate, and the distance between the light path

-

hole and the base of the cuvette is Z = 8,5 mm.

The in side and outside of the cuvette is clean.

-

There are no bubbles inside the cuvette.

-

The connections of tubing and adaptors are tight.

-

The teflon tubing is not strangled.

-

The filters wheel is properly positioned.

-

Press the function key EXIT, wash with distilled water and air the flow-thru

cuvette, by pressing the key WASH, put it in the stand-by position and l oosen

the peristaltic pump silicone tubing.

3.2.4. Peristaltic pump adjustment

This procedure describes the way to adjust the flow of the peristaltic pump and

the positioning of the sample in the cuvette. The pump flow depends on the

number of steps done by the motor and on the internal diameter of the

peristaltic tubing. Slight differences in the internal diameter in the different

tubes may result in variations in the flow, that can also be affected by slight

deformations caused by repeated use. Also slight differences in length or

diameter can affect the positioning of the sample. This adjustment is i ntended

to compensate the variations due to these tolerances and the aging of the

tubing.

3-8

3.2.4.1. Materials needed

Volume adjustment tool.

-

5 mL pipette (0.05 mL / mark).

-

Analytical balance (optional).

-

Caliper square (optional)

-

3.2.4.2. General remarks

Switch the instrument on at least 20 minutes before beginning the

-

adjustment.

This procedure can be performer either automatic or manually. The

-

automatic procedure is recommended.

The function CHECK allows input of a volume between 100 and 5000 • l,

-

that are checked by aspiration cycles. When selecting this option, the

cursor appears in the line:

CHECK VOLUME (• L): ____

Input i n the volume in • L to be checked and press ENTER. The message

-

“Insert tube with water and press PUMP” is displayed.

Insert a tube with water in position of aspiration and press PUMP.

-

3.2.4.3. Check method

SAMPLE VOLUME: Fill an assay tube with distilled water and weigh it in an

analytical balance. W eigh it again after an aspiration cycle. The difference i n

grams is equal to the volumen in mL.

POSITIONING: When the aspirati on cycl e i s completed, check that there i s a 5

mm-tail (0 – 10 mm) of the sample that has not yet entered the cuvette. Use the

caliper square if necessary.

3.2.4.4. Manual mode

Insert the flow-thru cuvette in its holder, making sure that its position is

-

correct.

SAMPLE VOLUME: It corresponds to the adjustment of the sipped volume.

-

Insert the number of quarters of step that the pump must perform to sip 5

mL and press ENTER. The theoretical value is 18340, equivalent to 1.09 • L

per step (the motor works with quarters of step: 0.2725 • l per each quarter

of step). The number to input is an estimate and should be determined by

“error and trial”, using the function CHECK of the menu ADJUST PUMP.

3-9

POSITIONING: It corresponds to the adjustment of the positioning of the

-

sample. Input the number of quarters of step needed for the sample to be

positioned into the cuvette with a tail of only 5 mm (0 – 10 mm) without

entering into the cuvette and press ENTER. The theoretical value is 600

quarters of step. The number is an estimate and should be determined by

“error and trial”, using the function CHECK of the menu ADJUST PUMP.

PUMP DELAY: It corresponds to the elapsed time between the aspiration

-

cycle and the positioning into the cuvette. Input the number of seconds

(recommended 2) and press ENTER.

The manual adjustment is completed. To check it, use the volume adjustment

tool, fill ed with water until the upper mark (3 mL).

Press the function key CHECK.

-

Input 2000 (2 mL) as sample volume.

-

Perform an aspiration cycle with the volume adjustment tool and check that:

-

a) The sample tail that has not entered the cuvette is 0 – 10 mm long.

b) The level of water remaining in the tool is between the two lower marks

(equivalent to 1 mL r tolerance)

Press EXIT and answer YES or NO to save the adjustment parameters or

-

not. Press ENTER. Press EXIT again to go back to the main menu.

3.2.4.5. Automatic mode

Insert the flow-thru cuvette in its holder, making sure that its position is

-

correct.

Press the function key AUTOMATIC.

-

Press the function key SAMPLE VOLUME. The message “Put a tube with 5

-

mL water and press PUMP” is displayed.

Pipet precisely 5 mL distilled water into an assay tube and proceed as

-

requested, taking special care that the end of the sipping tubing reaches the

bottom of the assay tube.

Approximately 4 mL are sipped at normal speed and then continues slowly.

-

The following message appears: “After sipping the last drop press ENTER”.

Look carefully at the bottom of the tube and proceed as requested.

-

Press the function key POSITION. The message “Insert tube with water and

-

press PUMP” is displayed.

3-10

Proceed as requested. The pump sips the water and, a few seconds later,

-

the following message appears: “Remove the tube and press ENTER”.

Proceed as requested. The pump works and the instrument calculates the

-

positioning. During this process the instrument performs photometric

readings, and therefore the cover must be closed. The whole process takes

70 seconds.

Press the function key CHECK.

-

Input 2000 as sample volume (2 mL).

-

Perform an aspiration cycle with the volume adjustment tool fi l l ed wi th wa te r

-

until the upper mark (3 mL) and check that:

a) The sample tail that has not entered the cuvette is 0 – 10 mm long.

c) The level of water remaining in the tool is between the two lower marks

(equivalent to 1 mL r tolerance).

Press EXIT and answer YES or NO to save the adjustment parameters or

-

not. Press ENTER. Press EXIT again to go back to the main menu.

3.3. Transformer and power supply checking

Before connecting the instrument to the mains:

a) Check that the voltage selector i s that of the supply vol tage (rear part of the

instrument). If not, select the correct one by slipping the selector (with the

help of a screw-driver).

b) Check the ground connection. W ith the mains wire unplugged, connect the

ohmmeter between the ground connection terminal in the power socket and

the checkpoint TP4 in the main board and check that the resistance is lower

than 0.1 ohm.

c) Disconnect the connector J4 of the main board (transformer) and plug the

instrument. Using a voltmeter, read the alternating voltages in the

transformer windings and check that they are within the tolerance limits in

the table of Section II.4.

d) Unplug the instrument and connect J4. Plug the instrument again.

3-11

3.4. – Fan checking

a) Check that the airflow is outward propelled.

b) Take a measurement of the voltage in the connector J8 (positive pin: 1;

negative pin: 3) and check that it is into the values showed in secti on II.8. If

they are not correct, look at the monocard heat sink silicone and the

properly fan condition.

3.5. – Optical system checking

If the optical system has been disassembled in order to replace one of i ts parts

(lens, Peltier cell, etc.) or by any other cause, once assembled again the

alignment must be checked.

a) Take the case away.

b) Take the photodiode away from its lodgement.

c) Insert the light beam centering checking tool into the cuvette holder. The

screen side must be faced towards the lamp.

d) Switch the instrument on.

e) Look at the tool screen through the photodiode lodgement.

f) Check that the light spot is into the outer circle (the inner circle simulates

the 1.5 mm light pass in the flow cuvette).

g) If the step f is correct, it means that the reading group is centered, then

jump to the step n, else continue from the next step.

h) Remove the lamp-holder set. Take note of its current position.

i) According to the point of view of deepness and incli nation, check i f the l amp

is properly positioned. In this case, place it again rotating it 180 degrees

and check the light spot again (see step f).

j) If there were problems with the lamp-holder set, fix them up, place it again

in the last position and check again the light spot (see step f). If the

problems persist, change the lamp position and jump to step f.

k) If the problems persist in spite of all the above handl ing, change the lamp

for a new one and jump to step f.

l) Place the photodiode in its lodgement again, taking care of its cleanness.

m) Cl ose the instrument.

3-12

n) At the end, a functional checking of the optical axis light beam centering is

done by a sensitivity test with a flow-cuvette with distill ed water (or a macro-

cuvette with distilled water)

3.6. Check of the sensitivity with flow cuvette

a) Switch the instrument on.

b) Clean the external faces of the cuvette with a mixture of ethyli c alcohol and

ether, then dry it with a soft paper (Section 2.1.6).

c) Insert the flow cuvette and its connections.

d) Wash the cuvette with 1 mL washing solution and then with abundant

distilled water, by means of the “WASH” key.

e) Make sure that the instrument is on for at least 20 minutes.

f) Fill the cuvette with distilled water, by means of the “WASH” key. Check the

absence of air bubbles inside the cuvette.

g) With the cuvette filled with water measure the sensitivity of each filter. To do

it, go to the menu:

UTILITIES / SERVICE / TESTS / PHOTOMETRIC / FILTERS SENSITIVITY

Make sure that, during the test, the cover is closed.

-

h) The reading process for each fi lter begins. A l ist of sensi tivities (expressed

in nA) for each filter is printed.

i) Once the list is completed, check that the values fall within the ranges

appearing in the table of Section II.6.

Otherwise, check that:

The inside and outside of the cuvette is clean.

-

There are no bubbles inside the cuvette.

-

The tubing connections are tight.

-

The teflon tube is not strangled anywhere.

-

The filter wheel is correctly positioned.

-

3-13

3-14

4. CHECK TESTS

4.1. Activation of a test

The program includes a set of test programs allowing the performance’s

verification of di verse parts of the instrument and help in trouble-shooti ng. To

perform a test, follow the path:

UTILITIES / SERVICE (Password) / TESTS

The tests available are described in the following sections.

4.2. Screen

When thi s test is carried out, each time the key ENTER is pressed a different

action is done on the screen. Check that the actions are uniform and there is

no anomalous function of the display.

4.3. Buzzer

When performing this test, the i n ternal beeper sounds several times.

4.4. Keyboard

Each time a key is pressed, the beeper sounds and the key is displ ayed. Press

EXIT twice to exit.

4.5. Printer

A set of characters is printed and then 10 rows of asterisks with the 10

programmable intensities.

Check that the characters listed are clear and legible and that the scale of

intensities i s growing and regular.

4.6. Serial Port RS-232

This test sends the key being pressed by the line TxD (pin 5 of the COM1

connector) (Fig. 2.7) and should be received by the line RxD (pin 3 of the

COM1 connector). To do this, it is necessary to make a bridge between these

lines. Each time a key is pressed, the corresponding character is showed in the

section of the display corresponding to the characters sent, and the same

character should appear in the section of characters recei ved. Exit by pressing

4-1

F5. From this test it is possible to modify the communication configuration

parameters.

4.7. Motors

This menu allows checking two motors: the peristaltic pump motor and the

filters wheel motor.

4.7.1. Loss of steps of the peristaltic pump

Proceed as follows:

a) Turn the pump rotor by hand, until the arrow is in front of that of its support.

b) Press ENTER. The pump operates for some seconds.

c) Check that the rotor turns without eccentricities or abnormal noises.

d) When stopped again, check that the two arrows keep the same original

position.

4.7.2. Loss of steps of the filters wheel

The filters wheel performs several movements. Afterwards, the instrument

displays “PASSED” if a loss of steps is not detected or “NOT PASSED”

otherwise.

4.8. Cuvette temperature

Allows the accuracy’s checking at a given temperature. To select this option,

press the function key CHECK in the UTILITIES / SERVICE (Password...) /

ADJUSTMENTS / HEATING menu. The cursor appears in the line:

TEMPERATURE TO CHECK: ____

Insert the calibrated digi tal thermometer’s temperature probe into the cuvette-

holder, Input the temperature to be checked and press ENTER. The message

“Heating” is displayed with a time counter going down.

After the five minutes, the screen’s prompt asks for a new temperature. Check

the reached temperature in the external thermometer.

4-2

4.9. Carry Over

This check allows studying the cross-contamination that happens in case of

consecutive readings of samples that strongly differ in absorbance (usuall y the

first with high absorbance and the second with low absorbance).

The instrument requests:

Reading filter

-

Stabilization time

-

Sample volume

-

Press F1 to begin readings. Insert the baseline and then 5 times the first

sample (R1 to R5) and 5 times the second (R6 to R10). The contamination is

calculated according to the formula:

R6

Contamination = ( -------------------- - 1 ) x 100

X av

R7 + R8 + R9 + R10

Where X av = ------------------------------ 4

4.10. Photometry

4.10.1. Filter sensitivity

This test allows knowing the current generated in the photodiode for a given

amount of light, as a measurement of the sensitivity of the instrument for each

filter.

The sensitivity is read for all the fil ters programmed in the filters table. This test

can be performed without cuvette (sensitivity with air) or with cuvette. In this

last case it is necessary to fill it with water by performing a WASH cycle.

The sensitivities read should fall within the ranges indicated in the table of

Appendix II, Section 4 (for sensitivity without cuvette) or in the table of

Appendix II, Section 6, for sensitivity with flow cuvette filled with water.

4.10.2. Electric noise

This test allows knowing the noise detected by the converter in the signal

coming from the logarithmic amplifier.

Check that the case and cover are closed to avoid entrance of light.

4-3

The instrument selects the 340 nm filter and zeroes. After approximately 1

minunte, the results are displayed. They must be within the tolerance ranges of

the table of Section II.5.

4.10.3. Stability of the readings

This test allows analyzing the stability of a set of repeated readings done with

the same sample.

When beginning, the instrument requests the following:

Reading filter (340)

-

Stabilization time (1)

-

Sample volume (400)

-

Interval time (1)

-

Number of intervals (30)

-

Values between brackets are those recommended for a routine test.

Program all these parameters, depending on the sample. The duration of the

test will be the result of the interval time and the number of intervals.

Press F1 to begin. The instrument requests the baseline and then the sample.

If the sample is the same as the baseline, the zero stability can be checked.

For a routine test, make the BASELINE wi th the ca librator nº 0 of the calibration

kit (SERVICE TOOLS, code 005) and use calibrator nº 4 as the SAMPLE.

The number of the reading, the time and the absorbance are printed. At the

end, the statistical data are printed: average, maximum and minimum

absorbance.

4.10.4. Precision

This test performs successive readings of different samples of the same liquid

(repetitivity between identical samples).

The instrument requests:

Reading filter.

-

Stabilization time.

-

Sample volume.

-

Number of intervals.

-

Press F1 to begin the test.

4-4

The instrument request the baseline and then as many samples as intervals

programmed. At the end, the statistical data are printed: average, coeffi cient of

variation, maximum and minimum absorbance.

4.10.5. Accuracy

This test allows checking the accuracy when reading a sample of know

absorbance.

WARNING: The reliability of this test requires a sample absorbance value

determined precisely with a reference method.

When beginning the test, the instrument requests:

Reading filter.

-

Stabilization time

-

Sample volume

-

Press F1 to begin the tst.

Insert the baseline. Then the instrument asks for the reference value. Insert the

theoretical value by means of the numeric keyboard. Insert the sample when

requested. The instrument prints the following data:

Reading number.

-

Absorbance applying the calibration.

-

Absorbance without applying the calibration.

-

Reference value (theoretical value of the sample).

-

Absolute and relative errors applying the calibration.

-

Absolute and relative errors without applying the cali bration.

-

4.11. Unlock / Lock QC techniques

When leavi ng the factory, some memory locations contai n the techniques used

for the in-house quality control. They are de-activated; if they are activated

again, the names of this techniques will appear again in the list of programmed

tests.

This option is for internal use and has no interest for the Technical Assistance

Service.

4-5

4-6

5. MAINTENANCE

5.1. Case replacement

If a case’s replacement is needed or it must be removed to operate the

instrument’s inside, proceed as follows (figure 5.1):

a) With the in strument turned off, remove the supply wire.

b) Remove the printer paper roll and take the aspiration tube out its guiding

tube.

c) Remove the two screws (1) located in the lower part of the instrument.

d) Remove the two screws (2) located in the rear part of the instrument.

e) Carefully lift the case, incli ning it a bit to the right side, and di sconnect the

supply strip (J7) as soon as you have room enough to introduce your hand

to the inside (in PCB version I33002A080499 also disconnect the J11 flat

band). Then incline the case to the right side totally, taking care that the

connecting strip that joins it to the main board is not stretched.

f) In case it to be fully removed, disconnect the fl at bands (J19 and J10) from

the main board, and the printer and display ground tab-in terminals (12 from

fig. 5.2).

It is recommended to remove the cuvette holder cover to avoid it falling down.

To place the case again or to put a new one:

a) Connect the flat bands (J9 and J10) again and the tab-in terminals.

b) Place the case again carefully, connecting the supply strip (J7) before

closing the case (in PCB version I33002A080499 also connect the J11 flat

band).

c) Screw the fixing screws.

d) Place the pri nter paper again and the aspiration tube (figures 2.6 and 2.7).

e) Place the cuvette-holder cover, if it was removed.

5-1

5-2

Fig. 5.1

5.2. Main board replacement

See figure 5.2

a) Disconnect all the strips reaching the board.

b) Cut the clamp that fixes the photodiode cable.

c) Unsolder the photodiode cable.

d) Remove the 5 Allen screws (1) fixing the radiator to the base.

e) Remove the three screws (2) fixing the main board to the respective

separators.

To mount the board again, proceed as follows:

a) Put a thin and uniform silicone layer in the lower part of the heat sink (3).

b) Place the board again and fix it with the five Allen screws (1) and the three

screws (2).

c) Solder the photodiode wire thoroughly cleaning the solder resin with

alcohol. Resin remaining in thi s point may cause instability of the reading

system.

d) Fix the photodiode wire to the board with a plastic clamp.

e) Connect all the strips again.

5.3. Change of the display board

See figure 5.3

a) Disconnect in the board itself, the keyboard band (J10) and the printer