Page 1

Rotofor®System

Instruction Manual

For Technical Service Call Your Local Bio-Rad Office or in the U.S. Call 1-800-4BIORAD (1-800-424-6723)

Page 2

Table of Contents

Page

Section 1 General Information ......................................................................1

1.1 Introduction................................................................................................1

1.2 Specifications ............................................................................................2

1.3 Isoelectric Focusing ...................................................................................3

1.4 Safety ........................................................................................................4

Section 2 Description of Major Components ...............................................5

Section 3 Setting Up For A Run ....................................................................6

3.1 Equilibration of the Ion Exchange Membranes ...........................................6

3.2 Assemble the Electrodes ...........................................................................7

3.3 Assemble the Focusing Chamber ..............................................................9

3.4 Prepare the Focusing Chamber ...............................................................10

3.5 Load the Sample......................................................................................10

3.6 Seal the Loading Ports.............................................................................10

3.7 Remove Air Bubbles ................................................................................11

Section 4 Running Conditions ....................................................................11

4.1 Starting the Fractionation .........................................................................11

4.2 Power Supply ..........................................................................................12

4.3 Fraction Collection ...................................................................................13

4.4 Refractionation.........................................................................................13

4.5 Final Purification ......................................................................................14

Section 5 Disassembly and Cleaning.........................................................14

Section 6 Sample Preparation.....................................................................15

6.1 Salt Concentration ...................................................................................15

6.2 Clarification..............................................................................................15

6.3 Solubility ..................................................................................................15

Section 7 Optimizing Fractionation ............................................................16

7.1 Ampholyte Choice....................................................................................16

7.2 Sample Capacity......................................................................................17

7.3 Power Conditions.....................................................................................17

7.4 Cooling ....................................................................................................17

7.5 Electrolytes ..............................................................................................18

7.6 Pre-running the Cell .................................................................................18

7.7 Prefocusing..............................................................................................18

7.8 Refractionation.........................................................................................19

Section 8 Analysis of Results .....................................................................19

8.1 Fraction Analysis .....................................................................................19

8.2 Separation of Ampholytes From Proteins.................................................19

Section 9 Troubleshooting Guide...............................................................20

9.1 Solubility and Precipitation of Proteins .....................................................20

9.2 Factors Affecting the pH Gradient ............................................................21

9.3 Recovery of Biological Activity .................................................................22

9.4 Maximizing Resolution .............................................................................23

9.5 Power Related Conditions........................................................................24

9.6 Uneven Harvesting ..................................................................................25

9.7 Mechanical Problems...............................................................................25

Page 3

Section 10 Maintenance Guide .....................................................................26

10.1 Vent Buttons ............................................................................................26

10.2 O-rings.....................................................................................................26

10.3 Cooling Finger O-rings.............................................................................26

10.4 Membrane Core.......................................................................................26

Section 11 Rotofor References.....................................................................27

Section 12 Rotofor Application Notes ..........................................................38

Section 13 Application for Preparative Two Dimensional

Electrophoresis System .............................................................39

13.1 Introduction..............................................................................................40

13.2 Methods...................................................................................................41

13.3 Results ....................................................................................................44

Section 14 Product Information ....................................................................45

Page 4

Note

To insure best performance from the Rotofor cell, become fully acquainted with

these operating instructions before using the cell to separate samples. Bio-Rad

recommends that you first read these instructions carefully. Then assemble and

disassemble the cell completely.

Bio-Rad also recommends that all Rotofor cell components and accessories be

cleaned with a suitable laboratory cleaner (such as Bio-Rad Cleaning Concentrate,

catalog number 161-0722) and rinsed thoroughly with distilled water before use.

Warranty

Bio-Rad Laboratories warrants the Rotofor cell against defects in materials and

workmanship for 1 year. If any defects occur in the instrument during this warranty

period, Bio-Rad Laboratories will repair or replace the defective parts free. The

following defects, however, are specifically excluded:

1. Defects caused by improper operation.

2. Repair or modification done by anyone other than Bio-Rad Laboratories or an

authorized agent.

3. Use of fittings or other parts supplied by anyone other than Bio-Rad

Laboratories.

4. Damage caused by accident or misuse.

5. Damage caused by disaster.

6. Corrosion due to use of improper solvent or sample.

For any inquiry or request for repair service, contact Bio-Rad Laboratories. Be

prepared to provide the model and serial number of your instrument.

Model

Catalog No.

Date of Delivery

Warranty Period

Serial No.

Invoice No.

Purchase Order No.

Page 5

Section 1

General Information

1.1 Introduction

Bio-Rad’s unique Rotofor System fractionates complex protein samples in free

solution using preparative isoelectric focusing. The Rotofor system is designed for

the initial clean up of crude samples and for use in purification schemes for the

elimination of specific contaminants from proteins of interest that might be difficult

to remove by other means.

The Rotofor cell provides up to 500-fold purification for a particular molecule in

less than 4 hours. Because electro-focusing is carried out in free solution, fractions

from an initial run can be easily collected, pooled and refractionated, resulting in up

to 1000-fold enrichment for a particular molecule. Purification using isoelectric

focusing is especially advantageous when protein activity needs to be maintained.

Bioactivity is maintained because the proteins remain in solution in their native

conformation.

The Rotofor cell incorporates a cylindrical focusing chamber with an internal

ceramic cooling finger. Rotation at 1 rpm around the focusing axis stabilizes

against convective and gravitational disturbances. Nineteen parallel, monofilament

polyester screens divide the focusing chamber into 20 compartments, each holding

one fraction. After focusing, the solution in each compartment is rapidly collected

without mixing using the harvesting apparatus supplied with the unit.

The Rotofor system is designed to accommodate a range of sample volumes

using interchangeable focusing chambers. The Mini Rotofor chamber is used for

sample volumes of 18 milliliters containing micrograms to milligrams of total protein.

The large Rotofor chamber is used for samples of 35 to 60 milliliters containing

milligrams to grams of total protein.

The Rotofor cell is used to purify a wide range of proteins. These include

monoclonal antibodies, cell surface receptor proteins, integral membrane proteins,

cytosolic and secreted enzymes, chemotactic factors, and recombinant proteins. It

has been used to separate isoenzymes, lipoproteins, and apolipoproteins.

Should a final purification step be required, we recommend the Model 491 Prep

Cell. The Prep Cell is a continuous elution gel electrophoresis device that uses

SDS-PAGE or Native-PAGE to completely purify individual proteins of interest. For

examples of published Rotofor cell applications, please refer to the Rotofor

Technical Folder (request Bulletin 1555A).

*Patent No. 4,588,492

1

Page 6

1.2 Specifications

Construction

Focusing chambers Acrylic

Vent buttons Porous polytetrafluoroethylene (PTFE)

membrane in molded plastic

Gaskets Silicone rubber

O-Rings Fluorocarbon elastomer

Cooling finger Ceramic

Housing Polycarbonate and acrylic

Harvest box and lid Polycarbonate and acrylic

Tubing Polyvinyl

Needle array Stainless steel and acrylic

Electrodes Platinum, 0.010 inch diameter

Membrane Core Molded polyethylene with polyester mem-

branes

Chemical The Rotofor cell components are not com-

compatibility patible with chlorinated hydrocarbons

(

e.g.

chloroform), aromatic hydrocarbons

(

e.g.

toluene, benzene), or acetone.

Use of organic solvents voids all warranties.

Shipping weight 9 kg

Overall size 45.7 cm (L) x 16.5 cm (W) x 22.8 cm (H)

Cell voltage limit 3000 VDC

Cell power limit 15 W

Cooling The Rotofor cell must be run with cooling or

excessive heating may occur, damaging the

unit. A refrigerated circulating water bath is

recommended to keep the coolant temperature at

4 °C.

Maximum coolant 12 L/minute

flow rate

Minimum coolant 50 ml/minute

flow rate

Sample volume 18–58 ml

Electrical 3 wire cord

connection

Input power 120 V Model: 100-120 VAC, 50/60 Hz, 12W

Requirements 240 V Model: 220-240 VAC, 50/60 Hz, 12W

Fuses 250 mA Type T (1 required, 1 spare)

2

Page 7

1.3 Isoelectric Focusing

Isoelectric focusing (IEF) is a gentle, non-denaturing technique; antibodies,

antigens, and enzymes usually retain their biological activities. IEF is also a high

resolution technique capable of resolving proteins that differ in pI by fractions of a

pH unit. IEF in the Rotofor has the added advantage that the proteins can be easily

recovered once they are focused.

Separation of proteins by isoelectric focusing is based on the fact that all proteins

have a pH-dependent net charge. The net charge is determined both by the amino

acid sequence of the protein and the pH of the environment. When a protein is

electrophoresed through an established pH gradient, it will migrate until it reaches the

pH where the net charge on the protein is zero; at that point it will stop migrating and

is said to be focused at its isoelectric point or pI.

Ampholytes which are small, charged buffer molecules are used to establish

the pH gradients increasing in pH from anode to cathode. When voltage is applied

to a system of ampholytes and proteins, all the components migrate to their

respective pIs. Ampholytes rapidly establish the pH gradient and maintain it for

long periods allowing the slower moving proteins to focus.

A protein with a net positive charge, for example, in a particular region of the pH

gradient will tend to migrate toward the cathode while concurrently giving up protons.

At some point, the net charge on the molecule will be zero and the protein will cease

to migrate. If the protein diffuses into a region of net charge, the resultant electrical

force on it will drive it back to its pI, so that the molecule becomes focused at that

point.

Fig. 1.1. Acidic Protein “Focusing” in a pH gradient.

ode

(+)

C

e

(

)

ge

(+2)

pH

3

0

(0)

(-2)

COOH

COOH

COOH

COOH

COOH

COOH

COOH

2

COO

COO

3

4 5 6 7 8 9 1

An

net char

athod

Page 8

1.4 Safety

This instrument is intended for laboratory use only.

This product conforms to the “Class A” standard for electromagnetic emissions

intended for laboratory equipment applications. It is possible that emissions from

this product may interfere with some sensitive appliances when placed nearby or in

the same circuit as those applicances. The user should be aware of this potential

and take appropriate measures to avoid interference.

Power to the Rotofor preparative IEF cell is to be supplied by an external DC

voltage power supply. This power supply must employ a safety isolation transformer

to isolate the DC voltage output with respect to ground. All of Bio-Rad’s power

supplies meet this important safety requirement. Regardless of which power supply

is used, the maximum specified operating parameters for the cell are:

3000 VDC maximum voltage limit

15 Watts maximum power limit

50 °C maximum ambient temperature limit

Current to the cell, provided by the external power supply, enters the unit

through the lid assembly, providing a safety interlock. Current to the cell is broken

when the lid is removed. Do not attempt to circumvent this safety interlock, and

always turn the power supply off before removing the lid, or when working with the

cell in any way.

Important: This Bio-Rad instrument is designed and certified to meet IEC1010-1*

safety standards. Certified products are safe to use when operated in accordance

with the instruction manual. This instrument should not be modified or altered in

any way. Alteration of this instrument will:

• Void the manufacturer’s warranty

• Void the IEC1010-1 safety certification

• Create a potential safety hazard

Bio-Rad is not responsible for any injury or damage caused by the use of this

instrument for purposes other than for which it is intended or by modifications of

the instrument not performed by Bio-Rad or any authorized agent.

*IEC1010-1 is an internationally accepted electrical safety standard for laboratory instruments.

4

!

Page 9

Section 2

Description of Major Components

Fig. 2.1. Rotofor components. Harvesting apparatus (1), safety cover (2), housing (3), cooling finger

(4), electrode assemblies (5), O-rings (6), ion exchange membranes (7), vent buttons (8), sealing tape

(9), membrane core (10), focusing chamber (11), cell covers (12), test tube rack (13).

Focusing chambers - Two focusing chambers are available with the Rotofor

cell. The Mini focusing chamber holds 18 ml of sample and should be used for

fractionating micrograms to milligrams of total protein. The Mini chamber is also

ideal for refractionation. The standard chamber holds from 35 to 60 ml of sample

and is used to fractionate milligrams to 3 grams of total protein. The focusing

chambers are machined acrylic cylinders 120 mm long. Twenty evenly-spaced

ports are bored in opposite sides for sample filling and collection.

Membrane core - The membrane core divides the focusing chamber into 20

compartments. The core assembly is a stack of 19 membrane units made from

monofilament polyester screens of 10 µm nominal pore size. This assembly is

inserted in the focusing chamber to stabilize the zones of focused proteins.

Electrode assemblies - There are two electrode assemblies. The assemblies

hold the cathode and anode electrolyte solutions and provide electrical contact

between the focusing chamber and the power supply. They are not interchangeable;

alignment pins prevent improper assembly. Ion exchange membranes, inserted in

the assemblies, isolate the electrolytes from the sample in the focusing chamber

while allowing establishment of an electrical field across the chamber. A plastic gear

mounted on the cathode assembly engages the drive motor to rotate the focusing

chamber.

Ion exchange membranes - Ion exchange membranes are used in the electrode

assemblies to separate the electrolytes from the sample while allowing current

5

7

8

9

10

11

13

12

6

5

4

3

2

1

Page 10

flow. The anion-exchange membrane is notched to fit only the cathode assembly (black

button) and the cation exchange membrane will fit only the anode assembly (red button).

Before the initial use, the membranes must be equilibrated overnight in the

appropriate electrolyte. Once wetted they cannot be allowed to dry. If they dry out,

membranes should be discarded. Membranes generally last 4–5 runs.

Anion Exchange Membranes are equilibrated in 0.1 M NaOH.

Cation Exchange Membranes are equilibrated in 0.1 M H3PO4.

Gaskets - Four grey colored silicone rubber gaskets are provided to seal the

ion exchange membranes within the electrode assemblies. These will fit either

electrode assembly.

Vent buttons - Both electrode assemblies have filling ports. Vent caps containing

integral, gas-permeable, PTFE membranes provide pressure relief form the gases

which build up in the electrolyte chambers during the run. The vent buttons will fit

either electrode assembly.

Housing - The stand supports the assembled focusing chamber during the run

and houses the rotation motor. Focusing power is transmitted to the focusing chamber

through brass contacts that are spring-loaded to maintain constant electrical contact

between the focusing chamber and the housing. The assembled focusing chamber

fits on the stand, with the anode (red) compartment to the left. If assembled correctly,

the cathode electrode assembly will engage with the gear on the housing. If any

connections are loose, the unit will not fit. Electrical contact to the case is through

jacks on the safety cover. The safety cover must be in place for safe operation of the

Rotofor cell.

Harvesting apparatus - A test tube rack which holds 20 test tubes (12 x 75 mm

culture tubes) is enclosed in the harvesting box. This box has a fitting for connection

to a vacuum source. House vacuum is usually sufficient for harvesting. Stainless

steel tubes on the lid of the box are connected to an array of needles by flexible

tubing. Individual fractions are collected through the tubing into the test tubes.

Cooling finger - The ceramic cooling finger extends through the focusing

chamber and the electrode assemblies. The cooling finger is in contact with the

sample and provides efficient heat dissipation up to 20 W.

Section 3

Setting Up For A Run

Assemble the anode and cathode electrolyte chambers first. Alignment pins prevent

misassembly of the two electrodes. The anion-exchange membrane is notched to fit

only the cathode compartment (black button) and the cation exchange membrane will fit

only the anode assembly (red button). The four silicone rubber gaskets can be used in

either electrode assembly. The procedure is identical for assembly of both the mini

focusing chamber and standard focusing chamber.

3.1 Equilibration of the Ion Exchange Membranes

Ion exchange membranes are used in the Rotofor cell to separate the sample

from the electrolyte while allowing current flow. The ion exchange membranes

used in the Rotofor cell are of two types: cation exchanger and anion exchanger.

The cation exchanger is negatively charged and repels negatively charged ions,

preventing them from contaminating the anolyte. The anion exchanger works in the

opposite way; it is positively charged and repels positive ions.

6

Page 11

Using the ion exchange membranes gives a concentration gradient of the

corresponding ions at the respective ends of the sample chamber. The highest

concentration of negative ions will be next to the cation exchanger and the highest

concentration of positive ions will be next to the anion exchanger.

Prior to assembly, the ion exchange membranes must be equilibrated

overnight in the appropriate electrolyte solution. Ion exchange membranes are

used for 4–5 runs prior to replacement.

Anion Exchange Membranes: These membranes are lighter in color than the

cation exchange membranes when dry. The color of the two membranes is similar

when wet. These membranes are equilibrated in 0.1 M NaOH. They are stored in

distilled water or electrolyte between runs.

Cation Exchange Membranes: These membranes are darker colored than

the anion exchange membranes when dry. These membranes are equilibrated in

0.1 M H3PO4. They are stored in distilled water or electrolyte between runs.

Note: The membranes can be stored indefinitely when dry. After rehydration, they

must be kept moist. If the membranes dry out, they should be discarded.

3.2 Assemble the Electrodes

1. Examine the inner portion of an electrode assembly. For the Standard Rotofor

there should be a small O-ring in the central hole on the flat side, and a large

O-ring seated in the large groove around the central shaft on the other side. For

the mini chamber, the outer portion contains only one large O-ring. Place a gasket

over the alignment pins and seat it on the flat surface of the inner assembly. The

three oblong holes in the ion-exchange gaskets should align with the six holes

of the electrolyte chamber. When properly aligned, the gasket should not

obstruct the six holes in any way.

Fig. 3.1. Outer and inner portions of the electrode assemblies. Arrows indicate O-rings. Electrolyte

buffer should just cover the central shaft when completely assembled. For the mini focusing chambers,

the six holes in the inner portion of each electrode assembly are much smaller in diameter than six

holes in the inner portion of the electrode assemblies used with the larger focusing chamber. In addition

the six holes for the mini chamber are drilled at a distinct angle to the central axis of the assembly.

These parts are not interchangeable!

7

Central shaft

Large o-ring

Inner portion

Outer portion

Page 12

2. Place the proper ion exchange membrane on the gasket by aligning the notches

in the membrane around the pins, and complete a “sandwich” with a second gasket

on top of the membrane. The cathode holds one anion exchange membrane and

the anode holds one cation exchange membrane.

Fig. 3.2. Ion exchange membrane and gasket sandwich on inner portion of electrode assembly.

3. Make sure that there is a small O-ring inset in the central shaft of the large,

outer portion of the electrode assembly and fasten the halves together with the

captive, threaded sleeve.

4. Repeat the assembly process for the second electrode.

5. Fill the electrode chambers with electrolytes immediately after assembly to prevent

the membranes from drying. Filling is most easily accomplished with the assembled

focusing chamber mounted on its stand. The anode (+) electrode assembly (red

button), containing the cation exchange membrane, is filled with acidic electrolyte,

usually 0.1 M H3PO4. The cathode (–) electrode assembly (black button), containing

the anion exchange membrane, is filled with basic electrolyte, usually 0.1 M

NaOH. To fill the compartments, remove the vent buttons, add 25–30 ml of the

appropriate electrolyte to each chamber, so that the chambers are about 65% full,

and replace the buttons. The electrolyte should just barely cover the central shaft

of the chamber. Excessive electrolyte does not provide sufficient air space to allow

gases to escape. Pressure may build up inside the electrode assembly and cause

leaking from the vent buttons or ion exchange membranes.

The vent buttons are interchangeable and can be used with either electrode

assembly. The life of these buttons is usually 4–5 runs. After 4–5 runs, electrolyte

may begin to leak from the vent buttons during the run. If a vent button is

inadvertently perforated or, if during focusing an inordinate amount of electrolyte

leaks from the filling port, stop the run and replace the vent cap.

When the cell is used for the first time, the electrode assemblies will contain fresh

electrolyte. If the cell has been run previously, the distilled water or electrolyte

solutions must be left in the electrode assemblies between runs to maintain

hydration of the ion exchange membranes. Use fresh electrolytes for each run. If

the membranes are allowed to dry, they must be replaced. Empty the electrode

assemblies and fill with fresh electrolyte solution before each focusing run.

8

Page 13

3.3 Assemble the Focusing Chamber

1. Slide the assembled anode electrode assembly over the ceramic cooling finger

so that the two protruding screw heads fit into the holes in the black plastic

base of the cooling finger support assembly.

Fig. 3.3. Anode electrode assembled on the cooling finger.

2. Slide the membrane core onto the ceramic cooling finger, making sure the core

abuts the acrylic ridge on the anode chamber.

3. Slide the focusing chamber over the membrane core, inserting the metal pin

into the small hole in the anode chamber. Position the focusing chamber so

that each membrane screen lies between two adjacent ports. These ports must

not be blocked by the membrane screens at either side, load or harvest. If the

ports are blocked, remove the focusing chamber, and slide it once more over

the membrane core. Tighten the black, nylon retaining screws. Check again to

make sure the membrane screens do not block the ports of the chamber.

Fig. 3.4. Slide the focusing chamber over the membrane core.

4. Slide the assembled cathode compartment over the cooling finger, aligning the

metal pin and hole in the cathode chamber, and tighten the nylon retaining

screws.

9

Page 14

Fig. 3.5. Assembled focusing chamber.

5. Mount the assembled focusing chamber in the stand. The gear on the cathode

electrode assembly should be fully engaged with the gear on the stand. If the

focusing chamber does not slide in easily, remove it to check that all parts are

properly assembled.

6. Attach the power cord to the back of the unit and connect it to an electrical outlet.

3.4 Prepare the Focusing Chamber

With the cell mounted on the stand, rotate the focusing chamber so the 20 collection

ports, identified by the two metal alignment pins, are facing up. Cover the ports with a

piece of the sealing tape provided with the cell. Reinforce the taped ports with one of the

two acrylic cell-cover blocks, and finger tighten the screws. We recommend pre-running

the cell with pure water for the first use or after cleaning the components in the focusing

chamber with NaOH. Pre-running the cell with water for 5 minutes at 5 watts constant

power will remove residual ionic contaminants from the membrane core and ion

exchange membranes before addition of the sample.

3.5 Load the Sample

Rotate the cell so the filling ports face up. This is easily accomplished by flipping

the toggle switches to ON and HARVEST. In the harvest mode the focusing chamber

will automatically stop with the filling ports facing up and the collection ports facing

down. Fill the cell with sample through the ports using a 50 ml syringe with a 1-1/2

inch 19-gauge needle. Typically, every other port is filled, and the sample spreads into

the adjoining compartments. For the large focusing chamber, the minimum sample

volume must be sufficient to cover the cooling finger. For the mini focusing chamber

load the maximum sample volume of 18 ml.

3.6 Seal the Loading Ports

A. Mini Rotofor chamber: Place the grey rectangular, silicone gasket in the slot

containing the loading ports then place the second cell cover block over the

gasket (tape is unnecessary), and the Rotofor cell is ready for operation.

B. Standard Rotofor chamber: Seal the filling ports with only the second cell

cover block (tape is unnecessary), and the Rotofor cell is ready for operation.

10

Page 15

11

3.7 Remove Air Bubbles

During filling, air bubbles can become trapped in the 6 ports of the electrolyte chamber.

This is especially true with the mini focusing chamber. If the bubbles are not removed, they

will produce occasional fluctuations in the voltage and currents due to the discontinuity they

create in the electrical field. Some power supplies, such as the Bio-Rad Power Pac 3000,

have safety sensors that may trip and shut off the voltage in response to the resistance

change that occurs when a bubble rotates into the electrical circuit. Thus, bubbles must be

eliminated prior to commencing electrophoresis. Remove the assembled, loaded cell from

the stand, turn it vertically and tap the electrode chamber to dislodge the bubbles. Then

turn the cell 180° and tap the other chamber. If any air bubbles remain in the 6 ports

between the sample and the ion exchange membranes, repeat this process. When all the

bubbles are eliminated from the electrode ports, return the cell to the stand and start the

fractionation.

Fig. 3.6. Loading the sample.

Section 4

Running Conditions

4.1 Starting the Fractionation

Excessive heating may denature proteins and damage the Rotofor cell.

Connect the ports of the cooling finger to a source of recirculating coolant and

begin coolant flow. The ports are interchangeable, so either one may be connected

to the coolant inlet. It is usually sufficient to set the chiller at 4°C. For more critical

temperature control, the chiller can be adjusted accordingly. At 12 W constant

power (normal operating mode) the coolant temperature should be set at 10°C less

than the temperature desired for the sample. In other words, if the coolant is -6°C

than the sample temperature will be maintained at about 4°C. Attach the cover of

the unit, mating its jacks to the plugs on the base. Allow the system to come to

thermal equilibrium at the cooling temperature before beginning the run, approximately

10–15 minutes.

Page 16

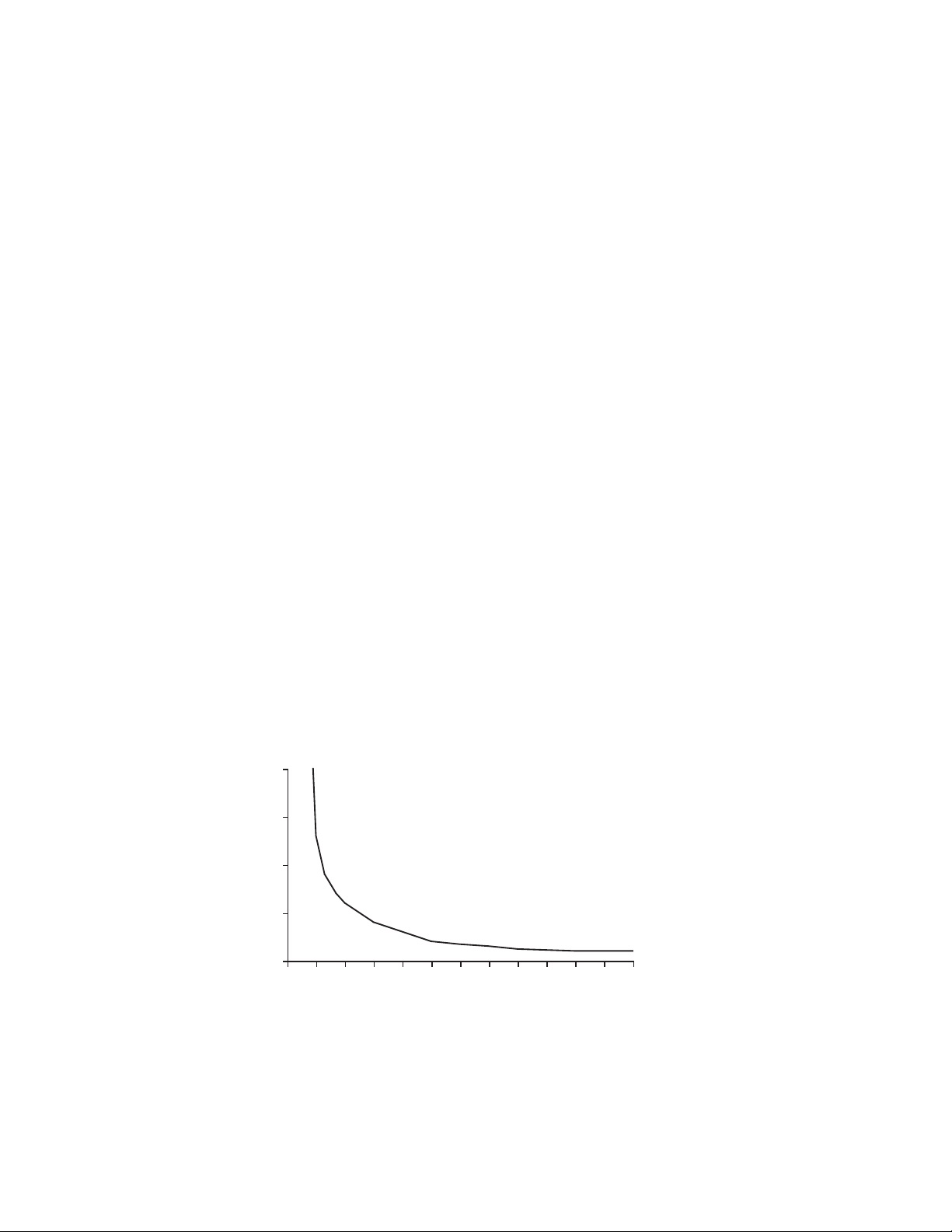

4.2 Power Supply

1. Never operate the Rotofor cell with the cover removed. When focusing power

is applied to the jacks without the cover in place, several high voltage elements

become exposed. To avoid personal injury due to accidental contact with these

elements, always operate the cell with the cover in place.

2. Attach the high voltage leads to the power supply, and the Rotofor cell is ready

for use. To begin rotation, flip the toggle switches to ON and RUN.

3. Power supply:

Standard Rotofor chamber - Set the supply to 15 W constant power and begin

the run.

Mini Rotofor chamber- Set the supply to 12 W constant power and begin the run.

The starting voltage and current will vary depending on the salt concentration of the

sample. For example, if the salt concentration of the sample is 10 mM, the starting

voltage will be 300–500 V, and the current will be 24–40 mA. The maximum power

that can be dissipated is about 15 W for an initial fractionation when the Rotofor cell

is operated at 4°C. If more than 15 W is applied to the cell, overheating can damage

the cell. The applied power is too high if the current increases or remains constant,

rather than decreases, during a run. If a constant power supply is not available,

check the graph in Figure 4.1 to determine the optimum starting voltage and

increase the voltage manually in increments over time. The voltage should be

increased as the run progresses to keep the power at a constant 12 W.

4. A typical run is completed in 3–5 hours. To monitor the progress of a run under

conditions of constant power, observe the voltage increase over time. The run

is complete when the voltage stabilizes. At that point, allow the run to continue

for 30 minutes before harvesting. The total run length should not exceed

6 hours. Longer run times do not tighten the focusing and may begin to break

down the gradient.

Fig. 4.1. The maximum power that should be applied to the Rotofor cell is 12-15 W. The graph

shows the voltage and current readouts for setting a constant voltage power supply. If the current

reading is too high at the set voltage (in the danger zone), reduce the voltage until a safe power level is

obtained. Watts = voltage x current.

m Amps

12 W

12

2000

1500

1000

Volts

500

0

0102030405060708090100110120

Page 17

4.3 Fraction Collection

1. Load the test tube rack with twenty 12 x 75 mm culture tubes and place it inside

the harvest box. Place the lid on the box, making certain that each stainless steel

collecting tube is inside a test tube. Connect a vacuum source to the vacuum port

on the box and turn on the vacuum to hold the lid in place. A vacuum pump or

house vacuum of 10–50 mm Hg is recommended.

2. When focusing is completed, move the black toggle switch to the HARVEST

position. This stops the cell rotation with the cell properly aligned for sample

collection, i.e., with the alignment pins and taped collection ports on the bottom

of the focusing chamber. All manipulations which follow the end of rotation

should proceed as quickly as possible to minimize mixing.

3. Turn the power supply off, disconnect the power supply, remove the cover, and

move the Rotofor cell and the harvesting box next to one another. Remove both

the upper and lower focusing chamber cell cover blocks. Mount the needle array

on the two alignment pins on the bottom of the chamber. Grasp the needle array

with the fingers of both hands while placing the thumbs on the top of the focusing

chamber. Take care not to block any of the uppermost ports. Quickly push the

needles firmly and uniformly all the way through the sealing tape into the chamber.

This will cause all 20 fractions to be simultaneously aspirated from the cell and

delivered to the collection tubes.

Fig. 4.2. Harvesting samples after focusing is complete. Make sure thumbs do not cover the

uppermost ports.

4. Turn off the vacuum source and remove the test tube rack. Note that all the

odd numbered fractions are in one row and the even numbered fractions are in

the other row of the rack.

4.4 Refractionation

The fractions containing the protein of interest may also contain other, contaminating

proteins after the initial fractionation. Refractionation of Rotofor fractions is one way to

increase sample purification. Because of its lower volume requirement the Mini Rotofor

chamber is ideal for refractionating pooled fractions.

13

Page 18

After screening the samples collected from the first fractionation, pool the fractions

containing the protein of interest. These pooled samples (typically 3–5 fractions) can

be reapplied either to the Rotofor or Mini Rotofor for refractionation. Rotofor fractions

obtained from an initial run contain ampholytes whose range spans the pI of the protein

of interest. It is best to add no additional ampholytes to the sample to be refractionated.

Because ampholytes and salts are not added prior to the refractionation, higher

voltages can be obtained because of the low ionic strength of the sample. High

voltages lead to better resolution during focusing. Upon refractionation, the

ampholyte range is much narrower and more specific to the protein of interest. The

pooled fractions contain a small part of the initial pH range which spans the pI of

the protein of interest. This is spread across the length of the chamber during

refractionation, providing a shallow pH gradient, and thereby increasing the likelihood

of obtaining one or more fractions of pure protein.

4.5 Final Purification

The Rotofor is designed to quickly separate proteins of interest from other proteins

in a sample. Bio-Rad’s Model 491 Prep Cell can purify individual proteins from Rotofor

fractions by continuous-elution electrophoresis. Conventional gel electrophoresis

buffer systems and media are used with the Model 491 Prep Cell. Using SDS-PAGE

or native-PAGE, the Prep Cell can isolate specific components from complex mixtures

containing micrograms to 200 milligrams of total sample. Up to 5 milligrams per band

can be resolved. Using SDS-PAGE the cell isolates molecules that differ in molecular

weight by 2%. Using non-denaturing PAGE the cell can isolate molecules that differ in

charge by 0.1 pH units. Electrophoretic purification can also be effective in removing

ampholytes from samples. See Section 12.

Section 5

Disassembly and Cleaning

1. Rinse the needle array and its associated tubing with water as soon as possible

after use. Do not use the vacuum box to pull water through the needle array.

This may damage the box. Rinse the box with water.

2. Take the focusing chamber from the stand. Loosen the nylon screws and

remove the cathode chamber.

3. Leave the cathode and anode chambers intact. The ion exchange membranes

must be stored wet. Remove the electrolyte and fill the electrode chambers with

distilled water. If properly stored, the membranes will not decrease in performance

between runs. Before starting a new run, the electrolytes must be replaced with

fresh solutions.

4. Loosen the nylon screws on the anode chamber and remove the focusing chamber

and membrane core. Rinse all chamber components with water and air dry. Do not

expose the focusing chamber to concentrated acid, base, or alcohol. The membrane

core requires additional care, especially if there has been protein precipitation during the

run. A spatula can be used to loosen and remove caked precipitates. Soak the membrane

screens in saline and then in detergent or 0.1 M NaOH to remove traces of protein. An

ultrasonic cleaner will facilitate the cleaning process. Finally, rinse the screens with

water. For complete removal or residual NaOH or other cleaning compounds, assemble

the Rotofor cell with the membrane core, add distilled water, and apply 5W power until

the current stabilizes. Then discard the solution and add the sample. Cleaning with

strong oxidizing agents, such as hypochlorite, or organic solvents should be avoided, as

they will damage the membrane core. If properly cleaned, the membrane core can be

immediately reused.

14

Page 19

Section 6

Sample Preparation

6.1 Salt Concentration

1. Samples should be desalted (e.g., by dialysis or Bio-Gel®P-6 chromatography)

prior to ampholyte addition to insure that the nominal pH range of the ampholyte

will extend over the full length of the focusing chamber and that the maximum

voltage can be applied. It is best to limit salt concentrations in the samples to

about 10 mM for optimum fractionation. However, the maximum salt capacity

will vary with the application, therefore optimum running conditions should be

determined empirically. During focusing, all salts migrate to the compartments

next to the anode and cathode, effectively desalting the sample.

2. The sample should not be in a buffer greater than 10 mM concentration.

Buffers add to the conductivity of a sample and decrease resolution. Also,

buffering solutions may flatten the pH gradient in the region of the pKaof the

buffer.

6.2 Clarification

Turbid sample solutions should be clarified by filtration or centrifugation to

remove extraneous cellular debris that might clog the membrane core.

6.3 Solubility

If the solubility of proteins presents a problem, adjusting the sample to 3–5 M

urea is recommended. Higher urea concentrations, up to 8M urea, can be used.

Be sure to deionize the urea using AG®501-X8 mixed bed ion exchange resin

(catalog number 143-7424). Addition of non-ionic detergents, such as: CHAPS,

CHAPSO, octylglucoside, digitonin, or Triton X-114 is also valuable in maintaining

the solubility of focused proteins. The concentration of detergents used is usually

between 0.1% and 1%. Alternatively, solubility can sometimes be maintained by

increasing the Bio-Lyte ampholyte concentration in the sample. Check the solubility

of the protein by diluting it in detergent or urea and running it on an analytical IEF

gel. If the protein does not show signs of precipitation in the IEF gel, it should not

precipitate in the Rotofor cell.

15

Page 20

Section 7

Optimizing Fractionation

7.1 Ampholyte Choice

1. Bio-Lyte®ampholytes are complex mixtures of synthetic buffering electrolytes with

closely spaced pI’s and high conductivity. Bio-Lytes are supplied at concentrations

of 40% (w/v), except in the pH ranges 3-5 and 8-10, which are at 20%. The final

concentration of Bio-Lytes used in the Rotofor system depends on the protein

concentration in a given sample:

Protein per Bio-Lyte

milliliter Ampholytes

>2 mg 2%

1 mg 1.5%

0.5 mg 1%

0.25 mg 0.5%

2. Up to 8% (w/v) ampholyte concentrations have been used for various applications.

Ampholytes at 1% permit higher applied voltages and are recommended if

refractionation is not required. 2% ampholytes will provide greater buffering and

are necessary when refractionation is performed. If protein precipitation occurs

during the run because of the desalting effect of focusing, sample solubility may

be maintained with higher ampholyte concentrations. Use the following formula to

determine the appropriate volume (V1) of a 40% Bio-Lyte ampholyte solution to

give a desired final concentration in your Rotofor sample.

For the equation: (C1)(V1)=(C2)(V2), solve for V

1.

where: C1= Starting concentration of Bio-Lyte (40%)

V

1

= Unknown volume of 40% Bio-Lyte to give desired final

concentration

C

2

= Final or desired concentration of Bio-Lyte

V

2

= Final volume of the sample to be applied to the Rotofor

(35–58 ml) or Mini Rotofor (18 ml)

3. The pI of the protein of interest can be determined by running the sample on a

flatbed slab IEF cell (such as the Model 111 mini IEF cell) using the broad pH

range of 3-10. IEF markers (catalog number 161-0310) run in the same gel

allow the pI of the protein of interest to be estimated. Alternatively, the pI can

be estimated by running the sample in the Rotofor cell using a broad range

3–10 ampholyte. The pI of the protein of interest will correspond to pH of the

Rotofor fraction where the protein of interest focuses.

4. A narrow pH range of ampholytes spanning the pI of the protein of interest should

be used for the initial fractionation. Narrow range fractionation first separates the

protein of interest from the bulk of its contaminants. The pI of the protein of interest

should fall in the middle of the ampholyte range.

16

Page 21

5. An example of the importance of using the proper ampholytes in a fractionation is

demonstrated by a purification of Japanese water moccasin snake venom. The

protein of interest has a pI of 6.1 as determined by IEF gels. Bio-Lyte ampholytes

pH 6-8 were used for the initial fractionation. The fractions were analyzed and the

ones containing the specific protein were pooled. After refractionation, the fractions

were again analyzed on IEF slab gels and multiple bands were observed in all

fractions. When the same snake venom sample was initially fractionated in 5-7 Bio-Lyte

ampholytes the results were dramatically different. After refractionation, the protein

of interest was almost completely free of contaminating proteins. The conditions for

both experiments were identical except for the initial Bio-Lyte range; however,

much greater purity was obtained from the experiment using the 5-7 Bio-Lyte

ampholytes.

7.2 Sample Capacity

Choosing between the Standard Rotofor Chamber and the Mini Rotofor

Chamber is a matter of sample size. The Standard Rotofor Chamber is designed to

optimally fractionate milligrams to grams of total protein. The Mini Rotofor chamber is

designed to fractionate micrograms to milligrams of total protein. The smaller volume

of the Mini Rotofor decreases sample volume and is best suited for use with samples

of low protein concentration. Protein concentrations should be adjusted for desired

yield or to provide convenient assays of focused material, assuming each component

will focus in 1–3 channels, approximately equal to 3 ml/fraction in the Rotofor and

800 µl/fraction in the Mini Rotofor.

For example, if Rotofor fractions are analyzed by SDS-PAGE on a Mini-PROTEAN

®

II cell (catalog number 165-2940) and silver stained, the sample should contain a

minimum of 50.0 µg per component. More sensitive assays, such as activity assays,

decrease the necessary protein load.

The maximum protein load varies with the solubility of each sample and must be

determined empirically. However, preparative fractionation of 51 ml of lyophilized

cell culture supernatant containing 2.4 g of protein has been successfully performed

using the Rotofor Cell.

7.3 Power Conditions

We recommend running the Rotofor cell at constant power. During the initial

fractionation the voltage values will vary between samples depending on the relative

concentration of proteins and salts. The Mini Rotofor should be run using 12W constant

power and standard Rotofor should be run using 15W constant power.

When voltage is applied to a system of ampholytes and proteins, all the

components migrate to their respective pIs. In electrofocusing, the higher the voltage

the better the resolution. The limiting factor in achieving high resolution is how

efficiently electrically generated heat can be dissipated.

In a constant power mode, voltage gradually increases as the components focus.

The progress of the run is easily monitored by observing the voltage increase over

time. When the sample is focused, voltage levels off at a maximum. Runs typically

last 2-4 hours at 12 watts constant power and can require up to 3000 volts.

7.4 Cooling

Sample temperature affects activity and resolution. Many proteins, especially

enzymes, are temperature labile. The water recirculation chiller should be set about

10 °C cooler than the temperature required to maintain stability of your protein. The

17

Page 22

heat generated during IEF keeps the temperature inside the focusing chamber

approximately 10 °C higher than that of the circulating coolant. Temperature settings

for chillers are generally between - 10°C and 4°C.

Diffusion rates of proteins are proportional to their temperature in solution.

Because proteins at steady state diffuse in and out of their focused zones it is

advisable to run the Rotofor cell at the lowest possible temperature to offset this

effect.

7.5 Electrolytes

The recommended electrolytes for the anode and cathode are 0.1 M H3PO

4

and 0.1 M NaOH, respectively. Because there can be a slight amount of electrolyte

exchanged through the ion exchange membranes during the focusing run, the first

one or two channels may be very acidic (<pH 3) and the last one or two channels

may be very basic (>pH 10). The result will be a concentration of the effective pH

gradient in the middle channels. This will have minimal affect on the final results of

the experiment. Alternative electrolytes, e.g., amino acids, acetic acid, etc., may be

used and perform as well as H3PO4and NaOH. These include:

7.6 Pre-running the Cell

The unit should be cleaned with distilled water prior to loading the sample.

Simply fill the focusing chamber with 55 ml of distilled water and run at standard

power for 5 minutes. Drain the unit using the harvesting apparatus. This will insure

that extraneous ions have been removed from both the cell and the surface of the

ion exchange membranes.

7.7 Prefocusing

Loading the sample into the Rotofor cell is usually accomplished by injecting a

homogeneous solution of the prepared sample containing ampholytes, the protein

of interest, and any required solubility agents into the focusing chamber. However,

some proteins are especially sensitive to rapid pH shifts or to extremes of pH and

may precipitate or become denatured. To avoid exposing your protein to these

potentially damaging conditions during initial focusing, “prefocus” the focusing

media (i.e. Bio-Lyte ampholytes and solubility additives), without protein for about

an hour. This will establish the pH gradient. Then inject your protein sample into

the sample chamber at or near the point in the pH gradient that corresponds either

to the pH of the protein sample solution or the pI of your protein of interest. To

avoid disrupting the pH gradient during injection of the sample, this technique

requires that the volume of the solution containing the protein sample be as small

as possible. Prefocusing decreases exposure of proteins to rapid pH shifts and pH

extremes, minimizes the amount of time the protein spends in the Rotofor cell, and

may reduce run times by up to 50%.

18

3-5

4-6

5-7

6-8

7-9

8-10

0.5 M acetic acid

0.5 M acetic acid

0.1 M glutamic acid

0.1 M glutamic acid

0.25 M MES

0.25 M MES

0.25 M HEPES

0.5 M ethanolamine

0.5 M ethanolamine

0.1 M NaOH

0.1 M NaOH

0.1 M NaOH

pH range of Anode Cathode

Bio-Lyte Electrolyte Electrolyte

Page 23

7.8 Refractionation

Better separation may be achieved by refractionating the sample. The mini Rotofor

is ideal for refractionation because samples are minimally diluted in its chamber. After

analyzing the fractions from the initial separation, the fractions containing the protein of

interest should be diluted in distilled water and reloaded in the standard Rotofor cell or

the Mini Rotofor cell. Upon refractionation the ampholyte concentration should be at

least 0.5%. We recommend that no less than 4–5 fractions be pooled and reapplied for

a second Rotofor run. If urea or non-ionic detergents are needed to maintain protein

solubility add the same concentration as used in the first fractionation. Do not add

additional ampholytes or salts at this stage.

1. Dilute pooled fractions appropriately, e.g., with water, up to 8 M urea, or a solution

containing non-ionic detergent for solubility, to a final volume of 55–60 ml in the

standard Rotofor or 18 ml for the Mini Rotofor. The customized ampholyte blend

obtained will span the pI of the protein of interest. Do not add additional ampholyte

to the refractionation mix; the amount present in the pooled samples is suitable for

focusing and provides a narrow range pH gradient to increase separation of the

protein of interest.

2. Load the diluted sample and re-run. Since the ionic strength of the sample will

be lower upon refractionation, higher voltages, yielding better separations can

be achieved. Refractionations of low ionic strength solutions have been carried

out at 2,000–3000 volts. Do not exceed the power limit of the cell. Focusing is

usually complete in 3–5 hours. The upper limit for voltage is dependent on how

well heat can be dissipated. Set the coolant temperature between -5°C and -10°C

for high voltage separations.

Section 8

Analysis of Results

8.1 Fraction Analysis

After harvesting, it is important to analyze the fractions to determine which contain

the protein of interest. There are many different ways of doing this, and the best

method is dependent on the protein being analyzed.

SDS-PAGE analysis or an IEF gel, usually pH 3-10, will give an accurate

representation of the fractionation. Other methods for assaying which channels

contain the protein of interest are dependent on the particular protein and include

activity assays and antibody tests. Analytical gels should be silver stained for high

sensitivity detection of contaminants.

8.2 Separation of Ampholytes From Proteins

Many applications can tolerate the presence of ampholytes in protein solutions.

However, ampholytes can interfere with some assays such as amino acid analysis.

Several methods for separating ampholytes from focused proteins are listed below.

1. Preparative Electrophoresis - Rotofor fractions containing the protein of interest

and any remaining contaminating proteins can be pooled and applied to a

preparative continuous-elution electrophoresis cell such as Bio-Rad’s Model

491 Prep Cell. Using the Model 491 Prep Cell as second and a final purification

step, samples (Rotofor fractions) are electrophoresed through a polyacrylamide

gel. In this way, the contaminating proteins and the ampholytes are effectively

separated from the protein of interest.

19

Page 24

2. Dialysis - Probably the simplest method for ampholyte removal is dialysis.

Adjust the pooled sample to 1 M NaCl. This will effectively strip electrostatically

bound ampholytes from proteins by ion exchange. Then dialyze into the buffer

appropriate for further uses.

3. Ammonium sulfate precipitation of proteins may also be effective in removing

ampholytes from samples.

4. Any number of chromatographic techniques, such as gel filtration, ion

exchange, hydroxylapatite, affinity chromatography, or use of AG 501-X8 resin,

can be used to separate proteins from ampholytes.

Section 9

Troubleshooting Guide

This guide is designed to answer common Rotofor cell questions. For further

information, please contact your local Bio-Rad representative. In the U.S., our

Technical Service department is available Monday to Friday, from 7:00 am to 5:00 P.M.

Pacific Time to answer all of your technical inquiries involving Bio-Rad equipment and

reagents. You can reach us by dialing 1-(800)-4BIORAD.

9.1 Solubility and Precipitation of Proteins

1. By definition, a protein at its isoelectric point (pI) has no net charge. Because little

charge repulsion exists between focused molecules, hydrophobic interactions

between proteins become predominant causing proteins to aggregate.

Maintaining the solubility of proteins in this case requires overcoming protein-protein

interactions. Several agents promote protein solubility. Detergents provide a

hydrophobic environment for proteins to mask interprotein interactions. Disulfide

bridges also may form between proteins leading to aggregation. This effect may

be overcome by the addition of reducing agents to the focusing media. Because

the solubility of proteins varies greatly, there is no one answer to the problem of

insolubility. Generally, the easiest method of getting proteins to remain in solution

is to add nonionic detergents, zwitterionic detergents, and/or chaotrophic agents

to the sample mixture.

In addition, glycerol from 5-25% (v/v) in the sample is highly effective for

maintaining the solubility and stability of proteins. Glycerol stabilizes water

structure and the hydration shell around proteins.

Table 9.1. Recommended Solubilizing Agents for the Rotofor System

Non-Ionic Zwitterionic Reducing Chaotropic

Detergents Detergents Agents Agents

0.1-3.0% Digitonin 0.1-3.0% CHAPS DTE 5-20 mM 1.0-8.0 M Urea

0.1-3.0% Octylglucoside 0.1-3.0% CHAPSO DTT 5-20 mM 0.1-2.0% Glycine

0.1-3.0% Triton X-114 BME 1-5 mM 0.1-2.0% Proline

2. When the solubility of a protein depends on maintaining high ionic strength during

focusing, increasing the concentration of Bio-Lyte ampholytes up to 5–8% in

your sample will help keep proteins in solution.

20

Page 25

3. Decreasing the protein load will also help keep the protein in solution. The

largest amount of protein concentration in solution that has been successfully

fractionated in the Rotofor cell is 4 grams. The lower limit for protein loading

depends on the sensitivity of your detection system.

9.2 Factors Affecting the pH Gradient

Non-linear pH gradients are rarely observed when sample is prepared properly

and the Rotofor cell and its parts are carefully maintained. A non-linear pH gradient

may be caused by one or more of the following:

1. Electrolyte leakage. Excessive leakage of electrolyte across the ion exchange

membranes into the focusing chamber will decrease the number of fractions on

the linear portion of the pH gradient and reduce the effective voltage across the

sample. To determine if this is occurring, check the pH of the fractions.

Alternatively, fill the Rotofor focusing chamber with distilled, deionized water

and run the Rotofor at 12 W constant power. If the amperage does not

decrease to < 6 mA and the voltage does not increase to near 2,000 V within

5–10 minutes, the chances are good that you have electrolyte leaking into your

sample. Some common causes are:

A) Expired Vent Buttons. Vent buttons lose their capacity to vent the gases

produced during electrolysis over time and when there is too much electrolyte

in the chamber. The pressure that results within the electrolyte chambers

forces electrolytes into the focusing chamber. Replace the vent buttons (catalog

number 170-2957) every 4 to 5 runs.

B) Worn O-rings and/or electrode Gaskets. The Rotofor repair kit contains

replacement parts for these items (catalog number 170-2953). Lubricating

the O-rings with a small amount of silicone O-ring grease or Cello-Seal

™

will extend their useful lifetime (catalog number 170-2954).

C) Cracked, dehydrated, or worn out Ion-exchange Membranes (catalog number

170-2956). These last 4 to 5 runs.

2. Uneven harvesting. Variations in the volumes of harvested fractions may affect

the linearity of the collected pH gradient. Be sure to remove both harvesting and

loading port covers before piercing the sealing tape with the harvesting block

needles. Also make sure that the harvesting tubes are clean and clear of blockages

by soaking in Bio-Rad cleaning concentrate (catalog number 161-0722) or dilute

0.05 M NaOH and rinsing well with DDI H2O after each run. Dry the tubes by

aspirating each individual tube with a vacuum line. Be careful not to block the

loading port holes with your fingers during harvesting.

The compartments of the focusing chamber contain unequal volumes at the

end of the run. As proteins become focused the osmotic pressure in each

Rotofor compartment may vary. If the focusing chamber is not completely full,

this may cause unequal distribution of fluids in the 20 compartments. This

effect will vary as a function of protein load and concentration of solubilizing

additives. Reproducibility of results, especially where isolation of a protein in a

particular fraction number is expected, will depend on the constancy of these

factors. To alleviate the osmotic effect, the Rotofor cell should be run with the

focusing chamber completely filled.

3. Premature harvest. Too short a run will result in a partially-formed pH gradient

and poorly focused proteins. The Rotofor cell is normally run for 3 to 6 hours.

To assure complete focusing, continue the run for 1/2 hour after the voltage

stabilizes, then stop the electrophoresis and harvest the focused protein.

21

Page 26

4. High salt sample. The salt (or buffer) concentration in the sample may be too

high. This will decrease the effective voltage across the sample and may reduce

the number of fractions on the linear portion of the pH gradient. Resolution is

dependent on both high voltage and maximizing the number of fractions on the

linear gradient. If a particularly high ion concentration is necessary to preserve

the stability and/or activity of your protein, Bio-Lyte ampholytes (which are ionic

molecules) may be substituted for salts. For example, preparation of the enzyme

aldose reductase (pI ~ 5.0) from porcine lens for purification using the Rotofor

cell required that the protein sample be at low ionic strength (< 1.0 mM buffer)

to maximize voltage and resolution10. Since aldose reductase is unstable under

these conditions, the following procedure was used to avoid exposure to low

ionic strength:

1.0 ml of 5% Bio-Lyte ampholytes, previously fractionated using the Rotofor cell at

4.5 to 5.5 pH range, were added to 1.0 ml of 5.0 mg / ml protein solution in a 10.0

mM phosphate buffer. This solution was exhaustively dialyzed against 25.0 ml of

the same 5% Bio-Lyte solution, thereby making the final phosphate concentration

less than 1 mM. The salt concentration in the sample was reduced to a reasonable

level while the ionic strength required to maintain the stability of the enzyme was

retained.

If the pH gradient plateaus or dips near the middle, this may be due to the presence

of excess buffer in the protein sample solution. The pH of the gradient will be

buffered at the pK of this buffer, creating a dip or plateau in the gradient in this

region. The symptom may be many fractions with the same pH. Reduce buffer

salts to < 10 mM.

5. High sample temperature. At 12 W, the temperature inside the chamber is generally

10 degrees higher than the temperature of the circulating coolant. The cooler the

run, the more stable the proteins will be. 4 °C is the optimum sample temperature.

6. Non-reproducible pH gradients. Use sufficient concentration of ampholytes.

Batches and brands of ampholytes may also vary. Do not run the Rotofor cell

more than 1–2 hours after voltage stabilization. Reduce salt to below 10 mM.

Always run the sample at or below 4°C. Check the integrity of the Bio-Lyte

ampholytes. Ampholytes should be stored at 4°C in the dark. Guaranteed shelf

life of opened Bio-Lyte ampholytes is 1 year.

9.3 Recovery of Biological Activity

1. pH. Some proteins are especially sensitive to rapid pH shifts and to extremes of

pH that exist at the extreme ends of the Rotofor focusing chambers. To avoid

exposing your protein to these potentially damaging pH extremes during initial

focusing, “prefocus” the focusing media (i.e. Bio-Lyte ampholytes, additives,

water, etc.), without protein, for about an hour. This will establish the pH gradient.

Then inject your protein sample into the sample chamber at or near the point in

the pH gradient that corresponds either to the pH of the protein sample solution

or to the pI of your protein of interest. Addition of your protein sample solution in

as small a volume as possible decreases exposure to rapid pH shifts and pH

extremes, minimizes the amount of time the protein spends in the Rotofor cell

and maintains native tertiary structure.

22

Page 27

2. Temperature. Many proteins, especially enzymes, are temperature labile. Make

sure that the water recirculation chiller is set 10°C cooler than the temperature

required to maintain stability of your protein. The heat generated during IEF

keeps the temperature inside the focusing chamber approximately 10°C higher

than that of the circulating coolant. Temperature settings for chillers are generally

between - 10°C and 4°C.

Diffusion rates of proteins are directly proportional to their temperature.

Because proteins at steady state diffuse in and out of their focused zones it is

advisable to run the Rotofor cell at the lowest possible temperature to offset

this effect.

3. Ampholytes. Ampholytes may form weak electrostatic complexes with proteins.

They can be removed by bringing pooled fraction(s) to 1.0 M NaCl and dialyzing

against appropriate buffer or water. The salt effectively exchanges for the

ampholytes on the protein. This may be followed by dialyzing against appropriate

assay buffer. Other methods for ampholyte removal include electrophoresis;

ammonium sulfate precipitation; and gel filtration, ion-exchange, and hydroxylapatite

chromatography. Be sure to measure the pH of the fractions before manipulating

them to remove ampholytes.

4. Urea. Urea in the focusing media at 3 M generally alleviates precipitation.

Without the use of urea, loss of activity due to precipitation may be excessive.

Urea at higher concentrations (4-8 M) is often used. Following focusing, dialysis

will remove urea from the solution.

5. Detergents. Both the concentration and the type of detergent used play an

important role in recovery of activity. Use the least amount of compatible detergent

required to maintain the solubility of your protein. Also try other non-ionic or

zwitterionic detergents. Removal of detergent from Rotofor fractions may be

necessary for full recovery of activity.

6. Precipitation. Protein-protein interactions may result in activity loss.

Decreasing the protein load, and addition of detergents, glycerol, reducing

agents and/or chaotropic agents keep proteins from forming complexes during

focusing.

7. Proteins are not always active at their pI. Adjust the pH of the solution for

assay.

8. Some proteins require the presence of a particular ionic species for activity

(i.e. mono- or divalent cations like Na+or Mg

2

+

). Replace the ions, if necessary,

for assay.

9.4 Maximizing Resolution

1. Diffuse or multiband protein IEF patterns can arise from molecular interactions

and conformational changes as well as from inherent isoelectric microheterogene-

ity. Ampholytes can reversibly bind to proteins, proteins can undergo sequential

pH dependent conformational changes, and proteins can interact with one anoth-

er. These types of reactions can artifactually alter the pH profiles of proteins. On

the other hand, many proteins are inherently heterogeneous, consisting of isoelec-

tric isomers. To distinguish between artifactual and inherent heterogeneity, it may

be necessary to run an analytical IEF gel in the presence of all constituents to be

used during focusing in the Rotofor cell (i.e., detergents, urea, glycerol, etc.) in the

same proportions to be used in the Rotofor cell. Single focused bands should be

cut out and rerun. If this single band splits into many bands, artifact formation is

indicated. In this case the Rotofor “prefocusing” protocol is recommended.

23

Page 28

2. Clarify all sample solutions before focusing. Membrane cores are composed of

polyester membranes with a pore diameter of approximately 10 µm. The membrane

core can become clogged with insolubles in sample solutions. Starting solutions can

be clarified by centrifugation. To clean the membrane core, soak it in detergent,

dilute NaOH, or sonicate. Rinse the core well in distilled water after cleaning. For

complete removal of residual base, assemble the Rotofor cell with the membrane

core and prerun the cell with H2O until the voltage stabilizes. Then discard the water

and add sample. Generally the membrane cores will last at least 20 runs if they are

well cared for.

3. Protein samples that contain a charged detergent, like SDS, may experience a

shift in apparent pI and migrate to one or another end of the cell as a result of

acquired net charge. Use only non-ionic or zwitterionic detergents for this reason.

Some proteins are inherently associated with phospholipids, heme groups, or

other charged groups that affect the electrophoretic migration of proteins in a

pH gradient. A means must often be found to neutralize the effects that these

charged groups have on proteins during focusing. For example, the non-ionic

detergent, digitonin, has been found to be effective at disassociating negatively

charged phospholipid from integral membrane proteins. Digitonin provides a

suitable hydrophobic environment for maintaining the stability and biological

activity of these proteins during focusing in the Rotofor cell.

9.5 Power Conditions

Voltage is the driving force behind isoelectric focusing. Maximizing the voltage is

the best way to increase resolution. The cooling finger is capable of dissipating up

to 15 W of power generated in the large focusing chamber. The main factor limiting

voltage is efficiency of heat dissipation. These are common problems related to the

application of power.

1. Voltage fluctuations are caused by air bubbles trapped between the sample

and the ion-exchange membranes. Remove the assembled Rotofor core, hold

it vertically and tap on it to dislodge the bubbles. Turn the cell 180° and repeat

the bubble removal process. The minimum running volume of sample solution

should not be less than 35 ml for the standard focusing chamber and 18 ml for

the mini chamber.

2. Voltage decreasing at the beginning of the run is normal. At the beginning

of a run mobile charge carriers migrate through the chamber creating a relative-

ly high initial current. Eventually, desalting ceases and the pH gradient forms. As

the run proceeds, the resistance of the focusing medium increases and voltage

climbs. Do not set a limit on the voltage below 2,000 volts. When the voltage

finally plateaus, steady state has been achieved. Let the run continue for an

additional 15-30 minutes, then harvest.

3. Arcing between the anode and/or the cathode contact plate(s) and the contact

assembly(s) may occur for either of two reasons: 1) the solid brass points of the

contact assembly(s) are worn down and electricity is jumping across the gap, or

2) there is a leak in the coolant from the cooling finger housing and the coolant is

making the electrical connection. Either replace the contact assemblies left side

(catalog number 100-3780) or right side (100-3790) or repair the leaking cooling

finger with new O-rings from the Cooling Finger Repair Kit (catalog number

170-2954).

24

Page 29

9.6 Uneven Harvesting

1. Use a stronger vacuum. Use vacuum that pulls >5 inches mercury.

2. Remove both harvesting and loading port covers. Before puncturing the

sealing tape to aspirate the fractions, remove both upper and lower covers. Do

not cover loading port holes with your fingers or gloves.

3. Run the Rotofor cell completely full. Volumes will vary in compartments as

the result of protein concentrations in each.

4. Check the needles in the harvesting block, the tubing and the harvest

block lid. They should not be loose, kinked, plugged, or unequal in height.

5. Check the plastic harvest tubing. If necessary, soak the tubes in dilute

NaOH (0.1 M) to remove residual matter then rinse the tubes with water.

Caution: DO NOT insert all of the needles into a water bath at the same time

with the vacuum on, as the harvest box may implode! Dry the tubes one at a time.

9.7 Mechanical Problems

1. The cell doesn’t rotate. Make sure that the core is assembled tightly, and that the

gear teeth are meshing well. With each hand, grab the big black rings that hold the

halves of the electrolyte chambers together and tighten them simultaneously for

better leverage. (Also make sure that the switch is set to “run” and not “harvest”).

Refer to the manual for proper assembly.

2. The unit leaks. Leaks from different places indicate different problems:

A) Vent buttons may become wet under normal operation, but this is usually

attributable to condensation during the run, not to leaking. If they are old

(>4–5 runs), or the electrolyte chamber is more than 2/3 full, they may

actually leak. Replace the vent buttons if they are old. Make sure electrolyte

solutions are 0.1 Molar.

B) Check the ion exchange gaskets between the two halves of the electrolyte

chamber to make sure that there is a good seal between them. They

should not be wrinkled, pinched, or out of alignment.

C) Check the O-rings that seal the chamber from the cooling finger. If one or

more of them is twisted, cracked, or missing, the unit may leak. To keep

the O-rings from twisting as you put the unit together, lubricate them with a

small amount of silicone grease, or Cello-Seal.

D) The cell must be seated firmly in the electrodes with the screws tightened.

3. The focusing chamber is too long for the base. Push the assembled

components all completely together on the cooling finger. To properly seat the

pieces together may require some force.

25

Page 30

Section 10

Maintenance Guide

10.1 Vent Buttons

The vent buttons should last four or five runs. They should be inspected before

use for tears in the fabric. If there are any tears, or if leaking occurs during the run,

replace the vent buttons (catalog number 170-2957). Leaking may be due to

overfilling the electrode assemblies. Make sure the assemblies are not filled more

than 65% full. Air space is needed above the electrolyte to allow gas to escape

through the buttons. If the air space is insufficient, pressure may build up and

cause leaking.

10.2 O-rings

The O-rings in the electrode assemblies should be inspected after the first

20–30 runs. If there are any signs of wear, replace them using the O-rings supplied

in the Repair Kit (catalog number 170-2953). If the O-rings are unworn after the

first 20 runs, check them every five runs after that until they need to be replaced.

10.3 Cooling Finger O-rings

Inspect the cooling finger O-rings every 200 runs or every year, which ever

comes first. If there are signs of wear, replace them using the O-rings supplied in

the Cooling Finger O-ring Kit (catalog number 170-2954).

10.4 Membrane Core

The membrane core does not have a replacement schedule. It should be

inspected after each run. If it becomes deformed (through overheating or mechanical stress), it should be replaced.

26

Page 31

Section 11

Rotofor References

Methods

Whether alone or in combination with other techniques- polyacrylamide gel