BIO RAD PTC-200 Operation Manual

DNA Engine®Thermal Cycler

Operations Manual

Version 4.0

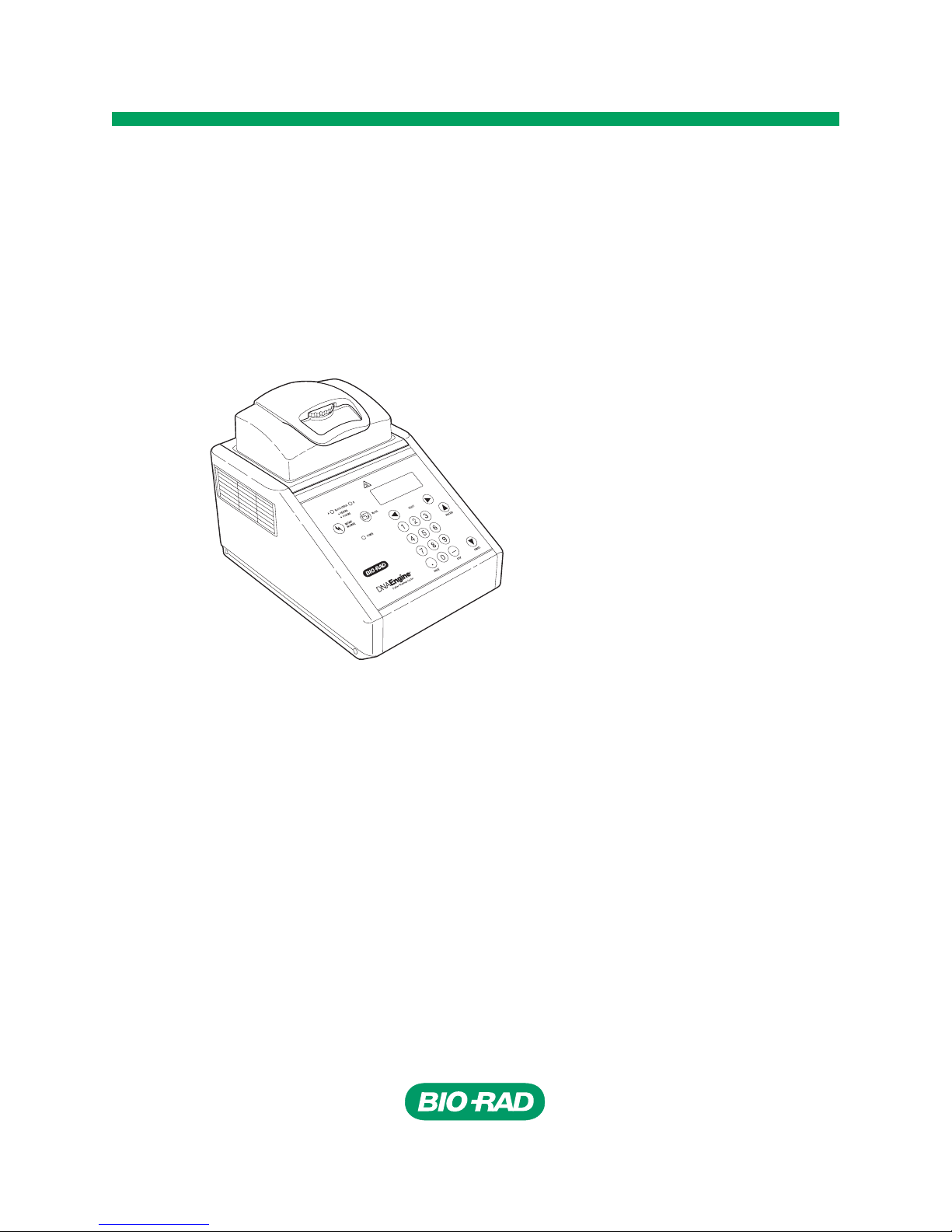

PTC-200 DNA Engine Cycler

DNA Engine

®

Peltier Thermal

Cycler

PTC-0200 DNA Engine Cycler

Operations Manual

Version 4.0

ii Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

Copyright ©2005, Bio-Rad Laboratories, Incorporated. All rights reserved. Reproduction in any form, either print or electronic,

is prohibited without written permission of Bio-Rad Laboratories, Inc.

Alpha, Chill-out, Concord, Dual Alpha, DNA Engine, DNA Engine Tetrad, Hard-Shell, Hot Bonnet, Microseal, Moto Alpha,

Multiplate, Power Bonnet, Remote Alpha Dock, Slide Chambers, and Tetrad are trademarks of Bio-Rad Laboratories, Inc.

NOTICE TO PURCHASER

This base unit, Serial No. ____________, in combination with its immediately attached Bio-Rad sample block module(s),

constitutes a thermal cycler whose purchase conveys a limited non-transferable immunity from suit for the purchaser’s own

internal research and development and for use in applied fields other than Human In Vitro Diagnostics under one or more of U.S.

Patents Nos. 5,656,493, 5,333,675, 5,475,610 (claims 1, 44, 158, 160-163 and 167 only), and 6,703,236 (claims 1-7 only), or

corresponding claims in their non-U.S. counterparts, owned by Applera Corporation. No right is conveyed expressly, by

implication or by estoppel under any other patent claim, such as claims to apparatus, reagents, kits, or methods such as 5’

nuclease methods. Further information on purchasing licenses may be obtained by contacting the Director of Licensing, Applied

Biosystems, 850 Lincoln Centre Drive, Foster City, California 94404, USA.

This DNA Engine thermal cycler, when combined with a Chromo4 detection module bearing a valid label license under U.S.

Patent No. 6,814,934, constitutes a real-time thermal cycler licensed under U.S. Patent No. 6,814,934 and corresponding claims

in any Canadian counterpart patent thereof owned by Applera Corporation, for use solely in research and all applied fields

except human and veterinary in vitro diagnostics, provided that the real-time thermal cycler royalty fee that is applicable to said

thermal cycler has been paid. No rights are conveyed expressly, by implication or estoppel to any patents on real-time methods,

including but not limited to 5' nuclease assays, or to any patent claiming a reagent or kit. For further information on purchasing

license rights, contact the Director of Licensing at Applied Biosystems, 850 Lincoln Centre Drive, Foster City, California, 94404,

USA.

05434 rev E

Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com iii

Explanation of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Safe Use Guidelines, Electromagnetic Interference, and FCC Warning . . . . . . . . . . . . .v

Documentation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

The DNA Engine

®

Peltier Thermal Cycler

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Layout and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Running Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Creating Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Editing Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Using the Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Networking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

The Remote Alpha Dock

™

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

Appendix A: Warranties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Appendix B: Factory-Installed Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .In-1

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DoC-1

Table of Contents

iv Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

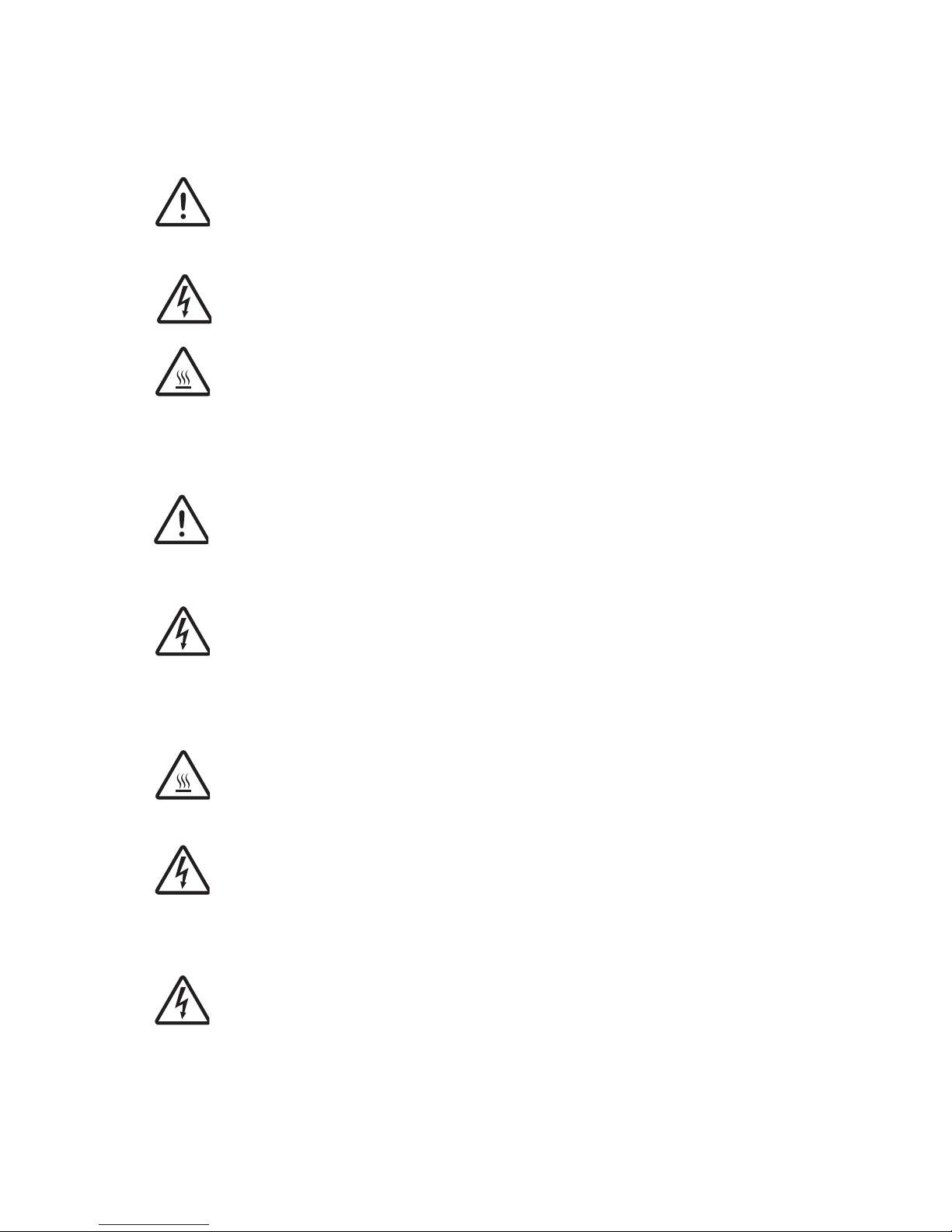

Explanation of Symbols

CAUTION: Risk of Danger! Wherever this symbol appears, always consult

note in this manual for further information before proceeding. This symbol

identifies components that pose a risk of personal injury or damage to the

instrument if improperly handled.

CAUTION: Risk of Electrical Shock! This symbol identifies components that

pose a risk of electrical shock if improperly handled.

CAUTION: Hot Surface! This symbol identifies components that pose a risk

of personal injury due to excessive heat if improperly handled.

Safety Warnings

Warning: Operating the DNA Engine®cycler before reading this manual can

constitute a personal injury hazard. Only qualified laboratory personnel

trained in the safe use of electrical equipment should operate these

machines.

Warning: Do not open or attempt to repair the DNA Engine or any Alpha

™

unit, or other DNA Engine accessory. Doing so will void your warranties and

can put you at risk for electrical shock. Return the DNA Engine instrument to

the factory (US customers) or an authorized distributor (all other customers) if

repairs are needed.

Warning: All Alpha unit blocks can become hot enough during the course of

normal operation to cause burns or cause liquids to boil explosively. Wear

safety goggles or other eye protection at all times during operation.

Warning: The DNA Engine instruments incorporate neutral fusing, which

means that live power may still be available inside the machines even when a

fuse has blown or been removed. Never open the DNA Engine or DNA Engine

Tetrad base; you could receive a serious electrical shock. Opening the base

will also void your warranties.

Caution: Never remove an Alpha unit from the DNA Engine with the power

turned on and a program running. Doing so can cause electrical arcing that

can melt the contacts in the connector joining the Alpha unit to the DNA

Engine.

Safe Use Guidelines

The DNA Engine instruments are designed to be safe to operate under the following

conditions:

• Indoor use

• Altitude up to 2000 m

• Ambient temperature 5–31°C

• Maximum relative humidity 90%, noncondensing

• Transient overvoltage per Installation Category II, IEC 664

• Pollution degree 2, in accordance with IEC 664

Electromagnetic Interference

These devices comply with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) these devices may not cause harmful interference, and (2) these devices

must accept any interference received, including interference that may cause undesired

operation.

These devices have been tested and found to comply with the EMC standards for emissions and susceptibility established by the European Union at time of manufacture.

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

LE PRESENT APPAREIL NUMERIQUE N’EMET PAS DE BRUITS RADIOELECTRIQUES

DEPASSANT LES LIMITES APPLICABLES AUX APPAREILS NUMERIQUES DE CLASS A

PRESCRITES DANS LE REGLEMENT SUR LE BROUILLAGE RADIOELECTRIQUE

EDICTE PAR LE MINISTERE DES COMMUNICATIONS DU CANADA.

FCC Warning

Warning: Changes or modifications to these units not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

This equipment qualifies as an “Exempted device” under Section 15.103(c) of the FCC Rules.

Nonetheless, the design has been verified to comply within limits for Class “A” digital device.

Note: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radiofrequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

Tech Support: 1-800-4BIORAD • 1-800-424-6723• www.bio-rad.com v

vi Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

Documentation Conventions

Typographic Conventions

The names of keyboard keys are set in double angle brackets:

Example «Proceed»

Items in programming menus are italicized:

Example Select Edit from the Main Menu.

Graphic Conventions

The programming screens displayed in the LCD window are represented by a box

containing four lines of text:

Example

Terminology

A programming option is termed “selected” when the cursor is positioned in front of it.

Use the «Select» keys (see fig. 2-2) to move the cursor. In some screens selected items

are also displayed in all-capital letters.

Run: 2-STEP

1= 92.0 for 0:05

Cycle: 1

Calc: 65.0

1-1

Introduction

1

Meet the DNA Engine Thermal Cycler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

DNA Engine Operations Manual

1-2 Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

Meet the DNA Engine®Thermal Cycler

Thank you for purchasing a Bio-Rad PTC-0200 DNA Engine thermal cycler. Designed

by a team of molecular biologists and engineers, the DNA Engine will meet your

needs for a versatile, easy-to-use, reliable, and compact programmable thermal

cycler.

• Interchangeable sample blocks—the Alpha

™

unit family— that accommodate

many types of tubes, microplates, and slides

• Hot Bonnet

®

heated lid (or its remote-controlled version, the motorized Moto

Alpha

™

Moto Alpha unit) for oil-free cycling

• Intuitive software with easy-to-read interface for quick and painless programming,

editing, file management, password protection, and much more

• Choice of calculated sample temperature control for highest speed and accuracy, or

block control for compatibility with protocols designed for a variety of instrument types

• Space-saving design for easy setup and transportation

• Instant Incubate feature for continuous-temperature incubations

• Networking of up to 15 machines, for convenient remote operation and documentation

of runs

• Customizable factory-installed protocols

Using This Manual

This manual contains all the information you need to operate your DNA Engine safely

and productively:

• Chapter 2 acquaints you with the physical characteristics of the DNA Engine.

• Chapters 3–5 present the basics of installing and operating the DNA Engine.

• Chapters 6 and 7 describe programming the DNA Engine.

• Chapter 8 outlines the utilities available for the DNA Engine.

• Chapter 9 describes how to network and remotely operate the DNA Engine.

• Chapter 10 explains the proper maintenance of the DNA Engine.

• Chapter 11 offers troubleshooting information for the DNA Engine.

Introduction

Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com 1-3

Important Safety Information

Safe operation of the DNA Engine begins with a complete understanding of how the

machine works. Please read this entire manual before attempting to operate the DNA

Engine. Do not allow anyone who has not read this manual to operate the machine.

The DNA Engine can generate enough heat to inflict serious burns and can deliver

strong electrical shocks if not used according to the instructions in this manual. Please

read the safety warnings and guidelines at the front of this manual, and exercise all precautions outlined in them.

2-1

Layout and Specifications

2

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Back View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Bottom View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Alpha Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Single-Block Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Dual-Block Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Slide Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Moto Alpha Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Gradient Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

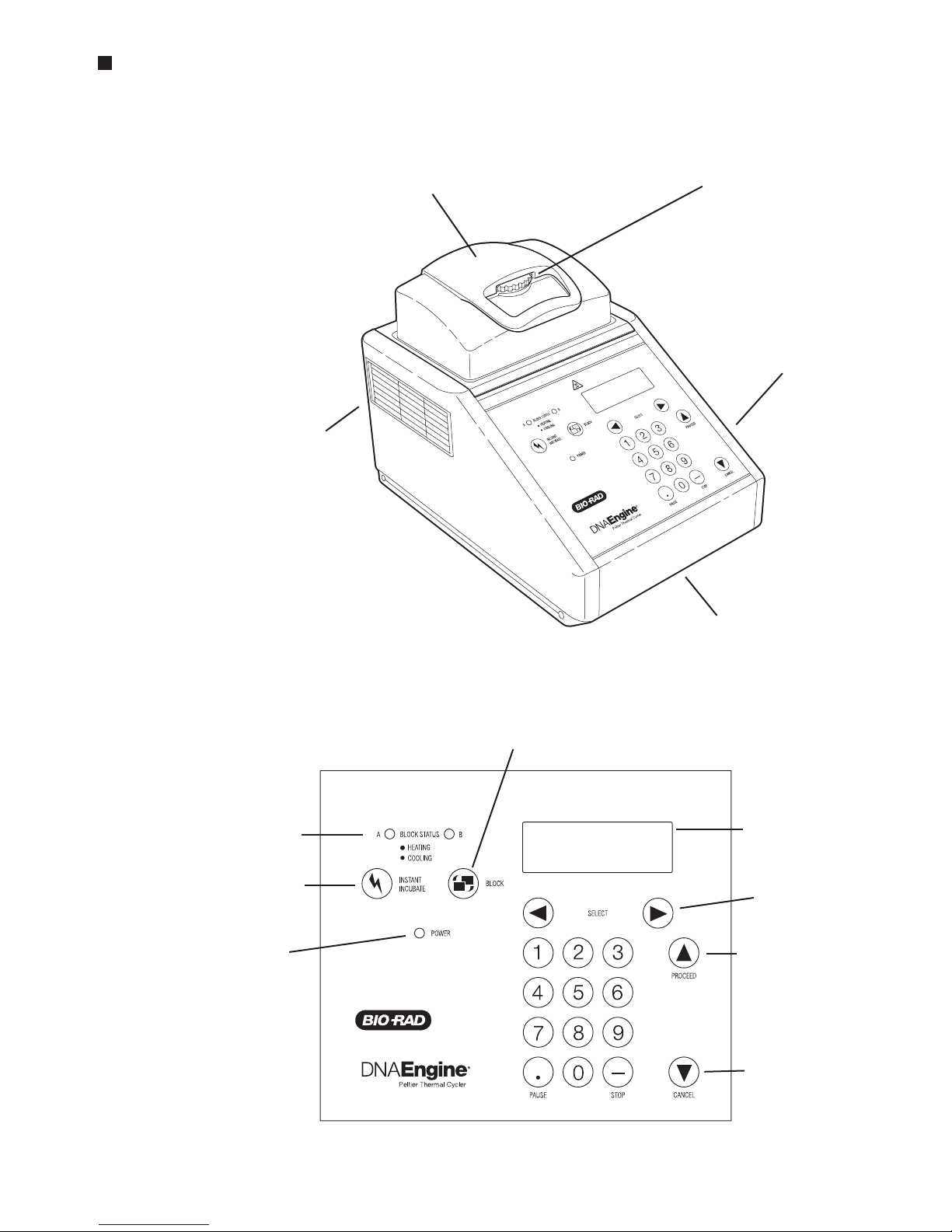

Front View

(Figure 2-1)

Control Panel

(Figure 2-2)

DNA Engine Operations Manual

2-2 Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

Alpha™unit, lid closed

Thumbwheel

Air intake vents

Control panel

Air exhaust vents

(also on other side)

Block status lights

Instant incubation key

Power light

Block key

LCD window

Left and right

selection keys

Proceed key

Cancel key

Layout and Specifications

Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com 2-3

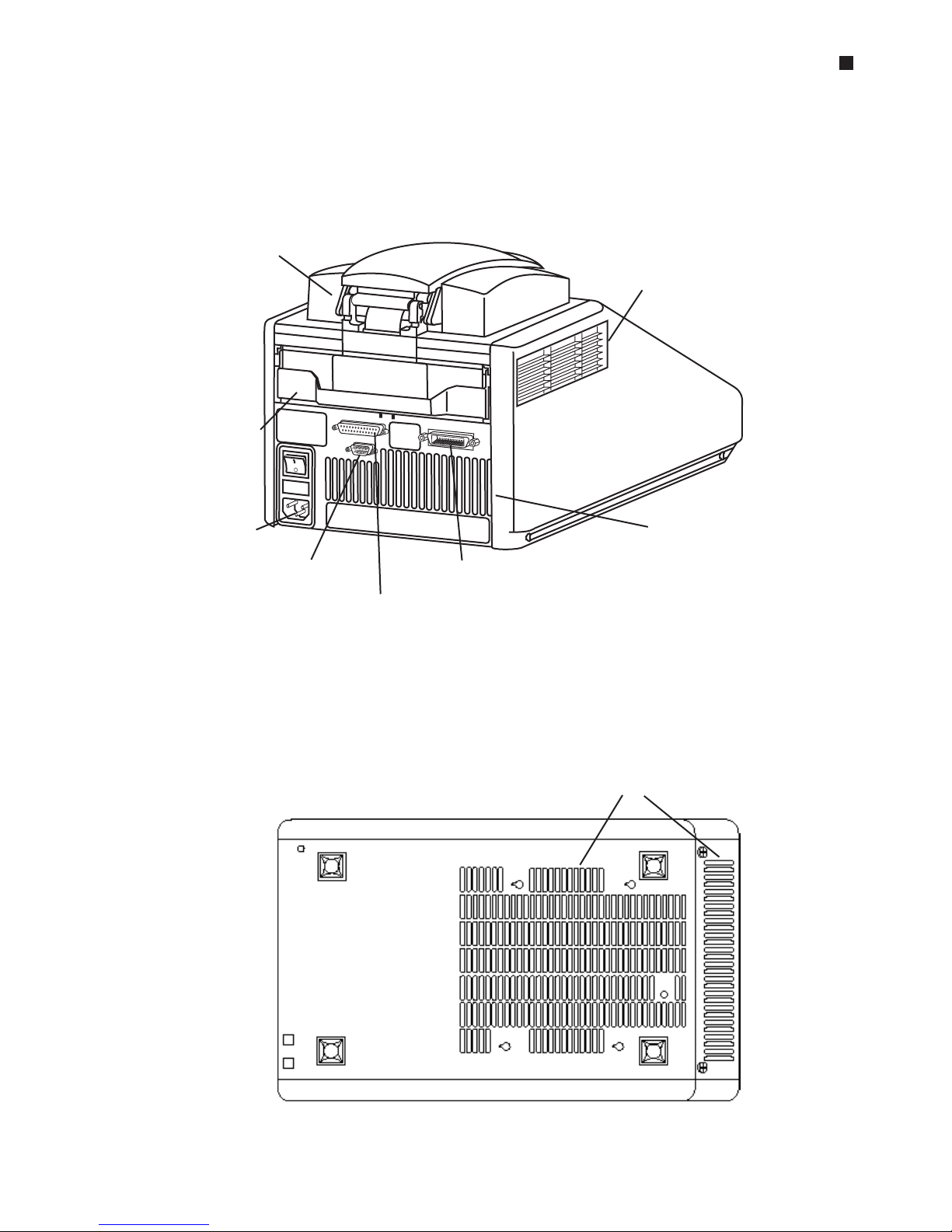

Back View

(Figure 2-3)

Bottom View

(Figure 2-4)

Air exhaust vents

(also on other side)

Alpha unit

Air intake vents

Alpha unit handle

Power cord jack

RS-232 port IEEE-488 port

Parallel printer port

Back

Front

Air intake vents

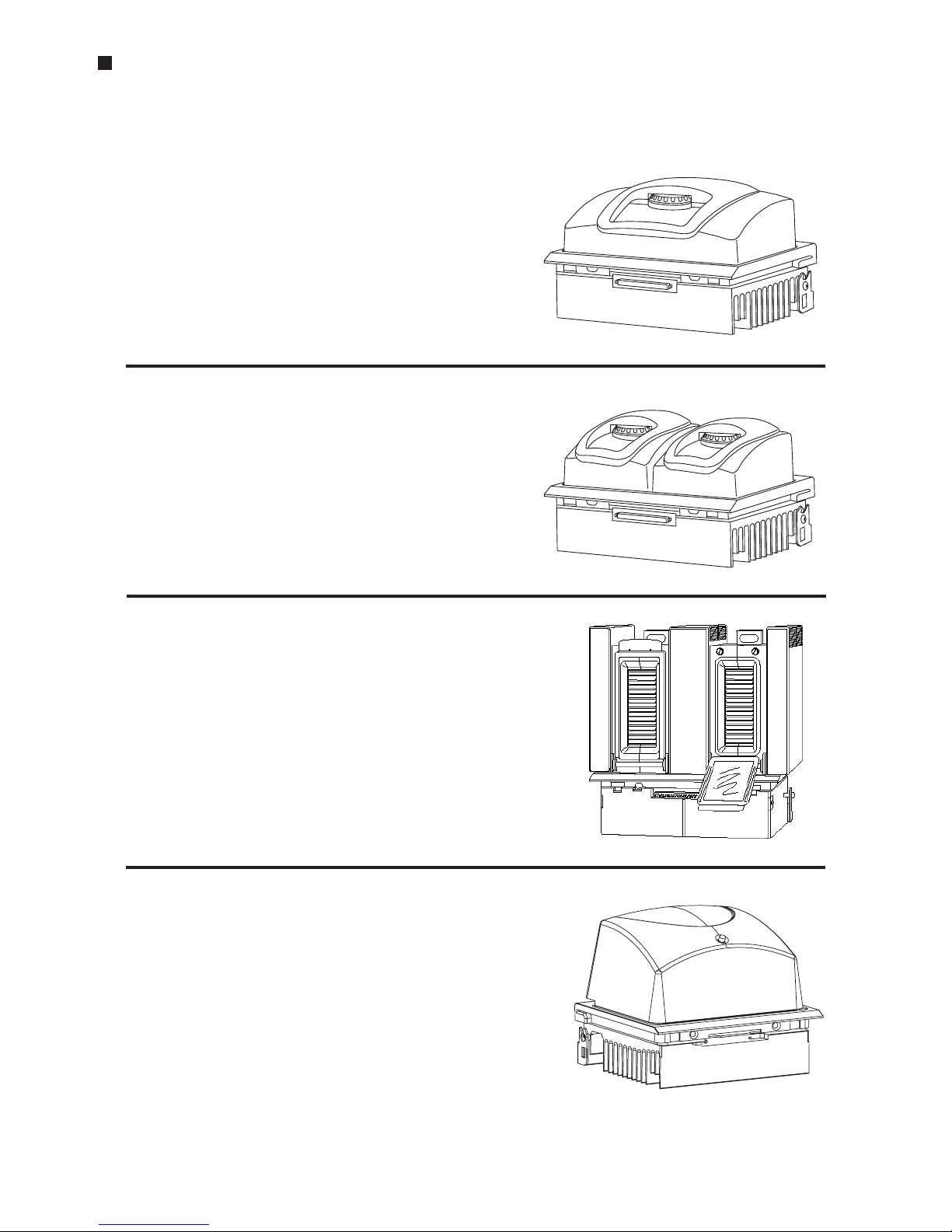

Alpha Units

Single-Block Models

60V Alpha unit: Holds 60 x 0.5 ml tubes

96V Alpha unit: Holds 96 x 0.2 ml tubes or

one 96-well microplate

384 Alpha unit: Holds one 384-well

microplate or one 96-well

microplate

Dual-Block Models

30/30 Dual Alpha

™

Holds 2 x 30 x 0.5

unit: ml tubes

30/48 Dual Alpha unit: Holds 1 x 30 x 0.5 ml

tubes and 1 x 48 x

0.2 ml tubes

48/48 Dual Alpha unit: Holds 2 x 48 x 0.2 ml

tubes or half plates

Slide Block

Slide Chambers™Alpha unit: Holds 2 x 16

standard slides

Moto Alpha™unit

Permits remote control of Alpha unit lid opening;

available in 96-well, 384-well, and flat-block

formats.

DNA Engine Operations Manual

2-4 Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

Layout and Specifications

Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com 2-5

Specifications

Thermal range: –5° to 105°C, but no more than 30°C below ambient

temperature (4° to 100°C for the Slide Chambers Alpha unit)

Thermal accuracy: ±0.3°C of programmed target at 90°C, NIST-traceable

Thermal uniformity: ±0.4°C well-to-well within 30 seconds of arrival at 90°C

(for most Alpha units; see specifications for individual

Alpha units)

Ramping speed: Up to 3°C/sec for all single- and dual-block Alpha units;

up to 1.2°C/sec for the Slide Chambers Alpha unit.

Sample capacity: Varies with installed Alpha unit

Line voltage: DNA Engine

®

cycler: 100–240 VAC rms (no adjustment

needed among voltages within these ranges)

Frequency: 50–60 Hz single phase

Power: DNA Engine cycler: 850 W maximum

Fuses: Two 6.3 A, 250 V, 5 x 20 mm

Displays: One 20 x 4 LCD alphanumeric display

Ports: One 25-pin 8-bit parallel interface printer port

One 9-pin RS-232 serial port for printer or remote use

One IEEE-488 bidirectional general purpose interface bus

Memory: 400 typical programs in up to 12 individual folders

DNA Engine Operations Manual

2-6 Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

Gradient Specifications (96V Alpha module only)

Accuracy: +0.3°C of programmed target at end columns, 30

seconds after the timer starts for the gradient step,

NIST–traceable

Column uniformity: +0.4°C, well–to–well within column, within 30

seconds of reaching target temperature

Gradient calculator accuracy: +0.4°C of actual well temperature

Lowest programmable temp: 30°C

Highest programmable temp: 105°C

3-1

Installation

3

Packing Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Setting Up the DNA Engine Cycler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Power Supply Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Air Supply Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Ensuring an Adequate Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Ensuring That Air Is Cool Enough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Requirements for Robotics Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

DNA Engine Operations Manual

3-2 Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

Packing Checklist

After unpacking the DNA Engine®cycler, check to see that you have received the following:

• One DNA Engine base

• One Alpha

™

unit (more if additional units were ordered)

• Two spare fuses

• One power cord

• DNA Engine Peltier Thermal Cycler, Operations Manual (this document)

If any of these components are missing or damaged, contact Bio-Rad or the authorized distributor from whom you purchased the DNA Engine cycler to obtain a replacement. Please

save the original packing materials in case you need to return the DNA Engine cycler for

service. See appendix A for warranty information.

Setting Up the DNA Engine Cycler

The DNA Engine cycler requires only minimal assembly: plugging in the power cord and

inserting an Alpha unit. Insert the power cord plug into its jack at the back of the machine

(see fig. 2-3 for location of jack), then plug the cord into an electrical outlet. With the

machine turned off, insert an Alpha unit (see “Installing an Alpha Unit,” chapter 4).

Caution: Do not insert or remove an Alpha unit with the DNA Engine cycler

turned on; electrical arcing can result. Read the safety warning at

the front of this manual regarding electrical safety when inserting or

removing an Alpha unit.

Environmental Requirements

Ensure that the area where the DNA Engine cycler is installed meets the following

conditions, for reasons of safety and performance:

• Nonexplosive environment

• Normal air pressure (altitude below 2000 m)

• Ambient temperature 5–31°C

• Relative humidity up to 90%

• Unobstructed access to air that is 31°C or cooler (see below)

Installation

Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com 3-3

• Protection from excessive heat and accidental spills (Do not place the DNA Engine

cycler near such heat sources as radiators, and protect it from danger of having

water or other fluids splashed on it, which can cause shorting in its electrical circuits.)

Power Supply Requirements

The DNA Engine cycler requires 100–240 VAC, 50–60 Hz, and a grounded outlet. The DNA

Engine cycler can use current in the specified range without adjustment, so there is no

voltage-setting switch.

Power cords for outlets other than the US 120V outlet may be purchased from computer

stores, since they are also used for most desktop computers and printers and meet

international standard IEC-320. The power cord must be rated to carry at least 10 A at

125 V or 250 V, depending on the voltage available in your nation. The quality of the

power cord can be further ensured by making certain it is inscribed with the trademark

of UL, CSA, TUV, VDE, or another national testing agency.

Note: Do not cut the supplied 120 V power cord and attach a different connector.

Use a one-piece molded connector of the type specified above.

Air Supply Requirements

The DNA Engine cycler requires a constant supply of air that is 31°C or cooler in order

to remove heat from the Alpha unit’s heat sink. Air is taken in from vents at the front,

back, and bottom of the machine and exhausted from vents on both sides (see figs. 21, 2-3, and 2-4). If the air supply is inadequate or too hot, the machine can overheat,

causing performance problems, software error messages (particularly “HS Overheating”

and “Slow Block Cycling”), and even automatic shutdowns. Special attention should be

paid to airflow and air temperature in robotics installations of DNA Engine cyclers.

Ensuring an Adequate Air Supply

• Do not block the air intake vents.

Position the DNA Engine cycler at least 10 cm from vertical surfaces and other thermal

cyclers (greater distances may be required; see below). Do not put loose papers under

the machine; they can be sucked into the air intake vents on the bottom of the machine.

• Do not allow dust or debris to collect in the air intake vents.

The bottom air vents are particularly liable to collect dust and debris, sometimes

completely clogging up. Check for dust and debris every few months, and clean the

intake vents as needed. Remove light collections of dust with a soft-bristle brush or damp

cloth. Severe collections of dust and debris should be vacuumed out. Turn the machine

off prior to cleaning or vacuuming air vents.

DNA Engine Operations Manual

3-4 Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

Ensuring That Air Is Cool Enough

• Do not position two or more DNA Engine cyclers (or other thermal cyclers) so that

the hot exhaust air of one blows directly into the air intake vents of another.

• Make sure the DNA Engine cycler receives air that is 31°C or cooler by measuring

the temperature of air entering the machine through its air intake vents.

Place the DNA Engine cycler where you plan to use it, and turn it on. Try to reproduce

what will be typical operating conditions for the machine in that location, particularly

any heat-producing factors (e.g., nearby equipment running, window blinds open,

lights on). Run a typical protocol (e.g., 2-Step) for 30 minutes to warm up the DNA

Engine cycler, then measure the air temperature at the back air intake vents. If more

than one machine is involved, measure the air temperature for each.

If the air intake temperature of any machine is warmer than 31°C, use table 3-1 to

troubleshoot the problem. Some experimentation may be required to determine the

best solution when more than one cause is involved. After taking steps to solve the

problem, verify that the temperature of the air entering the air intake vents has been

lowered, using the procedure outlined above.

Requirements for Robotics Installations

Robotics installations require special attention to airflow and air temperature. Typically in

these installations, DNA Engine cyclers and other thermal cyclers are crowded into a

small area, along with other heat-generating equipment. Overheating can quickly occur

when many of these machines are operating at once, unless preventive measures are

taken.

Follow the procedures described above to ensure adequate airflow and an air intake

temperature of 31°C or cooler. Air intake temperature must be verified by measurement.

Do not use oil to thermally couple sample vessels to the blocks of machines in a robotics

installation. Oil makes plates difficult to remove.

Table 3-1 Troubleshooting Air Supply Problems

Cause Possible Remedies

Air circulation is poor. Provide more space around machine or adjacent room ventilation.

Ambient air temperature is

high.

Adjust air conditioning to lower ambient air temperature.

Machine is in warm part of

room.

Move machine away from, or protect machine from, such heat

sources as radiators, heaters, other equipment, or bright sunlight.

Machines are crowded.

Arrange machines so that warm exhaust air does not enter intake

vents.

4-1

Operation

4

Turning the DNA Engine Cycler On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Understanding the Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Using the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Operation Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Status Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Using the Data Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Operating Alpha Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Installing an Alpha Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Removing an Alpha Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Opening an Alpha Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Closing an Alpha Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Selecting the Correct Sample Vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

0.5ml Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

0.2ml Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Microplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Thin-Walled Vs. Thick-Walled Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Sealing Sample Vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Sealing with Oil or Wax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Sealing with the Hot Bonnet Lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Adjusting the Hot Bonnet Lid’s Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Loading Sample Vessels into the Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Using Oil to Thermally Couple Sample Vessels to the Block . . . . . . . . . . . . . . . .4-10

Appendix 4-A: Tube, Microplate, and Sealing System Selection Chart . . . . . . . . . . .4-11

Appendix 4-B: Safety Warning Regarding Use of

35

S Nucleotides . . . . . . . . . . . . . .4-12

DNA Engine Operations Manual

4-2 Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

Turning the DNA Engine®Cycler On

Move the power switch to “1” (the “On” position). The fan will turn on and the power light

on the keyboard will glow red. In most cases a self-test of the heat pumps will begin

running (see note below). Its progress is tracked on a screen in the LCD window:

This screen disappears in 1 minute. If a problem is detected, the display shows an error

message.

Note: If the Alpha

™

unit’s block or heat sink is not at ambient temperature (typically

because the Alpha unit was recently in use), the machine will skip the self-test.

If the self-test does not detect any problems, the Main Menu is displayed:

The DNA Engine cycler is now ready to execute programs.

Understanding the Main Menu

The Main Menu is the common access point to all programming and machine configuration

screens.

• Run: Executes a program.

• Enter: Allows new programs to be entered.

• List: Accesses utilities that display or print a program’s steps.

• Edit: Allows modification of stored programs.

• Files: Accesses file management utilities.

• Setup: Accesses machine and networking configuration screens.

PTC-200:

Self testing

.

PTC-200:

_RUN Enter

List Edit

Files Setup

Operation

Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com 4-3

Using the Control Panel

The control panel (see fig. 2-2) includes operation keys, status indicator lights, an LCD

window for displaying programming and machine status text, and a numeric keypad

for entering values into programs.

Operation Keys

• Select keys (left and right arrows): Move the cursor one space or option to the left or

right in the LCD window; during a protocol run, display time and cycle information.

• Proceed: Accepts a selected menu or screen option; during a protocol run, advances

the program to its next step.

• Cancel: Terminates a running protocol; during program creation or editing, cancels

the last entry.

• Stop: Terminates a running protocol.

• Pause: Pauses a protocol during execution; accesses Japanese Katakana syllabary.

• Instant Incubate: Initiates a program that sets up the DNA Engine cycler as a

simple incubator.

• Block: Selects a different block when using a Dual Alpha

™

unit; switches between

block screens and the Main Menu in the LCD window during a protocol run.

Status Indicator Lights

• Power light: Glows red when the DNA Engine cycler is powered up.

• Block Status lights: Indicate which blocks are in use; glow red when blocks are

heating and green when blocks are cooling.

Using the Data Ports

The DNA Engine cycler has three data ports located at the rear of the machine: an RS232 port, an IEEE-488 port, and a parallel (printer) port. See chapters 8 and 9 for

information on using these ports to network machines, connect them to a computer, or

print data.

DNA Engine Operations Manual

4-4 Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

Operating Alpha Units

Note: Operation of the Slide Chambers™Alpha unit will not be discussed, owing to

the many differences between this type of Alpha unit and the others. Please see the

Slide Chambers Operations Manual for operating instructions.

Note: Moto Alpha™units are installed and removed as described below. See the

Moto Alpha Unit Operations Manual for instructions on opening and closing Moto

Alpha units.

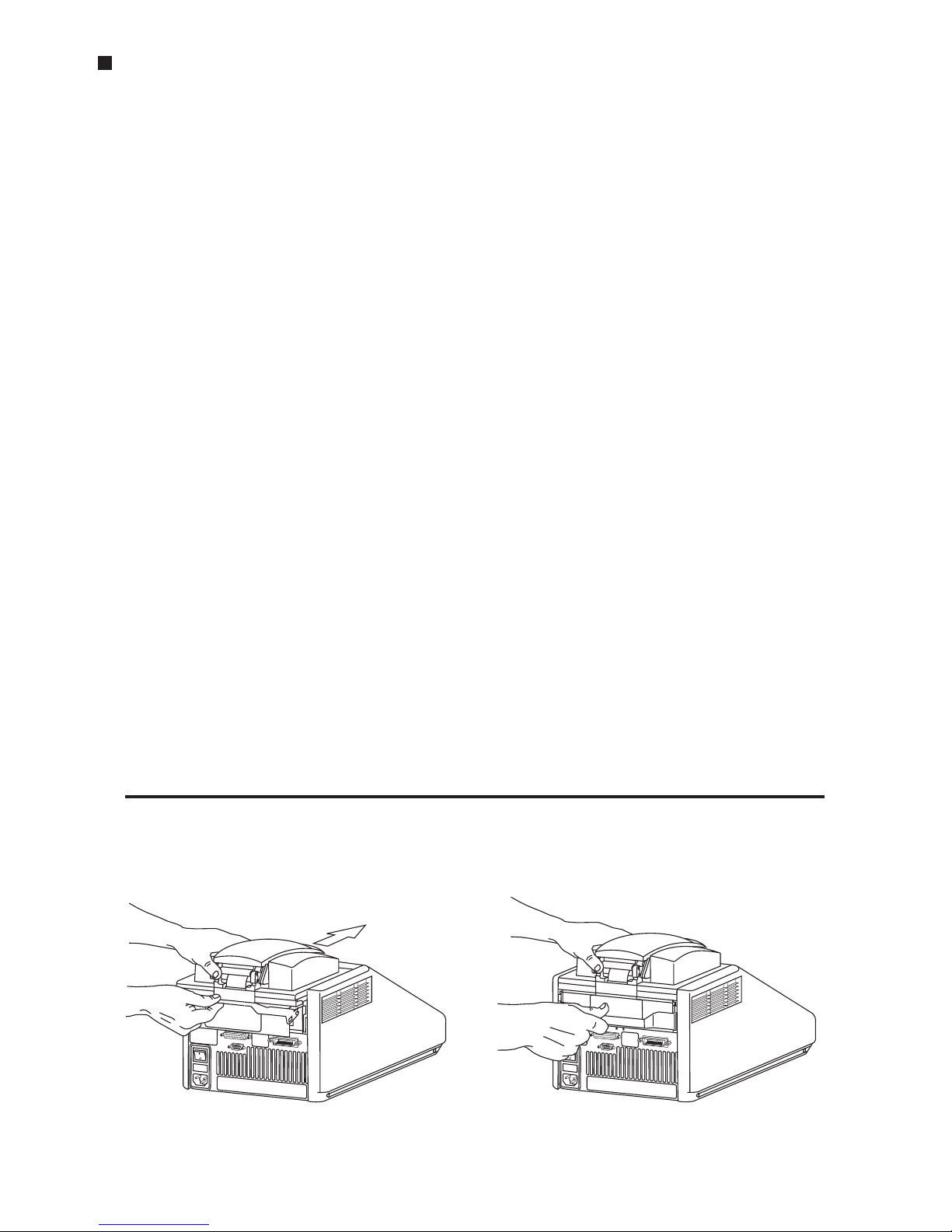

Installing an Alpha Unit

1. Turn the DNA Engine cycler off (see the Caution on p. 4-5).

2. Hold the Alpha unit at its front and back edges.

3. Lower the Alpha unit into the DNA Engine base, leaving at least 3cm between the

front edge of the Alpha unit and the front of the base.

4. Raise the handle at the back of the Alpha unit, and slide the block forward as far

as it will go (fig. 4-1A).

5. Push the handle down until it is completely vertical (fig. 4-1B); firm pressure may

be required. A definite click signals that the Alpha unit’s connectors have mated

with the DNA Engine cycler’s connectors.

When the handle is in the down position, the Alpha unit is locked into place.

Figure 4-1 Installing an Alpha unit.

A

B

Operation

Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com 4-5

Removing an Alpha Unit

1. Turn the DNA Engine cycler off (see the Caution below).

2. Pull upward on the handle. When the lock releases, you will hear a click, and the

Alpha unit will slide a little toward the back of the DNA Engine cycler. The electrical connectors of the Alpha unit and the DNA Engine cycler are now

disengaged, so there is no danger of electrical shock.

3. Slide the Alpha unit toward the rear of the DNA Engine cycler about 3 cm.

4. Grasp the front and back edges of the Alpha unit, and lift it out of the machine.

Caution: Do not insert or remove an Alpha unit with the DNA Engine

cycler turned on; electrical arcing can result. Read the safety

warning at the front of this manual regarding electrical safety

when inserting or removing an Alpha unit.

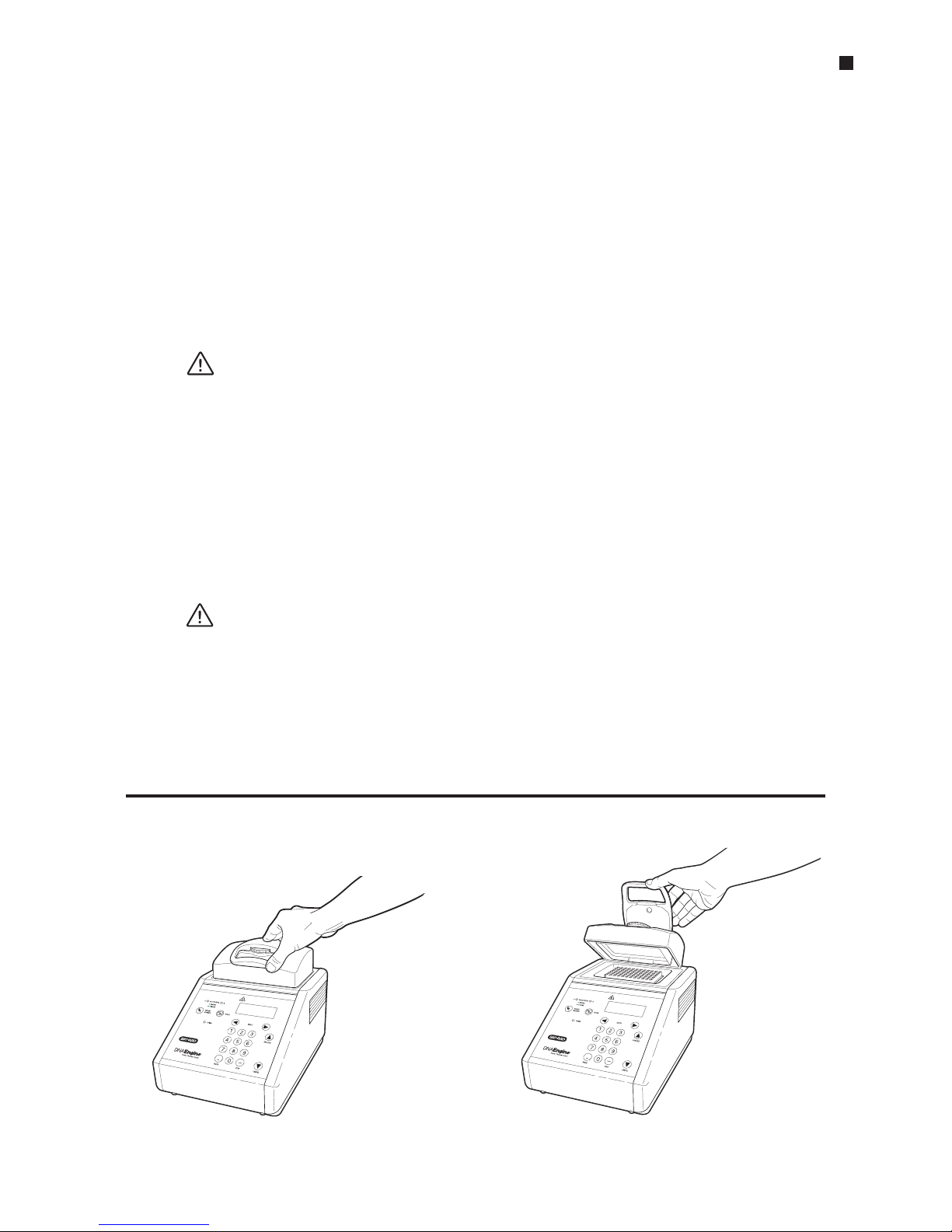

Opening an Alpha Unit

Grip the front edge of the top lever of the Hot Bonnet®lid as shown in figure 4-2A,

and pull upward firmly. The top lever will pop open to reveal the entire thumbwheel

(fig. 4-2B). Continue pulling upward to open the Hot Bonnet lid. The Hot Bonnet lid

will tip backward, revealing the entire block.

Caution: Do not pull on the thumbwheel to open the unit. This can

damage the Hot Bonnet lid’s closing mechanism.

Closing an Alpha Unit

Press down on the top lever. The lever will close down over the thumbwheel as the

Hot Bonnet lid closes down over the sample block. A click signifies that the

Hot Bonnet lid’s latch has engaged.

Figure 4-2 Opening an Alpha unit.

A

B

DNA Engine Operations Manual

4-6 Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

Selecting the Correct Sample Vessel

The DNA Engine cycler’s wide variety of interchangeable Alpha units affords you great

scope in choosing sample vessels. Keep in mind that differences in tube and plate composition and wall thickness among the many brands available can affect reaction

performance. Protocols may require some adjustment to ensure optimum performance

when using a new vessel type. Bio-Rad offers a full range of tubes and microplates, manufactured to the specifications of each type of Alpha unit to ensure a precise fit. See

chapter appendix 4-A for a complete list.

0.5 ml Tubes

Make sure thick-walled 0.5 ml tubes fit the wells snugly. Since these tubes were originally

designed for centrifuges, some brands may not fit tightly in thermal cycler wells. Thin-walled

0.5 ml tubes were specifically designed for thermal cycling, and the higher quality brands

provide a good and consistent fit. Bio-Rad provides thin- and thick-walled 0.5 ml tubes

designed for precise block fit.

0.2 ml Tubes

All types of thin-walled 0.2 ml tubes may be used. Bio-Rad sells high-quality 0.2 ml

tubes in a number of styles, including individual tubes and strips.

Microplates

A variety of 96-well polycarbonate or polypropylene microplates can be used in 96-well

Alpha units as long as they fit the wells snugly. Polypropylene microplates are usually

preferred because they exhibit very low protein binding and, unlike polycarbonate

microplates, do not lose water vapor through the vessel walls. This allows smaller

sample volumes to be used — as little as 5–10 µl. Polypropylene microplates and compatible sealing systems are available from Bio-Rad. (See “Sealing Sample Vessels” on

the next page for a description of available sealing systems from Bio-Rad.)

Thin-Walled Vs. Thick-Walled Tubes

The thickness of sample tubes directly affects the speed of sample heating and thus

the amount of time required for incubations. Thick-walled tubes delay sample heating,

since heat transfers more slowly through the tubes’ walls. For the earliest types of

thermal cyclers this delay mattered little. These machines’ ramping rates were so slow

(below 1°C/sec) that there was plenty of time for heat to transfer through the tube wall

to the sample, during a given incubation.

Modern thermal cyclers have much faster ramping rates (up to 2–3°C/sec), so the faster

heat transfer provided by thin-walled tubes allows protocols to be significantly shortened. On average, about 30 seconds can be saved per cycle by using thin-walled

tubes, for an overall savings of 15 minutes in a 30-cycle run.

Operation

Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com 4-7

Sealing Sample Vessels

To avoid changing the concentration of reactants, steps must be taken to prevent the

evaporation of water from reaction mixtures during thermal cycling. Only a layer of oil

or wax will completely prevent evaporation from the surface of the reaction fluid.

However, an adequate degree of protection can be achieved by sealing vessels with

caps, film, adhesive seals, or mats, then cycling the samples using the heated lid to

prevent condensation.

Sealing with Oil or Wax

Mineral oil, silicone oil, paraffin wax, or Chill-out™liquid wax may be used to seal samples.

Use only a small amount of oil or wax; 1–3 drops (15–50µl) are usually sufficient. (Include

this volume in the total volume when setting up a calculated-control protocol; see

“Choosing a Temperature Control Mode” in Chapter 5.) Use the same amount of oil or

wax in all sample vessels to ensure a uniform thermal profile.

Most paraffin waxes solidify at room temperature. The wax can then be pierced with a

micropipette and the samples drawn off from below the wax. Silicone oil and mineral oil

can be poured off or aspirated from tubes if the samples are first frozen (–15° to –20°C).

The samples are usually pure enough for analysis without an extraction.

Chill-out liquid wax (available from Bio-Rad) is an easy-to-use alternative to oil. This purified paraffinic oil solidifies at 10°C and is liquid at room temperature. By programming a

hold at low temperature, the wax can be solidified at the end of a run. A pipette tip can

then be used to pierce the wax in the tubes and remove the samples. The wax is available

in a clear, optical-assay grade or dyed red to assist in monitoring its use. The red dye has

no adverse effects on fluorescent gel analysis of reaction products.

Sealing with the Hot Bonnet Lid

The Hot Bonnet lid’s heated inner surface maintains the air in the upper part of

sample vessels at a higher temperature than the reaction mixture. This prevents condensation of evaporated water vapor onto the vessel walls and lid, so that solution

concentrations are unchanged by thermal cycling. The Hot Bonnet lid also exerts

pressure on the tops of vessels loaded into the block, helping to maintain a vaportight seal and to firmly seat tubes or the plate in the block.

Caps, film, adhesive seals, or mats must be used along with the Hot Bonnet lid to prevent

evaporative losses.

Note: When tubes are cooled to below-ambient temperatures, a ring of condensation

may form in tubes above the liquid level but below the top of the sample block. This

is not a cause for concern since it occurs only at the final cool-down step, when

thermal cycling is complete.

DNA Engine Operations Manual

4-8 Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com

Microseal®‘A’ film offers a quick alternative to sealing microplates or arrays of tube

strips. This film is specially designed to seal tightly during cycling, yet release smoothly

to minimize the risk of aerosol formation and cross-contamination of samples.

Microseal ‘A’ film is easily cut for use with fewer than 96 samples.

Microseal ‘B’ adhesive seals feature an aggressive adhesive, effective from –20°C to

110°C, which allows secure sample storage or transport before and after cycling. The

clear polyester backing allows easy inspection of sample wells. Microseal ‘B’ clear,

adhesive seals are ideal for thermal cycling in all polypropylene and polystyrene

microplates.

Microseal ‘F’ aluminized foil acts as a barrier against evaporation from –20°C to 105°C.

It is thin enough to pierce with a pipet tip for recovery of sample from individual wells.

96-well PCR plate sealing mats (223-9442) are an economical means to seal 96-well

microplates. An array of 96 dimples on the mat helps orient it on the microplate and prevents the mat from sticking to the heated lid. The mats may be cleaned with sodium

hypochlorite (bleach) for reuse, and they are autoclavable.

Microseal ‘P’/’P+’ pads are designed for use in applications such as cycle sequencing, in

which several successive runs may be sealed with the same pad. Use ‘P’ pads with the

original version of Power Bonnet

™

lids (ALP-1296 and ALP-1238) and use ‘P+’ pads with

the newer-design Moto Alpha

™

units (ALP-2296, ALP- 2238, ALP-2200, and ALP-2201).

Adjusting the Hot Bonnet Lid’s Pressure

The pressure exerted by the inner lid of the Hot Bonnet lid must be manually adjusted

to fit the sample vessels being used in a given reaction. Once set, the Hot Bonnet lid

can be opened and closed repeatedly without readjustment as long as neither the

tube or microplate type nor the sealing method changes. Any change in vessel type

or sealing method requires readjustment of the Hot Bonnet lid.

Follow these steps to adjust the pressure exerted by the Hot Bonnet inner lid:

1. Make sure the block’s wells are clean. Even tiny amounts of extraneous material

can interfere with the proper seating of a microplate or tubes, which would prevent

the inner lid from exerting uniform pressure on the loaded microplate or tubes.

2. Open the Hot Bonnet lid. Turn the green thumbwheel all the way counterclockwise to completely raise the inner lid.

3. Load either a microplate or at least eight individual tubes into the sample block. The

inner lid pivots around a central point, so it is important to distribute individual tubes

evenly. Load at least four tubes in the center of the block and at least one tube in

each of the four corners of the block. If using a sealing film or mat, apply it to the

loaded microplate according to the manufacturer’s directions.

Operation

Tech Support: 1-800-4BIORAD • 1-800-424-6723 • www.bio-rad.com 4-9

4. Close the Hot Bonnet lid by pressing down on the top lever. Turn the thumbwheel

clockwise to lower the Hot Bonnet inner lid onto the loaded microplate/tubes. The

thumbwheel turns easily at first since the inner lid has not yet come into contact

with anything. Stop turning the thumbwheel when you feel increased resistance,

which indicates that the inner lid has touched the microplate/tubes.

5. Open the Hot Bonnet lid. Turn the thumbwheel clockwise an extra half to three-quarters of a turn to set an appropriate lid pressure.

Caution: Do not turn the thumbwheel more than three-quarters of a

turn. This can make it hard or impossible to close the lid and

puts excessive strain on the latch holding the lid closed.

An extra half to three-quarters of a turn ensures the correct pressure for most types of

reaction vessels. Some empirical testing may be required to determine the optimum

pressure required for certain vessels. Once this pressure has been determined, the

thumbwheel position that delivers it may be marked with a colored marking pen or

piece of tape.

Note: As an aid in gauging how much the thumbwheel has been turned, mark it at

the quarter turn positions, or every sixth bump on the thumbwheel (there are 24 total

bumps).

6. Close the Hot Bonnet lid.

Loading Sample Vessels into the Block

When using a small number of tubes, they should all be placed in the center of the block,

to ensure uniform thermal cycling of all samples. Also load at least one empty tube in

each corner of the block, to ensure that the Hot Bonnet lid exerts even pressure on the

sample tubes (see “Adjusting the Hot Bonnet Lid Pressure,” above).

To ensure uniform heating and cooling of samples, sample vessels must be in complete

contact with the block. Adequate contact is ensured by always doing the following:

• Ensure that the block is clean before loading samples. (See chapter 10 for

cleaning instructions.)

• Firmly press individual tubes or the microplate into the block wells.

Loading...

Loading...