Page 1

ProteinChip®OQ Kit

Instruction Manual and

Documentation

Catalog #C70-00080

For technical support call your local Bio-Rad office, or in the US, call 1-800-4BIORAD (1-800-424-6723)

For use with the ProteinChip SELDI system, Personal or Enterprise Edition,

with embedded system processor (ESP) version 1.1.15 or higher

Page 2

Notices

No part of this publication may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopy, recording, or any information storage or retrieval

system, without permission in writing from Bio-Rad.

Bio-Rad reserves the right to modify its products and services at any time. This user guide is

subject to change without notice.

Although prepared to ensure accuracy, Bio-Rad assumes no liability for errors or for any damages

resulting from the application or use of this information.

ProteinChip is a trademark of Bio-Rad Laboratories. Microsoft and Excel are trademarks of

Microsoft Corporation.

The SELDI process is covered by U.S. patents 5,719,060, 6,225,047, 6,579,719, and 6,818,411

and other issued patents and pending applications in the U.S. and other jurisdictions.

Copyright

©

2007 by Bio-Rad Laboratories. All rights reserved.

Page 3

Table of Contents

Chapter 1 Introduction ............................................................................................1

1.1 Product and Protocol Description........................................................................1

1.2 Storage and Handling..........................................................................................2

Chapter 2 Use of the ProteinChip®OQ Kit ............................................................4

2.1 Overview..............................................................................................................4

2.2 File and Protocol Setup .......................................................................................5

2.3 OQ Maintenance Procedures..............................................................................9

2.3.1 Maintenance Procedure 1 — High Voltage (HV) Conditioning ..............9

2.3.2 Maintenance Procedure 2 — Detector Calibration ................................9

2.4 OQ Tests............................................................................................................12

2.4.1 Test 1 — Detector Sensitivity ...............................................................12

2.4.2 Test 2 — Mass Drift and Resolution at 5.96 kD...................................15

2.4.3 Test 3 — Mass Resolution at 1 kD.......................................................19

2.4.4 Test 4 — Mass Accuracy .....................................................................22

Appendix A Installation Qualification (IQ) Certificate ...........................................29

Appendix B Protocol Acceptance Form .................................................................30

Appendix C Data Export Procedure........................................................................31

i

Page 4

Chapter 1

Introduction

Qualification of analytical instruments is a formal process of documenting that an instrument is

fit for its intended use and that it is maintained and calibrated.

• Installation qualification (IQ) checks that the correct system or instrument was received and

that it was properly installed. IQ is performed by a Bio-Rad service engineer following

installation of the ProteinChip®SELDI system. The engineer will provide an IQ certificate

upon completion (see Appendix A for an example of this certificate. If you do not have a

copy of this certificate, contact technical support). IQ should also be performed by a service

engineer when the ProteinChip SELDI system is moved to a new location and when the

software is upgraded.

• Operational qualification (OQ) demonstrates that the ProteinChip SELDI system operates in

accordance with Bio-Rad’s requirements. The ProteinChip SELDI OQ kit is used to qualify

the installation and operation of the ProteinChip SELDI system, Personal or Enterprise

Edition. Bio-Rad recommends that the OQ protocols be performed in total upon installation

(following IQ), on a regular basis to confirm that the system is performing to specifications,

and whenever it is suspected that the instrument is not performing to specifications.

For audit review, maintain records of IQ and OQ of the ProteinChip SELDI system in a single

notebook or folder.

1.1 Product and Protocol Description

The ProteinChip OQ kit contains all the ProteinChip arrays and instrument protocols required to

perform OQ on a ProteinChip SELDI system, Personal or Enterprise Edition. The kit is designed

to qualify the operating specifications of the ProteinChip instrument and is a valuable tool that

allows discrimination between assay and instrumentation problems.

The components of each ProteinChip OQ kit support maintenance and testing for a three month

period. Each kit contains the following:

1 CD containing the OQ instrument protocols and the ProteinChip SELDI OQ form

2 ProteinChip detector calibration arrays

6 ProteinChip detector qualification arrays

2 ProteinChip peptide standard arrays

1 ProteinChip OQ kit instruction manual

The OQ protocol involves two maintenance procedures (detector calibration and high voltage

conditioning) followed by a series of four tests of instrument resolution, mass accuracy and drift,

and sensitivity (Table 1).

1

Page 5

Completion of each maintenance procedure and test is tracked using the ProteinChip SELDI OQ

form, a Microsoft Excel spreadsheet supplied on the CD. Test data are exported to the

ProteinChip SELDI OQ form, which then calculates whether the test passed or failed.

Upon completion of the OQ procedure, save, print, sign, date, and place copies of the following

documentation into a notebook or folder for audit review:

• Protocol acceptance page (Appendix B)

• ProteinChip SELDI OQ form summary

Table 1. Summary of procedures and tests.

RReeccoommmmeennddeedd CCoonnssuummaabbllee EEssttiimmaatteedd TTiimmee

TTiittllee FFrreeqquueennccyy UUsseedd RReeqquuiirreedd DDeessccrriippttiioonn

File and protocol

IInniittiiaall SSeettuupp

setup 20 min Complete this procedure the

first time you use the

ProteinChip OQ kit. This

procedure creates the

file structure necessary for

storing the protocols and creates

the routines for high voltage

conditioning and mass calibration.

MMaaiinntteennaannccee

High voltage Weekly N/A 1–2 hr HV conditioning helps to

PPrroocceedduurree 11

(HV) depending on decontaminate the surfaces

conditioning instrument in the instrument.

MMaaiinntteennaannccee

Detector Weekly ProteinChip 45 min to 4 hr This procedure uses the

PPrroocceedduurree 22

calibration detector depending on ProteinChip detector

calibration instrument calibration array to adjust

array the detector voltage. These

adjustments are based on a

rolling average that stabilizes

the gain, improving spectral

reproducibility over the lifetime

of the detector.

TTeesstt 11

Detector Biweekly ProteinChip 30 min to 1 hr This test uses the ProteinChip

sensitivity detector detector calibration array to

qualification measure the signal-to-noise

array ratio (S/N) of immunoglobubulin

(IgG) at two different

concentrations (10 fmol and

140 fmol). Measurements are

compared to a specification, and

a pass/fail disposition is

obtained.

2

Page 6

Table 1. Summary of procedures and tests (

continued).

RReeccoommmmeennddeedd CCoonnssuummaabbllee EEssttiimmaatteedd TTiimmee

TTeesstt FFrreeqquueennccyy UUsseedd RReeqquuiirreedd DDeessccrriippttiioonn

TTeesstt 22

Mass drift and Weekly ProteinChip 20 min to 1 hr This test uses the ProteinChip

resolution at peptide peptide standard array to

5.96 kD standard array measure the mass drift and

resolution of insulin. These

measurements are compared to a

specification, and a pass/fail

disposition is obtained.

TTeesstt 33

Resolution at Weekly ProteinChip 20 min to 1 hr This test uses the ProteinChip

1 kD peptide peptide standard array to

standard array measure the resolution of

Arg-vasopressin. These

measurements are compared to

a specification, and a pass/fail

disposition is obtained. The test

is run in higher-resolution

(lower source voltage) mode.

TTeesstt 44

Mass Weekly ProteinChip 30 min to 1 hr This test evaluates the mass

accuracy peptide accuracy when compared to

standard internal and external

array calibrations. These measurements

are compared to a specification,

and a pass/fail disposition is

obtained.

1.2 Storage and Handling

Store the arrays supplied in the kit in the original packaging at room temperature and in a dry

and dark location. Each array is individually wrapped. Do not open the array packaging until

ready to use. Take care when handling the ProteinChip arrays to avoid contaminating or disturbing

the matrix crystals on the surface of the arrays.

3

Page 7

Chapter 2

Use of the ProteinChip OQ Kit

2.1 Overview

This chapter outlines the protocols used to perform the procedures and tests that comprise the

ProteinChip OQ kit. Please note the following:

• Export data acquired during testing to the ProteinChip SELDI OQ form using the export

instructions described in Appendix C

• Protocol transfer from the CD to ProteinChip data manager software needs only to occur

once; however, new files must be created each time a test is run

• Neither spreadsheets nor protocols are write-protected. Overwriting may result in erroneous

results and calculations

• Always perform the two maintenance procedures before running any of the tests

• Maintenance procedure 2 (detector calibration) is designed to standardize and stabilize

detector performance over time, by resetting any drift in the response due to natural component

aging. First or delayed use of this procedure may alter system response after calibration. Do

not run this procedure within a series of related experiments if it has been more than two

weeks since the last detector calibration

• All tests require peak measurements that are compared to specification. Incorrect peak

selection may lead to erroneous results. While selecting peaks for measurement, zoom in on

them so that they resemble the peaks in the examples provided

• When running single ProteinChip arrays on the ProteinChip instrument, Enterprise Edition,

always fill empty locations in the cassette with blank, expired, or used arrays. Blank arrays

are available as components of the ProteinChip cassette-compatible bioprocessor (catalog

#C50-30011)

• The ProteinChip detector calibration array and ProteinChip peptide standard array can be

used multiple times. After opening, store these arrays in a dry and dark place and in their

original packaging

• When running protocols, you specify how many sections (partitions) the spot is divided into

for sampling. You also specify which of these partitions should be used. For spectra intended

for analysis, no more than four ("of 4") partitions should be used, with 10 shots/pixel

4

Page 8

2.2 File and Protocol Setup

Complete this procedure the first time you run the ProteinChip OQ kit. This procedure sets up

the file structure necessary for storing the protocols and creates the routines for high voltage

conditioning (procedure 1) and mass accuracy (test 4).

Task

Step 1

Import Protocols

From CD

Step 2

Create the File

Structure

Note: Create new folders each

time the OQ tests are run. The

instructions in this manual

assume you are following the

convention described here.

However, any file structure and

naming convention may be

used.

5

Import the protocols supplied on the CD into the Protocols folder of ProteinChip

data manager software:

1. Insert the CD into the computer and launch ProteinChip data manager

software.

2. Select Protocols > Protocols > Import Protocols.

3. Use the Import Protocols dialog to import all protocols (files with a .ptx

extension) from the CD to the Protocols folder.

Note: The protocols are NOT write-protected. Do not alter them.

Create a new folder for each test (1–4) to be run:

1. In the Explorer pane of ProteinChip data manager software, open the

Projects folder and select File > New > Folder.

2. Create a folder,

OQ_####,

where

####

is the serial number of the instrument.

3. Click on this folder and select File > New > Folder. Create a separate folder

for the date of the test.

4. Click on the folder created in step 3 and select File > New > Folder.

Create a separate folder for each of the following tests:

• Test 1 Detector sensitivity

• Test 2 Mass drift and resolution 5.96 kD

• Test 3 Resolution 1 kD

• Test 4 Mass accuracy

Page 9

Step 3

Set Up the

High Voltage (HV)

Conditioning Routine

6

1. Insert a blank ProteinChip array into the reader. If blank arrays are not

available, use expired arrays or arrays that have already been used.

a. For the Enterprise Edition instrument: place a cassette filled with

12 blank or used arrays into the instrument.

b. For the Personal Edition instrument: insert a blank ProteinChip

array.

2. In ProteinChip data manager software, select the instrument and click Start.

3. In the Protocol Mode tab, select Instrument > Quick Run.

4. Select all 8 spots, then set up a Quick Run protocol as shown below:

a. For the Enterprise Edition instrument:

RC3 HV pos 15 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 20 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 25 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 30 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV neg 15 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV neg 20 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV neg 25 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV neg 30 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 15 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 20 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 25 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 30 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 25 kV conditioning, partition 1 of 8, all 8 spots

b. For the Personal Edition instrument:

RC3 HV pos 15 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 20 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 25 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 30 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 15 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 20 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 25 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 30 kV conditioning, partition 1 of 8, all 8 spots

RC3 HV pos 25 kV conditioning, partition 1 of 8, all 8 spots

5. Click Save in the Quick Run dialog, and save the protocol as

SoftHV

in the

Quick Run directory (C:\\XXXXXXX). The Quick Run directory location is

defined by the user. The default location, "My Documents", will work as

well as any other location that is easy to remember.

Page 10

Step 4

Create a Standard

Mass Calibration

Routine

7

6. In the Explorer pane of ProteinChip data manager software, select Projects

and click on any spectrum file (for example, the spectrum obtained during

installation).

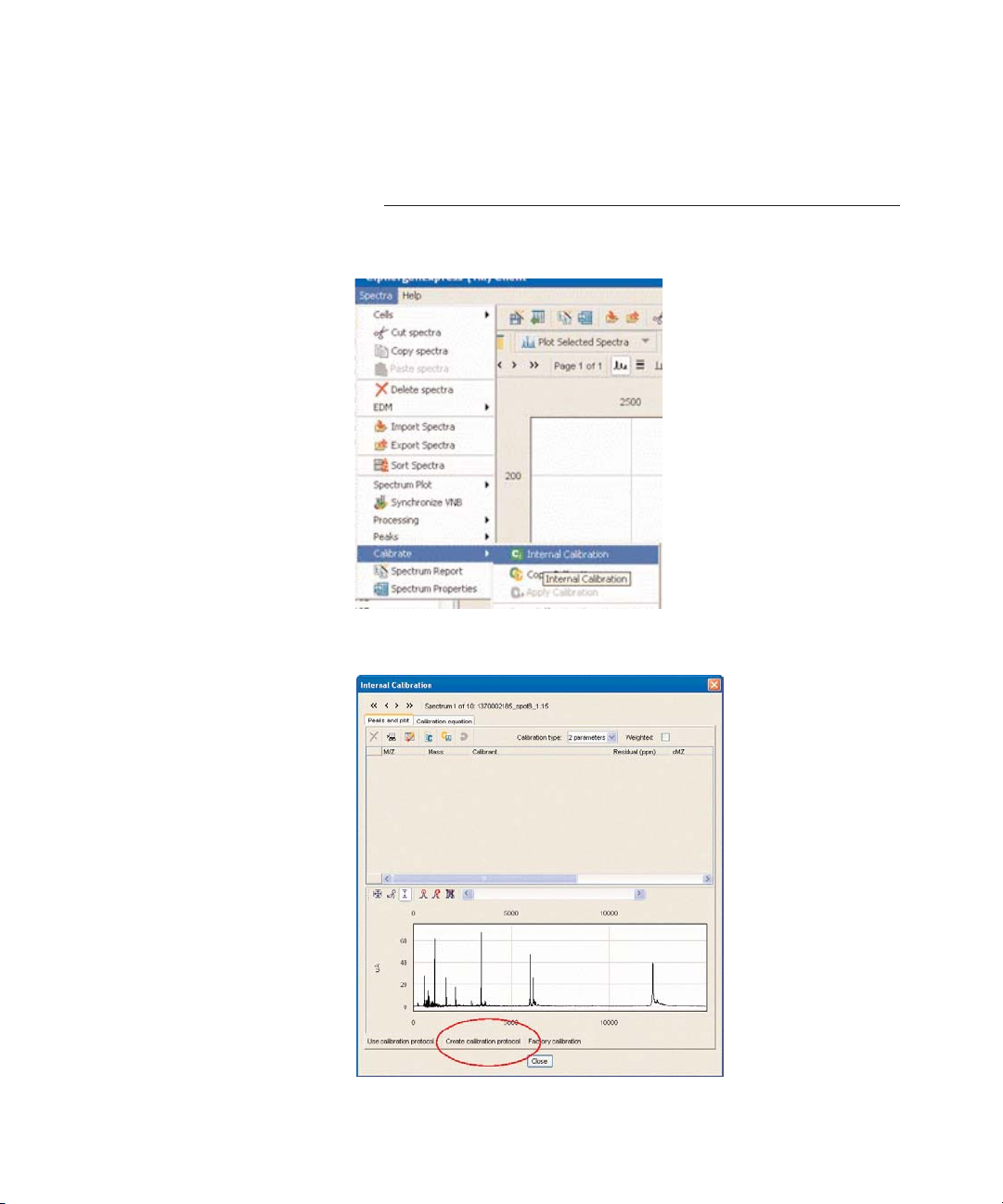

1. Select Spectra > Calibrate > Internal Calibration.

2. Select Create calibration protocol.

Page 11

8

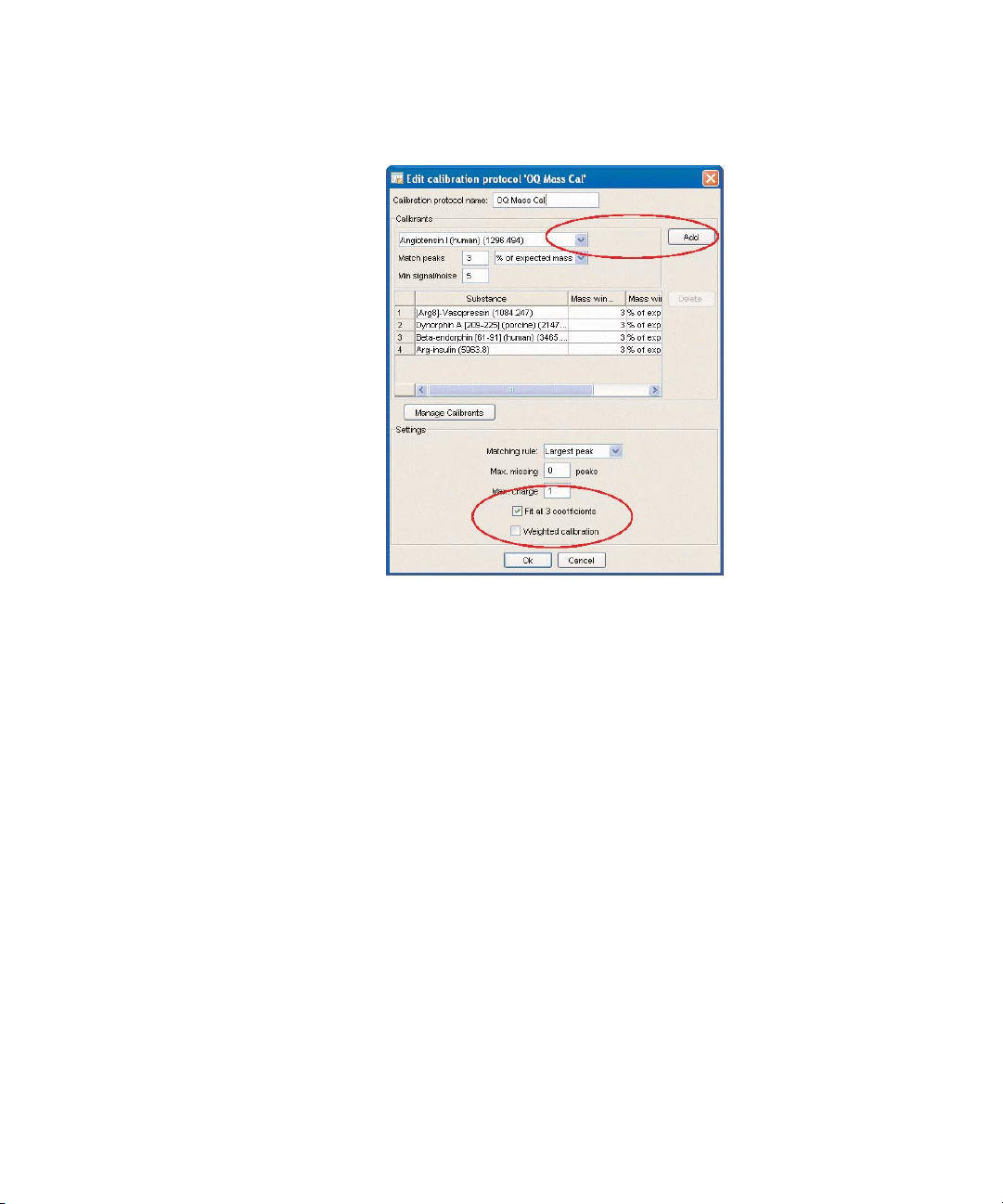

3. In the Calibration protocol name field, enter

OQ Mass Cal.

4. Select [Arg8]-Vasopressin (1084.247) from the drop-down list, and click Add

(keep the default values of 3% of expected peaks and minimum signal/noise

of 5).

5. Select Dynorphin A (2147.5) from the drop-down list, and click Add (keep the

default value of 3% of expected peaks and signal/noise of 5).

6. Select Beta-endorphin (3465.0) from the drop-down list, and click Add (keep

the default value at 3% of expected peaks and signal/noise of 5).

7. Select Arg-insulin (5963.8) from the drop-down list, and click Add (keep the

default value at 3% of expected peaks and signal/noise of 5).

8. Select Fit all 3 coefficients. Click OK.

Page 12

2.3 OQ Maintenance Procedures

2.3.1 Maintenance Procedure 1 –– High Voltage (HV) Conditioning

This procedure helps to decontaminate the surfaces of the ProteinChip instrument and is

essential for obtaining correct test results. Run this procedure weekly using any blank

ProteinChip array (or an array that has already been used). The procedure takes 1–2 hr to

complete. Therefore, to save time, we recommend running this protocol at the end of the day

prior to running the remaining tests. There is no need to stay with the instrument while the protocol

is running.

1. Launch ProteinChip data manager software, select the instrument, and click Start.

2. Insert a blank ProteinChip array into the instrument. If blank arrays are not available, use an

expired or used ProteinChip array.

Note: If using an Enterprise Edition instrument, place a cassette filled with used ProteinChip

arrays into the instrument. Blank arrays maybe used as long as at least one array in the

cassette has a bar code.

3. Open the Protocol Mode tab and select Instrument > Quick Run.

4. The Quick Run Protocol(s) dialog opens. Select the

SoftHV

protocol you saved during file

and protocol setup, step 3 and click Run.

5. After completion of the protocol, an “Acquisition Error” message appears. This is expected.

Click OK.

6. Record the operator name and date in the ProteinChip SELDI OQ form.

2.3.2 Maintenance Procedure 2 –– Detector Calibration

This procedure uses the ProteinChip detector calibration array to adjust the detector voltage.

These adjustments are based on a rolling average that stabilizes the gain, improving spectral

reproducibility over the lifetime of the detector. This procedure is essential for obtaining correct

test results and, when run on a weekly basis, is designed to improve reproducibility as the detector

ages.

Each run uses a single spot on the array, and each spot can only be used once. Store the array

in its original packaging and in a dry, dark location. Record usage data directly on the packaging.

The procedure requires 45 min to 4 hr to complete, depending on the state of the instrument.

Note: The detector calibration procedure is intended to standardize instrument performance

over time. First-time use may alter system response and is not recommended within a series of

experiments. It is, however, possible to manually set the voltage back to its original state through

the instrument’s web page.

9

Page 13

1. Insert the ProteinChip detector calibration array into the instrument.

Note: For the Enterprise Edition instrument, place the array into slot 1 of a cassette and fill the

rest of the slots with blank or used ProteinChip arrays.

2. Open the instrument’s interactive web page (http://pcs4000-####/index.jsp, where #### is

the instrument serial number). If the instrument is under local control, the web page will only

be on the local computer. If it is installed on an intranet, it will be available on all intranet

computers.

3. Select Calibrations > Automatic Detector Gain. The Detector Gain page opens. Check

that Automatic and NOT manual is selected.

4. If using the Enterprise Edition instrument, select Array number 1 (slot 1 in cassette).

5. If this is the first calibration performed on the instrument, or if the last calibration was performed

more than two weeks ago, select two previously unused spots. If this is a routine, weekly

calibration, select one unused spot.

6. Click Start.

10

Page 14

7. The time required to complete this procedure is variable, and it may require up to several

hours as the instrument continually collects data of a specific intensity. If the calibration routine

does not complete, run the procedure again with unused spots.

8. Once the procedure is complete, open ProteinChip data manager software, select the

instrument, and select Instrument > Reinitialize Instrument.

9. The maintenance procedure is complete. Record the operator name and date in the

ProteinChip SELDI OQ form.

11

Page 15

2.4 OQ Tests

2.4.1 Test 1 –– Detector Sensitivity

This test uses the ProteinChip detector qualification array to measure the signal-to-noise ratio

(S/N) of immunoglobubulin (IgG) at two different concentrations (10 fmol and 140 fmol).

Measurements are compared to a specification, and a pass/fail disposition is obtained.

Array Type ProteinChip detector qualification array

Usage Information Use once and discard; do not open until ready to use.

Recommended Testing Every other week

Frequency

Expected Testing Time 30 min to 1 hr

Pass/Fail Specification High concentration: pass if S/N is greater than 1,100

Low concentration: pass if S/N is greater than 5

1. Insert the ProteinChip detector qualification array into the instrument. If you are using an

Enterprise Edition instrument, place the array into any location within the cassette, fill the

remaining slots in the cassette with blank or used arrays, and place the cassette into the

instrument.

2. In ProteinChip data manager software, click Start and open the Protocol Mode tab.

3. Select Instrument > Preferences. In the Preferences dialog, click “…”. The Select Folder

dialog opens.

4. Select Projects > OQ_####/

Date

/Test 1 Detector Sensitivity, where #### is the serial

number of the instrument.

5. Run protocol “Test 1 Detector Sensitivity ” on partition 1 of 1 for all 8 spots on the array. Do

not change any values.

12

Page 16

6. Plot the peaks with noise set to 12,000 Da:

a. Select all 8 spectra.

b. Click on the data analysis icon . The Analysis Settings dialog opens.

c. Open the Noise tab and set Start Measuring Noise From to 12,000 Da. Click OK.

13

Page 17

7. Plot all 8 spectra and select the IgG peak using the peak selection tool.

Note: Spots with high concentrations (spots A, C, E, and G) alternate with those with low

concentrations (spots B, D, F, and H). Due to the different concentrations on different spots, it is

critical to export the peak data with the spots in alphabetical order from A to H.

8. Export the data following the instructions in Appendix C and selecting parameters for export

in the following order:

• Array bar code

• Spot name

• Substance mass

• Intensity

• Resolution

• S/N

9. Paste the data into the ProteinChip SELDI OQ form, data sheet “Test 1 Detector Sensitivity”.

10. The spreadsheet indicates if the test passed or failed.

11. If test 1 fails, run the detector calibration procedure (maintenance procedure), and repeat the

test. If the test fails a second time, contact technical support.

14

Page 18

2.4.2 Test 2 — Mass Drift and Resolution 5.96 kD

This test uses the ProteinChip peptide standard array to measure the mass drift and resolution

of insulin. These measurements are compared to a specification, and a pass/fail disposition is

obtained.

Array Type ProteinChip peptide standard array

Usage Information Each test uses 1 partition on all 8 spots on the array. The array

can be used up to 20 times (5 times on each of 4 partitions).

Store the array in the original packaging and record usage

information in the usage chart provided on the packaging. Laser

optimization steps use 1 of 15 partitions, and these reads do

not need to be recorded or monitored.

Recommended Testing Weekly

Frequency

Expected Testing Time 20 min to 1 hr

Pass/Fail Specification Mass drift: pass if less than 7 Da

Resolution: pass if average is greater than 750

1. Insert the ProteinChip peptide standard array into the instrument. If you are using an

Enterprise Edition instrument, place the array into a cassette, fill the remaining slots in the

cassette with blank or used arrays, and place the cassette into the instrument.

2. In ProteinChip data manager software, click Start and open the Protocol Mode tab.

3. Select Instrument > Preferences. In the Preferences dialog, click “…”. The Select Folder

dialog opens.

4. Select Projects > OQ_####/

Date

/Test 2 Mass Drift and Resolution 5.96 kD, where ####

is the serial number of the instrument.

5. Optimize the laser intensity. Run protocol “Test 2 Mass Drift and Resolution 5.96 kD” on any

partition (“n”) of 15 on spot D (for example, 1 of 15, 2 of 15, 3 of 15, etc). Adjust the laser

energy until the height of the insulin peak at 5,963 Da is 100–200 µA. This optimization step

does not need to be repeated on subsequent runs of test 2 unless the peak intensity falls

too low.

15

Page 19

6. Run the same protocol on partition “n” of 4 for all 8 spots. Record the

partition number on the usage chart provided with the product packaging.

7. Make sure that a peak intensity of 50–500 µA is visible on each spot. If peak intensities

appear out of this range, change the laser energy and run the test again.

16

Page 20

8. Plot the peaks with the filtering option turned off:

a. Select all 8 spectra. (Do not select the first laser optimization spectrum.)

b. Click the analysis settings icon. The Analysis Settings dialog opens.

c. Open the Filtering tab and deselect the On checkbox.

d. Click OK.

17

Page 21

9. Plot all 8 spectra. Using the peak selection tool, select the insulin peak (5.963 kD) in all spectra.

10. Export the data following the instructions in Appendix C and selecting the parameters for

export in the following order:

• Array bar code

• Spot name

• Substance mass

• Intensity

• Resolution

• S/N

11. Paste the data into the ProteinChip SELDI OQ form, data sheet “Test 2 Mass Drift and

Resolution”.

12. The spreadsheet indicates whether the test passed or failed.

13. If the test fails, run the HV conditioning procedure (maintenance procedure 1) and repeat the

test. Contact technical support if the test fails a second time.

18

Page 22

2.4.3 Test 3 –– Resolution at 1 kD

This test uses the ProteinChip peptide standard array to measure the resolution of Arg-8-vasopressin.

To do this, a higher-resolution, lower source mode (15 kV) is employed rather than the default

high-sensitivity source mode (voltage 25 kV).These measurements are compared to a specification,

and a pass/fail disposition is obtained.

Caution: Spectra taken using one source mode should not be compared either qualitatively or

quantitatively to spectra taken using other source modes. Spectra are only comparable within

modes.

Array Type ProteinChip peptide standard array

Usage Information Each test uses 1 partition on all 8 spots on the array. The array

can be used up to 20 times (5 times on each of 4 partitions).

Store the array in the original packaging and record usage

information in the usage chart provided and on the packaging.

Laser optimization steps use 1 of 15 partitions, and these reads

do not need to be recorded or monitored.

Recommended Testing Weekly

Frequency

Expected Testing Time 30 min to 1 hr

Pass/Fail Specification Pass if resolution is greater than 1000

1. Insert the ProteinChip peptide standard array into the instrument. If you are using an

Enterprise Edition instrument, place the array into a cassette, fill the remaining slots in the

cassette with blank or used arrays, and place the cassette into the instrument.

2. In ProteinChip data manager software, click Start and open the Protocol Mode tab.

3. Select Instrument > Preferences. In the Preferences dialog, click “…”. The Select Folder

dialog opens.

4. Select Projects > OQ_####/

Date

/Test 3 Resolution 1 kD, where #### is the serial number

of the instrument.

5. Optimize the laser intensity. Run protocol “Test 3 Resolution 1 kD” on any partition (“n”) of 15

on spot D. Adjust the laser energy until the height of the insulin peak at 5.96 kD is 100–200 µA.

This optimization step does not need to be repeated on subsequent runs of test 3 unless the

peak intensity falls too low.

6. Run the same protocol on partition “n” of 15 on spot D. Change the laser energy until the

height of the Arg-8-vasopressin peak at 1 kD is 100–200 µA.

7. Ensure that a peak intensity of 50–500 µA is visible on each spot. If peak intensities appear

out of this range, change the laser energy and run the test again.

19

Page 23

8. Plot the peaks with the filtering option turned off:

a. Select all 8 spectra.

b. Click the data analysis icon . The Analysis Settings dialog opens.

c. Open the Filtering tab and deselect the On checkbox.

d. Click OK.

20

Page 24

9. Plot all 8 spectra (do not select the first optimization spectrum). Using the peak selection

tool, select the Arg-8-vasopressin (1,084.247 Da) peak. Zoom in to ensure correct peak

selection.

10. Export the data following the instructions in Appendix C and selecting the parameters for

export in the following order:

• Array bar code

• Spot name

• Substance mass

• Intensity

• Resolution

• S/N

11. Paste data into the ProteinChip SELDI OQ form, data sheet “Test 3 Resolution 1 kD”.

12. The spreadsheet indicates if the test passed or failed. If the test fails, run the HV conditioning

procedure (maintenance procedure 1) and repeat the test. Contact technical support if the

test fails a second time.

21

Page 25

2.4.4 Test 4 — Mass Accuracy

This test uses the ProteinChip peptide standard array to test the mass accuracy of the system’s

internal and external calibrations. These measurements are compared to a specification, and a

pass/fail disposition is obtained.

Array Type ProteinChip peptide standard array

Usage Information Each test uses 1 partition on all 8 spots on the array. The array

can be used up to 20 times (5 times on each of 4 partitions).

Store the array in the original packaging and record usage

information in the usage chart provided and on the packaging.

Laser optimization steps use 1 of 15 partitions, and these reads

do not need to be recorded or monitored.

Recommended Testing Weekly

Frequency

Expected Testing Time 30 min to 1 hr

Pass/Fail Specification External calibration: Pass if average mass within 0.1% of

calibrant mass and pooled CV of <0.05

Internal calibration: Pass if average mass within 0.01% of

calibrant mass and pooled CV of <0.01

1. Insert the ProteinChip peptide standard array into the instrument. If you are using an

Enterprise Edition instrument, place the array into a cassette, fill the remaining slots in the

cassette with blank or used arrays, and place the cassette into the instrument.

2. In ProteinChip data manager software, click Start and open the Protocol Mode tab.

3. Select Instrument > Preferences. In the Preferences dialog, click “…”. The Select Folder

dialog opens.

4. Select Projects > OQ_####/

Date

/Test 4 Mass Accuracy, where #### is the serial number

of the instrument.

5. Optimize the laser intensity. Run protocol “Test 4 Mass Accuracy” on any partition (“n”) of 15

on spot D. Adjust the laser energy until the height of the insulin peak at 5.96 kD is 100–200 µA.

This optimization step does not need to be repeated on subsequent runs of test 4 unless the

peak intensity falls too low.

6. Run protocol “Test 4 Mass Accuracy”. Run on partition 1 of 1 for all 8 spots on chip. Do not

change any values.

22

Page 26

7. Plot the peaks with the filtering option turned off:

a. Select all 8 spectra.

b. Click the data analysis icon . The Analysis Settings dialog opens.

c. Open the Filtering tab and deselect the On checkbox.

d. Click OK.

8. Plot all 8 spectra. Using the peak selection tool, select all 7 peaks. Each spectrum should

resemble that shown below (intensities relative to each other may vary). Additional peaks

other than those indicated may consist of matrix, doubly-charged peaks, dimers or other

multimers, salt peaks, etc., as for any mass spectrum.

Peak Name Molecular Weight (Da)

1 Arg-8-vasopressin 1084.247

2 Somatostatin 1637.903

3 Dynorphin A 2147.5

4 ACTH 2933.5

5 Beta endorphin 3465

6 Arg-insulin 5963.8

7 Cytochrome C 12230.92

23

Page 27

Note: To ensure correct placement of the peak marker, zoom in on each peak during selection.

Though some plots appear acceptable when zoomed out, zooming in may reveal incorrect

placement of peak markers. This is more accurate when the expected peak width dialog box

option is set to 5.

24

Page 28

25

Page 29

9. Zoom in and check that all 7 peaks in all 8 spectra are marked correctly. Failure to do so

may result in incorrect results. Close the plot.

Mass Accuracy — External Calibration Test

Perform this test BEFORE the internal calibration test.

1. Click on the spectrum for spot D.

2. Select Spectra > Calibrate > Apply Calibration Protocol.

3. Select OQ Mass Cal.

4. Click OK. The spectrum flag changes from yellow to green.

5. In the main window, make sure that only the spectrum from spot D is selected. Click the

Copy Calibration button. The spectrum flag on spot D reverts to yellow.

6. Select all 8 spectra and click the Apply Calibration button. (Do not select the first

optimization spectrum.)

7. Export the data following the instructions in Appendix C and selecting the parameters for

export in the following order:

• Array bar code

• Spot name

• Substance mass

• Intensity

• Resolution

• S/N

• Peak #

8. Paste the data into the ProteinChip SELDI OQ form, data sheet “Test 4 Mass Accuracy”.

Paste the data into cell M41.

26

Spectrum

flag

Page 30

9. In the External Table, right-click on cell B3 and select Refresh Data.

10. The spreadsheet indicates if the test passed or failed. The test passes if the following

specifications are achieved:

• Peptide average mass within 0.1% of calibrant mass

• % Standard deviation (pooled CV) of <0.05

11. If the test fails, run the HV conditioning procedure (maintenance procedure 1), and repeat

the test. If the test fails a second time, contact technical support.

Mass Accuracy — Internal Calibration Test

Perform this test AFTER the external calibration test (above).

1. Check that all peaks have been selected and that all peaks are marked correctly (not on

shoulders, etc.).

2. Select all 8 spectra.

3. Select Spectra > Calibrate > Apply Calibration Protocol.

4. Select OQ Mass Cal.

27

Page 31

12. Click OK. The spectrum flag changes from yellow to green for all 8 spectra, once calibration

is complete.

13. Export the data following the instructions in Appendix C and selecting the parameters for

export in the following order:

• Array bar code

• Spot name

• Substance mass

• Intensity

• Resolution

• S/N

• Peak #

14. Paste the data into the ProteinChip SELDI OQ form, data sheet “Test 4 Mass Calibration”.

Paste the data into cell V41.

15. In the Internal Table, right-click on cell B21 and select Refresh Data.

16. The spreadsheet indicates if the test passed or failed. The test passes if the following

specifications are achieved:

• Peptide average mass within 0.01% of calibrant mass

• % Standard deviation (pooled CV) of <0.01

17. If the test fails, run maintenance procedure 1 (HV conditioning) and repeat the test. Contact

technical support if the test fails a second time.

28

Page 32

Appendix A

29

Page 33

Appendix B

Protocol Acceptance Form

Bio-Rad Laboratories recommends that the operational qualification (OQ) protocols be performed

in total on a regular basis to confirm that the ProteinChip SELDI system is performing to

specifications, or whenever it is suspected that the instrument is not performing to specifications.

I have reviewed the ProteinChip OQ kit instruction manual and agree that it provides the

appropriate procedures for the operational qualification of the ProteinChip SELDI system,

Personal or Enterprise Edition.

Customer Name (print)___________________ Signature___________________Date________

Reviewer Name/Title (print)________________ Signature__________________ Date________

30

Page 34

Appendix C

Data Export Procedure

Use this procedure to export the data obtained during testing to the Microsoft Excel spreadsheet

provided with the kit (ProteinChip SELDI OQ form). Following export, open the resulting .csv file

using the Excel program and copy and paste the contents into a COPY of the spreadsheet

provided. Retain this copy for your records.

1. In the Explorer pane, open the Projects folder and select the spectra to be exported. Click

the Export Spectra button in the toolbar. The Export Spectra dialog opens.

2. In the Export Spectra dialog, select Peak Information and click Export. The Peak

Information Export dialog opens.

3. Select parameters and the order in which they are to be exported. (These parameters are

specific to the test and are described in the instructions for the test.)

4. Click OK. The Save File dialog box opens. Enter the file name and click OK.

31

Page 35

Bio-Rad

10010680 Rev A

Laboratories, Inc.

Life Science

Group

Bulletin 0000 US/EG Rev A

Web site www.bio-rad.com USA 800 4BIORAD Australia 61 02 9914 2800 Austria 01 877 89 01 Belgium 09 385 55 11 Brazil 55 21 3237 9400

Canada 905 712 2771 China 86 21 6426 0808 Czech Republic 420 241 430 532 Denmark 44 52 10 00 Finland 09 804 22 00

Germany 089 318 84 0 Greece 30 210 777 4396 Hong Kong 852 2789 3300 Hungary 36 1 455 8800 India 91 124 4029300 Israel 03 963 6050

Italy 39 02 216091 Japan 03 5811 6270 Korea 82 2 3473 4460 Mexico 52 555 488 7670 The Netherlands 0318 540666 New Zealand 0508 805 500

Norway 23 38 41 30 Poland 48 22 331 99 99 Portugal 351 21 472 7700 Russia 7 495 721 14 04 Singapore 65 6415 3188 South Africa 27 861 246 723

Spain 34 91 590 5200 Sweden 08 555 12700 Switzerland 061 717 95 55 Taiwan 886 2 2578 7189 United Kingdom 020 8328 2000

France 01 47 95 69 65

00-0000 0000 Sig 1106

Loading...

Loading...