Page 1

Operating Manual

Translation of the original operating manual

KT (E6.1)

Cooling Incubator

with Peltier Refrigerating Technology and program controller

Model Model version Art. No.

KT 53 KT053-230V 9020-0311

KT 53-UL KT053UL-120V 9020-0312

KT 115 KT115-230V 9020-0313

KT 115-UL KT115UL-120V 9020-0314

KT 170 KT170-230V 9020-0289

KT 170-UL KT170UL-120V 9020-0310

BINDER GmbH

Address: Post office box 102, 78502 Tuttlingen, Germany Phone: +49 7462 2005 0

Fax: +49 7462 2005 100 Internet: http://www.b ind er -world.com

E-mail: info@binder-world.com Service Hotline: +49 7462 2005 555

Service Fax: +49 7462 2005 93 555 Service E-Mail: customerservice@binder-world.com

Service Hotline USA: +1 866 885 9794 or +1 631 224 4340 x3

Service Hotline Asia Pacif ic: +852 390 705 04 or +852 390 705 03

Service Hotline Russia and CIS: +7 495 988 15 16

Issue 11/2020 Art. No. 7001-0291

Page 2

Contents

1. SAFETY .................................................................................................................. 6

1.1 Personnel Qualification ....................................................................................................................... 6

1.2 Operating manual ................................................................................................................................ 6

1.3 Legal considerations ........................................................................................................................... 6

1.4 Structure of the safety instructions ...................................................................................................... 7

1.4.1 Signal word panel ..................................................................................................................... 7

1.4.2 Safety alert symbol ................................................................................................................... 7

1.4.3 Pictograms ................................................................................................................................ 8

1.4.4 Word message panel structure ................................................................................................. 8

1.5 Localization / position of safety labels on the chamber ...................................................................... 9

1.6 Type plate............................................................................................................................................ 9

1.7 General safety instructions on installing and operating the chambers ............................................. 11

1.8 Intended use ..................................................................................................................................... 12

1.9 Foreseeable Misuse .......................................................................................................................... 14

1.10 Residual Risks .................................................................................................................................. 15

1.11 Operating instructions ....................................................................................................................... 16

1.12 Measures to prevent accidents ......................................................................................................... 16

2. CHAMBER DESCRIPTION .................................................................................. 17

2.1 Chamber overview ............................................................................................................................ 18

2.2 Instrument panel ............................................................................................................................... 18

2.3 Chamber rear .................................................................................................................................... 19

3. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

LOCATION OF INSTALLATION .......................................................................... 20

3.1 Unpacking, and checking equipment and completeness of delivery ................................................ 20

3.2 Guidelines for safe lifting and transportation ..................................................................................... 21

3.3 Storage .............................................................................................................................................. 21

3.4 Location of installation and ambient conditions ................................................................................ 21

4. INSTALLATION OF THE EQUIPMENT ............................................................... 23

4.1 Spacer for wall distance .................................................................................................................... 23

4.2 Electrical connection ......................................................................................................................... 24

5. START UP ............................................................................................................ 25

5.1 Behavior when opening the door ...................................................................................................... 25

6. FUNCTIONAL OVERVIEW OF THE T4.12 CHAMBER CONTROLLER ............. 25

6.1 Menu structure .................................................................................................................................. 26

6.1.1 General menu ......................................................................................................................... 26

6.1.2 Quick menu ............................................................................................................................. 28

6.1.3 “User” menu ............................................................................................................................ 28

6.2 Operating modes ............................................................................................................................... 29

6.2.1 Activating the “control off” mode or change to “fixed value” operating mode ......................... 29

6.3 Performance during and after power failure ...................................................................................... 31

6.4 Information ........................................................................................................................................ 31

7. CONFIGURATION OF OPTIONAL EQUIPMENT ................................................ 32

7.1 Setting the optional door heating ...................................................................................................... 32

7.2 Turning on / off the optional interior socket ....................................................................................... 33

7.3 Switching on or off the optional zero-voltage relay control outputs .................................................. 34

7.4 Functional test of the optional alarm output ...................................................................................... 34

7.5 Switching on or off the optional object temperature display ............................................................. 35

KT (E6.1) 11/2020 Page 2/139

Page 3

8. SET-POINT ENTRY IN “FIXED VALUE” OPERATING MODE ........................... 35

8.1 Setting ranges: .................................................................................................................................. 35

8.2 Entering the set-points via “quick menu” ........................................................................................... 36

8.3 Entering the set-points via general menu ......................................................................................... 37

9. TIME PROGRAMS ............................................................................................... 39

9.1 Starting and running an existing time program ................................................................................. 40

9.2 Cancelling a running time program ................................................................................................... 43

9.3 Creating a new time program ............................................................................................................ 44

9.3.1 Section handling ..................................................................................................................... 46

9.3.2 Temperature setpoint .............................................................................................................. 47

9.3.3 Section duration ...................................................................................................................... 47

9.3.4 Repeating one or several sections within a time program ...................................................... 48

9.3.5 Tolerance range ...................................................................................................................... 49

9.3.6 Set-point ramp and set-point step modes ............................................................................... 50

9.3.7 Switching on or off the optional zero-voltage relay outputs .................................................... 52

9.3.8 Calling up the next parameter ................................................................................................. 53

9.3.9 Saving the time program and leaving the program editor ....................................................... 55

9.4 Program interruption ......................................................................................................................... 56

9.5 Deleting a time program .................................................................................................................... 57

10. WEEK PROGRAMS ............................................................................................. 58

10.1 Starting and running an existing week program................................................................................ 59

10.2 Cancelling a running week program ................................................................................................. 62

10.3 Creating a new week program .......................................................................................................... 62

10.3.1 Section handling ..................................................................................................................... 65

10.3.2 Temperature setpoint .............................................................................................................. 65

10.3.3 Day of the week ...................................................................................................................... 66

10.3.4 Time of the day ....................................................................................................................... 67

10.3.5 Activity of the shift-point .......................................................................................................... 67

10.3.6 Switching on or off the optional zero-voltage relay outputs .................................................... 68

10.3.7 Calling up the next parameter ................................................................................................. 68

10.3.8 Saving the week program and leaving the program editor ..................................................... 70

10.4 Deleting a week program .................................................................................................................. 71

11. KEY LOCK ........................................................................................................... 72

11.1 Directly activating the key lock function ............................................................................................ 73

11.2 Automatic key lock ............................................................................................................................ 74

11.3 Changing the password for unlocking the key lock ........................................................................... 75

12. GENERAL CONTROLLER SETTINGS ................................................................ 76

12.1 Setup wizard ..................................................................................................................................... 77

12.2 Date and time settings ...................................................................................................................... 78

12.3 Selecting the menu language of the T4.12 controller ....................................................................... 79

12.4 Setting display brightness ................................................................................................................. 79

12.5 Changing the temperature unit.......................................................................................................... 80

12.6 Defining the data recording rate ........................................................................................................ 80

12.7 Factory reset ..................................................................................................................................... 81

12.8 Network configuration ....................................................................................................................... 81

12.9 Display of the entire network configuration ....................................................................................... 85

12.10 Display and entry of the chamber configuration – for service purpose ............................................. 85

13. DATA TR AN SFER VIA U SB INTERFACE........................................................... 86

13.1 Exporting data to USB drive .............................................................................................................. 86

13.2 Importing data from USB drive .......................................................................................................... 87

14. NOTIFICATIONS AND ALARMS ......................................................................... 88

14.1 Notifications overview ....................................................................................................................... 88

KT (E6.1) 11/2020 Page 3/139

Page 4

Alarms overview ................................................................................................................................ 88

14.2

14.3 Alarm status ...................................................................................................................................... 89

14.4 Confirming a “set” alarm .................................................................................................................... 90

14.5 Alarm configuration and overview ..................................................................................................... 90

14.5.1 List of active alarms ................................................................................................................ 91

14.5.2 History – list of all alarms ........................................................................................................ 91

14.5.3 Activating, deactivating, and testing the alarm buzzer ........................................................... 92

14.5.4 Activating / deactivating all alarm functions ............................................................................ 93

14.5.5 Setting the delay time after opening the door ......................................................................... 93

15. EVENT LIST ......................................................................................................... 94

16. GRAPHICAL DISPLAY OF THE MEASURED VALUES ..................................... 95

16.1 Setting the sampling rate .................................................................................................................. 95

16.2 Defining the display range................................................................................................................. 96

16.3 Selecting the parameters .................................................................................................................. 97

17. TEMPERATURE SAFETY DEVICES ................................................................... 97

17.1 Overtemperature protective device (class 1) .................................................................................... 97

17.2 Overtemperature safety controller (temperature safety device class 3.1) ........................................ 97

17.2.1 Safety controller modes .......................................................................................................... 98

17.2.2 Setting the safety controller .................................................................................................... 98

17.3 Over- and undertemperature safety controller (temperature safety device class 3.3) (option) ...... 101

17.3.1 Safety controller modes ........................................................................................................ 102

17.3.2 Setting the Safety controller .................................................................................................. 102

18. NOTES ON REFRIGERATING OPERATION .................................................... 106

19. OPTIONS ............................................................................................................ 106

19.1 APT-COM™ 4 Multi Management Software (option) ...................................................................... 106

19.2 Data logger kit (option) .................................................................................................................... 106

19.3 Object temperature display with flexible Pt 100 temperature sensor (option) ................................ 107

19.4 Zero-voltage relay alarm output (option) ......................................................................................... 107

19.5 Zero-voltage relay control outputs (option) ..................................................................................... 109

19.6 Water protected internal socket (option) ......................................................................................... 109

20. CLEANING AND DECONTAMINATION ............................................................ 110

20.1 Cleaning .......................................................................................................................................... 111

20.2 Decontamination / chemical disinfection ......................................................................................... 112

21. MAINTENANCE AND SERVICE, TROUBLESHOOTING, REPAIR, TESTING . 113

21.1 General information, personnel qualification................................................................................... 113

21.2 Maintenance intervals, service ........................................................................................................ 114

21.3 Simple troubleshooting .................................................................................................................... 114

21.4 Sending the chamber back to BINDER GmbH ............................................................................... 117

22. DISPOSAL.......................................................................................................... 118

22.1 Disposal of the transport packing .................................................................................................... 118

22.2 Decommissioning ............................................................................................................................ 118

22.3 Disposal of the chamber in the Federal Republic of Germany ....................................................... 118

22.4 Disposal of the chamber in the member states of the EU except for the Federal Republic of

Germany.......................................................................................................................................... 119

22.5 Disposal of the chamber in non-member states of the EU ............................................................. 120

23. TECHNICAL DESCRIPTION .............................................................................. 121

23.1 Factory calibration and adjustment ................................................................................................. 121

23.2 Over current protection ................................................................................................................... 121

23.3 Definition of usable volume ............................................................................................................. 121

KT (E6.1) 11/2020 Page 4/139

Page 5

KT (E6.1) technical data .................................................................................................................. 122

23.4

23.5 Equipment and Options (extract) .................................................................................................... 123

23.6 Spare parts and accessories (extract) ............................................................................................ 124

23.7 KT / KT-UL 53 dimensions .............................................................................................................. 125

23.8 KT / KT-UL 115 dimensions ............................................................................................................ 126

23.9 KT / KT-UL 170 dimensions ............................................................................................................ 127

24. CERTIFICATES AND DECLARATIONS OF CONFORMITY ............................. 128

24.1 EU Declaration of Conformity.......................................................................................................... 128

24.2 Certificate for the GS mark of conformity of the “Deutsche Gesetzliche Unfallversicherung e.V.“

(German Social Accident Insurance) DGUV ................................................................................... 131

25. PRODUCT REGISTRATION .............................................................................. 133

26. CONTAMINATION CLEARANCE CERTIFICATE ............................................. 134

26.1 For chambers located outside the USA and Canada ..................................................................... 134

26.2 For chambers located in the USA and Canada .............................................................................. 137

KT (E6.1) 11/2020 Page 5/139

Page 6

Dear customer,

For the correct oper ation of the chambers, it is important t hat you r ead this op erating m anual com pletely

and carefully and observe all instructions as indicated. Failure to read, understand and follow the

instructions may result in personal injury. It can also lead to damage to the chamber and/or poor equipment

performance

1. Safety

1.1 Personnel Qualification

The chamber m ust only be installed, tested, and start ed up by personn el qualified for as sembly, startup,

and operation of the chamber. Qualified personnel are persons whose professional education, knowledge,

experience and knowledge of relevant standards allow them to assess, carry out, and identify any potential

hazards in the work as s igned to t hem. They must have been tra ine d an d i nstr uc t ed, a nd b e a uthorized, to

work on the chamber.

The chamber should only be operated b y laborator y personnel especially trained for this purpose and

familiar with all precautionary measures required for working in a laboratory. Observe the national

regulations on minimum age of laboratory personnel.

1.2 Operating manual

This operating m anual is part of the com ponents of delivery. Alwa ys keep it handy for referenc e in the

vicinity of the chamber. If selling the unit, hand over the operating manual to the purchaser.

To avoid injuries and damage observe th e safety instructions of the operating m anual. Failure to follow

instructions and safety precautions can lead to significant risks.

DANGER

Dangers due to failure to observe the ins truc tions and safety precautions.

Serious injuries and chamber damage. Risk of death.

Observe the safety instructions in this Operating Manual.

Follow the operating procedures in this Operating Manual.

Carefully read the complete operating instructions of the chamber prior to installing and

using the chamber.

Keep the operating manual for future reference

Make sure that all persons who use the chamber and its associated work equipment have

read and understood the Operating Manual.

This Operating Manu al is supplemented a nd updated as needed. Alwa ys use the mos t recent version of

the Operating Manual. When in doubt, call the BINDER Service Hotline for information on the up-todateness and validity of this Operating Manual.

1.3 Legal considerations

This operating manual is for informational purposes only. It contains information for correct and safe

installing, start-up, operation, decommissioning, cleaning and maintenance of the product. Note: the

contents and the product descr ibed are subj ect to cha nge with out not ice.

KT (E6.1) 11/2020 Page 6/139

Page 7

Understanding and observing the instructions in this operating manual are prerequisites for hazard-free use

and safety during operation and maintenance. Images are to provide basic understanding. They may

deviate from the actual version of the chamber. The actual scope of delivery can, due to optional or special

design, or due to recent technical changes, deviate from the information and illustrations in these

instructions this oper ating manual. In no event shall BINDER be held liable for any dam ages, direct or

incidental arising out of or related to the use of this manual.

This operating manual can not cover all conce ivable applications . If you would lik e additional inform ation,

or if special problem s arise that are not suff iciently addressed in th is manual, please ask your dealer or

contact us directly, e.g. by phone at the number located on page one of this manual

Furthermore, we emphasize that the contents of this operating manual are not part of an earlier or existing

agreement, descriptio n, or l ega l rel ati ons h ip, nor d o t h e y m odify such a relationship. Al l o bliga tio ns on the

part of BINDER derive from the respective purchase contract, which also contains the entire and exclusively

valid statement of warranty administration and the general terms and conditions, as well as the legal

regulations valid at the t ime the contract is concluded. The statements in this manual neit her au gment nor

restrict the contractual warranty provisions.

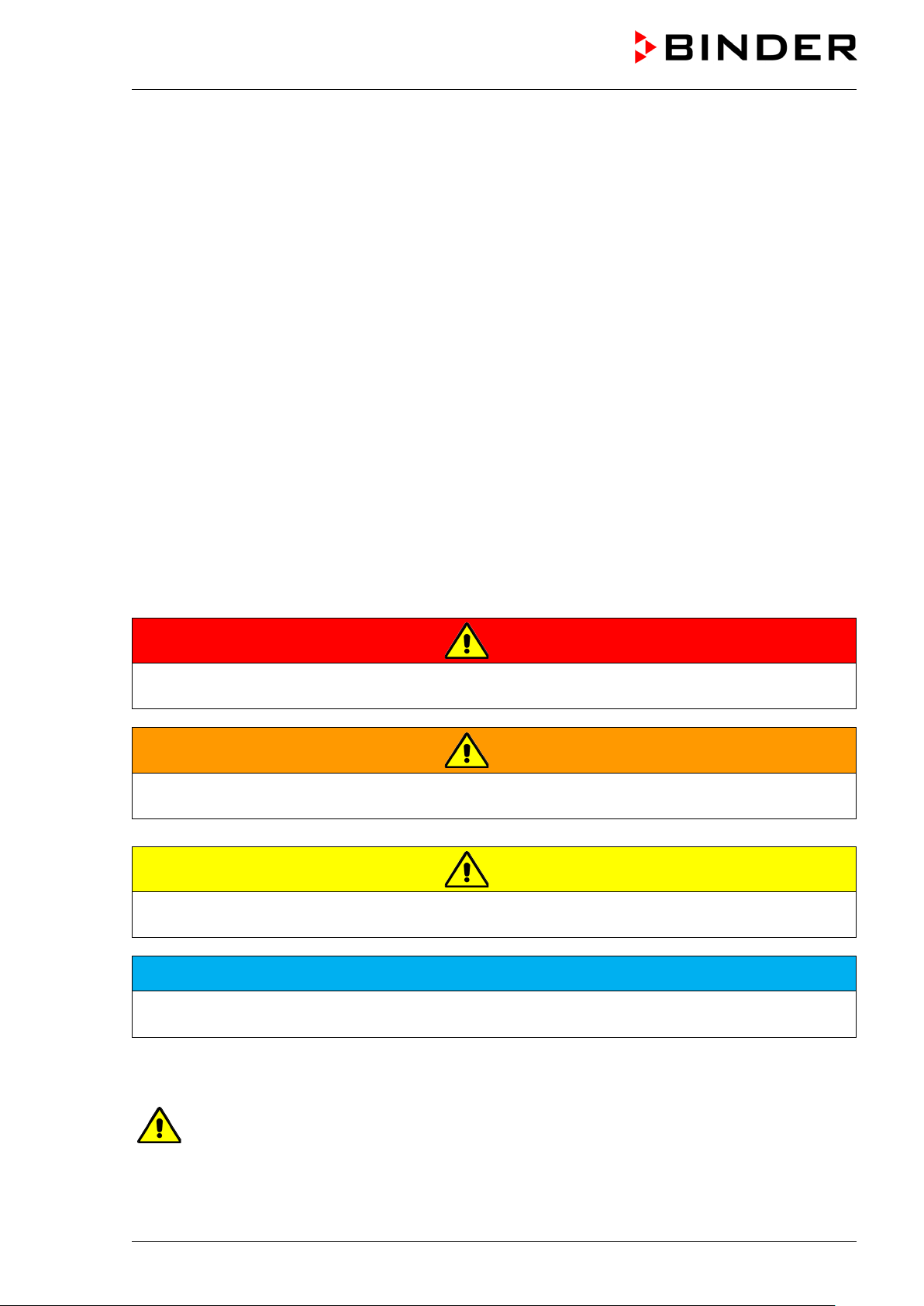

1.4 Structure of the safety instructions

In this operating manual, the following safety definitions and symbols indicate dangerous situations

following the harmonization of ISO 3864-2 and ANSI Z535.6.

1.4.1 Signal word panel

Depending on the probability of serious consequences, potential dangers are identified with a signal word,

the corresponding safety color, and if appropriate, the safety alert symbol.

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious

(irreversible) injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

(irreversible) injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor

(reversible) injury.

NOTICE

Indicates a potentially hazardous situation which, if not avoided, may result in damage to the product

and/or its functions or of a property in its proximity.

1.4.2 Safety alert symbol

Use of the safety alert symbol indicates a risk of injury.

Observe all measures that are marked with the safety alert symbol in order to avoid death or

injury.

KT (E6.1) 11/2020 Page 7/139

Page 8

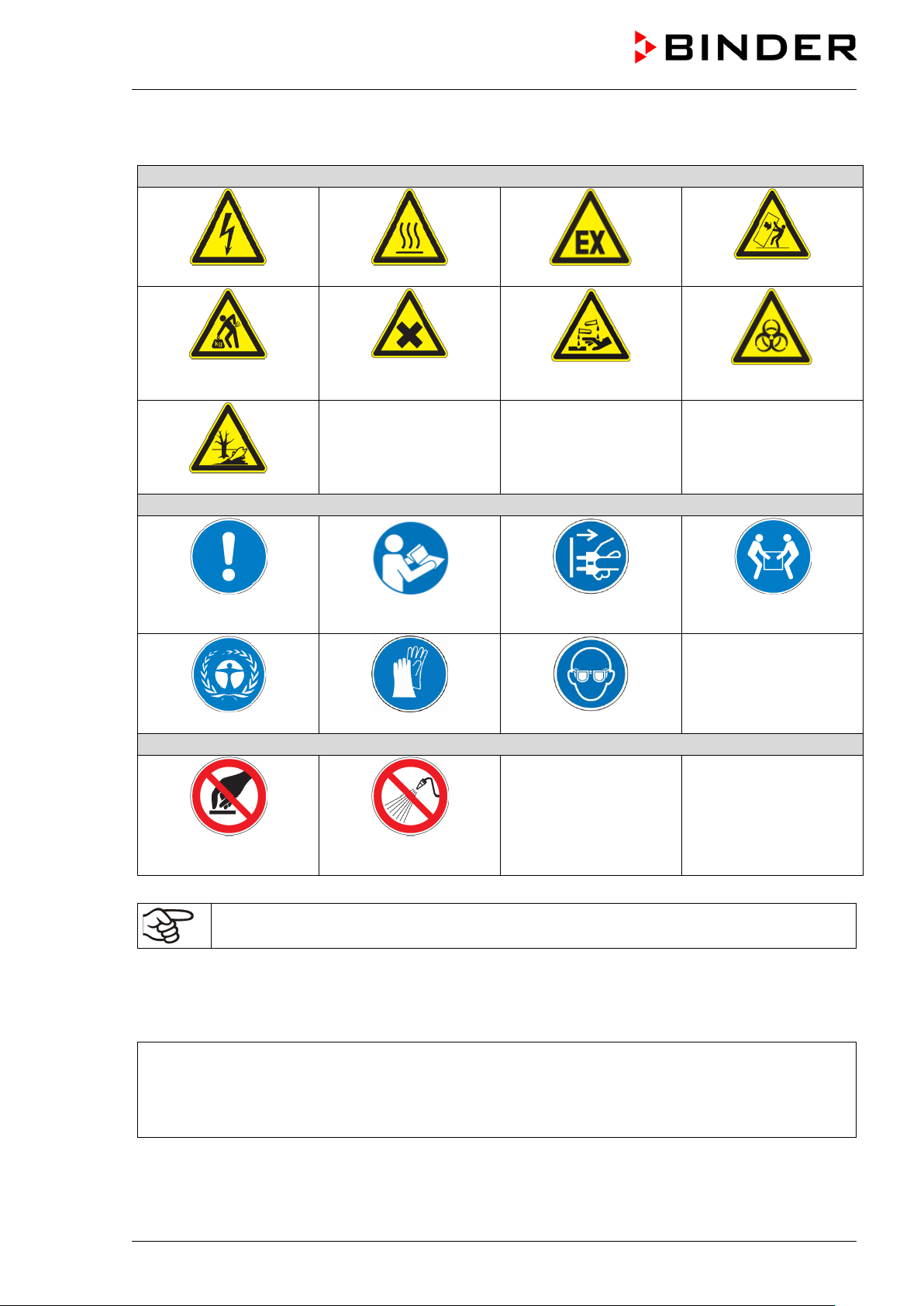

Warning signs

Electrical hazard

Hot surface

Explosive atmosphere

or chemical burns

Pollution Hazard

Mandatory action signs

instructions

plug

Environment protection

Wear protective gloves

Wear safety goggles

Prohibition signs

water

1.4.3 Pictograms

Lifting hazard

Mandatory regulation

Harmful substances

Read operating

Risk of corrosion and /

Disconnect the power

Stability hazard

Biohazard

Lift with several persons

Do NOT touch

Information to be observed in order to ensure optimum function of the product.

Do NOT spray with

1.4.4 Word message panel structure

Type / cause of hazard.

Possible consequences.

Instruction how to avoid the hazard: prohibition

Instruction how to avoid the hazard: mandatory action

Observe all other n otes and informat ion not necessarily em phasized in the sam e way, in order to a void

disruptions that could result in direct or indirect injury or property damage.

KT (E6.1) 11/2020 Page 8/139

Page 9

Pictograms (Warning signs)

Service label

Nominal temp.

100 °C

0,80 kW / 3,0 A

Thermoelectric cooli ng

212 °F

200-230 V / 50 Hz

Peltier

IP protection

20

200-230 V / 60 Hz

Safety device

DIN 12880

1 N ~

Class

3.1

Art. No.

9020-0289

Project No.

Built

2020

Cooling incubator

BINDER GmbH

www.binder-world.com

KT 170

Serial No. 00000000000000

1.5 Localization / position of safety labels on the chamber

The following labels are located on the chamber:

Hot surface

• Inner glass door next to the glass door

handle

Read operating manual

• UL chambers: outer chamber door

• KT with optional interior socket: below

the interior socket

Figure 1: Position of labels on KT-UL

Keep safety labels complete and legible.

Replace safety labels that are no longer legible. Contact BINDER service for these replacements.

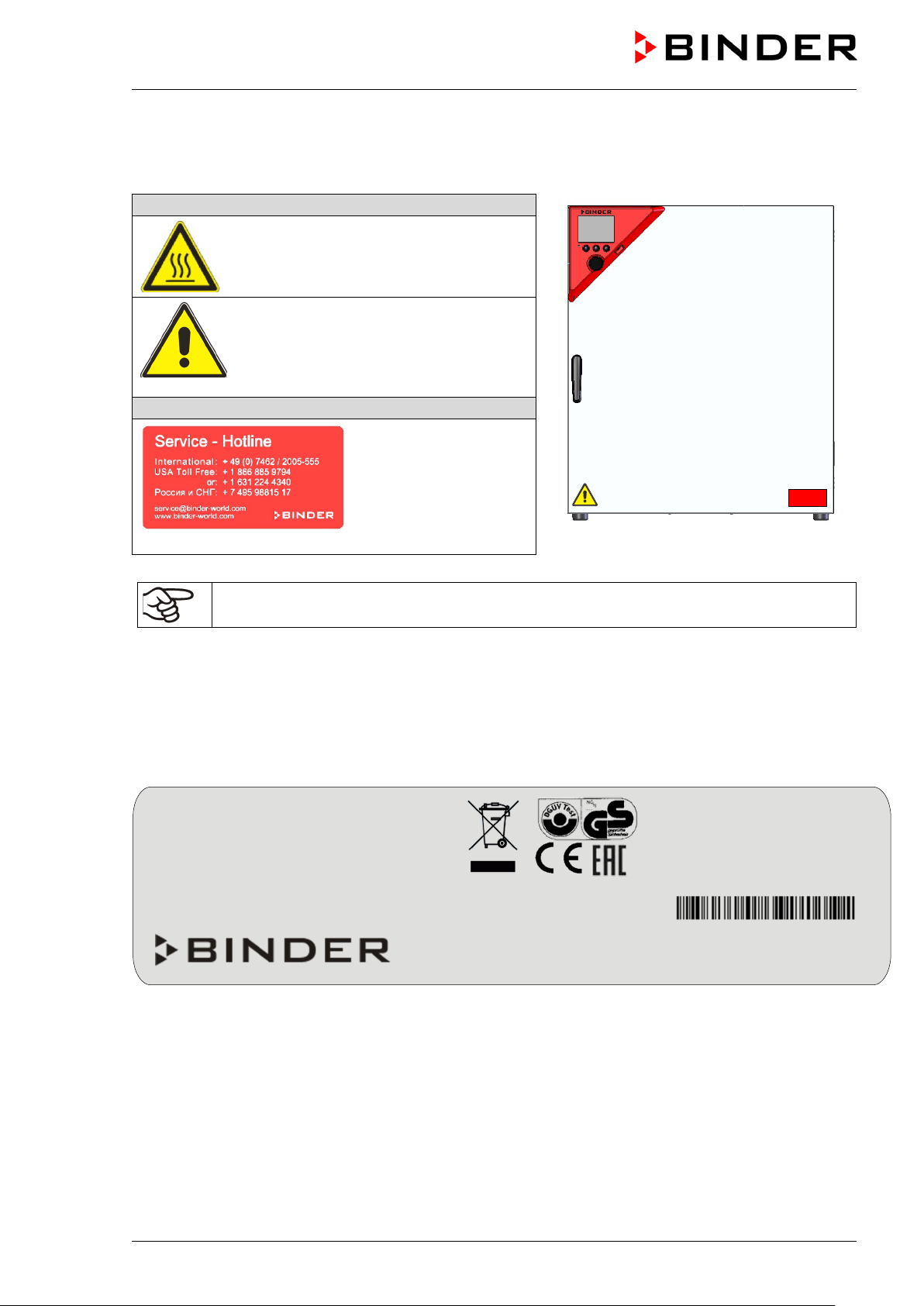

1.6 Type plate

The type plate is located on the left chamber side, on the bottom, right side.

Im Mittleren Ösch 5

78532 Tuttlingen / Germany

E6.1

Figure 2: Type plate (example of KT 170 regular chamber)

Made in Germany

KT (E6.1) 11/2020 Page 9/139

Page 10

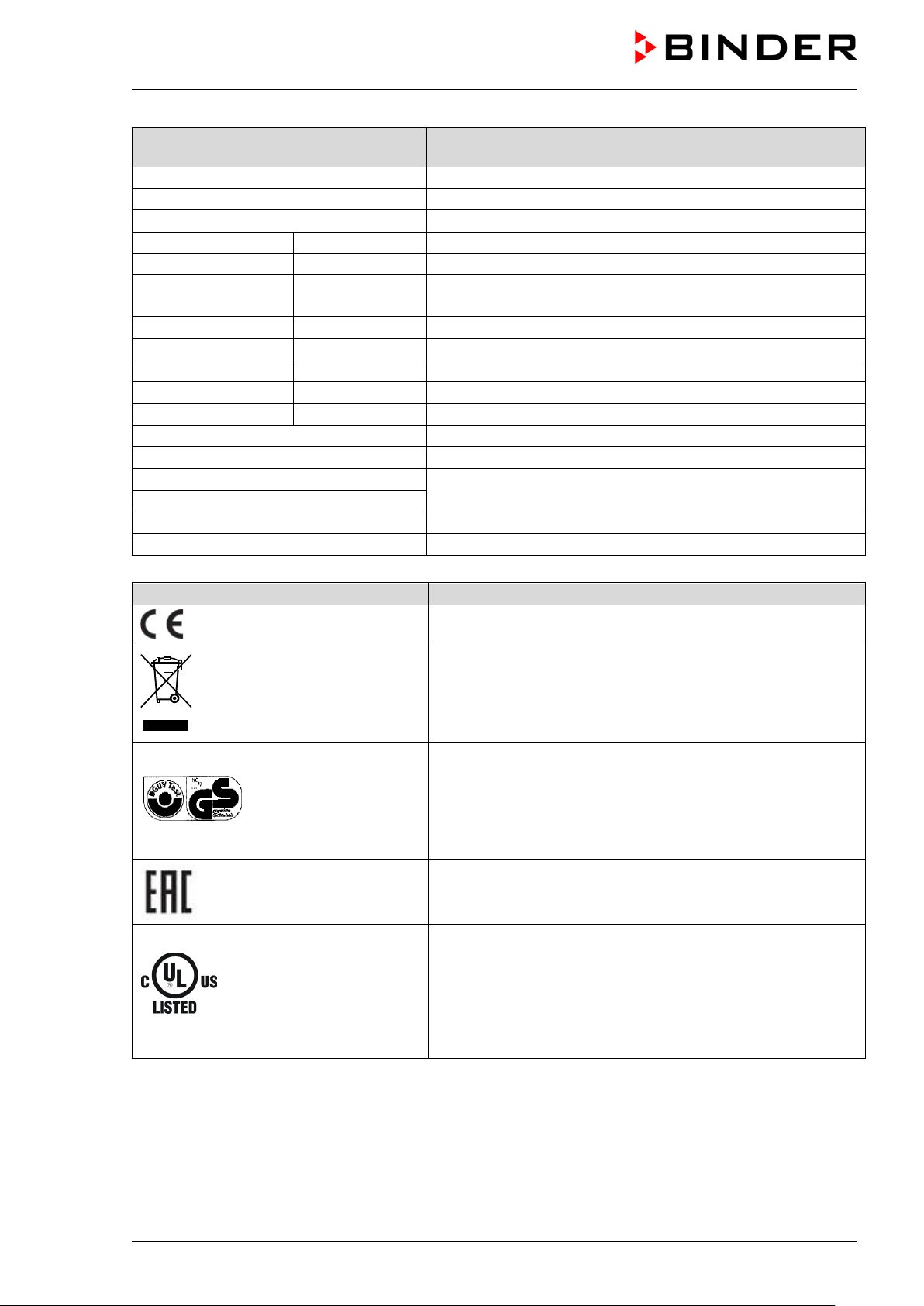

Indications of the type plate

(example)

Information

BINDER

Manufacturer: BINDER GmbH

KT 170

Model

Cooling incubator

Device name

Serial No.

000000000000

Serial no. of the chamber

Built

2020

Year of construction

Nominal

100 °C

212 °F

IP protection

20

IP type of protection acc. to standard EN 60529

Temp. safety device

DIN 12880

Temperature safety device acc. to standard DIN 12880:2007

Class

3.1

Class of temperature safety device

Art. No.

9020-0289

Art. no. of the chamber

Project No.

---

Optional: Special application acc. to project no.

0,80 kW

Nominal power

3,0 A

Nominal current

200-230 V / 50 Hz

200-230 V / 60 Hz

1 N ~

Current type

Thermoelectric cooling Peltier

Peltier refrigerating technology

Symbol on the type plate

Information

LABORATORY EQUIPMENT

43KM

temperature

Nominal temperature

Nominal voltage range +/-10% at the indicated power

frequency

CE conformity marking

Electrical and electronic equipment manufactured / placed on

the market in the EC after 13 August 2005 and to be

disposed of in separate collection according to Directive

2012/19/EU on waste electrical and electronic equipment

(WEEE).

(KT-UL only)

GS mark of conformity of the “Deutsche Gesetzliche

Unfallversicherung e.V. (DGUV), Prüf- und

Zertifizierungsstelle Nahrungsmittel und Verpackung im

DGUV Test“ (German Social Accident Insurance (DGUV),

Testing and Certification Body for Foodstuffs and Packaging

Industry in DGUV Test). (Not valid for UL chambers)

The chamber is certified according to Customs Union

Technical Regulation (CU TR) for the Eurasian Economic

Union (Russia, Belarus, Armenia, Kazakhstan Kyrgyzstan).

The chamber is certified by Underwriters Laboratories Inc.

®

according to the following standards:

rd

• UL 61010-1, 3

• CAN/CSA-C 22.2 No. 61010-1, 3

Edition, 2012-05, Rev. 2015-07

rd

Edition, 201 2-05, Rev.

2015-07

rd

• IEC/EN 61010-1:2014, 3

Edition

KT (E6.1) 11/2020 Page 10/139

Page 11

1.7 General safety instructions on installing and operating the chambers

With regard to operating the chambers and to the installation location, please observe the local and national

regulations relevant for your country (for Germany: DGUV guidelines 213-850 on safe working in

laboratories, issued by the employers’ liability insurance association).

BINDER GmbH is only respons ible for th e safet y features of th e chamber provided sk illed elec tricians or

qualified personnel authorized by BINDER perform all maintenance and repair, and if components relating

to chamber safety are replaced in the event of failure with original spare parts.

To operate the chamber, use only original BINDER ac cessories or ac cessories f rom third-par ty suppliers

authorized by BINDER. The user is responsible for any risk caused by using unauthorized accessories.

NOTICE

Danger of overheating due to lack of ventilation.

Damage to the chamber.

∅ Do NOT install the chamber in unventilated recesses.

Ensure sufficient ventilation for dispersal of the heat.

Observe the prescribed minimum distances when installing the chamber (chap. 3.4)

Do not install or operate the chamber in hazar dous lo c ations .

DANGER

Danger of explosion due to combustible du sts or explosive mixtures in the vicinity

of the chamber.

Serious injury or death from burns and / or explo sion pressure.

∅ Do NOT operate the chamber in potentially explosive areas.

KEEP combustible dust or air-solvent mixtures AWAY from the chamber.

The chamber does not dispose of any measures of explosion protection.

DANGER

Danger of explosion due to introduction of flammable or explosive substances in

the chamber.

Serious injury or death from burns and / or explo sion pressure.

∅ Do NOT introduce any substance into the chamber which is combustible or explosive at

working temperature.

∅ Do NOT introduce any combustible dust or air-solvent mixture in the inner chamber.

Any solvent contai ned in th e charging m aterial m ust not be explosive or inflammabl e. I.e., irres pective of

the solvent concentrati on in the steam room, NO explos ive mixture with air must f orm. The temperature

inside the cham ber m ust lie belo w the f lash point or belo w the su blim ation point of the ch arging mater ial.

Familiarize yourself with the physical and chemical properties of the charging material, as well as the

contained moisture constituent and its behavior with the addition of heat energy.

Familiarize yourself with any potential health risks caused by the charging material, the contained moisture

constituent or by reaction products which may arise during the temperature process. Take adequate

measures to exclude such risks prior to putting the chamber into operation.

KT (E6.1) 11/2020 Page 11/139

Page 12

DANGER

Electrical hazard by water entering the chamber.

Deadly electric shock.

∅ The chamber must NOT become wet during operation, cleaning, or maintenance.

∅ Do NOT install the chamber in damp areas or in puddles.

Set up the chamber in a splash-proof manner.

The chambers were produced in accordance with VDE regulations and were routinely tested in accordance

to VDE 0411-1 (IEC 61010-1).

During and shortl y after operation, th e temperatur e of the inner s urfac es almos t equals the set-point. The

glass door, the glass door handles, and the inner chamber will become hot during operation.

CAUTION

Danger of burning by touching hot chamber parts during operation.

Burns.

∅ Do NOT touch the glass door, the glass door handles, the inner surfaces or the

charging material during oper atio n.

1.8 Intended use

Following the instructions in this operating manual and conducting regular maintenance work

(chap. 21.2) are part of the intended use.

Any use of the chambers that does not comply with the requirements specified in this Operating

Manual shall be considered improper use.

Other applications than those described in this chapter are not approved.

Use

Cooling incubators KT are suitab le for exac t conditioni ng of harmles s materials. Because of the ir precise

temperature accurac y these d evices ar e espec ially us eful for c ultivation of m icroorgan isms with a narro w

temperature optim um in a range of 4 °C / 39.2°F to 37 °C / 98.6°F. Main fields of app lication are t ests of

long-term stor age (e.g. at 4 °C / 39.2°F), ref rigerated incubat ion between 20 ° C / 68°F and 25 °C / 77°F

and incubation at 37 °C / 98.6°F (also with add iti on al int roduc t ion of heat) or with alter n ati ng temperatures

(e.g. 37 °C / 98.6°F and 4 °C / 39.2°F).

Requirements for the chamber load

Any solvent must not be explosive and flammable. A mixture of any component of the loading material with

air must NOT be explosive. The operating temperature must lie below the flash point or below the

sublimation point of the chargin g material. Any com ponent of the c harging m aterial must NO T be able to

release toxic gases.

The charging material shall not contain any corrosive ingredients that may damage the machine

components made of stain less steel, aluminum , and copper. Such ingr edients include in part icular acids

and halides. Any corrosive damage caused by such ingredients is excluded from liability by BINDER GmbH.

KT (E6.1) 11/2020 Page 12/139

Page 13

The chamber does not dispose of any measures of explosion protection.

DANGER

Explosion or implosion hazard and danger of poisoning through the introduction of

unsuitable loading material.

Poisoning. Serious injury or death from burns and / or explosion pressure.

∅ Do NOT introduce any substance combustible or explosive at working temperature into

the chamber, in particular no energy sources such as batteries or lithium-ion batteries.

∅ NO explosive dust or air-solvent mixture in the inner chamber.

∅ Do NOT introduce any substance which could lead to release of toxic gases.

Contamination of the chamber by toxic, infectious or radioactive substances must be prevented

WARNING

Danger of intoxication and infection through contamination of the chamber with

toxic, infectious or radioactive substances.

Damages to health.

Protect the interior of the chamber from contamination by toxic, infectious or radioactive

substances.

Take suitable protective measures when introducing and removing toxic, infectious or

radioactive material

In case of foreseeable use of the chamber there is no risk for the user through the integration of the chamber

into systems or by special environmental or operating conditions in the sense of EN 61010-1:2010. For this,

the intended use of the chamber and all its connections must be observed.

Medical devices

The chambers are not classified as medical devices as defined by the Medical Device Directive 93/42/EEC.

Due to the special demands of the Medical Device Directive (MDD), these chambers are not

qualified for sterilization of medical devices as defined by the directive 93/42/EWG.

Personnel Requirements

Only trained personnel with knowledge of the Operating Manual can set up and install the chamber, start it

up, operate, clean, and tak e it out of op eration. Ser vic e and repairs call for f urther techn ical req uirem ents

(e.g. electrical know-how), as well as knowledge of the service manual.

Installation site requirements

The chambers are designed for setting up inside a building (indoor use).

The requirements des cribed in the Operating Manua l for installation site and ambient conditions (Chap.

3.4) must be met.

WARNING: If customer should use a BINDER chamber running in non-supervised

continuous operation, we strongly recommend in case of inclusion of irrecoverable specimen

or samples to split such specimen or samples and store them in at least two chambers, if

this is feasible.

KT (E6.1) 11/2020 Page 13/139

Page 14

1.9 Foreseeable Misuse

Other applications than those described in chap. 1.8 are not approved.

This expressly incl udes the following misuses (the list is not exhaustive), which pos e risks despite the

inherently safe construction and existing technical safety equipment:

• Non-observance of Operating Manual

• Non-observance of information and warnings on the chamber (e.g. control unit messages, safety

identifiers, warning signals)

• Installation, startup, operation, maintenance and repair by untrained, insufficiently qualified, or

unauthorized personnel

• Missed or delayed maintenance and testing

• Non-observance of traces of wear and tear

• Insertion of materials excluded or not permitted by this Operating Manual.

• Non-compliance with the admissible parameters for processing the respective material.

• Installation, testing, service or repair in the presence of solvents

• Installation of replacement parts and use of accessories and operating reso urces not specified and

authorized by the manufacturer

• Installation, startup, operation, maintenance or repair of the chamber in absence of operating

instructions

• Bypassing or c hang in g pr ot ec tive systems, operation of the c hamber without the designated pr otec t ive

systems

• Non-observance of messages regarding cleaning and disinfection of the chamber.

• Spilling water or clean ing agent on the cham ber, water penetrating into the c hamber dur ing operat ion,

cleaning or maintenance.

• Cleaning activity while the chamber is turned on.

• Operation of the chamber with a damaged housing or damaged power cord

• Continued operation of the chamber during an obvious malfunction

• Insertion of objects, particularly metallic objects, in louvers or other openings or slots on the chamber

• Human error (e.g. insufficient experience, qualification, stress, exhaustion, laziness)

To prevent these and other risks fr om incorrect operati on, the operator s hall issue operating instruc tions.

Standard operating procedures (SOPs) are recommended.

KT (E6.1) 11/2020 Page 14/139

Page 15

1.10 Residual Risks

The unavoidable design features of a chamber, as well as its proper field of application, can also pose risks,

even during correct operation. These residual risks include hazards which, despite the inherently safe

design, existing technical protective equipment, safety precautions and supplementary protective

measures, cannot be ruled out.

Messages on the chamber and in the Operating Manual warn of residual risks. The consequences of these

residual risks and the measures required to prevent them are listed in the Operating Manual. Moreover, the

operator must take measures to minimize hazards from unavoidable residual risks. This includes, in

particular, issuing operating instructions.

The following list s ummarizes the hazar ds against which this Operating Manua l and the Service Manua l

warn, and specifies protective measures at the appropriate spots:

Unpacking, Transport, Installati on

• Sliding or tilting the chamber

• Setup of the chamber in unauthorized areas

• Installation of a damaged chamber

• Installation of a chamber with damaged power cord

• Inappropriate site of installation

• Missing protective conductor connection

Normal operation

• Assem bly errors

• Contact with hot surfaces on the housing

• Contact with hot surfaces in the interior and inside of doors

• Emission of non-ionizing radiation from electrical operating resources

• Contact with live parts in normal state

Cleaning and Decontamination

• Penetration of water into the chamber

• Inappropriate cleaning and decontamination agents

• Enclosure of persons in the interior

Malfunction and Damage

• Continued oper atio n of th e c ham ber during an ob vious m alfunc tion or out age of the he ating or cooling

system

• Contact with live parts during error status

• Operation of a unit with damaged power cord

Maintenance

• Maintenance work on live parts.

• Execution of maintenance work by untrained/insufficiently qualified personnel

• Electrical safety analysis during annual maintenance not performed

Trouble-shooting and Repairs

• Non-observance of warning messages in the Service Manual

• Trouble-shooting of live parts without specified safety measures

KT (E6.1) 11/2020 Page 15/139

Page 16

• Absence of a plausibility check to rule out erroneous inscription of electrical components

• Performance of repair work by untrained/insufficiently qualified personnel

• Inappropriate repairs which do not meet the quality standard spec if ied b y BINDER

• Use of replacement parts other than BINDER original replacement parts

• Electrical safety analysis not performed after repairs

1.11 O perating instructions

Depending on the a pplicati on and loc ation of the chamber, the operator of the chamber mus t provide th e

relevant information for safe operation of the chamber in a set of operating instructions.

Keep these operating instructions with the chamber at all times in a place where they are

clearly visible. They must be comprehensible and written in the language of the employees.

1.12 Measures to prevent accidents

The operator of the chamber must observe the following rule: “Betreiben von Arbeitsmitteln. Betreiben von

Kälteanlagen, Wärmepumpen und Kühleinrichtungen“ (Operation of work equipment. Operation of

refrigeration systems, heat pumps and refrigeration equipment) (GUV-R 500 chap. 2.35) (for Germany).

The manufacturer took the follo wing m eas ures to prevent ign iti on and ex plos io ns :

• Indications on the type plate

See operating manual chap. 1.6.

• Operating manual

An operating manual is available for each chamber.

• Overtemperature monitoring

The chamber is equipped with a temperature display, which can be read from outside.

The chamber is equipped with an addition al saf ety contr oller ( tem perature s afet y device clas s 3.1 acc .

to DIN 12880:2007). Visual and audible (buzzer) signals indicate temperature exceeding.

• Safety, measurement, and control equipment

The safety, measuring, and control equipment is easily accessible.

• Electrostatic ch arg e

The interior parts are grounded.

• Non-ionizing radiation

Non-ionizing radiation is not intentionally produced, but released only for technical reasons by electrical

equipment (e.g. elec tr ic motors, power cables, sol eno i ds) . The machine has no permanent magnets. If

persons with active im plants (e.g. pacemakers, def ibrillators) keep a safe distance (distance of field

source to implant) of 30 cm, an influence of these implants can be excluded with high probability.

• Protection against touchable surfaces

Tested according to EN ISO 13732-1:2008.

• Floors

See operating manual chap. 3.4 for correct installation

KT (E6.1) 11/2020 Page 16/139

Page 17

• Cleaning

See operating manual chap. 21.3.

• Examinations

The chamber has been inspected by the “Deutsche Gesetzliche Unfallversicherung e.V. (DGUV)

(German Social Accident Insurance (DGUV)” (German Social Accident Insurance (DGUV), Testing and

Certification Body for Food stuffs and Pack aging Indus try in DGU V Test) and bears the GS mark. (Not

valid for UL chambers)

®

UL units only: The cham ber is certified by Underwr iters Laboratories Inc.

rd

standards: UL 61010-1, 3

2012-05, Rev. 2015-07; IEC/EN 61010-1:2014, 3

Edition, 2012-05, Rev. 2015-07; C AN/CS A-C22.2 N o. 61010-1, 3rd Edition,

rd

Edition

accord-ing to the following

2. Chamber description

A high level of precision, reliability, and safety for all growth parameters ensures optimum incubation

conditions. Moreover , the KT cooling i ncubator is designed f or maximum usability – even in continuous

operation year after year. It fulfills all technical and application-specific requirements arising in

experimentation such as in the areas of biotechnology, medicine, the nutrition industry, pharmaceutical and

cosmetics industries, botany, and zoology.

Two important temperature technologies have been combined to achieve perfect temperature control. The

Peltier refrigerating system, in conjunc tion with the APT .line™ preheating chamber technology, satisf ies

the unique prerequisites for attaining highly-precise temperature control and particularly short recovery

times after opening the door.

The refrigerating s ystem is dis tingu ished b y direc t, pr ec ise, and r apid tem perature conduct ion . Due to the

Peltier cooling, s hocks are om itted which would occ ur during start and stop of c onventional refrigerat ion

systems with a compressor.

The APT.line™ preheating chamber system ensures high level of spatial and time-based temperature

precision, thanks to the direct and distributed air circulation into the interior. This is especially important for

maintaining temper atures – especially with full cham bers – and for rapid restor ation of optimum growth

conditions after ope ning the door. The inner glass door ensures that the tem perature remains constant

when observing the incubation process. The air turbine supports exact attainment and maintenance of the

desired temperature accuracy. The fan speed is digitally adjustable. The heating and refrigerating systems

are microprocess or regulated to a te nth of a degree. In addition, the chamber provides alm ost unlimited

possibilities for adaptation to individual customer requirements based upon extensive programming options

and on the week program timer and real time clock of the controller.

All chamber f unctions are easy and comf ortable to us e thanks to the ir clear arra ngement. Maj or features

are easy cleaning of all chamber parts and avoidance of undesired contamination.

The inner chamber , the pre-heating cham ber and the interior si de of the doors a re all made of stainles s

steel V2A (German material no. 1.4301, US equivalent AISI 304). The housing is RAL 7035 powder-coated.

All corners and edges are also completely coated.

The chambers come equipped with an Ethernet interfac e for computer comm unication, e.g. via the APTCOM™ 4 Multi Management Software (option, chap. 19.1). For further options, see chap. 23.5.

Temperature range with an ambient temperature of +22 °C +/- 3 °C / 71.6 °F +/- 5.4 °F:

+4 °C / 23 °F up to +100 °C / 212 °F

Fan speed range with temperature values from 4 °C up to 70 °C: 40 % up to100 %

Fan speed with temperature values above 70 °C: 100 %

KT (E6.1) 11/2020 Page 17/139

Page 18

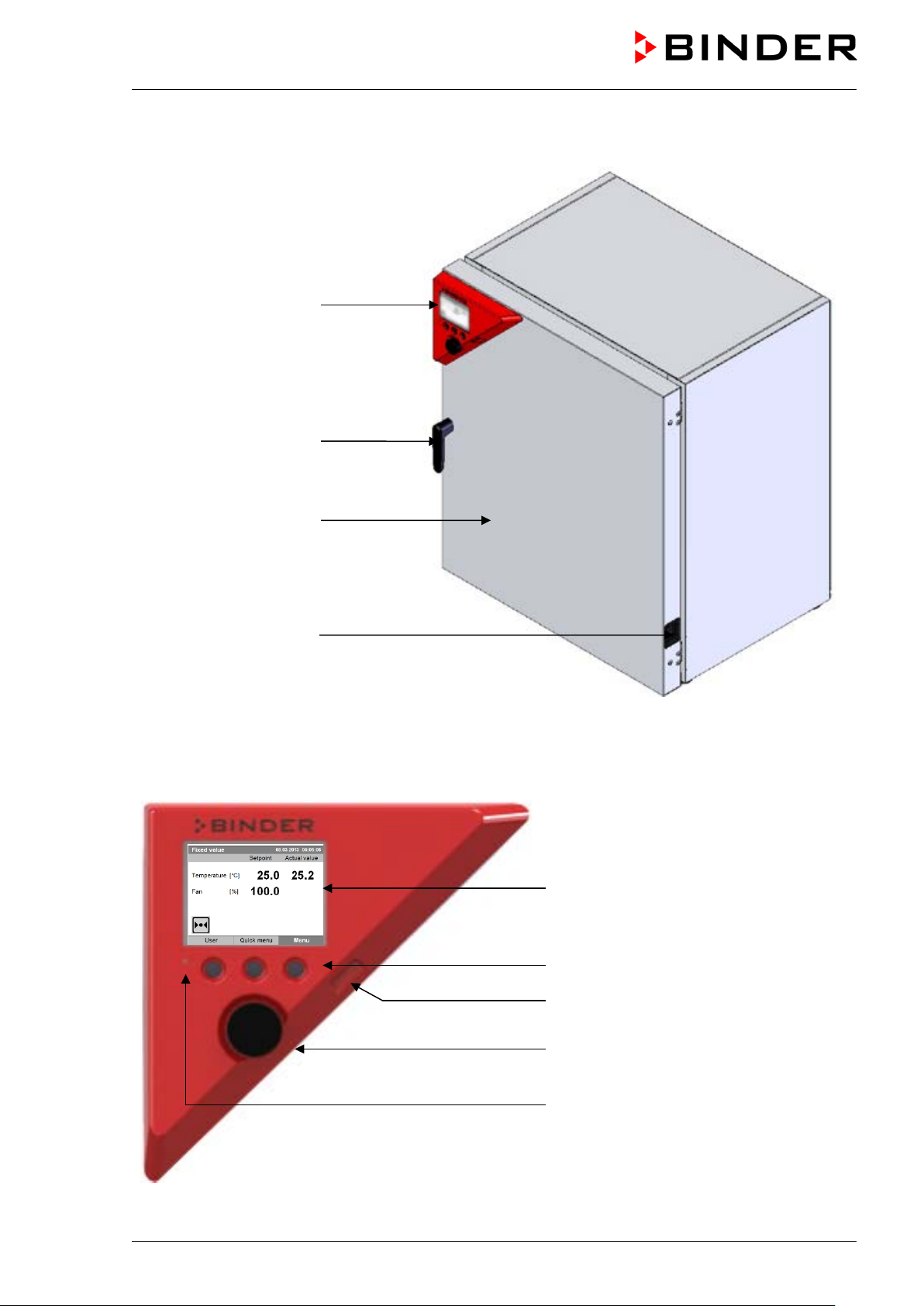

2.1 Chamber overview

Instrument panel with

microprocessor controller

T4.12 and USB interface

Door handle

Chamber door

Main power switch

2.2 Instrument panel

Figure 3: Cooling incubator KT (example: model KT 170)

5,7" controller display

Context-sensitive buttons

USB interface

Operating button

Pilot lamp: ready for operation

Figure 4: Instrument panel with microprocessor controller T4.12 and USB interface

KT (E6.1) 11/2020 Page 18/139

Page 19

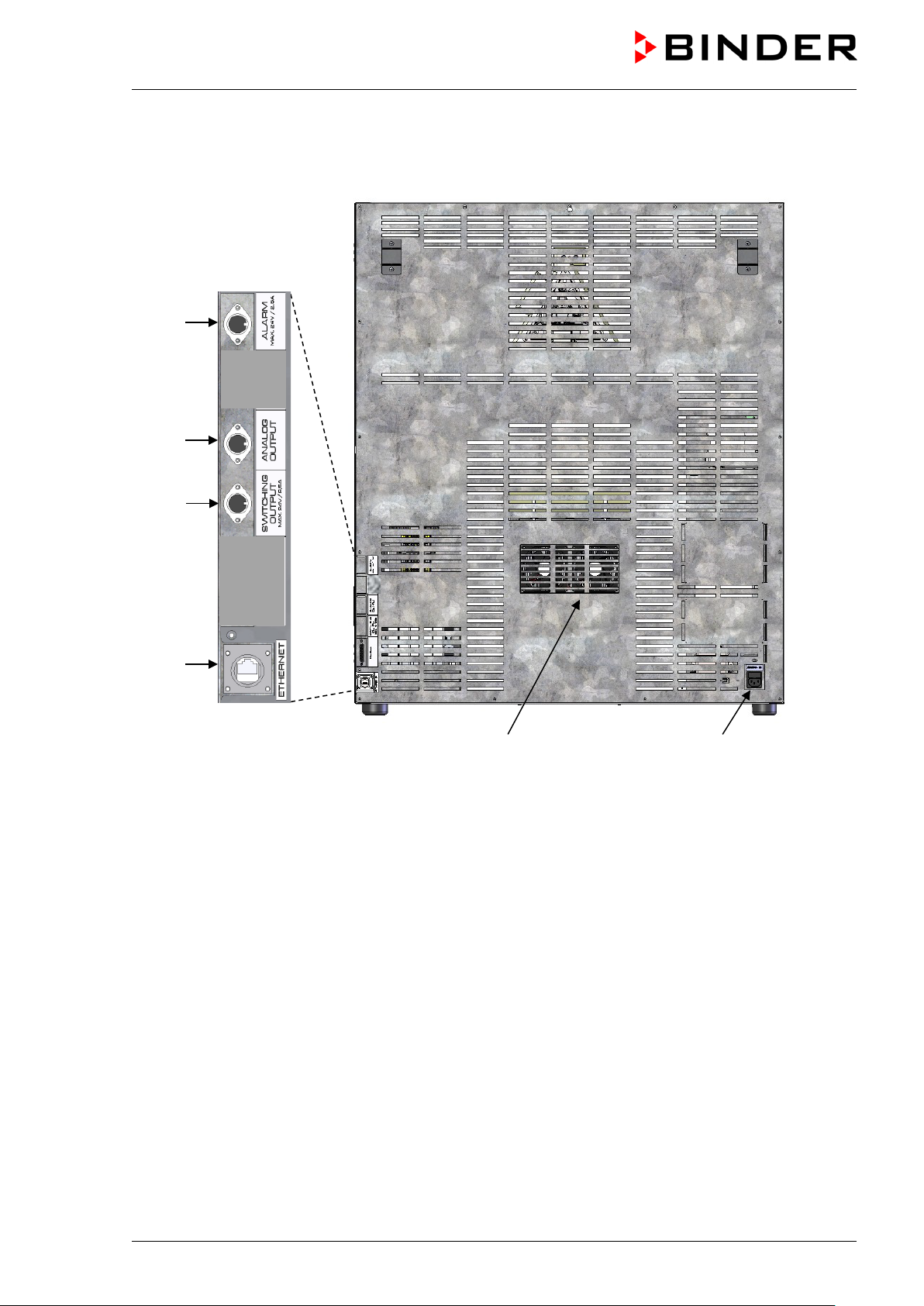

(7) (8)

2.3 Chamber rear

(1)

(3)

(4)

(6)

Figure 5: Chamber rear with position of options (example KT 170)

(1) DIN-socket for zero-voltage relay alarm outputs (option)

(2) (not used)

(3) DIN socket for analog output 4-20 mA (option)

(4) DIN-socket for zero-voltage relay control outputs (option)

(5) (not used)

(6) Ethernet interface for computer communication

(7) Peltier fan grid

(8) Socket for IEC connector plug with power cable

KT (E6.1) 11/2020 Page 19/139

Page 20

nd 115 from the pa llet with the aid of four peopl e in the area of

3. Completeness of delivery, transportation, storage, and location of

installation

3.1 Unpacking, and checking equipment and completeness of delivery

After unpacking, p lease check the chamber and its optional acces sories, if any, based on the del ivery

receipt for completenes s and for transportation damage. Inf orm the carrier immediately if tr ansportation

damage has occurred.

The final tests of the manufacturer may have caused traces of the shelves on the inner surfaces. This has

no impact on the function and performance of the chamber.

Please remove any transportati on protection devices and adhes ives in/on the chamber and on the do ors

and remove the operating manuals and accessory equipment.

CAUTION

Risk of injury and damages by lifting heavy loads and by sliding or tilting of the

chamber due to improper lifting.

Injuries, damage to the chamber.

Do NOT lift or transport the chamber using the door or the door handle.

Lift chambers size 53 a

all 4 chamber feet.

Lift chambers size 170 from the pallet with the aid of six people in the area of all 4

chamber feet.

If you need to return the chamber, please use the original packing and observe the guidelines for safe lifting

and transportation (chap. 3.2).

For disposal of the transport packing, see chap. 22.1.

Note on second-hand chambers (Ex-Demo-Units):

Second-hand chambers are chambers that were use d for a short time for tests or exhib itions. They are

thoroughly tested before resale. BINDER ensures that the chamber is technically sound and will work

flawlessly.

Second-hand chambers are marked with a sticker on the chamber door. Please remove the sticker before

commissioning the chamber.

KT (E6.1) 11/2020 Page 20/139

Page 21

NOTICE

3.2 Guidelines for safe lifting and transportation

After operation, please observe the guidelines for temporary decommissioning (chap. 22.2).

CAUTION

Risk of injury and damages by lifting heavy loads and by sliding or tilting of the

chamber due to improper transportation.

Injuries, damage to the chamber.

Transport the chamber in its original packaging only.

For moving or shipping, secure the chamber with transport straps.

Do NOT lift or transport the chamber using the door or the door handle.

Lift the chamber size 53 and 115 at the four lower corners with the aid of 4 people and

place it on a rolling pallet.

Lift the chamber size 170 at the four lower corners with the aid of 4 people and place it

on a rolling pallet.

Permissible ambient temperature range during transport: 10 °C / 14°F to +60 °C / 140°F.

You can order transport packing for moving or shipping purposes from BINDER service.

3.3 Storage

Intermediate storage of the chamber is possible in a closed and dr y room. Observe the guidelines for

temporary decommissioning (chap. 22.2).

• Permissible ambient temperature range during storage: -10 °C / 14°F to +60 °C / 140°F.

• Permissible ambient humidity: max. 70 % r.h., non-condensing

When after storage in a cold location you transfer the chamber to its warmer installation site, condensation

may form. Befor e s tart -up, wait at le as t o ne ho ur un ti l t he c hamber has attained a mbient temperature and

is completely dry.

3.4 Location of installation and ambient conditions

Set up the chamber on a flat, even surface, free from vibration, in a well-ventilated, dry location and align it

using a spirit level. The site of installation must be capable of supporting the chamber’s weight (see

technical data, chap. 23.4). The chambers are designed for setting up inside a building (indoor use).

Danger of overheating due to lack of ventilation.

Damage to the chamber.

∅ Do NOT install the chamber in unventilated recesses.

Ensure sufficient ventilation for dispersal of the heat.

Observe the prescribed minimum distances when installing the chamber.

KT (E6.1) 11/2020 Page 21/139

Page 22

Do not install or operate the chamber in potentially explosive areas.

DANGER

Danger of explosion due to combustible du sts or explosive mixtures in the vicinity

of the chamber.

Serious injury or death from burns and / or explo sion pressure.

∅ Do NOT operate the chamber in potentially explosive areas.

KEEP explosive dust or air-solvent mixtures AWAY from the vicinity of the chamber.

Ambient conditions

• Permissible ambient temperature range during operation: +18 °C / 64.4 °F to +25 °C / 77 °F.

At elevated ambient temperature values, fluctuations in temperature can occur.

The ambient temperature should not be substantially higher than the indicated ambient

temperature of +22 °C +/- 3 °C / 71.6 °F ± 5.4 °F to which the specified technical data

relates. Deviations from the indicated data are possible for other ambient conditions.

Lower values of the temperature range indicated in the technical data are valid at an

ambient temperature of max. 25 °C / 77 °F.

With each degree of ambient temperature > +25 °C / 77°F, the refrigeration power

decreases by 1.5 K.

• Permissible ambient humidity: 70 % r.h. max., non-condensing.

When operating the chamber at temperature set-points below ambient temperature, high ambient

humidity may lead to condensation on the chamber.

• Installation height: max. 2000 m / 6.6 ft. above sea level.

Minimum distances

• When placing several chambers of the same size side by side, maintain a minimum distance of 250 mm

/ 9.84 in between each chamber.

• Wall distances (minimum distances): rear 100 mm / 3.94 in, sides 240 mm / 9.45 in.

• Spacing above the chamber of at least 100 mm / 3.94 in must also be maintained

Stacking

Two devices of the following sizes can be piled on top of each other:

• KT 53 on KT 53 or KT 115 or KT 170

• KT 115 on KT 115 or KT 170

• KT 170 on KT 170

Place rubber pads under all four feet of the upper chamber to prevent the device from slipping.

NOTICE

Danger of sliding or tilting of the upper chamber when stacking.

Damage to the chambers.

When stacking, place rubber pads under all four feet of the upper chamber.

Other requirements

To completely separat e the chamber f rom the power s upply, you m ust disconnect the power p lug. Install

the chamber in a way that the power plug is easily accessible and can be easily pulled in case of danger.

For the user there is no risk of temporary overvoltages in the sense of EN 61010-1:2010.

KT (E6.1) 11/2020 Page 22/139

Page 23

With an increased amount of dust in the ambient air, clean the Peltier fan grid (7) by suction or b lowing

several times a year.

Avoid any conductive dust in the ambiance according to the chamber layout complying with pollution degree

2 (IEC 61010-1).

4. Installation of the equipme nt

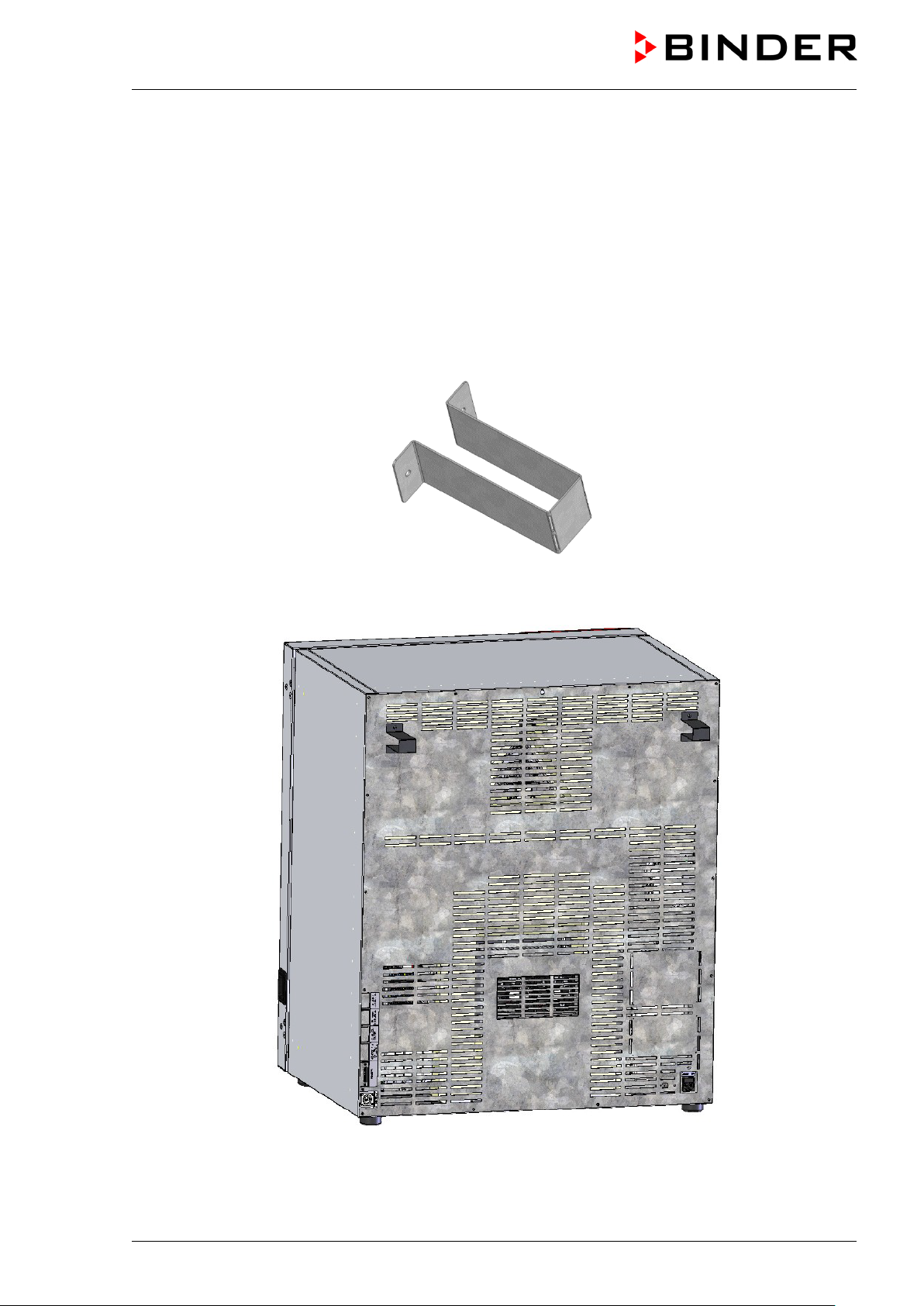

4.1 Spacer for wall distance

Please fix both spacers with the supplied screws at the chamber rear. This serves to ensure the prescribed

minimum distance to the rear wall of 100 mm / 3.94 in.

Figure 6: Spacer for wall distance

Figure 7: KT 170 rear with mounted spacers

KT (E6.1) 11/2020 Page 23/139

Page 24

KT 53

KT 170

KT 53-UL

KT 170-UL

NOTICE

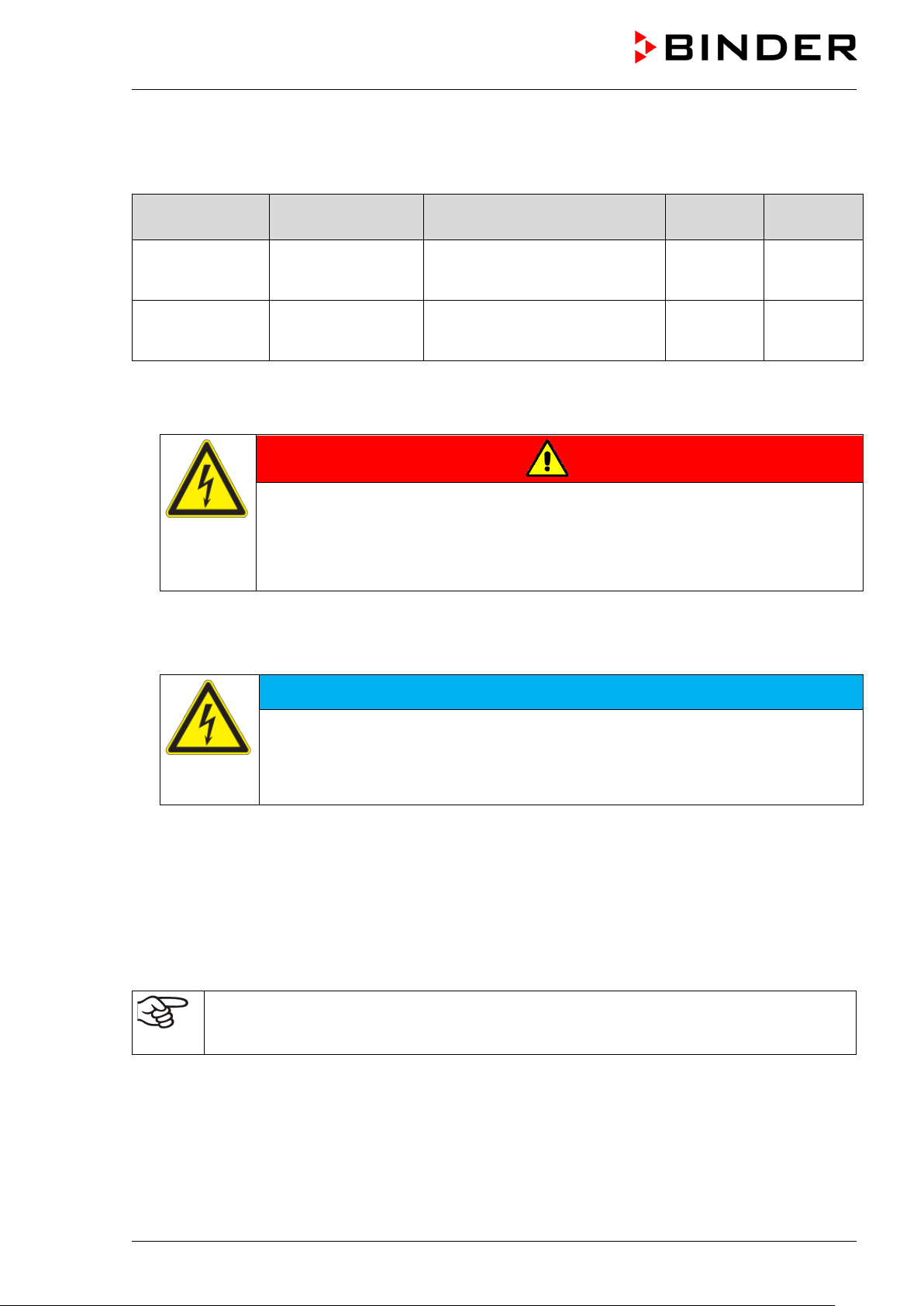

4.2 Electri cal co nn ect io n

The chambers are supplied ready for connection. They come with an IEC connector plug.

Model Power plug

KT 115

KT 115-UL

• The domes tic socket must also provide a protec tive conductor. Make s ure that the connection of the

protective conductor of the domestic installations to the chamber’s protective conductor meets the latest

technology. The protective conductors of the socket and plug must be compatible!

Shock-proof plug

NEMA 5-15P

Nominal voltage ± 10% at the

indicated power frequency

200-230 V at 50 Hz

200-230 V at 60 Hz

100-120 V at 50 Hz

100-120 V at 60 Hz

Current

type

1N~ 10 A

1N~ 10 A

Chamber

fuse

DANGER

Electrical hazard due to missing protective conductor connection.

Deadly electric shock.

Make sure that the chamber’s power plug and the power socket match and

securely connect the electrical protective conductors of the chamber and the house

installation.

• Only use original connection cables from BINDER according to the above specification.

• Prior to con nection and s tar t-up, chec k the po wer su ppl y voltag e. Com pare th e v alues to t he sp ecif ied

data located on the chamber’s type plate (left chamber side, bottom right-hand, see chap. 1.6).

Danger of incorrect power supply voltage due to improper connection.

Damage to the chamber.

Check the power supply voltage before connection and start-up.

Compare the power supply voltage with the data indicated on the type plate.

• When connect ing, please o bserve the regul ations spec ified by the local e lectricity s upply com pany as

well as the local or national electrical regulations (VDE directives for Germany).

• Observe a sufficient current protection according to the number of devices that you want to operate. We

recommend the use of a residual current circuit breaker.

• Pollution degree (acc. to IEC 61010-1): 2

• Over-voltage category (acc. to IEC 61010-1): II

See also electrical data (chap. 23.4).

To completely separate the chamber from the power supply, you must disconnect the power

plug. Install the chamber in a way that the power plug is easily accessible and can be easily

pulled in case of danger.

KT (E6.1) 11/2020 Page 24/139

Page 25

5. Start up

After connecting the e lect ri c al su pply (chap. 4.2) turn on the chamber by the main power sw itch. The pilot

lamp shows the chamber is ready for operation.

Observe a delay time of about 30s between turning Off and On again. Otherwise an

initialization problem may occur.

Note that the cham ber is in stand-by mode when the main power s witch has bee n turned on and yet the

controller display is dark. Turn on the chamber by pressing any controller button.

Warming chambers may release odors in the first few days after commissioning. This is not a quality defect.

To reduce odors quick ly we recomm end heating up the chamber to its nominal tem perature for one day

and in a well-ventilated location.

WARNING: If customer should use a BINDER chamber running in non-supervised

continuous operation, we strongly recommend in case of inclusion of irrecoverable specimen

or samples to split such specimen or samples and store them in at least two chambers, if

this is feasible.

5.1 Behavior when opening the door

When you open the door, heating and fan turn off. After a delay time of von 60 seconds (KT 53), 40 seconds

(KT 115) or 20 seconds (KT 170) they turn on again.

6. Functional overview of the T4.12 chamber controller

The T4.12 chamber controller controls the temperature (range: 4 °C up to 100 °C) and the fan speed (range:

40 % up to 100 %) inside the chamber. You can enter the desired set point values in fixed value operating

mode or in program mode in the display controller. The controller also offers a week program function and

various notifications and alarm messages with visual and audible indication, a trace file and remote alarms

via e-mail. You can enter values or program s directl y at the controller k eypad or using th e APT-COM™ 4

Multi Management Software (option, chap. 19.1) specially developed by BINDER.

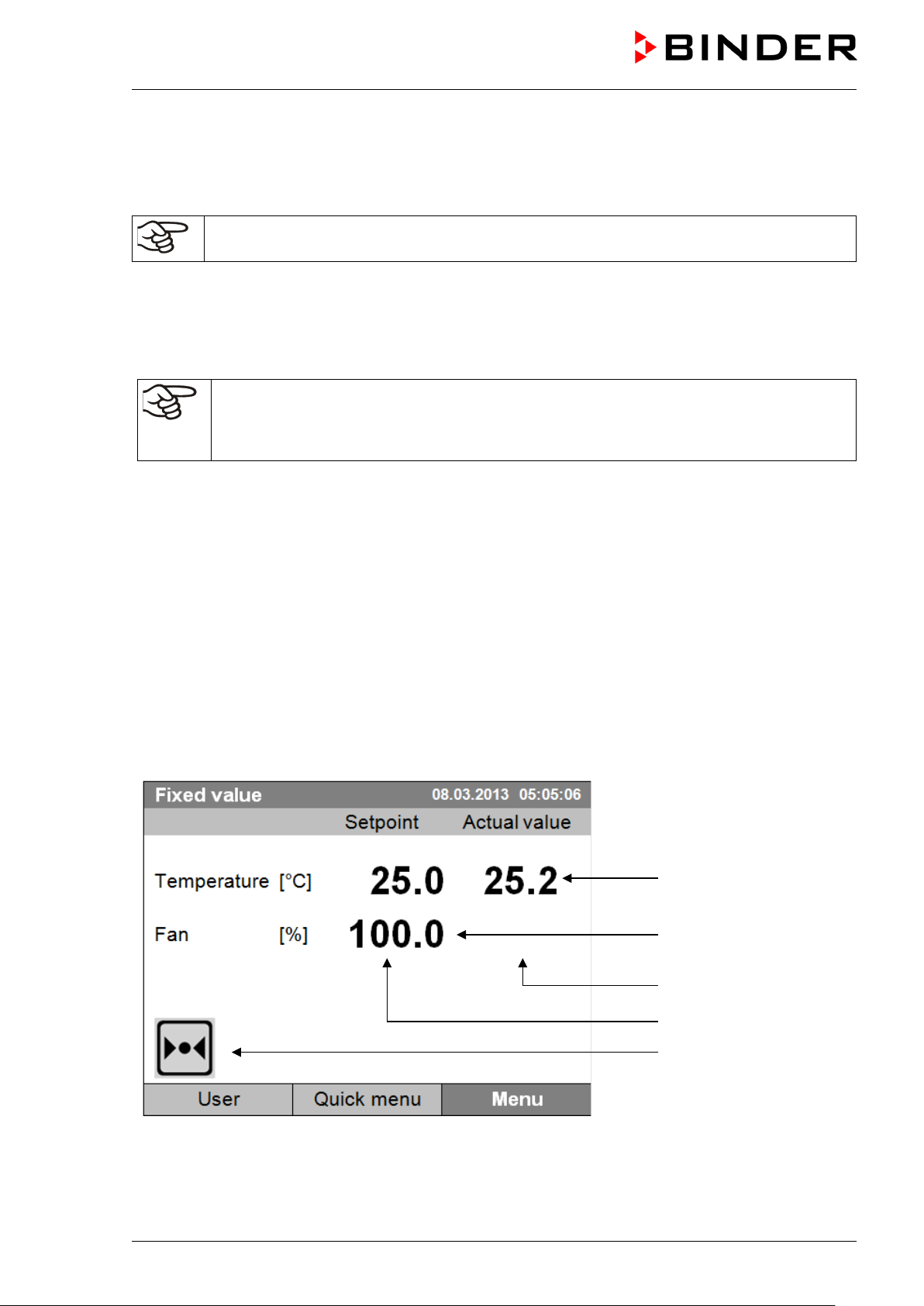

Temperature values

Fan speed value

Actual values

Set-point values

Icons:

Controller operating in “fixed

value” operating mode

Figure 8: T4.12 microprocessor controller, initial view in “fixed value” controller mode (sample values)

KT (E6.1) 11/2020 Page 25/139

Page 26

Fixed value

Setpoint

Actual value

25.0

25.2

100.0

Fixed value

..\ Menu

Controller mode

Event list

Alarms

Setpoints

Safety controller

Programs

Import/Export

Settings

Close

Home

6.1 Menu structure

08.03.2015 05:05:06

Temperature [°C]

Fan [%]

User Quick menu Menu

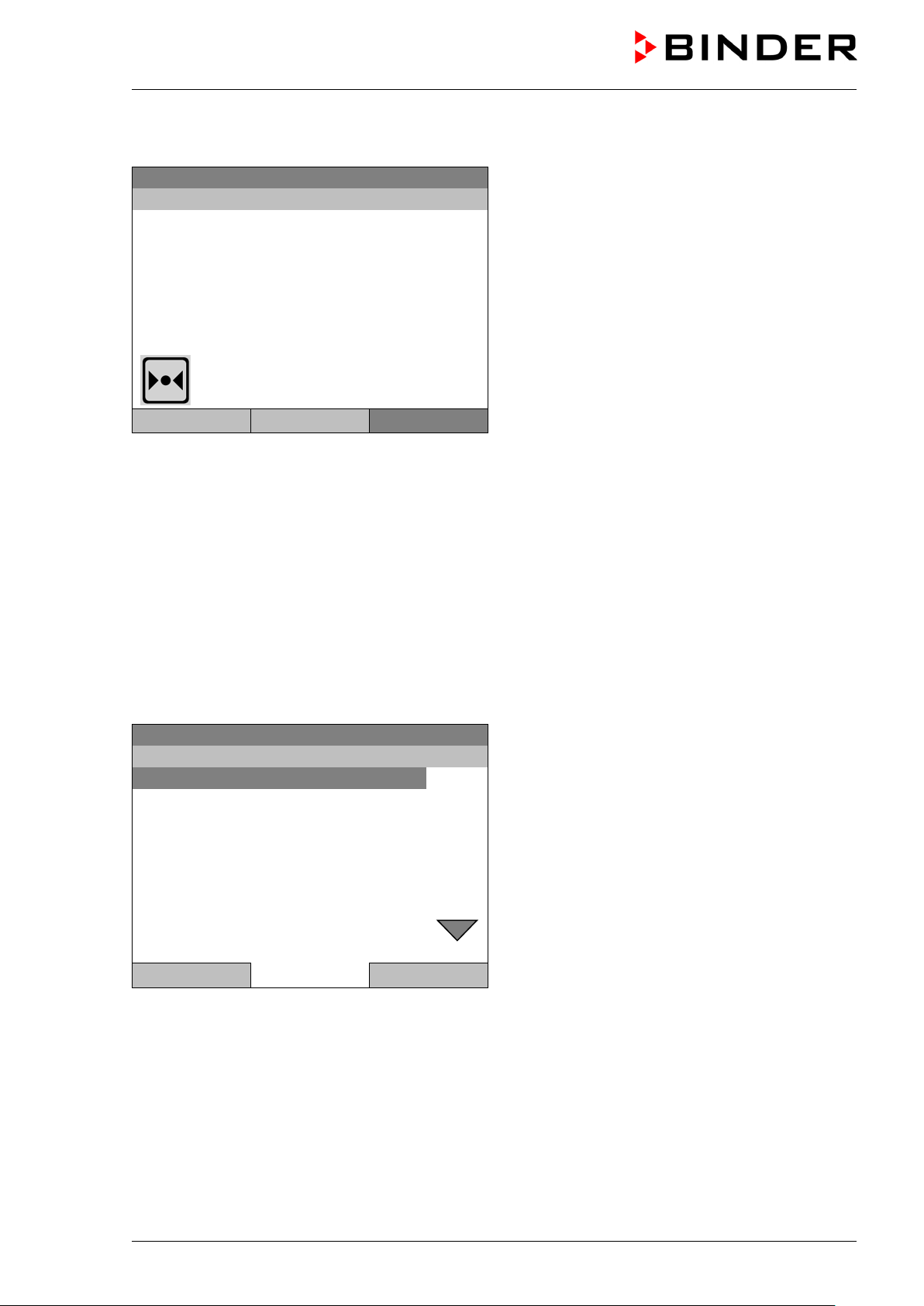

From the Initial view you ha ve acc es s to dif f erent menus using the menu buttons “User”, “Quick menu” , or

“Menu”. From there you can access the desired control functions. To do this, select the function by turning

the operating button and press the operating button to confirm the selection.

In any menu, you can re turn to the previous disp lay pressing t he "Close" button or to th e initial vie w with

the "Home" button.

Depending on the logged-in user or administrator, the available menu functions may vary. These

instructions present the functions which are available to the logged-in administrator.

Initial view (sample values).

Press the desired menu button.

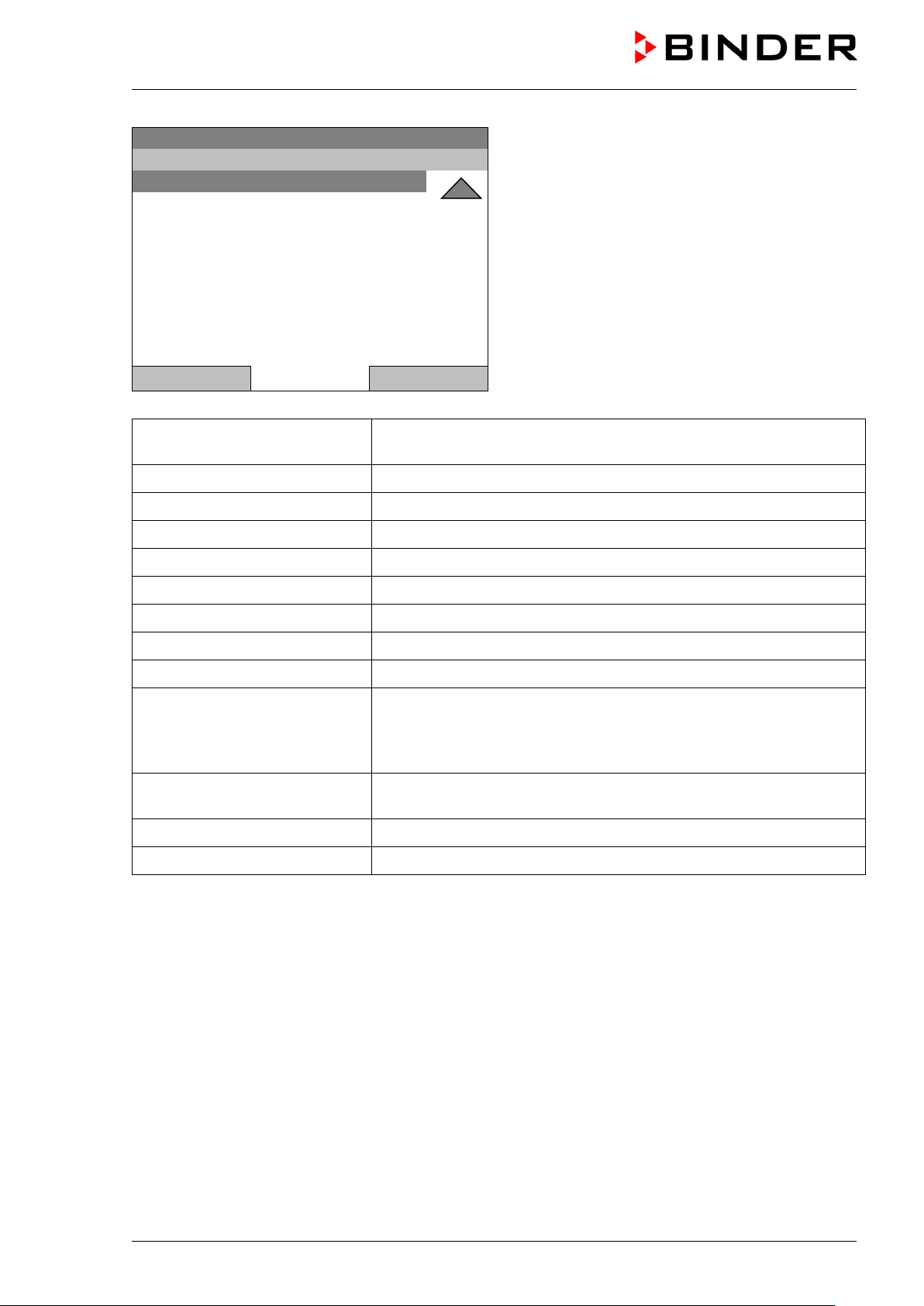

6.1.1 General menu

The general menu provides access to all setting functions of the controller, a graphical display of the

measured values, and the possibility to read and give out data via the USB interface. In addition, supporting

functions like a settings wizard or a contact page are available.

08.03.2015 05:05:06

General menu

Turn the operating butt on to see additional menu items.

KT (E6.1) 11/2020 Page 26/139

Page 27

Fixed value

..\ Menu

Measurement chart

Optional equipment

Sensor adjustment

Service contact

System information

08.03.2015 05:05:06

General menu (next page)

(“Optional equipm ent” menu item is visible onl y with

optional chamber equipment)

Close Home

Controller mode

Switching between the operating modes “control off” or “fixed value”,

chap. 6.2.1

Event list Display of status information and errors, chap. 15

Alarms Alarm settings, chap. 14.5

Setpoints Setpoint entry in “Fixed value” operating mode, chap. 8

Safety controller Setting the safety controller, chap. 17.2

Programs Time and week programs, chap. 9 and 10

Import/Export Data transfer via USB interface, chap. 13

Settings General controller settings, chap. 12

Measurement chart Graphical display of the measured values, chap. 16

Setting for optional equipment like door heating, interior socket,

Optional equipment

zero-voltage relay control outputs, alarm output, object temperature

display, chap. 7

(menu item is visible only with optional chamber equipment)

Sensor adjustment

Adjustment menu for single-point and two-point adjustments (for

Service purpose)

Service contact Service information

System information Chamber information (model, name, serial no., firmware etc.)

KT (E6.1) 11/2020 Page 27/139

Page 28

Fixed value

..\ Quick menu

Measurement chart

Active alarms

Temperature setpoint

Fan speed setpoint

Safety controller setpoint

Time program

Week program

Close

Home

Fixed value

..\ User

Key lock

Show event list

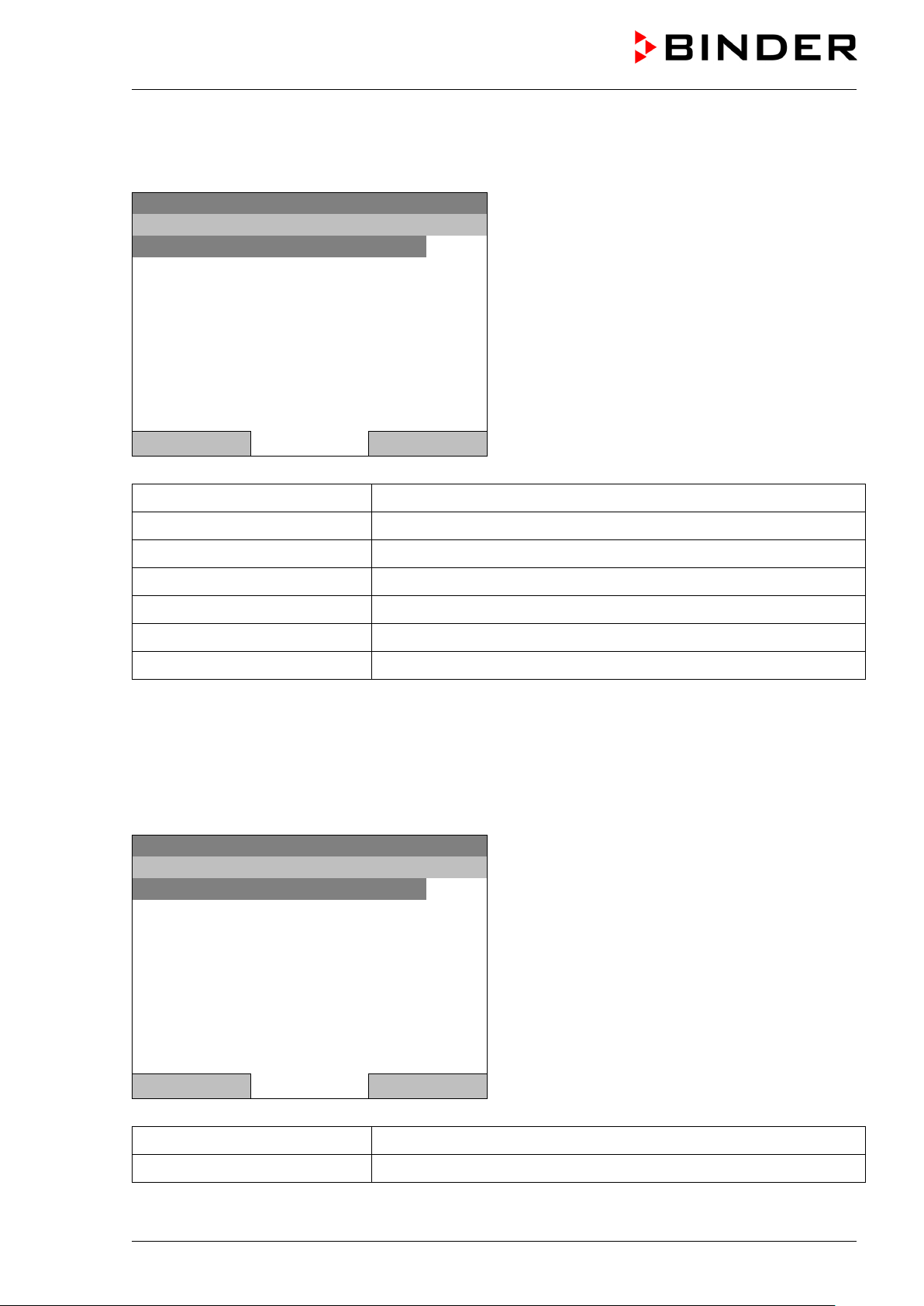

6.1.2 Quick menu

The Quick menu provides fast access to frequently used functions.

08.03.2015 05:05:06

“Quick menu”

Measurement chart

Active alarms

Temperature setpoint

Fan speed setpoint

Safety controller setpoint

Time program

Week program

Graphical display of the measured values, chap. 16

Alarm settings, chap. 14.5

Temperature setpoint entry in “Fixed value” operating mode, chap. 8

Fan speed setpoint entry in “Fixed value” operating mode, chap. 8

Setting the safety controller setpoint, chap. 17.2

Starting and cancelling a time program, chap. 9.1, 9.2

Starting and cancelling a week program, chap. 10.1, 10.2

6.1.3 “User” menu

The user menu includes the key lock function and provides quick access to the event list. The key lock

function serves to block the access to the controller. An overview of logon, logoff, and other events is

given in the event list.

08.03.2015 05:05:06

Key lock Configuring the key lock function, chap. 11

Show event list Displaying the event list, chap. 15

KT (E6.1) 11/2020 Page 28/139

“User” menu

Close Home

Page 29

Fixed value

..\ Menu

Controller mode

Event list

Alarms

Setpoints

Safety controller

Programs

Import/Export

Settings

Fixed value

..\ Controller mode

Control off

Fixed value

6.2 Operating modes

In the “control off” mode (chap. 6.2.1), the controller is non-functional and displays only the actual values.

There is no heating or ref rigeration. The tem perature approxim ates the ambient va lue, the fan turns with

40 % speed.

You can enter the d esired s et point values in “fixed v alue” mode ( chap. 8). T he controller t hen operates

as a fixed-point control, i.e., it reaches and maintains the defined temperature set-point until the next manual

change.

The T4.12 program c ontroller also perm its running a time program (chap. 9) or a week p rogram (chap.

10). You can program temperature cycles and define also the fan sp eed for each program section. The

controller offers 52 time program places with u p to 100 sections e ach. The week progr am mode offer s 8

week program places with up to 30 shift points for each week program.

6.2.1 Activating the “control off” mode or change to “fixed value” operating mode

To select the “control off” or “fixed value” operating mode, go to Menu > Controller mode

08.03.2015 05:05:06

Close Home

Close Home

General menu.

Select “Controller Mode”

and press the operating button.

08.03.2015 05:05:06

Submenu “Controller Mode”.

Select the desired controller mode

“Control off” or “Fixed value”

and press the operating button.

KT (E6.1) 11/2020 Page 29/139

Page 30

Control off

..\ Menu

Controller mode

Event list

Alarms

Setpoints

Safety controller

Programs

Import/Export

Settings

Control off

08.03.2015 05:05:06

Actual value

25.2

40.0

Menu

08.03.2015 05:05:06

General menu with controller mode “Control off”.

The controller mode “Fixed value” or “Control off” is

indicated in the display headline.

Close Home

Go back to the initial view with “Home”.

Temperature [°C]

Fan [%]

User Quick menu

The controller is non-functional, i.e., there is no heating or refrigerating. The fan turns at 40 % speed.

In the “Control off” mode, no program can be started.

Initial view in “Control off” mode

(sample picture).

KT (E6.1) 11/2020 Page 30/139

Page 31

Fixed value

..\ System information

Chamber type: KT

Chamber name: KT_E6.1

Serial number: 00-00000

Special application number: 00-0000

Parameter version: 511B-0006-0011

Firmware version (1): 521C-0001-002A

Firmware version (2): 521B-0005-001E

Fixed value

..\ Service contact

Service hotline

International:

+49 7462 2005 555

USA Toll Free:

+ 1 866 885 9794

or

+ 1 631 224 4340

CIS:

+ 7 495 988 1516

service@binder-world.com

www.binder-world.com

6.3 Performance during and after power failure

During a power failure, all controller functions are shut down. The optional zero-voltage relay alarm output

(chap. 19.3) is switched to alarm position for the whole duration of the power failure.

After the power returns, all functions return to the same status the chamber had before power failure. . The

controller continues t o function in the or iginal op eratin g m ode it was in pr evious ly befor e the power failure

occurred.

• Performance after power failure in “fixed value” operation mode

All functions return to the same status the chamber had before power failure. The set-points are

immediately resumed.

• Performance after power failure during time program operation

The program is res umed at the point where th e int er ruptio n oc c urr ed with t he latest set-points reac h ed

during the program run.

• Performance after power failure during week program operation

The week program continues with the values corresponding to the current time.

In the “Control off” controller mode, no program can be started.

If the temperature has dropped below the alarm limit during power failure, confirm the alarm with the RESET

button as soon as the correct values are reached again (chap. 14.4).

6.4 Information

You access chamber information like the chamber type, serial no., firmware version etc. To display the

system information, go to Menu > System information

08.03.2015 05:05:06

Submenu “System information” (sample values).

Close Home

To display the BINDER Service contact data, go to Menu > Service contact

08.03.2015 05:05:06

Close Home

KT (E6.1) 11/2020 Page 31/139

Submenu “Service contact”.

Page 32

Fixed value

..\ Optional equipment

Door heating

Interior socket

Zero-voltage relay control outputs

Functional test – alarm output

Object temperature display

Fixed value

..\ Door heating On/Off

Door heating On/Off

Door heating Offset

Further information windows are accessible under Menu > Settings > Network settings > Show network

settings (chap. 12.9) and – f or service purpose – under Menu > Settings > Chamber configuration

(chap. 12.10).

7. Configuration of optional equipment

The “Optional equipment” menu item is visible only with optional chamber equipment.

To access the selection menu, go to Menu > Optional equipment

08.03.2015 05:05:06

Submenu “Optional equipment”.

Select the desired function

and press the operating button.

Close Home

7.1 Setting the optional door heating

For chambers equipped with an optional door heating, you can turn it on and off via the controller. You can

also set the door heating off s et to the temperature set-point.

To access the door heating setting menu, go to Menu > Optional equipment > Door heating

08.03.2015 05:05:06

Submenu “Door heating”.

Select the desired function

and press the operating button.

“Door heating On/Off” = Turning on or off the door

heating

“Door heating Offset” = Temperature difference to

the entered setpoint

Close Home

KT (E6.1) 11/2020 Page 32/139

Page 33

Fixed value

..\ Door heating On/Off

Door heating: Off

Fixed value

..\ Door heating \ Offset

1

[°C]

Ins Pos1 End Ok

1 2 3 4 5 6 7 8 9 ,

Fixed value

..\ Interior socket

Interior socket: Off

Turning on or off the door heating:

08.03.2015 05:05:06

Submenu “Door heating On/Off ”.

The current setting is indicated.

To change the setting,

press the operating button.

The modified setting is displayed.

“Door heating: On” = door heating turned on

“Door heating: Off” = door heating turned off

Close Home

Setting the offset value:

08.03.2015 05:05:06

Entry menu „Offset“.