Binder BD, ED, FD User manual

BD/ED/FD (E2) Service Manual

State: 01/2002 Created: 06/2002 / Jochen Tussinger

BD/ED/FD (E2)

Service Manual

Version of chamber described in this service manual:

Standard equipped BD, ED, FD

with

R3 Controller

BD/ED/FD (E2) Service Manual

State: 01/2002 Created: 06/2002 / Jochen Tussinger

Contents

1 Chamber Description ..............................................................................................................3

1.1 BD (E2) ..................................................................................................................................3

1.2 ED (E2) ..................................................................................................................................3

1.3 FD (E2)..................................................................................................................................3

1.4 Description of the Chamber BD, ED and FD.............................................................................3

2 Function....................................................................................................................................4

2.1 BD (E2) ..................................................................................................................................4

2.2 Flow Chart of the Heating System of a BD (E2) (Standard BD 115 (E2)).....................................4

2.3 ED (E2) ..................................................................................................................................5

2.4 Flow Chart of the Heating System of a ED (E2) (Standard ED 115 (E2)).....................................5

2.5 FD (E2)..................................................................................................................................6

2.6 Flow Chart of the Heating System of a FD (E2) (Standard FD 115 (E2)).....................................6

2.7 PT100 Temperature Probe Resistance/Temperature Table .......................................................7

2.8 Description of the R3 controller Inputs and Outputs...................................................................7

3 Trouble Shooting.....................................................................................................................8

3.1 BD Chamber ..........................................................................................................................8

3.2 ED Chamber ..........................................................................................................................8

3.3 FD Chamber...........................................................................................................................9

3.4 APT-COM at BD, ED and FD...................................................................................................9

4 Most common service works...............................................................................................10

4.1 Changing of the controller R3 ................................................................................................10

4.2 Changing of the fan at FD (E2) chamber ................................................................................ 11

4.3 Calibration Procedure “One Point Calibration”......................................................................... 13

4.4 Change Display from °C (Celsius) to °F (Fahrenheit)............................................................... 15

4.5 Activation or deactivation of 0.1 steps at the temperature display. ............................................16

5 BD, ED and FD connected to APT-COM..........................................................................18

5.1 Communication Software APT-COM......................................................................................18

5.2 Settings at the controller R3..................................................................................................18

5.3 Connection of one chamber BD, ED or FD ............................................................................. 19

2

BD/ED/FD (E2) Service Manual

State: 01/2002 Created: 06/2002 / Jochen Tussinger

1 Chamber Description

1.1 BD (E2)

The BD (E2) chamber was developed for microbiology. The chamber is equipped with a R3 controller and

as an Option available with a RS422 Interface. The highest achievable temperature is 100°C.

The BD (E2) Chamber is available in the sizes 53, 115, 240, 400 and 720.

1.2 ED (E2)

The ED (E2) chamber was developed for drying and hot air sterilizing with natural convection. The

chamber is equipped with a R3 controller and as an Option available with RS422 Interface. The highest

achievable temperature is 300°C.

The ED (E2) Chamber is available in the sizes 53, 115, 240, 400 and 720.

1.3 FD (E2)

The FD (E2) chambers was developed for drying and hot air sterilizing with forced convection. The

chamber is equipped with a R3 controller and as an Option available with RS422 Interface. The highest

achievable temperature is 300°C.

The FD (E2) Chamber is available in the sizes 53, 115, 240, 400 and 720.

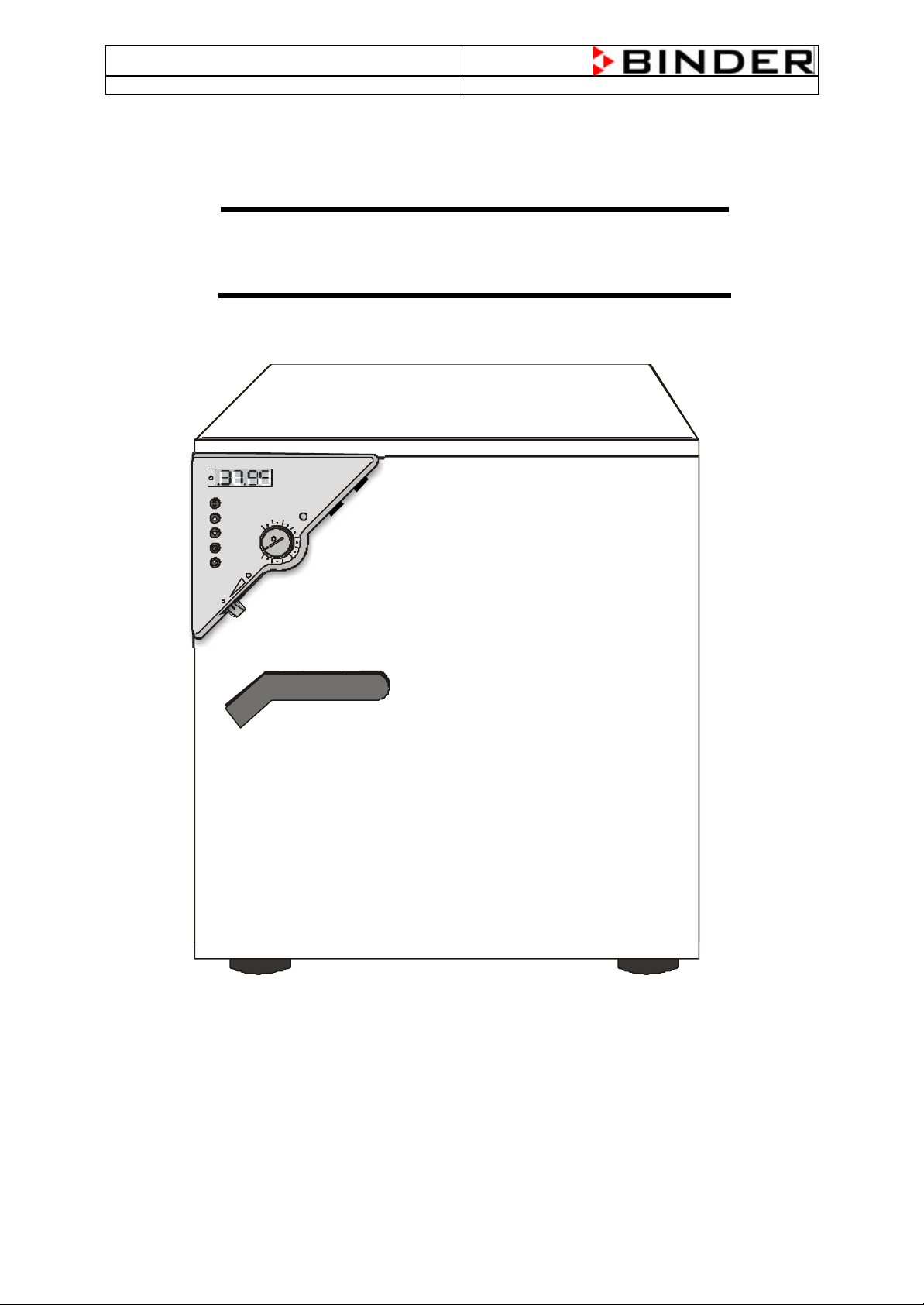

1.4 Description of the Chamber BD, ED and FD

1. Display

2. Required value key

3. Selector keys

4. Timer key

5. Main switch

6. Lever for ventilationslide

7. Safety device

8. Lever door open/close

9. Unit door

Picture 1: Heating Oven with R3-Controller

3

BD/ED/FD (E2) Service Manual

Ω

State: 01/2002 Created: 06/2002 / Jochen Tussinger

2 Function

2.1 BD (E2)

The BD (E2) chamber gives the possibility to heat up the chamber to a maximum temperature of 100°C.

The measuring of the temperature will be realized by a PT100 temperature probe which is placed directly

in the inner of the chamber .

The controller R3 measures the resistance of the PT100 temperature probe and compares the incoming

signal with the actual engaged value and decides to give a Signal to activate the heating elements or not.

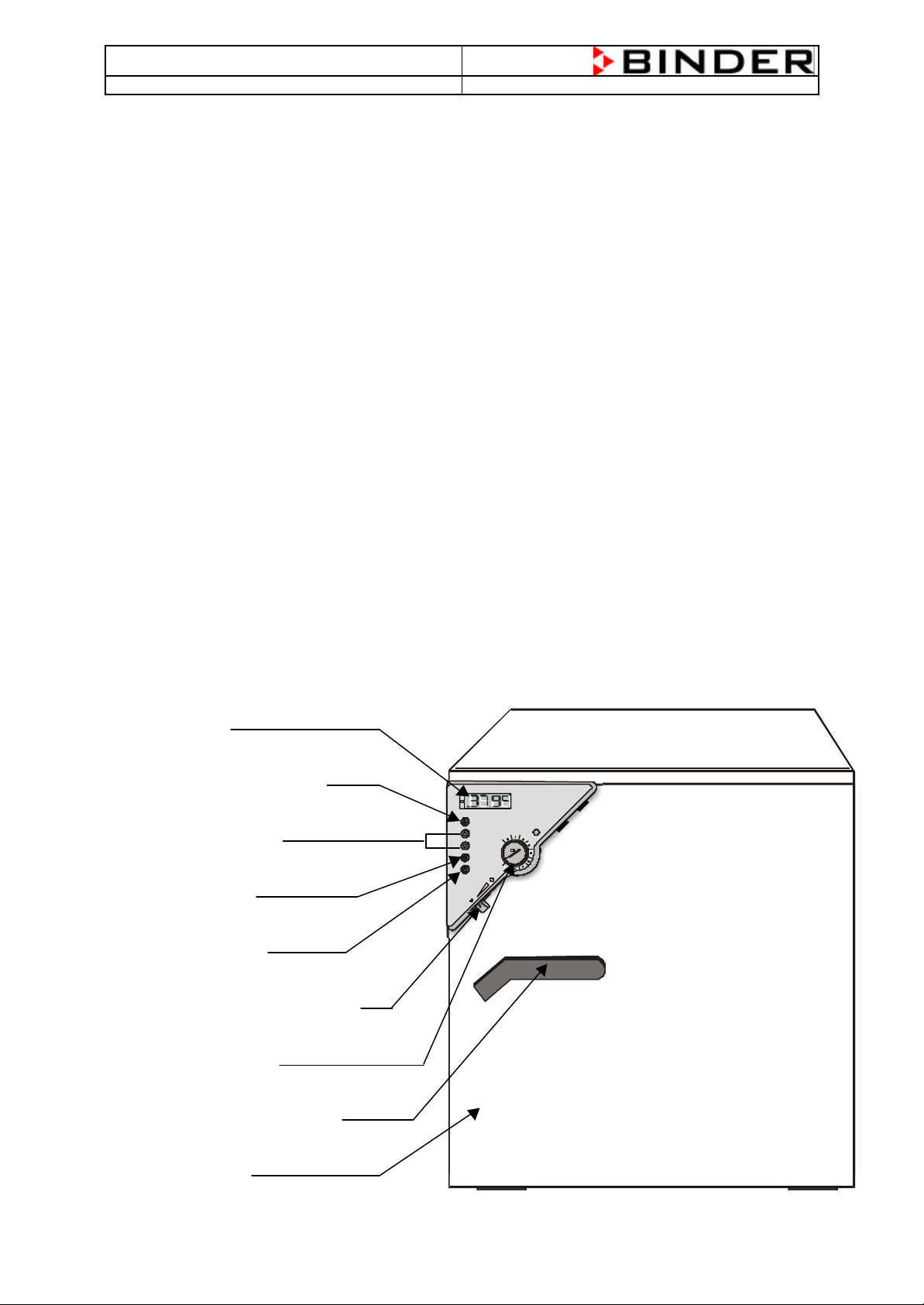

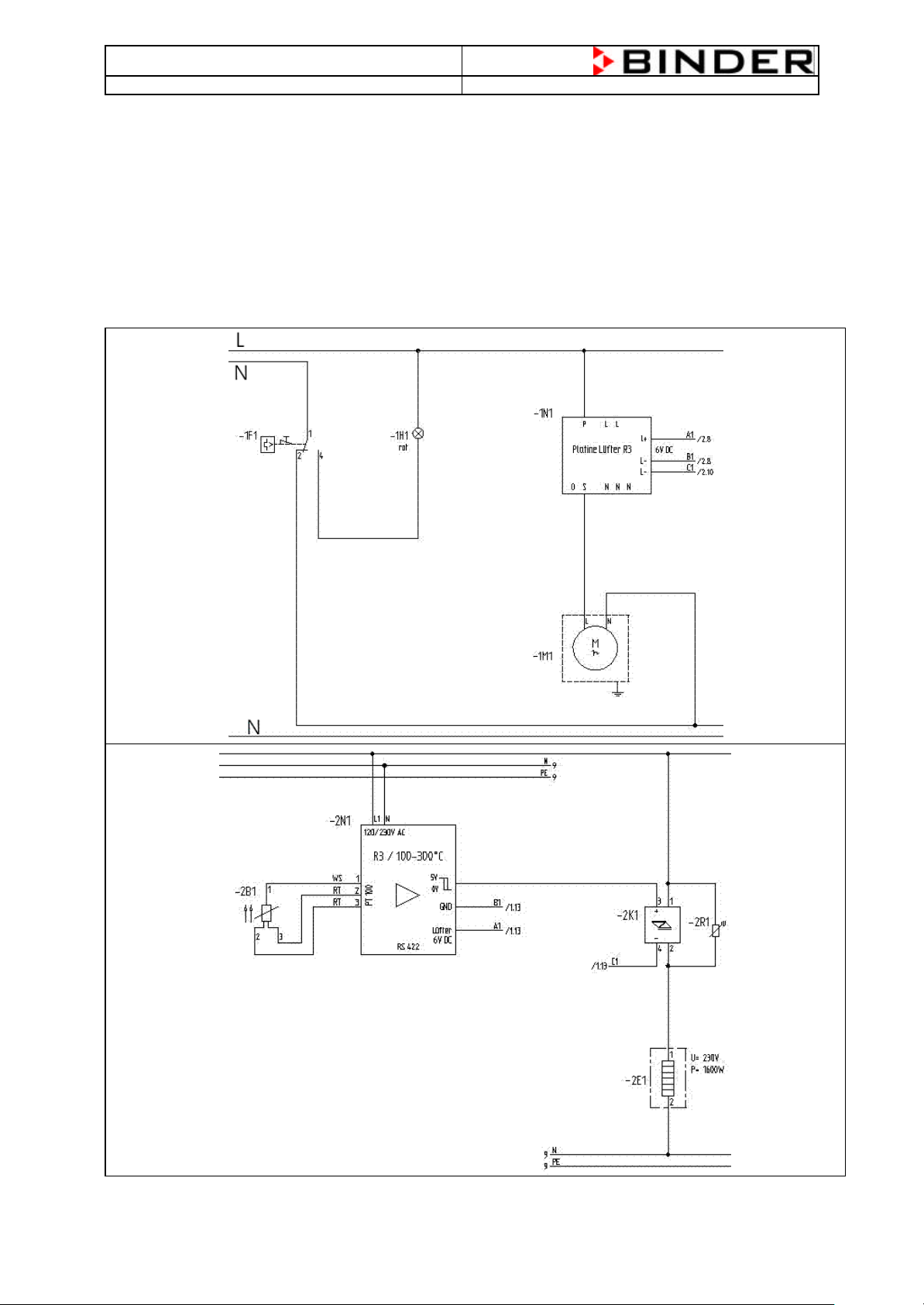

2.2 Flow Chart of the Heating System of a BD (E2) (Standard BD 115 (E2))

PT100 –> Controller R3 à Solid State Relay à Heating Element

The PT100 temperature probe is a resistance-measurement system. This means that the PT100 changes

his resistance at different temperatures. For example: at 37°C, the resistance of the PT100 have to be

114,380 Ω. To measure the resistance, disconnect all three cables from the controller and measure

between the white cable and one of the red cables, don’t measure between both red cables.

Measuring of the PT100 resistance

between the white cable 1 and one of the

two red cables 2 or 3

4

BD/ED/FD (E2) Service Manual

Ω

Measuring of the PT100 resistance

State: 01/2002 Created: 06/2002 / Jochen Tussinger

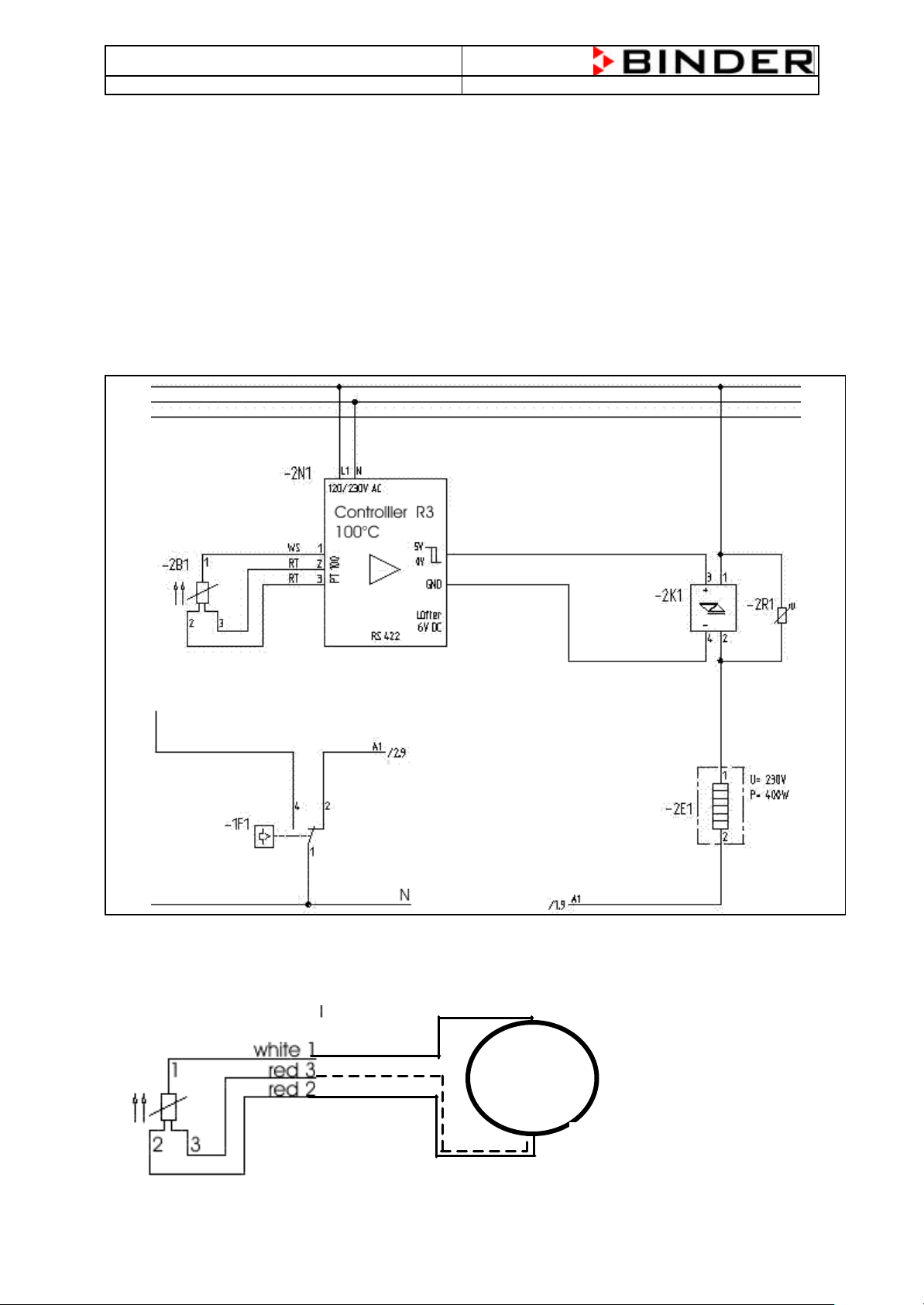

2.3 ED (E2)

The ED (E2) chamber gives the possibility to heat up the chamber to a maximum temperature of 300°C.

The measuring of the temperature will be realized by a PT100 temperature probe which is placed directly

in the inner of the chamber .

The controller R3 measures the resistance of the PT100 temperature probe and compares the incoming

signal with the actual engaged value and decides to give a Signal to activate the heating elements or not.

2.4 Flow Chart of the Heating System of a ED (E2) (Standard ED 115 (E2))

PT100 –> Controller R3 à Solid State Relay à Heating Element

The PT100 temperature probe is a resistance-measurement system. This means that the PT100 changes

his resistance at different temperatures. For example: at 37°C, the resistance of the PT100 have to be

114,380 Ω. To measure the resistance, disconnect all three cables from the controller and measure

between the white cable and one of the red cables, don’t measure between both red cables.

between the white cable 1 and one of the

two red cables 2 or 3

5

BD/ED/FD (E2) Service Manual

State: 01/2002 Created: 06/2002 / Jochen Tussinger

2.5 FD (E2)

The FD (E2) chamber gives the possibility to heat up the chamber to a maximum temperature of 300°C.

The measuring of the temperature will be realized by a PT100 temperature probe which is placed directly

in the inner of the chamber .

The controller R3 measures the resistance of the PT100 temperature probe and compares the incoming

signal with the actual engaged value and decides to give a Signal to activate the heating elements or not.

2.6 Flow Chart of the Heating System of a FD (E2) (Standard FD 115 (E2))

PT100 –> Controller R3 à Solid State Relay à Heating Element

6

BD/ED/FD (E2) Service Manual

96,086

96,478

96,870

97,262

97,653

98,045

98,436

98,827

99,218

99,609

100,000

100,000

100,391

100,781

101,172

101,562

101,953

102,343

102,733

103,123

103,513

103,902

103,902

104,292

104,681

105,071

105,460

105,849

106,238

106,627

107,016

107,404

107,793

107,793

108,181

108,570

108,958

109,346

109,734

110,122

110,509

110,897

111,284

111,672

111,672

112,059

112,446

112,833

113,220

113,607

113,994

114,380

114,767

115,153

115,539

115,539

115,925

116,311

116,697

117,083

117,469

117,854

118,240

118,625

119,010

119,395

119,395

119,780

120,165

120,550

120,934

121,319

121,703

122,087

122,471

122,855

123,239

123,239

123,623

124,007

124,390

124,774

125,157

125,540

125,923

126,306

126,689

127,072

127,072

127,454

127,837

128,219

128,602

128,984

129,366

129,748

130,130

130,511

130,893

130,893

131,274

131,656

132,037

132,418

132,799

133,180

133,561

133,941

134,322

134,702

134,702

135,083

135,463

135,843

136,223

136,603

136,982

137,362

137,741

138,121

138,500

138,500

138,879

139,258

139,637

140,016

140,395

140,773

141,152

141,530

141,908

142,286

State: 01/2002 Created: 06/2002 / Jochen Tussinger

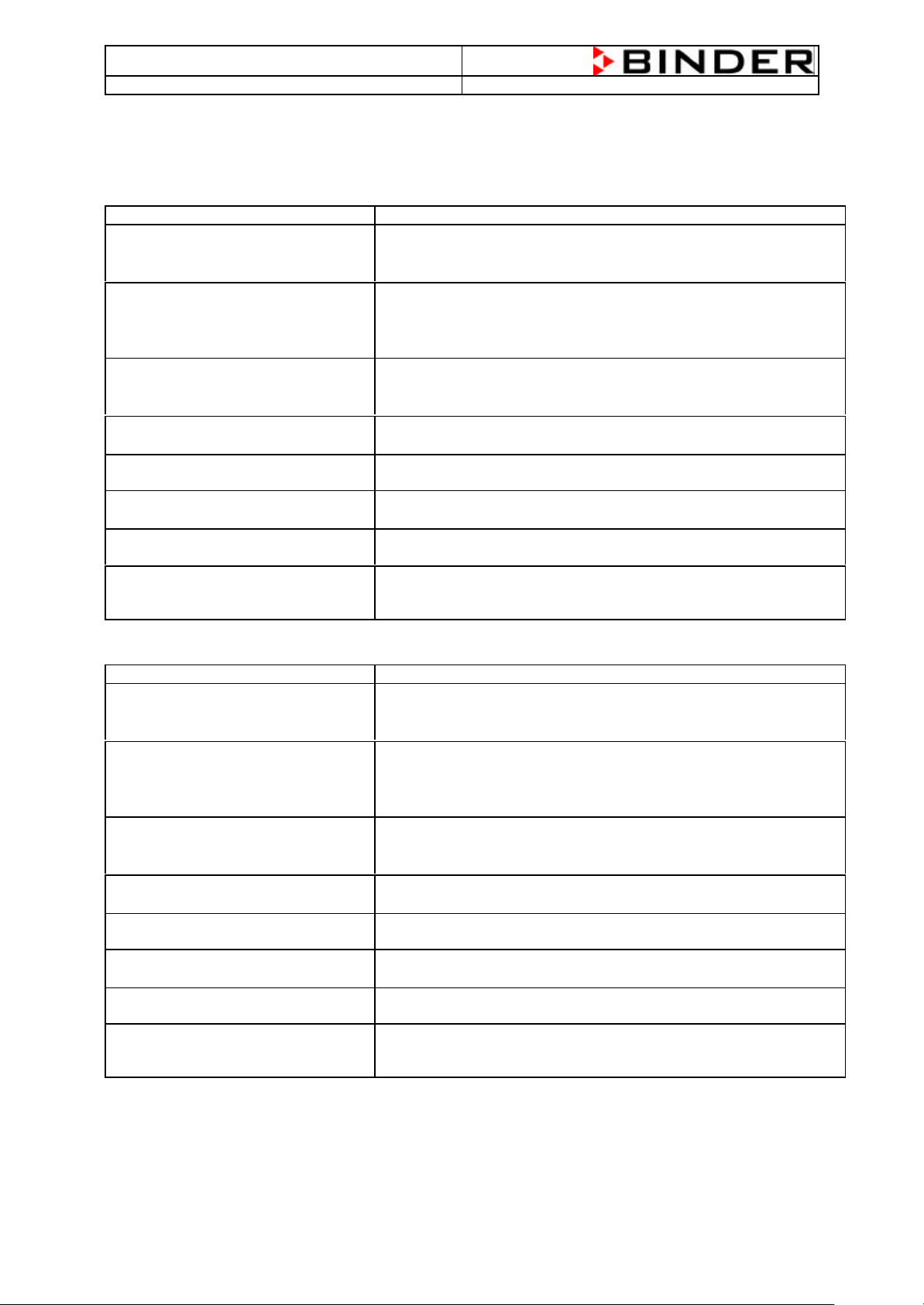

2.7 PT100 Temperature Probe Resistance/Temperature Table

T (°C) 0 1 2 3 4 5 6 7 8 9 10

-10

0

10

20

30

40

50

60

70

80

90

100

For Example: Your resistance measurement system shows you 114,380 Ω this corresponds to 37°C.

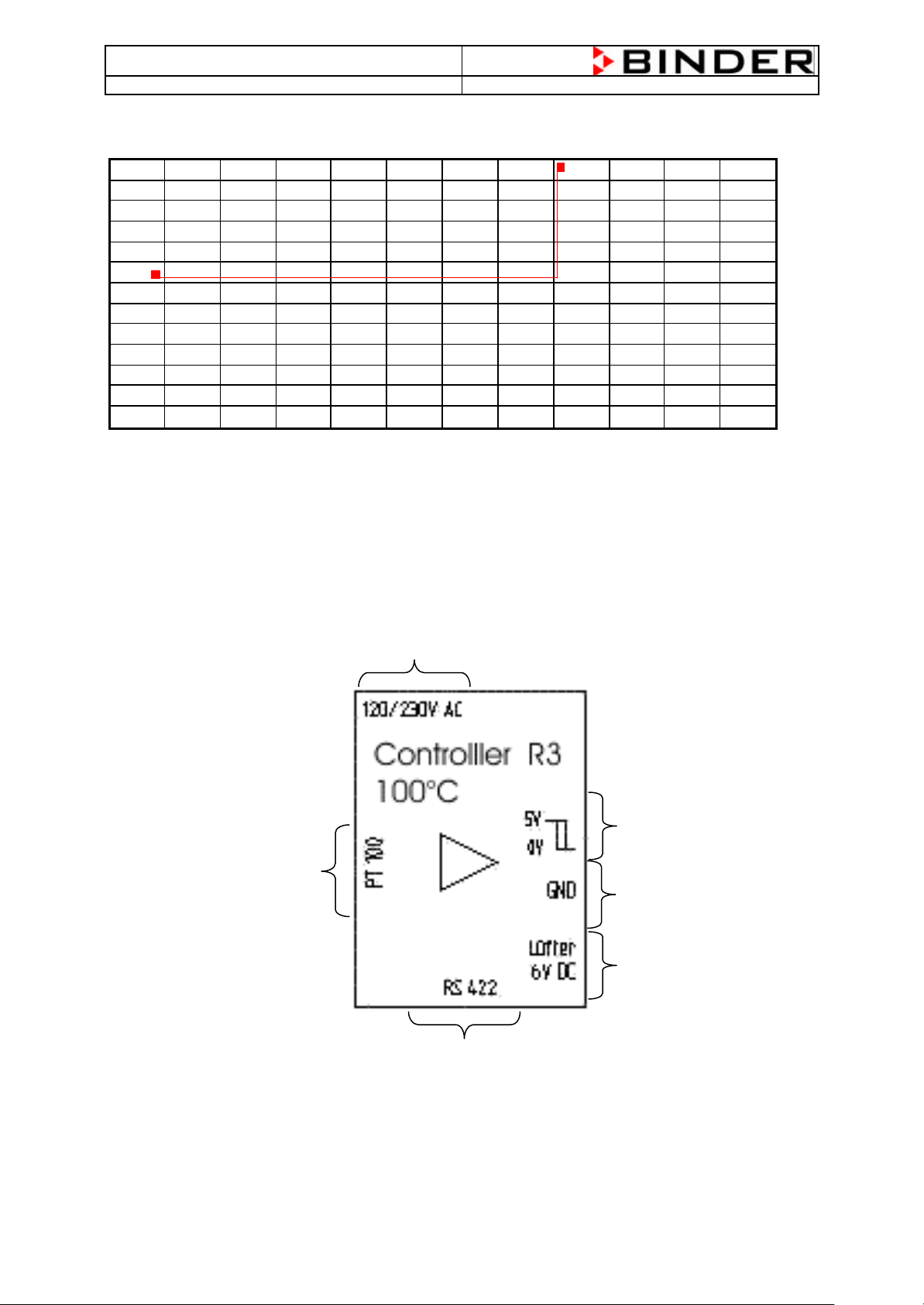

2.8 Description of the R3 controller Inputs and Outputs

Power Supply Input

PT100 input

Output Solid State Relay

Ground

Output for fan (only FD)

At BD and ED not in use

RS422 Interface

7

BD/ED/FD (E2) Service Manual

State: 01/2002 Created: 06/2002 / Jochen Tussinger

3 Trouble Shooting

3.1 BD Chamber

Fault Description Fault Cause

Not possible to reach the

temperature within the specification

time

The chamber heats over the

temperature setting

The chamber doesn’t heat any time,

the indicator light doesn’t lights up

The chamber doesn’t heat any time,

the indicator light lights up

The glass door of the chamber

doesn’t close.

The chamber doesn’t do anything

The chamber doesn’t do anything,

only the green LED lights

No data transfer to and from the

APT-Com possible. The installation is

correctly. (At BD with Interface)

• The door doesn’t close completely.

• The door sealing is broken or damaged

• The controller need a calibration

• The solid state relay could be defect

• The controller could be defect

• The PT100 could be defect

• The controller need a calibration

• The safety device has switched off the chamber

• Timer off

• The controller is defect

• The solid state relay is defect

• The Heating element(s) is/are defect

• The plastic catcher is defect

• Check if the power supply cable is connected to the mains

• Check if the mains has 115V or 230V voltage

• The chamber is in Stand-by mode

• Wrong chamber address is set at the controller

3.2 ED Chamber

Fault Description Fault Cause

Not possible to reach the

temperature within the specification

time

The chamber heats over the

temperature setting

The chamber doesn’t heat any time,

the indicator light doesn’t lights up

The chamber doesn’t heat any time,

the indicator light lights up

The glass door of the chamber

doesn’t close.

The chamber doesn’t do anything

The chamber doesn’t do anything,

only the green LED lights

No data transfer to and from the

APT-Com possible. The installation is

correctly. (At ED with Interface)

• The door doesn’t close completely.

• The door sealing is broken or damaged

• The controller need a calibration

• The solid state relay could be defect

• The controller could be defect

• The PT100 could be defect

• The controller need a calibration

• The safety device has switched off the chamber

• Timer off

• The controller is defect

• The solid state relay is defect

• The Heating element(s) is/are defect

• The plastic catcher is defect

• Check if the power supply cable is connected to the mains

• Check if the mains has 115V or 230V voltage

• The chamber is in Stand-by mode

• Wrong chamber address is set at the controller

8

BD/ED/FD (E2) Service Manual

State: 01/2002 Created: 06/2002 / Jochen Tussinger

3.3 FD Chamber

Fault Description Fault Cause

Not possible to reach the

temperature within the specification

time

The chamber heats over the

temperature setting

The chamber doesn’t heat any time,

the indicator light doesn’t lights up

The chamber doesn’t heat any time,

the indicator light lights up

The glass door of the chamber

doesn’t close.

The chamber doesn’t do anything • Check if the power supply cable is connected to the mains

The chamber doesn’t do anything,

only the green LED lights

No data transfer to and from the

APT-Com possible. The installation is

correctly. (At FD with Interface)

• The door doesn’t close completely.

• The fan doesn’t work

• The door sealing is broken or damaged

• The controller need a calibration

• The solid state relay could be defect

• The controller could be defect

• The PT100 could be defect

• The controller need a calibration

• The safety device has switched off the chamber

• Timer off

• The controller is defect

• The solid state relay is defect

• The Heating element(s) is/are defect

• The plastic catcher is defect

• Check if the mains has 115V or 230V voltage

• The chamber is in Stand-by mode

• Wrong chamber address is set at the controller

3.4 APT-COM at BD, ED and FD

Fault Description Fault Cause

No Function

No data transfer to and from the

APT-Com possible. The installation is

correctly.

• Connection is wrong, check the connection like described in

• Address in the controller is wrong

• Controller is in Stand-By mode

• Wrong chamber address is set at the controller

• The connection cable is broken/defect

• The Switch at the converter is set to DCE (correct = DTE)

• The converter doesn’t get the needed current

Chapter 5 APT-COM Connection

9

BD/ED/FD (E2) Service Manual

State: 01/2002 Created: 06/2002 / Jochen Tussinger

4 Most common service works

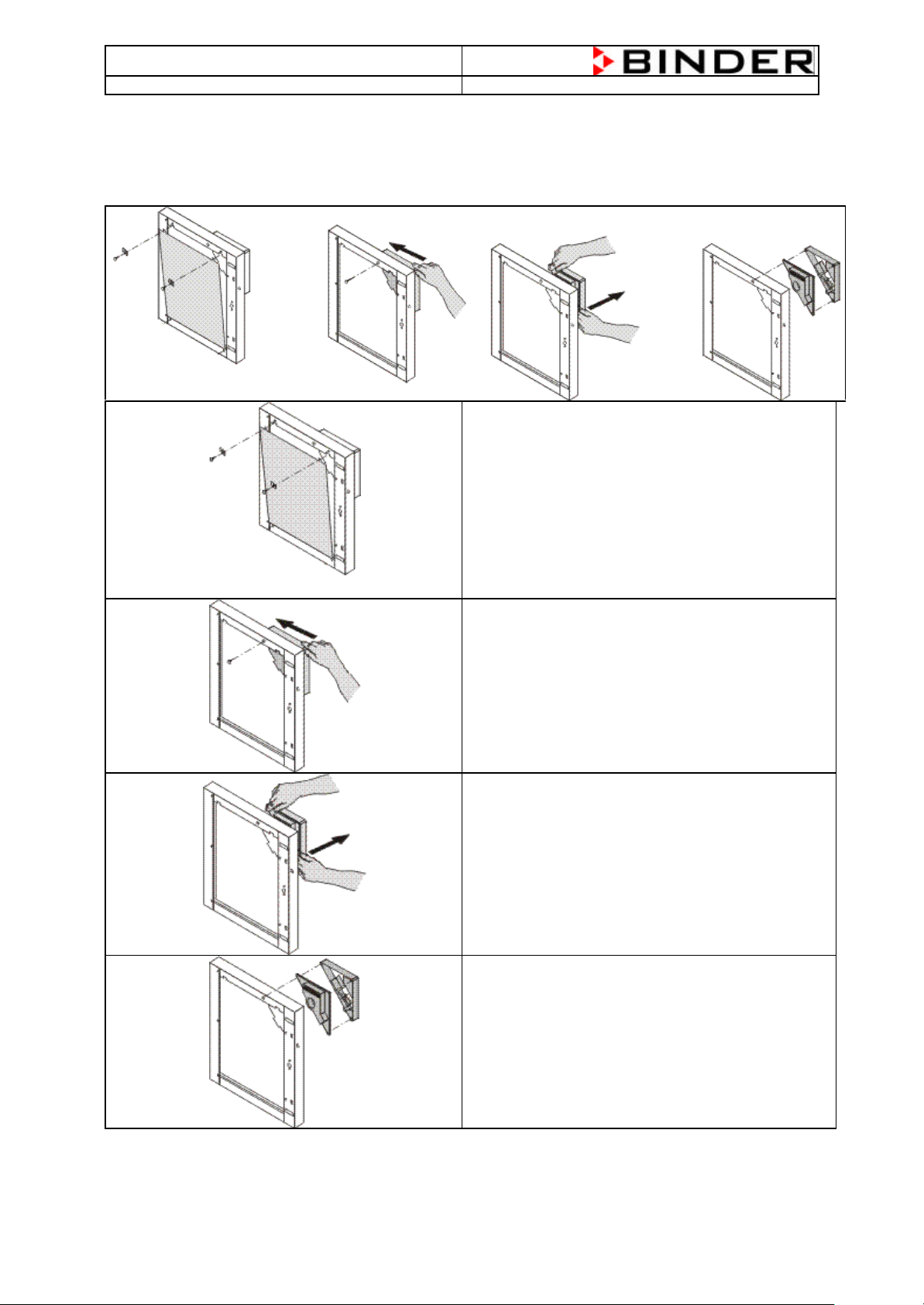

4.1 Changing of the controller R3

You have to open the two screws at the top of the

inner door. After that you can lift out the inner door,

but be careful the temperature safety device is

inside the door.

Now open the screw behind the white plastic cover.

The plastic cover could be broken after that.

Now you have to press like shown picture at the

perpendiculars side to bring out the controller

housing. Please press only in arrow direction.

Now you can take off the complete housing, be

careful, the temperature safety device is connected.

At the rear side of the housing you’ll find two screws,

you have to open them to work on the controller.

To bring back the controller in starting situation,

please fit it together in opposite direction.

10

BD/ED/FD (E2) Service Manual

State: 01/2002 Created: 06/2002 / Jochen Tussinger

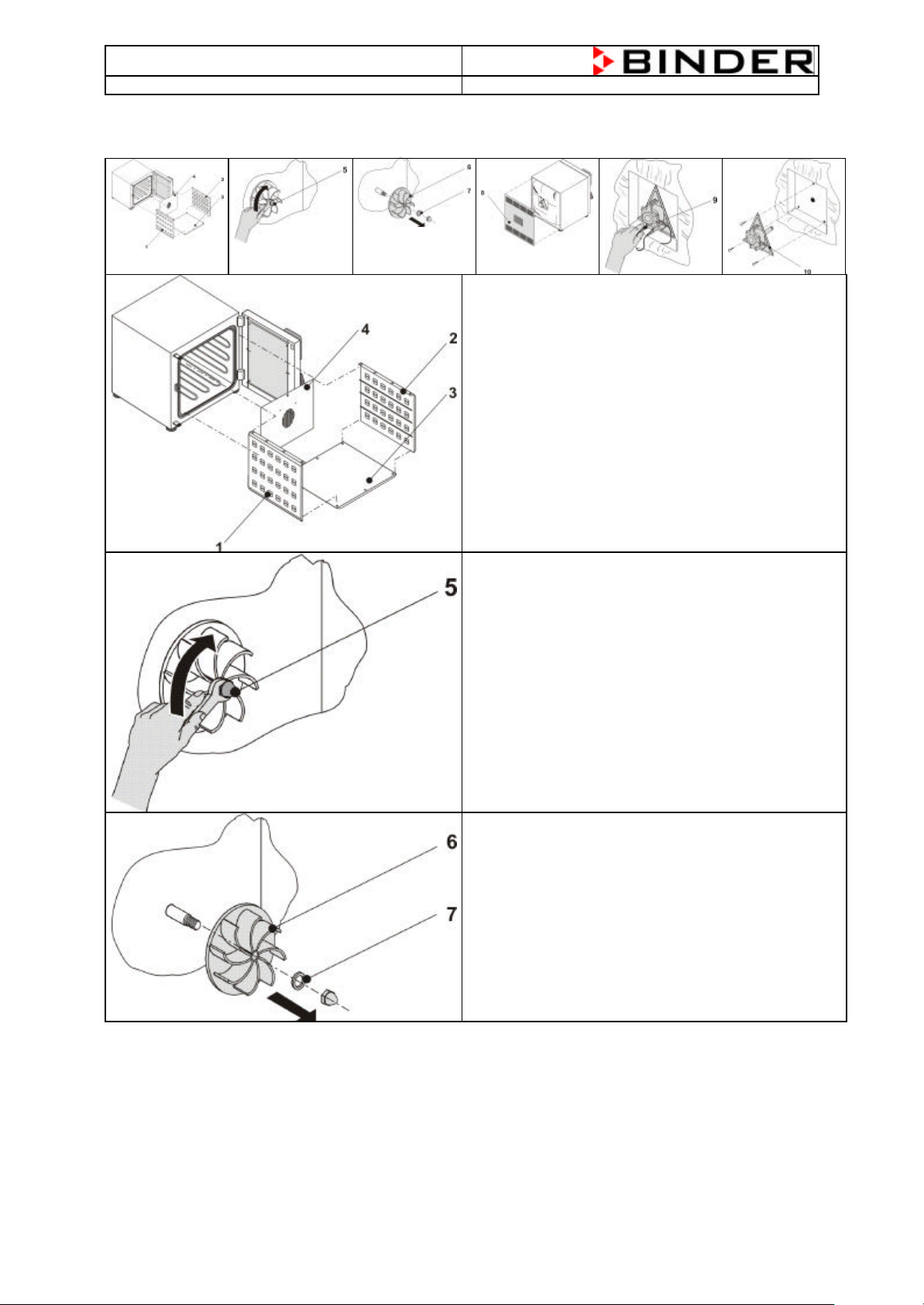

4.2 Changing of the fan at FD (E2) chamber

You have to unscrew the two side-walls (1 + 2), the

bottom (3) and the rear-wall (4) to reach the fanwheel.

The side-walls are screwed at the topside.

Before you could bring out the rear-wall, you have to

remove the PT-100 holder.

After this you can see the heating elements and also

the fan-wheel

Now you have to open the nut at the front of the fanwheel.

Notice: It is a left-thread.

Tool: box wrench size 13

Now it is possible to remove the washer and also the

fan-wheel.

11

BD/ED/FD (E2) Service Manual

State: 01/2002 Created: 06/2002 / Jochen Tussinger

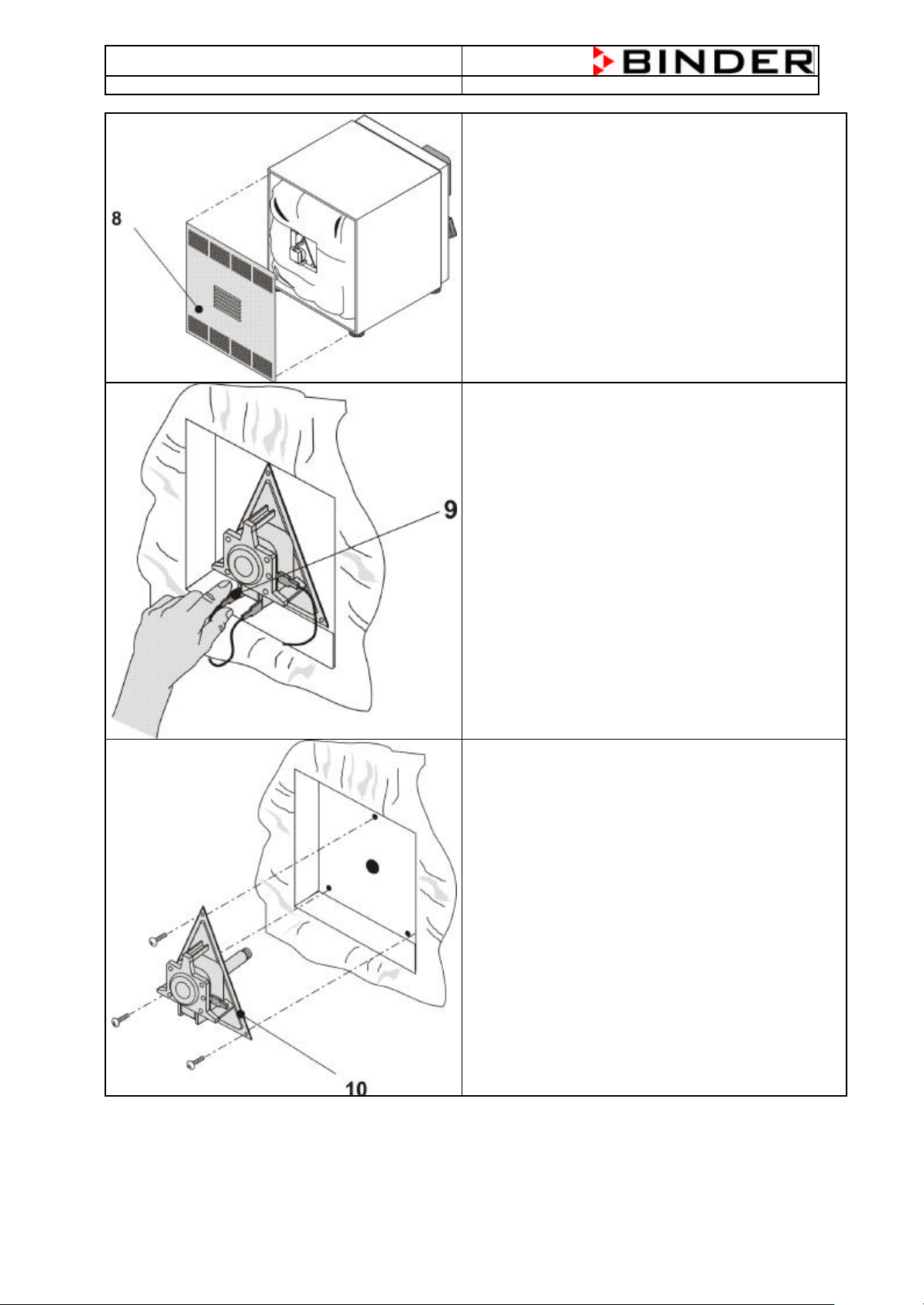

To take out the fan-motor with axis, you have to

remove the rear-wall of the chamber.

Tool: Screwdriver (Phillips-Screw)

Now disconnect the connection-wires at the fan,

if possible mark them for right connection when you

put in the new fan.

To take out the fan-motor with axis, you have to

remove the three Phillips-screw at the triangle.

Now it is possible to take out the complete part.

12

Loading...

Loading...