Doc. No. 0905BE20500

Rev. B

D:\Binder_E\Manuals_en\COMBIMASS_compact\Titelseite_en.cdr

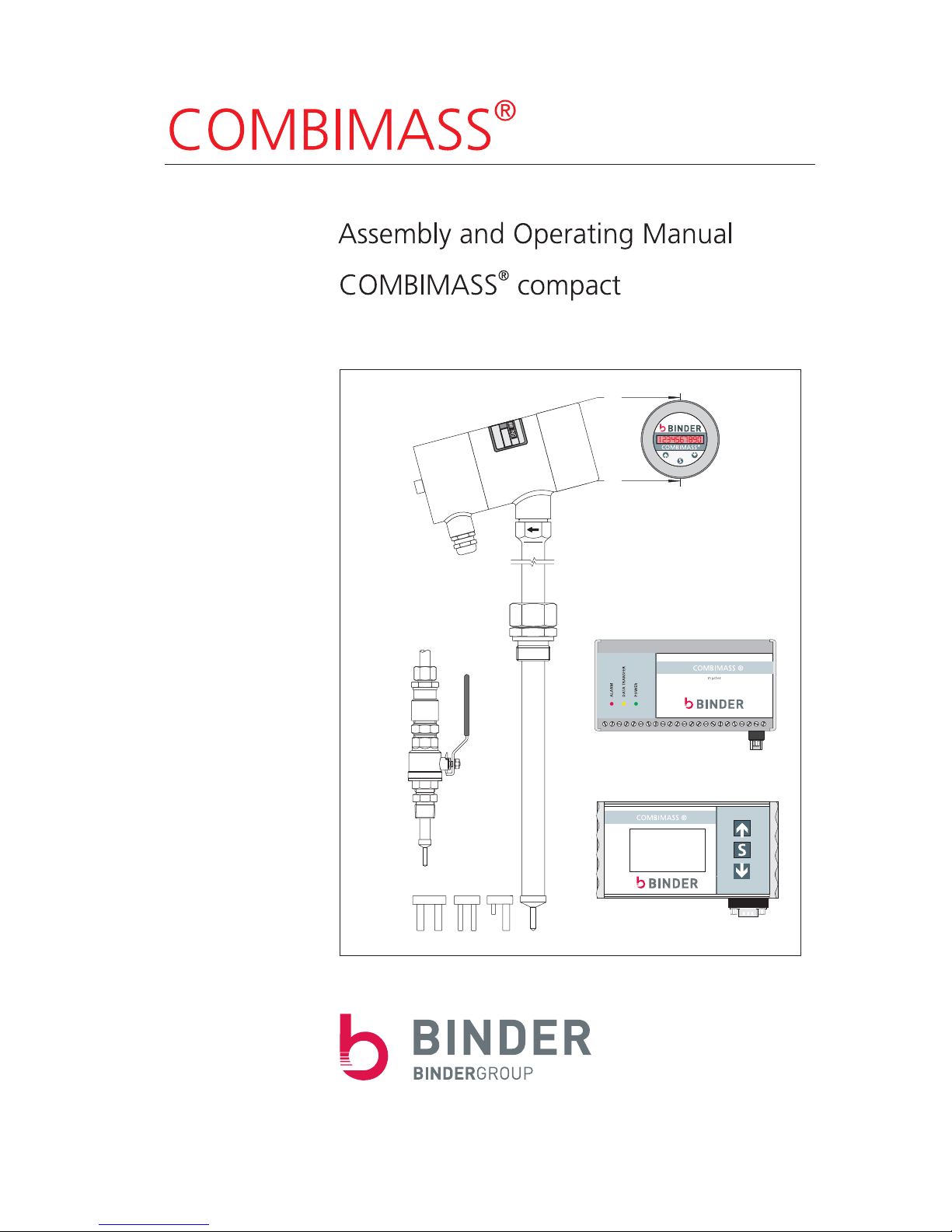

D:\Binder_E\Manuals_en\Komponenten_alle_Combimass_compact_en.cdr

D:\Binder_E\Montage\Begriffsbestimmung_compact_en.cdr

D:\Binder_E\Montage\B_Maß_nurMuffe_2_en.cdr

D:\Binder_E\Montage\B_Maß_Kugelhahn_1_2_en.cdr

D:\Binder_E\Montage\B_Maß_Kugelhahn_2_2_en.cdr

D:\Binder_E\Montage\Inst_Sensor_compact_en.cdr

D:\Binder_E\Elektronik\Verdrahtung compact Feldgeraet IP und EEx ed_en.cdr

D:\Binder_E\Elektronik\Verdrahtung_Feldgehaeuse_compact_IP_en.cdr

D:\Binder_E\Uebersichtsplaene\Tabelle_Wiring_Combimass_compact_IP_en.cdr

D:\Binder_E\Schaltschrank\Combimass_compact_EEx ia Rittal 400x400_en.cdr

D:\Binder_E\Datenblaetter\fertige Datenblaetter\Seite1_Verdrahtung Compact EEx ia Vers 1 v3_en.cdr

D:\Binder_E\Datenblaetter\fertige Datenblaetter\Seite2_Tabellen Compact EEx ia modular_en.cdr

D:\Binder_E\Error\Fehleranzeige Master_Speisetrenner Combimass CIII_en.cdr

D:\Binder_E\Datenblaetter\Combimass_compact_en.cdr

D:\Binder_E\Montage\Ein_Auslaufstrecke_2004-02-24_combimass_en.cdr

Copyright © BINDER GmbH - Ulm 2005

All rights reserved.

This Assembly and Operating Manual is protected by copyright. No part of this publication may be copied, photocopied, reproduced or translated in any form or processed,

duplicated or distributed electronically without the prior express permission in writing of

BINDER GmbH.

Printed by BINDER GmbH

4

COMBIMASS® compact

IMPRESSUM

____________________________________________

BINDER GmbH

Buchbrunnenweg 18

89081 Ulm, Germany

Tel. +49 731 18998-0

Fax +49 731 18998-88

info@binder-flow.com

www.binder-flow.com

Assembly and Operating Manual

COMBIMASS

®

compact

COMBIMASS® compact

5

Contents

Doc. No.: 0905XE20500

Chapter 1 Safety, General Information 7

SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

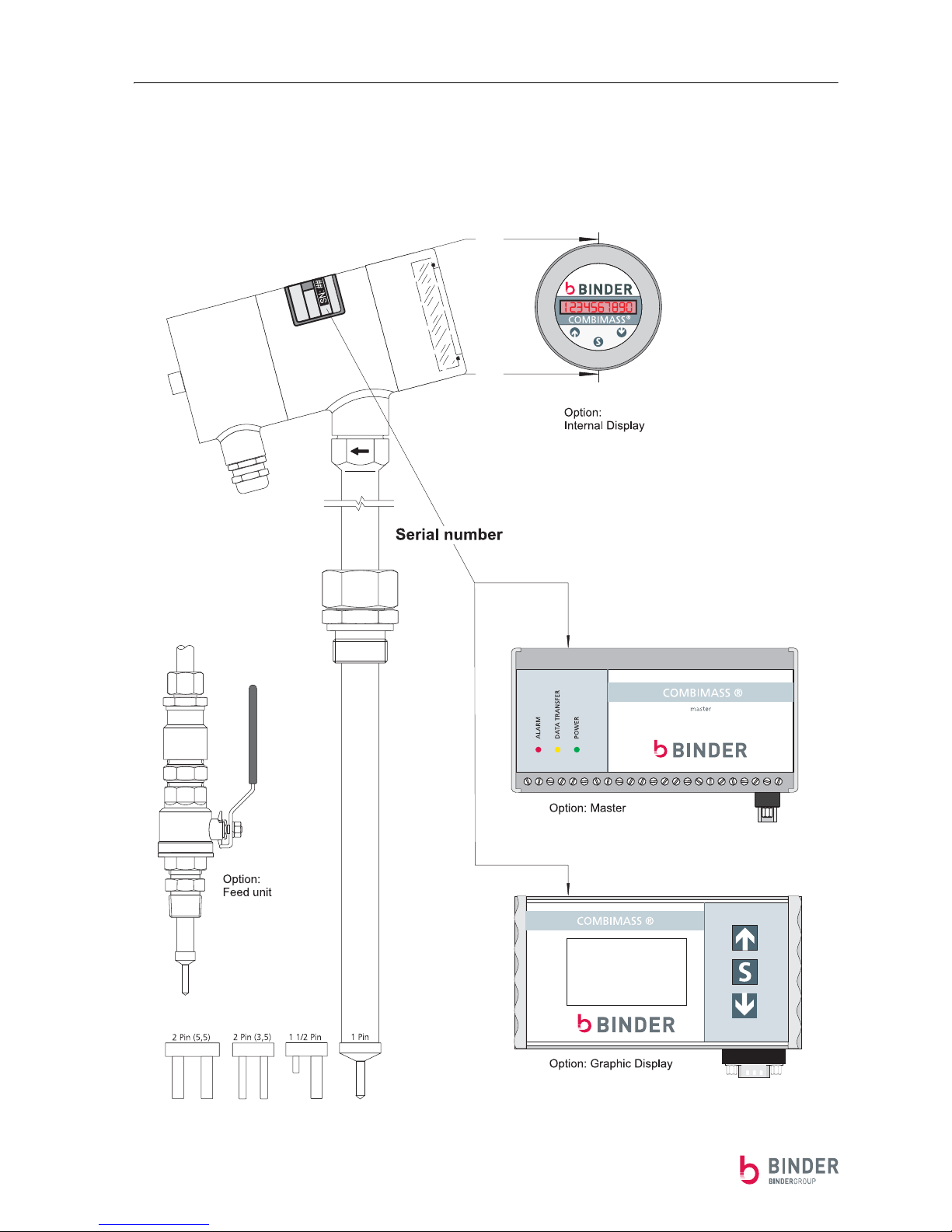

Components of the COMBIMASS® compact unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Important Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 2 Installation 11

Preparation for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Receipt of goods: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Complaints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Calibration note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ESD (damage caused by electrostatic discharges) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation of the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Positioning the sensor rod, determining dimension B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

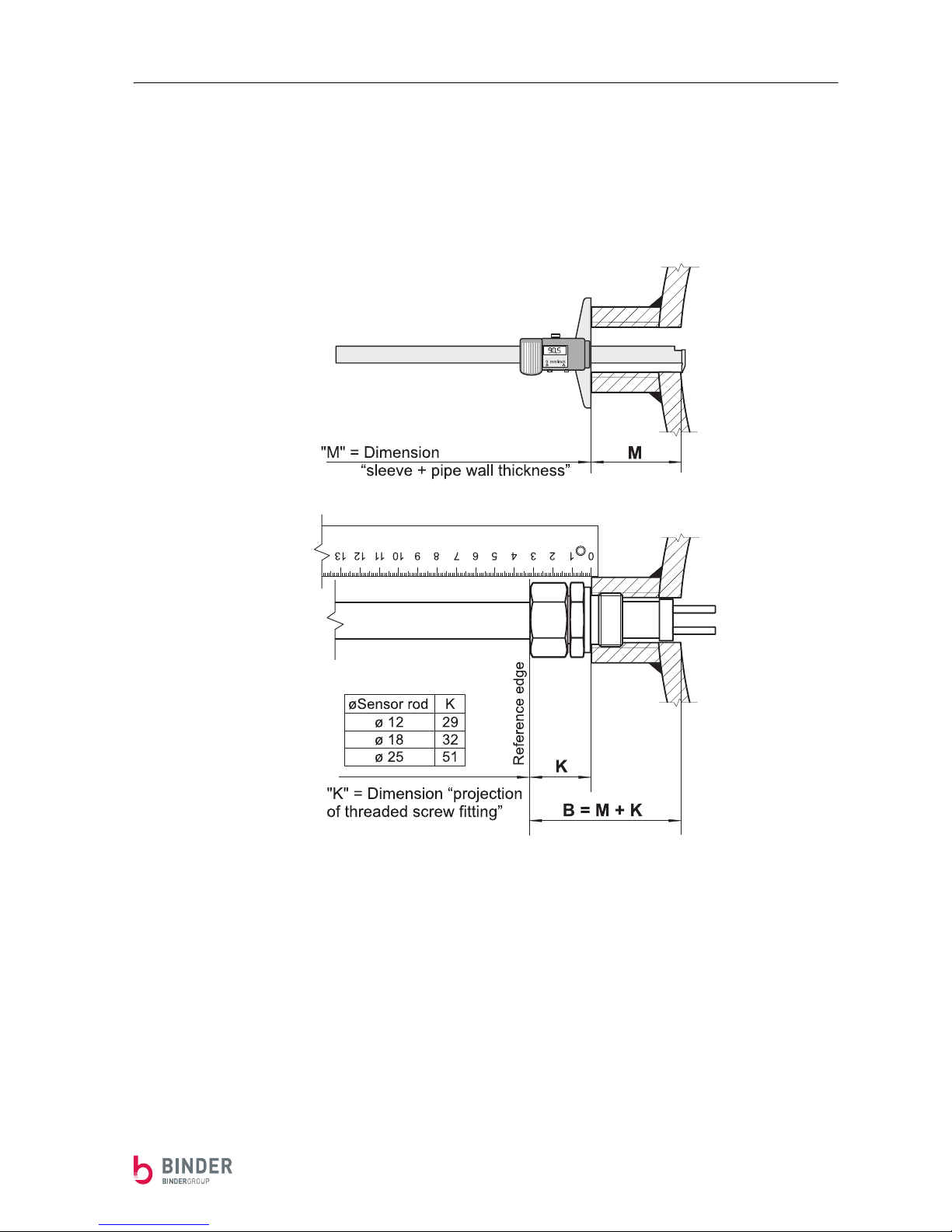

Determining dimension B (without a feed unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

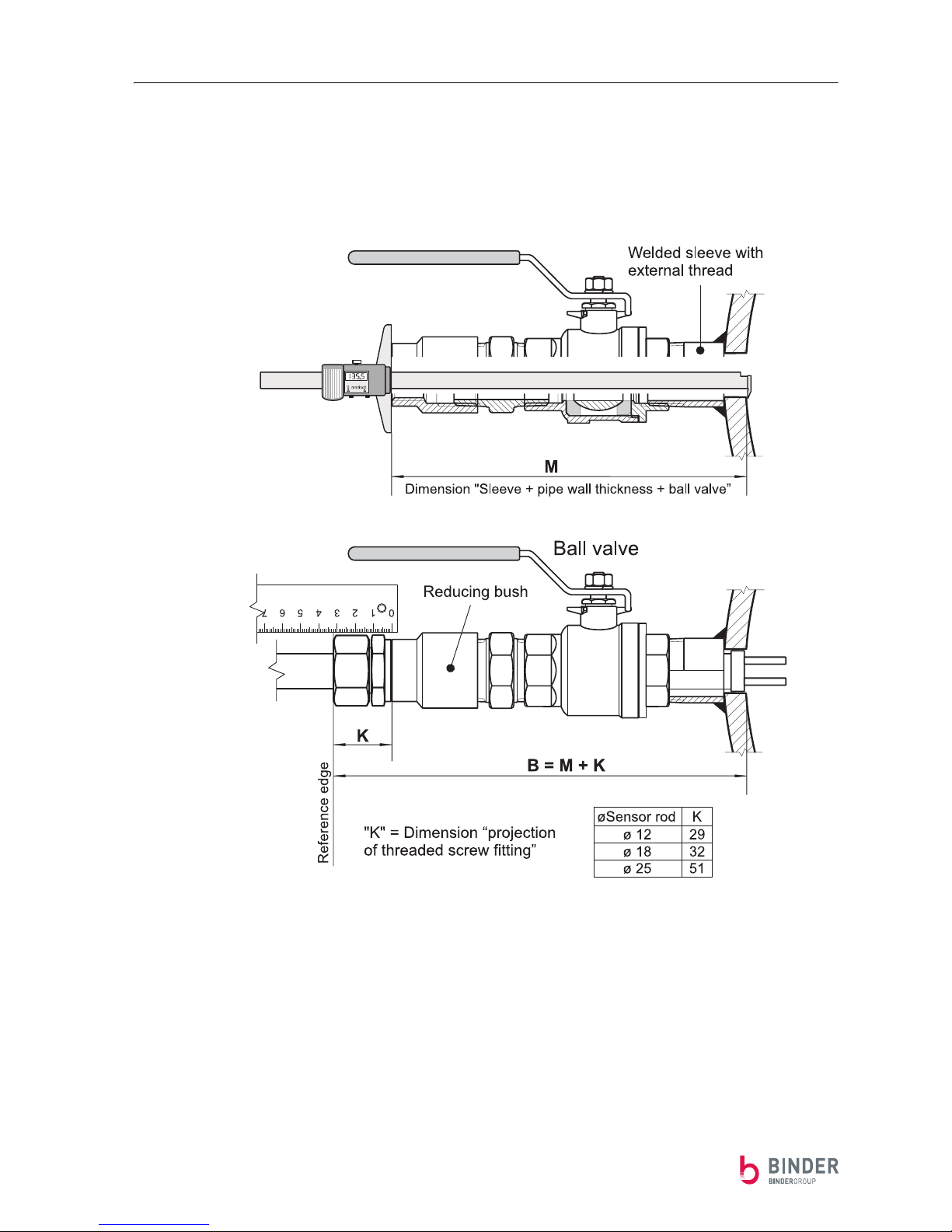

Determining the B dimension (feed unit, welded sleeve with external thread) . . . . . . . . . . . . . . . . . . 14

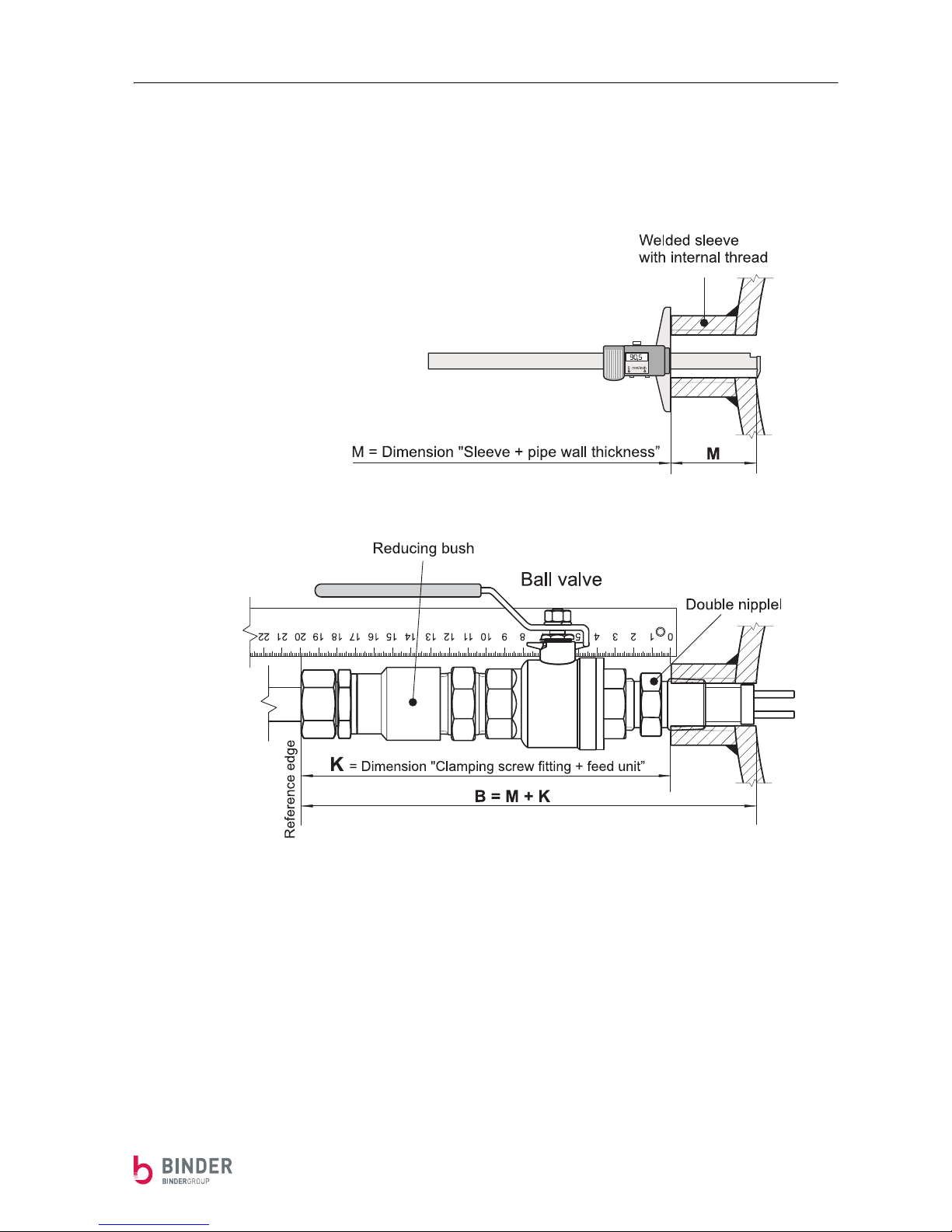

Determining the B dimension (feed unit, welded sleeve with internal thread) . . . . . . . . . . . . . . . . . . . 15

Positioning the sensor rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

(When sensor rod is longer than the internal diameter of the pipe) . . . . . . . . . . . . . . . . . . . . . . . . . . 16

(When sensor rod is shorter than the internal diameter of the pipe) . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Diagram: Positioning the sensor rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wiring of the sensor electronic for field unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Protection class: IP65und EEx [ed]

Diagram: Wiring of the sensor for field unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wiring of the sensor electronic with field housing (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Protection class: Sensor IP and EEx [ed], field housing IP65

Diagram: Wiring of the sensor electronic with field housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table: Wiring of the sensor electronic with field housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Wiring of the sensor electronic with supply isolator and field housing (optional) . . . . . . . . . . . . . . . . . . . . . . . 21

Protection class: Sensor EEx [ia], field housing IP55

Diagram: Wiring of the sensor electronic with supply isolator and field housing . . . . . . . . . . . . . . . . . . . . 21

Table: Wiring of the sensor electronic with supply isolator and field housing . . . . . . . . . . . . . . . . . . . . . . 22

Wiring of the sensor electronic with supply isolator in modular form (optional) . . . . . . . . . . . . . . . . . . . . . . . . 23

Protection class: Sensor EEx [ia]

Table: Wiring of the sensor electronic with supply isolator in modular form . . . . . . . . . . . . . . . . . . . . . . . . 24

Error detection: Wiring error in the sensor electronic with supply isolator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

25

Chapter 3 Appendix 27

Appendix: Specification electronic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Appendix: Specification sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Appendix: Specification Massflow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Appendix: Dimensional drawing of COMBIMASS® compact components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Appendix: Inlet and outlet straight pipe runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Option: Operating the Graphic-Display Combimass CIII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

In general: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Entering the menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Setting the inner diameter of the pipe: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

The summation: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

The pulse: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Analog-Output: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

The correction menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

The info menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Structure of the menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6

COMBIMASS® compact

Contents

Doc. No.: 0905XE20500

Option: Operating Internal Display Combimass CIII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Operating with a magnet in general: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Entering the menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Exiting a menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Changing a value: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Changing the diameter: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

The summation: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

The pulse: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

The analog output: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

The correction menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Structure of the menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Appendix: Declaration on the Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Chapter 4 Index 53

COMBIMASS® compact

Doc. No.: 0905EE20500

7

Chapter 1 Safety, General Information

Chapter 1 Safety, General Information

SYMBOLS

This Assembly and Operating Manual highlights safety information as follows:

The danger information directs the attention of the operator towards a special procedure or practice which

can cause serious injury to persons if carried out incorrectly.

The information warning the user against certain procedures indicates that failure to observe this information can cause serious damage to the equipment.

The notes highlight important information in the text.

SAFETY PRECAUTIONS

This document describes general safety precautions for handling units of the COMBIMASS® series with

regard to installation, operation and maintenance.

This document is intended as additional information and not as a substitute for the specific safety regulations of the country of destination. Compliance with the safety regulations is the responsibility of the customer, the user and/or the expert personnel involved.

Before using COMBIMASS

®

products, please observe the relevant documentation. Please also note the

safety information given in this chapter and in the operating manuals.

Before using the unit, the user should read this operating manual carefully. BINDER GmbH will accept no

responsibility for complete or partial failure to comply with the information included in the manual, incorrect use by untrained personnel, unauthorized manipulation and any use which does not comply with the

national regulations. During installation, setup and maintenance work, all instructions included in this operating manual must be complied with.

The measuring system with a stainless steel sensor tube and a stainless steel sensor (standard version) is

suitable for the mass flow measurement of gases.

It is not suitable for measuring flowing liquids.

Please note: The maintenance measures described in this manual must be carried out by experpert

personnel only.

DANGER

ATT EN TI ON !

NOTE

DANGER

COMBIMASS® compact

Doc. No.: 0905EE20500 8

Chapter 1 Safety, General Information

Components of the COMBIMASS® compact unit.

The COMBIMASS® compact system consists of the following components:

COMBIMASS® compact

Doc. No.: 0905EE20500

9

Chapter 1 Safety, General Information

GENERAL INFORMATION

The following description in the operating manual provides information on installation, initial operation,

control of the electronics, and the gas flow measuring system.

Only careful observance of the operating manual can ensure perfect functioning of the system and prevent

exposing the expert personnel to unnecessary danger. For the specifications of your measuring system,

please see the calibration specifications enclosed in duplicate.

Functional Description

The COMBIMASS® compact series of gas mass flow meters are field transmitters for flow rate measurement

■ The flow meters are especially designed for high temperature and high operating pressure process

applications of up to 1100°C and 100 bars.

■ Optionally, the units are available in explosion-proof versions for Zone 1 or Zone 0.

■ The flow transmitters apply thermal dispersion technology in order to measure directly the normal vo-

lumetric or gas mass flow, regardless of the operating pressure and temperature of the medium.

■ For the purposes of practical operation the transmitter electronics features temperature compensation

and the possibility to select different measuring modes (choice of constant current or constant temperature principle).

■ For transmission of the flow signal an isolated 4-20 mA analog output as well as a field selectable pulse

output is available.

■ For intrinsically safe operation a dedicated process interface module has been developed for the power

supply of the flow transmitter. The signal output is taken off via an I/O module that is installed after

the process interface module.

■ Both the circuit boards of the process interface module and the I/O module are mounted in top hat rail

housing for easy assembly in the field cabinet.

■ Also an optionally available graphic display may be installed.

■ The flow transmitter can be combined with a wide range of different sensors of the COMBIMASS@

family and assembled individually according to the specific application.

■ Each flow meter will be tested prior to shipment and calibrated at our CAMASS@ calibration centre

under actual operating conditions.

Technical specification see page 27

Important Points

1. The electronic enclosure and the electronics (master or slave) must both have the same serial number

as each measurement system is calibrated individually depending on the measurement point used (for

the serial number please see page 8).

2. The actual internal diameter of the piping should be measured in order to ensure that it corresponds

with the diameter given in the calibration specification.

3. For flow rate measurement of wet process gases with condensation of water (eg. digester gas), the

sensors have to be installed from the side. It is recommended to clean the sensor every 3-6 month, in

particular if no filter is installed upstream of the sensor.

4. If the sensor tube is twisted with regard to the connecting head during assembly, it must be newly

sealed in.

5. Always transport or dispatch the sensor in the protective tube.

NOTE

ATT EN TI ON !

COMBIMASS® compact

Doc. No.: 0905EE20500 10

Chapter 1 Safety, General Information

COMBIMASS® compact

Doc. No.: 0905ME20500

11

Chapter 2 Installation

Chapter 2 Installation

Preparation for installation

Receipt of goods:

■ Carefully unpack the measuring system.

■ Check that all items were correctly and completely delivered in accordance with the delivery note.

■ Check the measuring system for damage before you install it.

If you have observed all the points, then continue with the installation of the sensor.

■ If there are any reasons for complaint, please contact customer service.

Complaints

Please contact first the responsible service technician. If you don’t know the telephone number of your

service technician please contact our headquarter in

Ulm/Germany. We will be pleased to help you.

Please return a damaged or incorrectly supplied system to the following address:

BINDER GmbH

Buchbrunnenweg 18

D-89091 Ulm

Tel. : +49 (0)731 189 98-0

Fax : +49 (0)731 189 98-88

■ Please include a note on the covering letter such as, e.g. "System defective, device has not been used"

or "Incorrect supply, device has not been used". In these cases, no clearance certificate is required

(see page 51).

Calibration note

The mass flow measuring system is calibrated to suit your application. All relevant information regarding

the calibration of your system can be obtained from the calibration data sheet.

No further settings or adjustments are required. The system is ready for operation.

ESD (damage caused by electrostatic discharges)

The electronics can be damaged by electrostatic discharge (ESD). Carry out repairs, modifications and tests

at an ESD workplace.

If such a workplace is not available, wear an antistatic wrist strap or touch a suitably conductive, earthed

body.

Damage which arises as a result of incorrect handling cannot be accepted under the terms of the guarantee.

NOTE

ATT EN TI ON !

COMBIMASS® compact

Doc. No.: 0905ME20500 12

Chapter 2 Installation

Installation of the sensor

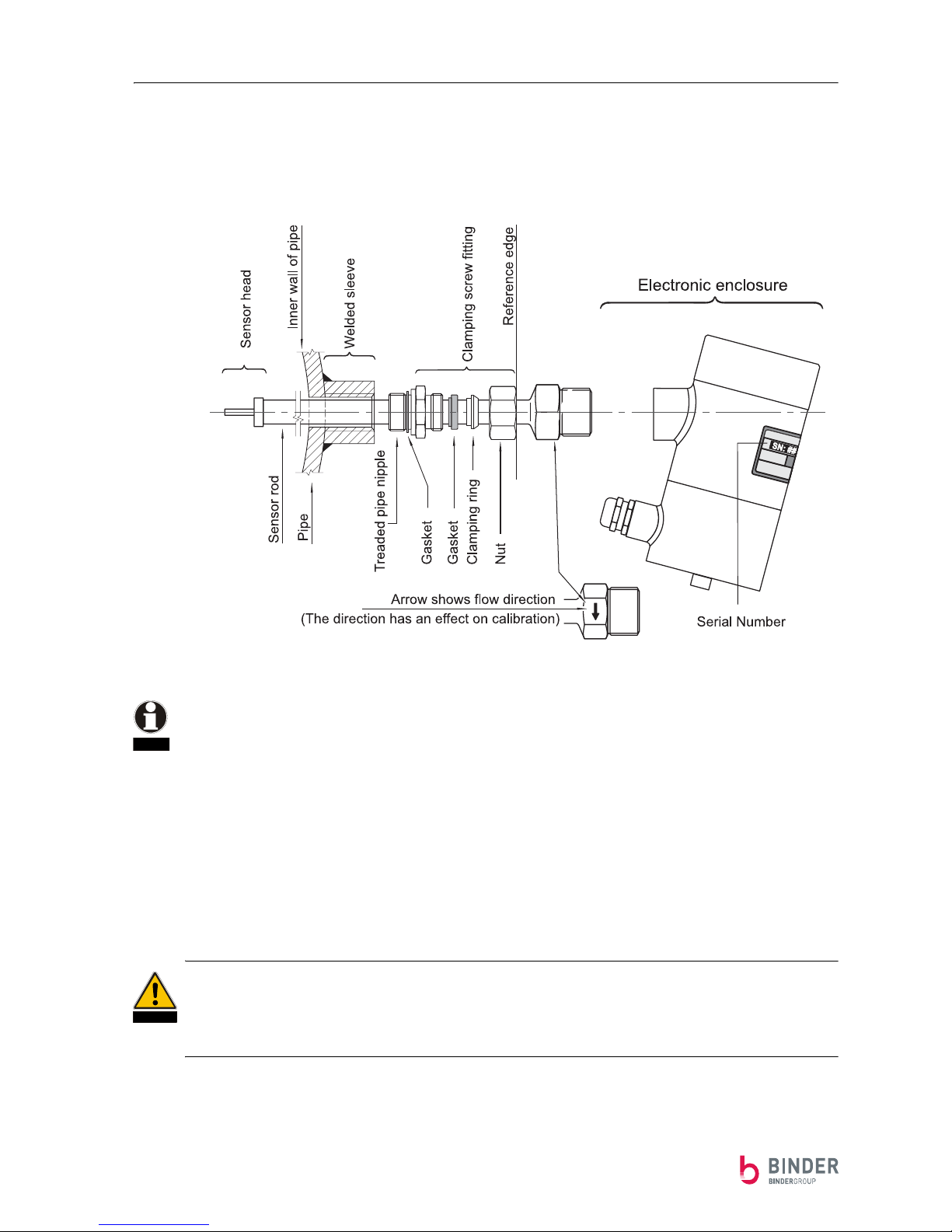

Definition

The following points must be observed for optimum operation in service:

■ The ideal conditions are an inflow length of 20 x pipe diameter and an outflow length of 10 x pipe

diameter.

■ In cases where the installation situation deviates from this, an adaptation must be made.

■ The sensor must be installed so that the installation position corresponds to the calibration position,

see data sheet (vertical/horizontal pipe etc.).

■ The angle of incidence to the sensor must be 90°.

■ The sensor is provided with flats situated between the process connection and the connecting

head for the purpose of alignment.

■ Align these flats parallel to the pipe axis (+/- 3°).

■ The flow direction is marked on the flats in the form of an arrow.

■ The actual internal diameter should be measured and should correspond to the diameter specified on

the calibration data sheet.

■ The sensor head must be located in the centre of the pipe. To position the sensor head, proceed by

following one of the two methods given in the instructions below.

The clamping ring connection is to be inserted into the process connection using the prescribed sealing

material.

Otherwise, aggressive gases could escape. The consequences would be injuries to the skin or respiratory

tracts and corrosion of the surrounding materials.

In the case of combustible gases, a leak will give rise to a fire or explosion hazard.

NOTE

DANGER

COMBIMASS® compact

Doc. No.: 0905ME20500

13

Chapter 2 Installation

Positioning the sensor rod, determining dimension B

Determining dimension B (without a feed unit)

Before installing the sensor, you should measure the length of the welded sleeve up to the inner wall of

the pipe (dimension "M" as on the left of the following diagram) in order to determine dimension "B".

Screw the threaded pipe nipple into the welded sleeve. Please use sealing material according to the specifications.

Screw the nut with the pressing ring and the cutting ring onto the threaded pipe nipple in such a way that

the sensor rod can still move.

Measure dimension "K" = reference edge up to sleeve (see on the left of above diagram).

Add dimensions "K" and "M" to obtain dimension "B".

COMBIMASS® compact

Doc. No.: 0905ME20500 14

Chapter 2 Installation

Determining the B dimension (feed unit, welded sleeve with external

thread)

First, with the feed unit installed, measure the whole length from the inner wall of the pipe to the end of

the reducing bush (dimension "M" as on the left of the following diagram) in order to determine dimension "B".

Screw the threaded pipe nipple of the clamping screw fitting into the reducing bush. Please use sealing

material according to the specifications.

Screw the nut with the pressing ring and the cutting ring onto the threaded pipe nipple in such a way that

the sensor rod can still move.

Measure dimension "K" = reference edge up to reducing bush (see on the left of above diagram).

Add dimensions "K" and "M" to obtain dimension "B".

COMBIMASS® compact

Doc. No.: 0905ME20500

15

Chapter 2 Installation

Determining the B dimension (feed unit, welded sleeve with internal

thread)

Before installing the feed unit, you should measure the length of the welded sleeve up to the inner wall

of the pipe (dimension "M" as on the left of the following diagram) in order to determine dimension "B".

Install the feed unit. Please use sealing material according to the specifications. Screw the threaded pipe

nipple of the clamping screw fitting into the reducing bush. Screw the nut with the pressing ring and the

cutting ring onto the threaded pipe nipple in such a way that the sensor rod can still move.

Measure dimension "K" = reference edge up to the welded sleeve (see on left of above diagram).

Add dimensions "K" and "M" to obtain dimension "B".

COMBIMASS® compact

Doc. No.: 0905ME20500 16

Chapter 2 Installation

Positioning the sensor rod

(When sensor rod is longer than the internal diameter of the pipe)

The sensor head must be located in the centre of the pipe (see Fig. B of the following diagram)

The simplest way to guarantee this is to assemble the 3/4" thread or the flange, and then push the sensor

into the pipe up to the stop. Then, pull the sensor back by exactly one half of the nominal diameter of the

pipe (minus 6mm) and now fix it in position by means of the cutting ring connection (max. 1¼ turns).

Where a stainless steel cutting ring is used, the sensor can be positioned only once!

The sensor rod must be fixed securely. Where the pipe is subjected to high pressure, there is a risk of the

sensor being ejected as far as the clamping ring in the manner of a projectile and thereby endangering

personnel.

(When sensor rod is shorter than the internal diameter of the pipe)

In the case of larger pipe diameters, proceed as shown in Fig. A of the following diagram.

The sensor is pulled back to the reducing pipe nipple. Mark the sensor rod at a distance of

"DI/2 + B - N"

DI/2 = half internal diameter of pipe

B = Inner wall of pipe up to reference edge

Look up dimension “B“ corresponding to the variant of mounting in the instructions on

page 13, page 14, or page 15.

N = KL + S - 6 mm KL = Screw fitting, S = Sensor head

Please choose dimension “N“ from the table on page 17.

Push the sensor into the clamped connection up to this mark (see Fig. B of the following diagram) and fix

it in position by means of the cutting ring connection.

Where a stainless steel cutting ring is used, the sensor can be positioned only once!

The sensor rod must be fixed securely. Where the pipe is subjected to high pressure, there is a risk of the

sensor being ejected as far as the clamping ring in the manner of a projectile and thereby endangering

personnel.

DANGER

DANGER

Loading...

Loading...