Page 1

Bimba Manufacturing Company

Ultran and Ultran Slide

Preventative Maintenance Lubrication

Ultran rodless cylinders are pre-lubricated at the factory for extensive, maintenance

free operation. The life of the cylinder can be greatly lengthened by providing

additional lubrication with an air line mist lubricator or direct introduction of oil to the

cylinder every 100 linear miles of travel. Recommended oils are medium to heavy

(20 to 30 weight).

The carriage should also be lubricated every 100 linear miles of travel with a high

grade of silicone based bearing grease. The lubricant used by the factory can

be purchased in 14 oz. grease gun containers as part number MS-2861-14OZ.

Contact your authorized Bimba distributor for details.

The guide rod shafts on Ultran Slide units are self lubricating and require no

external lubricant in most applications. A lightweight oil can be added to the shafts

if needed.

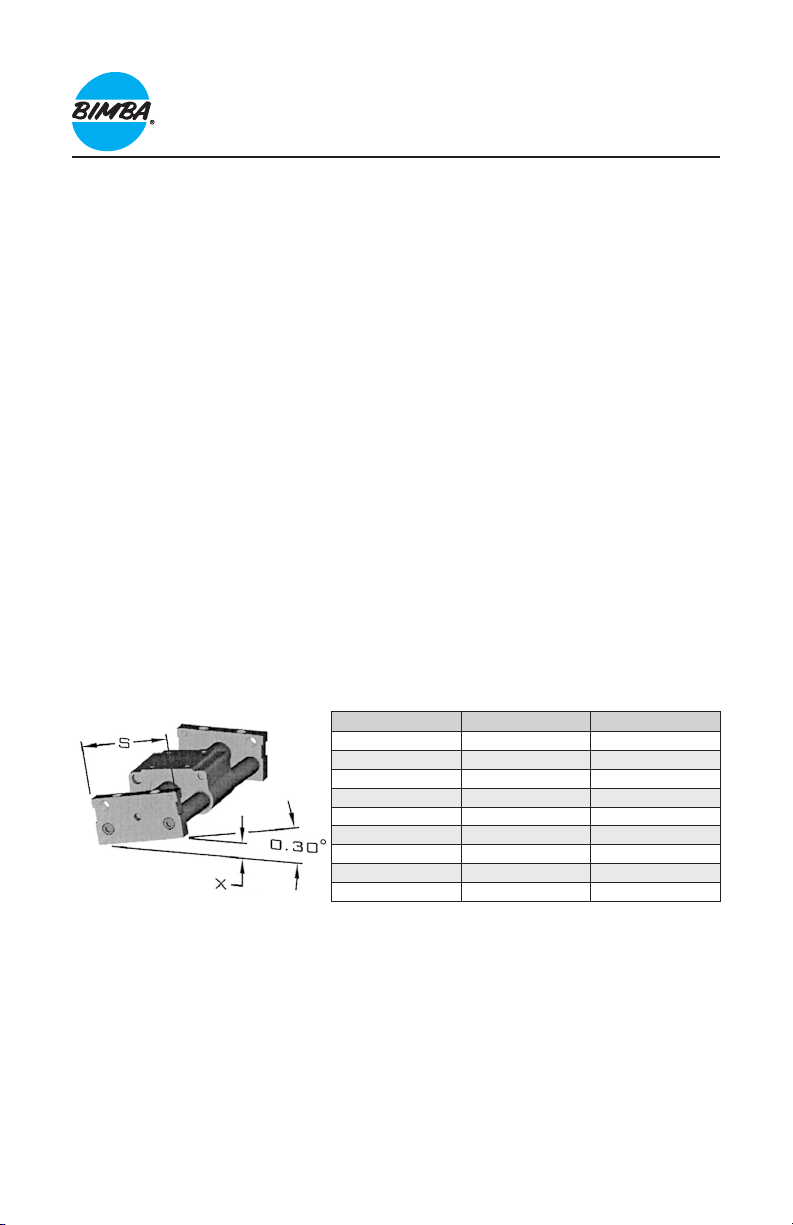

Ultran Slide Mounting Instructions

Improper mounting of the Ultran Slide could result in binding and/or excess breakaway. As a rule of thumb, the end blocks should be mounted at with no more

than 0.30° of differential misalignment end-to-end (including both end blocks, i.e.,

0.30° on one end block if other end block is square. If both end blocks are out of

square, the total between them cannot exceed 0.30°. The X dimension represents

how much displacement 0.30° represents using 0.0175" per inch per degree of

misalignment.)

For example:

A Model 007 (5/16" Bore) has a S dimension of 2.00". 0.30° of misalignment would yield •

approximately 0.010" of differential misalignment from end-to-end before binding and/or

excess breakaway would occur.

A Model 17 (1-1/2" Bore) has a S dimension of 6.00". 0.30° of misalignment would yield •

approximately 0.031" of differential misalignment from end-to-end before binding and/or

excess breakaway would occur.

Bimba Manufacturing Company

Monee, IL 60449-0068

TEL: 708/534-8544 • FAX: 708/235-2014

Support: 1-800-44-BIMBA

Visit our website at: www.bimba.com Form ULLMI-201

The following table shows the S dimension (end block width

dimension as found in the catalog) for all bore sizes:

Model S in (mm) X in (mm)

007 (5/16" Bore) 2.000 (50.8) 0.010 (0.25)

01 (7/16" Bore) 2.312 (58.7) 0.012 (0.30)

02 (9/16" Bore) 3.000 (76.2) 0.016 (0.40)

04 (3/4" Bore) 3.375 (85.7) 0.018 (0.46)

06 (7/8" Bore) 3.750 (95.3) 0.020 (0.51)

09 (1-1/16" Bore) 4.250 (108.0) 0.022 (0.56)

12 (1-1/4" Bore) 4.812 (122.2) 0.025 (0.64)

17 (1-1/2" Bore) 6.000 (152.4) 0.031 (0.79)

31 (2" Bore) 8.000 (203.2) 0.042 (1.07)

Loading...

Loading...