Bimba PCS User Manual

Bimba Model PCS

Pneumatic Motion Control System

Operating Manual

Please read this manual carefully before implementing your Pneumatic Control System.

www.bimba.com |

Technical Assistance: 800-44-BIMBA |

1 |

General Warnings and Safety Guidelines

Start by Reading These Important Safety Rules

THIS SAFETY ALERT SYMBOL MEANS CAUTION ― PERSONAL SAFETY, PROPERTY/FIXTURING DAMAGE, OR DANGER FROM ELECTRICAL SHOCK. READ INSTRUCTIONS WITH THIS SYMBOL CAREFULLY.

READ ALL INSTRUCTIONS CAREFULLY BEFORE INSTALLATION. SAVE THIS MANUAL FOR FUTURE REFERENCE.

IF ACTUATOR BECOMES JAMMED, DISCONNECT ALL COMPRESSED AIR CONNECTIONS TO THE ACTUATOR BEFORE ATTEMPTING TO RELEASE OR REMOVE JAMMED ITEM.

IF FULL SYSTEM PRESSURE IS APPLIED WITH A LARGE ERROR SIGNAL PRESENT, THE ACTUATOR WILL ATTEMPT TO INSTANTANEOUSLY MOVE TO THE COMMAND SIGNAL POSITION. THIS COULD POTENTIALLY CAUSE PHYSICAL HARM OR DAMAGE TO APPLICATION TOOLING. ONCE SYSTEM IS INSTALLED, ALWAYS ENSURE THAT THE COMMAND SIGNAL AND FEEDBACK SIGNAL ARE EQUAL AT START UP, OR START SYSTEM UP AT LOW PRESSURE.

This symbol represents boxes that contain helpful hints and recommendations.

This symbol represents boxes that contain important notes, reminders, and items that may need special attention.

www.bimba.com |

Technical Assistance: 800-44-BIMBA |

2 |

Table of Contents

General Overview ................................................................................................... |

Page 4 |

Typical Applications ................................................................................................ |

Page 5 |

Glossary of Terms and Formulas ............................................................................ |

Page 5 |

Installation Instructions ............................................................................................ |

Page 9 |

1.Install the Bimba Actuator….……………………………………………………Page 9

2.Mount the PCS……………………………………………………………………Page 9

3.Make the Pneumatic Connections...................………………………………..Page 9

4.Connect the Power Cable………………..…………………………….………Page 11

5.Connect the Feedback Cable………………………………………………….Page 12

6.Connect the Command Signal Cable…………………………………………Page 13

7.Perform the Following Step For Option N Only……………………………...Page 14

8.Check All Electrical and Pneumatic Connections…………………………...Page 14

9.Apply 24 VDC Power …………………………………………………………..Page 14

10.Apply Pneumatic Pressure…………………………………………………….Page 15

11.Set the “Deadband” ……………………………………………………………Page 15

12.Command the Bimba Actuator to its Zero Position…………………………Page 16

13.Preliminary “Zero” Adjustment………………………………………………..Page 16

14.Preliminary “Span” Adjustment……………………………………………….Page 18

15.Final “Zero” and “Span” Adjustment………………………………………….Page 19

16.“Decel” Range Adjustment…………………………………………………….Page 19

Application Example .............................................................................................. |

Page 21 |

Specifications ........................................................................................................ |

Page 22 |

Application Sizing and Rules of Thumb ................................................................ |

Page 22 |

Troubleshooting .................................................................................................... |

Page 24 |

Frequently Asked Questions ................................................................................. |

Page 32 |

Appendix A |

|

PFC System Block Diagram....................................................................... |

Page 30 |

PFCN System Block Diagram ................................................................... |

Page 31 |

PTF System Block Diagram ...................................................................... |

Page 32 |

Appendix B - PFC probe replacement instructions ................................................ |

Page 33 |

Appendix C - PFCN Probe adjustment and replacement instructions ................... |

Page 35 |

© Copyright 2008 Bimba Manufacturing Company, Monee, Illinois, USA.

www.bimba.com |

Technical Assistance: 800-44-BIMBA |

3 |

General Overview

The Bimba Pneumatic Control System (PCS) is a closed loop electronic controller with pneumatic valves that can move the rod or shaft of a pneumatic position feedback actuator and hold it in any desired position with accuracy and force. The PCS system is designed for series PFCN, PFCNL, PFC, and PFCL cylinders for linear motion and the Position Feedback Pneu-Turn (PTF) for rotary motion. The PFC should be ordered with the -L option, low friction seals, for the best positioning accuracy and smoothest operation. The standard PTF includes low friction seals.

The standard PCS accepts a 0 to 10 VDC or 4 to 20mA analog command signal, jumper selectable (refer to the illustration on page 11). The command signal defines the position the rod must move to. The rod stops when the feedback voltage from the probe is equal to the command signal.

For example, if the application has a stroke of 10 inches and zero and span adjustments are set for zero to ten inches as well, then a 1 volt change in the command voltage is equal to a 1 inch movement. Similarly, a change in command signal of 0.005 of a volt equals a position change of 0.005 of an inch for the same 10 inch stroke application. If the application has a stroke of 5 inches, a change of 1 volt in the command signal represents a half inch movement. For rotary applications, the convention is similar. If the application has a rotation of 180 degrees, then a 1 volt change in the command signal is equal to 18 degrees of rotation.

The system utilizes the feedback from the actuator to close the control loop. The control loop compares the 0-10 VDC or 4-20mA input command signal to the feedback signal from the actuator. The difference between the command and feedback is referred to as the error term. When the error term is zero, all valves close, trapping air on both sides of the actuator piston. (The error term is considered to be zero when it is within the deadband range. The deadband is defined in the Glossary of Terms section.) This holds the rod at its commanded position. If a force attempts to move the rod or shaft out of the commanded position, the system will react by increasing the restoring force to maintain position. Likewise, if the command signal changes, the system will respond to make the feedback equal the command signal.

The actual accuracy/repeatability of the movements will depend on many factors, including signal noise, load, velocity, supply pressure, supply voltage, and application friction. Refer to the Application Sizing charts for detailed information regarding sizing and suggestions for your application.

www.bimba.com |

Technical Assistance: 800-44-BIMBA |

4 |

Typical Applications

The PCS system is ideal whenever increased flexibility and adaptability is needed in a process; for example, in order to accommodate various size parts and assemblies, or to add control for improved consistency, quality, and productivity. Typical applications are listed below.

Flow Gate

The PCS system can control the position of a flow gate, controlling the rate of product that flows to downstream processes. The position of the gate can be changed to allow more or less product flow depending on the requirements of the process. Sometimes this is controlled manually, resulting in wasted manpower and less control.

Robotic End Effector

The PCS system can control the open position of an end effector for a robotic arm. If the robotic arm is picking and placing differently sized products, the cycle rate can be increased if the open position is automatically adjusted to be only slightly larger than the product itself, reducing the time it takes to grasp the product.

Exhaust Control

The PCS system can control the position of exhaust dampers used in process control systems for increased control in plant emissions, smoke houses, and similar applications.

Labeling

The PCS system can position differently sized parts under a label applicator, allowing the labeling process to continue without any down time for a setup change to adjust for product size.

Animatronics

The PCS system can produce lifelike movements of puppets and figures, such as those used in amusement and entertainment industries. Using an industrial computer or PC, movements can be changed without a hardware change, simplifying new shows and edits.

Glossary of Terms and Formulas

For clarity, please review the definitions below. Descriptions for linear motion actuators (PFCN, PFC, PFCNL, PFCL) are often different from descriptions for rotary actuators (PTF).

ZERO (ZERO Position)

When the PFC rod is fully retracted or the PTF shaft is rotated fully counterclockwise (CCW), it will reach a mechanical stop, due to either a mechanical limit in the application or the actuator’s end of stroke or rotation. The PCS’ Zero adjustment allows you to adjust the position of the cylinder at 0 VDC control voltage input. Adjustment range is from the fully retracted mechanical limit to approximately 50% of the full actuator stroke or rotation. Refer to the installation section for a description of the adjustment procedure.

www.bimba.com |

Technical Assistance: 800-44-BIMBA |

5 |

SPAN (Full Scale Position)

When the PFC rod is fully extended or the PTF shaft is rotated fully clockwise (CW), it will reach a mechanical stop, due to either a mechanical limit in the application or the actuator’s end of stroke or rotation. The PCS’ Span adjustment allows you to adjust the position of the cylinder at 10 VDC control voltage input. Adjustment range is from the fully extended mechanical limit to approximately 50% of the full actuator stroke or rotation. Refer to the installation section for a description of the adjustment procedure.

The Zero and Span adjustments can be combined for a total adjustment window of only 50% of total actuator travel, i.e., if the Zero Adjustment is adjusted out to 50% of actuator travel, then the Span Adjustment cannot be adjusted lower than 100%. The effective travel of the actuator in this case would be between 50 and 100%.

Special Note for PTF’s with less than 180 degrees of Travel: Due to the 50% window limitation, the minimum effective electrical

rotation for PTF’s is 180 degrees of rotation. This is explained further in the PTF application example on Page 21.

MAIN CONTROL (Command or Input Signal)

The Main Control command signal is a variable analog signal, either 0-10 VDC or 4-20 mA depending on the position of jumper JO2 (see the illustration on page 11 for instructions on setting jumpers). The command signal, proportional to the displacement of the actuator, can be supplied by a PLC analog output card or any other low noise signal source. The low end of the range affects the zero position of the actuator and the high end of the range affects the full scale position of the actuator.

The command signal can be translated into actuator displacement with the following formula:

CS = (d * R / t ) + Z

where:

CS = the command signal required to achieve a desired position

d = the displacement the desired position is from the zero position R = the full range of the command signal

t = full scale travel of the actuator (Note: for PTF rotary actuators with total rotation less than 180º, always make t = 180)

Z = the command signal for the zero position

Example 1: A system uses a 0-10 volt command signal, “R” is 10 and “z” is 0. If a position of 2 inches is desired from a 7 inch stroke cylinder, the required Command signal (CS) is ( 2 * 10 / 7 ) + 0 or 2.857 volts.

Example 2: A system uses a 4-20 mA command signal, “R” is 16 and “z” is 4. If a 30º position is desired from a 90º rotary actuator, the required Command signal (CS) is (30 * 16 / 180) + 4 or 6.67 mA.

www.bimba.com |

Technical Assistance: 800-44-BIMBA |

6 |

FEEDBACK SIGNAL

The feedback signal is a voltage signal from the actuator that corresponds to the displacement or rotation of the actuator. The feedback signal range is approximately 0 - 10 VDC.

PTF Note:

The PTF has a fixed electrical rotation span of 340 degrees. This will affect some of the following adjustments and signals for PTF’s with full scale rotations of less than 180 degrees.

DEADBAND

The Deadband is a bi-directional band, centered on the commanded position. Once the actuator is within this zone, the error term will be considered zero and all valves will be closed. This deadband is measured in volts and can be adjusted between 0.005 and 0.500 volts. This voltage can be translated to a deadband width with the following formula:

w = 1/10V * t

Where:

w = deadband width

V = voltage reading from the PCS

t= full scale travel of the actuator (Note: for PTF rotary actuators with total rotation less than 180º, always make t = 180)

The full deadband zone is the deadband width above and below the target position.

Example 1: If the deadband is set for 20mV (0.02 of a volt) for a 6 inch stroke cylinder, the width of the deadband zone will be 1/10 * 0.02 * 6 or ±0.012 of an inch.

Example 2: If the deadband is set for 20mV (0.02 of a volt) for a 180º actuator, the width of the deadband zone will be 1/10 * 0.02 * 180 or ±0.72º.

DECEL RANGE

Once the PCS receives a command signal to move the actuator rod or shaft to a new position, two of the pneumatic valves are opened causing the actuator to move toward the desired position. The Decel Range is an adjustable zone outside the Deadband in which the PCS control begins to slow (decelerate) the actuator rod. The Decel Range enables the PCS system to accurately position the actuator inside the Deadband. The Decel Range is measured in volts and can be adjusted between 0.5 and 13.5 volts. Optimal decel settings vary with the load and application. However, 1.5 volts is a good default setting for PCS models 1, 2, and 3, and 9 to 11 volts usually works well for PCS models 5, 7, and 8.

www.bimba.com |

Technical Assistance: 800-44-BIMBA |

7 |

The following formula will translate the voltage reading into the Decel Range.

DR = 0.01485 * V * t

Where:

DR = decel range

V = voltage reading from the PCS

t = full scale travel of the actuator (Note: for PTF rotary actuators with total rotation less than 180º, always make t = 180)

Example 1: If the Decel Range is set to 5 volts for an 8 inch stroke cylinder, then deceleration will occur for 0.60 inches (0.0149 * 5 * 8).

Example 2: If the Decel Range is set to 5 volts for a 180º rotary actuator, then deceleration will occur for 13.4º (0.0149 * 5 * 180).

CURRENT POSITION

Current Position is a 0 to 10 volt output signal that mirrors the feedback signal from the actuator, fully scalable with the Zero and Span adjustments. In other words, its output will always be 0 to 10 volts no matter how Zero and Span are adjusted. It can be used to monitor the motion of the actuator and the output may be sent to a calibrated display.

AT POSITION (@ POS)

At Position is a digital output signal that is normally open and switches to ground when the actuator is within the Deadband zone. This signal is useful for utilizing a PLC I/O card to receive a signal indicating that the actuator is within the Deadband zone, potentially eliminating the need for an analog input card.

Be cautious when utilizing the @ POS signal. If there is overshoot in the application, the actuator may momentarily go through the Deadband Zone, causing the @ POS signal to momentarily transition back open, before finally stopping in the Deadband Zone.

REPEATABILITY AND STABILITY

It is important to understand the difference between repeatability and stability. A system is considered repeatable if it comes to a stop inside the deadband zone. A system is considered stable if it comes to a stop in the deadband zone time after time with no overshoot. There are different degrees of instability. The first is a system that approaches the commanded position and overshoots it just a little and has to reverse itself before settling to a stop in the deadband zone. This level of instability may be acceptable in many applications. The worst type of instability is oscillation around the deadband zone, never settling to a stop. This level of instability must always be resolved.

MOVEMENT DIRECTIONS

Movements of the actuator may be described as “Increasing” or “Decreasing.” An “Increasing” move is one that moves toward the Full Scale Position. A “Decreasing” move is one that moves toward the Zero position.

www.bimba.com |

Technical Assistance: 800-44-BIMBA |

8 |

Installation Instructions

Before installing your system, refer to the Application Sizing and Rules of Thumb section to ensure your system is sized properly for your application. Use the following steps to successfully install and operate your PCS system. There are a couple of application examples that follow this section which are helpful in gaining a full understanding of the adjustments that will be made.

1.INSTALL THE BIMBA ACTUATOR

Install the actuator as you would any other actuator, ensuring that the feedback cable routes away in a careful and protected manner.

2.MOUNT THE PCS

Select a mounting location for the PCS not more that 18 inches from the actuator if possible. Positioning accuracy and efficiency improves when the PCS is mounted close to the actuator. Be sure to allow sufficient room for both the pneumatic connections and the electrical connections on opposite sides of the PCS enclosure. Drill four mounting holes (for up to 5/16 diameter mounting bolts) and secure the PCS in position by the enclosure’s mounting flanges.

Option-N (No Enclosure)

If Option-N is specified, the PCS system will be shipped with the PCS printed circuit board, a snap track, a valve manifold, and four 25 foot valve cables. The snap track allows for easy mounting inside a larger enclosure box. Mount the snap track in the enclosure and snap the PC Board in place. Mount the valve manifold near the actuator. Be careful to mount the manifold in a place where the valves will not be vulnerable to physical damage.

3.MAKE THE PNEUMATIC CONNECTIONS

Pressures above 100 psi may damage the PCS control’s valves.

Pressures below 70 psi may result in erratic operaion.

The supply air must be 70 to 80 psi. Air supply pressure affects system performance, not just force. Air must be filtered to 5 microns and regulated, and the connections must be leak free. Leaks of any kind in the plumbing wil cause the PCS to adjust to make up for this air loss, creating unnecessary wear on the valves and generating chattering that might be interpreted as a malfunction. All of the pneumatic fittings, tubes, etc., must seal perfectly. For a perfect seal, push-in fittings with O-rings inside perform well. If Teflon tape is employed, care must be taken to ensure that loose pieces don’t get into the system. Liquid thread sealants must not be used; they can attack the materials of the transducer. It is also important that tubing used between the PCS valve manifold and the actuator does not expand with pressure. Volume changes, even though slight, will cause the system to work harder. Metal tubing is the best, but nylon is also satisfactory. Do not use very soft, easy to expand tubing like Tygon®.

www.bimba.com |

Technical Assistance: 800-44-BIMBA |

9 |

The following table shows recommended tubing sizes. Oversized tubing will degrade positioning repeatability.

|

Bore Size |

|

|

Tubing Size |

|

|||

|

PFC |

|

|

PTF |

|

|

|

|

|

|

|

|

|

|

|

||

1-1/16" (09) |

|

|

|

|

|

5/32" OD |

||

1-1/2" (17) |

|

1-1/2" (098/196) |

|

|

5/32" OD |

|||

2" (31) |

|

2" (247/494) |

|

|

1/4" OD |

|||

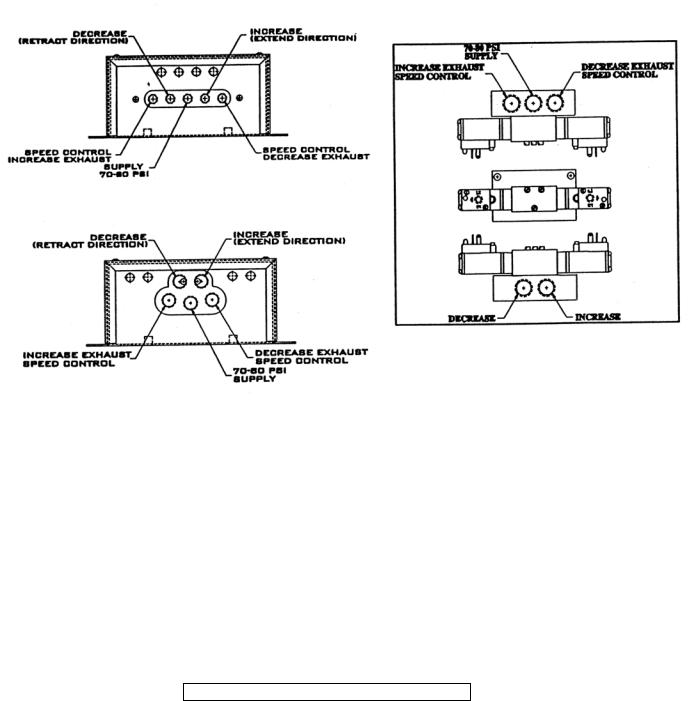

Air line connections are described in the illustrations below. Instructions follow. Also consult the Appendix for air and electrical connections to PFCN, PFC, and PT.

Air hose connections for enclosed controls PCS models 1, 2, 3

Air hose connections for option N PCS controls (without enclosures)

Air hose connections for enclosed controls PCS models 5, 7, 8

•Connect the 70 -80 psi supply air to the center port of the valve manifold.

•Connect the valve manifold retract port (the port directly to the left of the center port when the manifold is facing you) to the rod end of the cylinder.

o For PTF rotary actuators, connect this to the port on Body “A” for single rack models (left side when the PTF shaft is facing toward you), or connect to bodies “A” and “D” for double rack models (lower left and upper right when the PTF shaft is facing toward you).

•Connect the extend port (the port directly to the right of the center port when the manifold is facing you) to the cap end of the PFC cylinder.

o For PTF rotary actuators, connect this to the port on Body “B” for single rack models (right side when the shaft is facing toward you), or connect to bodies “B” and “C” for double rack models (upper left and lower right when the shaft is facing toward you).

Do not turn the air supply on at this time.

www.bimba.com |

Technical Assistance: 800-44-BIMBA |

10 |

For best positioning results, consider using a precision relieving regulator and an air reservoir with a check valve before the regulator to ensure that there are no pressure drops to the PCS system. You may want to install mufflers into the exhaust ports of the valve manifold (the two outer ports). This will make the system quieter during operation. Do not to use mufflers with low flow rates; that may slow the actuator.

4.CONNECT THE POWER CABLE

Standard Enclosure

Carefully remove the enclosure cover. Use a two conductor cable, 22 gage minimum, with an outside diameter between 0.114 and 0.250 inch. Pass the cable through the bulkhead strain relief and connect to the POWER terminal block (TB1) on the PCS circuit board (refer to illustration below). If a shield wire is used, twist the Ground wire and the Shield wire together and connect to the Ground terminal (do not terminate the other side of the shield).

TB1

TB2

TB3

TB4

Deadband set switch

Deadband set switch

Deadband adjustment

Deadband adjustment

Decel adjustment

Decel adjustment

Zero adjustment

Zero adjustment  Span adjustment

Span adjustment

You may adjust the jumper on JO2 for 0- 10V (left and center terminals connected) or 4-20 mA (right and center terminals connected) operation.

Do NOT change the jumper JO1. This adapts the board for use as PCS-4 through PCS-8 operation. Different valves must be installed as well.

Set jumper J02 for 4-20 mA or 0-10 V control voltage input in accordance with the illustration above. Refer to Appendix A for air and electrical connections to PFCN, PFC, and PT.

Option N

Connect a two conductor, 22 gage minimum shielded cable to the POWER terminal block (TB1) on the PCS circuit board. Twist the ground and shield wire together and connect to the Ground terminal (do not terminate the other side of the shield).

www.bimba.com |

Technical Assistance: 800-44-BIMBA |

11 |

Loading...

Loading...