Page 1

GENERAL REPAIR INSTRUCTIONS

PNEU-TURN ROTARY ACTUATORS

Disassembly

1. Remove the cylinder body assembly from the actuator body by removing the retainer ring cap

screws.

2. Rotate the shaft until one piston contacts the actuator body. Further rotation of the shaft will

remove the piston from the rack.

3. Remove the remaining piston and rack as a unit from the actuator body. Lift out the rack support

piece.

4. Use a hex key to loosen the shaft bearing set screw. The shaft and pinion assembly and the front

bearing may now be removed from the housing.

5. Clean and inspect all parts, replacing any that are worn.

Re-Assembly

1. Place rack support piece in position in actuator body.

2. Assemble one piston to rack. Lubricate rack with bearing grade grease and insert through central

housing. Press second piston onto rack. (A small press may be necessary.)

3. Lubricate seals and inside surface of the cylinder bodies with oil. Assemble the cylinder body

assembly over the piston and center in pilot recess of housing. Secure with retaining ring and

cap screws. Recommended tightening torque as follows: 9/16"– 10 in.-lbs.; 3/4" and 1-1/16"– 12

in.-lbs.; 1-1/2" and 2"– 20 in.-lbs.

4. Lubricate shaft bearing lightly with oil. Lubricate pinion with bearing grade grease. Slide shaftpinion assembly into position engaging pinion teeth to rack for desired orientation of shaft key.

5. Slide front shaft bearing into place allowing the set screw to engage the notch on outer diameter.

6. Proper axial running clearance of bearings is achieved by placing assembled unit on a bench

with shaft vertically upward. Manually rotate unit to verify smooth operation. Press down on front

bearing to assure its proper positioning against pinion and rear bearing. Release pressure on

the front bearing and secure by tightening set screw. DO NOT place pressure on bearing while

tightening set screw.

7. Recheck for smooth effortless operation. Unit is now ready for service.

Ball Bearing (R Option) Repair

(NOTE: The side from which the logo can be read is considered the front.) Care should be taken

when removing and installing the ball bearings to prevent damage to the ball bearings or actuator.

The housing should always be secured and an arbor press used to press the ball bearings into or

out of the housing, using only the inner and outer races of the bearing.

TO REMOVE THE BEARINGS: Remove the rear-retaining ring and press the shaft and pinion assembly (including the front bearing) out of the housing from the back side. The front retaining ring,

the front ball bearing and shims can then be removed from the shaft. Finally, the rear ball bearing

can be pressed out of the housing.

3/4" BEARING REMOVAL: Use a screw driver to remove the retaining ring. Remove the front ball

bearing, shaft spacers and gear/shaft assembly by pressing the shaft from the rear side of the

housing.

TO INSTALL THE BEARINGS: Press the rear bearing into the rear of the housing. Press the shaft/

pinion assembly into the rear bearing. Next, press the shaft and pinion assembly through the rear

bearing from the front side of the housing and attach the rear retaining ring. Finally, press the front

bearing over the shaft and into the housing and attach the front retaining ring. (Shims are used as

needed to reduce axial play.)

3/4" BEARING INSTALLATION: After assembling rear bearing as stated above, assemble the

front and rear shaft spacers on the shaft. Then, proceed to assemble the shaft/pinion assembly as

stated above.

Page 2

Assembly Notes

Piston seals are replaced by stretching over the piston and snapping into the piston groove. Seal

lips face the applied pressure.

Bumpers are stretched over and snapped onto the retaining groove on the end of the piston.

The angle adjustment thread pressure seal can be replaced by rst threading the screw inward past

the seal. (The screw cannot be removed from the head.) The seal is then removed using a pick instrument. A new seal is worked into the groove and then the screw is backed out to the desired rotation

limiting position. The lock nut secures the screw and activates the seal.

The yellow dots on the piston magnets are installed in the piston grooves facing towards the shaft.

The cushion seal located in the tube end cap head and the cushion adjusting screw and seal are

NOT repairable. They are furnished installed in a new cylinder body assembly.

When tting a new rear shaft bearing, an arbor press is required to remove the worn bearing and to

seat the new bearing.

When installing the racks, be sure to maintain the same position (twin rack units) and “end for end”

orientation. This will assure being able to re-establish the original alignment of shaft key relative to

unit rotation. The ends of replacement racks are coded “A, B, C, or D” identifying the tube they match

with. (See diagram)

Cylinder body assemblies may not be interchangeable, maintain original position (A, B, C, or D – see

diagram) at re-assembly. The heads of replacement cylinder body assemblies are coded “A, B, C,

or D” to assure correct placement.

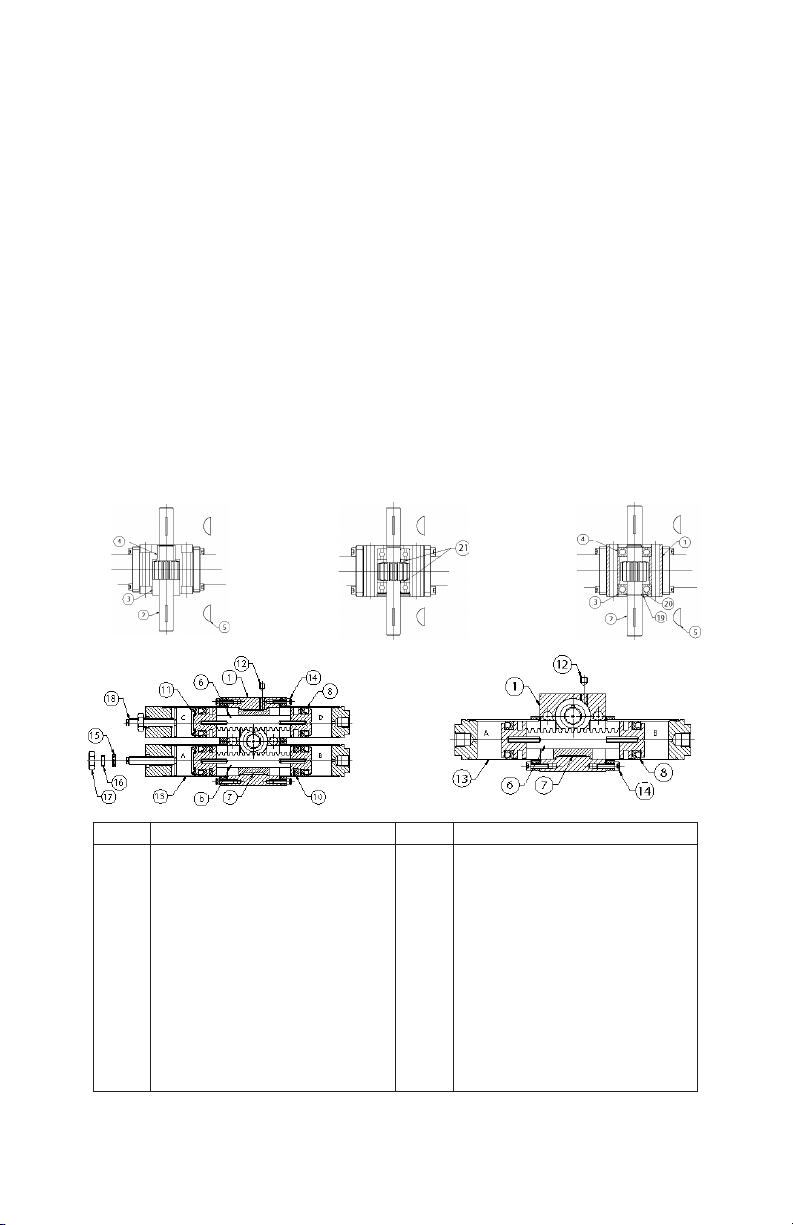

Standard Shaft

3/4" Bore Model Ball Bearing

(R Option)

9/16", 1-1/16", 2" Bore

Models

Double Rack Model

Single Rack Model

Repair Parts

No. Part Description No. Part Description

PT-1

Actuator Body

PT-2

Shaft/Piston Assembly

PT-3

Front Shaft Bearing

PT-4

Rear Shaft Bearing

PT-5

Shaft Woodruff Key

PT-6

Piston/Rack Assembly (includes

Rack, Poll Pins and two Pistons)

PT-7

Rack Support

PT-8

Piston Seal (Double Quantity for Oil

Service)

PT-9

Piston Wear Ring (required for

Oil Service only)

PT-10

Magnet

PT-11

Bumper

PT-12

Bearing Retainer Set Screw

PT-13

Cylinder Body Assembly (includes

Body, End Cap, and Retainer Ring)

PT-14

Cylinder Body Retainer Cap Screw

PT-15

Cylinder Body Thread Seal

PT-16

Cylinder Body Thread Seal Ring

PT-17

Cylinder Body Jam Nut

PT-18

Angle Adjustment Screw

PT-19

Retaining Ring

PT-20

Shim Package

PT-21

Shaft Spacers

Bimba Manufacturing Company

Monee, IL 60449-0068

TEL: 708/534-8544 • FAX: 708/235-2014

Support: 1-800-44-BIMBA

Visit our website at: www.bimba.com Form PTRI-102

Loading...

Loading...