Page 1

Original Line Electric Actuator,

Electric Thruster, Motor, and

Driver Quick Start Manual

Please read this manual carefully

before implementing your

Original Line Electric or

Electric Thruster Actuator

Page 2

Scope of this manual

This instruction manual supports Bimba standard

components only. If special motion control components, including but not limited to power supplies,

encoders, motors, controls, and drivers, are included

based on a customer’s specications or special

request, it is the customer’s responsibility to consult

support materials and technical support specic to

these special components provided by the third party

manufacturers. Bimba assumes no liability for misuse,

misapplication, or support for components that are not

the Bimba brand.

Page 3

Original Line Electric Actuator,

Electric Thruster, Motor, and

Driver Quick Start Manual

Contents

1. Actuator-only Models ..................................................................... 2

Installing your motor

2. Actuator and Motor Models ............................................................ 4

Motor specications and wiring diagram

3. Actuator, Motor, and Driver Models ............................................... 6

a. Mount your drive ..................................................................... 6

b. Connect the DC power supply to the driver ............................ 7

c. Connect the motor to the driver .............................................. 7

d. Set rotary switch for motor selected ....................................... 8

e. Adjust running and idle current ............................................... 8

f. Set load inertia ........................................................................ 9

g. Select step resolution ............................................................. 9

h. Apply power and run self test ............................................... 10

i. Connect input signals ........................................................... 10

j. FAULT output ........................................................................ 13

k. Set step pulse type ............................................................... 14

l. Step pulse noise lter ........................................................... 14

m. Technical specications ........................................................ 15

n. Alarm codes .......................................................................... 16

Troubleshooting Guide and FAQ ..................................................... 17

1

Page 4

Congratulations on purchasing an Original Line Electric actuator from

Bimba. Our OLE and OLET actuators are designed, built, and tested to

provide the longest life, greatest durability, highest speed, and greatest

thrust per dollar. We look forward to serving your electric actuator needs

with the same responsiveness and engineering expertise you are accustomed to receiving for our pneumatic products.

Every OLE and OLET actuator is backed by a one-year warranty. Extend

it to a two-year warranty by registering on our website at

www.bimba.com/pdf/OLEwarrantyregistration.pdf.

1. Actuator-only Models

Installing your motor

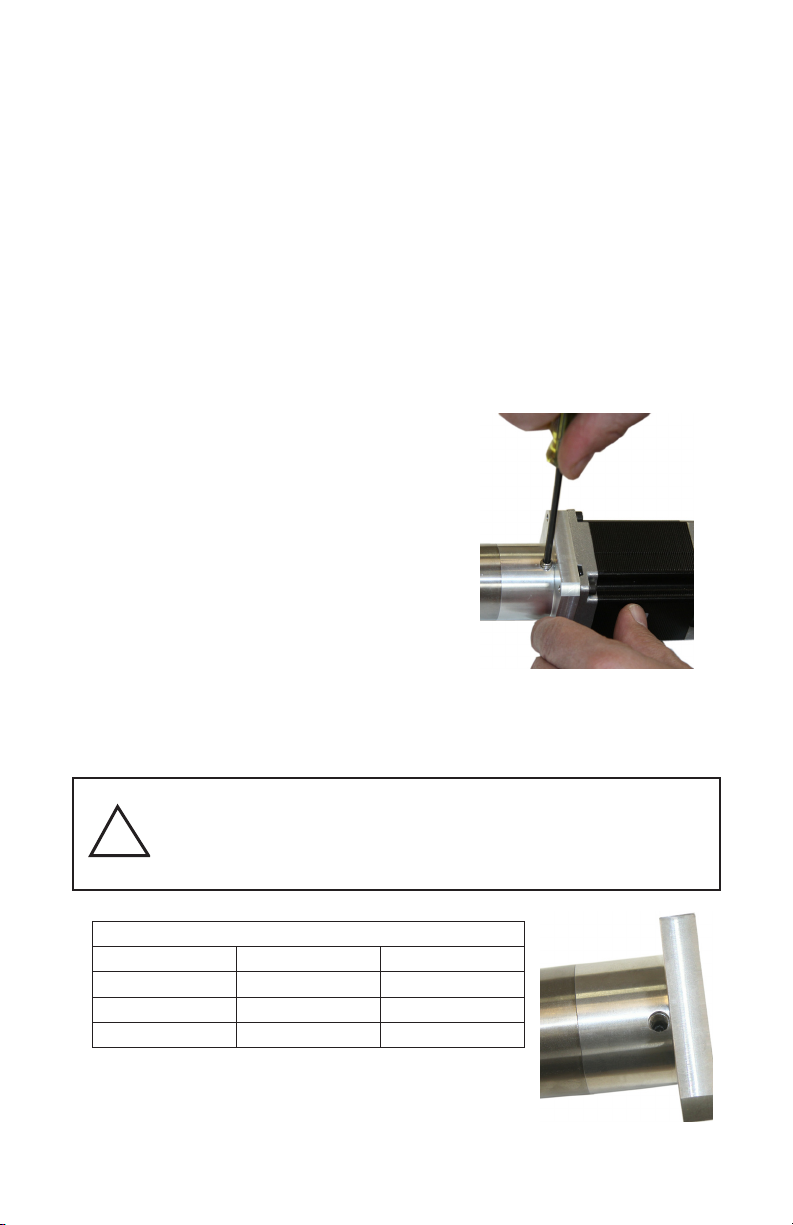

a. Remove plug to provide access to

coupler. Use a 1/8 inch allen key.

b. Turn the actuator coupler so the clamp screw is aligned with the

access hole. Loosen coupler setscrew using allen key. Allen key

sizes are identied in Table 1.

Only loosen the clamp screw until it no longer secures the

motor shaft. Loosening it too much may result in the screw

!

falling out of the coupler, or binding against the actuator’s

inside wall.

Table 1

Actuator Allen Key Torque

75 5/64" 3.8 in-lbs.

150 3/32" 8 in-ibs.

350 3/32" 8 in-lbs.

Note: Torque range is ± 10%.

2

Page 5

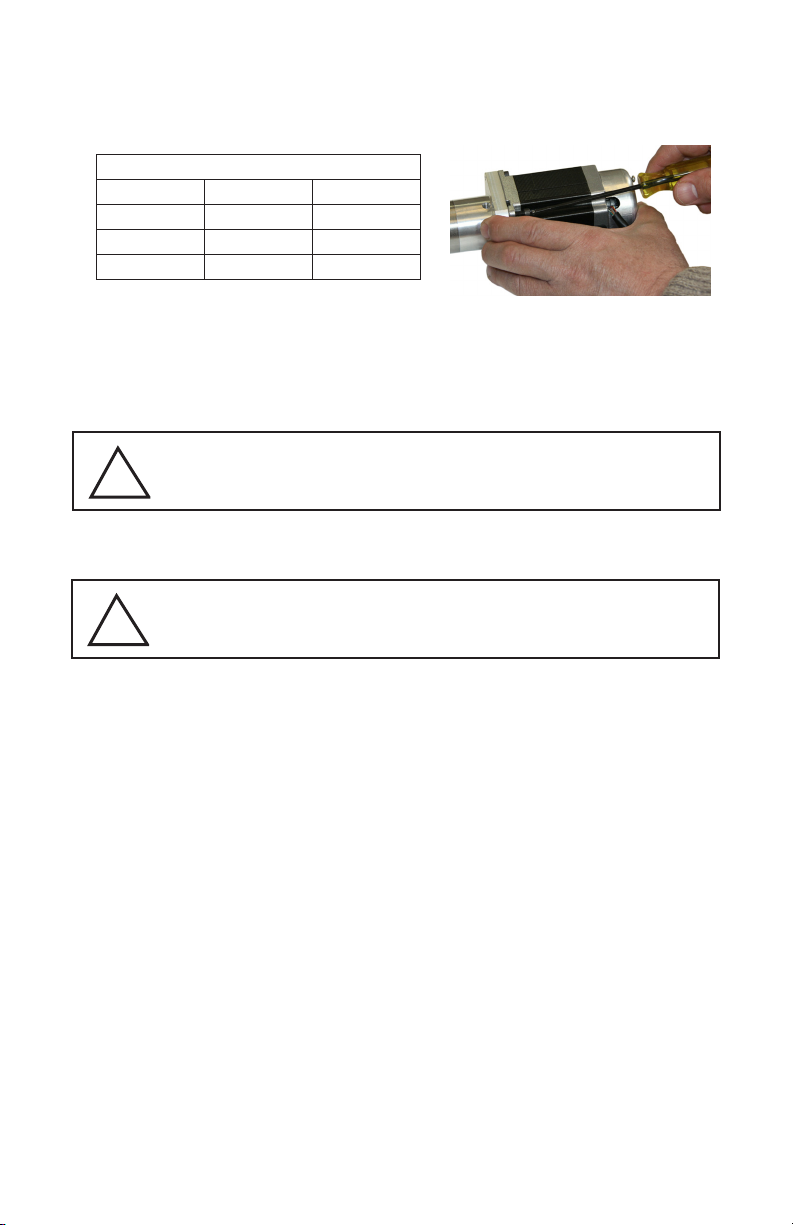

c. Mount motor to actuator, slip shaft into coupler. Secure motor to

actuator using 4 screws provided. Allen key sizes and torque values

are provided in Table 2. Be careful not to turn the coupler.

Table 2

Actuator Allen Key Torque

75 9/64" 12 in-lbs.

150 9/64" 12 in-lbs.

350 5/32" 35 in-lbs.

Note: Torque range is ± 10%.

d. Tighten coupler clamp screw so motor shaft is secured (refer to

Table 1 for torque specication). The coupler clamps around the

circumference of the motor shaft. The orientation of any at (or key-

way) on the shaft does not matter.

Tighten the coupler clamp screw to the torque value in Table 1.

!

e. Replace the coupler access plug.

DO NOT screw the plug in to a hard stop. Only screw it in far

enough so that the top of the plug is ush with the outside

!

surface of the actuator.

3

Page 6

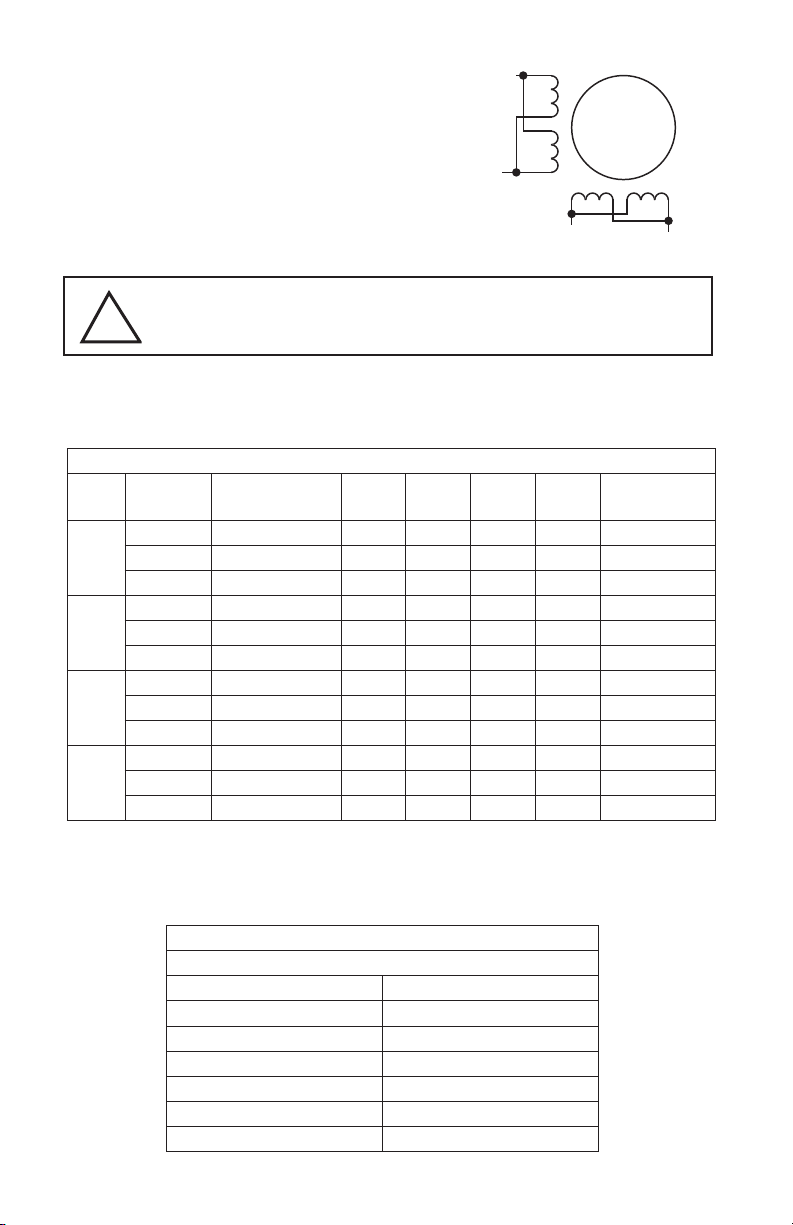

2. Actuator and Motor Models

Orange

All Bimba step motors use the same

8-wire wiring color code convention, as

shown below. .

$

Blk/Wht

Org/

Wht

$²

Black

Figure 1

Red

%

3DUDOOHO

Yel/

Wht

Red/Wht

Yellow

%²

Warning: Be sure power is off before connecting or discon-

!

necting the motor.

Specications for Bimba 8-lead 1.8 degree step motors are provided in

Table 3.

Table 3

Frame

17

23

23

34

Winding

Connection

Parallel 62.3 2.9 1.7 1.7 2.5 0.44/82

Series 62.3 5.6 0.85 6.6 10.0 0.44/82

Unipolar 43.9 4.0 1.2 3.3 2.5 0.44/82

Parallel 177 2.1 4.2 0.37 1.2 1.64/300

Series 177 4.2 2.1 1.5 4.8 1.64/300

Unipolar 125 3.0 3.0 0.75 1.2 1.64/300

Parallel 269.1 2.1 4.2 0.5 1.7 2.51/460

Series 269.1 4.2 2.1 2.0 6.8 2.51/460

Unipolar 191.2 3.0 3.0 1.0 1.7 2.51/460

Parallel 1260 2.72 5.6 0.48 5.4 15.0/2750

Series 1260 5.43 2.8 1.94 21.6 15.0/2750

Unipolar 906 3.88 4.0 0.97 5.4 15.0/2750

Min. Holding

Torque (oz-in)

Volts Amps Ohms mH

Rotor Inertia

(oz-in2/g-cm2)

If you have ordered your actuator with a motor/encoder combination, the

encoder specications are listed in Table 4.

Table 4

Incremental Encoder Specications

Power Input 5 V DC, 160 mA

Resolution 2000 pulses per rev.

Output High 2.5 V DC Min.

Output Low 0.5 V DC Max.

Operating Frequency 500 kHz Max.

Operating Temperature -30 to 115°C

Enclosure Rating IP40

4

Page 7

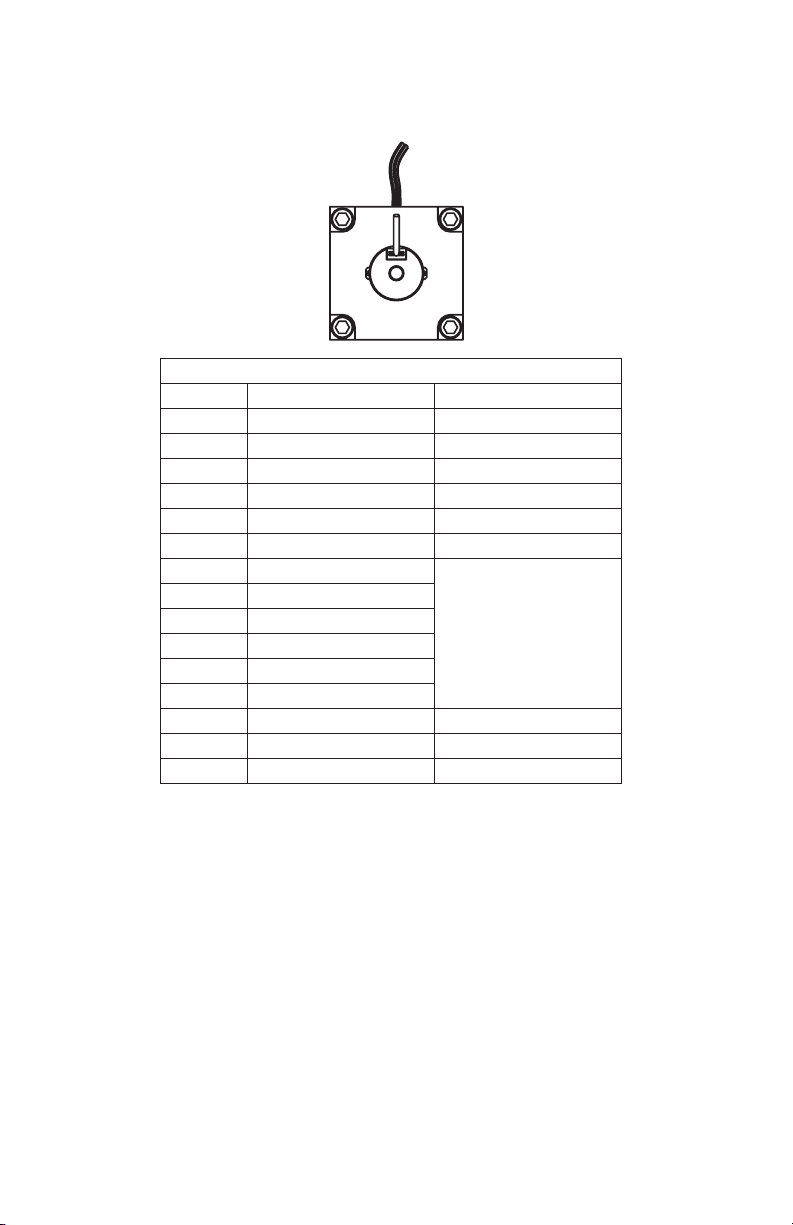

Encoder connections for Bimba step motors are identied in Table 5.

The cable provided has ying leads which can be connected to your

controller.

Table 5

Pin No. Wire Color Function

1 Yellow Channel A

2 Yellow/White Channel A3 Blue Channel B

4 Blue/White Channel B5 Orange Index

6 Orange/White Index7 Green

8 Green/White

9 Brown

10 Brown/White

11 White

12 Gray/White

13 Red +5 V DC input power

14 Black Encoder ground

15 Gray Drain/shield

Not used

5

Page 8

3. Actuator, Motor, and Driver Models

You will need:

• An OLE or OLET actuator with motor attached.

• A small at blade screwdriver for tightening the connectors.

• Wires - 18 to 20 gage recommended

• Wire cutter/stripper

• An appropriate DC power supply.

Warning: Do not apply power until all connections are made.

!

The DRV-4 accepts power supply voltages from 24 to 48 VDC, while the

DRV-8 accepts power supply voltages from 24 to 75 VDC. The current

demand will never exceed double the motor current (see Table 3, Amps

column). However, the DRV will convert a high voltage low current power

supply into a lower voltage higher current power supply. A 24V 4A supply will

perform similarly to a 48V 2A supply. Use Table 7 below as a guideline.

Use unregulated power supplies without overvoltage protection

!

to avoid problems with regeneration during rapid deceleration.

Table 7

OLE Drive

-75 DRV-4 24-48 17 frame 1.7 3.4 4 2 4.5

-75 DRV-4 24-48 23 frame 4.0 4.5 4 2 4.5

-150 DRV-8 24-75 23 frame 4.2 8.4 8 4 7.8

-350 DRV-8 24-75 34 frame 5.6 11.2 12 6 7.8

Power

Supply

Voltage

Bimba

Motor

Parallel

Current

Draw

Parallel

Current

Draw Max

24V Power

Supply

.

Amperage

48V Power

Supply

Amperage

Max

Amps per

Phase

a. Mount your drive

Mount the drive using #6 screws.

Installing on a metal surface

(recommended) helps dissipate heat.

Forced air ow from a fan is also

good practice.

Motor & Power Supply

Connector

Run Current, Idle Current

Steps/rev, Inertia, Self Test

6

Input & Output

Signals

Motor Selector

Status LEDs

Page 9

Warnings:

• Do not install drive where ambient air is more than 104° F.

• Do not install drive where there is no air ow

!

• Do not install drive where drive can get wet.

• Do not install drive where electrically conductive material can

fall on the driver.

• Drives must be mounted at least one-half inch apart.

b. Connect the DC power supply to the driver -- Do not

apply power

Warning: Observe proper polarity when connecting wires.

!

I. Make sure the power supply is not on. Connect V+ and V- from the

power supply to the V+ and V- terminals of your driver.

II. Ensure a proper earth ground connection by

using the screw on the left side of the chassis.

All system components must be grounded to

a single point common earth ground.

If using an external fuse, we recommend the

following in-line with the V+ connection:

DRV-4: 3AG, 4 amp (Littlefuse 313004P)

DRV-8: 3AG, 6.25 amp (Littlefuse 3136.25P)

c. Connect the motor to the driver

Warning: Never connect or disconnect the motor when power is

!

applied.

Connect OLE or OLET eight lead motors in parallel, as shown below. If using a motor from another source, please refer to your motor specs for wiring

information. A motor wiring diagram is shown in Figure 1.

7

orange+blk/wht

black+org/wht

red+yel/wht

yellow+red/wht

A+ A- B+ B-

Page 10

d. Set rotary switch for the motor selected

12

(This is normally set by the factory for the motor specied.)

Turn the rotary switch to the number that represents

the motor you have. This sets current and antiresonance settings for optimum performance.

OLE

-150 23 frame P2, E2, Y2, Z2 6

-350 34 frame P3, E3, Y3, Z3 F

Bimba Motor

Frame

-75 17 frame P1, E1, Y1, Z1 5

-75 23 frame P2, E2, Y2, Z2 7

Option Code Setting

e. Adjust running and idle current

Switch 1 and 2 set the running

current to 70%, 80%, 90%

or 100% of the motor’s

rated maximum current.

12

100%

12

90%

12

80%

70%

• Use 100% position in most ap-

plications (factory default)

• Use lower setting during

initial setup to avert

!

accidental damage

• Use lower settings to address

safety issues

• Use lower settings to reduce

motor temperature

Switch 4 sets the idle current

to either 50% or 90% of the

selected running current.

Factory default is 90%.

• Use lower settings for self locking threads (OLE 12, 16, and

20 leads).

• Use lower settings to reduce

motor temperature

• Use higher settings for full holding torque

4

50%490%

8

Page 11

f. Set load inertia

Switch 3 chooses between

two load inertia ranges.

This information is used in the

anti-resonance conguration.

• Values are multiples of rotor

inerta (see Table 3)

• Use 0-4x for smaller (0.2" or

smaller) leads and shorter

strokes (factory default)

• Use 5-10x for longer (0.25" or

3

5-10X

3

0-4X

larger) leads and greater loads

• 5-10x may reduce performance.

g. Select step resolution

There are 4 microstep resolutions to choose from as well as full and half

step

• 200

• 200µ (microstep emulation)

factory default

• 400

• 400µ (microstep emulation)

• 2000

567

20000

567

567

12800

567

567

5000

567

567

2000

567

• 5000

• 12800

400

SMOOTH

µ

400

200

SMOOTH

µ

200

• 20000

The 200µ and 400µ settings use microstep emulation to provide smooth

rotation at low speeds. Microstep emulation imparts a slight delay to the

motion. If this is not acceptable, use the non-ltered 200 or 400 settings.

9

Page 12

Microstepping provides smoothest rotation. However, a faster step pulse

Steps/rev, Inertia, Self Test

rate (frequency) is required for a given RPM as shown in Table 8 below.

Table 8

Pulses per

revolution

Degrees per

step

Pulse frequency re-

quired for 300 RPM

Pulse frequency re-

quired for 3000 RPM

200 1.8 1,000 Hz 10,000 Hz

400 0.9 2,000 Hz 20,000 Hz

2000 0.18 10,000 Hz 100,000 Hz

5000 0.072 25,000 Hz 250,000 Hz

12800 0.028 64,000 Hz 640,000 Hz

20000 0.018 100,000 Hz 1,000,000 Hz

h. Apply power and run self test

The DRV-4 and DRV-8 have built in Self Test functions.

When switch 8 is moved to the ON position, the

8

drive will automatically rotate the motor back and

forth, two turns in each direction. This feature can

be used to conrm that the motor is correctly wired,

selected and operational. Factory default is “OFF.”

ON

SELF TEST

8

OFF

i. Connect input signals

The drives have three inputs:

• STEP: a high speed digital input for step pulse commands, 5-24 volt logic

• DIR: a high speed digital input for the direction signal, 5-24 volt logic

• EN: a 5-24V input for commanding the removal of power from the motor

STEP and DIR inputs can be converted to STEP CW and STEP CCW by

moving the internal jumper S3. For detailed instructions, go to Step “K” of

this section.

Refer to the illustration below for identication of step, direction, and

enable inputs on the driver screw terminal blocks.

STEP+

STEP

DIR+

–

Motor & Power Supply

FAULT+

FAULT–

DIR–

EN+

EN

–

Connector

Run Current, Idle Current

Input & Output

Signals

Motor Selector

10

Status LEDs

STEP+

STEP-

DIR+

DIR-

220 pF

220 pF

inside drive

Page 13

Connection Examples: STEP & DIR

STR

COM

DIR-

DIR DIR+

STEP-

STEP STEP+

Indexer

with

Sourcing

Outputs

STR

+5V OUT

DIR+

DIR DIR-

STEP+

STEP STEP-

Indexer

with

Sinking

Outputs

STR

DIR+

DIR+

DIR- DIR-

STEP+

STEP-

STEP+

STEP-

Indexer

with

Differential

Outputs

Connecting to indexer with Sourcing Outputs

Connecting to Indexer with Sinking Outputs

DRV

DRV

DRV

Connecting to Indexer with Differential Outputs

(Many High Speed Indexers have Differential Outputs)

11

Page 14

STR

EN-

EN+

Si drive

OUT+

OUT–

5-24

VDC

Power

Supply

-

+

STR

NPN

Proximity

Sensor

EN-

EN+

output

+

–

12-24

VDC

Power

Supply

-

+

STR

PNP

Proximity

Sensor

EN+

output

+

–

EN-

12-24

VDC

Power

Supply

-

+

STR

switch or relay

(closed=logic low)

EN-

EN+

5-24

VDC

Power

Supply

-

+

Connection Examples: EN

The 5-24 V EN input disables power to the motor.

Connecting an Input to a Switch or Relay

DRV

DRIVE

Connecting another drive to EN

(When output closes, input closes)

DRV

Connecting an NPN Type Proximity Sensor to an input

(When prox sensor activates, input closes)

Connecting a PNP Type Proximity Sensor to an input

(When prox sensor activates, input closes)

12

DRV

DRV

Page 15

j. FAULT output

STR

5-24 VDC

Power Supply

+ –

Load

FAULT-

FAULT+

PLC

STR

5-24 VDC

Power Supply

+ –

FAULT-

FAULT+

IN

COM

STR

FAULT-

FAULT+

1N4935 suppression diode

5-24 VDC

Power Supply

+ –

relay

The DRV drives feature a digital FAULT output. This output closes to signal a

fault condition.

This output can be used to drive LEDs, relays and the inputs of other elec-

tronic devices like PLCs. The “+” (collector) and “-” (emitter) terminals of the

output transistor are available at the connector. This allows you to congure

the output for current sourcing or sinking. Diagrams of each type of connection follow.

Do not connect the output to more than 30 VDC.

!

The current through the output terminal must not exceed 80 mA.

DRV

DRV

Sinking Output

Sourcing Output

DRV

Driving a Relay

13

Page 16

k. Set step pulse type

Most indexers and motion controllers provide motion commands in the “Step

and Direction” format. The Step signal pulses once for each motor step and

the direction signal commands direction. However, a few PLCs use a different type of command signal: one signal pulses once for each desired step in

the clockwise direction (called STEP CW), while a second signal pulses for

counterclockwise motion (STEP CCW). The drives can accept this type of

signal if you remove the cover and move jumper S3 from the “1-2” position to

the “1-3” position. Factory default is the 1-2 position. As you can see in the

image, the jumper terminals (2, 1, 3) and S3 and S4 designators are printed

in white on the circuit board.

Jumper S4: noise lter

Shown in 1-2 position

Jumper S3: step pulse type

Shown in 1-2 position

l. Step pulse noise lter

Electrical noise can cause the drive to think that one step pulse is two or

more pulses, resulting in extra motion and inaccurate motor and load posi-

tioning. To combat this problem, the drive includes a digital noise lter on the

STEP and DIR inputs. The default factory setting of this lter is 150 kHz.

If you are operating the drive at high speeds with step rates above 150 kHz,

remove the cover and move jumper S4 from the 150 kHz position (1-3) to the

2 MHz position (1-2) as shown below.

Your maximum pulse rate will be the highest motor speed times the steps/

rev. For example, 40 revs/second at 20,000 steps/rev is 40 x 20,000 = 800

kHz. Please consider this when deciding if you must increase the lter frequency.

14

Page 17

m. Technical specications

Amplier

Digital Inputs

Fault Output

Physical

Mating Connectors

Motor/power supply: PCD P/N ELV06100 (Phoenix Contact 1757051),

included with drive.

Signals: PCD P/N ELVH08100 (Phoenix Contact 1803633), included with

drive.

Digital MOSFET. 20 kHz PWM. Suitable for driving two

phase and four phase step motors with four, six or eight

leads.

Supply voltage:

DRV-4

24-48 VDC

Under voltage alarm: 20 VDC

Over voltage shutdown: 60 VDC

DRV-8

24-75 VDC

Under voltage alarm: 20 VDC

Over voltage shutdown: 85 VDC

Motor current:

0.5 to 7.8 amps/phase peak of sine (DRV8)

0.25 to 4.5 amps/phase peak of sine (DRV4)

Optically isolated, 5 - 24V logic. Sourcing, sinking or

differential signals can be used.

Minimum “on” voltage: 4 VDC.

Maximum voltage: 30 VDC.

Input current: 5 mA typ at 4V, 15 mA typ at 30V.

Photodarlington, 80 mA, 30 VDC max. Voltage drop: 1.2V

max at 80 mA.

1.3 x 3.0 x 4.65 inches (33 x 75.5 x 118 mm) overall. 10.8

oz (305 g) including mating connectors.

Ambient temperature range: 0° C to 40° C.

15

Page 18

n. Alarm codes

In the event of a drive fault or alarm, the green LED will ash one or two

times, followed by a series of red ashes. The pattern repeats until the alarm

is cleared. You may clear the alarm by cycling power off and then on.

Code Error Action Required

no alarm, motor

disabled

no alarm, motor

enabled

conguration or

memory error

power supply

voltage too high

over current/short

current

internal voltage out

of range

power supply

voltage too low

open enable input

none

repair

reduce power

supply voltage

check motor

connections

check motor

connections

repair

increase power

supply voltage

G R R R R

G R R R R R

G R R R RR R

G G R R R

G G R

G

solid green

ashing green

G G

ashing red

R R

1 green, 4 red

1 green, 5 red

1 green, 6 red open motor winding

2 green, 3 red

R

R R

2 green, 4 red

16

Page 19

Troubleshooting Guide and FAQ

Problem: Actuator does not move when step motor is energized.

Solution: Step motor windings may be shorted. Use an Ohmmeter to

measure the resistance between pairs of windings (should be innite)

and between the leads of each winding (should be the same for each

winding). Use your motor’s wiring diagram to identify the correct leads.

If windings are shorted, the motor must be replaced.

Problem: Actuator operation is stiff, seems to be binding.

Solution: Check for dents on the body tube, motor end bell, and dam-

age to the square rod. If there are signs of visible damage, the actuator

or motor or both may need to be replaced. Dents on the motor shaft or

endbells may cause the rotor to seize or rub, producing binding and stiff

operation. While the nut of the OLE actuator is self-lubricating, rod lubrications is recommended at regular intervals. Use Bimba HT-99 grease.

Problem: Can I use switches with my OLE for end of stroke sensing?

Solution: All OLE actuators have magnetic pistons. OLE actuators can

use the same switches as Original Line pneumatic cylinders. Refer to the

Bimba catalog for switch recommendations.

Problem: The motor gets hot.

Solution: Step motors tend to run hot (the actual maximum case tem-

perature is 80° C). However, the motor should not get too hot to touch.

If it is overheating, the drive current may be set too high. All standard

OLE step motors are 8-wire motors. Refer to Table 3 in this manual for

required drive current levels. Also consider duty cycle; reduce either the

running current, idle current, or duty cycle. Instructions for adjusting idle

and running current are provided in section 3.e.

Problem: The motor is not producing enough torque or it stalls at low

speeds.

Solution: If the motor previously ran well, check the resistance of the

windings. Use an Ohmmeter to measure the resistance between differ-

ent windings (should be innite) and between the leads of each winding

(should be the same for each winding). Use your motor’s wiring diagram

to identify the correct leads. If windings are shorted, the motor must be

replaced.

If lack of torque is observed at the initial start up with a load and desired

speeds are not reached, check connections between the motor and drive

and check drive settings.

17

Page 20

Inspect the motor and rotate the shaft when the motor is not connected.

If you feel any rubbing or there are any dents on the motor, there is probably an alignment problem and the motor may need to be replaced.

If the rotor was removed from the stator, it could have been demagnetized. The motor would need to be replaced.

If you still cannot solve the problem, the size of your power supply (volt-

age output) may need to be greater. When a step motor rotates, it acts

like a generator pumping voltage (back EMF) back into the drive. Back

EMF rises as motor speed and inductance increase and can cause a

stall. The solution is to either change from a series to a parallel connec-

tion (series connections quadruple inductance) or use a power supply

with a higher output voltage.

Problem: The motor doesn’t produce any holding torque.

Solution: Make sure that line power is on, the drive is powered up, and

the motor phases are connected correctly to the drive.

Problem: The motor (actuator) oscillates back and forth at low speeds.

Solution: This is due to resonance, common between 1-4 rps. If this is

observed with no load, add a load to the motor (the load will dampen out

resonance). Changing from full-step to half-step or microstepping will

also solve resonance problems.

Step and Direction Drives

Note: Please read your manual rst before and during your setup. Bimba

manuals, available at www.bimba.com/OLE/manuals, are short, to the

point, and comprehensive.

Problem: The drive’s power LED does not illuminate when power is ap-

plied.

Solution: Check the fuse and replace if necessary with one of the extra

fuses included with your drive. If you have no fuses or continuously blow

fuses, call Bimba Technical Support. Check your power supply to be sure

it is not providing an excessively high voltage to the drive.

Problem: The motor runs then suddenly dies. The connections are correct.

Solution: Turn off power. Refer to your motor wiring diagram. Disconnect the motor. Using an ohmmeter, measure the resistance between the

A+ and A- and B+ and B- terminals. The reading should be in the megaOhms. If resistance is low, the H-bridge is damaged and the drive must

be returned on a RGA (Returned Good Authorization). If the resistance is

normal, inspect the board for any visible damage to the components and

check the motor for a short circuit in the windings.

18

Page 21

Problem: The motor does not move when a step signal is sent to the

drive.

Solution: If the enable input is on (low with respect to a 5-24 volt signal),

it will disable the motor. Do not connect anything to the enable input if

there is no reason to disable the motor.

Problem: The motor will not run slow enough with a potentiometer con-

nected to my drive (it has an internal oscillator).

Solution: Some drives’ internal potentiometers cannot be adjusted to

zero speed. Check the specications in the manual that came with the

drive.

Problem: At startup, the motor does not run although the wiring is

correct.

Solution: Make sure that dip switches and jumpers are set properly.

Read your driver manual carefully.

Problem: System not working properly.

Solution: Troubleshoot by replacing the drive and see if the problem

persists. Please read your drive manual before and during your setup.

Bimba manuals, concise and comprehensive, are available for download

at our website, www.bimba.com.

19

Page 22

Bimba Manufacturing Company

Monee, Illinois 60449-0068

Tel: 708.534.8544

Tech Support: 800.44BIMBA

Fax: 708.235.2014

support@bimba.com

www.bimba.com

OLE-513 Manual

D-110340 Effective May 2013

Loading...

Loading...