Page 1

BPGS PNEUMATIC

GRIPPER SYSTEM

BPGS10 and BPGS11

User Manual

We make

®

things MOVE

Page 2

BPGS PNEUMATIC GRIPPER SYSTEM

User Manual

SCOPE OF THIS MANUAL

This instruction manual supports Bimba standard components only. If special components, including but

not limited to serial hubs, power supplies, and drivers, are included based on a customer’s specifications

or special request, it is the customer’s responsibility to consult support materials and technical support

specific to these special components provided by the third party manufacturers. Bimba assumes no liability

for misuse, misapplication, or support for components that are not the Bimba brand.

WARNING

Using the equipment in a manner not specified in this manual can impair the safety of the equipment.

Technical support is available from:

Bimba Manufacturing Company

25150 S Governors Hwy University Park, Illinois 60484

Phone: 708-534-8544 Toll Free: 800-44-BIMBA Fax: 708-235-2014

Email: cs@bimba.com • www.bimba.com

2

BIM-BPGSM-0519 Rev 1 | For Technical Assistance: 800-442-4622

Page 3

BPGS PNEUMATIC GRIPPER SYSTEM

User Manual

TABLE OF CONTENTS

Port Size and Operation 4

Gripper Unlock 4

Jaw Removal 4

Jaw Replacement

Setting Jaw Open Angle 6

Installing a Side Plate or Indirect Sensor 7

Pad Replacement 8

Calibrating In-Direct Sensor 8

Installing an In-Pad Sensor 9

Cleaning and Maintenance 10

Quality Assurance Requirements 10

Specifications 10

5

BIM-BPGSM-0519 Rev 1 | For Technical Assistance: 800-442-4622

3

Page 4

BPGS PNEUMATIC GRIPPER SYSTEM

User Manual

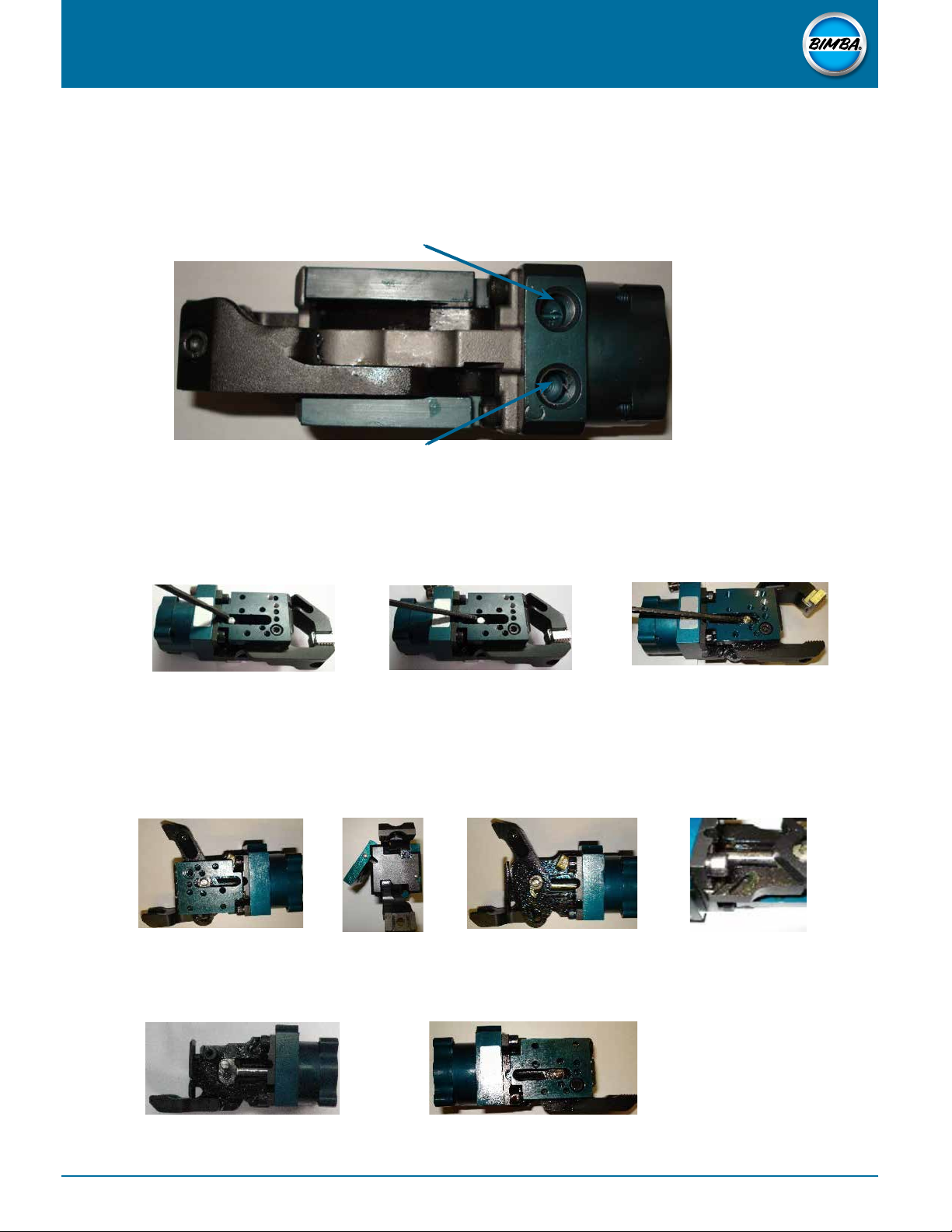

PORT SIZE AND OPERATION

1. Ports are available in 1/8" NPS or 1/8 Rc.

Gripper open

Gripper close letter “C” to identify part

GRIPPER UNLOCK

1. Release jaw by using a hex key or flat screwdriver and pushing on drive pin through slot in side plate

JAW REMOVAL

1. Unlock gripper as shown in step above and remove pad(s) from existing jaws. Set a side for reassembly.

2. Top jaw should always be removed first. Remove Socket Head Cap Screw (SHCS) from side plate or indirect

sensor. Rotate side plate/sensor up to about 45° and remove side plate/sensor from gripper. Set SHCS and

Side Plate/Sensor aside for re-assembly. Remove bumper from gripper.

3. Remove jaw from gripper and flip gripper over to remove other jaw

4

BIM-BPGSM-0519 Rev 1 | For Technical Assistance: 800-442-4622

Page 5

BPGS PNEUMATIC GRIPPER SYSTEM

User Manual

4. Remove SHCS from side plate/sensor. Rotate side plate/sensor up to about 45° angle and remove from gripper.

Set SHCS and Side Plate/Sensor aside for re-assembly.

5. Remove bushing from lower jaw using a small flat screwdriver or hex key and set aside for re-assembly. Lower jaw

should be rotated completely down before removal. Lift up on front of jaw by pad so there is an angle between

jaw and frame. Remove lower jaw from gripper.

Angle

JAW REPLACEMENT

1. For lower jaws (B10151, B11105, B11105-01, B11105-02, B11106, B11106-01, B11106-02, B11103, B12978,

B12978-01, B12978-02, B12985, B12985-01, B12985-02): Apply grease to cam and inside of jaw. Angle new

jaw so that tail of jaw goes in pocket of frame. Align pivot hole with boss and drive pin with the bottom side of the

cam slot. Carefully slide jaw over boss and onto gripper. Replace bushing over pin and into cam. Apply grease to

outside of jaw.

Tail of jaw in pocket

2. Refer to steps for "Installing a Side Plate or Indirect Sensor"

3. Flip gripper over for top jaw installation

BIM-BPGSM-0519 Rev 1 | For Technical Assistance: 800-442-4622

5

Page 6

BPGS PNEUMATIC GRIPPER SYSTEM

User Manual

4. For upper jaws: Apply grease to cam and inside of jaw. Replace bushing over drive pin and onto gripper. Align

hole in jaw with boss on frame and cam with bushing. Slide jaw over boss and drive pin so that jaw rests on

gripper. Apply grease to outside of jaw.

5. Refer to "Setting Jaw Open Angle" step 2 to set bumper position. Refer to "Gripper Unlock" for installing a Side

Plate or Indirect Sensor.

SETTING JAW OPEN ANGLE

1. Look for bumper which should be on the upper jaw side. Remove M5X12mm SHCS from side plate. If indirect

sensor is in place of side plate remove M5X30mm from indirect sensor. Rotate side plate/sensor up to about a

45° and remove from gripper. Set SHCS and Side Plate/Sensor aside for re-assembly. Remove bumper from

gripper.

2. Insert bumper into new position, based on required open jaw angle. Bumpers should only be on the top jaw side

of gripper. Jaws do not need to be removed to change bumper position. Insert bumper into frame and insure

bumper is seated properly.

22° Open Jaw Angle 45° Open Jaw Angle

70° Open Jaw Angle

6

BIM-BPGSM-0519 Rev 1 | For Technical Assistance: 800-442-4622

Page 7

BPGS PNEUMATIC GRIPPER SYSTEM

User Manual

INSTALLING A SIDE PLATE OR INDIRECT SENSOR

1. With the Side Plate at 45°, align pins of side plate with slots of frame. Slide pins into slot. When pins are fully

seated, rotate side plate and slide down onto frame.

2. If an Indirect Sensor is to be installed, move brass bushing in sensor to align with drive pin in gripper. This must

be done to correctly install sensor. Align dowel pins with slots of frame. Once pins are fully into slots, rotate sensor

down onto frame. As rotation begins make sure bushing and drive pin are still aligned.

Note: Whenever any part of the gripper is replaced including pads the sensor will need to be recalibrated, see

"Calibrating In-Direct Sensor".

3. Clean and apply Loctite 262 or equivalent to M5 X 12mm SHCS for side plate or M5 X 30mm SHCS for sensor.

Insert through side plate/sensor and into frame. Tighten M5 SHCS to 72in-lb.

Side Plate

BIM-BPGSM-0519 Rev 1 | For Technical Assistance: 800-442-4622

Indirect Sensor

7

Page 8

BPGS PNEUMATIC GRIPPER SYSTEM

User Manual

PAD REPLACEMENT

1. Unlock jaws on gripper & open jaws to get access to pads. Side plates/sensor DO NOT need to be removed.

Refer to Gripper Unlock.

2. Remove M5X8mm SHCS from jaw.

3.

3. Apply Loctite 262 to M5 X 8mm SHCS and insert into one of the jaws. Take replacement pads and insert it into

the opposite side of the jaw with SHCS sticking out. Thread SHCS into pad and tighten to 72in-lb. Repeat step

for other jaw. Chisel jaws only require one pad

CALIBRATING IN-DIRECT SENSOR

Sensor must be calibrated whenever any part of the gripper is replaced including pads.

1. Part Present

a.) To program the sensor for a particular material thickness, apply air to the gripper and grip on the material

thickness which is to be used for the particular job. With an object such as a small Allen wrench, press the

button until the Red LED corresponding to the material range of the job lights as shown on the label.

b.) Verify calibration:

(1) Close the gripper with no material between the pads. The LED should be o.

(2) Close the gripper on a single blank of material. The Red LED corresponding to your material range

should be on.

8

BIM-BPGSM-0519 Rev 1 | For Technical Assistance: 800-442-4622

Page 9

BPGS PNEUMATIC GRIPPER SYSTEM

User Manual

2. Double Blank

1) To program the sensor for a particular material thickness, apply air to the gripper and grip on the material

thickness which is to be used for the particular job. With an object such as a small Allen wrench, press the

button until the Red LED(s) corresponding to the material range of the job lights as shown on the label.

2) Verify calibration:

(a.) Close the gripper with no material between the pads. The LED(s) should be o.

(b.) Close the gripper on a single blank of material. The Red LED(s) corresponding to you material range should

be on.

INSTALLING AN IN-PAD SENSOR

1. If an In-Pad Sensor is to be installed, it goes on top of the side plate assembly. Wrap sensor cable through

holder and align holes on side plate. Clean and apply Red Loctite 262 or equivalent to 2X M5 X 10mm SHCS

and thread thru sensor into side plate. Tighten both SHCS to 36in-lb.

2. Shim is only used for part numbers listed. If a shim is to be used on an angle pad, smaller tabs go on the

narrow side of the pads.

BPGS10RXXXXX1XXX

BPGS10FXXXXX1XXX

BPGS10CXXXXX1XXX

BPGS10DXXXXX4XXX

BPGS10EXXXXX7XXX

BPGS10SXXXXX1XXX

BPGS10TXXXXX4XXX

BPGS10UXXXXX7XXX

BPGS10VXXXXX1XXX

BPGS10WXXXXX4XXX

BPGS10YXXXXX7XXX

Small Tabs

BIM-BPGSM-0519 Rev 1 | For Technical Assistance: 800-442-4622

9

Page 10

BPGS PNEUMATIC GRIPPER SYSTEM

User Manual

3. Apply Red Loctite 262 or equivalent to sensor stud, place thru jaw and tighten sensor nut to 72in-lb.

Cable should follow

the contour of the

gripper jaw

Cable storage loop

can be adjusted with

a push/pull motion to

provide more or less

cable slack in gripper

jaw area

CLEANING AND MAINTENANCE

1) Remove excess grease from outer surfaces of gripper.

2) No required maintenance.

QUALITY ASSURANCE REQUIREMENTS

1) Verify that jaws shall open freely. Look for any irregular movement, binding, or interference.

SPECIFICATIONS

Gripper Throat Depth

Inch (mm)

BPGS10C

BPGS10D

BPGS10E

BPGS10F

BPGS10R

BPGS10S

BPGS10T

BPGS10U

BPGS10V

BPGS10W

BPGS10Y

.76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

.76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

.76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

.92 23.4 1.21 (30.6mm) 60 psi (413kPa) Min. –

.75 19 1.03 (26.3mm) 60 psi (413kPa) Min. –

.76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

.76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

.76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

.76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

.76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

.76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

Flange Height

Inch (mm)

Working Pressure Double Sided Grip

Force Up To

100 psi (689 kPa) Max.

100 psi (689 kPa) Max.

100 psi (689 kPa) Max.

100 psi (689 kPa) Max.

100 psi (689 kPa) Max.

100 psi (689 kPa) Max.

100 psi (689 kPa) Max.

100 psi (689 kPa) Max.

100 psi (689 kPa) Max.

100 psi (689 kPa) Max.

100 psi (689 kPa) Max.

450lbs (200kgf) @ 80

psi (551kPa)

450lbs (200kgf) @ 80

psi (551kPa)

450lbs (200kgf) @ 80

psi (551kPa))

450lbs (200kgf) @ 80

psi (551kPa)

450lbs (200kgf) @ 80

psi (551kPa)

450lbs (200kgf) @ 80

psi (551kPa)

450lbs (200kgf) @ 80

psi (551kPa)

450lbs (200kgf) @ 80

psi (551kPa)

450lbs (200kgf) @ 80

psi (551kPa)

450lbs (200kgf) @ 80

psi (551kPa)

450lbs (200kgf) @ 80

psi (551kPa)

Actuation Time

.050±.010 sec close /

<.090 sec open

.050±.010 sec close /

<.090 sec open

.050±.010 sec close /

<.090 sec open

.050±.010 sec close /

<.090 sec open

.050±.010 sec close /

<.090 sec open

050±.010 sec close /

<.090 sec open

.050±.010 sec close /

<.090 sec open

.050±.010 sec close /

<.090 sec open

.050±.010 sec close /

<.090 sec open

.050±.010 sec close /

<.090 sec open

.050±.010 sec close /

<.090 sec open

10

BIM-BPGSM-0519 Rev 1 | For Technical Assistance: 800-442-4622

Page 11

BPGS PNEUMATIC GRIPPER SYSTEM

User Manual

Chisel jaw / shovel Regular / flange jaw

Single blank

thickness

0.50mm to 2.0mm

2.01mm to 3.5mm

3.51mm to 5.0mm

5.01mm to 6.5mm

6.51mm to 8.0mm

8.01mm to 9.5mm

Note: A shim is required under a black pad when it is installed on a chisel jaw gripper. This shim is included in all black replacement pad kits for the chisel jaw gripper.

Movable jaw

pad color

Opposing fixed

jaw color

Moveable jaw

pad color

Black (note 1) Black Black

Silver Black Silver

Black (note 1) Silver Gold

Silver Silver n/a

Black (note 1) Gold n/a

Silver Gold n/a

Opposing jaw

pad color

Black

Silver

Silver

n/a

n/a

n/a

BIM-BPGSM-0519 Rev 1 | For Technical Assistance: 800-442-4622

11

Page 12

BPGS PNEUMATIC GRIPPER SYSTEM

User Manual

TECHNICAL DOCUMENTS

Visit the Bimba website for additional models, drawings, and further documentation.

www.bimba.com

SUPPLIER CONTACT

To purchase electric motion products, accessories, or receive further information,

contact your local Bimba distributor or contact Bimba directly.

Bimba Manufacturing Headquarters

25150 S Governors Hwy University Park, Illinois 60484

Phone: 708-534-8544

Toll Free: 800-44-BIMBA

Fax: 708-235-2014

Email: cs@bimba.com

www.bimba.com

© Copyright 2019 Bimba Manufacturing Company. All Rights Reserved. HM-BIM-BPGSM-0519 Eective May 2019.

12

BIM-BPGSM-0519 Rev 1 | For Technical Assistance: 800-442-4622

Loading...

Loading...