Page 1

AERIAL WORK PLATFORMS

AERIAL WORK PLATFORMS

AERIAL WORK PLATFORMSAERIAL WORK PLATFORMS

XLB-4232 DC

Hydraulic Boom Lift

Operation and

Maintenance Manual

B33-01-0088

Page 2

BOOM PERSONNEL LIFT

This equipment is designed and manufactured in compliance with the duties,

responsibilities, and standards set forth for manufacturers in the ANSI 92.2

standard in effect at the time of manufacture.

This equipment will meet or exceed applicable OSHA codes and ANSI A92.2

standards when used in accordance with sections 7, 8, 9, 10 & 11 of ANSI A92.2 and

all other manufacturer’s recommendations.

It is the responsibility of the user of this equipment to follow all applicable ANSI,

OSHA, Federal, State, and local codes and regulations that govern the safe

operation of this equipment.

Page 3

Table of Contents

1111 Safety ............................................................................................................... 1-1

1-1 Introduction........................................................................................ 1-1

1-2 Before Operation............................................................................... 1-3

1-3 During Operation............................................................................... 1-4

1-4 Maintenance Safety........................................................................... 1-6

1-5 Damaged Equipment Policy............................................................. 1-7

2222 Introduction .................................................................................................... 2-1

2-1 General Description........................................................................... 2-1

2-2 Specifications..................................................................................... 2-2

2-3 Warranty............................................................................................. 2-2

3333 Operation ........................................................................................................ 3-1

3-1 Operator Controls.............................................................................. 3-1

3-2 Normal Operating Procedure............................................................ 3-6

3-3 Emergency Lowering.........................................................................3-8

3-4 Manual Boom Rotation.................................................................... 3-8

3-5 Battery Recharge (DC Model Only)............................................... 3-9

3-6 Boom Lift Transport....................................................................... 3-11

4444 Maintenance.................................................................................................... 4-1

4-1 Scheduled Service Checks................................................................ 4-1

4-2 Wheel Nut Torque Requirements.................................................... 4-3

4-3 Lubrication......................................................................................... 4-3

4-4 Hydraulic System.............................................................................. 4-6

4-5 Axle Switches Adjustment..............................................................4-11

4-6 Troubleshooting ............................................................................... 4-12

4-7 Material Safety Data Sheets .......................................................... 4-17

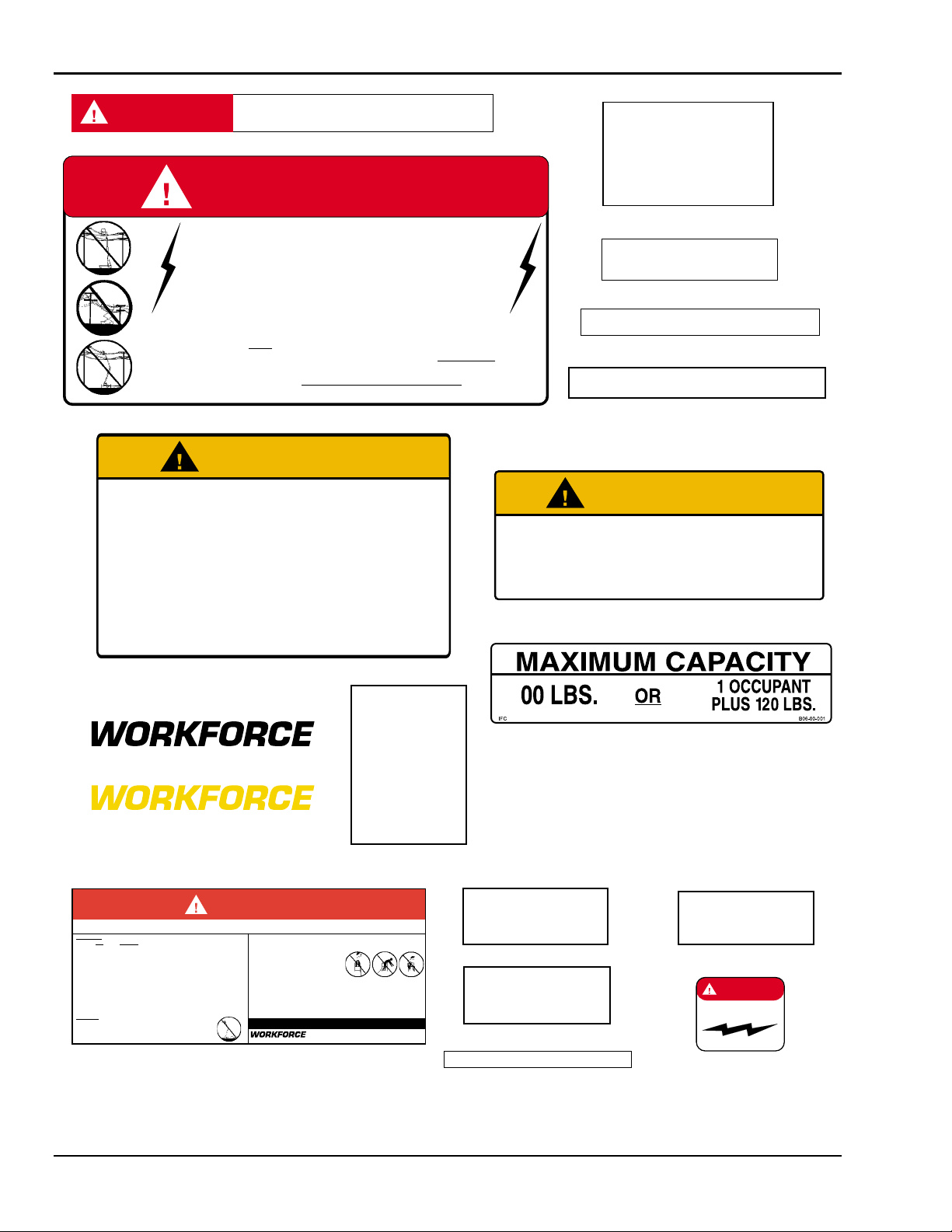

5555 Replacement Decals........................................................................................ 5-1

6666 Parts List ......................................................................................................... 6-1

6-1 Upper Boom Parts List.................................................................... 6-2

6-2 Lower Boom Parts List.................................................................... 6-4

6-3 Turntable Parts List.......................................................................... 6-6

6-4 DC Model Bat t ery Co mpa r tment P a rts Lis t...................................... 6-8

6-5 DC Model Power Compartment Parts List.................................. 6-10

6- 6 Ter mi na l E n cl o s u r e Par t s L is t............................................................ 6-14

6-7 Frame and Rotation Unit List....................................................... 6-16

6-8 Hitch and Jack Assembly Parts List............................................ 6-18

6-9 Square Tube Axle and Wheel Assembly Parts List................... 6-22

6-10 Hex Tube Axle and Wheel Assembly Parts List........................ 6-26

6-11 Tail Lights and Outrigger Display Transmitter Box Parts List. 6-28

6-12 Right Front/Left Rear Outriggers Parts List................................ 6-30

6-13 Left Front/Right Rear Outriggers Parts List................................ 6-32

6-14 Basket Parts List............................................................................. 6-34

6-15 Upper Control Box – External Parts List...................................... 6-38

6-16 Lower Control Box – Internal Parts List...................................... 6-39

6-17 Combination Valve Assembly Parts List...................................... 6-40

6-18 Surge Brakes Parts List................................................................. 6-41

6-19 DC Model Hydraulic System Parts List ...................................... 6-42

6-20 Power Unit Parts List ...................................................................... 6-44

7777 ANSI Reprint................................................................................................. 7-1

i

Page 4

List of Illustrations

Figure 3-1. Battery ON/OFF Switch..........................................................................3-1

Figure 3-2. Lower Control Panel ............................................................................... 3-2

Figure 3-3. Upper Control Panel...............................................................................3-4

Figure 3-4. Emergency Lowering Valve....................................................................3-8

Figure 3-5. Boom Rotation........................................................................................ 3-8

Figure 3-6. Battery Charger and Receptacle..............................................................3-9

Figure 3-7. Battery Charger..................................................................................... 3-10

Figure 3-8. Breakaway Safety Cable.......................................................................3-11

Figure 3-9. Jack Travel Position.............................................................................. 3-11

Figure 3-10. Trailer Hitching Checkpoints................................................................3-12

Figure 4-1. Wheel Nut Tightening Sequence.............................................................4-3

Figure 4-2. Lubricate Monthly...................................................................................4-3

Figure 4-3. Lubricate Semi-Annually........................................................................4-4

Figure 4-4. Lubrication of Dexter Axles....................................................................4-5

Figure 4-5. Hydraulic Cylinder Removal ..................................................................4-7

Figure 4-6. Hydraulic Cylinder Repair...................................................................... 4-9

Figure 4-7. Adjusting Axle Position Switches.........................................................4-11

Figure 4-8. Electrical Layout................................................................................... 4-14

Figure 4-9. Level Sensor .........................................................................................4-15

Figure 4-10. DC Model Hydraulic Diagram..............................................................4-16

Figure 5-1. Replacement Decals, Sheet 1 of 3...........................................................5-2

Figure 5-1. Replacement Decals, Sheet 2 of 3...........................................................5-3

Figure 5-1. Replacement Decals, Sheet 3 of 3...........................................................5-4

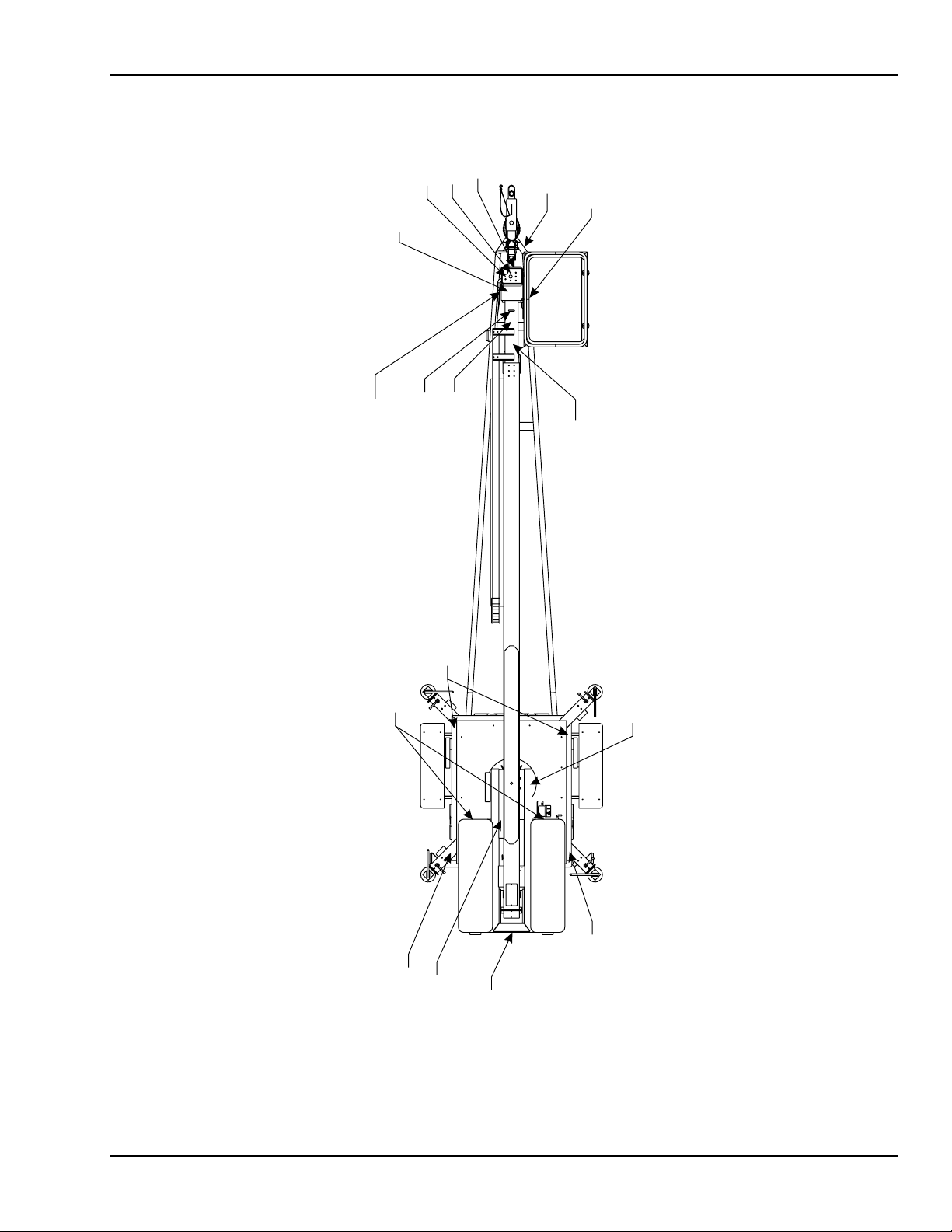

Figure 5-2. Decal Locations, Top View ....................................................................5-5

Figure 5-3. Decal Locations, Passenger Side.............................................................5-6

Figure 5-4. Decal Locations, Driver Side..................................................................5-7

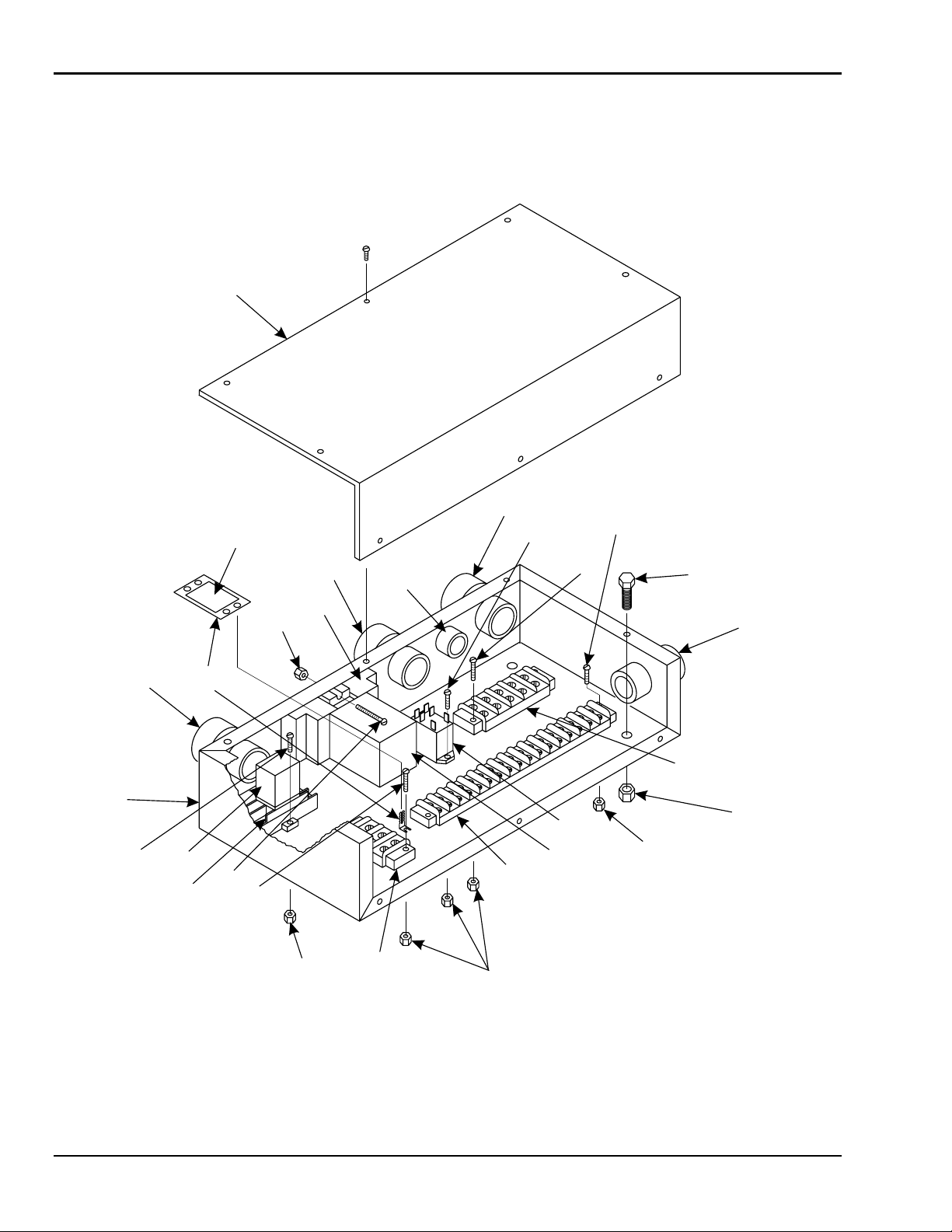

Figure 6-1. Upper Boom............................................................................................6-2

Figure 6-2. Lower Boom........................................................................................... 6-4

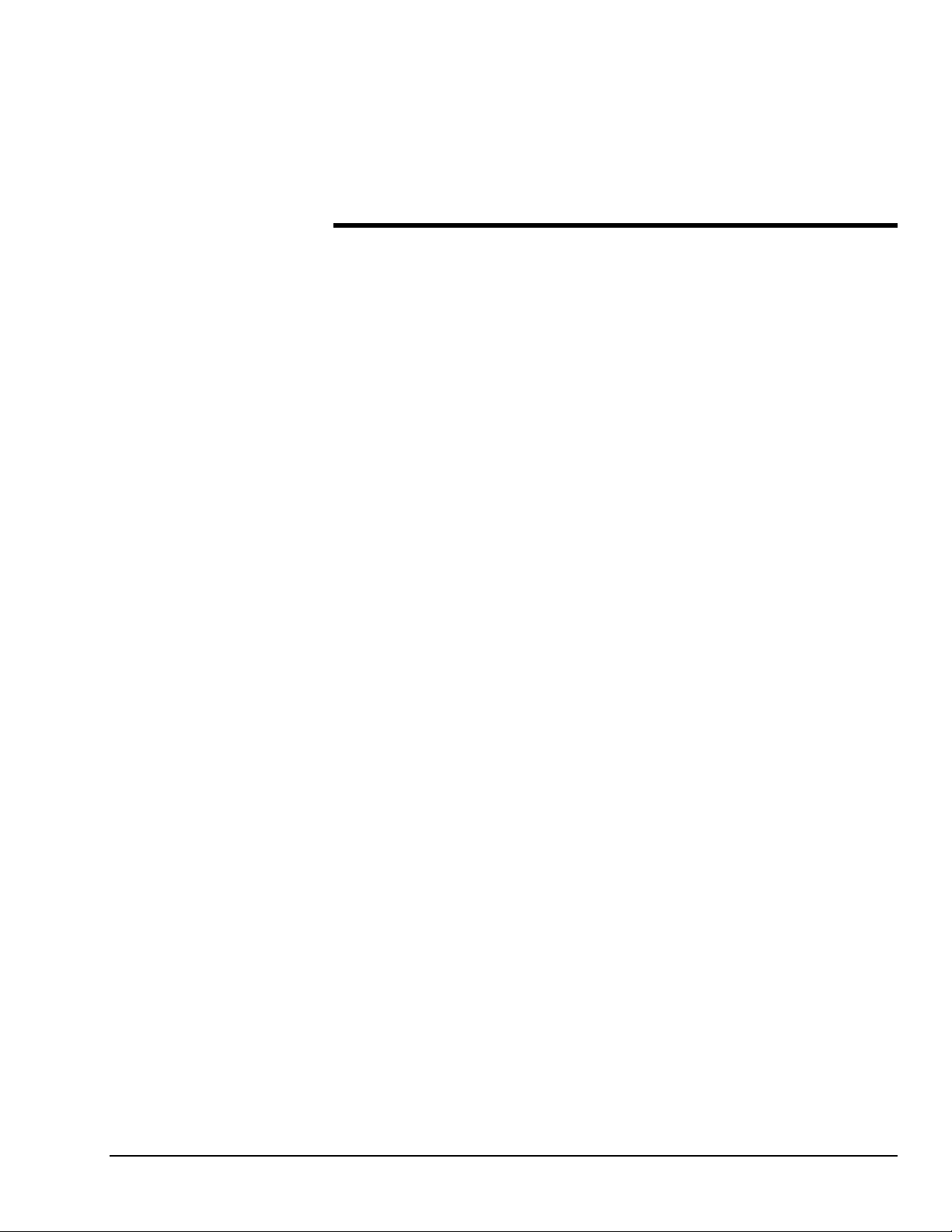

Figure 6-3. Turntable................................................................................................. 6-6

Figure 6-4. DC Model Battery Compartment............................................................ 6-8

Figure 6-5. DC Model Power Compartment............................................................6-10

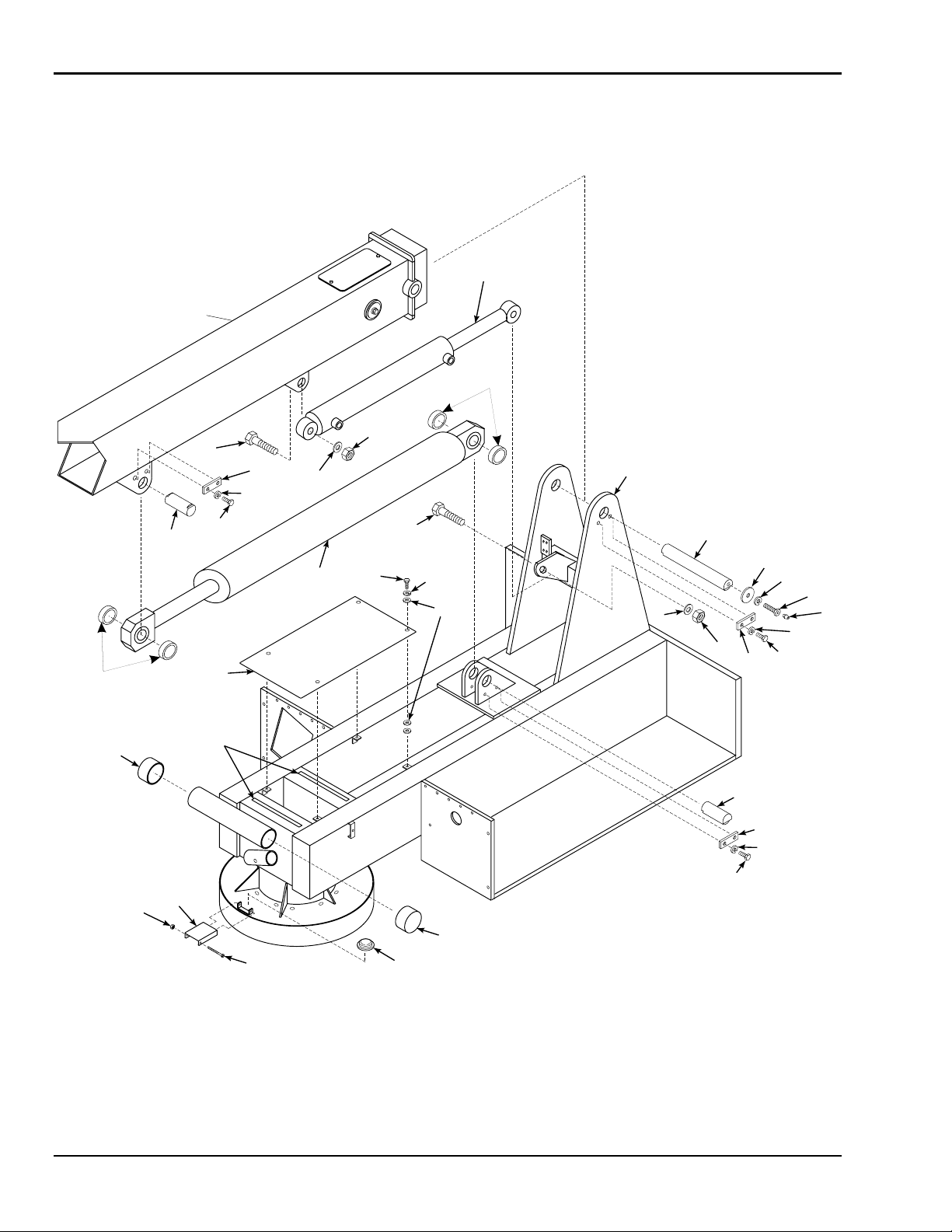

Figure 6-6. Terminal Enclosure............................................................................... 6-14

Figure 6-7. Frame and Rotation Unit.......................................................................6-16

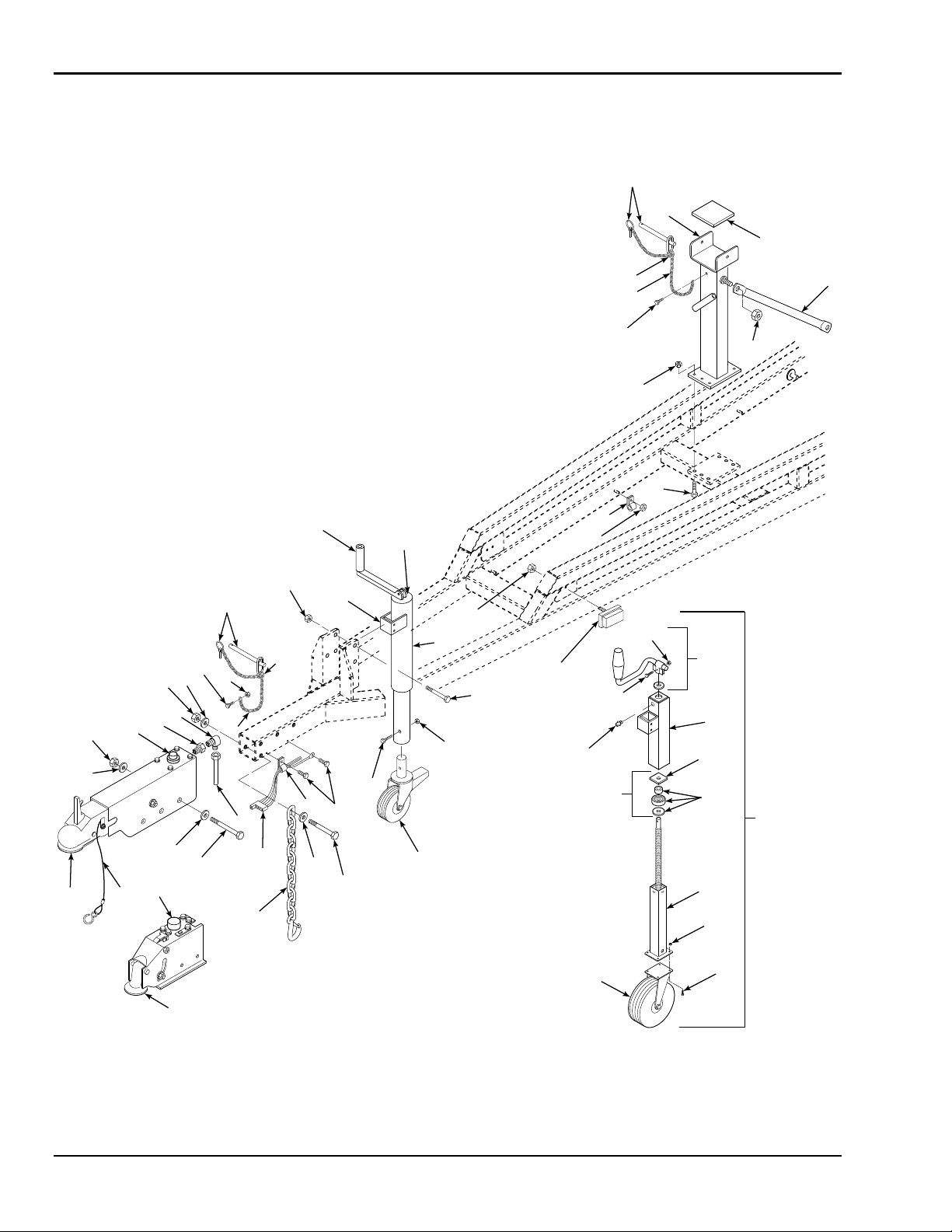

Figure 6-8. Hitch and Jack Assembly......................................................................6-18

Figure 6-9. Square Tube Axle and Wheel Assembly...............................................6-22

Figure 6-10. Hex Tube Axle and Wheel Assembly...................................................6-26

Figure 6-11. Tail Lights and Outrigger Display Transmitter Box .............................6-28

Figure 6-12. Right Front/Left Rear Outriggers..........................................................6-30

Figure 6-13. Left Front/Right Rear Outriggers..........................................................6-32

Figure 6-14. Basket ...................................................................................................6-34

Figure 6-15. Upper Control Box................................................................................6-38

Figure 6-16. Lower Control Box...............................................................................6-39

Figure 6-17. Combination Valve Assembly...............................................................6-40

Figure 6-18. Surge Brakes.........................................................................................6-41

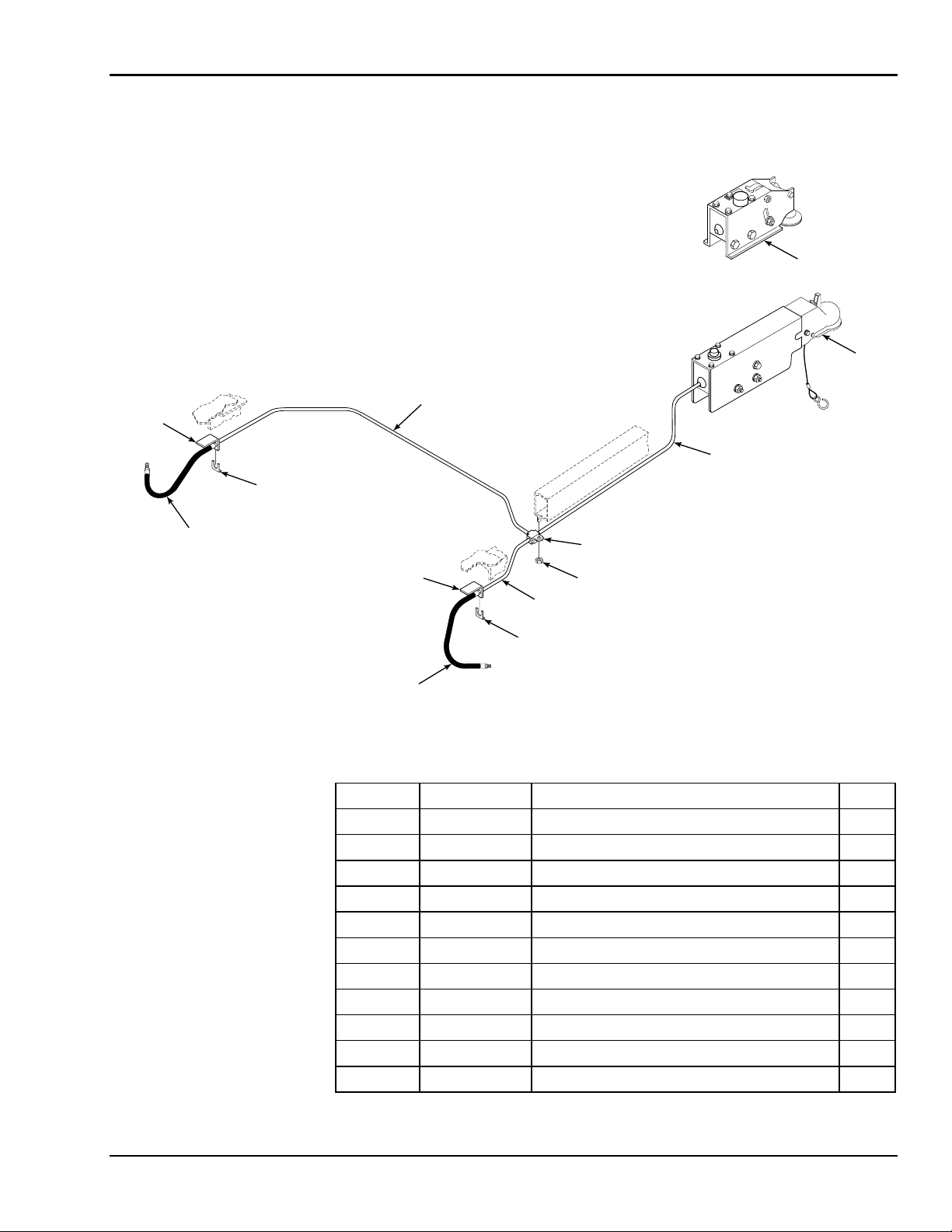

Figure 6-19. DC Model Hydraulic System................................................................ 6-42

Figure 6-20. Power Unit............................................................................................6-44

ii

Page 5

List of Tables

Table 1-1. Minimum Safe Approach Distances....................................................... 1-4

Table 2-1. Specifications.......................................................................................... 2-2

Table 4-1. Daily/Weekly Service Checks ................................................................ 4-1

Table 4-2. Monthly Service Checks......................................................................... 4-2

Table 4-3. Troubleshooting Chart.......................................................................... 4-12

Table 4-7. Level Sensor LEDs............................................................................... 4-15

Table 5-1. Replacement Decals, DC Model............................................................. 5-1

Table 6-1. Upper Boom Parts List........................................................................... 6-3

Table 6-2. Lower Boom Parts List........................................................................... 6-5

Table 6-3. Turntable Parts List ................................................................................ 6-7

Table 6-4. DC Model Battery Compartment Parts List............................................ 6-9

Table 6-5. DC Model Power Compartment Parts List........................................... 6-11

Table 6-6. Terminal Enclosure Parts List...............................................................6-15

Table 6-7. Frame and Rotation Unit Parts List ...................................................... 6-17

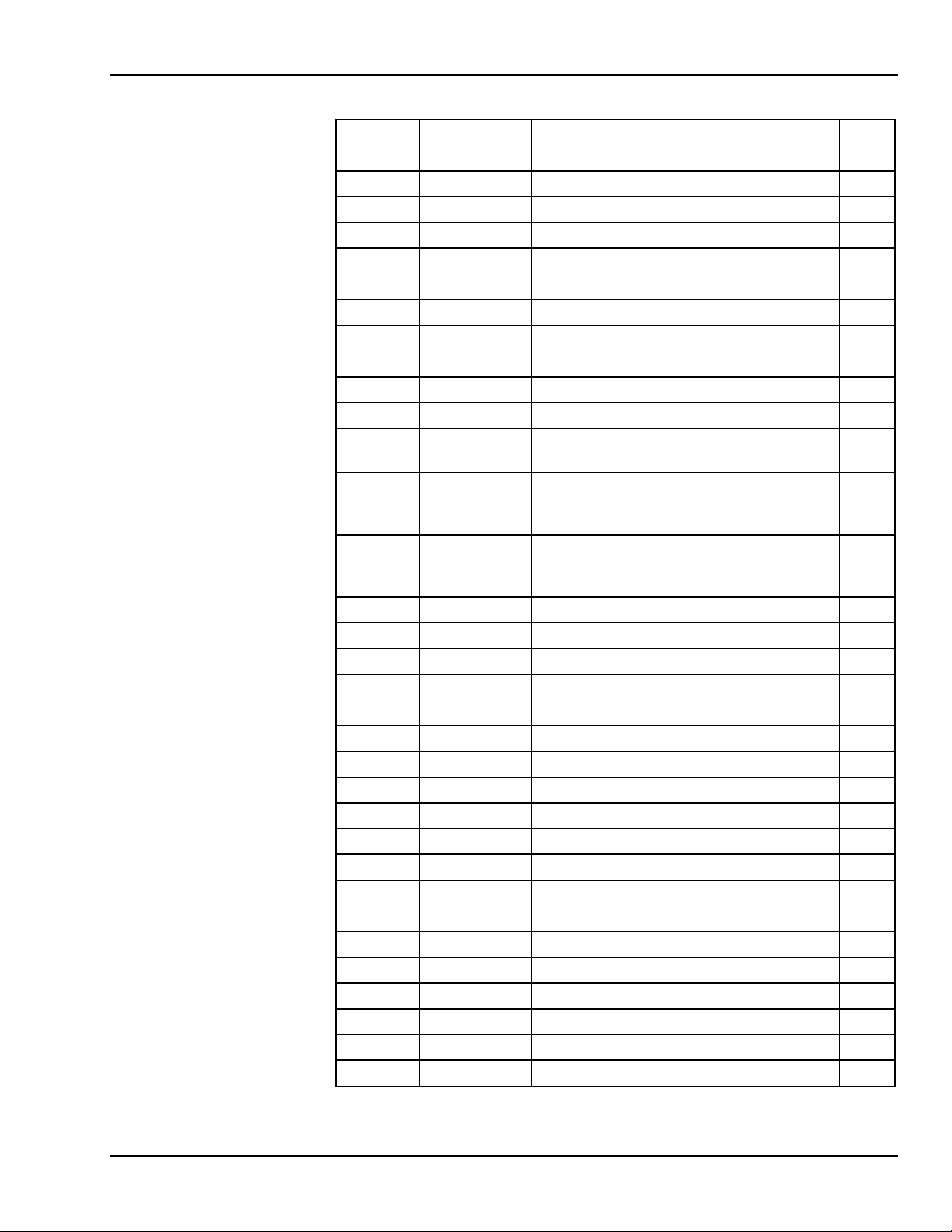

Table 6-8. Hitch and Jack Assembly Parts List...................................................... 6-19

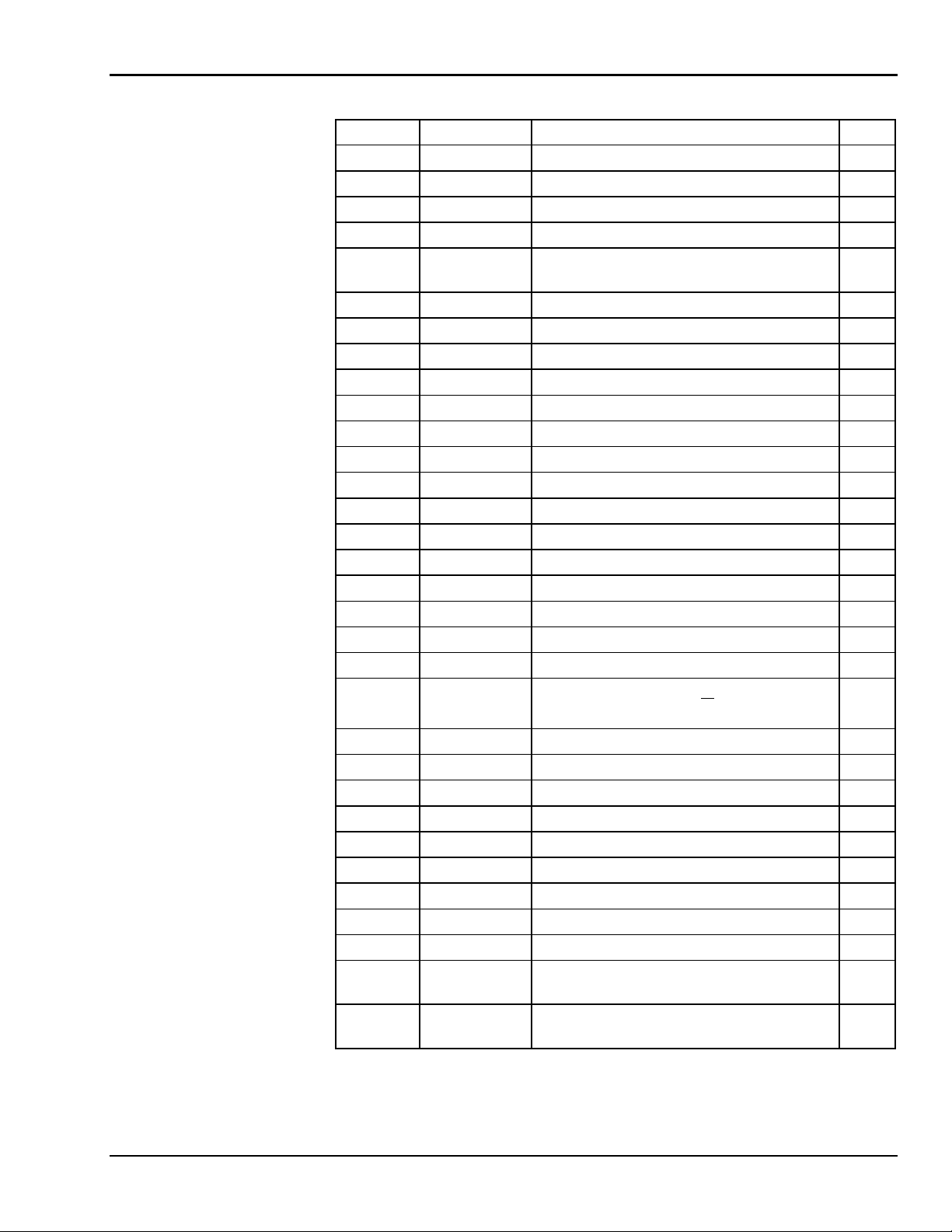

Table 6-9. Square Tube Axle and Wheel Assembly Parts List .............................. 6-23

Table 6-10. Hex Tube Axle and Wheel Assembly Parts List................................... 6-27

Table 6-11. Tail Lights and Outrigger Display Transmitter Box Parts List............. 6-29

Table 6-12. Right Front/Left Rear Outriggers Parts List.......................................... 6-31

Table 6-13. Left Front/Right Rear Outriggers Parts List.......................................... 6-33

Table 6-14. Basket Parts List................................................................................... 6-35

Table 6-15. Upper Control Box Parts List............................................................... 6-38

Table 6-16. Lower Control Box Parts List............................................................... 6-39

Table 6-17. Combination Valve Assembly Parts List.............................................. 6-40

Table 6-18. Surge Brakes Parts List......................................................................... 6-41

Table 6-19. DC Model Hydraulic System Parts List................................................ 6-43

Table 6-20. Power Unit Parts List............................................................................ 6-45

Table 7-1. Minimum Safe Approach Distance (M.S.A.D.) to energized

(exposed or insulated) power lines and parts........................................ 7-10

iii

Page 6

iv

Page 7

1

1

11

Safety

1-1 INTRODUCTION

Familiarity and proper training are required for the safe operation of mechanical

equipment. Equipment operated improperly or by untrained personnel can be dangerous.

Read the operating instructions in this manual and become familiar with the location and

proper use of all controls. Inexperienced operators should receive instruction from

someone familiar with the equipment before being allowed to operate the machine. The

use of intelligence and common sense in the operation of mechanical equipment is the

best practice in any safety policy. Be professional and always observe the safety

procedures set forth in this manual.

All OSHA, ANSI, state, and local codes and regulations pertaining to this equipment

should be ob tained, read, a nd thoroughly understood before attempting to operate this

equipment. Persons under the influence of drugs, alcohol, or prescription medication

should not be on or near this equipment. Common sense should be implemented at all

times during the use of this equipment. Do not operate this equipment in areas where the

equipment or user may come in contact with a live power source.

The information contained herein is not to be considered as legal advice and is intended

for informational purposes only. This information is offered to alert Bil-Jax customers to

procedures that may be of concern to them.

This information is not intended to be all inclusive and is to be followed in the use of BilJax equipment only.

For any questions concerning the safe use of this equipment, call 419.445.9675 before

operating.

1-1

Page 8

XLB-4232 DC

Safety Notes

This manual contains DANGERS, WARNINGS, CAUTIONS, and NOTES that must be

followed to prevent the possibility of improper service, damage to the equipment, or

personal injury.

DANGER

Dangers warn of equipment operation near electrical power lines that could lead

to personal injury or death.

WARNING

Warnings describe conditions or practices that could lead to personal injury or

death.

CAUTION

Cautions provide information important to prevent errors that could damage

machine or components.

NOTE: Notes contain additional information important to a procedure.

1-2

Page 9

1 — SAFETY

1-2 BEFORE OPERATION

Ensure the following general safety precautions are followed before operating the

XLB-4232 DC Boom Lift.

• ALWAYS survey the usage area for potential hazards such as untamped earth

fills, unlevel surfaces, overhead obstructions, and electrically charged conductors

or wires. Be aware of any potential hazards and always consider what could

happen. Watch for moving vehicles in t he operating are a.

• ALWAYS read, understand, and follow the procedures in this manual before

attempting to operate equipment.

• ALWAYS inspect the equipment for damaged or worn parts. Check for cracked

welds, hydraulic leaks, damaged wiring, loose wire connectors, damaged

outriggers, low tire pressure, uneven tire wear, or tire damage. Also check for

any improper operation. NEVER operate equipment if damaged in any way.

Improperly operating equipment must be repaired before using.

• ALWAYS wear proper clothing for the job. Wear protective equipment as

required by federal, state, or local regulations. The operator MUST wear a safety

harness and lanyard.

• ALWAYS locate, read, and follow all directions and warnings displayed on the

equipment.

• ALWAYS inspect the equipment for “DO NOT USE” tags. NEVER use

equipment tagged in this way until all repairs are made and all “DO NOT USE”

tags are removed by authorized maintenance personnel.

• ALWAYS make sure the basket and outrigger shoes are free of mud, grease, or

other slippery material to reduce the possibility of slipping.

• NEVER allow improperly trained personnel to operate this equipment. Only

trained and authorized personnel shall be allowed to operate this equipment.

• NEVER operate this equipment if you are under the influence of alcohol or

drugs, or if you feel ill, dizzy, or unsteady in any way. Operators must be

physically fit, thoroughly trained, and not easily excitable .

• NEVER modify, alter, or change the equipment in any way that would affect its

original design or operation in any way.

• NEVER operate this equipment in ways for which it is not intended.

1-3

Page 10

XLB-4232 DC

1-3 DURING OPERATION

Ensure the following general safety precautions are followed during the operation of the

XLB-4232 DC Boom Lift.

DANGER

This machine is not insulated for use near electrical power lines and DOES NOT

provide protection from contact with or close proximity to any electrically charged

conductor. Operator must maintain safe clearances at all times (10 feet minimum)

and always allow for platform movement such as wind induced sway. Always

contact the power company before performing work near power lines. Assume

every line is hot. Remember, power lines can be blown by the wind.

Refer to Table 1-1 for minimum safe approach distances between machine and electrical

power lines.

Table 1-1. Minimum Safe Approach Distances

Voltage Range

(Phase to Phase)

0 to 300V Avoid Contact

Over 300V to 50KV 10 3.05

Over 50KV to 200KV 15 4.60

Over 200KV to 350KV 20 6.10

Over 350KV to 500KV 25 7.62

Over 500KV to 750KV 35 10.67

Over 750KV to 1000KV 45 13.72

Minimum Safe Approach Distance

(Feet) (Meters)

• ALWAYS position lift far enough away from power sourc es to ensure that no

part of the lift can accidentally reach into an unsafe area. This includes full

extension of the boom through 360 degrees rotation.

• ALWAYS operate only on a firm and level surface. NEVER use on surfaces that

do not support the equipment with its rated load capacity and the resulting force

exerted on the outriggers during boom extension and rotation.

• ALWAYS keep yourself and all personnel away from potential pinch or shear

points.

• ALWAYS report any misuse of equipment to the proper authorities. Horseplay is

prohibited.

• ALWAYS maintain good footing on the work platform. NEVER wear slippery

soled shoes.

• ALWAYS make certain all personnel are clear and there are no obstructions

before repositioning basket.

• ALWAYS cordon off area around the outriggers to keep personnel and other

equipment away from it while in use.

• ALWAYS stay clear of wires, cables, and other overhead obstructions.

• ALWAYS engage the boom travel locking pin before towing the trailer.

1-4

Page 11

1 — SAFETY

• NEVER allow electrode contact with any part of the basket if welding is being

performed from the platform.

• NEVER use without the outriggers fully extended, locked, and firmly based.

When on soft surfaces, ALWAYS use outrigger base plates.

• NEVER override or by-pass manufacturer's safety devices.

• NEVER attach a safety harness to an adjacent structure, pole, or equipment

while working from the boom platform.

• NEVER release outrigger locks or move unit with a person or materials on

board.

• NEVER release the outriggers or move the trailer with the boom extended.

• NEVER stand or sit on cage bars. Work only within the work cage and do not

lean out over the cage to perform work.

• NEVER attempt to increase working height with boxes, ladders, or other means.

• NEVER oper ate this equipment when exposed to high winds, thunderstorms, ice,

or any other weather conditions that would compromise operator safety.

• NEVER allow ropes, electric cords, hoses, etc. to become entangled in the

equipment when the basket is being raised or lowered.

• NEVER exceed manufacturer's load limits or use the lift as a crane for lifting

heavy materials. Make sure all tools and equipment are safely stowed.

• NEVER exceed load ratings by transferring loads to the basket at elevated

heights.

• NEVER use cage to carry materials and never allow overhang of materials when

raising or lowering the basket.

• NEVER push or pull with the boom or basket and NEVER use the boom to lift

any part of the trailer.

• NEVER use the boom or basket to place a “dead man” load against any

structure, materials, or equipment.

• NEVER climb up or down boom.

• NEVER leave the keys in the boom lift while unattended or not in use.

1-5

Page 12

XLB-4232 DC

1-4 MAINTENANCE SAFETY

Ensure the following safety precautions are observed whenever maintenance is performed

on the XLB-4232 DC Boom Lift.

General Maintenance

• ALWAYS perform maintenance procedures according to manufacturer's

requirements. NEVER short change maintenance procedures.

• ALWAYS check hydraulic system. Make sure all lines, connectors, and fittings

are tight and in good condition.

• ALWAYS turn the MASTER POWER switch OFF before connecting or

disconnecting wiring to or from valve soleno i ds or other load devices.

• ALWAYS disconnect power to the hydraulic pump drive motor before making

electrical checks of the hydraulic valves.

• ALWAYS keep all mechanisms properly adjusted and lubricated according to

maintenance schedule and manufacturer’s specifications.

• ALWAYS perform a function check of operating controls before each use and

after repairs have been made.

• ALWAYS locate and protect against possible pinch points prior to performing

maintenance and repairs.

• ALWAYS use factory-approved parts to repair or maintain this equipment. If

this equipment is rebuilt, retesting is required in accordance with factory

instructions.

• NEVER allow water or foreign particles into the DC electric motor housing.

Ingestion of water or foreign particles may cause serious damage to the motor. If

the motor gets wet, oven dry the motor to remove all moisture before operating;

consult motor manufact urer for drying instruct ions.

• NEVER test or operate the hydraulic components when another person is near

the equipment.

• NEVER add unauthorized fluids to the hydraulic system or battery. Check

original manufacturer specifications.

• NEVER exceed the manufacturer's recommended relief valve settings.

• NEVER touch or allow metal tools to contact static discharge sensitive

electronic components. ALWAYS use static discharge prevention mats and

grounding devices when handling electro ni c components.

• NEVER tamper with cylinder counter balance valves. Contact the Bil-Jax

Service Department at 419.445.9675 if the cylinder counter balance valves need

adjusting.

• NEVER attempt repairs you do not unde rstand. Consult manufacturer if you

have any questions regarding proper maintenance, specific ations, or repa ir.

1-6

Page 13

1 — SAFETY

Battery Maintenance

Ensure the following general safety precautions are followed whenever performing

battery maintenance on the XLB-4232 DC Boom Lift.

• ALWAYS check battery acid level daily. Check battery test indicator for proper

state of charge on maintenance free batteries before using lift.

• ALWAYS wear safety glasses when working near battery.

• ALWAYS avoid contact with battery acid. Battery acid causes serious burns.

Avoid contact with skin or eyes. If accidental contact occurs, flush with water

and consult a physician immediately.

• ALWAYS disconnect ground cable first when removing battery.

• ALWAYS connect ground cable last when installing battery.

• ALWAYS charge batteries in open, well-ventilated areas.

• NEVER smoke when servicing battery.

• NEVER allow batteries to overcharge and boil.

• NEVER short across battery posts to check for current. NEVER break a live

circuit at battery.

• NEVER jump start other vehicles using boom lift battery.

1-5 DAMAGED EQUIPMENT POLICY

Safety Statement

At Bil-Jax, we are dedicated to the safety of all users of our products. Therefore, all BilJax lifts are designed, manufactured and tested to comply with current applicable Federal

OSHA and ANSI codes and regulations.

Damage Policy

There may be occasions when a Bil-Jax lift is involved in an incident that results in

structural damage to the lift. This can seriously compromise the ability of the lift to

perform in a safe manner. Therefore, whenever a Bil-Jax lift is damaged structurally or

when there is the possibility of structural damage (this damage may be internal and is not

always visible to the naked eye), Bil-Jax requires that the lift be returned to our facility at

125 Taylor Parkway, Archbold, Ohio, for reconditioning. If you have any questions

concerning what constitutes structural damage, please call the Bil-Jax Service Department

at 419.445.9675.

Damage Repair Notice

There may be occasions when a Bil-Jax lift is involved in an incident resulting in nonstructural damage. When this occurs and repairs are made by the owner or area

distributor, please notify Bil-Jax of these non-maintenance repairs and request a repair

form to be filled out and returned to Bil-Jax.

1-7

Page 14

XLB-4232 DC

1-8

Page 15

2

2

22

Introduction

2-1 GENERAL DESCRIPTION

The XLB-4232 DC Boom Lift is designed and manufactured for positioning personnel

with their tools and equipment at overhead work locations. The rated work basket load

capacity is 300 lbs. for the XLB-4232. Basket elevation is by two hydraulic cylinders

acting on the boom sections. A hydraulic powered motor and worm gear rotates the boom

360° around a vertical axis. The hydraulic power unit includes a reservoir, pump, and

control valves.

On the battery powered (DC Model) boom lift, dual 24 Volt, 39 Amp, one horsepower,

DC electric motors drive the hydraulic pump. The DC motor is powered by four 6 Volt

DC, 245 Amp-hour, deep charge batteries connected in series. A 40 amp, automatic, onboard battery charger is provided for recharging the batteries at the end of each work

period.

Two control panels use directional selector switches and hydraulic valves to control the

direction and speed of boom lift and rotation. One set of operator controls is provided for

ground operation and another set is provided for operation from the basket. Elevation and

rotation controls are operational only when the moving boom section is within a

programmed safe operating zone. Only one boom motion is permitted at a time, and only

as long as the boom is within the safe operating zone. When a selected boom motion

reaches a safe operating limit, the motion ceases and another motion must be selected

within the safe operating zone.

Outrigger and wheel position interlock safety switches prevent lifting operations until the

four outriggers are properly deployed and the full weight of the boom lift is loaded onto

the outriggers.

Boom elevation speeds are selected from low to high by a toggle switch. A hydraulic hose

failure at either retract-cylinder port will cause a velocity fuse to close and stop the return

oil flow. It is strongly recommended that no one adjust or tamper with these safety

devices. If service is required, please notify Bil-Jax for detailed instructions.

Emergency lowering of the basket is by a manual valve on the base of the lift cylinder.

Pushing in and turning 1/4 turn manually retracts the upper boom lift cylinder. The boom

may need to be manually rotated to a clear area before lowering.

The boom lift cylinders will not rust or corrode during storage since the cylinder rod is

fully immersed in oil. It is important that the cylinder rods be kept clean and undamaged

for the protection of the cylinder head packings.

2-1

Page 16

XLB-4232 DC

2-2 SPECIFICATIONS

Boom Lift Work Platform

Model Number XLB-4232 DC Serial Number ________________

Manufactured by: Bil-Jax, Inc.

125 Taylor Parkway

Archbold, Ohio 43502

419.445.9675

Table 2-1. Specifications

Feature XLB-4232 DC Model

Rated Platform Load 300 lbs (136.1 kg) total (1 man plus tools)

Maximum Work Height 42 ft (12.80 m)

Extended Basket Height 35 ft-5 in. (10.80 m)

Elevation Rate,

Maximum

Horizontal Reach 32.0 ft (9.8 m)

Boom Rotation 360° Continuous

Rotation Speed 8 in. per Second, Maximum

Basket Dimensions 36 in. W x 24 in. D x 42 in. H

Power Source 24 Volt DC, Deep Cycle, 245 Amp-hour Battery

Battery Charger 110/120 Volt, 40 Amp

Hydraulic Pressure 2000 psi (13,790 kPa)

Reservoir Capacity 6 Gallons (22.7 Liters)

Hydraulic Capacity 8 Gallons (30.3 Liters)

Hydraulic Oil AW-46

Gross Vehicle Weight 4760 lbs (2159 kg)

Tongue Wei ght 275 lbs (124.7 kg)

Trailer Brakes Hydraulic Surge; Optional – Electric

8 in./sec (203 mm/sec)

[40 ft/min (12.2 m/min)]

(91.4 cm x 61.0 cm x 106.7 cm)

2-3 WARRANTY

Bil-Jax warrants its boom lifts for one year from the date of delivery against all defects of

material and workmanship, provided the unit is operated and maintained in compliance

with Bil-Jax’s operating and maintenance instructions; structural components are

warranted for three years. Bil-Jax will, at its option, repair or replace any unit or

component part which fails to function properly in normal use.

This warranty does not apply if the lift and/or its component parts have been altered,

changed, or repaired without the consent of Bil-Jax or by anyone other than Bil-Jax or its

factory trained personnel, nor if the lift and/or its components have been subjected to

misuse, negligence, accident or any conditions deemed other than those considered as

occurring during normal use.

Components not manufactured by Bil-Jax are covered by their respective manufacturer’s

warranties. A list of those components and their warranties is available upon written

request to Bil-Jax.

Bil-Jax shall not in any event be liable for the cost of any special, indirect, or

consequential damages to anyone, product, or thing. This warranty is in lieu of all other

warranties expressed or implied. We neither assume nor authorize any representative, or

other person, to assume for us any other liability in connection with the sale, rental, or use

of this product.

2-2

Page 17

3

3

33

Operation

3-1 OPERATOR CONTROLS

The XLB-4232 DC Boom Lift is equipped with multiple operator controls. Electrical

boom lift and rotation control panels are located at ground level and in the basket. Manual

boom rotation and lowering controls are at the ground level.

Battery ON/OFF Switch

A battery ON/OFF switch (Figure 3-1) is mounted on the front end of the hydraulic power

compartment. Turn the switch to the ON position to turn battery power on to the boom lift

electrical system. Turn the switch to the OFF position to conserve battery power when the

lift is not in use.

BATTERY

ON/OFF

SWITCH

Figure 3-1. Battery ON/OFF Switch

3-1

Page 18

XLB-4232 DC

Lower Control Panel

The lower control panel (Figure 3-2) is located on the side of the hydraulic power

compartment. The following controls and indicators are on the lower control panel.

Figure 3-2. Lower Control Panel (DC Model)

EMERGENCY STOP Pushbutton

When pressed, the EMERGENCY STOP pushbutton disconnects electrical power to the

upper and lower control panels. The EMERGENCY STOP pushbutton should only be

pressed to immediately stop all boom motion. To resume control, pull to disengage the

emergency stop switch contacts.

BOOM UP/DOWN Selector Switch

Holding the BOOM UP/DOWN selector switch in the UP position enables the boom to

rise. Holding the selector switch in the DOWN position enables the boom to descend.

The up or down boom motion continues until the selector switch is released, or the boom

reaches a hard stop or a safe travel limit.

UPPER/OFF/LOWER Controls Selector Switch

The UPPER/OFF/LOWER controls selector switch enables boom lift control from either

the lower control panel or the work platform. When operating the boom lift from ground

level, hold the switch in the LOWER position while simultaneously selecting a motion

function.

3-2

Page 19

3 — OPERATION

BOOM IN/OUT Selector Switch

Holding the BOOM IN/OUT selector switch in the OUT position extends the boom out.

Holding the selector switch in the IN position retracts the boom. The in or out boom

motion continues until the selector switch is released, or the boom reaches a hard stop or

a safe travel limit.

BOOM FAST/SLOW Selector Switch

The BOOM FAST/SLOW selector switch controls the speed of the selected boom

motion. Generally, the switch is set on FAST to position the boom in the general

proximity of the work area. Then, the switch is set on SLOW to fine tune the position of

the boom to get closer to the work area.

ROTATION CW/CCW Selector Switch

Holding the ROTATION CW/CCW selector switch in the CW position enables the boom

to rotate in the clockwise direction. Holding the selector switch in the CCW position

enables the boom to rotate in the counterclockwise direction.

OUTRIGGERS Indicator

The OUTRIGGERS indicator lights up when the boom outriggers are properly deployed

and the boom weight is removed from the trailer axle.

3-3

Page 20

XLB-4232 DC

Upper Control Panel

The upper control panel (Figure 3-3) is mounted in the work basket. The following

controls and indicators are available on the upper control panel.

BATTERY CHARGE

INDICATOR

Figure 3-3. Upper Control Panel (DC Model)

BUCKET TILT COMPENSATOR Switch (DC Model Only)

A BUCKET TILT COMPENSATOR switch allows for slight adjustment to the level of

the work basket. Adjustment is limited to 3 degrees in either direction.

Battery Charge Indicator (DC model only)

Indicator LEDs light up to indicate the level of charge remaining in the batteries. Lighted

green LEDs indicate a good charge level. Lighted yellow LEDs indicate the need for

charging soon. Lighted red LEDs warn that the battery charge level is low; boom

operations should be halted until the batteries are recharged.

BOOM FAST/SLOW Selector Switch

The BOOM FAST/SLOW selector switch controls the speed of the selected boom

motion. Generally, the switch is set on FAST to position the boom in the general

proximity of the work area. Then, the switch is set on SLOW to fine tune the position of

the boom to get closer to the work area.

EMERGENCY STOP Pushbutton

When pressed, the EMERGENCY STOP pushbutton disconnects electrical power to the

upper and lower control panels. The EMERGENCY STOP pushbutton should only be

pressed to immediately stop all boom motion. To resume control, pull to disengage the

emergency stop switch contacts.

3-4

Page 21

3 — OPERATION

UPPER CONTROLS ON/OFF Deadman Switch

The UPPER CONTROLS ON/OFF deadman switch must be held in the ON position

simultaneously with any other boom motion function. This prevents accidental movement

of the work basket.

ROTATION CW/CCW Selector Switch

Holding the ROTATION CW/CCW selector switch in the CW position enables the boom

to rotate in the clockwise direction. Holding the selector switch in the CCW position

enables the boom to rotate in the counterclockwise direction.

BOOM IN/OUT Selector Switch

Holding the BOOM IN/OUT selector switch in the OUT position extends the boom out.

Holding the selector switch in the IN position retracts the boom. The in or out boom

motion continues until the selector switch is released, or the boom reaches a hard stop or

a safe travel limit.

BOOM UP/DOWN Selector Switch

Holding the BOOM UP/DOWN selector switch in the UP position enables the boom to

rise. Holding the selector switch in the DOWN position enables the boom to descend.

The up or down boom motion continues until the selector switch is released, or the boom

reaches a hard stop or a safe travel limit.

3-5

Page 22

XLB-4232 DC

3-2 NORMAL OPERATING PROCEDURE

Perform the following procedures to operate the XLB-4232 DC Boom Lift.

1. Read and follow all safety precautions contained in Section 1 and all

responsibilities outlined in the ANSI A92.2 reprint contained in Section 7 of this

manual.

2. Position the lift at the work area. Make sure the lift is on a firm and level surface

and that there are no potential hazards such as overhead obstructions or

electrically charged conductors. Do not operate the lift if such hazards exist.

3. Check the tow trailer and boom lift for damaged or worn parts. Repair or replace

parts as necessary. Do not use a damaged boom lift.

4. Lower the t railer tongue jack and unhitch the tra iler from the tow vehicle . The

trailer must be unhitched before the outriggers are deployed.

5. Deploy the boom lift outriggers as follows:

a. Lift up on the locking pin and slide each outrigger out from the trailer frame.

Slide the outriggers out until the locking pins engage again.

b. P ull out the quick-adjust jack pins and lower the jack feet. With the jack feet

near the ground, reinstall the jack pins at the lowest available setting.

c. Turn the BATTERY ON/OFF switch to the ON position. Lift the bubble

level cover plate in front of the boom rotation housing (slew ring housing).

d. Jack up the outriggers to evenly raise the trailer; refer to the bubble level.

Raise the boom lift evenly until at least one trailer wheel is off the ground

and all outrigger LED’s are lit.

e. Flip outrigger jack handles over to keep them from being damaged by

falling objects or bent by lowering the boom onto them.

NOTE: An axle position switch will prevent boom operation if at least one wheel

is not lifted off the ground. The load o f the boom lift must be placed on

the outriggers to enable power.

6. Remove the pin keeper and transport pin that secures the boom to the trailer

frame. Stow the transport pin in its storage tube.

7. Unlock and open the base controls door.

8. Toggle the UPPER/OFF/LOWER controls switch to the LOWER position.

9. Use the lower control panel to operate the lift controls. Raise, lower, extend, and

rotate the boom in slow speed to get familiar with the controls. Learn to

smoothly start and stop the boom lift.

10. To place the basket at an easier entry height:

a. Raise the boom clear of its support post by holding the controls selector

switch to LOWER position and also activating the UP function.

b. Rotate the boom clockwise from its transport position by holding the

controls selector switch to LOWER position and also activate CW function.

Rotate until there is clearance between the support post and the boom.

c. Lower the boom until the basket just touches the ground by holding the

controls selector switch to LOWER position and also activate the DOWN

function.

11. Switch the controls selector switch to UPPER controls. Control of the boom is

now directed to the basket control panel.

3-6

Page 23

3 — OPERATION

12. Raise the safety bar and enter the basket. Put on the safety harness and attach the

lanyard to the basket railing.

13. The lift is now ready for operation from the basket. Operate in slow speed to get

familiar with the controls. The UPPER CONTROLS ON/OFF deadman switch

must be held in the ON position simultaneously with any other boom motion

function.

14. Should the basket become tilted out of the normal vertical axis, adjustment can

be made using the BUCKET TILT COMPENSATOR switch. This function is

protected with a 3 degree limit safety switch in either direction.

15. Monitor the BATTERY CHARGE INDICATOR during operation and charge

the batteries as necessary. (See Section 3-5)

3-7

Page 24

XLB-4232 DC

3-3 EMERGENCY LOWERING

The XLB-4232 DC Boom Lift is equipped with a manual emergency lowering valve that

can lower the basket in case of a power failure or an emergency situation. The emergency

lowering valve is located at the base of the lift cylinder.

Before lowering, it may be necessary to manually rotate the boom if it is over hanging an

obstruction. See the following section for this procedure.

To lower the work basket, push and turn the knurled knob counter-clockwise to desired

speed of descent (Figure 3-4). After lowering, press and turn the knob clockwise to close

the valve.

EMERGENCY

LOWERING

KNOB

Figure 3-4. Emergency Lowering Valve

3-4 MANUAL BOOM ROTATION

The boom lift is equipped with an emergency rotation handle (crank) that can be used to

rotate the boom in case of a power failure or other emergency situation.

Use the following procedure to manually rotate the boom:

1. Loosen the crank stowage tube thumbscrew (Figure 3-5).

2. Remove the crank.

3. Install the crank on the hex end of the worm gear drive screw as shown.

4. Turn the crank handle to rotate the boom.

CRANK

STOWAGE

TUBE

THUMBSCREW

CRANK

IN USE

Figure 3-5. Boom Rotation

3-8

Page 25

3 — OPERATION

3-5 BATTERY RECHARGE (DC MODEL ONLY)

The DC boom lift batteries should be recharged after each 8-hour work shift or more

often if needed. When the boom lift is not in use, the batteries should be recharged at least

once per week.

The normal charge time is 10 to 12 hours. If the battery charge is extremely low, a full

recharge may take up t o 24 hours.

Recharge the DC boom lift batteries as follows:

WARNING

Recharge the batteries in a well ventilated area only. Do not charge batteries near

fire, flame, or other ignition sources. Batteries being charged may emit highly

explosive hydrogen gas. Failure to properly ventilate the charge gases may result

in serious injury or death.

1. Move the boom lift to a well ventilated area with direct access to a grounded

120 VAC electrical outlet. Make sure the recharge area is not near fire, flame or

other ignition sources.

2. Turn the BATTERY ON/OFF switch to the OFF position.

3. Plug a short, heavy-duty power cord into the battery charger receptacle on the

front of the battery compartment. The recommended power cord should be an

12 AWG multi-strand, grounded cord no longer than 20 feet (6 meters).

NOTE: Using an underrated or lo ng power cord will reduce the output of the

battery charger, resulting in longer charge time.

BATTERY

CHARGER

RECEPTACLE

BATTERY

CHARGER

Figure 3-6. Battery Charger and Receptacle

4. Plug the power cord into a grounded 120 VAC receptacle. Verify that the red

ON-CHARGING indicator LED lights up on the battery charger.

3-9

Page 26

XLB-4232 DC

5. To determine the charge rate at any time during the charge cycle, observe the

DC ammeter (Figure 3-7). The ammeter needle moves to the right at the start of

the charge cycle. As the battery charge rises, the needle moves farther left.

Figure 3-7. Battery Charger

CAUTION

Always remember to unplug the battery charger power cord before moving the

boom lift. Failure to unplug the power cord will cause damage to the equipment.

6. Inspect the charge indicator LEDs near the end of the expected charge cycle. If

all indicator LEDs are off, the battery is fully charged. (The DC ammeter needle

should point to the left.)

NOTE: The yellow 80% CHARGE indicator lights up when the battery voltage is

nearing full charge. At full charge (3-1/2 hours after the 80% CHARGE

indicator lights up), the charger turns off.

If the battery voltage does not reach the 80% CHARGE level in 14 hours,

the charger turns off and the red CHECK BATTERY indicator LED

lights up. This prevents extended charging of a faulty battery.

7. Unplug the power cord from the 120 VAC receptacle and the charger receptacle.

Properly store the power cord for next use.

3-10

Page 27

3 — OPERATION

3-6 BOOM LIFT TRANSPORT

The boom lift trailer is a single axle trailer fitted with a two-inch ball hitch, surge brakes,

breakaway safety cable, safety chains, brake lights, and side marker lights. Proper boom

lift transport requires the correct hookup and inspection of these trailer components

before towing. Use the following procedures to hitch, tow, and back the boom lift trailer:

Trailer Hitching

Trailer hitching requires a sec ond person to give t ow vehicle backing instructions.

1. Back the tow vehicle to the trailer. Verify that the ball and hitch are in line and

that the trailer hitch will clear the ball. Jack up the tongue as needed.

2. Align the ball and hitch. Wrap and fasten the breakaway safety cable around the

ball hitch (Figure 3-8).

HITCH

RELEASE

HANDLE

BREAKAWAY

SAFETY CABLE

Figure 3-8. Breakaway Safety Cable

3. Hold ball hitch release lever open and lower the hitch onto the ball. Let go of the

release lever to secure the ball.

4. Crank the jack down to check for secure coupling. If jacking will raise the tow

vehicle bumper two or three inches, the ball hitch coupling is secure.

5. Pull the pin keeper and pivot locking pin, raise the jack to the travel position as

shown in Figure 3-9, and reinstall the pivot locking pin and pin keeper.

Figure 3-9. Jack Travel Position

3-11

Page 28

XLB-4232 DC

CAUTION

Always cross and attach the safety chains before towing. Failure to attach safety

chains properly will allow tongue to drop in case of ball hitch failure, resulting in

serious damage to the trailer and equipment.

6. Attach the trailer safety chains to the tow vehicle. Make sure the chains cross

under the trailer tongue as shown in (Figure 3-10). If needed , cross the chains

over then under the tow bar to prevent dragging.

BREAKAWAY

SAFETY CABLE

SAFETY

CHAINS

Figure 3-10. Trailer Hitching Checkpoints

7. Connect the trailer lights to the tow vehicle power plug.

8. Before towing the trailer, check the following and make all necessary

adjustments, corrections, or repairs:

a. Check that trailer jack and outriggers are locked in travel positions.

b. Verify that the transport pin secures the lower boom to the trailer frame. If

the boom is not secured, install the transport pin and pin keeper at this time.

c. Verify that all onboard equipment is secured.

d. Check that the BATTERY ON/OFF switch is in the OFF position.

e. Verify that trailer brake lights and marker lights work properly.

f. Check that the trailer tires are evenly inflated and not low on air.

3-12

Page 29

3 — OPERATION

WARNING

Improper tightening of boom lift trailer wheel nuts can cause wheel lugs to shear,

causing serious injury or damage to equipment. Check and maintain the proper

wheel nut torque according to the maintenance instructions in this manual.

Periodically check the wheel nut torque according to the instructions in Section 4-2 of this

manual. More frequent torque checks are required when a wheel is recently installed.

After towing, while the trailer wheels are elevated for boom lift operation, check for loose

wheels and for wheel lug wear indications. If a loose wheel mounting is indicated, remove

and inspect the wheel lugs for damage. Do not tow the boom lift with worn or damaged

wheel lugs.

3-13

Page 30

XLB-4232 DC

3-14

Page 31

4

4

44

Maintenance

4-1 SCHEDULED SERVICE CHECKS

Daily/Weekly Service Checks

Perform the following daily/weekly service checks as listed in Table 4-1.

Table 4-1. Daily/Weekly Service Checks

Service Check

Check battery electrolyte level. If battery charge is low, add

water to bring electrolyte just above plates. If batteries are

fully charged, raise electrolyte to full mark in each cell.

Check and retighten all nuts and bolts.

Check that cage gate is secure.

Check to see that all decals are present.

Check that controls and indicators on upper and lower

control panels operate properly.

Check/add hydraulic oil.

Check trailer tires for proper inflation. When cold, tires

should be inflated to 65 psi.

Check trailer running lights for proper operation.

Check trailer hitch components for damage and proper

operation. Refer to Trailer Hitching in paragraph 3-6.

Check electrical wiring for cuts, loose terminals, broken

wires, chaffing, corrosion, or other damage. Repair all

damage, remove corrosion, and seal exposed connections.

Use small diameter probe to check upper control box drain

holes for clogging. If clogged, open box and remove debris.

Lubricate grease fittings labeled LUBRICATE WEEKLY

with NLGI Grade 2 multi-purpose grease.

Check trailer and boom lift for missing or loose hardware.

Replace or tighten missing or loose hardware as needed.

Daily

before use Weekly

4-1

Page 32

XLB-4232 DC

Monthly Service Checks

Perform the following monthly service checks as listed in Table 4-2.

Table 4-2. Monthly Service Checks

Service Check

Clean battery terminals and check battery

charger operation.

Check operat ion of manual emergency

lowering valve.

Check wheel nut torque per paragrap h 4-2.

Check for excess wear, free play, or binding in

outrigger screws. Replace damaged parts.

Lubricate power compartment hinges and

latches with light weight machine oil.

Lubricate grease fittings labeled LUBRICATE

MONTHLY per paragraph 4-3.2.

Lubricate trailer tongue jack (2 places) with

NLGI Grade 2 multi-purpose grease.

Lubricate grease fittings labeled LUBRICATE

SEMI-ANNUALLY per paragraph 4-3.3.

Lubricate wheel bearings per paragraph 4-3.4.

Check battery cables and wiring for loose

connections and damaged wires.

Check outrigger bushings and replace if

necessary per paragraph 4-5.

Replace hydraulic oil and oil filter.

Check boom pivot points for bearing wear.

Replace worn or damaged bearings.

Check slew bearing for wear or damage; torque

bearing bolts to 200 lb-ft (271 N

Inspect and adjust trailer brakes.

Load test boom with 300 pounds.

·m).

month

Every

Every

6 months

Every

12 months

4-2

Page 33

4 — MAINTENANCE

4-2 WHEEL NUT TORQUE REQUIREMENTS

It is very important to apply and maintain the correct wheel nut torque on the boom lift

trailer. The wheel nuts must be evenly tightened to the following specified torque

increments whenever a trailer wheel is removed and installed. Use the following

tightening procedure:

1. Evenly tighten the wheel lug nuts to 25 lb-ft (34 N

shown in Figure 4-1.

Figure 4-1. Wheel Nut Tightening Sequence

2. Evenly tighten the wheel lug nuts to 60 lb-ft (81.4 N

sequence shown.

3. Evenly tighten the wheel lug nuts to 100 lb-ft (135.6 N

tightening sequence shown.

4-3 LUBRICATION

Lubrication makes operation of the XLB-4232 DC Boom Lift more efficient and extends

the equipment life. Use the following procedures to lubricate the boom lift components.

1. Lubricate trailer and outrigger jack posts and all grease fittings labeled

LUBRICATE WEEKLY with NLGI Grade 2 multi-purpose grease.

·m) in the tightening sequence

·m) using the nut tightening

·m) using the nut

2. Lubricate all LUBRICATE MONTHLY grease fittings with NLGI Grade 2

multi-purpose grease. Wipe off dirt and grease residue. Add approximately ½

ounce of fresh grease to each fitting. See Figure 4-2 for grease fitting locations.

Figure 4-2. Lubricate Monthly

4-3

Page 34

XLB-4232 DC

3. Lubricate the slew ring bearing grease fitting labeled LUBRICATE SEMIANNUALLY with NLGI Grade 2 multi-purpose grease. Wipe off dirt and

grease residue. Rotate the boom and add approximately ½ ounce of grease to

each bearing quadrant. See Figure 4-3 for the location of the slew ring bearing

grease fitting.

Figure 4-3. Lubricate Semi-Annually

16. Determine whether the boom lift is equipped with an Al-Ko axle (hex tube) or

Dexter axle (square tube). Lubricate the boom lift axle per the applicable

procedure in step 5 or 6.

17. Clean and repack Al-Ko axle wheel bearings according to the following

general instructions:

a. Use the outriggers to raise the trailer wheels.

b. Remove the spindle caps, cotter pins, spindle nuts, washers, outer wheel

bearings, and wheels. Remove inner wheel bearings.

c. Clean wheel bearings, bearing races, and spindle with solvent and lint-free

cleaning cloths.

d. Repack inner and outer wheel bearings with a reputable NLGI Grade 2

polyurea type, lithium-based, high-temperature, wheel bearing grease

(minimum 440°F dropping point).

e. Apply a thin film of grease to the bearing races and spindles.

f. At each wheel, install inner bearing, wheel, outer bearing, washer, and

spindle nut. Turn wheel and tighten spindle nut until wheel hub binds.

g. Hold the wheel stationary and loosen the spindle nut. Finger tighten the

spindle nut, then back off as needed to align the cotter pin hole. The wheel

should be free to spin without binding or excess free play.

h. Install cotter pin and spindle cap.

4-4

Page 35

4 — MAINTENANCE

18. Lubricate a Dexter axle according to the following procedure:

a. Remove the rubber plug to expose the grease fitting.

b. Grease the bearings with an NLGI Grade 2 polyurea type, lithium-based,

high-temperature, wheel bearing grease (minimum 440°F dropping point).

Rotate the hub while applying grease.

c. Continue to apply fresh grease until all the old grease is purged. When new

grease starts to flow from the front bea ring, remove the grease gun. Remove

the excess grease and reinstall the rubber plug.

INNER

BEARING

RUBBER

OUTER

BEARING

PLUG

GREASE

FLOW

GREASE

FITTING

METAL

END CAP

Figure 4-4. Lubrication of Dexter Axles

19. When installing the hub of a Dexter axle or if a wheel bearing adjustment is

necessary, use the following instructions:

a. Install the inner bearing, wheel, outer bearing, washer, and spindle nut.

While rotating the hub, tighten the spindle nut to 50 lb-ft.

b. Hold the hub stationary and loosen the spindle nut. Finger tighten the

spindle nut, then back off the nut to align the cotter key hole. The wheel hub

should be free to spin without binding or excess free play.

c. Install the locking tang and end cap.

d. Lubricate the bearings according to the instructions in step 6.

4-5

Page 36

XLB-4232 DC

4-4 HYDRAULIC SYSTEM

Hydraulic system maintenance varies with equipment use and the environment in which

the boom lift is used. Constant attention to keep the oil clean and the reservoir properly

filled will help prevent possible damage to the system. Hydraulic diagrams are provided

at the end of this section for general reference.

Hydraulic System Inspection

Check the hydraulic hose and fittings for leaks and damage daily. Tighten or replace as

necessary to prevent hydraulic oil loss.

Fluid Check and Replacement

The oil level sight gage should be checked with the boom down and the trailer on a level

surface. The reservoir is originally filled with AW-46, a high-grade, non-foaming

hydraulic oil designed for temperatures as low as -20°F (-33°C).

Use Dextron Automatic Transmission Fluid Type A for low temperatures reaching -40°F

(-40°C). If either oil is not available, a good grade SAE 10W hydraulic oil may be used

where the low temperature is above 32°F (0°C). SAE 5W hydraulic oil may be used

where low temperatures reaching 0°F (-18°C).

Do not mix hydraulic oils. Clean the reservoir sump strainer and replace the hydraulic oil

once a year or whenever the oil becomes contaminated.

Air Bleeding

Delayed response or sporadic boom lift motions may indicate air in the lift cylinders. Use

the following procedure to bleed entrapped air from the hydraulic system.

1. Fill the reservoir with the proper hydraulic fluid. Replace, but do not tighten the

reservoir fill cap.

2. Fully raise and lower the boom to return oil with entrapped air to the reservoir.

3. Allow several minutes for air to escape the reservoir oil.

4. Repeat steps 1 thr ough 3 as needed. Add oil slowly and only when the boom is

lowered to prevent adding more air to the system.

4-6

Page 37

4 — MAINTENANCE

Hydraulic Cylinder Repair

Cylinder Removal and Installation

1. Lower boom onto travel support, turn off the main power switch, and remove the

PLATFORM/OFF/GROUND key.

2. Support lift cylinder with wood shoring between cylinder and boom. Secure both

ends of lower boom lift cylinder with lifting straps and overhead lifting device.

Support upper boom lift cylinder with padded lift truck forks.

3. P lace absorbent drip cloths below cylinder ports. Remove hydraulic hoses from

lift cylinder. Elevate hoses above hydraulic reservoir and protect exposed hose

fittings and cylinder ports with protective caps.

4. Refer to Figure 4-5. Remove screws (1), lock washers (2), and locking plate (3)

from elevated end of cylinder (6).

3

2

1

5

5

5

6

5

4

3

2

1

1. Screws 4. Pivot Pin

2. Lock Washers 5. Spacer

3. Locking Plate 6. Cylinder

Figure 4-5. Hydraulic Cylinder Removal

4

4-7

Page 38

XLB-4232 DC

5. Using a pry bar and shoring, unweight the cylinder end. Remove pivot pin (4)

and spacers (5).

6. Lower the free end of cylinder (6) onto support shoring or a lifting strap.

7. Repeat steps 4 through 6 at the opposite end of the cylinder.

8. Lift the lower end of the cylinder from its pivot block. Use an overhead lifting

device and lifting straps and/or a lift truck to remove the cylinder.

9. After repairing the hydraulic cylinder, reinstall the cylinder in the reverse order

of removal.

10. Power up the hydraulic system and check for leakage. Tighten hydraulic fittings

as needed.

11. Bleed entrapped air from the hydraulic cylinder according to instructions in

paragraph 4-4.

4-8

Page 39

4 — MAINTENANCE

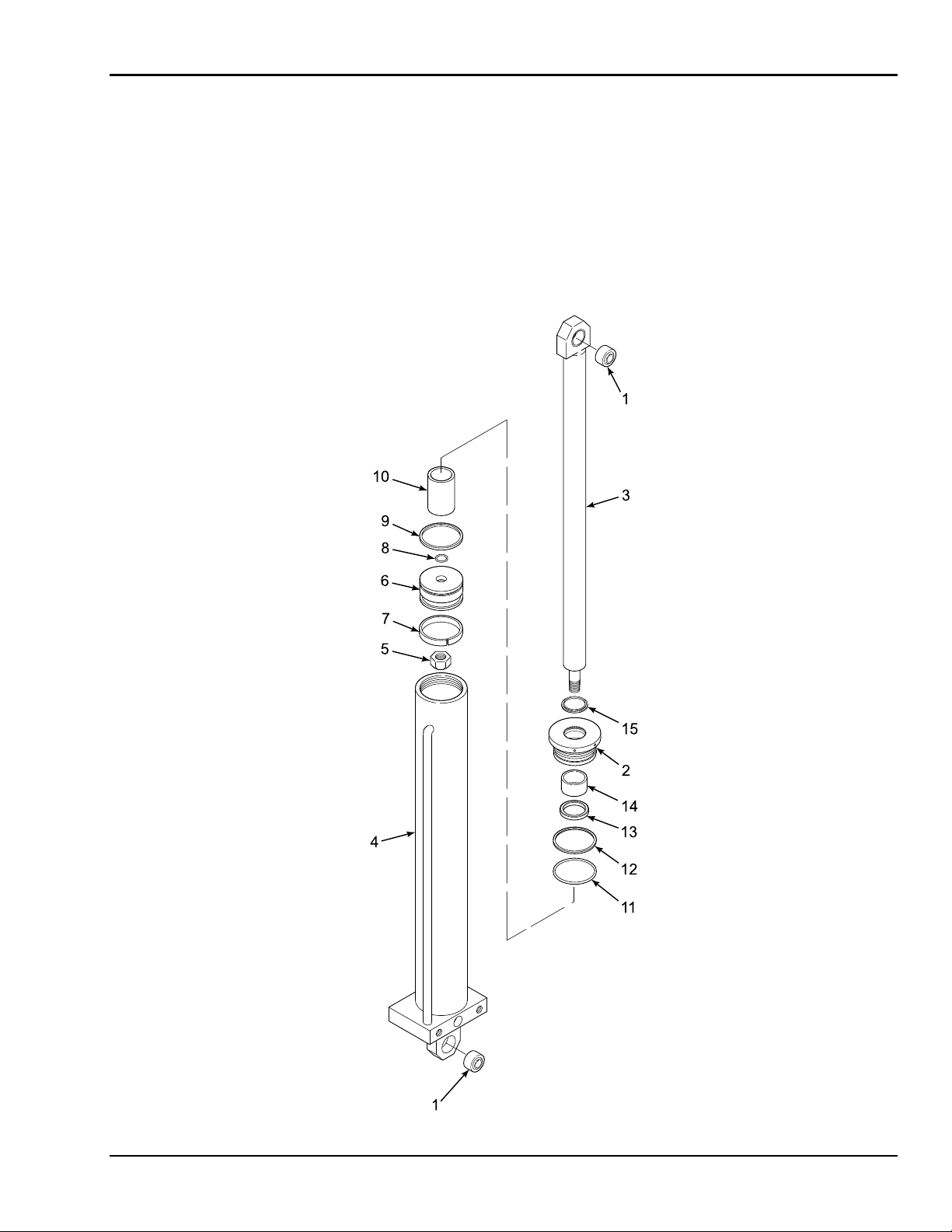

Cylinder Disassembly and Inspection

Perform the following procedure to disassemble the upper or lower hydraulic lift cylinder.

Whenever the hydraulic cylinder is disassembled, all seals must be replaced. Refer to

replacement seal kit, Figure 6-3 or 6-4.

1. Check bearings (1, Figure 4-6) for wear and excess play. Replace bearings if

necessary.

2. Unscrew headstock (2) and slide cylinder rod (3) from housing (4).

3. Remove slotted nut (5) and piston (6). Remove and discard wear ring (7), o-rings

(8 and 9). Remove sleeve (10).

1. Bearings

2. Headstock

3. Cylinder Rod

4. Housing

5. Slotted Nut

6. Piston

7. Wear Ring

8. O-Ring

9. O-Ring

10. Sleeve

11. O-Ring

12. Backup Ring

13. Seal

14. Bushing

15. Wiper

Figure 4-6. Hydraulic Cylinder Repair

4-9

Page 40

XLB-4232 DC

4. Remove headstock (2). Remove and discard o-ring (11), backup ring (12), and

seal (13). Remove bushing (14) and wiper (15). Discard wiper.

5. Inspect the cylinder rod (3) for scratches or pits. Pitting in the base metal is not

acceptable. Wear indications that catch the fingernail, but do not extend into the

base metal nor extend more than 1/2 inch along the rod length are acceptable if

they will not cut the seal material. The chromium plating must not be worn

through. Replace the cylinder rod if not acceptable by these inspection criter ia.

6. Inspect the headstock (2). Check the inside bore for scratches; deep scratches or

cracks are unacceptable. Check the bore for polished wear surfaces. Polishing

indicates uneven loading. Check the bore for out-of-roundness. If the bore is

more than 0.007 inch out-of-round, replace the head. Seal groove damage is

unacceptable. Replace the headstock if these conditions are not met.

7. Inspect piston (6). Check the outside surface for scratches; deep scratches are

unacceptable. Check the outside surface for polished wear surfaces. If polishing

is noticed, check the piston for out-of-roundness. If out-of roundness exceeds

0.007 inch, replace the piston. Seal groove damage is unacceptable. Replace the

piston if these conditions are not met.

8. Inspect cylinder housing (4) for scratches or pits. Pits or scratches that are deep

enough to catch the fingernail are not acceptable. Scratches that catch the

fingernail, but extend less than 1/2 inch along the tube length, are acceptable

providing they are not sharp enough to cut the seals. Replace the cylinder tub e if

these conditions are not met.

Cylinder Assembly

1. Lubricate headstock (2, Figure 4-6), wiper (15), seal (13), backup ring (12), and

o-ring (11) with hydraulic fluid.

2. Twist seal (13) into a ‘C’ shape and seat it in mating groove of headstock (2).

3. Seat wiper (15), backup ring (12), and o-ring (11) in mating groove of headstock

(2). Make sure the back-up ring is installed above the o-ring. Use brass tools or

plastic tools to avoid seal groove damage during installation. Scratching the seal

grooves may cause by-pass leakage. Allow the assembled headstock to sit one

hour for the seals to regain their original shape.

4. Lubricate piston (6) and o-rings (8 and 9) with hydraulic fluid.

5. Install wear ring (7). Allow the assembled cylinder head to sit one hour for the

seals to regain their original shape.

6. Thoroughly rinse the inside of cylinder housing (4) with a high-pressure rinse

and wipe with lint free cleaning cloths.

7. Install the headstock (2), bushing (14), stop sleeve (10), piston (6) and nut (5 )

onto the cylinder rod (3). Tighten the nut from 100 to 120 lb-ft (136 to 162

N

·m).

8. Apply anti-seize to the headstock threads and installed o-ring (11).

9. Coat the cylinder rod with hydraulic fluid and insert the rod into the cylinder

housing. When insert i ng headstock (2) make sure t hat static o-ring (11) does not

extrude from the o-ring groove. Be careful not to nick the seals as they enter the

cylinder housing.

10. Screw headstock into the cylinder housing and tighten for a snug fi t of the wiper

(15) on the cylinder rod (3).

11. Pr ess in new bearings (1).

4-10

Page 41

4 — MAINTENANCE

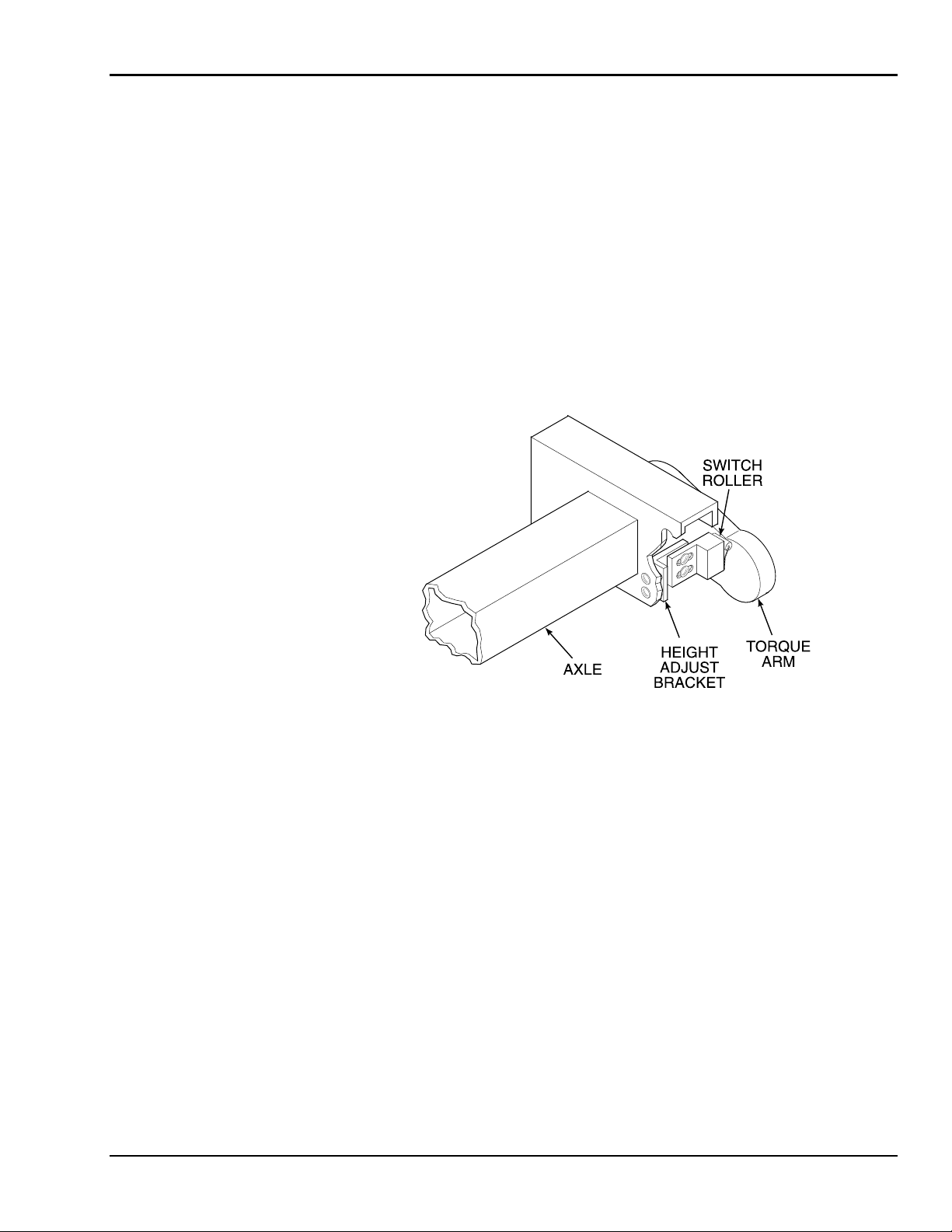

4-5 ADJUSTING AXLE POSITION SWITCHES

The axle position switches are set up to detect when the boom lift load is transferred from

the trailer wheels to the outriggers. After the first 100 miles of road travel the axle torque

arms wear in. Torque arm wear-in causes the wheels to ride higher in relation to the trailer

frame. Following wear-in, the axle position switches need to be readjusted. Use the

following procedure to readjust the axle position switches:

1. Deploy the outriggers and raise the trailer wheels off the ground. The wheels

should spin freely.

2. Loosen the switch bracket, Figure 4-7.

3. Adjust the switch position to where the roller just touches the upper edge of the

torque arm. Tighten the switch bracket.

4. Repeat the adjustment procedure for the axle position switch at the opposite

wheel.

Figure 4-7. Adjusting Axle Position Switches

4-11

Page 42

XLB-4232 DC

4-6 TROUBLESHOOTING

Table 4-3. Troubleshooting Chart

Problem Cause Correction

1. Outriggers indicator lamp

will not light up.

a. Master power switch turned off.

b. Emergency stop or power button

engaged (pushed in).

c. All outriggers not deployed.

d. At least one wheel not raised.

a. Turn on master power switch.

b. Rotate emergency stop buttons

clockwise to dise ngage.

c. Deploy all outriggers.

d. Raise at least one wheel off the

ground.

2. Boom UP/DOWN and

ROTATION functions do not

work.

3. Single boom lift or rotation

function does not work.

4. Boom lift and rotate

functions do not operate

properly.

a. Master power switch turned off.

b. Low battery power.

c. Boom lift is out of level.

d. Emergency stop or power button

engaged (pushed in).

e. Battery ground or in-series cable

loose.

f. All outriggers not deployed

g. At least one wheel is not raised.

h. Battery cable or equipment ground

lead loose or corroded.

i. Hydraulic pump not pumping.

a. Loose wiring connector.

b. Valve solenoid not operating

properly.

c. System interlock fault.

d. Broken or loose wire.

a. Valve solenoid not operating

properly.

b. Loose solenoid wiring.

a. Turn on master power switch.

b. Check battery charge LEDs on upper

control panel. Recharge batteries if

yellow or red LED is lighted.

c. Level boom lift with outrigger jacks.

d. Rotate emergency stop button

clockwise to dise ngage.

e. Check for and repair loose battery

connections or ground fault.

f. Check outrigger display. Lower

outrigger ja cks to engage switches.

g. Check outrigger display. Raise at

least one wheel off the ground.

h. Clean and reconnect loose or corroded

battery cable or ground lead.

i. Check pump motor operation; repair

or replace if not running. Check gear

pump; replace if hot to touch.

a. Check wiring terminals in control box

and at valve manifold; repair loose

wiring terminal.

b. Swab out valve solenoids and recheck

function; replace solenoid if faulty.

c. Check display for system status.

Correct indicated fault conditions.

d. Repair or replace wire.

a. Swab out valve solenoids and recheck

function; replace solenoid if faulty.

b. Check wiring terminals in control box

and at valve manifold; repair loose

wiring terminal.

4-12

Page 43

4 — MAINTENANCE

Table 4-3. Troubleshooting Chart, Continued

Problem Cause Correction

5. Boom lift and rotate

functions operate

intermittently.

a. Loose connection.

b. Loose connector at valve coil.

a. Reconnect wiring.

b. Check wiring connection to valve coil;

repair loose wiring.

4-13

Page 44

XLB-4232 DC

T2

T1

T4

T3

T5

T6

Rotate

Battery

Charger

B

R

110v AC

(-)

(-)

-

Tel e

+

-

+

+

-

-

+

+

-

Power

Switch

Master

L1

L2

R2

R1

T2

T1

BL2

BL1

R1-5

T8

T6

T4

Lift UP

Hi/

CCW

Tele

T12

T11

05

Low

6

In

Comp

Bucket

Comp

Bucket

4

8

CCW

CW

2

T-2

Lift DN

5

T5

CW

06

Out

Tele

R1-6

12

11

Beeper

Outrigger

Lift

-

W

B

+

Light

Cylinder

(-)

1

R1

Hi/Low

W

B

W

R

B

T9T8T7

(-)

T2

B

R1

7

R1

A

R1

T10T

Level Sensor

789

6

T

18

13

Outrigger

Display

514

1

3

0

W

Rot.

Lift

Selector

1

1

1

2

G

Cond

B

E-Stop

Lower Control box

Drive Rear

Pass Front

Drive Front

2

2

1

2

1

B

Pass Axle

G

W

6

514

3

1

0

789

1

Pass Rear

Drive Axle

Upper Control

Lift

Tele

Rotate

Box

T1

T3

T6

1

1

2

2

1

1

3

1

(-)

14

Panel

Bucket

Transport

Hour Meter

Limit Switch

E

+

-

N

N0N

-

Side

Protected

+

T

16

T

18

(-)

20

0

N

-

+

Low

Pump

Speed

-

+

+

-

T9

+

-

High

Pump

Speed

GRD

White

Bl B

R

Hot

3 Deg

B

T7

Switch

Mercury

Y

R

T

Comp/switch

Surge

Suppressor

T

20

T

19

AMP

c

C

E

-

Line Side

+

T

12

T

11

T

G

15

T

R

11

T

W

18

T

B

14

7

A

R1

Level

Outrigger

9B8

246

135

Sensor

123

456

Display

R2

Outriggers

0

4

9

5

8

6

7

-

-

-

-

-

BW

G

20

19

18

17

16

15

14

13

12

11

10

9

8

7

TR2

(-)

6

14

6

5

4

T2

T4

T5

Dead Man

B

(-)

R

Gauge

Battery

T

10

E-Stop

Comp

Bucket

T

T

12

Hi/Low

T9

T7

T8

20

T

T

19

11

T1Black

T2Blue

T3Brown

T4Orange

T5Yellow

T6Pink

T7Blue/Black

T8Brown/Red

T9Pink/Black

T10Orange/Black

T11Yellow/Red

T12Orange/Red

T19Black/Red

T20Yellow/Black

(-)Blue/Red

Extend

Hi Speed

4

3

2

1

R3

7

8

5

6

Red

Black

3

2

1

Blue

110v

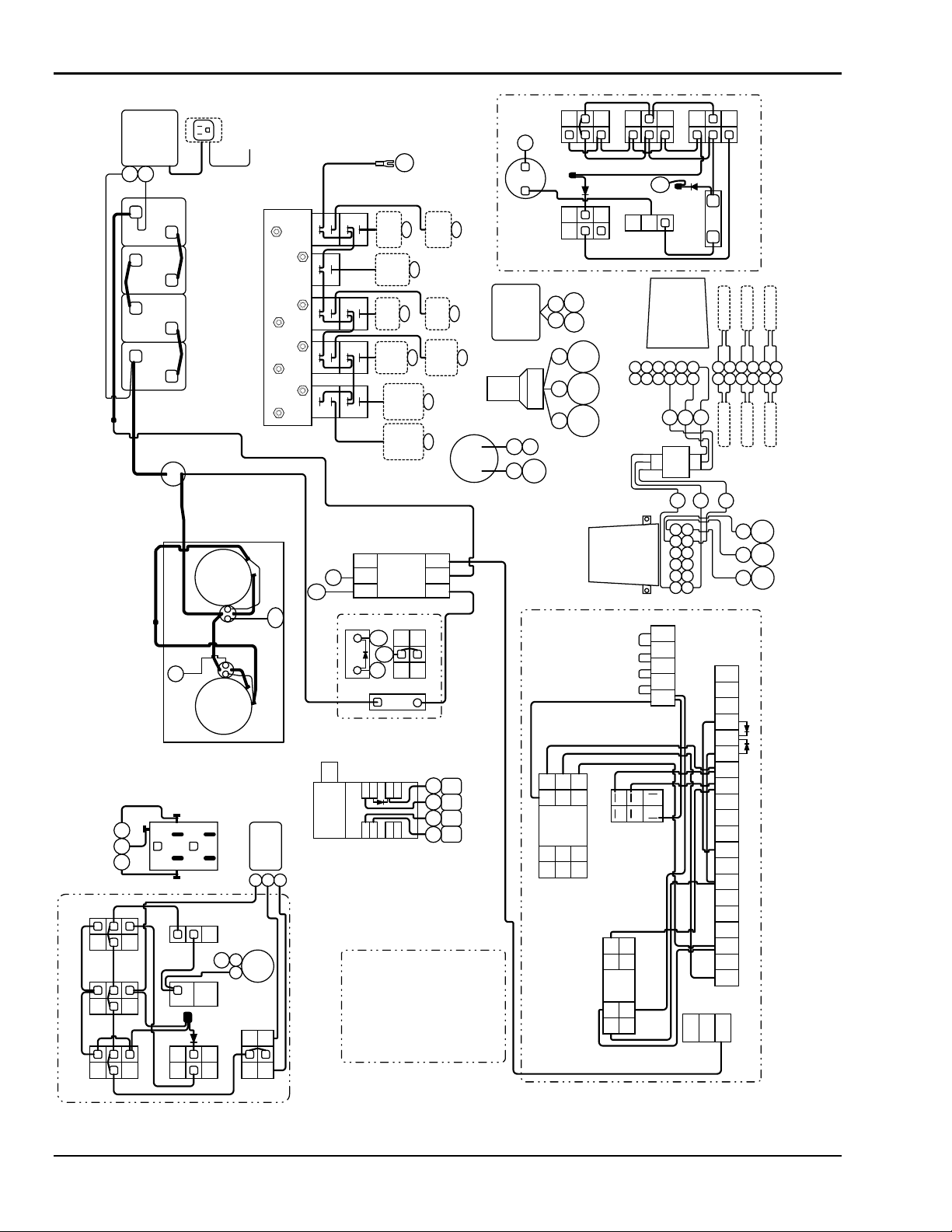

Figure 4-8. Electrical Layout

4-14

Page 45

4 — MAINTENANCE

YELLOW LED

OUT OF LEVEL

(MOMENTARY)

GREEN LED

INPUT POWER

RED LED

OUTPUT SIGNAL

(ON WHEN LEVEL)

Figure 4-9. Level Sensor

Table 4-4. Level Sensor LEDs

Color Description

Yellow Boom lift out of level. Signals alarm after 2 second delay.

Green Boom lift power is on.

Red Boom lift level. Goes out after time delay.

4-15

Page 46

XLB-4232 DC

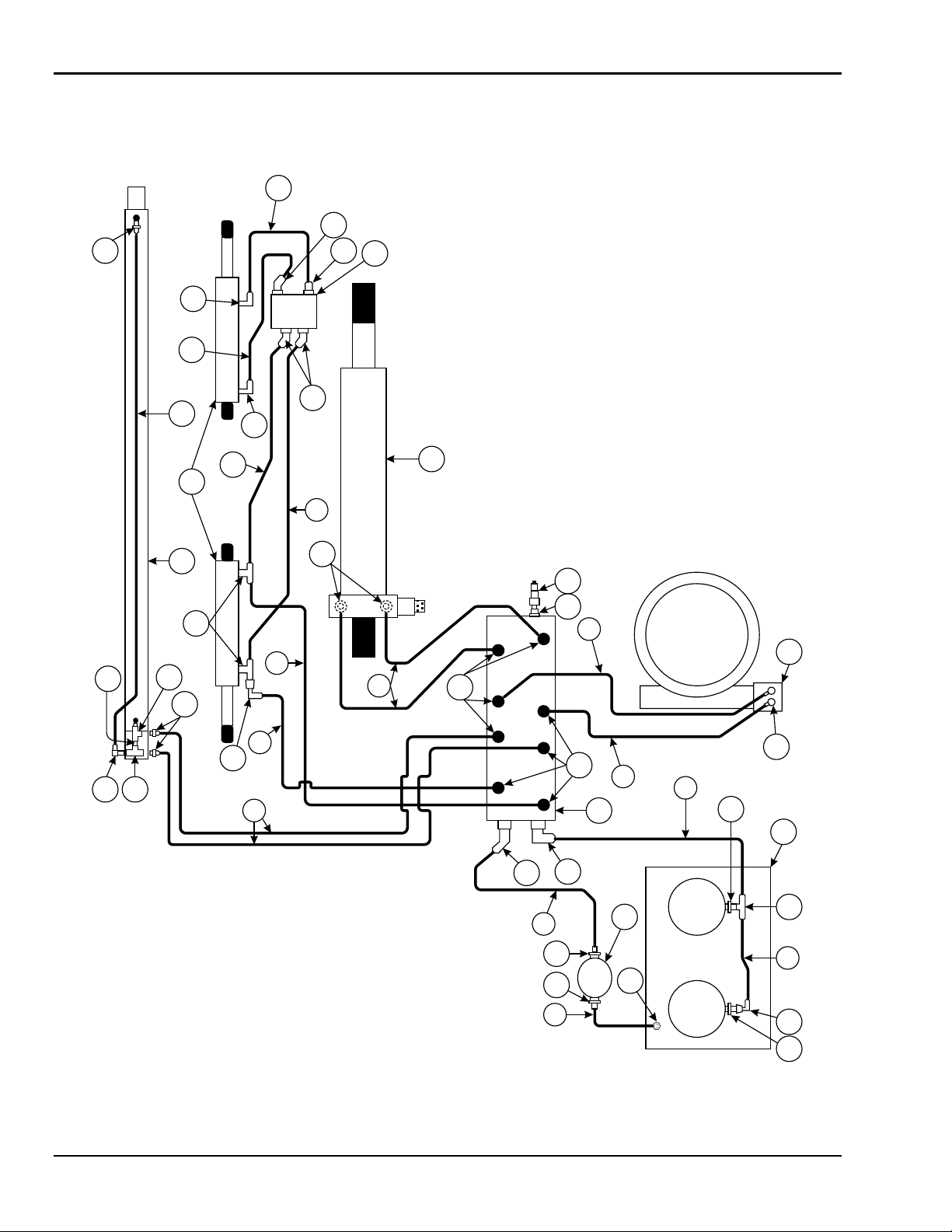

8

L2

L1

Dual Pump Unit

Manifold Combo Valve

Piloted Operated Check Valve

Extention Cylinder

Master/Slave Cylinder

Double Piloted Operated Check Valve

Rotation Motor

Lift Cylinder

7

5

C2

C1

V2

V1

6

5

R2

R1

T2

T1

BL1

B02-05-0017 1

B02-04-0069 1

B02-04-0009 1

B02-03-0020 1

B02-03-0007 2

B02-04-0068 1

B02-06-0006 1

B02-03-0024 1

1

2

3

4

5

6

7

8

2

1

1.6

GPM

BL2

3

4

2.5

GPM

Figure 4-10. DC Model Hydraulic Diagram

4-16

Page 47

4 — MAINTENANCE

4-7 MATERIAL SAFETY DATA SHEETS

MATERIAL SAFETY DATA SHEET

FOR LEAD ACID BATTERIES, WET, FILLED WITH ACID

SECTION I: GENERAL INFORMATION

Manufacturer’s Name: Crown Battery Mfg. Company EMERGENCY NO: 800 487-2879

Street Address: 1445 Majestic Drive OR 800 OIL-TANK

City, State, Zip Fremont, Ohio 43420

Phone Number: 419 334-7181 REVISION DATE: 5/18/2000

SECTION II: MATERIAL IDENTIFICATION AND INFORMATION

COMPONENTS PERCENT OSHA ACGIH OTHER LIMITS CAS NUMBER

Hazardous Components PEL TLV

1% or greater

Carcinogens 0.01% or greater

METALLIC LEAD METAL 25.5% 0.05 mg/m3 0.05 mg/m3 NONE 7439-92-1

LEAD SULFATES 18.2% 0.05 mg/m3 0.05 mg/m3 NONE 7439-92-1

LEAD OXIDES 18.0% 0.05 mg/m3 0.05 mg/m3 NONE 7439-92-1

POLYPROPYLENE CASE MTL 6.4%

SEPARATORS 3.5%

SULFURIC ACID (H2SO4) 5.2% 1.0 mg/m3 1.0 mg/m3 NONE 7664-93-9

WATER 19.2%

REGULATORY INFORMATION: Those ingredients listed above are not subject to

the reporting requirements of 313 of Title III of the Superf und Amendments and

Reauthorization Act. The items are covered in an exemption as a “ Manufact ured

Article”. 372.30(b)

SECTION III: PHYSICAL / CHEMICAL CHARACTERISTICS

Boiling Point Approximately 203F Vapor Density: Greater Than 1

Vapor Pressure 14 @ 37% @ 80 F Melting Point: -36 F to -10.6 F

Solubility in Water 100% Water Reactive: Yes, Produces Heat

Specific Gravity 1.245 - 1.295 Battery E l ectrolyte

Appearance & Odor Clear Liquid with Sharp Pungent Odor

SECTION IV: FIRE AND EXPLOSION HAZARD DATA:

Flash Point: Not Combustible

Auto Ignition Temperature N/A Flammability Limits in Air % by Volume: N/A

Extinguishing Media: Dry Chemical Carbon Di oxide, Water Fog, Wat er

Special Fire Fighting Procedures

released when acid decomposes. Wear NIOSH approved self-contained breathing apparatus.

Unusual Hazards