Page 1

LOG SPLITTER

VERTICAL TYPE

Part No. 0108-0104H

Operation and

Maintenance Manual

20 TON

WARNING

hihkjnlkjh

BEFOREUSE

dopthe theruohjo

TUIBE

dhiugoj yho jk;lk poj;lm

UIHU HUDE FORE

gygytbjkj jklj kpj

HOUH

[pl\

BEFIREN

OPERATINGINSTRUC

hjohoipoio

GUI

OOIP

THGY HYGF FDYTIU

DURINGUSE

VBHVJH

[p]][p\[\

huigbnmlkh nhfgij bj l

VHGUTRHIO KK

p

hguijkp

jtbvktv

hioiupo

ipjip jk

ji0\ junoitgb

‘

gutjguit uyo

TUYUYO FGJ FRREWHFVHGI

njtu you jlpi

BJHGYOUTGYUFRJ ETRY

huopo[k

HUHOIGUYGGHFJHVJH

FGYYFGOIU

HUOHIOIIYUY FYFIGUGL

UGIUGG YGI

HUOFGYUGUO UOOIPP

WARNING

STAY

CLEAR

WARNING

STAYCLEAR

35 MPH

opjop

WEDGE

CONTROL

FUNCTION

RETURN

INTERRUPT

SPLIT

MAXIMUM TOWING SPEED

LL-204-44

Copyright © Bil-Jax, Inc. 2006

Page 2

VERTICAL TYPE LOG SPLITTER

This equipment is designed and manufactured in

compliance with the duties, responsibilities, and standards

set forth for manufacturers in the ANSI B71.7 standard in

effect at the time of manufacture.

This equipment will meet or exceed applicable OSHA

codes and ANSI B71.7 standards when used in accordance

with ANSI B71.7 and all other manufacturer’s

recommendations.

It is the responsibility of the user of this equipment to

follow all applicable ANSI, OSHA, Federal, State, and

local codes and regulations that govern the safe operation

of this equipment.

Page 3

Table of Contents

1 Safety........................................................................................1

1 Introduction..................................................................1

2 Before Operation.........................................................3

3 During Operation.........................................................4

4 Fire Prevention............................................................5

5 Towing Safety..............................................................6

6 Maintenance Safety.....................................................7

7 Hydraulic Safety .........................................................8

8 Damaged Equipment Policy ......................................9

2 Introduction...........................................................................11

1 General Description..................................................11

2 Specifications.............................................................12

3 Operation...............................................................................13

1 Operation Zone .........................................................13

2 Operator Controls .....................................................14

3 Operating Procedure .................................................16

4 Maintenance ..........................................................................19

1 Scheduled Service Checks.......................................19

5 Replacement Decals.............................................................21

6 Parts List................................................................................25

1 I-Beam, Cylinder, and Frame Parts List ..................26

2 Hydraulic Tank and Wheel Parts List....................28

3 Hydraulic Pump, Lines, and Valves Parts List .....30

4 Valve Linkage Parts List.........................................32

5 Engine and Mounting Hardware Parts List............34

6 Hitch and Mounting Hardware Parts List..............36

7 Warranty ...............................................................................38

i

Page 4

List of Illustrations

Figure 3-1. Operation Zone.................................................................13

Figure 3-2. Operator Controls.............................................................14

Figure 3-3. Function Interrupt Control Assembly...............................15

Figure 3-4. Wedge Control Assembly ................................................15

Figure 3-5. I-Beam Lock Pin ..............................................................16

Figure 5-1. Replacement Decals .........................................................22

Figure 5-2. Decal Locations................................................................23

Figure 6-1. I-Beam, Cylinder, and Frame Exploded View.................26

Figure 6-2. Hydraulic Tank and Wheel Exploded View.....................28

Figure 6-3. Hydraulic Pump, Lines, and Valves Exploded View.......30

Figure 6-4. Valve Linkage Exploded View ........................................32

Figure 6-5. Engine and Mounting Hardware Exploded View.............34

Figure 6-6. Hitch and Mounting Hardware Exploded View...............36

List of Tables

Table 2-1. Specifications.....................................................................12

Table 4-1. Daily Service Checks.........................................................19

Table 4-2. Yearly Service Checks.......................................................20

Table 5-1. Replacement Decals...........................................................21

Table 6-1. I-Beam, Cylinder, and Frame Parts List............................27

Table 6-2. Hydraulic Tank and Wheel Parts List................................29

Table 6-3. Hydraulic Pump, Lines, and Valves Parts List..................31

Table 6-4. Valve Linkage Parts List ...................................................33

Table 6-5. Engine and Mounting Hardware Parts List........................35

Table 6-6. Hitch and Mounting Hardware Parts List..........................37

ii

Page 5

1

Safety

1 NTRODUCTION

I

Familiarity and proper training are required for the safe

operation of mechanical equipment. Equipment operated

improperly or by untrained personnel can be dangerous. Read

the operating instructions in this manual and become familiar

with the location and proper use of all controls. Inexperience

operators should receive instruction from someone familiar

with the equipment before being allowed to operate the

machine. The use of intelligence and common sense in the

operation of mechanical equipment is the best practice in any

afety policy.

s

procedures set forth in this manual.

All OSHA, ANSI, state and local codes and regulations

pertaining to this equipment should be obtained, read, and

thoroughly understood before attempting to operate this

equipment. Persons under the influence of drugs, alcohol, or

prescription medication should not be on or near this

quipment. Common sense should

e

during the use of this equipment.

This manual covers the AU-5V20H 20 Ton Vertical Log

Splitter manufactured by bil-jax, inc. Additional safety,

operation, and maintenance information for the Honda GX 240

ngine is available in the

e

provided with the splitter.

The information contained herein is not to be considered as

legal advice and is intended for informational purposes onl

This information is offered to alert bil-jax custom

procedures that may be of concern to them.

Be professional and always observe the safety

Honda Engines Owner’s Manual

d

be implemented at all times

y.

ers to

1

Page 6

This information is not intended to be all inclusive and is to be

followed in the use of bil-jax equipment only.

For any questions concerning the safe use of this equipment,

call 419.445.9675 before operating.

Safety Notes

This manual contains DANGERS, WARNINGS, CAUTIONS,

and NOTES that must be followed to prevent the possibility of

improper service, damage to the equipment, or personal injury.

DANGER

Dangers warn of equipment operation that could lead to

personal injury or death.

WARNING

Warnings describe conditions or practices that could lead

to personal injury or death.

CAUTION

Cautions provide information important to prevent

errors that could damage machine or components.

NOTE: Notes contain additional information important

to a procedure.

2

Page 7

2 BEFORE OPERATION

Ensure the following general safety precautions are observed

before operating the splitter.

• Read and understand this manual completely. For your

own safety and the safety of others, become familiar

with the splitter BEFORE attempting to operate it.

Failure to do so, or any deliberate misuse of the

splitter, may result in serious injury or death.

• DO NOT allow any untrained adults to operate your

splitter unless they have read and understood this

manual or have been thoroughly instructed in the safe

use of the splitter.

• DO NOT allow children to operate your splitter.

• Always inspect your splitter for loose, damaged, or

worn parts before use. DO NOT use if any of these

conditions exist.

• ONLY one person should load logs and operate the

splitter. If a helper is assisting in log loading, never

activate the controls unless all persons are in the

“operation zone” or clear of the area, a minimum of 10

feet away.

• DO NOT operate your splitter under the influence of

alcohol, drugs, or other medication.

• DO NOT operate if you feel tired, ill, dizzy, or

unsteady in any way.

• DO NOT use your splitter for any other purpose than

splitting wood.

• DO NOT attempt to move the splitter over hilly or

uneven terrain without a tow vehicle or other help.

• DO NOT operate the splitter without wearing the

safety goggles provided with the splitter or equivalent

eye protection. Flying wood could cause serious injury

to your eyes.

• DO NOT operate without wearing safety shoes.

Dropped logs may cause serious injury to feet.

3

Page 8

• DO NOT operate without wearing protective hearing

devices.

• NEVER wear loose clothing, jewelry or gloves that

could be caught by moving parts. Keep clothing away

from all moving parts of splitter. Wear proper head

gear to keep loose hair away from moving parts.

3 DURING OPERATION

Ensure the following general safety precautions are observed

during the operation of the splitter.

• DO NOT attempt to operate the splitter from outside

of the operation zone.

• DO NOT use the wood splitter with the I-beam in any

position other than vertical. The splitter was designed

to split wood only in the vertical position. Using it in

any other position could cause serious injury to the

user or damage to the splitter.

• DO NOT operate splitter on slopes, hills, or uneven

terrain. Operate only on level ground. The splitter

could tip over causing serious injury.

• DO NOT operate splitter on slippery, muddy, or icy

surfaces.

• ALWAYS block splitter wheels to prevent movement

while in use.

• ALWAYS keep operation zone and adjacent area clear

for safe and secure footing. Remove split wood

immediately so that you do not stumble over it and

fall.

• ALWAYS use both hands to operate the Function

Interrupt Valve and Wedge Controls. DO NOT use

any other means to operate the controls.

• ALWAYS operate your splitter with all safety

equipment in place and all controls properly adjusted.

DO NOT modify or attempt to override or defeat the

safety devices.

4

Page 9

• NEVER place hand, foot, or other body part between

log and wedge or log and stripper. When loading

splitter, place hands on the sides of the log.

• DO NOT attempt to split logs across the grain. Logs

split in this manner may snap away from the wedge

with enough force to cause injury.

• NEVER attempt to split more than one log at a time.

One may fly out and cause injury.

• NEVER attempt to load splitter while wedge is in

motion.

• DO NOT step across the splitter while engine is

running. ALWAYS walk around.

• NEVER straddle the splitter while in use. Any kind of

slip could cause serious injury.

• ALWAYS split logs with ends cut square. A log that is

not cut square can be placed with the longest section

against the I-beam and the most square part placed

against the stop.

• NEVER operate in an enclosed building or where

there is not adequate ventilation.

• NEVER operate splitter without adequate light.

• NEVER move the splitter while engine is running.

• NEVER leave splitter unattended while engine is

running.

4 FIRE PREVENTION

Ensure the following safety precautions are observed to

prevent fires during the operation of the splitter.

• The splitter is equipped with an internal combustion

engine and should not be used in or near any

unimproved forest, brush or grass covered areas unless

the exhaust system is equipped with a spark arrester. If

a spark arrester is used, it must be maintained in

effective working order. Check federal, state, and local

code for spark arrester requirements.

5

Page 10

• ALWAYS have a fire extinguisher available during

splitter operation as a precaution against flying sparks.

• NEVER operate the splitter near flames or sparks.

Gasoline is extremely flammable.

• DO NOT smoke while operating or refueling the

splitter. Gas fumes are explosive and extremely

flammable.

• NEVER refuel a hot or running engine. Allow engine

to cool before refueling.

• Only refuel splitter outdoors in a clear area free of

fumes and spilled fuel. ALWAYS use an approved

fuel container. ALWAYS replace gas cap securely.

• If fuel is spilled, move splitter away from the area of

the spill to avoid creating a fire hazard.

• Fuel should always be stored in an approved, tightly

sealed safety container. ALWAYS store container in a

cool, dry place away from any sources of ignition.

• ALWAYS drain the fuel tank prior to long term

storage.

5 TOWING SAFETY

Ensure the following safety precautions are observed during

the towing of the splitter.

• ALWAYS obey all state and local regulations when

towing on public roads and highways.

• Before towing, ensure the I-beam is stowed in the

down position and secured with the lock pin.

• Before towing, be certain the splitter is securely

attached to the towing vehicle and the safety chains

are in place. ALWAYS leave slack in chains for

turning allowance.

• NEVER exceed 35 M.P.H when towing splitter.

Adjust towing speed for terrain and conditions. Use

extra caution when towing over bumpy or rough

terrain including railroad crossings.

6

Page 11

• ALWAYS allow for splitter length when turning

corners, parking, crossing intersections, and in all

other driving situations.

• ALWAYS use caution when backing up splitter. It is

easy to jack-knife the splitter when backing up.

• NEVER allow anyone to ride on the splitter during

towing.

• NEVER transport cargo or logs on splitter during

towing.

• ALWAYS disconnect the splitter from the towing

vehicle before operation.

6 MAINTENANCE SAFETY

Ensure the following safety precautions are observed when

maintenance is performed on the splitter.

• Check for worn or damaged parts before each use.

Replace any worn or damaged parts immediately.

NEVER operate with worn or damaged parts.

• ALWAYS perform maintenance procedures according

to manufacturer’s requirements. NEVER skip or short

change maintenance procedures.

• ALWAYS keep all mechanisms, nuts, bolts, etc.

properly adjusted and lubricated according to the

manufacturer’s specifications.

• ALWAYS shut engine off while repairing or adjusting

the splitter except as directed by the manufacturer.

• Clean debris from splitter and engine regularly. This

must be done with the engine off.

• NEVER alter the splitter in any way. DO NOT add to

the width or height of the wedge. DO NOT readjust

pressure valves from original manufacturer’s

specifications.

• NEVER run the engine at excessive speeds. DO NOT

readjust from manufacturer’s preset specifications.

• NEVER service or repair the splitter without first

removing the spark plug wire.

7

Page 12

• Use only manufacturer approved parts. Parts must

comply with strict manufacturer specifications. Only

parts purchased from the manufacturer can be

guaranteed to comply with these specifications.

7 HYDRAULIC SAFETY

Ensure the following safety precautions are observed when any

hydraulic system maintenance is being performed on the

splitter.

WARNING

Hydraulic system under high pressure. Escaping fluid

can have enough force to penetrate skin causing serious

personal injury, even death.

• NEVER check for hydraulic system leaks with hands.

Leaks can be detected by passing cardboard or wood

over the suspected area and checking for discoloration

or fluid on the material used.

• If injured by escaping fluid, consult a physician

immediately. Serious infection or reaction can develop

if proper medical treatment is not administered

immediately.

• The hydraulic system of the splitter requires careful

inspection. Be sure to replace frayed, kinked, cracked,

or otherwise damaged hydraulic components to avert

total hydraulic system failure.

• Before loosening or removing any hydraulic fitting or

line, relieve all pressure by shutting off the engine and

moving the control handle back and forth several

times.

• NEVER remove the hydraulic reservoir while the

splitter is running. Hot oil under pressure could result

in serious injury.

• NEVER adjust the pressure relief valve. The pressure

relief valve on the splitter is preset at the factory. Only

a qualified service technician should perform this

adjustment.

8

Page 13

8 DAMAGED EQUIPMENT POLICY

Safety Statement

At bil-jax, we are dedicated to the safety of all users of our

products. Therefore, all bil-jax log splitters are designed,

manufactured and tested to comply with current applicable

Federal OSHA and ANSI codes and regulations.

Damage Policy

There may be occasions when a bil-jax log splitter is involved

in an incident that results in structural damage to the splitter.

This can seriously compromise the ability of the splitter to

perform in a safe manner. Therefore, whenever a bil-jax log

splitter is damaged structurally or when there is the possibility

of structural damage (this damage may be internal and is not

always visible to the naked eye), call the bil-jax Service

Department at 419.445.9675. The bil-jax Service Department

will decide if the splitter is required to be returned to our

facility at 125 Taylor Parkway, Archbold, Ohio, for

reconditioning or can be repaired by a qualified repair shop.

Damage Repair Notice

There may be occasions when a bil-jax log splitter is involved

in an accident resulting in non-structural damage. When this

occurs and repairs are made by the owner or area distributor,

please notify bil-jax of these non-maintenance repairs and

request a repair form to be filled out and returned to bil-jax.

9

Page 14

10

Page 15

2

Introduction

1 GENERAL DESCRIPTION

The Lumber-Jax 20 Ton Vertical Log Splitter, model AU5V20H manufactured by bil-jax, is designed and built to split

s

quare cut

diameter.

The splitter is powered by an 8 horsepower Honda GX240

engine. The gas engine drives a 2-stage hydraulic pump that

delivers up to 2500 psi to the hydraulic ram cylinder. Du

operation, a steel wedge attached to the cylinder moves

ownward splitting the cut log. Cylinder movement is

d

controlled by two hand controls on the splitter control panel

The Lumber-Jax is designed to be towed by a standard tow

vehicle and is equipped with a standard 2-inch ball hitch rated

t 3500 pounds. The Lumb

a

over normal road conditions.

Safety of operation is assured by proper inspection and

maintenance procedures as set forth in this manual. Carefully

r

ead all the safety instructions contained in the Safety section

of this manual before operating the Lumber-Jax log splitter.

logs up to 24 inches long and up to 8 inches in

er-Jax can be towed up to 35 mph

ring

.

11

Page 16

2 SPECIFICATIONS

Lumber-Jax 20 Ton Vertical Log Splitter

Model Number AU-5V20H

Serial Number __________________

Manufactured by: bil-jax, inc.

125 Taylor Parkway

Archbold, Ohio 43502

419.445.8915

Table 2-1. Specifications

Force 20 tons

Engine Honda GX240, 8 hp

Pump 2-Stage, 11 gpm (0.7 lps)

Cylinder 4 in. bore x 2 in. rod (10.2 x 5.1 cm)

Stroke 26 in. (66.1 cm)

Hydraulic

2500 psi maximum

System

Pressure

Extend Time 9 seconds

Retract Time 8 seconds

Total Cycle

17 seconds

Time

Frame 6 in. (15.3 cm) I-beam

Wedge Height 8 in. (20.3 cm)

Hitch 2 in. (5.1 cm) 3500 lbs. (1587.6 kg)

Wheel Size 5.3 in. x 12 in. (12.7 cm x 30.5 cm)

Overall Length 108 in. (274.3 cm)

Overall Width 45 in. (114.3 cm)

Overall Height

58 in. (147.3 cm)

(Towed)

Overall Height

77.25 in. (196.2 cm)

(Operational)

Overall Weight 755 lbs (342.5 kg)

12

Page 17

3

Operation

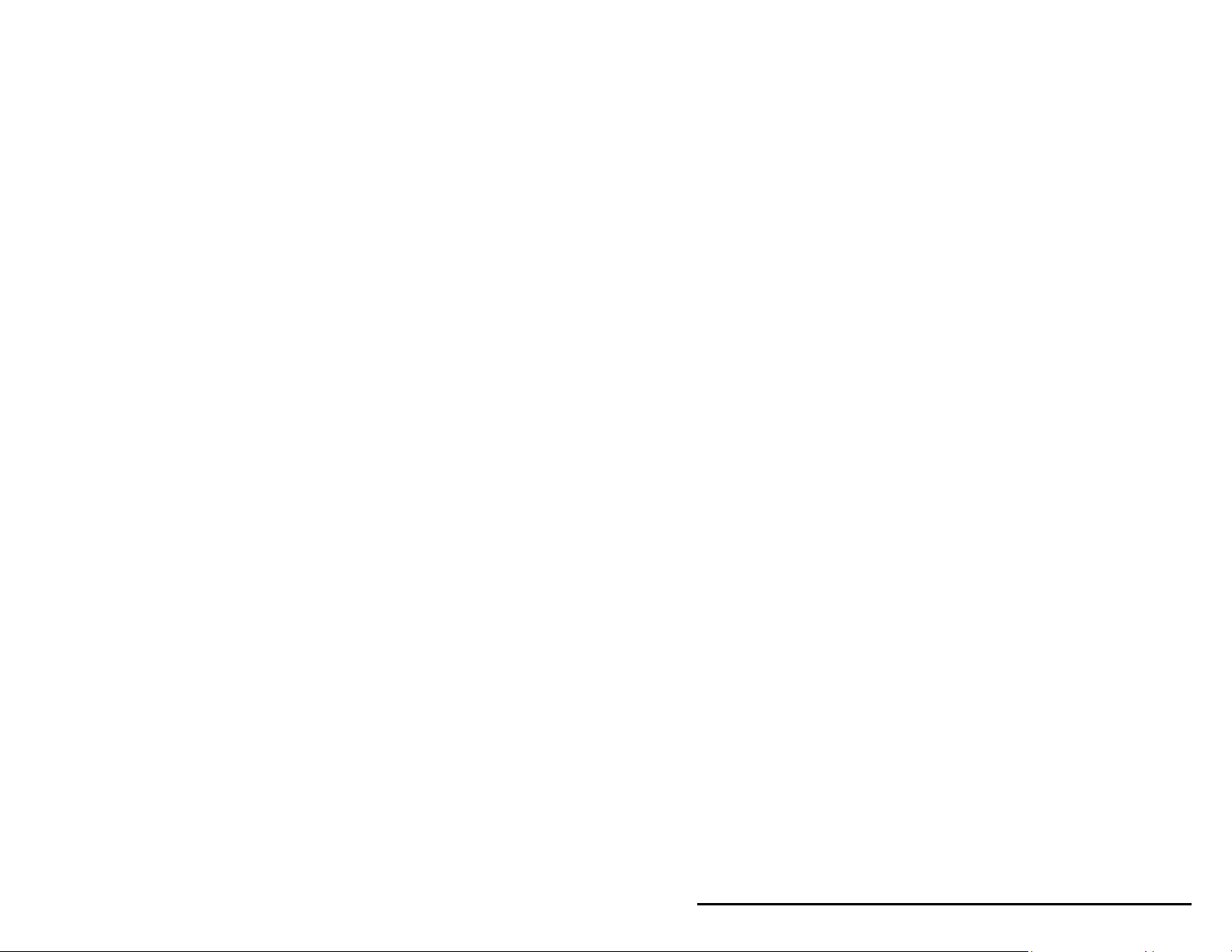

1 OPERATION ZONE

The Operation Zone is an area located in front of a line

extending out 10 feet from the rear of the control panel

180° around the front of the unit. Refer to Figure 3-1.

JAX

OPERATION ZONE

LUMBER

20TON

lkjh

WARNING

jn

k

ih

E

h

S

U

hjo

o

E

u

j;lm

R

o

r

O

p

e

F

E

E

th

R

;lk

B

e

O

jk

F

th

o

h

E

p

j

E

o

D

jy

kp

d

IB

U

o

lj

U

H

g

T

jk

j

U

iu

C

H

h

jk

H

U

d

I

U

b

R

t

U

T

O

y

S

H

N

yg

E

IN

IU

g

l\

IR

T

G

F

[p

Y

E

IN

D

io

T

B

F

A

F

l

po

R

j

i

G

E

E

b

o

Y

P

S

h

ij

IP

H

O

U

fg

I

Y

hjo

O

h

G

U

G

n

O

IN

G

K

H

R

K

T

H

lkh

U

J

m

\[\

D

V

IO

n

H

H

b

B

]][p

R

V

ig

T

[p

u

U

h

p

G

ijk

I

H

u

p

G

V

ktv

g

p

jo

v

H

h

V

o

p

jtb

F

p

o

b

H

jk

iu

itg

W

io

jip

o

h

E

Y

n

R

R

ip

ju

R

T

o

\

F

E

y

u

J

J

ji0

it

R

G

H

u

F

F

J

‘

i

g

V

U

O

Y

tj

H

jlp

Y

J

u

G

U

F

u

g

T

o

H

Y

y

U

G

U

u

O

L

T

G

Y

jt

G

Y

[k

n

U

o

U

p

G

IG

JHG

I

o

F

B

u

O

Y

h

F

H

IU

O

U

Y

H

G

U

F

Y

I

Y

P

I

Y

IP

G

IO

O

F

I

H

O

G

O

U

Y

U

O

G

H

U

G

G

U

IU

Y

G

WEDGE

G

U

F

O

U

H

CONTROL

FUNCTION

INTERRUPT

WARNING

S

T

AY

C

LE

A

R

WARNING

S

T

AYC

L

E

A

R

and

OWINGSPEED

35MPH

MAXIMUMT

RETURN

SPLIT

OPERATION

ZONE

Figure 3-1. Operation Zone

DANGER

Always operate splitter while inside the operation zone.

Operating the splitter from outside the operation zone

may cause serious personal injury or death.

Always operate the splitter while inside the operation zone. If

a second individual is assisting in the loading and unloading

wood, that person must be in the operation zone within

eyesight of the operator before wedge movement can begin.

of

13

Page 18

2 OPERATOR CONTROLS

The operator controls are located on the control panel. The

Function Interrupt and the Wedge Control direct the movement

of the wedge during splitter operation. Refer to Figure 3-2.

Before operation of the splitter can begin, hardware for the

Function Interrupt and the Wedge Control must be assembled.

The hardware is located in the tool box attached to the unit. A

pair of needle-nose pliers and a 3/8 inch wrench or adjustable

wrench are needed for control hardware assembly.

CONTROL

PA N E L

WEDGE

CONTROL

FUNCTION

35 MPH

MAXIMUM TOWING SPEED

STAYCLEAR

WARNING

TINGINSTRUCTUIBE

BEFIRENUI HU HUDE FORE

OPERA

THGY HYGF FDYTIU HOUH

VBHVJH

VHGUTRHIO KKOO IP

GUI

TUYUYO FGJ FRREWHFVHGI

BJHGYOUTGYUFRJ ETR

HUHOI GUYGGHFJHVJH

FGYYFGOIU

HUOHIOI I YUY FYFIGUGL

UGIUGG

HUOFGYUGUO UOOIPP

YGI

WARNING

BEFOREUSE

dopthe ther uohjohihkjnlkjh

dhiugoj yho jk;lk poj;lm

gygytbjkj jklj kpj

hjohoipoio [pl\

DURINGUSE

huigbnmlkh nhfgij bj l

Y

hguijkp[p]][p\[\

hioiupop

ji0\ junoitgbjtbvktv

gutjguit uyoip jip jkop jop

‘

njtu you jlpi

huopo[k

FUNCTION

INTERRUPT

WEDGE

CONTROL

RETURN

SPLIT

INTERRUPT

TOOL BOX

Figure 3-2. Operator Controls

Function Interrupt Control Hardware Assembly

1. In the back of the control panel, connect the link to the

handle with the short clevis pin and cotter pin

provided in the hardware kit. Refer to Figure 3-3.

2. In the front of the control panel, attach the knob with

threaded stud to the handle with the 3/8-16 nut and

3/8-16 locking nut provided in the hardware kit.

Tighten both nuts to secure the knob to the handle.

Press the handle down to test Function Interrupt

control operation.

14

Page 19

COTTER PIN

SHORT

CLEVIS PIN

FUNCTION

INTERRUPT

VALVE

LINK

3/8-16

LOCKING NUT

HANDLE

3/8-16

NUT

KNOB

Figure 3-3. Function Interrupt Control Assembly

Wedge Control Hardware Assembly

1. Slide the ball handle through the control panel so the

slot in the end of the ball handle rests against a pin in

back of the Wedge Control valve actuator. Refer to

Figure 3-4.

2. Align the front hole on the ball handle with the hole in

the actuator and secure with the long clevis pin and

cotter pin provided in the hardware kit. Move ball

handle up and down to test Wedge Control operation.

WEDGE

CONTROL

VALVE

COTTER

PIN

ACTUATOR

BALL

HANDLE

LONG

CLEVIS

PIN

Figure 3-4. Wedge Control Assembly

15

Page 20

3 OPERATING PROCEDURE

Perform the following procedures to operate the Lumber-Jax

log splitter.

1. Read and follow all safety precautions contained in

Section 1 of this manual.

2. Position the splitter on a firm and level surface at the

work area. Block the wheels to prevent movement of

the splitter. Unhitch the splitter from the tow vehicle.

3. Ensure that all personal protective equipment such as

goggles, hearing protection, and safety shoes are being

worn.

4. Remove the lock pin from the splitter I-beam hold

down. Refer to Figure 3-5.

I-BEAM

HOLD

DOWN

LOCK PIN

Figure 3-5. I-Beam Lock Pin

WARNING

The splitter is designed to operate with the I-beam in the

vertical position only. Operating the splitter with the

I-beam in any other position may cause serious personal

injury or damage to the splitter.

5. Ensuring the I-beam path is clear, lift the I-beam into

the vertical position. Do not split logs with the I-beam

in any other position.

16

Page 21

6. Check the engine oil and fuel levels. Refer to the

Honda Engines Owner’s manual in the tool box for

detailed information on the operation and service of

the engine.

7. Start the engine.

WARNING

Load only one log at a time, and with the grain parallel to

the wedge. Loading more than one log and/or against the

grain may cause wood to splinter. Flying debris can cause

serious personal injury.

8. Load only one log at a time with the grain parallel to

the wedge. Do not attempt to split more than one log at

a time. Do not attempt to split a log against the grain.

9. Adjust the stripper bars on each side of the wedge to

the height of the logs to be split. The stripper bars

prevent the wedge from becoming stuck in a partially

split log.

10. Alway s stay in the operation zone, Figure 3-1, when

operating the splitter controls.

11. Depress the Function Interrupt control with one hand

to activate the Wedge Control.

12. With the other hand, move the Wedge Control lever

down to “Split” a log, then up to “Return” the wedge

to the ready position.

13. When finished splitting all logs, raise the wedge to the

“Return” position and return the stripper bars to their

retracted position.

14. Stop the engine.

15. Move the I-beam into the stowed position and insert

the lock pin.

17

Page 22

18

Page 23

4

Maintenance

1 CHEDULED SERVICE CHECKS

S

Daily Service Checks

Perform

listed in Table

Service engine per instructions in the Honda Engines Owner’s

Manual.

the following service checks daily before each use as

4-1.

T e Checks

able 4-1. Daily Servic

Daily Service Checks

Check ball hitch coupler for damage and missing parts. Ensure ball

hitch operates properly.

Check safety chains and hooks for wear and damage from

dragging. Ensure chains are properly attached to the coupler.

Check side to side movement of the wedge. Movement should be

no more that 1/4 inch. Adjust or replace wear plates as necessary.

Check the hydraulic system for leaks and damaged or worn hoses.

Check hydraulic oil level at the sight gage on the hydraulic tank.

Check all nuts, bolts, screws, and pins for proper tightness and

installation.

Check all safety devices and controls for proper working order.

Check that Operation Manual, Honda Engines Owner’s Manual,

instructional video, and two pairs of goggles are with

Check that all decals are in place and fully readable.

Check tires for proper inflation.

unit.

19

Page 24

Yearly Service Checks

Perform the following yearly service checks as listed in Table

4-2.

Table 4-2. Yearly Service Checks

Yearly Service Checks

Replace hydraulic oil. Clean out any debris in the bottom of the

hydraulic reservoir and sump strainer.

Clean, check, and pack wheel bearings with fresh grease.

20

Page 25

5

Replacement Decals

Refer to Table 5-1, and Figures 5-1 and 5-2 for descrip

and locations itter.

of decals on the Lumber-Jax log spl

Table als

5-1. Replacement Dec

tions

Decal No. Descripti Qt

0202-0340 Function Interrupt 1

0202-0341 Max. Towing Speed 35 mph 2

0202-0342 Lumber-Jax (Transfer type decal) 2

0202-0344 Warning...Stay Clear (Square) 1

0202-0348 20 Ton 1

0202-0380 Warning...Stay Clear While Raising... 3

0202-0381 Warning...Stay Clear 1

0202-0382 Wedge Control 1

0202-0383 Main Warning Decal 1

B06-00-0192 Operation/Service Manual Inside 1

on of Decal y

21

Page 26

MAX. TOWING SPEED

35 MPH

0202-0341

0202-0340

0202-0342

20 TON

0202-0348

0202-0344

22

0202-0380

STAY

CLEAR

202-380

CFU

0202-0381

0202-0383

Figure 5-1. Replacement Decals

0202-0382

B06-00-0192

Page 27

0342

0348

0381

0380

20 TON

0340

0383

0341

0380

WARNING

BEFOREUSE

dopthe ther uohjohihkjnlkjh

dhiugoj yho jk;lk poj;lm

gygytbjkjjkljkpj

BEFIRENUI HU HUDE FORE

OPERATINGINSTRUCTUIBE

hjohoipoio [pl\

THGY HYGF FDYTIU HOUH

DURINGUSE

VBHVJHGUI

huigbnmlkh nhfgij bj l

VHGUTRHIO KKOO IP

hguijkp[p]][p\[\

hioiupop

ji0\ junoitgbjtbvktv

gutjguit uyoip jip jkop jop

TUYUYO FGJ FRREWHFVHGI

njtu you jlpi ‘

BJHGYOUTGYUFRJ ETRY

huopo[k

HUHOI GUYGGHFJHVJH

FGYYFGOIU

HUOHIOI I YUY FYFIGUGL

UGIUGG YGI

HUOFGYUGUO UOOIPP

WARNING

STAY

CLEAR

WARNING

STAYCLEAR

FUNCTION

INTERRUPT

WEDGE

CONTROL

RETURN

SPLIT

0382

MAXIMUM

TOWING SPEED

35 MPH

0192

0344

Figure 5-2. Decal Locations

23

Page 28

24

Page 29

6

Parts List

25

Page 30

1 I-BEAM, CYLINDER, AND FRAME

PARTS LIST

Refer to Table 6-1 for the parts list for the I-beam, cylinder,

and frame.

2

3

23

1

5

11

10

12

15

17

16

18

24

25

19

28

29

30

13

2

3

4

8

13

34

33

9

7

6

20

14

2

31

33

32

16

26

27

21

22

Figure 6-1. I-Beam, Cylinder, and Frame Exploded View.

26

Page 31

Table 6-1. I-Beam, Cylinder, and Frame Parts List

Item

No.

1 0192-0021 Cylinder, Hydraulic 4 in. Bore 1

2 0090-0155 Pin, Cotter, 3/16 x 1-3/4 in. 3

3 0108-0010 Pin, Clevis, 3-1/2 in. (part of 1) 2

4 0108-0165 Wedge 1

5 0090-0991 Screw, Cap, 1/2-13 x 2-3/4 in. 8

6 0108-0197 Plate, Wear, Middle 2

7 0108-0152 Plate, Wear, Bottom 2

8 0090-0159 Nut, Hex, 1/4-20 6

9 0090-0697 Screw, Cap, 1/4-20 x 1 in. 6

10 0090-0212 Washer, Lock, 1/2 in. 8

11 0090-0169 Nut, Hex, 1/2-13 8

12 0068-061 Pin, Snap, 2 in. 3

13 0108-0002 Tube, Stripper 2

14 0108-0136 I-Beam 1

15 0090-0185 Nut, Lock, 5/16-16 2

16 0090-0037 Screw, Cap, 5/16-18 x 2-1/2 in. 1

17 0108-0162 Shock, Tube, Outer 1

18 0192-0060 Shock, Gas, Long 1

19 0108-0158 Shock, Tube, Inner 1

20 0108-0168 Pin, Pivot 1

21 0090-0032 Screw, Cap, 5/16-18 x 1-1/2 in. 1

22 0108-0140 Frame and Axle Weldment 1

23 B30-00-0009 Pad, Boom Support 1

24 0108-0154 Arm Rest, I-Beam 1

25 0090-0162 Nut, Hex, 3/8-16 2

26 0090-0210 Washer, Lock, 3/8 in. 2

27 0090-0053 Screw, Cap, 3/8-16 x 3 in. 2

28 0054-092 Cable, Assembly 1

29 0090-0419 Washer, Flat, 1/4 in. 1

30 0090-0344 Screw, Threadcut, 10-24 x 1/2 in. 1

31 0108-0196 Wear Strip 2

32 0090-0068 Screw, Cap, 1/2-13 x 1-3/4 in 4

33 0090-0574 Washer, Flat, 1/2 in. 8

34 0090-0192 Nut, Lock, 1/2-13 4

Part No. Description Qty

27

Page 32

2 HYDRAULIC TANK AND WHEEL

PARTS LIST

Refer to Table 6-2 for the parts list for the hydraulic tank and

wheels.

8

9

10

11

12

13

14

15

27

18

29

31

15

17

16

20

28

32

1

4

2

3

3

5

6

7

19

17

18

22

21

24

21

26

30

33

23

21

25

34

35

28

Figure 6-2. Hydraulic Tank and Wheel Exploded View

Page 33

Table 6-2. Hydraulic Tank and Wheel Parts List

Item No. Part No. Description Qty

1 0090-0010 Screw, Cap, 1/4-20 x 1-1/2 in. 1

2 0108-0166 Shock, Tube, Inner 1

3 0090-0183 Nut, Lock, 1/4-20 11

4 0192-0061 Shock, Gas, Short 1

5 0090-0033 Screw, Cap, 5/16 x 1-3/4 in. 1

6 0090-0208 Washer, Lock, 5/16 in. 1

7 0090-0160 Nut, Hex, 5/16-18 1

8 0192-0025 Cap, Filler/Breather 1

9 0192-0058 Fitting, Bushing, Hex Reducer 1

10 0108-0163 Panel, Control, Weldment 1

11 0090-0005 Screw, Cap, 1/4-20 x 3/4 in. 10

12 0108-0149 Reservoir, Hydraulic Oil 1

13 0108-0188 Nut, Sight Gauge 1

14 0090-0049 Screw, Cap, 3/8-16 x 2-1/4 in. 2

15 0090-0422 Washer, Flat, 3/8 in. 4

16 0192-0047 Gauge, Sight 1

17 0090-0210 Washer, Lock, 3/8 in. 4

18 0090-0162 Nut, Hex, 3/8-16 4

19 0090-0042 Screw, Cap, 3/8-16 x 1 in. 2

20 0108-0095 Box, Plastic 1

21 0090-0415 Washer, Flat, #10 6

22 0090-0344 Screw, Threadcut, 10-24 x 1/2 in. 2

23 0054-092 Cable Assembly 2

24 0090-0182 Nut, Lock, #10-24 2

25 0090-236 Screw, Machine, #10, 3/4 in. 2

26 0192-0042 Hub, Group (items 27 thru 33) 2

27 B32-00-0009 Seal, Bearing 2

28 B25-00-0056 Bearing, Wheel 4

29 0192-0103 Hub, 5 Hole (w/Bearings, item 28) 2

30 0090-0882 Washer, Spindle 2

31 0090-0881 Pin, Cotter, 5/32 x 2 in. 2

32 0090-0278 Nut, Castle, 1-14 2

33 B32-00-0011 Cap, Hub 2

34 0192-0035 Assembly, Wheel, Tire 2

35 0090-0624 Nut, Lug 10

29

Page 34

3 HYDRAULIC PUMP, LINES, AND

VALVES PARTS LIST

Refer to Table 6-3 for the parts list for the hydraulic pump,

lines, and valves.

2

1

3

1

4

1

5

6

8

7

6

9

13

12

5

14

6

17

19

5

20

21

5

16

18

5

5

11

6

10

1

15

Figure 6-3. Hydraulic Pump, Lines, and Valves

Exploded View

30

Page 35

Item

No.

Table 6-3. Hydraulic Pump, Lines, and Valves Parts List

Part No. Description Qty

1 0192-0174

Fitting, 90° Elbow, 1/2 NPTM-

5

1/2 Bead

2 0192-0064 Hose, Hydraulic, #8 x 59 in. 1

3 0192-0066 Hose, Hydraulic, #8 x 30 in. 1

4 B05-02-0001 Hose, Suction, 3/4 in. 15 in.

5 0108-0092 Clamp, Hose, #20 6

6 0192-0053

Fitting, 90° Elbow, 3/4 NPTM

4

7 0192-0007 Valve, Directional, 3-Position 1

8 0192-0018 Valve, Function Interrupt 1

9 B02-02-0090 Fitting, Hex NIP, 8JICM-8ORN 1

10 0192-0065 Hose, Hydraulic, #8 x 36 in. 1

11 0192-0048 Fitting, Tee 3/4 in. 1

12 B02-02-0007

Fitting, 90° Elbow,

1

8JICM-8ORM

13 B02-02-0094 Fitting, 8ORM-8NPTFM 1

14 0192-0049

Fitting, 90° Elbow, JIC-3/4

1

15 0192-0087 Hose, Hydraulic, #8 x 10 in. 1

16 B05-02-0001 Hose, Suction, 3/4 in. 4 in.

17 0192-0058 Fitting, Bushing, Hex Reducer 1

18 0192-0015 Pump, Hydraulic, 2-Stage 1

19 0192-0092 Hose, Suction, 1 in. 12 in.

20 0192-0059

Fitting, 90° Elbow, Hose Bead

1

21 0082-0756 Strainer, Bushing, 1 x .75 NPT 1

31

Page 36

4 VALVE LINKAGE PARTS LIST

Refer to Table 6-4 for the parts list for the valve linkage.

1

5

4

2

3

10

7

8

9

11

5

6

5

6

12

15

14

13

Figure 6-4. Valve Linkage Exploded View

32

Page 37

Item

No.

Table 6-4. Valve Linkage Parts List

Part No. Description Qty

1 0192-0007 Valve, Directional, 3-Position

(includes items 2-5)

2 0192-0051 Handle, Directional Valve 1

3 0090-0717 Knob, Ball, Black, 1 in. Dia. 1

4 0082-0784 Pin, Clevis, Directional Valve 2

5 0090-0143 Pin, Cotter, 1/16 x 3/4 in. 5

6 0108-0074 Pin, Clevis, Interrupt Valve 3

7 0090-0159 Nut, Hex, 1/4-20 1

8 0108-0070 Adapter, Mount, 1/4-20 1

9 0108-0072 Link, Connecting 1

10 0192-0018 Valve, Function Interrupt 1

11 0108-0075 Pin, Clevis, Pilot Stem 1

12 0108-0174 Handle, Function Interrupt Valve 1

13 0090-0188 Nut, Lock, 3/8 in. 1

14 0090-0162 Nut, Hex, 3/8-16 1

15 0090-0734 Knob, Ball, Black, 2-1/2 in. 1

1

33

Page 38

5 ENGINE AND MOUNTING HARDWARE

PARTS LIST

Refer to Table 6-5 for the parts list for the engine and

mounting hardware.

2

1

3

4

5

5

8

9

6

7

10

12

6

13

14

11

Figure 6-5. Engine and Mounting Hardware

Exploded View

8

15

34

Page 39

Table 6-5. Engine and Mounting Hardware Parts List

Item

No.

Part No. Description Qty

1 0192-0012 Engine, Honda, GX240 1

2 0090-0035 Screw, Cap, 5/16 x 18 x 3 in. 1

3 0090-0420 Washer, Flat, 5/16 in. 1

4 0090-0046 Screw, Cap, 3/8-16 x 1-3/4 in. 3

5 0090-0421 Washer, Flat, 3/8 in. 7

6 0090-0210 Washer, Lock, 3/8 in. 7

7 0090-0162 Nut, Hex, 3/8-16 3

8 0090-0208 Washer, Lock, 5/16 in. 5

9 0090-0160 Nut, Hex, 5/16-18 1

10 0192-0030 Mount, Pump/Engine 1

11 0090-0043 Screw, Cap, 3/8-16 x 1-1/4 in. 4

12 0192-0026 Coupler, Half, AL-095-1 1

13 0192-0028 Coupler, Spider 1

14 0192-0027 Coupler, Half, AL090-1/2 1

15 0090-0032 Screw, Cap, 5/16-18 x 3/4 in. 4

35

Page 40

6 HITCH AND MOUNTING HARDWARE

PARTS LIST

Refer to Table 6-6 for the parts list for the hitch and mounting

hardware.

1

2

3

4

3

2

6

5

6

36

Figure 6-6. Hitch and Mounting Hardware Exploded View

Page 41

Table 6-6. Hitch and Mounting Hardware Parts List

Item

No.

Part No. Description Qty

1 0090-0081 Screw, Cap, 1/2-13 x 5 in. 1

2 0090-0574 Washer, Flat, 1/2 in. 2

3 B03-00-0017 Chain, Safety 2

4 0090-0463 Screw, Cap, 1/2-13 x 4 in. 1

5 0192-0099 Hitch, Ball, 2 in. 1

6 0090-0192 Nut, Lock, 1/2-13 2

37

Page 42

7

Warranty

bil-jax warrants its log splitters for one year from the date of

delivery against all defects of material and workmanship,

provided the unit is operated and maintained in compliance

with bil-jax operating and maintenance instructions. bil-jax

will, at its option, repair or replace any unit or com

which fails to function properly in normal use.

This warranty does not apply if the log splitter and/or its

component parts have been altered, changed, or repaired

without the consent of bil-jax or by anyone other than bil

or its factory trained personnel, nor if the lift and/or its

components have been subjected to misuse, negligence,

ccident or any conditions deem

a

as occurring during normal use.

Components not manufactured by bil-jax are covered by th

respective manufacturers’ warranties. A list of those

ponents and their warranties is available upon written

om

c

request to bil-jax.

bil-jax shall not in any event be liable for the cost of any

special, indirect, or consequential damages to any person

product, or thing. This warranty is in lieu of all other

warranties expressed or implied. We neither assume nor

authorize any representative or other person to assume for us

ny other liabilit

a

his product.

t

y in connection with the sale, rental, or use of

ed other than those considered

ponent part

-jax

eir

,

38

Page 43

39

Page 44

125 Taylor Parkway

Archbold, OH 43502

Phone (419) 445-8915

(800) 537-0540

Fax (419) 445-0367

http://www.

biljax.com

Loading...

Loading...