Page 1

®

Model ET 12000

Operation and Service Manual

The ET 12000 E

level roll-on loading and roll-off unloading of

equipment with

hydraulic lift deck allows one person to load and

unload equipment.

Contents

SAFETY ................................................................. 2

SPECIAL FEATURES .......................................... 2

SPECIFICATIONS ................................................. 3

WARRANTY .......................................................... 3

TRAILER HITCHING ............................................ 4

EQUIPMENT LOADING ....................................... 5

SERVICE ............................................................... 7

PARTS LIST ......................................................... 10

Load Capacity: 12000 lbs

SCALATE

non-tilting lowering deck. The

®

T

RAILER

offers ground

B33-01-0085

Page 2

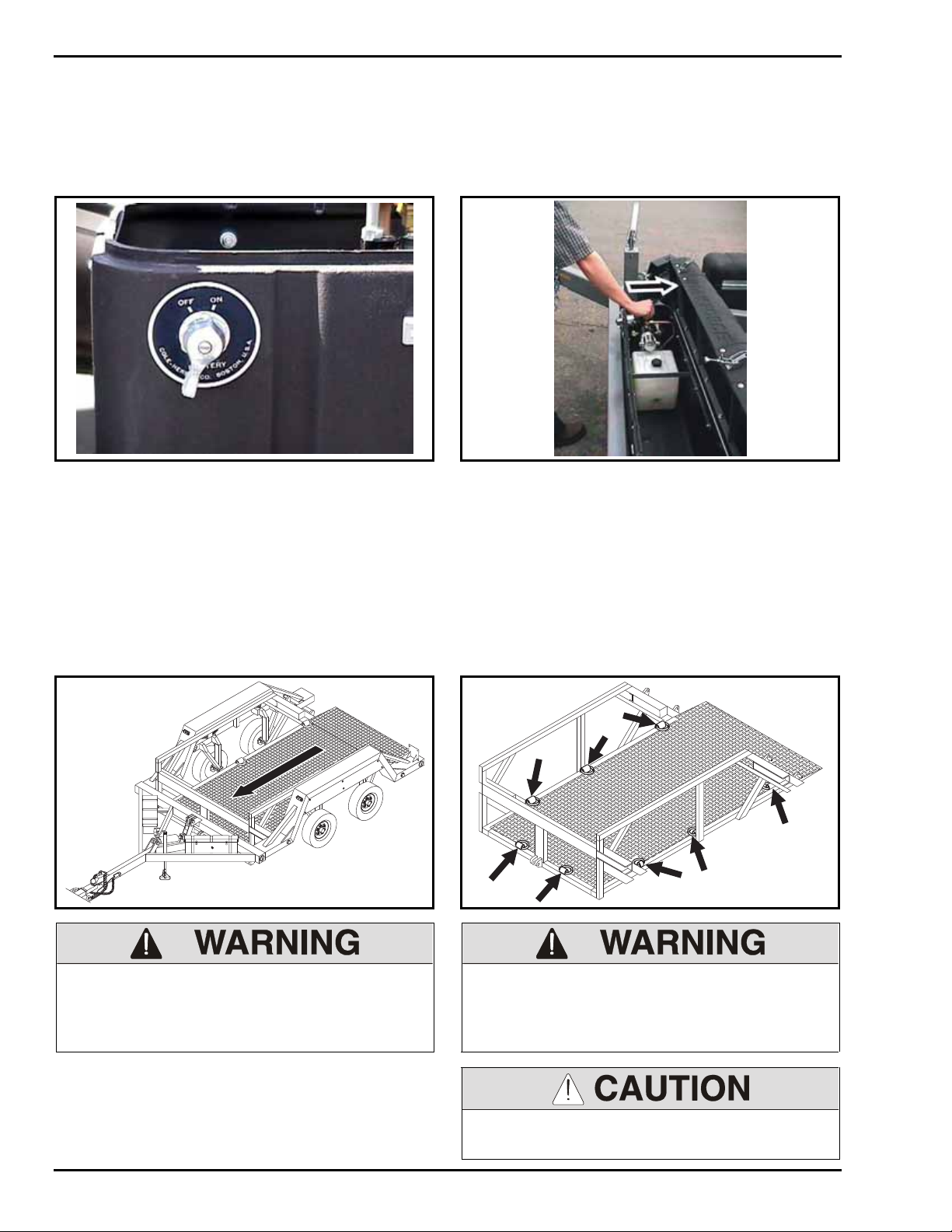

SAFETY

Warnings and Cautions

Observe all warning labels on

the trailer. The trailer warning

labels are shown here as a

reminder. Other warnings and

cautions are included in this

manual.

Failure to observe all warnings

may result in serious injury or

death. Failure to observe all

cautions may result in equipment

damage.

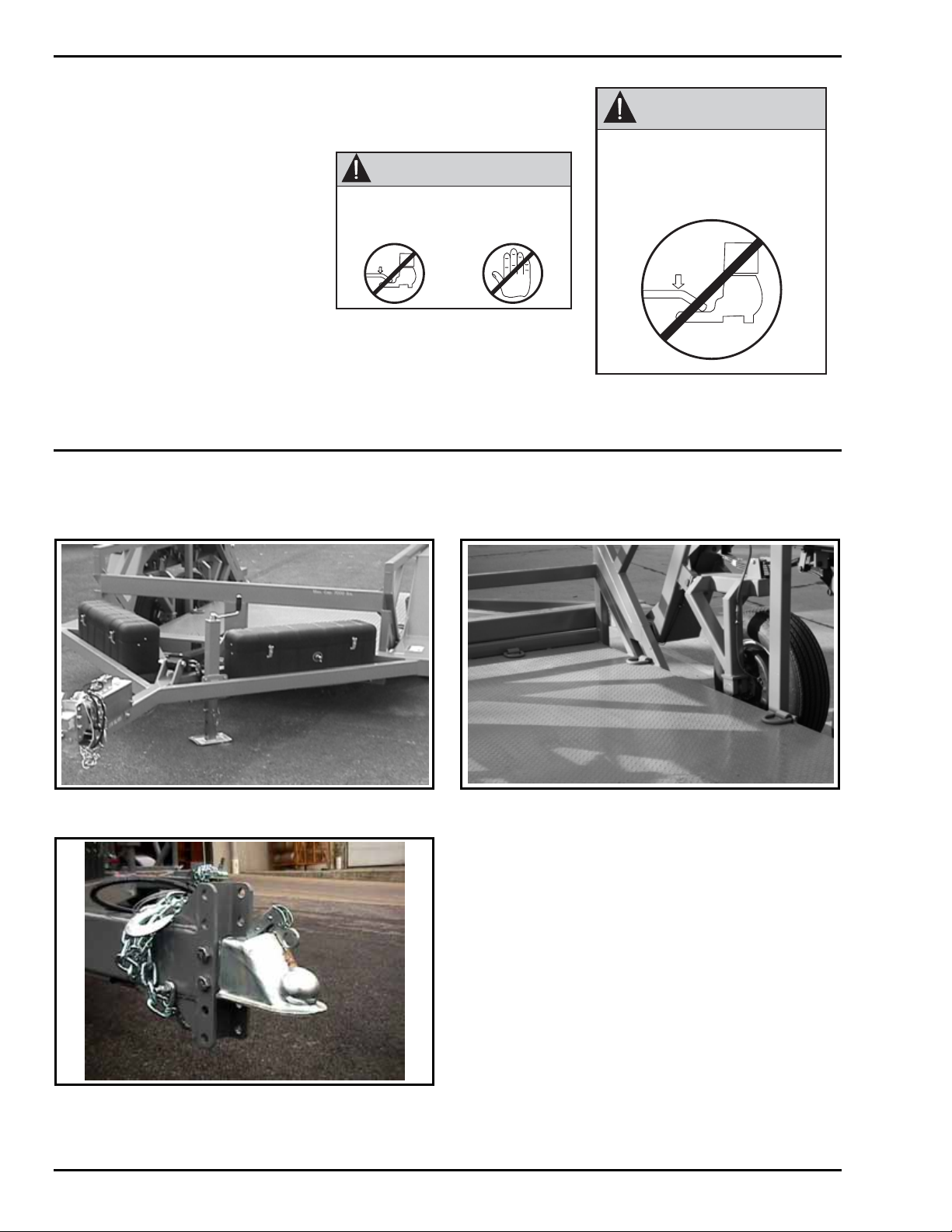

SPECIAL FEATURES

®

The Bil-Jax E

SCALATE

T

RAILER

WARNING

Standclearof trailer while deck

WARNING

Stand clear of trailer while deck is being raised or

lowered.Moving deck will create pinch points

causing serious crushing injury.

includes all the features of a heavy duty trailer, plus:

is being lowered. Contactwith

trailer deck will cause serious

crushing injury.

Escalator Deck and Hydraulic Lift Heavy Duty Tie-Down Brackets

Adjustable Hitch

2

Page 3

SPECIFICATIONS

®

SCALATE

E

Model Number ET 12000 Serial Number ________________

Manufactured by: Bil-Jax, Inc.

Rated Capacity 12000 lbs. (5443 kg) max.

Weight (Empty) 4500 lbs. (2041 kg)

Overall Width 102 in. (259.1 cm)

Overall Length 263 in. (668.0 cm)

Overall Height (Bed Raised) 56 in. (142.2 cm)

Bed Height (Raised) 13 in. (33.0 cm)

Bed Size (Flat Surface) 75 in. wide x 144 in. long

Overall Bed Size

(Including Ramp)

Ramp Grade 6 degrees

Hitch Size 2-5/16 in. (5.87 cm) ball

Suspension Tandem Axle Leaf Spring

Brakes Standard – Electric; Optional – Hydraulic Surge

T

RAILER

125 Taylor Parkway

Archbold, Ohio 43502

800-537-0540

Specifications

(190.5 cm wide x 365.8 cm long)

75 in. wide x 168 in. long

(190.5 cm wide x 426.7 cm long)

WARRANTY

Bil-Jax warrants its trailers for one year from the date of delivery against all defects of material and

workmanship, provided the unit is operated and maintained in compliance with Bil-Jax’s operating and

maintenance instructions; structural components are also warranted for one year. Bil-Jax will, at its

option, repair or replace any unit or component part which fails to function properly in normal use.

This warranty does not apply if the trailer and/or its component parts have been altered, changed, or

repaired without the consent of Bil-Jax or by anyone other than Bil-Jax or its factory trained personnel,

nor if the trailer and/or its components have been subjected to misuse, negligence, accident or any

conditions deemed other than those considered as occurring during normal use.

Components not manufactured by Bil-Jax are covered by their respective manufacturers warranties. A

list of those components and their warranties is available upon written request to Bil-Jax.

Bil-Jax shall not in any event be liable for the cost of any special, indirect or consequential damages to

anyone, product, or thing. This warranty is in lieu of all other warranties expressed or implied. We

neither assume nor authorize any representative, or other person, to assume for us any other liability in

connection with the sale, rental, or use of this product.

3

Page 4

Bil-Jax, Inc.

125 Taylor Parkway

Archbold, Ohio 43502

Reporting Safety Defects

If you believe that your vehicle has a defect which could cause a crash or could cause

injury or death, you should immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying Bil-Jax, Inc.

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a

safety defect exists in a group of vehicles, it may order a recall and remedy campaign.

However, NHTSA cannot become involved in any individual problems between you, your

dealer, or Bil-Jax, Inc.

To contact NHTSA you may either call the Auto Safety Hotline toll-free at 1-800-424-9393

(366-0123 in Washington, DC area) or write to:

NHTSA

U.S. DEPARTMENT of TRANSPORTATION

th

400 7

Washington, DC 20590

You can also obtain other information about motor vehicle safety from the Hotline.

Street SW, (NSA-11)

4

Page 5

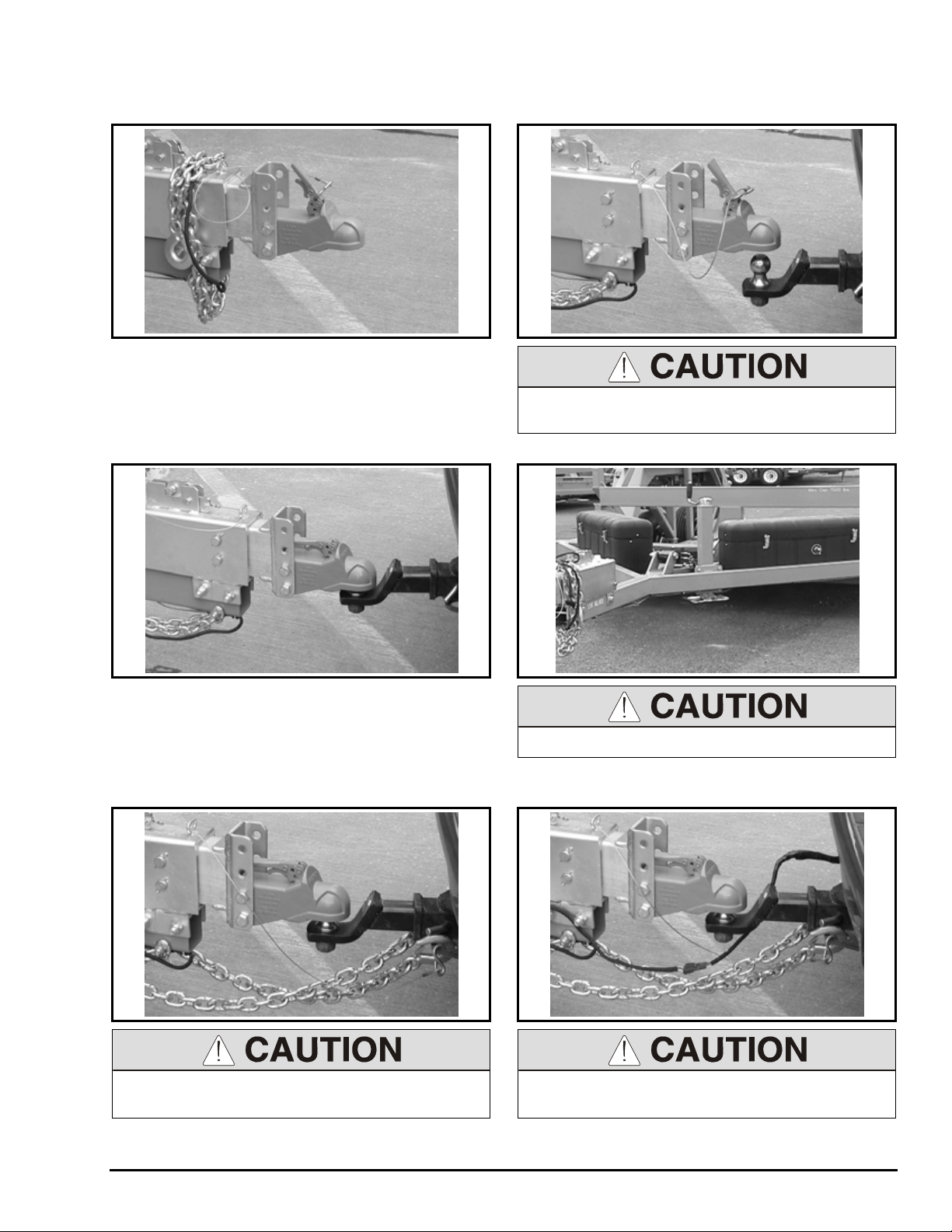

TRAILER HITCHING

Hook Up the Trailer

1. Raise trailer and open ball latch.

2. Line up ball with hitch.

NOTE: The trailer hitch uses a 2-5/16 inch ball.

3. Lower hitch onto ball and close ball latch.

NOTE: Trailer frame should be level when hitch

is on ball. See page 10 to adjust hitch height.

5. Hook safety chains and attach breakaway

cable.

2-5/16 inch ball on tow vehicle must have a

20,000 lb. capacity rating.

4. Raise the jack.

Always raise the jack before towing.

6. Connect and check trailer lights.

Always cross safety chains below tongue.

Safety chains must hold tongue up if hitch fails.

Always check the tail lights and brake lights

before towing.

5

Page 6

EQUIPMENT LOADING

Lower the Deck

NOTE: Trailer must be hitched to vehicle according to page 5 before lowering or raising the deck.

1. Turn power switch to ON position.

NOTE: The trailer should be on a level surface

when lowering the deck.

Load the Equipment

2. Hold control lever in the direction shown until

the deck reaches ground level, then release.

1. Load equipment so that the resulting tongue

weight is 15 to 20% of the total load.

Maximum capacity = 12000 lbs. Do not exceed. Always secure the load with tie-down straps

2. Install tie-down straps to keep the load from

shifting. Use 8 tie-down anchors shown.

before towing. Failure to properly secure the

load may result in injury, death, or equipment

damage.

Do not hook tie-down straps on the roller

guides.

6

Page 7

Raise the Deck (trailer must be hitched to vehicle)

1. Turn power switch to ON position. Hold

control lever in the direction shown. Release

control lever when deck is in fully raised

position.

2. Turn power switch to OFF position.

EQUIPMENT LOADING

Make sure people are away from the trailer

before raising the deck. Keep hands and feet

away from deck and rails. Hands and feet can

get crushed between the deck and frame.

7

Page 8

SERVICE

Tire Maintenance Wheel Torque Requirements

At least once each week, use an accurate tire

pressure gage to check the air pressure in all four

trailer tires. Inflate to the pressure recommended

by the tire manufacturer (located on the tire.

Low or uneven tire pressures will not properly

support a loaded trailer and could lead to

premature tire wear.

When replacing tires, it is important to use a tire

of appropriate size and load rating

(LT215/75R17.5).

Failure to maintain proper torque on the lug nuts

may result in the wheel shearing off of the

trailer, possibly causing an accident and

seriously damaging the equipment.

Lubrication (every 6 months)

It is extremely important to apply and maintain

proper wheel mounting torque on your axle.

Wheel nuts should be retorqued after 50 miles

and 100 miles and periodically there after.

The tightening of the lug nuts should be torqued

in the sequence above.

Lug nuts should be torqued in stages:

Stage 1 Stage 2 Stage 3

75 Ft-Lbs 150 Ft-Lbs 300 Ft-Lbs

This procedure should be followed after each

time the tire is removed.

Lubricate the following parts with clean motor oil or wheel bearing grease

where shown.

Lift Bearings

Hitch

Jack

8

Page 9

SERVICE

Hydraulic Fluid Levels

1. Open cover enclosing hydraulic pump. Check

fluid level in hydraulic reservoir. When trailer

deck is fully raised, hydraulic fluid level should

be approximately 1 inch above 1/2 of reservoir

volume.

2. If reservoir volume is below 1/2 when trailer

deck is fully raised, add enough BP type HLP46 or 10W hydraulic oil to bring fluid level in

reservoir to approximately 1 inch above 1/2

full.

Batteries

1. Use hydrometer to check charge in batteries

daily or weekly, depending on frequency of

use. If the charge drops below 25% of full

charge (S.G. below 1.155 as corrected to

80°F) the batteries must be recharged. Refer

to step 2 before charging batteries.

2. Check the electrolyte level weekly. If battery

charge is low, add water to bring electrolyte

level just above plates.

If batteries are fully charged, add water to

raise electrolyte to full mark in each cell.

3. Charge batteries at one of the following

charge rates. The slow charge rate is

preferred.

22 hours @ 5 amps

25 hours @ 20 amps

22 hours @ 50 amps

9

Page 10

SERVICE

Adjusting the Hitch Height

The trailer frame and deck should be level for equipment loading and unloading. If the trailer hitch is too

high or too low when hitched to the towing vehicle, readjust the hitch height.

1. Unhitch trailer. Remove hitch mounting bolts

and nuts.

Adjust hitch height when trailer is empty. Use

jack to aid in hitch adjustment.

2. Install hitch in new position.

Failure to install and tighten all 4 hitch mounting

bolts may cause serious equipment damage.

10

Page 11

This page intentionally left blank

11

Page 12

PARTS LIST

Model ET 12000 E

Item No. Part No. Description

1 0090-0346 Screw, Self-tapping, #10-24 x 3/4 8

2 B01-10-0179 Side Marker, Amber, Ear Mount – Front 2

2A B01-10-0241 Side Marker, Red, Ear Mount – Rear 2

3 B01-10-0153 Plug Assembly, Marker Lights 2

4 B01-10-0152 Grommet, 2-1/2 inch 2

5 B01-10-0151 Side Light, Amber, 2-1/2 inch 2

6 0090-0344 Screw, Self-tapping, #10-24 x 1/2 2

7 0090-0042 Screw, Cap, 3/8-16 x 1 4

8 0090-0188 Nut, Lock, 3/8-16 4

9 B12-00-0166 Outer Tube Weldment, Jack 1

10 B23-02-0062 Tongue Jack Assembly (includes items 11 through 17) 1

11 B23-02-0066 Drop Leg, Quick Adjust 1

12 B25-00-0068 Kit, Bearing 1

13 B04-06-0030 Washer, 2.18 inch Square 1

14 B46-00-0028 Kit, Handle Replacement (includes items 15 & 16) 1

15 0090-0007 Screw, Cap, 1/4-20 x 1-1/4 1

16 0090-0183 Nut, Lock, 1/4-20 1

17 B36-00-0039 Pin 1

18 B03-00-0017 Safety Chain Assembly 2

19 0090-0081 Bolt, 1/2-13 x 5 1

20 0090-0574 Washer, Flat, 1/2 2

21 0090-0192 Nut, Lock, 1/2-13 1

22 B01-01-0141 Wiring Harness, Electric Brake 1

23 B12-00-0167 Coupler, 2-5/16 inch 1

24 B01-02-0062 Switch, Breakaway 1

25 0090-1001 Bolt, 5/8-11 x 1-3/4 4

26 0090-0194 Nut, Lock, 5/8-11 4

27 0090-0513 Screw, Self-tapping, 1/4-28 x 1/2 1

28 B04-07-0032 Clamp, Hose 13

29 0090-0183 Nut, Lock, 1/4-20 13

30 B06-00-0357 Transfer, 2-5/16 Ball Hitch 1

SCALATE

®

T

RAILER

, Hitch Section

Qty

12

Page 13

PARTS LIST

1

2, 2A

26

23

22

21

20

24

2 5/16” BALL

18

27

20

30

19

25

28

29

10

15

16

14

12

13

11

17

9

8

7

6

3

4

5

Model ET 12000 E

SCALATE

®

T

RAILER

, Hitch Section

13

Page 14

PARTS LIST

Model ET 12000 E

Item No. Part No. Description

1 B02-05-0028 Pump Unit, Hydraulic, Manual Valve 1

2 B02-01-0147 Hose, Hydraulic 2

3 B02-02-0012 Fitting, Hydraulic 2

4 B01-04-0001 Battery, 6 V, 190 Amp 2

5 B01-01-0010 Battery Cable, 13 inch 2

6 B01-01-0067 Battery Cable, 60 inch 1

7 0090-0160 Nut, Hex, 5/16-18 4

8 B01-01-0013 Battery Cable, 30 inch 1

9 B07-06-5882 Strap, Battery Hold Down 2

10 B04-07-0003 Rod, Battery Hold Down, 1/4-20 x 10 4

11 B18-00-0147 Box w/Lid, Battery/Pump 2

12 B42-01-1014 Hinge, Continuous 2

13 0090-0236 Screw, Machine, #10-24 x 3/4 40

14 0090-0415 Washer, Flat, #10 96

15 0090-0182 Nut, Lock, #10-24 48

16 B42-00-0018 Latch, Draw 4

17 0090-0813 Screw, Machine, #8-32 x 3/4 20

18 0090-0181 Nut, Lock, #8-32 20

19 B01-02-0060 Switch, Master Power 1

20 B00-00-0112 Face Plate, Power Switch 1

21 B01-09-0018 Boot, Terminal 2

22 0090-0816 Nut, Hex, 5/16-24 1

23 B42-00-0019 Keeper, Draw Latch 4

24 0054-092 Cable, Lid 4

25 0090-0232 Screw, Machine, #10-24 x 5/8 8

26 0090-0183 Nut, Lock, 1/4-20 4

27 0090-0419 Washer, Flat, 1/4 4

28 0090-0042 Screw, Cap, 3/8-16 x 1 6

29 0090-0210 Washer, Lock, 3/8 2

30 0090-0422 Washer, Flat, 3/8 4

31 0090-0997 Screw, Cap, 1-8 x 9 3

32 0090-0429 Washer, Flat, 1 10

33 0090-0689 Nut, Lock, 1-8 5

34 B12-00-0162 Linkage 1

35 B12-00-0161 Linkage Plate Weldment 1

36 0090-0998 Screw, Cap, 1-8 x 10 1

37 0090-0901 Screw, Cap, 1-8 x 6-1/2 1

38 B02-03-0031 Hydraulic Cylinder 1

38A B02-13-0123 Seal Kit, Hydraulic Cylinder 1

39 B02-02-0084 Fitting, Hydraulic 2

40 0090-0188 Nut, Lock, 3/8-16 2

SCALATE

®

T

RAILER

, Lift Section

Qty

14

Page 15

13

14

15

5

21

18

PARTS LIST

12

17

16

1

2

2

3

6

22

28

19

15

14

11

9

5

4

24

14

10

7

8

25

26

27

33

38, 38A

32

37

30

29

36

33

11

39

2

32

28

32

33

32

35

32

31

33

18

30

40

23

17

20

19

32

32

31

31

32

32

33

34

Model ET 12000 E

SCALATE

®

T

RAILER

, Lift Section

15

Page 16

PARTS LIST

Model ET 12000 E

Item No. Part No.

1 B12-00-0158 Deck Weldment 1

2 B12-00-0163 Bar, Guide 2

3 0090-0428 Washer, Flat, 3/4 8

4 0090-0103 Screw, Cap, 3/4-10 x 2-

5 B31-00-0029 Wear Pad, Guide Bar 2

6 B12-00-0155 Frame Weldment 1

7 0090-0509 Screw, Cap, Nylon, 3/8-

8 B01-10-0235 Tail Light, Oval 2

9 B01-10-0237 Plug, 3 Way, Oval 2

10 B01-10-0236 Grommet, Oval 2

11 B01-10-0153 Plug Assembly, Marker

12 B01-10-0239 Grommet, 2 inch 2

13 B01-10-0238 Side Light, Red, 2 inch 2

14 0090-0344 Screw, #10-24 x 1/2 2

15 B07-07-5029 Block, Suspension Pin 8

16 B07-07-1023 Suspension Pin 4

17 B07-06-5697 Suspension Pin Plate 8

18 0090-0988 Screw, Cap, 5/8-11 x 3-

19 B39-00-0044 Leaf Spring, Slipper 4

20 B12-00-0164 Hanger, Leaf Spring 4

21 B39-00-0045 Hanger Kit, Tandem

22 B07-07-5037 Strap, Leaf Spring 8

23 0090-0058 Screw, Cap, 3/8-16 x 4 16

24 B07-07-5035 Block, Leaf Spring

25 0090-0633 Screw, Cap, 5/8-11 x 1-

26 0090-0422 Washer, Flat, 3/8 16

27 0090-0188 Nut, Lock, 3/8-16 16

28 B12-00-0160 Suspension Arm, Right

29 0090-0195 Nut, Lock, 3/4-10 4

30 0090-0428 Washer, Flat, 3/4 8

31 0090-0999 Screw, Cap, 3/4-10 x 7 4

32 B12-00-0159

Description Qty

1/2

16 x 3/8

Lights

1/2, Grade 8

Slipper Spring

Clamp

1/2

Rear, Left Front

Suspension Arm, Right

Front, Left Rear

SCALATE

®

T

4

8

2

16

2

4

8

2

2

RAILER

, Deck and Frame Section

Item No. Part No. Description Qty

33 0090-1003 Nut, Lock, 1/2-20 16

34 B12-00-0152 Dust Shield 4

35 0090-1002 Screw, Cap, 1/2-20 x 1-

3/4

36 B12-00-0153 Wire Grommet 4

37 B12-00-0148 Electric Brake

Assembly, Left Hand

37A B12-00-0147 Electric Brake

Assembly, Right Hand

38 B12-00-0151 Hub-Drum Assembly 4

39 0090-0994 Washer, Spindle 4

40 0090-0993 Nut, Lock, 1-14 4

41 B06-00-0446 Decal, Torque Setting 4

42 B12-00-0154 Cap, Grease 4

43 B08-02-0016 Wheel Assembly,

LT215/75R17.5

44 0090-0995 Nut, Wheel Lug 32

45 B30-00-0051 Plate, Wear 2

46 0090-0422 Washer, Flat, 3/8 8

47 0090-0042 Screw, Cap, 3/8-16 x 1 8

48 B12-00-0121 Roller, Lift 4

49 0090-0954 Screw, Cap, 1-8 x 11 4

50 B04-07-0117 Shaft, Cam Follower 4

51 0090-0949 Screw, Nylon, 1-8 x 1/2 4

52 B07-05-0115 Fender 2

53 0090-0013 Screw, Cap, 1/4-20 x 2-

1/4

54 0090-0419 Washer, Flat, 1/4 16

55 0090-0183 Nut, Lock, 1/4-20 8

56

57 B06-00-0447 Transfer, 12000# Max. 1

58 Not

59 B06-00-0312 Decal, “Moving Deck…” 2

60 B06-00-0448 Transfer, “ET 12000” 2

61 B06-00-0317 Decal, Escalate Trailer

62 B06-00-0313 Decal, “Stand Clear…” 2

Ref. B01-10-0240 Bracket, License Plate,

B06-00-0161Y

Replaceable

Transfer, Bil-Jax 2

Plate, Serial # 1

Logo

with Lamp

16

2

2

4

8

2

16

Page 17

PARTS LIST

1

2

3

4

5

49

58

57

48

50

51

59

47

46

60

45

52

19

31

30

26

22

32

7

23

20

56

27

21

30

24

25

31

6

21

22

26

30

33

36

55

16

29

34

37, 37A

23

54

20

28

30

18

25

27

53

21

17

19

15

29

35

62

14

61

8

10

9

11

12

13

43

44

40

39

41

38

42

Model ET 12000 E

SCALATE

®

T

RAILER

, Deck and Frame Section

17

Page 18

PARTS LIST

B02-05-0028 Hydraulic Pump Assembly

Item No. Part No. Description Qty

1 B02-15-0398 Motor, DC - 12V 1

2 B02-15-0399 Pump Assembly 1

3 B02-15-0400 Tank, Plastic 1

4 B02-15-0401 Tube, Interior Return 1

5 B02-15-0402 Tube, Relief Valve Return 1

6 B02-15-0403 Tube, Suction 1

7 B02-15-0404 Filter, Suction 1

8 0090-0975 Bolt, Socket Head, 1/4-20 x 3 4

9 B02-15-0405 Valve Assembly (includes items 10 & 11) 1

10 B02-15-0406 Switch Assembly Cam (includes item 11) 1

11 B02-15-0407 Contact, Start Switch 1

12 B02-15-0408 Elbow, 90 Degree, 3/8 Tube x 1/4 NPT 1

13 B02-15-0409 Adapter, Pump/Valve, 2-1/2 Long 1

14 B02-15-0410 Valve, Check 1

15 B02-15-0411 Handle Assembly 1

16 B02-15-0412 Clamp 1

17 B02-15-0413 Tube, Exterior Return 1

18 B02-15-0414 Connector Assembly 1

19 B02-15-0415 Valve, Relief 1

20 B02-15-0416 Bracket, Plate Mount, 3-1/4 Hole Spacing 1

21 0090-0976 Bolt, Socket Head, 3/8-16 x 1 2

22 B01-01-0010 Cable, 2GA x 13, Eyelet Ends 1

23 B02-15-0417 Base Assembly 1

24 B02-15-0418 Cap, Fill 1

18

Page 19

15

PARTS LIST

23

1

22

R

A

N

C

O

H

M

H

Y

C

D

I

L

R

A

U

24

S

17

18

16

19

20

"A" PORT

21

3 1/4"

6 15/16"

12

13

14

9 1/16"

3/4"

16 3/8”

B02-05-0028 Hydraulic Pump Assembly

"B" PORT

9

10

9 1/4”

11

5

4

2

6

7

3

8

19

Page 20

125 Taylor Parkway Archbold, OH 43502

Phone 800-537-0540 Fax 419-445-0367

Loading...

Loading...