Page 1

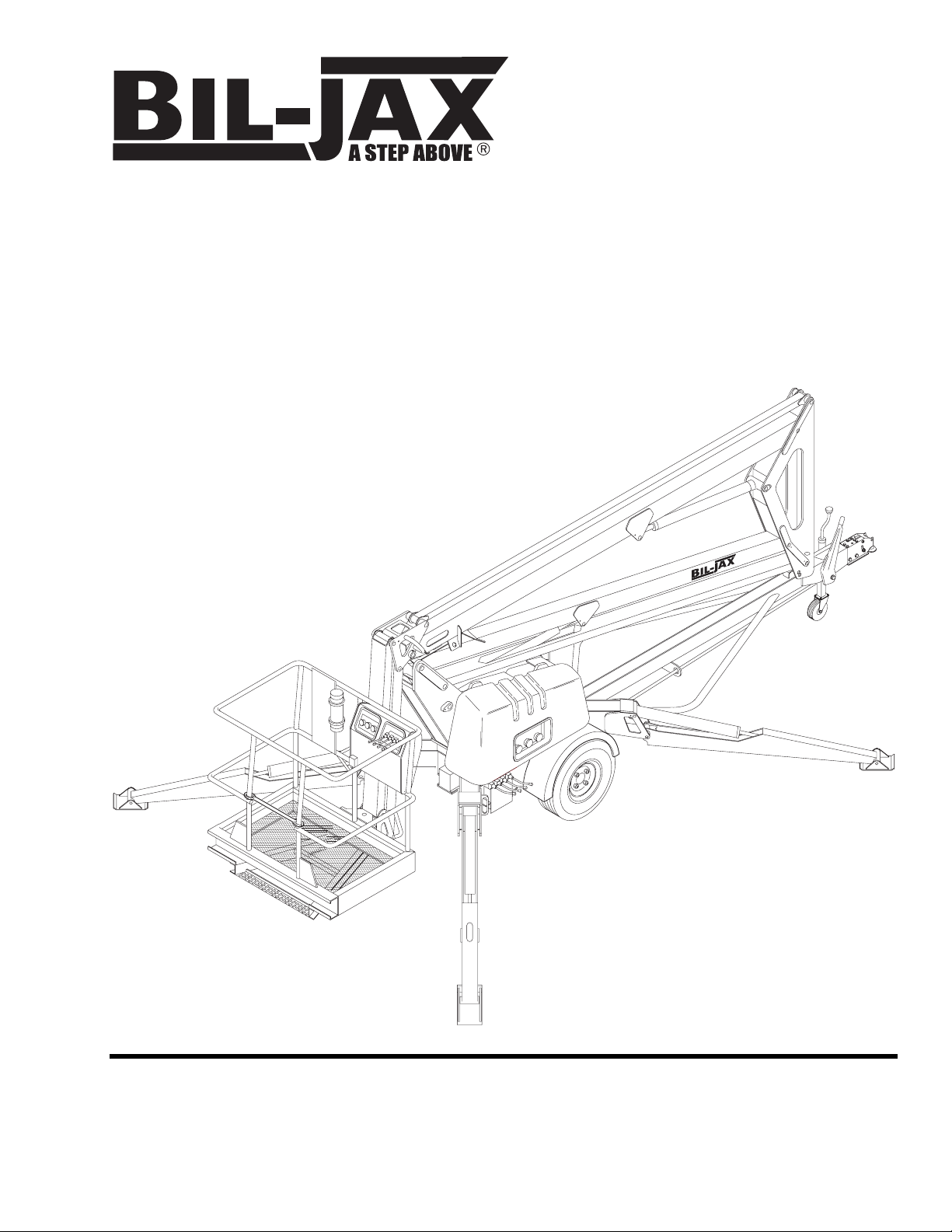

AERIAL WORK PLATFORMS

XLB-4319

Hydraulic Boom Lift

Operation and

Maintenance Manual

B33-01-0080

XLB-4319

Page 2

BOOM PERSONNEL LIFT

This equipment is designed and manufactured in compliance with the duties, responsibilities, and standards set forth for manufacturers in the ANSI 92.2 standard

in effect at the time of manufacture.

This equipment will meet or exceed applicable OSHA codes and ANSI A92.2 standards when used in accordance with sections 7, 8, 9, 10 & 11 of ANSI A92.2 and all

other manufacturer’s recommendations.

It is the responsibility of the user of this equipment to follow all applicable ANSI,

OSHA, Federal, State, and local codes and regulations that govern the safe operation of this equipment.

Page 3

Table of Contents

Preface................................................................................................................ v

1 Safety................................................................................................................1-1

1-1 Introduction.........................................................................................1-1

1-2 Before Operation ................................................................................1-2

1-3 During Operation................................................................................1-3

1-4 Maintenance Safety.............................................................................1-5

General Maintenance......................................................................1-5

Battery Maintenance.......................................................................1-6

1-5 Damaged Equipment Policy ...............................................................1-6

Safety Statement.............................................................................1-6

Damage Policy................................................................................1-6

Damage Repair Notice....................................................................1-6

Reporting Safety Defects................................................................1-7

2 Introduction.....................................................................................................2-1

2-1 General Description............................................................................2-1

2-2 Specifications......................................................................................2-4

Boom Lift Work Platform..............................................................2-4

2-3 Warranty.............................................................................................2-5

3 Operation.........................................................................................................3-1

3-1 Operator Controls ...............................................................................3-1

Ground Control Station.......................................................................3-1

Basket Control Station....................................................................3-4

3-2 Normal Operating Procedure..............................................................3-6

3-3 Emergency Lowering..........................................................................3-8

3-4 Manual Boom Rotation.......................................................................3-9

3-5 Battery Recharge (DC MODEL ONLY)..........................................3-10

3-6 Boom Lift Transport.........................................................................3-11

Trailer Hitching............................................................................3-11

4 Maintenance ....................................................................................................4-1

4-1 Scheduled Service Checks..................................................................4-1

Daily/Weekly Service Checks........................................................4-1

Monthly Service Checks.................................................................4-2

4-2 Wheel Nut Torque Requirements .......................................................4-3

4-3 Lubrication..........................................................................................4-4

4-4 Hydraulic System................................................................................4-5

Hydraulic System Inspection..........................................................4-5

Fluid Check and Replacement........................................................4-5

Return Filter Replacement..............................................................4-6

Air Bleeding ...................................................................................4-6

Hydraulic Pressure Checks and Adjustments.................................4-7

Hydraulic Cylinder Replacement .................................................4-10

4-5 SLEW RING BEARING..................................................................4-17

Check Free Play............................................................................4-17

4-6 Limit Switch checks and adjustments...............................................4-18

Adjusting Boom Down Limit Switch...........................................4-18

Adjusting Outrigger Position Switches ........................................4-19

4-7 Troubleshooting................................................................................4-20

Troubleshooting Aids...................................................................4-22

4-8 Material Safety Data Sheets..............................................................4-31

i

Page 4

5 Replacement Decals........................................................................................ 5-1

6 Parts List......................................................................................................... 6-1

6-1 Upper Boom Parts List....................................................................... 6-2

6-2 Lower Boom Parts List...................................................................... 6-4

6-3 Jib Boom Parts List............................................................................ 6-6

6-4 Compartment Covers Parts List......................................................... 6-8

6-5 Reservoir Compartment Parts List, Gas model................................ 6-10

6-6 Pump Compartment Parts List, DC Model ...................................... 6-12

6-7 Chassis and Rotation Unit Parts List................................................ 6-16

6-8 Hitch and Jack Assembly Parts List................................................. 6-18

6-9 Axle and Wheel Assembly Parts List.............................................. 6-20

6-10 Rear Lights and Junction Box Parts List.......................................... 6-23

6-11 Outriggers Parts List ........................................................................ 6-25

6-12 Basket Parts List............................................................................... 6-27

6-13 Outrigger Hydraulic Controls Parts List .......................................... 6-29

6-14 Lower Controls Parts List ................................................................ 6-31

6-15 Upper Controls Parts List................................................................. 6-33

6-16 Engine Compartment Parts List, Gas Model.................................... 6-35

6-17 Boom Control Hydraulics Parts List, Basket................................... 6-39

6-18 Boom Control Hydraulics Parts List, Ground, Gas Model.............. 6-41

6-19 Boom Control Hydraulics Parts List, Ground, DC Model............... 6-43

6-20 Lower Boom Cylinder Hydraulics Parts List................................... 6-45

6-21 Upper Boom Cylinder Hydraulics Parts List ................................... 6-46

6-22 Pushbutton Panel Parts List, Basket................................................. 6-47

6-23 Pushbutton Panel Parts List, Ground Controls................................. 6-49

7 ANSI Reprint.................................................................................................. 7-1

ii

Page 5

List of Illustrations

Figure 2-1. XLB-4319 Hydraulic Boom Lift.............................................................2-1

Figure 2-2. Basket and Ground Station Controls.......................................................2-2

Figure 2-3. Safe Operating Zone ...............................................................................2-3

Figure 3-1. Ground Control Station Access...............................................................3-1

Figure 3-2. Ground Control Station...........................................................................3-2

Figure 3-3. Engine Keyswitch ...................................................................................3-3

Figure 3-4. Basket Control Station ............................................................................3-4

Figure 3-5. Outrigger Controls ..................................................................................3-6

Figure 3-6. Manual Lowering Valve .........................................................................3-8

Figure 3-7. Basket Control Station ............................................................................3-8

Figure 3-8. Emergency Rotation................................................................................3-9

Figure 3-9. Battery Charger .....................................................................................3-10

Figure 3-10. Trailer Hitching .....................................................................................3-11

Figure 4-1. Wheel Bolt Tightening Sequence............................................................4-3

Figure 4-2. Lubricate Monthly...................................................................................4-4

Figure 4-3. Lubricate Semi-Annually........................................................................4-4

Figure 4-4. Hydraulic Reservoir ................................................................................4-5

Figure 4-5. Main Bypass Valve and Pressu re Test Port (Gas Engine Model)...........4-7

Figure 4-6. Outriggers Bypass Valve ........................................................................4-8

Figure 4-7. Boom Control Bypass Valve, Basket Station..........................................4-9

Figure 4-8. Hydraulic Cylinder Removal ................................................................4-11

Figure 4-9. Jib Boom Components..........................................................................4-14

Figure 4-10. Basket Swivel Cylinder.........................................................................4-16

Figure 4-11. Slew Ring Position Measurement.........................................................4-17

Figure 4-12. Boom Down Limit Switch....................................................................4-18

Figure 4-13. Outrigger Position Switch.....................................................................4-19

Figure 4-14. Simplified Electrical Diagram, DC Model............................................4-22

Figure 4-15. Detailed Electrical Diagram, DC Model...............................................4-23

Figure 4-16. Simplified Electrical Diagram, Gas Model...........................................4-24

Figure 4-17. Detailed Electrical Diagram, Gas Model ..............................................4-25

Figure 4-18. Hydraulic Diagram, DC Model.............................................................4-26

Figure 4-19. Hydraulic Diagram, Gas Model............................................................4-28

Figure 4-20. Level Sensor..........................................................................................4-30

Figure 5-1. Replacement Decals................................................................................5-2

Figure 5-2. Decal Locations, Trailer and Boom ........................................................5-5

Figure 5-3. Decal Locations, Control Compartment Exterior....................................5-6

Figure 5-4. Lubri cate Monthly Decal ........................................................................5-6

Figure 5-5. Lubricate Semi-Annually Decal..............................................................5-6

Figure 6-1. Upper Boom............................................................................................6-2

Figure 6-2. Lower Boom ...........................................................................................6-4

Figure 6-3. Jib Boom .................................................................................................6-6

Figure 6-4. Compartment Covers ..............................................................................6-8

Figure 6-5. Reservoir Compartment, Gas Model....................................................6-10

Figure 6-6. Pump Compartment, DC Model............................................................6-12

Figure 6-7. Chassis and Rotation Unit.....................................................................6-16

Figure 6-8. Hitch and Jack Assembly......................................................................6-18

Figure 6-9. Axle and Wheel Assembly....................................................................6-20

Figure 6-10. Rear Lights and Junction Box...............................................................6-23

iii

Page 6

Figure 6-11. Outriggers............................................................................................. 6-25

Figure 6-12. Basket................................................................................................... 6-27

Figure 6-13. Outrigger Hydraulic Controls............................................................... 6-29

Figure 6-14. Lower Controls..................................................................................... 6-31

Figure 6-15. Upper Controls..................................................................................... 6-33

Figure 6-16. Engine Compartment Parts List, Gas Model........................................ 6-35

Figure 6-17. Boom Control Hydraulics, Basket........................................................ 6-39

Figure 6-18. Gas Model Boom Control Hydraulics, Ground.................................... 6-41

Figure 6-19. DC Model Boom Control Hydraulics, Ground .................................... 6-43

Figure 6-20. Lower Boom Cylinder Hydraulics ....................................................... 6-45

Figure 6-21. Upper Boom Cylinder Hydraulics........................................................ 6-46

Figure 6-22. Basket Pushbutton Panel, Gas Model................................................... 6-47

Figure 6-23. Pushbutton Panel, Ground Controls..................................................... 6-49

List of Tables

Table 1-1. Minimum Safe Approach Distances....................................................... 1-3

Table 2-1. Specifications ......................................................................................... 2-4

Table 4-1. Daily/Weekly Service Checks................................................................ 4-1

Table 4-2. Monthly Service Checks ........................................................................ 4-2

Table 4-3. Troubleshooting Chart.......................................................................... 4-20

Table 4-4. Level Sensor LEDs............................................................................... 4-30

Table 5-1. Replacement Decals............................................................................... 5-1

Table 6-1. Upper Boom Parts List........................................................................... 6-3

Table 6-2. Lower Boom Parts List........................................................................... 6-5

Table 6-3. Jib Boom Parts List ................................................................................ 6-7

Table 6-4. Compartment Covers Parts List.............................................................. 6-9

Table 6-5. Reservoir Compartment Parts List, Gas Model.................................... 6-11

Table 6-6. Pump Compartment Parts List, DC Model........................................... 6-13

Table 6-7. Chassis and Rotation Unit Parts List.................................................... 6-17

Table 6-8. Hitch and Jack Assembly Parts List..................................................... 6-19

Table 6-9. Axle and Wheel Assembly Parts List................................................... 6-21

Table 6-10. Rear Lights and Junction Box Parts List.............................................. 6-24

Table 6-11. Outriggers Parts List............................................................................. 6-26

Table 6-12. Basket Parts List................................................................................... 6-28

Table 6-13. Outrigger Hydraulic Controls Parts List............................................... 6-30

Table 6-14. Lower Controls Parts List..................................................................... 6-32

Table 6-15. Upper Controls Parts List..................................................................... 6-34

Table 6-16. Engine Compartment Parts List, Gas Model........................................ 6-36

Table 6-17. Boom Control Hydraulics Parts List, Basket........................................ 6-40

Table 6-18. Gas Model Boom Control Hydraulics Parts List, Ground.................... 6-42

Table 6-19. DC Model Boom Control Hydraulics Parts List, Ground.................... 6-44

Table 6-20. Lower Boom Cylinder Hydraulics Parts List....................................... 6-45

Table 6-21. Upper Boom Cylinder Hydraulics Parts List........................................ 6-46

Table 6-22. Basket Pushbutton Panel Parts List...................................................... 6-48

Table 6-23. Pushbutton Panel Parts List, Ground Controls..................................... 6-49

Table 7-1. Minimum Safe Approach Distance (M.S.A.D.)

to energized (exposed or insulated) power lines and parts........................................... 7-11

iv

Page 7

PREFACE

The purpose of this manual is to provide a thorough understanding of the XLB-4319

Hydraulic Boom Lift operation and controls. Read the safety and operating instructions

in this manual and become familiar with the location and use of all controls.

Follow all warnings, cautions, and instructions in this manual and any attached to and

supplied with the boom lift. All OSHA, ANSI, state, and local codes and regulations

concerning this equipment should obtained, read, and thoroughly understood before

attempting to operate this equipment.

To ensure proper and safe use of this equipment, only trained and qualified personnel

should operate and maintain the boom lift.

SAFETY NOTES

This manual contains DANGERS, WARNINGS, CAUTIONS, and NOTES that must be

followed to prevent the possibility of improper service, personnel injury or death, and

damage to equipment.

DANGER

Dangers warn of equipment operation near electrical power lines that could lead to

personal injury or death.

WARNING

Warnings describe conditions or practices that could lead to personal injury or

death.

CAUTION

Cautions provide information important to prevent errors that could damage

machine or components.

NOTE: Notes contain additional information important to a procedure.

v

Page 8

vi

Page 9

1

Safety

1-1

INTRODUCTION

Familiarity and proper training are required for the safe operation of mechanical equ

ment. Equipment operated improperly or by untrained personnel can be dangerous. Read

the operating instructions in this manual and become familiar with the location and

proper use of all controls. Inexperienced operators should receive instruction from so

one familiar with the equipment before being allowed to operate the machine. The use of

intelligence and common

practice in any safety policy. Be professional and always observe the safety procedure

set forth in this manual.

All OSHA, ANSI, state, and local codes and regulations pertaining to this equipment

should be obtained, read, and thoroughly understood before attempting to operate this

equipment. Persons under the influence of drugs, alcohol, or prescription medication

should not be on or near this equipment. Common sense should be

times during the use of this equipment. Do not operate this equipment in areas where the

equipment or user may come in contact with a live power source.

The information contained herein is not to be

for informational purposes only. This information is offered to alert Bil-Jax customers

procedures that may be of concern to them.

This information is not intended to be all inclusive and is to b e followed in the use of

Bil-Jax equipment only.

For any questions concerning the safe use of this equipment, call 800-937-0540 before

operating.

sense in the operation of mechanical equipment is the best

implemented at all

considered as legal advice and is intended

ip-

me-

s

to

1-1

Page 10

XLB-4319

1-2 BEFORE OPERATION

Ensure the following general safety precautions are followed before operating the

XLB-4319 Hydraulic Boom Lift.

• ALWAYS survey the usage area for potential hazards such as untamped earth

fills, unlevel surfaces, overhead obstructions, and electrically charged conductors or wires. Be aware of any potential hazards and always consider what could

happen. Watch for moving vehicles in the operating area.

• ALWAYS read, understand, and follow the procedures in this manual before attempting to operate equipment.

• ALWAYS inspect the equipment for damaged or worn parts. Check for cracked

welds, hydraulic leaks, damaged wiring, loose wire connectors, damaged outriggers, low tire pressure, uneven tire wear, or tire damage. Also check for any

improper operation. NEVER operate equipment if damaged in any way. Improperly operating equipment must be repaired before using.

• ALWAYS wear proper clothing for the job. Wear protective equipment as required by federal, state, or local regulations. The operator MUST wear a safety

harness and lanyard.

• ALWAYS locate, read, and follow all directions and warnings displayed on the

equipment.

• ALWAYS inspect the equipment for “DO NOT USE” tags. NEVER use equipment tagged in this way until all repairs are made and all “DO NOT USE” tags

are removed by authorized maintenance personnel.

• ALWAYS make sure the basket and outrigger shoes are free of mud, grease, or

other slippery material to reduce the possibility of slipping.

• NEVER allow improperly trained personnel to operate this equipment. Only

trained and authorized personnel shall be allowed to operate this equipment.

• NEVER operate this equipment if you are under the influence of alcohol or

drugs, or if you feel ill, dizzy, or unsteady in any way. Operators must be physically fit, thoroughly trained, and not easily excitable.

• NEVER modify, alter, or change the equipment in any way that would affect its

original design or operation in any way.

• NEVER operate this equipment in ways for which it is not intended.

1-2

Page 11

1 — SAFETY

1-3 DURING OPERATION

Ensure the following general safety precautions are followed during the operation of the

XLB-4319 Hydraulic Boom Lift.

DANGER

This machine is not insulated for use near electrical power lines and DOES NOT

provide protection from contact with or close proximity to any electrically

charged conductor. Operator must maintain safe clearances at all times (10 feet

minimum) and always allow for platform movement such as wind induced sway.

Always contact the power company before performing work near power lines. Assume every line is hot. Remember, power lines can be blown by the wind.

Refer to Table 1-1 for minimum safe approach distances between machine and electrical

power lines.

Table 1-1. Minimum Safe Approach Distances

Voltage Range

(Phase to Phase)

0 to 300V Avoid Contact

Over 300V to 50KV 10 3.05

Over 50KV to 200KV 15 4.60

Over 200KV to 350KV 20 6.10

Over 350KV to 500KV 25 7.62

Over 500KV to 750KV 35 10.67

Over 750KV to 1000KV 45 13.72

Minimum Safe Approach Distance

(Feet) (Meters)

• ALWAYS position lift far enough away from power sources to ensure that no

part of the lift can accidentally reach into an unsafe area. This includes full extension of the boom through 360 degrees rotation.

• ALWAYS operate only on a firm and level surface. NEVER use on surfaces

that do not support the equipment with its rated load capacity and the resulting

force exerted on the outriggers during boom extension and rotation.

• ALWAYS keep yourself and all personnel away from potential pinch or shear

points.

• ALWAYS report any misuse of equipment to the proper authorities. Horseplay

is prohibited.

• ALWAYS maintain good footing on the work platform. NEVER wear slippery

soled shoes.

• ALWAYS make certain all personnel are clear and there are no obstructions before repositioning basket.

• ALWAYS cordon off area around the outriggers to keep personnel and other

equipment away from it while in use.

• ALWAYS stay clear of wires, cables, and other overhead obstructions.

• ALWAYS engage the boom travel locking pins before towing the trailer.

1-3

Page 12

XLB-4319

• NEVER allow electrode contact with any part of the basket if welding is being

performed from the platform.

• NEVER use without the outriggers fully extended and firmly based.

• NEVER override or by-pass manufacturer's safety devices.

• NEVER attach a safety harness to an adjacent structure, pole, or equipment

while working from the boom platform.

• NEVER move unit with a person or materials on board.

• NEVER try to move the trailer with the boom extended.

• NEVER stand or sit on cage bars. Work only within the work cage and do not

lean out over the cage to perform work.

• NEVER attempt to increase working height with boxes, ladders, or other means.

• NEVER operate this equipment when exposed to high winds, thunderstorms,

ice, or any other weather conditions that would compromise operator safety.

• NEVER allow ropes, electric cords, hoses, etc. to become entangled in the

equipment when the basket is being raised or lowered.

• NEVER exceed manufacturer's load limits or use the lift as a crane for lifting

heavy materials. Make sure all tools and equipment are safely stowed.

• NEVER exceed load ratings by transferring loads to the basket at elevated

heights.

• NEVER use cage to carry materials and never allow overhang of materials when

raising or lowering the basket.

• NEVER push or pull with the boom or basket and NEVER use the boom to lift

any part of the trailer.

• NEVER use the boom or basket to place a “dead man” load against any structure, materials, or equipment.

• NEVER climb up or down boom.

• NEVER leave the keys in the boom lift while unattended or not in use.

1-4

Page 13

1 — SAFETY

1-4 MAINTENANCE SAFETY

Ensure the following safety precautions are observed whenever maintenance is performed on the XLB-4319 Hydraulic Boom Lift.

General Maintenance

• ALWAYS perform maintenance procedures according to manufacturer's requirements. NEVER short change maintenance procedures.

• ALWAYS check hydraulic system. Make sure all lines, connectors, and fittings

are tight and in good condition.

• ALWAYS turn the key switch off before connecting or disconnecting wiring to

or from valve solenoids or other load devices.

• ALWAYS disconnect power to the hydraulic pump drive motor before making

electrical checks of the hydraulic valves.

• ALWAYS keep all mechanisms properly adjusted and lubricated according to

maintenance schedule and manufacturer’s specifications.

• ALWAYS perform a function check of operating controls before each use and

after repairs have been made.

• ALWAYS locate and protect against possible pinch points prior to performing

maintenance and repairs.

• ALWAYS use factory-approved parts to repair or maintain this equipment. If

this equipment is rebuilt, retesting is required in accordance with factory

instructions.

• NEVER allow water or foreign particles into the DC electric motor housing. Ingestion of water or foreign particles may cause serious damage to the motor. If

the motor gets wet, oven dry the motor to remove all moisture before operating;

consult motor manufacturer for drying instructions.

• NEVER test or operate the hydraulic components when another person is near

the equipment.

• NEVER add unauthorized fluids to the hydraulic system or battery. Check original manufacturer specifications.

• NEVER exceed the manufacturer's recommended relief valve settings.

• NEVER touch or allow metal tools to contact static discharge sensitive elec-

tronic components. ALWAYS use static discharge prevention mats and grounding devices when handling electronic components.

• NEVER tamper with cylinder counter balance valves. Contact the Bil-Jax Service Department at 800-537-0540 if the cylinder counter balance valves need

adjusting.

• NEVER attempt repairs you do not understand. Consult manufacturer if you

have any questions regarding proper maintenance, specifications, or repair.

1-5

Page 14

XLB-4319

Battery Maintenance

Ensure the following general safety precautions are followed whenever performing battery maintenance on the XLB-4319 Hydraulic Boom Lift.

• ALWAYS check battery acid level daily on the DC model boom lift. Check

battery test indicator for proper state of charge on maintenance free batteries

before using lift.

• ALWAYS wear safety glasses when working near battery.

• ALWAYS avoid contact with battery acid. Battery acid causes serious burns.

Avoid contact with skin or eyes. If accidental contact occurs, flush with water

and consult a physician immediately.

• ALWAYS disconnect ground cable first when removing battery.

• ALWAYS connect ground cable last when installing battery.

• ALWAYS charge batteries in open, well-ventilated areas.

• NEVER smoke when servicing battery.

• NEVER allow batteries to overcharge and boil.

• NEVER short across battery posts to check for current. NEVER break a live

circuit at battery.

• NEVER jump start other vehicles using boom lift battery.

1-5 DAMAGED EQUIPMENT POLICY

Safety Statement

At Bil-Jax, we are dedicated to the safety of all users of our products. Therefore, all

Bil-Jax lifts are designed, manufactured and tested to comply with current applicable

Federal OSHA and ANSI codes and regulations.

Damage Policy

There may be occasions when a Bil-Jax lift is involved in an incident that results in structural damage to the lift. This can seriously compromise the ability of the lift to perform in

a safe manner. Therefore, whenever a Bil-Jax lift is damaged structurally or when there is

the possibility of structural damage (this damage may be internal and is not always visible to the naked eye), Bil-Jax requires that the lift be returned to our facility at 125 Taylor Parkway, Archbold, Ohio, for reconditioning. If you have any questions concerning

what constitutes structural damage, please call the Bil-Jax Service Department at

800-537-0540.

Damage Repair Notice

There may be occasions when a Bil-Jax lift is involved in an incident resulting in nonstructural damage. When this occurs and repairs are made by the owner or area distributor, please notify Bil-Jax of these non-maintenance repairs and request a repair form to

be filled out and returned to Bil-Jax.

1-6

Page 15

1 — SAFETY

Bil-Jax, Inc.

125 Taylor Parkway

Archbold, Ohio 43502

Reporting Safety Defects

If you believe that your vehicle has a defect which could cause a crash or could cause injury or

death, you should immediately inform the National Highway Traffic Safety Administration

(NHTSA) in addition to notifying Bil-Jax, Inc.

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a safety

defect exists in a group of vehicles, it may order a recall and remedy campaign. However,

NHTSA cannot become involved in any individual problems between you, your dealer, or

Bil-Jax, Inc.

To contact NHTSA you may either call the Auto Safety Hotline toll-free at 1-800-424-9393

(366-0123 in Washington, DC area) or write to:

NHTSA

U.S. DEPARTMENT of TRANSPORTATION

th

Street SW, (NSA-11)

400 7

Washington, DC 20590

You can also obtain other information about motor vehicle safety from the Hotline.

1-7

Page 16

XLB-4319

1-8

Page 17

2

Introduction

2-1

GENERAL DESCRIPTION

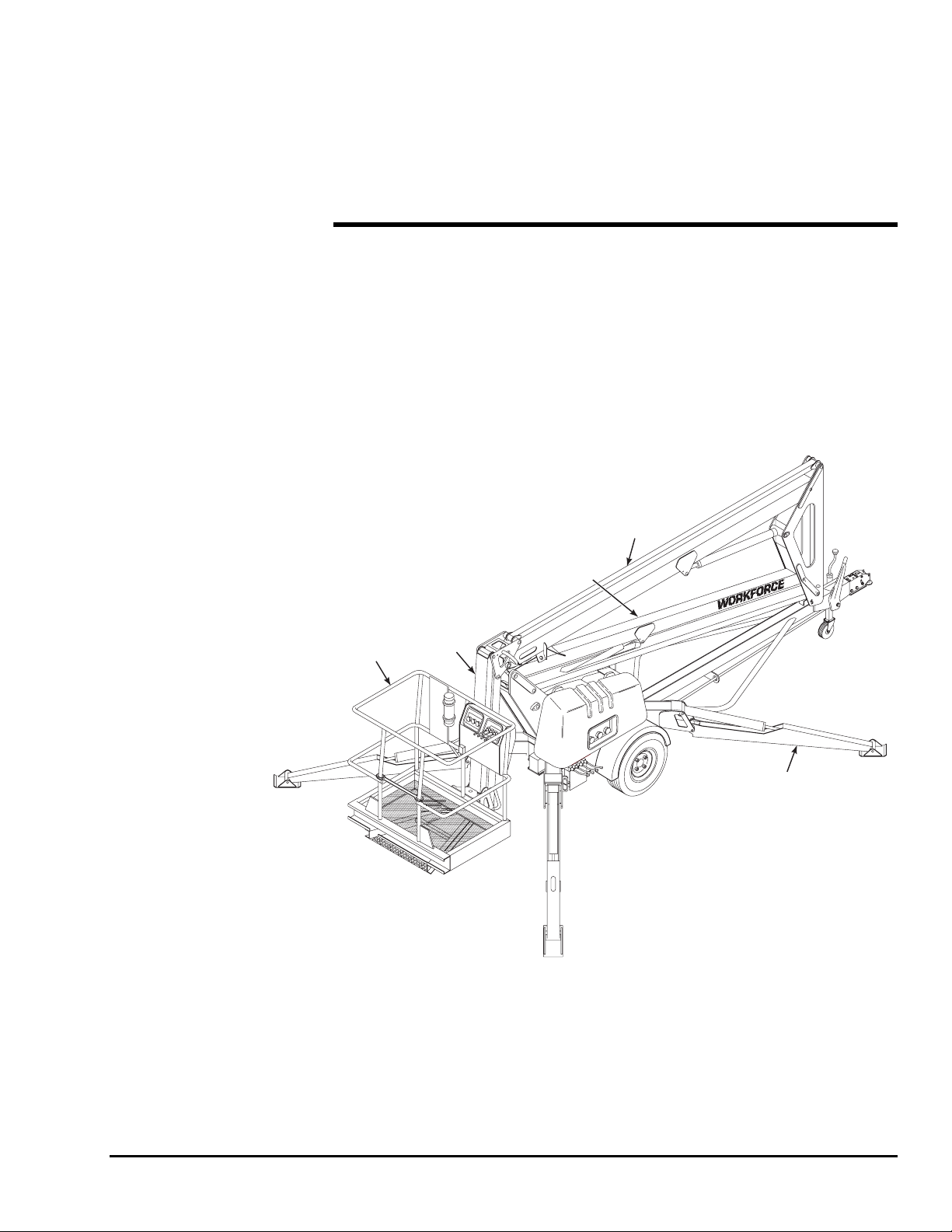

The XLB-4319 Hydraulic Boom Lift (Figure 2-1) is designed to position personnel with

their tools and equipment at overhead work locations. The work basket load capacity i

450 lbs. During all boom operations, the unit is supported by four extended outriggers.

Two versions of the XLB-4319 boom lift are available – gasoline powered or battery

powered. On both versions the hydraulic power unit includes a reservoir, pump, and con

trol valves. Three hydraulic cylinders elevate the lower boom, upper boom, and jib

boom. A hydraulic motor and worm gear rotates the boom 360° around a vertical axis.

UPPER

BOOM

LOWER

BOOM

WORK

BASKET

JIB

BOOM

XLB-4319

s

-

OUTRIGGER

Figure 2-1. XLB-4319 Hydraulic Boom Lift

2-1

Page 18

XLB-4319

The gasoline powered boom lift (gas model) uses a 4-cycle, 8-horsepower Honda engine.

The engine drive shaft is directly coupled to the hydraulic pump. A 12 Volt DC storage

battery powers the engine starter circuit. An auxiliary voltage regulator/rectifier provides

up to 18 Amps charge current while the engine is running.

The battery powered boom lift (DC model) uses a 24 Volt, 39 Amp, one horsepower,

DC motor to drive the hydraulic pump. The DC motor is powered by four 6 Volt DC,

245 Amp-hour, deep charge batteries connected in series. A 40 Amp, automatic, onboard battery charger is provided for recharging the batteries at the end of each work period.

The boom lift is equipped with basket and ground station control panels (Figure 2-2).

The control panels include motion enable pushbuttons and proportional hydraulic valves

for controlling the direction and speed of boom lift and rotation. The gas model basket

station control panel includes an engine start pushbutton. Boom elevation and rotation

controls are operational only when the outriggers are correctly extended and the moving

boom sections are within a programmed safe operating zone.

GROUND STATION CONTROLS BASKET STATION CONTROLS

Figure 2-2. Basket and Ground Station Controls

2-2

Page 19

2 — INTRODUCTION

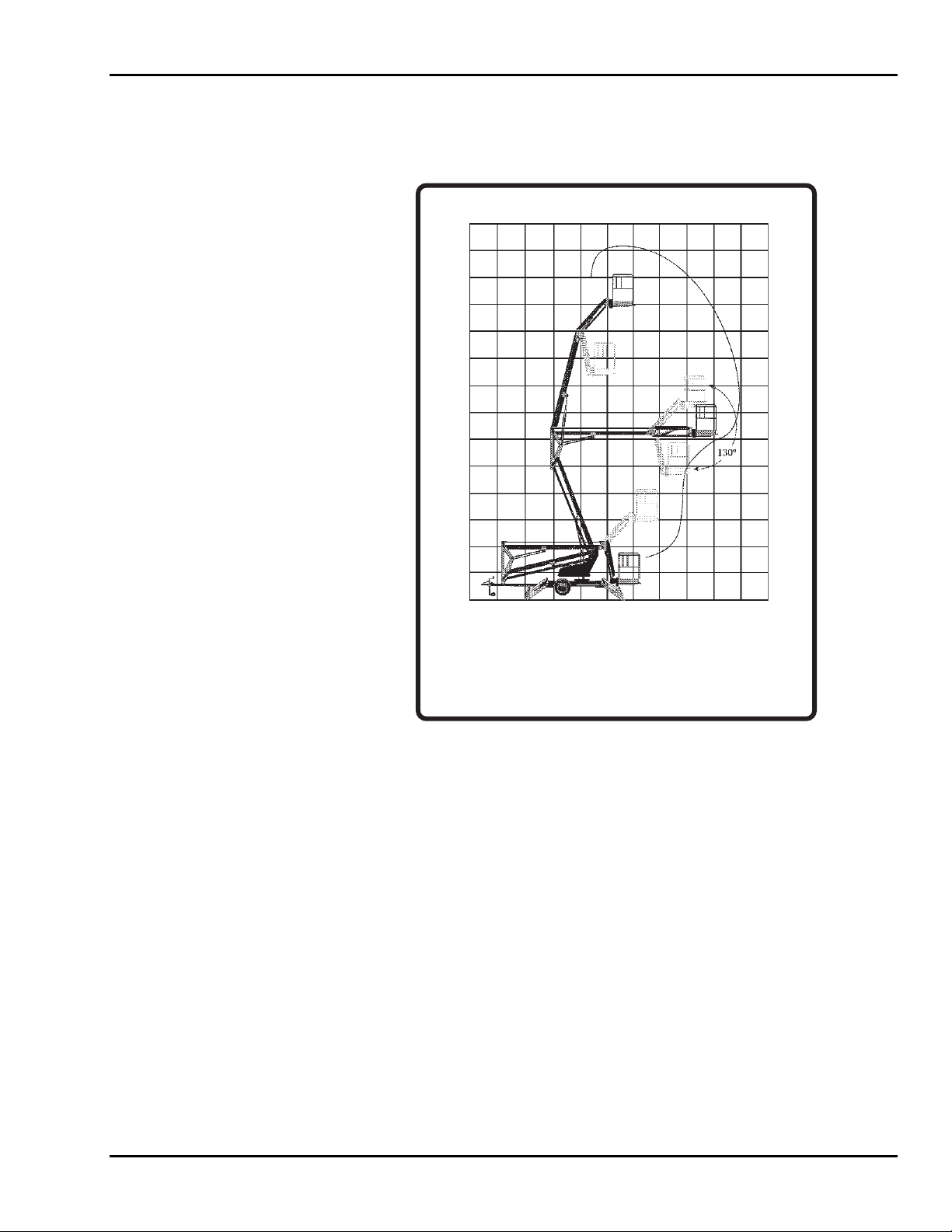

Only one boom motion is permitted at a time, and only as long as the boom is within the

safe operating zone (Figure 2-3). When a selected boom motion reaches a safe operating

limit, the boom motion ceases and another boom motion must be selected within the safe

operating zone.

XLB-4319 SPECIFICATIONS

45.9

42.6

39.4

36

32.8

24.5

26.3

23

19.7

16.4

13

9.8

6.5

3.2

0

9.8 6.5 3.2 0 3.2 6.5 9.8 1 3 16.4 19.7 23

CAPACITY.......................................... 450 LB.

MAXIMUM PLATFORM HEIGHT ....... 37 FT.

WORK HEIGHT .................................. 43 FT.

POWER SOURCE.............................. 24V DC BATTERY OR GAS

FTC

B06-00-0430

Figure 2-3. Safe Operating Zone

Outrigger load sensing interlocks and interlock safety switches prevent all boom lifting

operations until the four outriggers are properly extended, the trailer is level, and the full

weight of the boom lift is loaded onto the outriggers. An interlock prevents the retracting

of any outrigger while the upper or lower boom is raised two inches (50 mm) or more.

Boom elevation speeds are adjustable from zero to 5.3 inches per second (0 to 27 ft/min).

A hydraulic hose failure at either retract-cylinder port will cause a counterbalance valve

to stop the return oil flow. It is strongly recommended that no one adjust or tamper with

these safety devices. If service is required, please notify Bil-Jax for instructions.

Emergency lowering of the basket is by manual valve plungers on the upper and lower

boom lift cylinders or by manual operation of a hand pump in the basket. Firmly pushing

in and holding a valve plunger manually retracts the boom lift cylinder. Smooth pumping

of the hand pump while engaging a single hydraulic valve lever enables boom operation

in case of a hydraulic power failure.

The XLB-4319 Hydraulic Boom Lift cylinders will not rust or corrode during storage

since the cylinder rod is fully immersed in oil. It is important that the cylinder rods be

kept clean and undamaged for the protection of the cylinder head packings.

2-3

Page 20

XLB-4319

2-2 SPECIFICATIONS

Boom Lift Work Platform

Model Number: XLB-4319 Serial Number ________________

Manufactured by: Bil-Jax, Inc.

125 Taylor Parkway

Archbold, Ohio 43502

800-537-0540

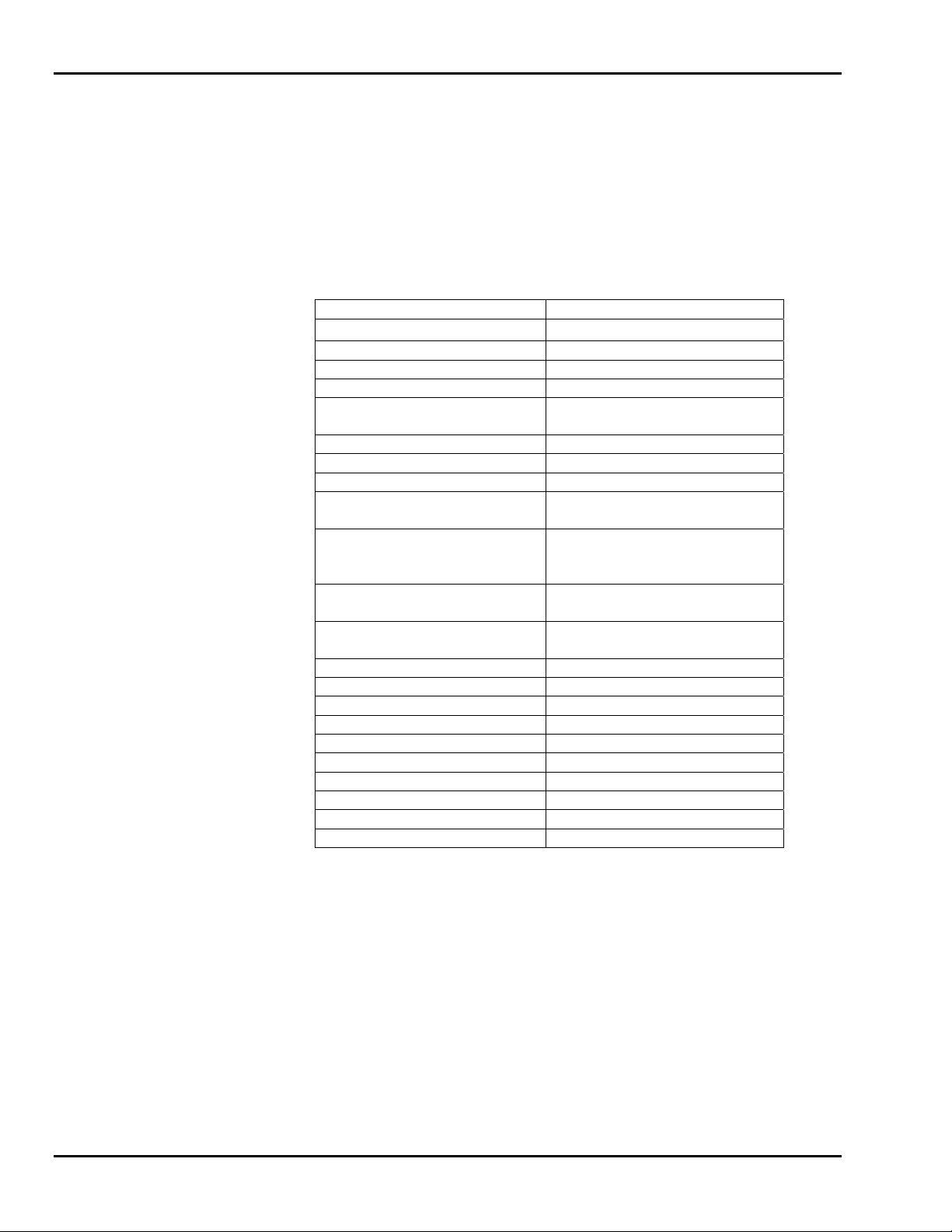

Table 2-1. Specifications

Feature Data

Rated Platform Load 450 lbs (204 kg) total

Maximum Work Height 43 ft (13.1 m)

Extended Basket Height 37 ft (11.3 m)

Maximum Outreach 19 ft (9.8 m)

Elevation Rate,

Nominal

Horizontal Reach 19 ft (5.9 m)

Boom Rotation 700°

Rotation Speed 318° per minute, nominal

Basket Dimensions 51 in. W x 30 in. D x 45 in. H

Power Source, Gas Model 8 Horsepower, 4-Cycle,

Storage Battery, Gas Model 12 Volt DC, 195 Amp Storage

Power Source, DC Model 24 Volt DC, 4 Deep Cycle,

Battery Charger, DC Model 110/120 Volt, 40 Amp

Hydraulic Pressure 2756 psi (19,000 kPa)

Reservoir Capacity 2.75 Gallons (10.4 Liters)

Hydraulic Capacity 7 Gallons (26.5 Liters)

Hydraulic Oil Energol HLP-HD46 (BP Oil)

Gross Vehicle Weight, DC Model 2860 lbs (1297 kg)

Gross Vehicle Weight, Gas Model 3200 lbs (1452 kg)

Tongue Weight, DC Model 100 lbs (45.4 kg)

Tongue Weight, Gas Model 160 lbs (72.6 kg)

Trailer Brakes Mechanical Surge

5.3 in./sec (135 mm/sec)

[26.7 ft/min (8.14 m/min)]

(129.5 cm x 76 cm x 114.3 cm)

Gasoline Engine with Remote Start

Control and Alternator Circuit

Battery, NAPA P/N 5022NF

245 Amp-hour Batteries

2-4

Page 21

2 — INTRODUCTION

2-3 WARRANTY

Bil-Jax warrants its boom lifts for one year from the date of delivery against all defects of

material and workmanship, provided the unit is operated and maintained in compliance

with Bil-Jax’s operating and maintenance instructions. Bil-Jax will, at its option, repair

or replace any unit or component part which fails to function properly in normal use.

This warranty does not apply if the lift and/or its component parts have been altered,

changed, or repaired without the consent of bil-jax or by anyone other than Bil-Jax or its

factory trained personnel, nor if the lift and/or its components have been subjected to

misuse, negligence, accident or any conditions deemed other than those considered as

occurring during normal use.

Components not manufactured by Bil-Jax are covered by their respective manufacturer’s

warranties. A list of those components and their warranties is available upon written request to Bil-Jax.

Bil-Jax shall not in any event be liable for the cost of any special, indirect, or consequential damages to anyone, product, or thing. This warranty is in lieu of all other warranties

expressed or implied. We neither assume nor authorize any representative, or other person, to assume for us any other liability in connection with the sale, rental, or use of this

product.

2-5

Page 22

XLB-4319

2-6

Page 23

3

Operation

3-1

OPERATOR CONTROLS

The XLB-4319 Hydraulic Boom Lift is equipped with

ment power and outrigger controls are located at ground level. Boom lift and rotation

controls are located at ground leve

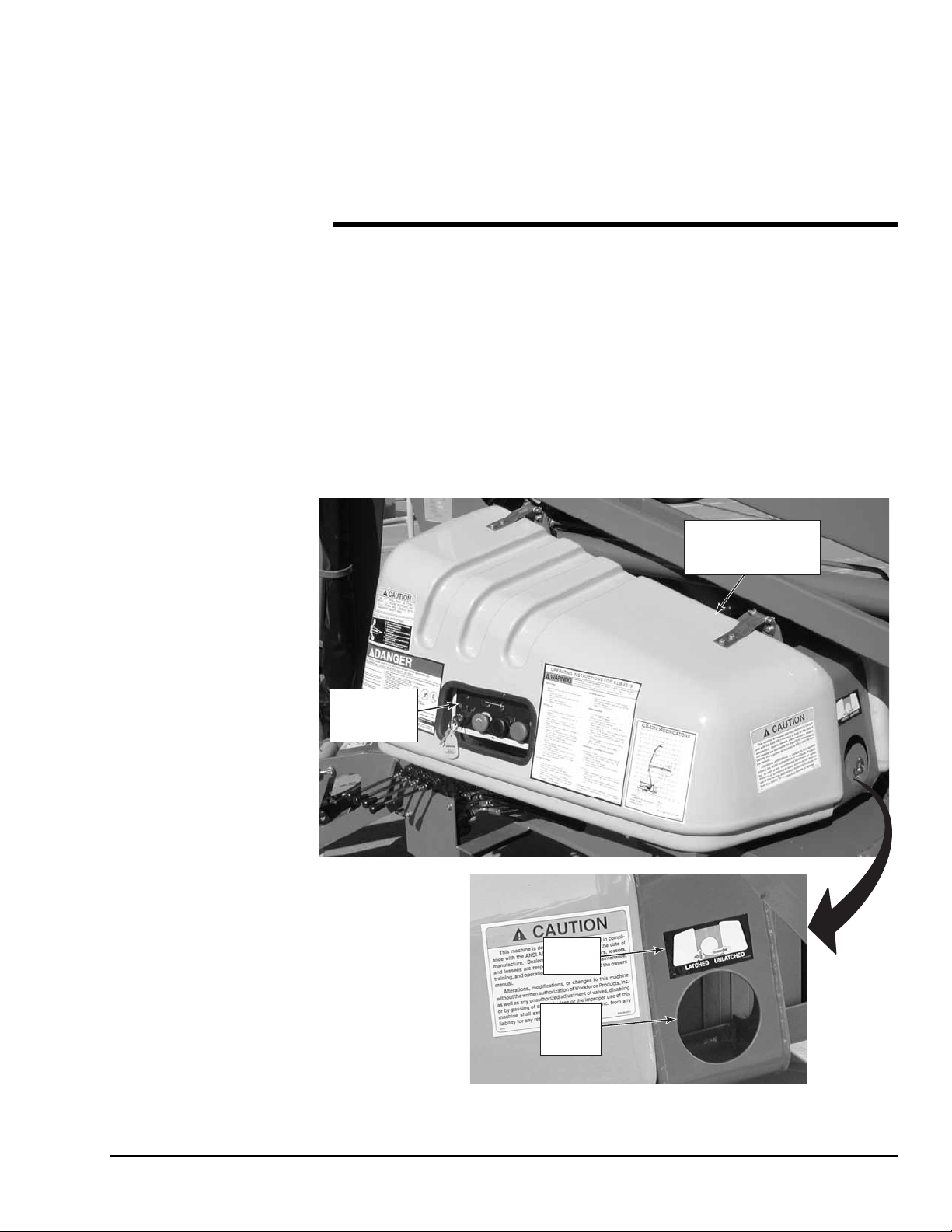

Ground Control Station

The ground control station (Figure 3-1) operates the outriggers and lift booms. To access

the boom controls, reach into the cover latch port and release the cover latch according to

the latch decal. Open the control compartment cover. Unhook the support rod behind the

front edge of the cover and place the rod end into the mating hole in the battery bracket.

GROUND

CONTROL

STATION

l and in the basket.

multiple operator controls. Equip-

CONTROL

COMPARTMENT

COVER

LATCH

DECAL

COVER

LATCH

PORT

Figure 3-1. Ground Control Station Access

3-1

Page 24

XLB-4319

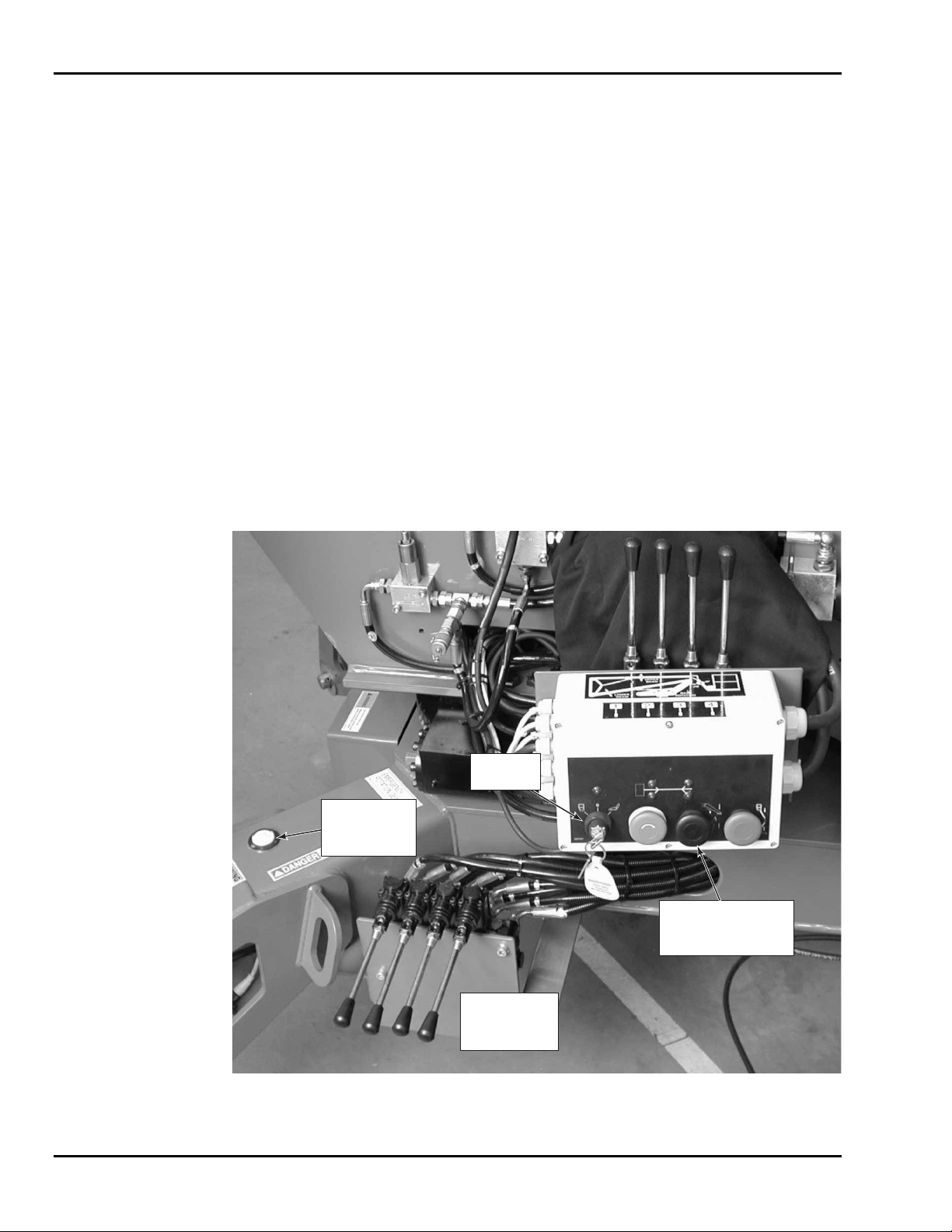

The ground control station (Figure 3-2) includes the following electrical and hydraulic

controls.

BOOM OPERATOR

LEVERS

Key Switch

OUTRIGGER INDICATORS

KEY

SWITCH

EMERGENCY

STOP

PUSHBUTTON

OUTRIGGER

OPERATOR

LEVERS

Figure 3-2. Ground Control Station

OUTRIGGERS

RUN

PUSHBUTTON

BOOM

RUN

PUSHBUTTON

Turning the key switch to the left selects o

peration from the basket control station. Turning the key switch to the right selects operation from the ground control station. The center (Off) position disables electrical and

hydraulic operations. Removing the key protects

against unauthorized boom lift operation.

EMERGENCY STOP Pushbutton

When pressed, the EMERGENCY STOP pushbutton disconnects electrical powe

r from

the upper and lower control stations. Pressing the EMERGENCY STOP pushbutton also

shuts off the gasoline eng

ine or DC motor to interrupt hydraulic power. Before you can

restore power, you must rotate the EMERGENCY STOP pushbutton clockwise.

Outrigger Indicators

Four green OUTRIGGER indicators l

and the boom weight is removed f

ight up when the boom lift outriggers are extended

rom the trailer axle. All four indicators must be lit and

the trailer must be level to enable operation of the lift booms.

3-2

Page 25

3 — OPERATION

Outriggers Run Pushbutton

Holding the black outriggers run pushbutton in enables operation of the outrigger cylinders. The outrigger cylinders can only be operated when the lift boom cylinders are retracted.

Boom Run Pushbutton

Holding the green boom run pushbutton in enables operation of the lift boom cylinders.

The lift boom cylinders can only be operated when the outrigger cylinders are extend

ed,

the boom weight is removed from the trailer axle, and the trailer is level.

Outrigger Operator Levers

Four outrigger operator levers position the hydr

rigger cylinders. Lifting an o

Pushing down on an operato

perator lever retracts the cylinder to raise the outrigger.

r lever lowers the related outrigger. When released, the op-

erator levers return to the center (valve-off) position. Starting on your left, the outrigger

aulic valves to extend and retract the out-

s

are numbered 1 through 4. A decal located below the outrigger valve manifold indicates

which operator lever controls which outrigger.

Boom Operator Levers

Four boom operator levers position proportional hydraulic valves to extend and retract

the boom lift cylinders

and the boom rotation drive motor. Pulling a boom operator lever

extends the cylinder to raise the boom. Pushing a boom operator lever lowers the related

boom. How far the lever is pushed or pulled controls the boom lift speed.

Pulling the boom

rotation operator lever turns the boom clockwise. Pushing the operator

lever turns the boom counterclockwise. How far the lever is pushed or pulled controls the

boom rotation speed.

When released, the boom operator levers return to the center (valve-off) position. A dec

al

located in front of the valve manifold shows which boom motion is controlled by each

operator lever.

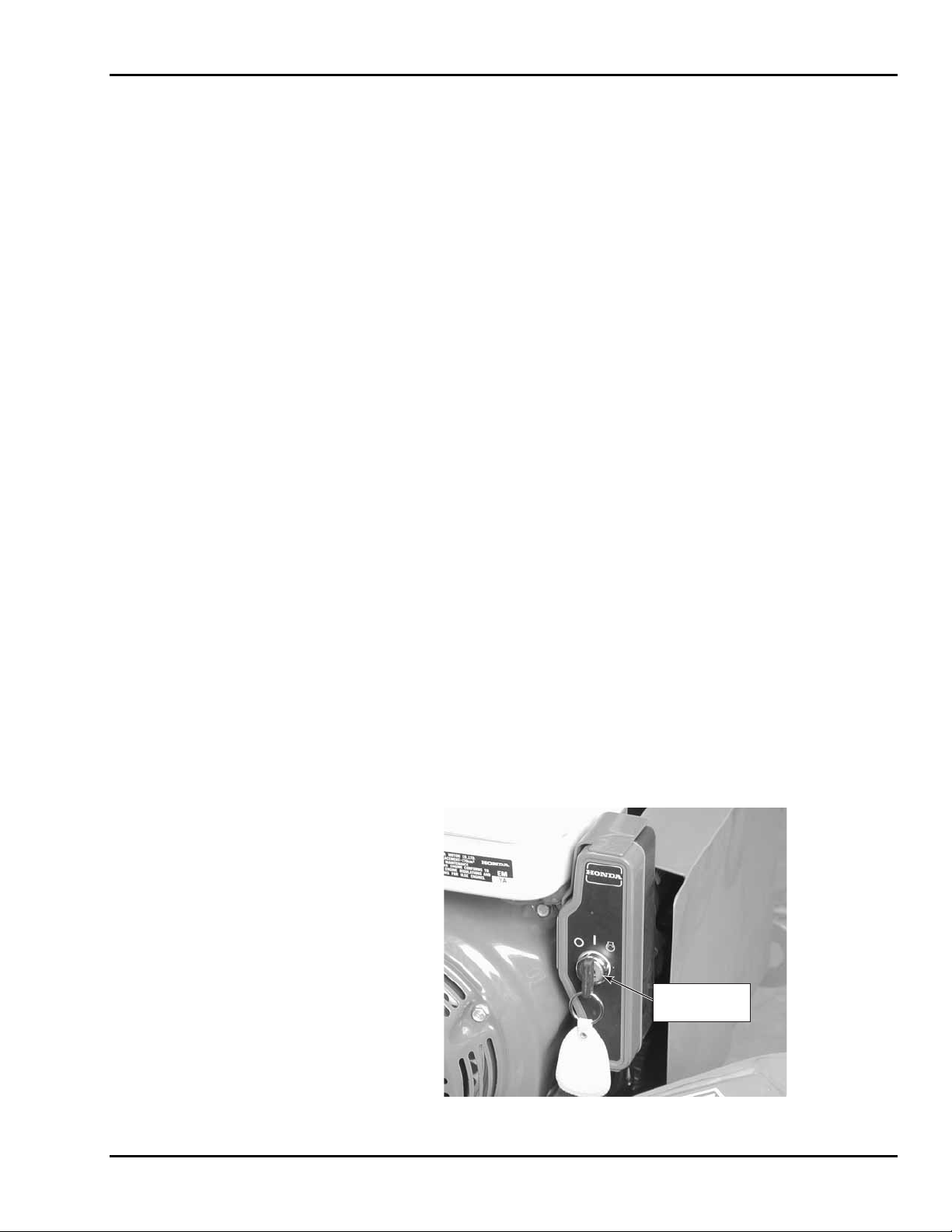

Engine Keyswitch (Gas M

On the gas model start and stop

boom lift, the engine keyswitch (Figure 3-3) is used to

the gasoline engine from ust be in the ON position

odel only)

the ground position. The keyswitch m

(as shown) to enable engine start-up from the work basket control station.

ENGINE

KEYSWITCH

Figure 3-3. Engine Keyswitch

3-3

Page 26

XLB-4319

Basket Control Station

The basket control station (Figure 3-3) operates the hydraulic boom lift, boom rotation.

and basket rotation motions. The basket control station includes the following electrical

and hydraulic controls.

ENGINE START

BOOM RUN

PUSHBUTTON

HYDRAULIC

HAND PUMP

EMERGENCY

STOP PUSHBUTTON

PUSHBUTTON

(GAS MODEL ONLY)

AUDIBLE

ALARM

BOOM

OPERATOR LEVERS

115 VOLT

OUTLET

Figure 3-4. Basket Control Station

EMERGENCY STOP Pushbutton

When pressed, the EMERGENC

Y STOP pushbutton disconnects electrical power from

the upper and lower control stations. Pressing the EMERGENCY STOP pushbutton also

shuts off the gasoline engine or DC motor to interrupt hydraulic power. Before you can

restore power, you must rotate the EMERGENCY STOP pushbutton clockwise.

Boom Run Pushbutton

Holding the green boom run pushbutton in enables operation of the boom lift and rotation functions. Boom lift and rotation can only be operated when the outrigger cylinders

are extended, the boom weight is supported by all four outriggers, and the trailer is level.

3-4

Page 27

3 — OPERATION

Boom Operator Levers

Five boom operator levers position proportional hydraulic valves to extend and retract

three boom lift cylinders, the boom rotation drive motor, and the basket swivel cylinder.

Pulling a boom operator lever extends the cylinder to raise the boom. Pushing a boom lift

operator lever lowers the related boom. How far the lever is pushed or pulled controls the

boom lift speed.

Pulling the boom rotation or basket rotation operator lever turns the boom or basket

clockwise. Pushing the operator lever turns the boom or basket counterclockwise. How

far the lever is pushed or pulled controls the rotation speed.

When released, the boom operator levers return to the center (valve-off) position. A decal

located in front of the valve manifold shows which boom motion is controlled by each

operator lever.

Hydraulic Hand Pump

The basket control station is equipped with a hydraulic hand pump. In case lift boom operating power is lost, the hand pump is available to manually lower the lift boom. Holding the related operator lever in position and smoothly operating the hand pump lowers

the lift boom or swivels the work basket to another position.

Engine Start Pushbutton (Gas Model only)

Pressing the engine start pushbutton restarts the gasoline engine while in the work basket. The pushbutton should only be pressed until the engine starts. The engine should not

be cranked longer than 15 seconds at a time. Over-cranking will burn up the starter motor.

Audible Alarm

An audible alarm is located in the basket station control panel. The audible alarm sounds

whenever the key switch is on and the boom lift is out of level.

115 Volt Outlet

The 115 Volt AC outlet is provided for running electrical power tools in the work basket.

A connecting power cord must be plugged in to a suitable power source. The power plug

is located on the inside of the trailer frame, near the tow end of the trailer. The o utlet is

rated for a 15-ampere load. Do not overload the accessory power circuit.

3-5

Page 28

XLB-4319

3-2 NORMAL OPERATING PROCEDURE

Perform the following procedures to operate the XLB-4319 Hydraulic Boom Lift.

1. Read and follow all safety precautions contained in Section 1 and all responsibilities outlined in the ANSI A92.2 reprint contained in Section 7 of this manual.

2. Position the lift at the work area. Make sure the lift is on a firm and level surface

and that there are no potential hazards such as overhead obstructions or electrically charged conductors. Do not operate the lift if such hazards exist.

3. Check the tow trailer and boom lift for damaged or worn parts. Repair or replace parts as necessary. Do not use a damaged boom lift.

4. Apply the trailer parking brake.

5. Lower the trailer tongue jack and unhitch the trailer from the tow vehicle. The

trailer must be unhitched before the outriggers are lowered.

6. See Figure 3-4 and lower the boom lift outriggers as follows:

a. Start the engine or motor.

b. Turn the key switch to the ground control position.

c. Press and hold in the black outrigger run pushbutton.

KEY

SWITCH

BUBBLE

LEVEL

INDICATOR

OUTRIGGERS

RUN

PUSHBUTTON

OUTRIGGER

OPERATOR

LEVERS

Figure 3-5. Outrigger Controls

3-6

Page 29

3 — OPERATION

WARNING

Always verify that the green outrigger LEDs light up when the outrigger feet become loaded. If an outrigger LED fails to light up or lights up before the outrigger

foot becomes loaded, the limit switch or switch setting is faulty. Using the boom

lift with a faulty limit switch or switch setting can cause severe injury, death, or

damage to the equipment.

d. Push down on the rear outrigger levers (1 & 2) to lower the rear outriggers.

Lower the rear outriggers only until the rear outrigger LEDs light up on the

control panel.

e. Push down on the front outrigger levers (3 & 4) to lower the front outrig-

gers. Raise the trailer wheels off the ground. Verify that the front outrigger

LEDs light up on the control panel.

f. Watch the bubble level indicator and adjust the outriggers as needed to

level the trailer.

NOTE: An LED level switch and four outrigger position switches prevent boom

motions if the trailer is not level or if one or more outriggers is not supporting the vehicle load. The load of the boom lift vehicle must be placed

on all four outriggers and the trailer must be level to enable motorpowered boom lift operations.

7. Remove the keeper pins and transport pins that secure the upper and lower

booms. Stow the transport pins in the retainer clips provided.

8. Use the ground control station to operate the boom lift controls. Raise, lower,

and rotate the boom to get familiar with the controls. Learn to smoothly start

and stop all boom motions.

9. Lower the boom sections to position the basket for boarding. Turn the key

switch to the basket control position.

10. Raise the safety bar and enter the basket. Put on the safety harness and attach

the lanyard to the attachment position on the basket railing. Operate the boom

lift carefully.

11. When boom lift operations are complete, retract the boom and outriggers for

trailer towing according to the following procedure:

a. Using the basket control station, rotate the basket to the center position.

b. Fully retract the jib boom, the upper boom, and the lower boom.

c. Exit the basket and turn the key switch to the ground control position.

d. Retract the two rear outriggers until the trailer tires touch. Do not fully re-

tract the rear outriggers.

e. Retract the front outriggers until fully raised.

f. Retract the rear outriggers until fully raised.

g. Prior to towing, install the transport pins and keeper pins to secure the up-

per and lower booms. Refer to paragraph 3-6 for towing instructions.

3-7

Page 30

XLB-4319

3-3 EMERGENCY LOWERING

The XLB-4319 Boom Lift is equipped with two manual lowering valves and a hydraulic

hand pump. These devices can be used to lower the basket in case of a power failure, a

load shift, or other emergency situation.

The manual lowering valves are located on the upper and lower boom lift cylinders and

are manually operated from the ground. The hydraulic hand pump is located in the work

basket. Use the hand pump in case an assistant is not available on the ground.

To lower the work basket from the ground, push in the valve plunger (Figure 3-6) on the

lower boom lift cylinder. Continue pushing the valve plunger to fully retract the lower

boom. Push in and hold the valve plunger on the upper boom lift cylinder until the upper

boom is retracted.

VALVE

PLUNGER

Figure 3-6. Manual Lowering Valve

To manually lower the boom lift from the work basket, push the upper or lower boom

operator lever (Figure 3-7) down and use the hand pump to lower the boom. Apply a

steady up-and-down pumping action. The hydraulic cylinders are dual acting; boom

motion will continue throughout pump handle operation.

BOOM OPERATOR

LEVERS

HAND

PUMP

Figure 3-7. Basket Control Station

3-8

Page 31

3 — OPERATION

3-4 MANUAL BOOM ROTATION

The hydraulic boom lift is equipped with an emergency rotation handle (crank) that can

be used to rotate the boom in case of a power failure or other emergency situation.

Use the following procedure to manually rotate the boom:

1. Remove the crank from its stowage rack and install the crank on the hex end of

the worm gear drive screw (Figure 3-8).

2. Hold the boom rotation valve lever in the correct position for boom rotation and

turn the crank to rotate the boom.

BOOM ROTATION

VALVE LEVER

BOOM ROTATION

CRANK

Figure 3-8. Emergency Rotation

3-9

Page 32

XLB-4319

3-5 BATTERY RECHARGE (DC MODEL ONLY)

The DC model boom lift batteries should be recharged after each 8-hour work shift or

more often if needed. When the boom lift is not in use, the batteries should be recharged

at least once per week.

The normal charge time is 10 to 12 hours. If the battery charge is extremely low, a full

recharge may take up to 24 hours.

Recharge the DC model boom lift batteries as follows:

WARNING

Recharge the batteries in a well ventilated area only. Do not charge batteries near

fire, flame, or other ignition sources. Batteries being charged may emit highly explosive hydrogen gas. Failure to properly ventilate the charge gases may result in

serious injury or death.

1. Move the boom lift to a well ventilated area with direct access to a grounded

120 VAC electrical outlet. Make sure the recharge area is not near fire, flames

or other ignition sources.

2. Plug a short, heavy-duty power cord into the battery charger receptacle on the

electrical cord connected to the charger. The recommended power cord should

be an 12 AWG multi-strand, grounded cord no longer than 50 feet (16 meters).

NOTE: Using an underrated or long power cord will reduce the output of the

battery charger, resulting in longer charge time.

3. Plug the power cord into a grounded 120 VAC receptacle. Verify that the red

ON-CHARGING indicator LED lights up on the battery charger.

4. To determine the charge rate at any time during the charge cycle, observe the

DC ammeter (Figure 3-9). The ammeter needle moves to the right at the start of

the charge cycle. As the battery charge rises, the needle moves farther left.

Figure 3-9. Battery Charger

3-10

Page 33

3 — OPERATION

CAUTION

Always remember to unplug the battery charger power cord before moving the

boom lift. Failure to unplug the power cord will cause damage to the equipment.

5. Inspect the charge indicator LEDs near the end of the expected charge cycle. If

all indicator LEDs are off, the battery is fully charged. (The DC ammeter needle

should point to the left.)

NOTE: The yellow 80% CHARGE indicator lights up when the battery voltage is

nearing full

indicator lig

If the battery voltage does not reach the 80% CHARGE level in 14 hours,

the charger turns off and the red CHECK BATTERY indicator LED

lights up. This prevents extended charging of a faulty battery.

6. Unplug the power cord from the 120 VAC receptacle and the charger receptacle. Properly store the power cord for next

charge. At full charge (3-1/2 hours after the 80% CHARGE

hts up), the charger turns off.

3-6 BOOM LIFT TRA

The boom lift trailer is a single axle trailer fitted with a two-inch ball hitch, surge brakes,

brea

kaway safety cable, safety chains, brake lights, and side marker lights. Proper boom

lift t

ransport requires the correct hookup and inspection of these trailer components be-

fore towi hitch, tow, and back the boom lift trailer:

ng. Use the following procedures to

use.

NSPORT

Traile

Trai give tow vehicle backing instructions.

r Hitching

ler hitching requires a second person to

1. Back the tow vehicle to the trailer. Verify that the ball and hitch are in lin e and

that the trailer hitch will clear

2. Align the ball and hitch (Figure 3-10). Fasten the breakaway safety

cable to the tow vehicle.

PARKING

BRAKE

BALL AND

HITCH

PO E

W R

PLUG

SAFETY

CHAINS

the ball. Jack up the tongue as needed.

JACK IN

PIVOT

LOCKING

PIN

BREAKAWAY

SAFETY CABLE

JACK IN

RAISED

RAISED

POSITION

POSITION

Figure 3-10. Trailer Hitching

3-11

Page 34

XLB-4319

3. l

Ho d ball hitch release lever open and lower the hitch onto the ball. Let go of

the release lever to secure the ball.

4. the tow

Crank the jack down to check for secure coupling. If jacking will raise

vehicle bumper two or three inches, the ball hitch coupling is secure.

5. Release the trailer parking brake.

6. Pull the pivot locking pin. Swivel the jack 90 degrees to the travel position and

release the pivot locking pin.

CAUTION

Always cross and attach the safety chains before towing. Failure to attach safety

chains properly will allow tongue to drop in case of ball hitch failure, resulting in

serious damage to the trailer and equipment.

7. Attach the trailer safety chains to the tow vehicle. Make sure the chains cross

under the trailer tongue. If needed, cross the chains over then under the tow bar

to prevent dragging.

8. Connect the trailer lights to the tow vehicle power plug.

9. Check the breakaway safety cable. If the safety cable does not have adequate

slack, the brakes may drag.

10. Before towing the trailer, check the following and make all necessary adjustments, corrections, or repairs:

a. Check that the trailer jack and outriggers are in their travel positions.

b. Verify that the transport pins and pin keepers secure the upper and lower

booms. If the booms are not secured, install the transport pins and pin keep-

ers at this time.

c. Verify that the basket is centered and that all onboard equipment is secured.

d. Check that the key switch is in the OFF position. Remove the key.

e. Verify that trailer brake lights and marker lights work properly.

f. Check that the trailer tires are evenly inflated and not low on air.

WARNING

Improper tightening of boom lift trailer wheel nuts can cause wheel lugs to shear,

causing serious injury or damage to equipment. Check and maintain the proper

wheel nut torque according to the maintenance instructions in this manual.

Periodically check the wheel nut torque according to the instructions in Section 4 of this

manual. More frequent torque checks are required when a wheel is recently installed.

Prior to towing, while the trailer wheels are elevated for boom lift operation, check for

loose wheels and for wheel lug wear indications. If a loose wheel mounting is indicated,

remove and inspect the wheel lugs for damage. Do not tow the boom lift with worn or

damaged wheel lugs.

3-12

Page 35

4

Maintenance

4-1 ECKS

SCHEDULED SERVICE CH

Daily/Weekly Service Checks

Perform the following -1.

Check to see that all decals are present.

Check that controls and indicators at ground and basket

control stations operate properly.

Raise booms and press emergency stop pushbutton. Verify

that booms remain elevated and do not drift down.

Check that boom down limyit switch and outrigger position

Check/add hydraulic oil.

Check/add engine oil.

Check engine air filter element. Clean or replace dirty or

damaged air filter element.

Check trailer tires for proper inflation. When cold, tires

should be inflated to 55 psi (3.8 bar).

Check trailer running lights for proper operation.

Check battery electrolyte level. If battery charge is low, add

water to bring electrolyte just above plates. If batteries a

fully charged, raise electrolyte to full mark in each cell.

Check trailer hitch components for damage and proper

operation. Refer to Trailer Hitching in paragraph 3-6.

Check electrical wiring for cuts, loose terminals, broken

wires, chaffing, corrosion, or other damage. Repair all

damage, remove corrosion, and seal exposed connections.

Lubricate grease fittings labeled LUBRICATE WEEKLY

with NLGI Grade 2 multi-purpose grease.

Check trailer and boom lift for missing or loose hardware.

Replace or tighten missing or loose hardware as needed.

daily/weekly service checks as listed in Table 4

Table 4-1. Daily ks

Service Check

. switches operate properl

/Weekly Service Chec

Daily

before use Weekly

re

4-1

Page 36

XLB-4319

Monthly Service Checks

Perform the following monthly service checks as listed in Table 4-2.

Table 4-2. Monthly Service Checks

Service Check

month

Check/add hydraulic oil per paragraph 4-4.

Clean battery terminals and battery charger

operation.

Check operation of manual lowering valves

and hand pump.

Check wheel nut torque per paragraph 4-2.

Lubricate compartment hinges and latches with

light weight machine oil.

Lubricate grease fittings labeled LUBRICATE

MONTHLY per paragraph 4-3.2.

Lubricate trailer tongue jack (2 places) with

NLGI Grade 2 multi-purpose grease.

Lubricate grease fittings labeled LUBRICATE

SEMI-ANNUALLY per paragraph 4-3. 3.

Change engine oil.

Check battery cables and wiring for loose

connections and damaged wires.

Replace spark plug.

Replace hydraulic oil and oil filter.

Check boom pivot pin and sleeve bearings for

wear. Replace worn or damaged pivot pins and

sleeve bearings.

Check slew bearing for wear or damage per

paragraph 4-5.

Inspect and adjust trailer brakes.

Load test boom lift operations with 450

pounds (204 kg).

Every

Every

6 months

Every

12 months

4-2

Page 37

4 — MAINTENANCE

4-2 WHEEL NUT TORQUE REQUIREMENTS

It is very important to apply and maintain the correct wheel bolt torque on the boom lift

trailer. The wheel bolts must be evenly tightened to the following specified torque increments whenever a trailer wheel is removed and installed. Use the following tightening

procedure:

1. Evenly tighten the wheel bolts to 25 lb-ft (34 N

shown in Figure 4-1.

·m) in the tightening sequence

1

4

2

Figure 4-1. Wheel Bolt Tightening Sequence

2. Evenly tighten the wheel bolts to 60 lb-ft (81,4 N

quence shown.

3. Evenly tighten the wheel bolts to 100 lb-ft (135,6 N

quence shown.

3

·m) using the tightening se-

·m) using the tightening se-

4-3

Page 38

XLB-4319

4-3 LUBRICATION

Lubrication makes operation of the XLB-4319 Boom Lift more efficient and extends the

equipment life. Use the following procedures to lubricate the boom lift components.

1. Lubricate trailer jack post and all grease fittings labeled LUBRICATE

WEEKLY with NLGI Grade 2 multi-purpose grease.

2. Lubricate all LUBRICATE MONTHLY grease fittings with NLGI Grade 2

multi-purpose grease. Wipe off dirt and grease residue. Add approximately ½

ounce (15 cc) of grease to each fitting. See Figure 4-2 for grease fitting locations.

GREASE

FITTINGS

Figure 4-2. Lubricate Monthly

3. Lubricate the slew ring bearing grease fitting (Figure 4-3) with NLGI Grade 2

multi-purpose grease. Wipe off dirt and grease residue. Rotate the boom and add

approximately ½ ounce (15 cc) of grease to each bearing quadrant.

GREASE

FITTING

GREASE

FITTINGS

Figure 4-3. Lubricate Semi-Annually

4-4

Page 39

4 — MAINTENANCE

4-4 HYDRAULIC SYSTEM

Hydraulic system maintenance varies with equipment use and the environment in which

the boom lift is used. Constant attention to keep the oil clean and the reservoir properly

filled will help prevent possible damage to the system. Hydraulic diagrams are provided

in this section for general reference.

WARNING

Hydraulic system pressure settings are factory settings and should not need readjustment. The only time readjustment is needed is when a component in the hydraulic control circuit is replaced. Only the adjustments covered in this manual

are permitted. If you believe that any other hydraulic component needs adjustment, notify Bil-Jax for additional instruction. Hydraulic motions are quiet,

quick, and can be dangerous to persons on or near the lift vehicle. Failure to heed

this warning can result in serious injury or death.

Hydraulic System Inspection

Check the hydraulic hose and fittings for leaks and damage daily. Tighten or replace as

necessary to prevent hydraulic oil loss. Secure hoses and lines as needed to prevent rubbing and chafing.

Fluid Check and Replacement

The oil level should be checked with the engine or motor off, the boom down, and the

trailer on a level surface. Pull the dipstick out of the reservoir (Figure 4-4) and wipe off

any oil with a clean shop cloth, then reinsert the dipstick. Pull the dipstick to check the

oil level. The oil level should be between the full and add oil marks on the dipstick.

DIPSTICK

HYDRAULIC

RESERVOIR

Figure 4-4. Hydraulic Reservoir

4-5

Page 40

XLB-4319

Do not mix hydraulic oils. The reservoir is originally filled with Energol HLP-HD46, a

high-grade, non-foaming hydraulic oil designed for temperatures as low as -20°F (-

33°C). For temperatures reaching -40°F (-40°C), use Dextron Automatic Transmission

Fluid Type A.

If either oil is not available, a good grade SAE 10W hydraulic oil may be used where the

low temperature is above 32°F (0°C). SAE 5W hydraulic oil may be used where low

temperatures reach 0°F (-18°C).

Once a year or whenever the oil becomes contaminated, drain the reservoir, clean the

sump strainer, and replace the hydraulic oil and return filter.

Return Filter Replacement

The hydraulic oil filter should be replaced yearly or whenever filter contamination has a

noticeable effect on the beam lift functions. If return filter clogging is suspected, check

the system hydraulic pressure.

With engine or motor running and no controls actuated, hydraulic system pressure should

be near 0 (zero), or minimal. If the pressure exceeds 30 psig (2 bar) (200 kPa gage), the

return filter should be replaced as follows:

1. Use cleaning cloths and alcohol solvent to clean away dirt on filter cover and

housing (Figure 4-4). Be sure to place reusable components on new cleaning

cloths. Do not allow filter parts to become contaminated.

2. Use a wrench to loosen filter cover.

3. Remove filter cover. Place reusable filter parts on new cleaning cloths.

4. Lift filter element and element holder above reservoir oil level. Drain residual

oil back into filter housing.

5. Remove and discard used filter element.

6. Locate OUT marking on one end of new filter element.

7. With OUT end up, seat new filter element in center of filter holder.

8. Seat filter holder and element in filter housing.

9. Wipe o-ring and mating seal surface of cover with cleaning cloth. If o-ring is cut

or gouged, replace o-ring.

10. Install and hand tighten filter cover. Do not over-tighten filter cover.

Air Bleeding

Delayed response or sporadic boom lift motions may indicate air in the lift cylinders. Use

the following procedure to bleed entrapped air from the hydraulic system.

1. Fill the reservoir with the proper hydraulic fluid. Replace, but do not tighten the

reservoir fill cap.

2. Fully raise and lower the boom to return oil with entrapped air to the reservoir.

3. Allow several minutes for air to escape the reservoir oil.

4. Repeat steps 1 through 3 as needed. Add oil slowly and only when the boom is

lowered to prevent adding more air to the system.

4-6

Page 41

4 — MAINTENANCE

Hydraulic Pressure Checks and Adjustments

Hydraulic pressures are set at the factory and should not be adjusted unless a hydraulic

component has been replaced in the regulated circuit.

On the gas engine model a pressure test port (Figure 4-5) is located at the ground station

boom control valves. A hydraulic pressure gage [0-6000 psig (0-400 bar) (41 000 kPa

gage) minimum range] must be connected to the test port when adjusting hydraulic pressures. This is the only pressure test port on the boom lift.

On the DC model boom lift, the main bypass valve and pressure test port are mounted on

the hydraulic manifold located between the hydraulic pump and reservoir. To prevent

tampering, the main bypass valve cap is secured with locking wire and a seal. If a pressure adjustment is required, call Bil-Jax and request a replacement lock wire and seal.

The boom lift has four bypass valves that regulate hydraulic operating pressures. These

include (1) the main bypass valve, (2) the outriggers bypass valve, (3) the basket station

boom controls bypass valve, and (4) the ground station boom controls bypass valve.

Check/Adjust System and Outriggers Hydraulic Pressures

The system hydraulic pressure (pump output pressure) is regulated by the main bypass

valve. The system hydraulic pressure is used to power all hydraulic operations. The main

bypass valve and pressure test port for the gas model boom lift are shown in (Figure 4-5).

MAIN

BYPASS

VALVE

PRESSURE

TEST PORT

Figure 4-5. Main Bypass Valve and Pressure Test Port

(Gas Engine Model)

4-7

Page 42

XLB-4319

To adjust the system hydraulic pressure, we must first set the outriggers bypass pressure

very high. This ensures that you are reading system pressure when fully retracting an

outrigger cylinder. After adjusting the system pressure, we must readjust the outriggers

bypass pressure to specification.

Adjust System Pressure

1. Connect a hydraulic pressure gage to the pressure test port.

2. Remove the cap from the outriggers bypass valve (Figure 4-6). Turn the adjust

screw to the right exactly two turns. This adjustment will allow the main bypass

valve to regulate the test pressure.

3. Reinstall and tighten the cap to prevent oil leakage. Do not over tighten the cap.

OUTRIGGERS

BYPASS VALVE

Figure 4-6. Outriggers Bypass Valve

4. Start the gasoline engine or DC motor. Run the engine or motor for at least five

minutes to warm the hydraulic oil to the normal operating temperature.

5. Pull up one outrigger control lever to fully retract the outrigger. While the outrigger control lever is pulled up, read the pressure gage. If the pressure is rising,

allow the pressure to reach its highest reading.

6. On the gas model boom lift, if the pressure gage reading is 3045 psig [210 bar

(21 000 kPa)] nominal, no adjustment is required. If an adjustment is required,

proceed with step 8.

7. On the DC model boom lift, if the pressure gage reading is 2750 psig [190 bar

(19 000 kPa)] nominal, no adjustment is required. If an adjustment is required,

proceed with step 8.

NOTE: Loosening the adjust lock nut will cause hydraulic oil to leak from the

main bypass valve. It is recommended that you shut the engine off before

making adjustments to the main bypass valve.

8. Press the emergency stop pushbutton to turn off the hydraulic pump.

9. Loosen the adjust lock nut for the main bypass valve.

4-8

Page 43

4 — MAINTENANCE

10. Use hex wrench to turn the pressure adjust screw. Turn the adjust screw right

for higher pressure or left for lower pressure. Turning the adjust screw 1/4 turn

will adjust the pressure about 150 psig [10,4 bar (1 037 kPa gage)].

11. Tighten the adjust lock nut.

12. Reset the emergency stop pushbutton and restart the engine or motor.

13. Pull up one outrigger control lever and recheck the system pressure. If the pressure is still too high or too low, repeat the adjustment starting with step 6.

14. When the system pressure is properly adjusted, remove the cap from the outriggers bypass valve (Figure 4-6). Turn the adjust screw to the left two turns.

15. Reinstall and tighten the adjust screw cap. Do not over tighten the cap.

Check/Adjust Outriggers Pressure

1. Pull up one outrigger control lever and read the pressure at the gage. If the gage

reading is 2750 psig [190 bar (19 000 kPa)] nominal, no adjustment is required.

2. If the outriggers pressure is too high or too low, remove the cap (Figure 4-6)

and adjust the pressure. Turning the adjust screw to the rig ht 1/4 turn will raise

the pressure about 150 psig [10,4 bar (1 037 kPa gage)].

3. Reinstall and tighten the adjust screw cap. Do not over tighten the cap.

4. Repeat steps 1 through 3 as needed to properly adjust outrigger pressure.

5. If no other hydraulic pressures are to be checked, shut down the engine or motor

and remove the pressure gage.

Check/Adjust Boom Hydraulic Pressure

The hydraulic pressure for the basket station boom controls is regulated by a bypass

valve (Figure 4-7) at the front of the basket station valve bank. The hydraulic pressure

for the ground station boom controls is regulated by an identical valve at the back of the

ground station boom controls. The regulated pressure is used to extend and retract all

basket and boom positioning cylinders.

VALVE

CAP

BYPASS VALVE

ADJUST SCREW

Figure 4-7. Boom Control Bypass Valve, Basket Station

4-9

Page 44

XLB-4319

Check and adjust the hydraulic bypass pressure for the basket or ground station boom

controls as follows:

1. Connect a hydraulic pressure gage to the pressure test port.

2. Start the gasoline engine or DC motor. Run the engine or motor for at least five

minutes to warm the hydraulic oil to the normal operating temperature.

3. Extend the outriggers to fully support and level the boom lift.

4. Turn the ground control station key switch to basket or ground position, according to which bypass pressure (basket or ground control) is to be adjusted.

NOTE: When adjusting the bypass pressure for the basket station boom controls,