Page 1

®

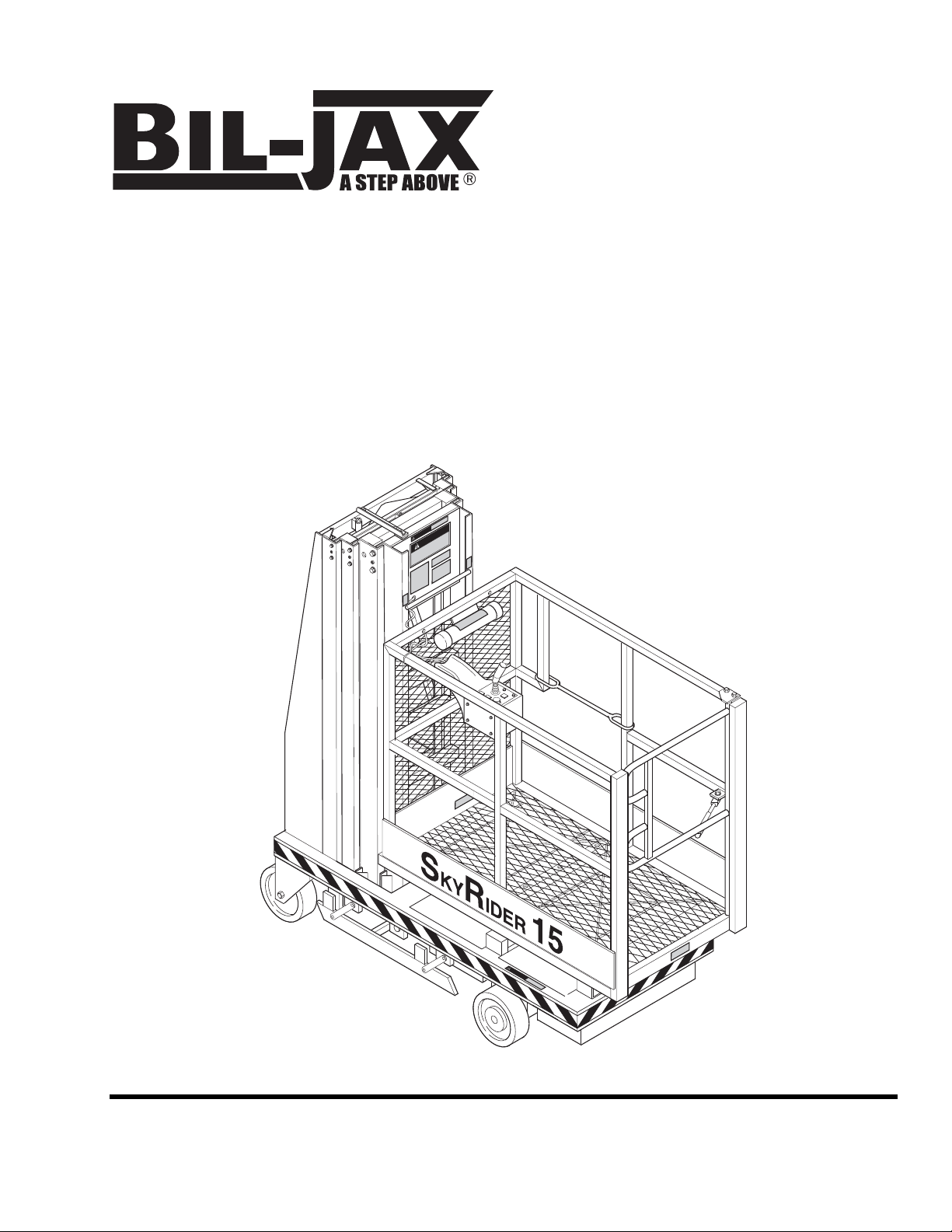

AERIAL WORK PLATFORMS

SkyRider 15

Electric Hydraulic Lift Platform

Operation and

Maintenance Manual

WARNING

DANGER

W

O

R

K

F

O

R

C

E

WARNING

B33-01-0078

Page 2

TELESCOPIC PERSONNEL LIFT

This equipment is designed and manufactured in compliance with the duties, responsibilities, and standards set forth for manufacturers in the ANSI 92.6 standard

in effect at the time of manufacture.

This equipment will meet or exceed applicable OSHA codes and ANSI A92.6 standards when used in accordance with sections 5, 6, 7, 8, 9, 10, and 11 of ANSI A92.6

and all other manufacturer’s recommendations.

It is the responsibility of the user of this equipment to follow all applicable ANSI,

OSHA, Federal, State, and local codes and regulations that govern the safe operation of this equipment.

Page 3

Table of Contents

1 Safety................................................................................................................1-1

1-1 Introduction.........................................................................................

1-2 Before Operation ...............................................................................

1-3 During Operation................................................................................

1-4 Maintenance Safety............................................................................

1-5 Damaged Equipment Policy .............................................................

2 Introduction.....................................................................................................

2-1 General Description...........................................................................

2-2 Specifications......................................................................................

2-3 Warranty.............................................................................................

3 Operation.........................................................................................................

3-1 Operator Controls ..............................................................................

3-2 Normal Operating Procedure............................................................

3-3 Emergency Lowering Procedures.....................................................

3-4 Lift Vehicle Transport ......................................................................

4 Maintenance ....................................................................................................

4-1 Scheduled Service Checks................................................................

4-2 Lubrication..........................................................................................

4-3 Hydraulic System...............................................................................

4-4 Electrical System .............................................................................

4-5 Lift Chains and Slide Blocks ........................................................

4-6 Troubleshooting................................................................................

5 Replacement Decals ........................................................................................

1-1

1-3

1-4

1-6

1-7

2-1

2-1

2-2

2-2

3-1

3-1

3-3

3-5

3-6

4-1

4-1

4-3

4-5

4-11

4-12

4-15

5-1

6 Parts List..........................................................................................................

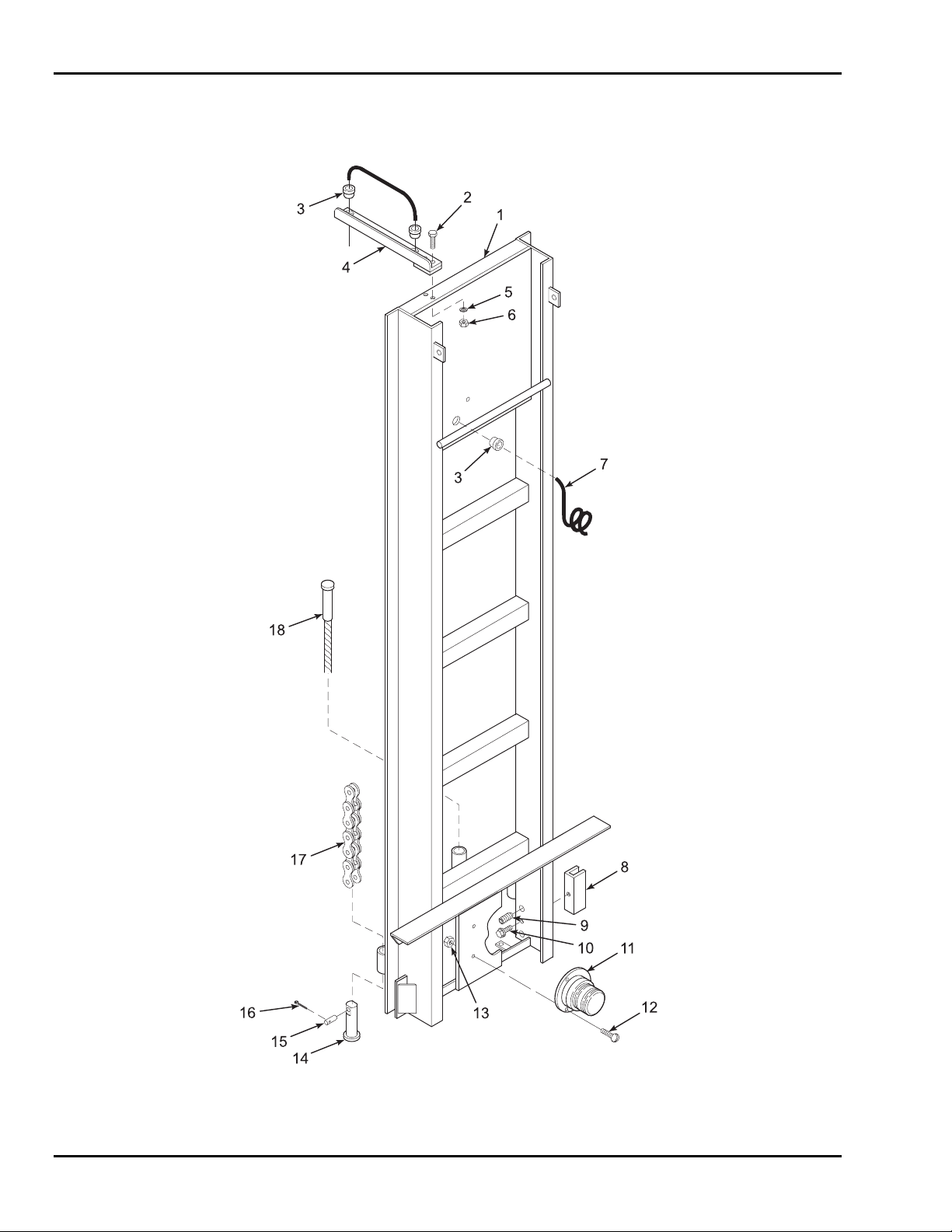

6-1 Top Mast Parts List..........................................................................

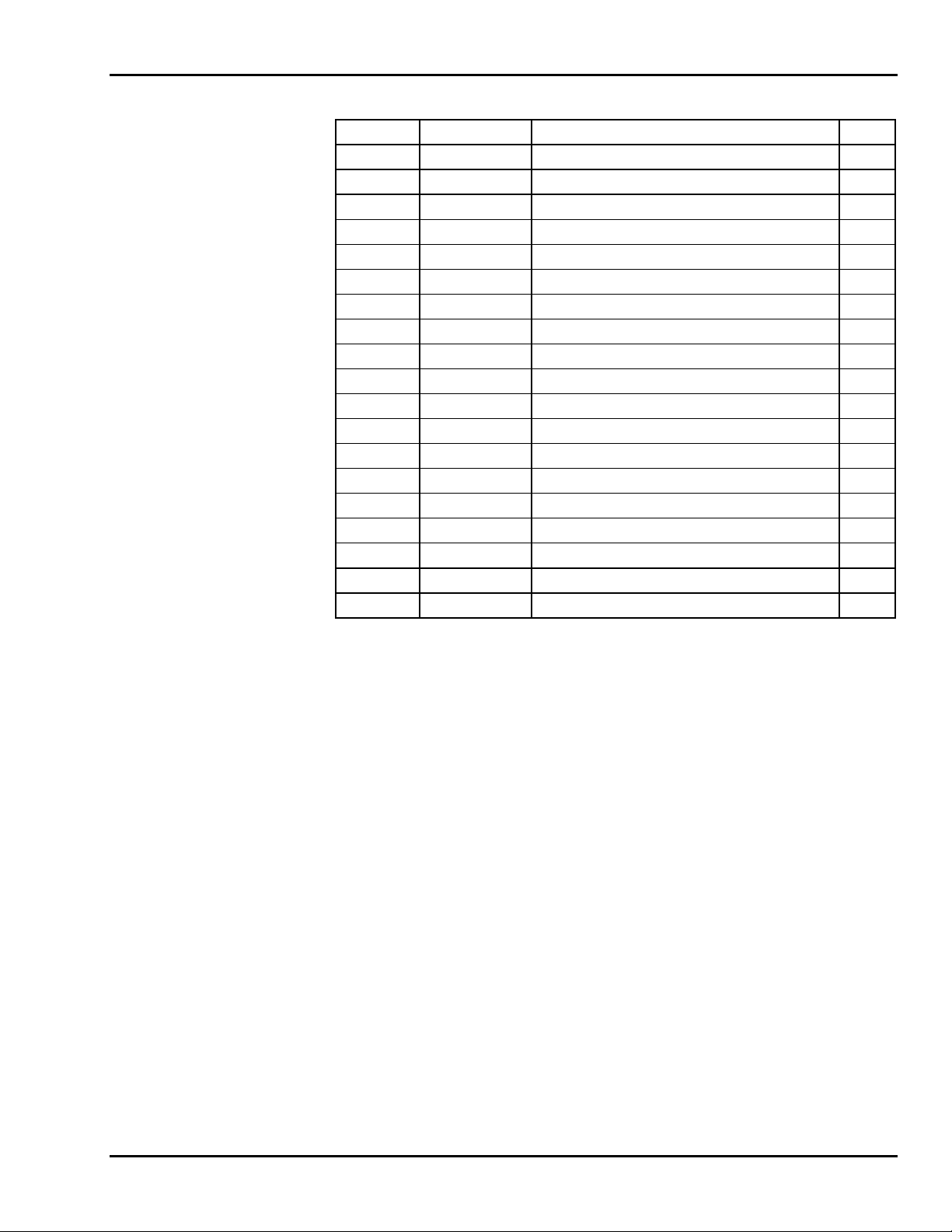

6-2 Center Mast Parts List......................................................................

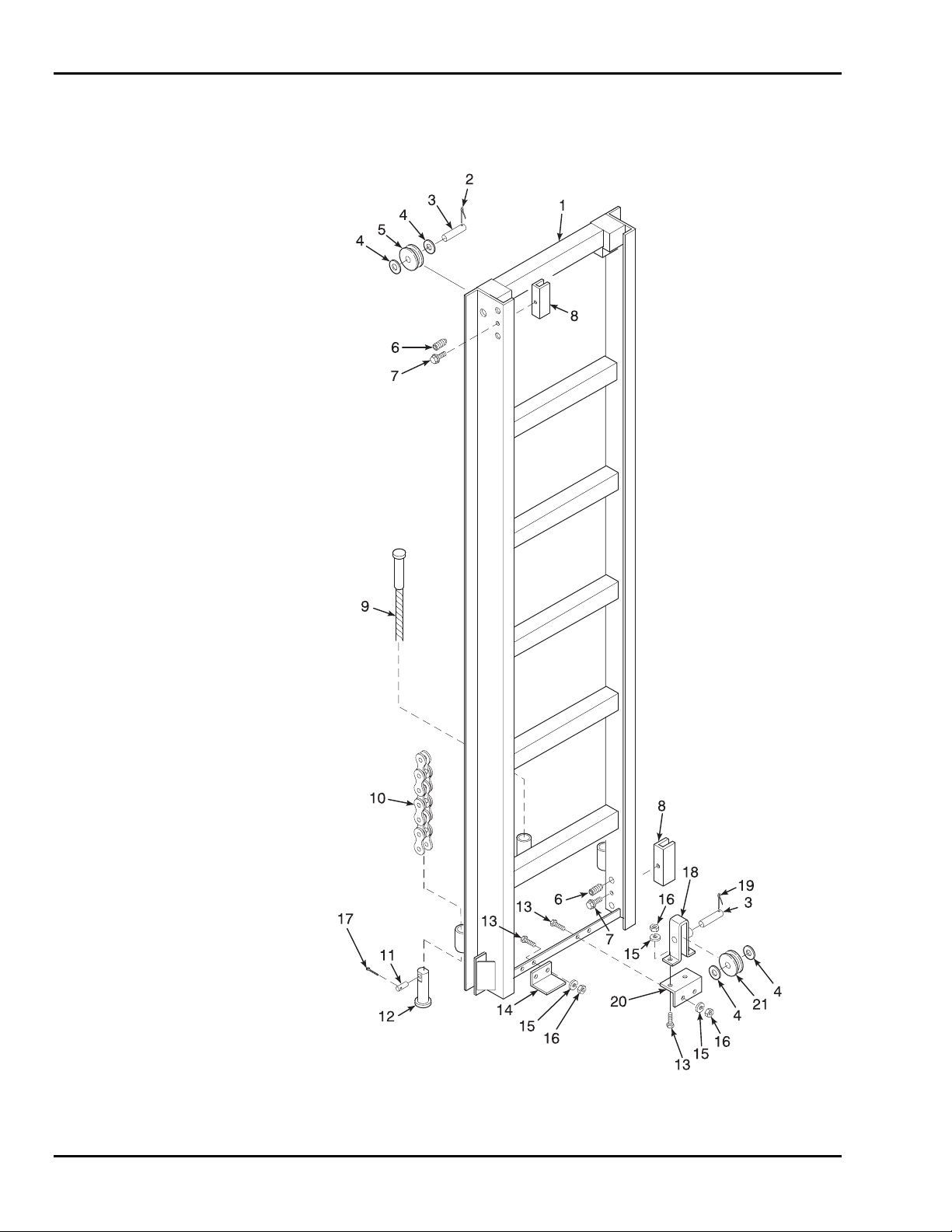

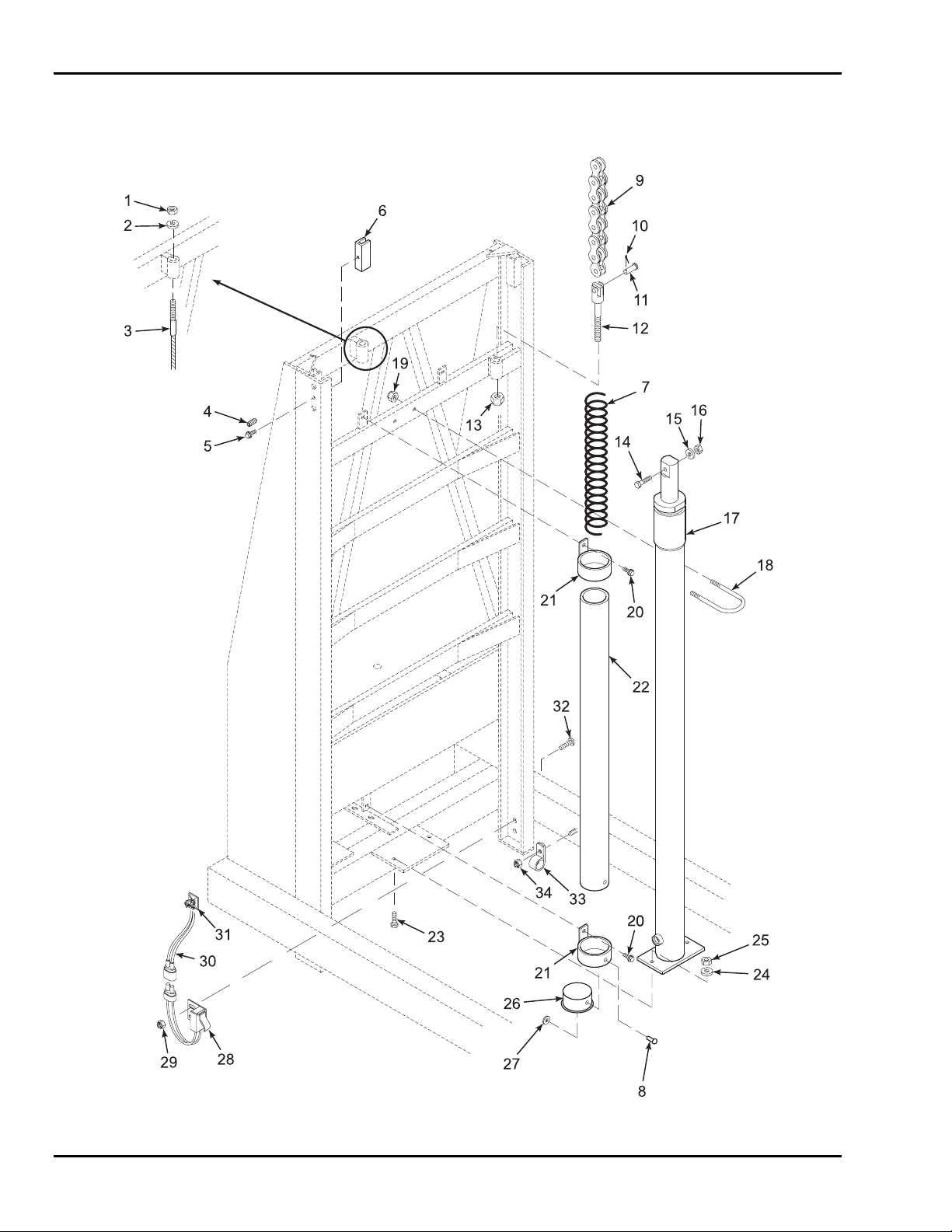

6-3 Lower Mast Parts List......................................................................

6-4 Battery Compartment Parts List.......................................................

6-5 Hydraulic Pump Compartment Parts List.....................................

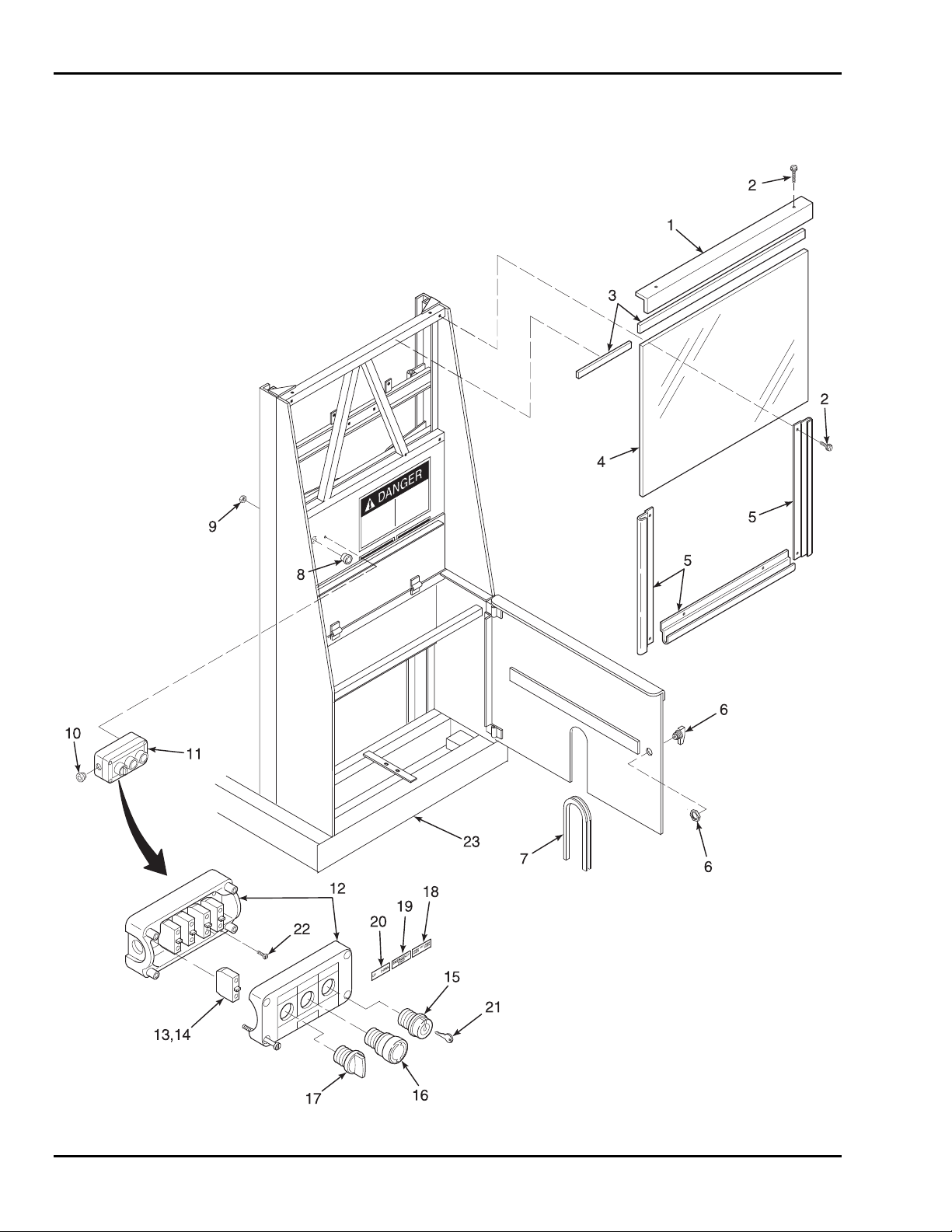

6-6 Base Parts List ................................................................................

6-7 Base Mast Parts List ......................................................................

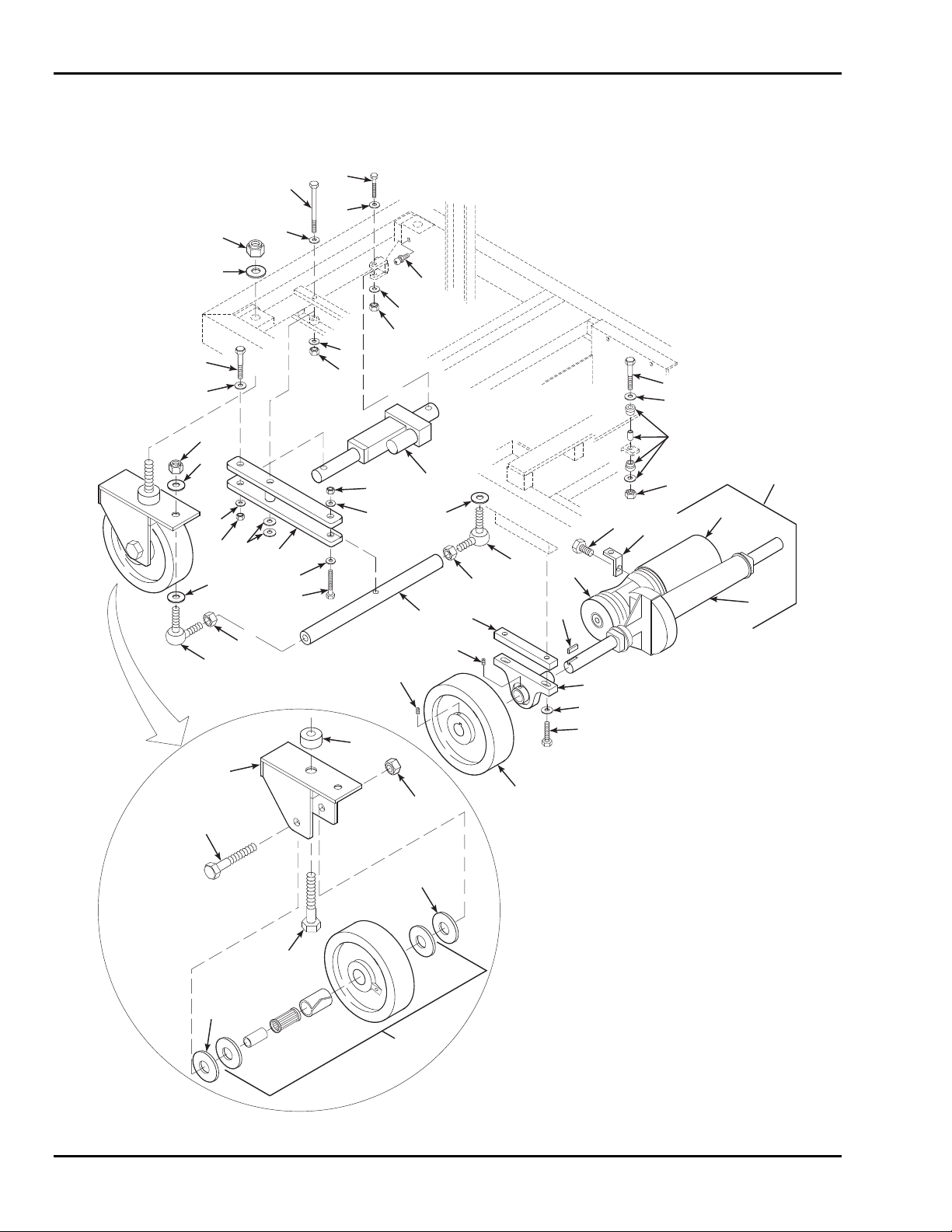

6-8 Drive Axle and Steering Parts List ..............................................

6-9 Pothole Guard Parts List................................................................

6-10 Platform Parts List..........................................................................

6-11 Upper Control Box Parts List .......................................................

6-12 Hydraulic Unit Parts List...............................................................

6-13 Hydraulic Cylinder, Fittings, and Hoses Parts List......................

7 ANSI Reprint..................................................................................................

6-1

6-2

6-4

6-6

6-8

6-10

6-12

6-14

6-16

6-18

6-20

6-22

6-24

6-26

7-1

i

Page 4

List of Illustrations

Figure 3-1. Lower Control Box................................................................................. 3-1

Figure 3-2. Upper Control Box.................................................................................

Figure 3-3. Battery On/Off Switch............................................................................

Figure 3-4. Emergency Lowering Valve...................................................................

Figure 3-5. Lifting Brackets and Tie Down Rings....................................................

Figure 3-6. Travel Brake and Steering Linkage........................................................

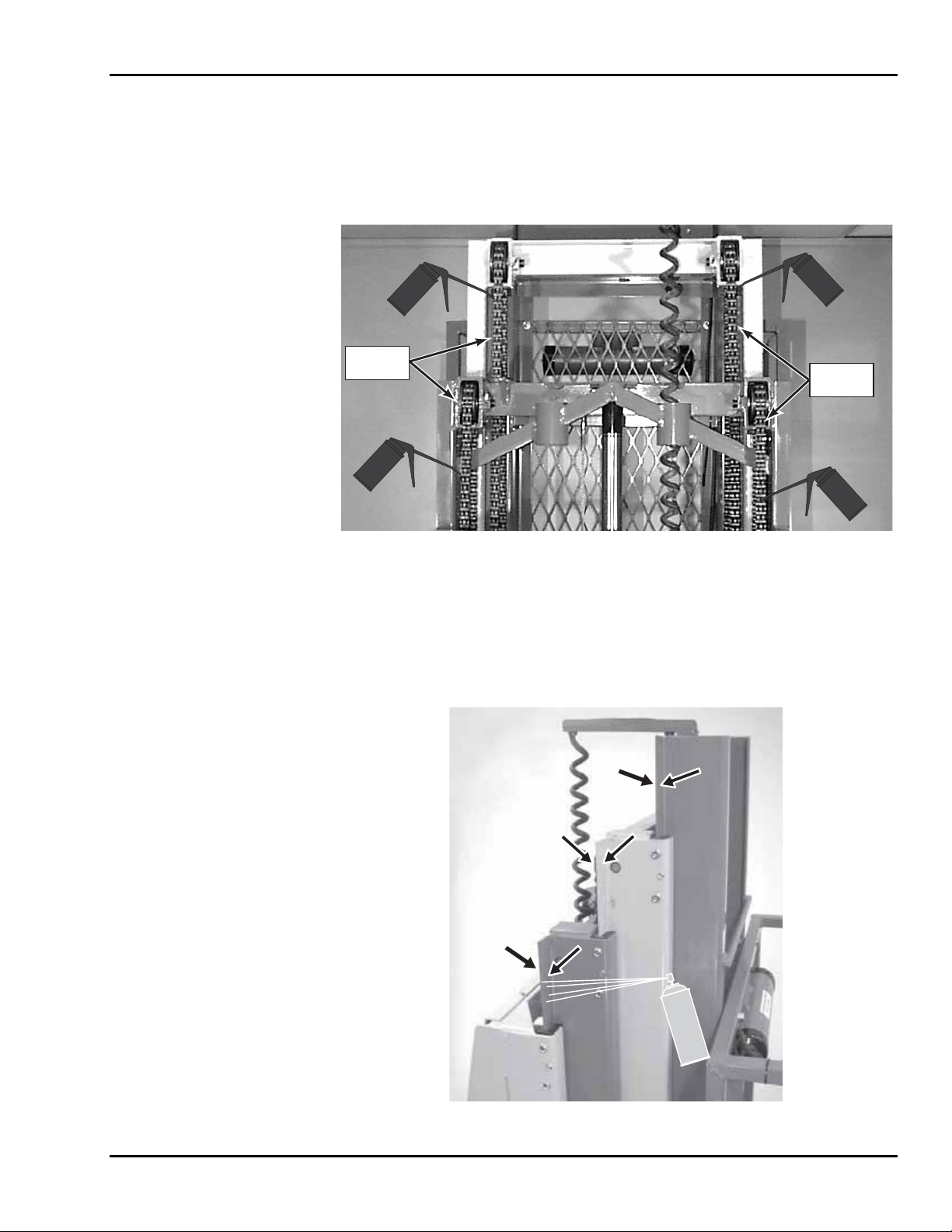

Figure 4-1. Lift Chains Lubrication..........................................................................

Figure 4-2. Mast Slide Ways Lubrication.................................................................

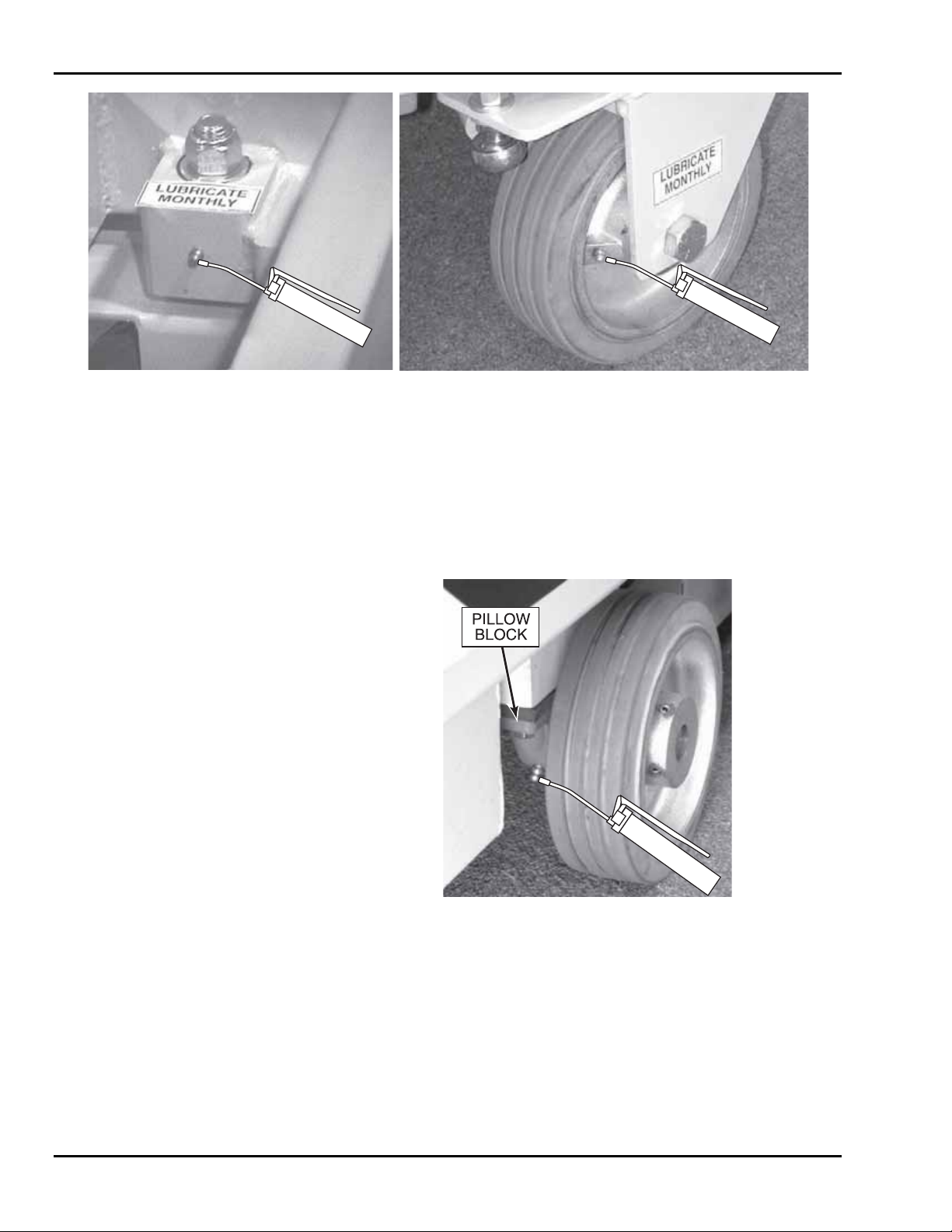

Figure 4-3. Rear Casters Lubrication........................................................................

Figure 4-4. Front Caster Pillow Blocks Lubrication.................................................

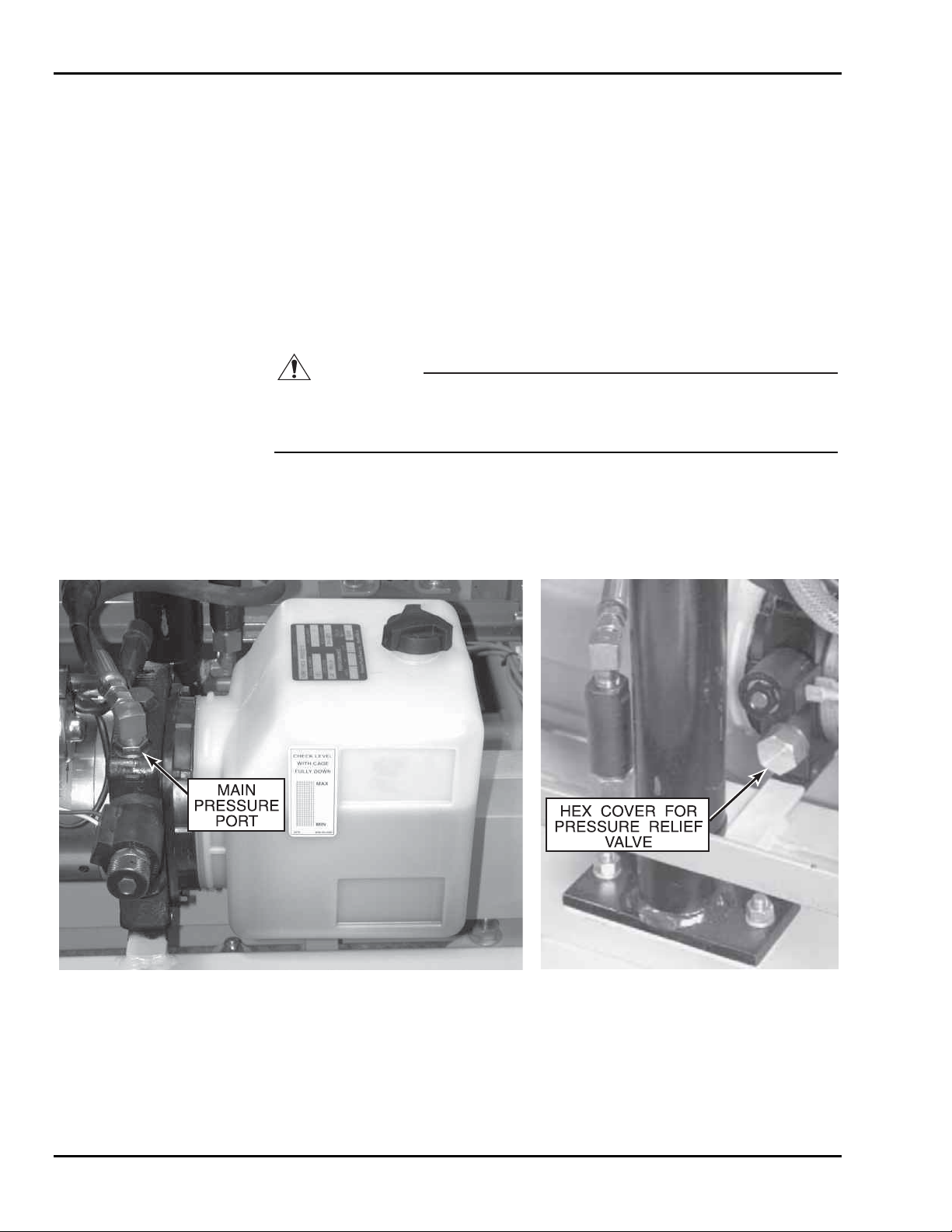

Figure 4-5. Pressure Relief Valve Adjustment..........................................................

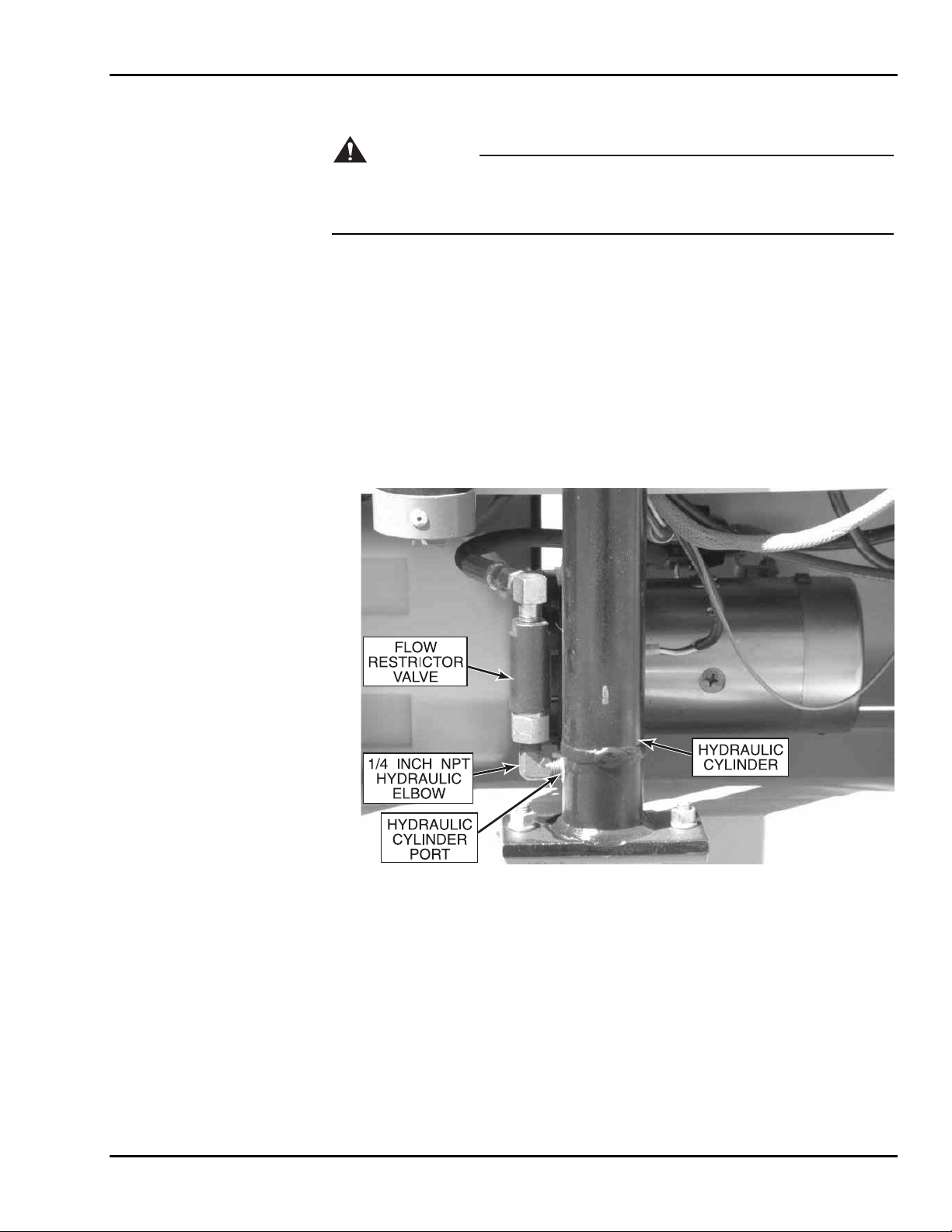

Figure 4-6. Flow Restrictor Valve ............................................................................

Figure 4-7. Up Valve Operation Check ....................................................................

Figure 4-8. Hydraulic Cylinder Disassembly..........................................................

Figure 4-9. Battery Charger Receptacle..................................................................

Figure 4-10. Chain Elongation Inspection................................................................

Figure 4-11. Lift Chains Adjustment........................................................................

Figure 4-12. Slide Blocks Adjustment......................................................................

Figure 4-13. Main Controller Board .........................................................................

Figure 4-14. Hydraulic Diagram...............................................................................

Figure 4-15. PC Logic Diagram................................................................................

Figure 4-16. Lower Control Wiring Diagram...........................................................

Figure 4-17. Drive Wiring Diagram..........................................................................

Figure 4-18. Upper Control Wiring Diagram ...........................................................

Figure 5-1. Replacement Decals ...............................................................................

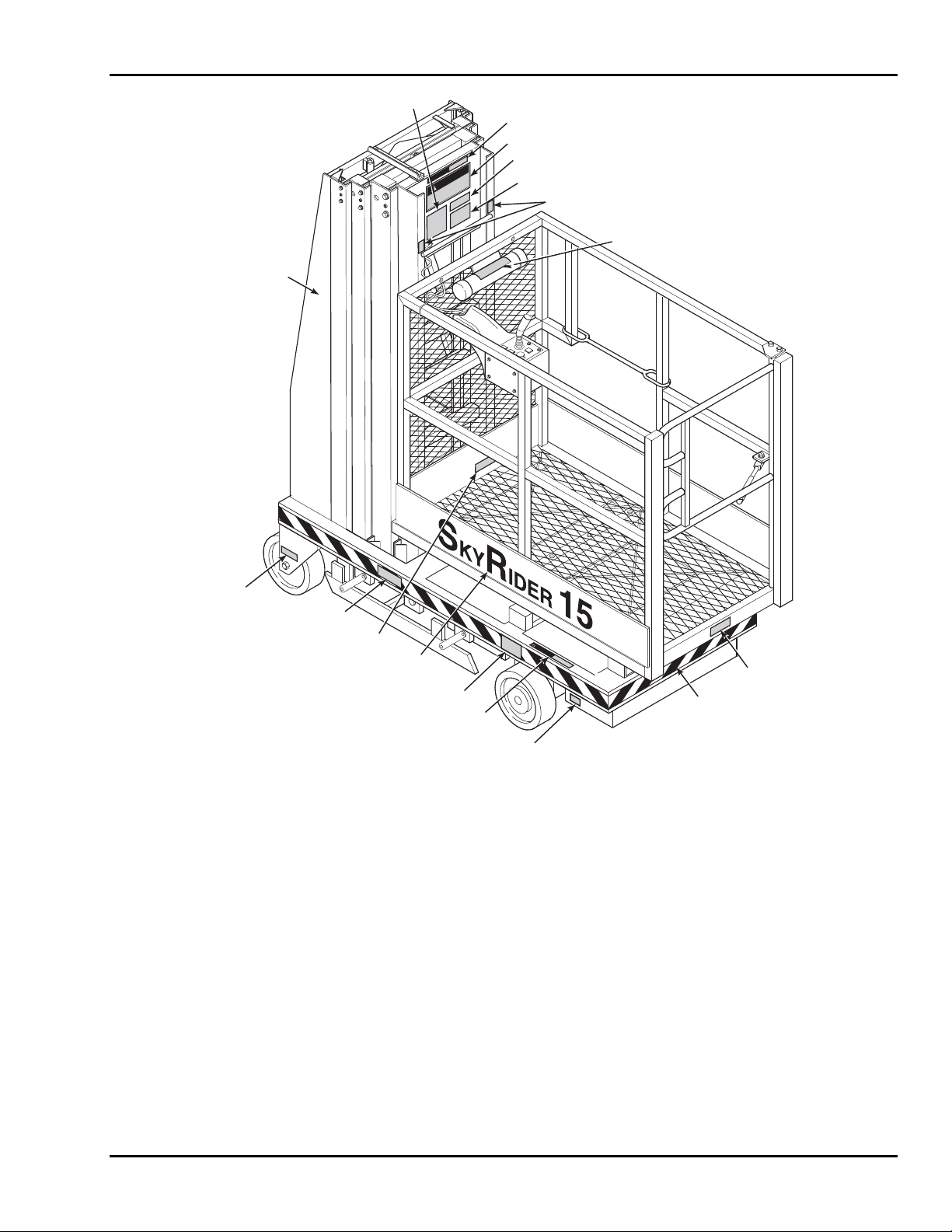

Figure 5-2. Decal Locations, Side View...................................................................

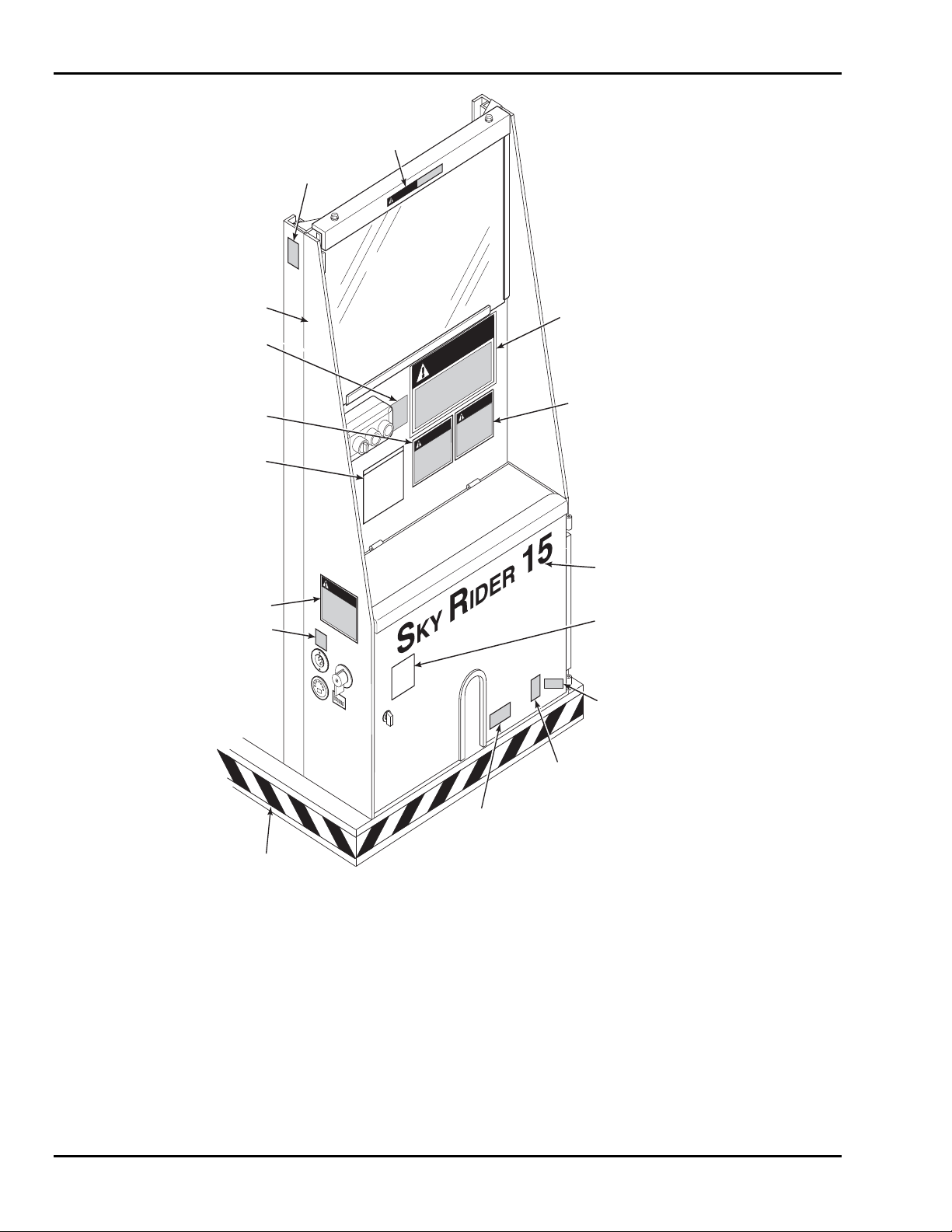

Figure 5-3. Decal Locations, Rear View...................................................................

Figure 6-1. Top Mast ................................................................................................

Figure 6-2. Center Mast ............................................................................................

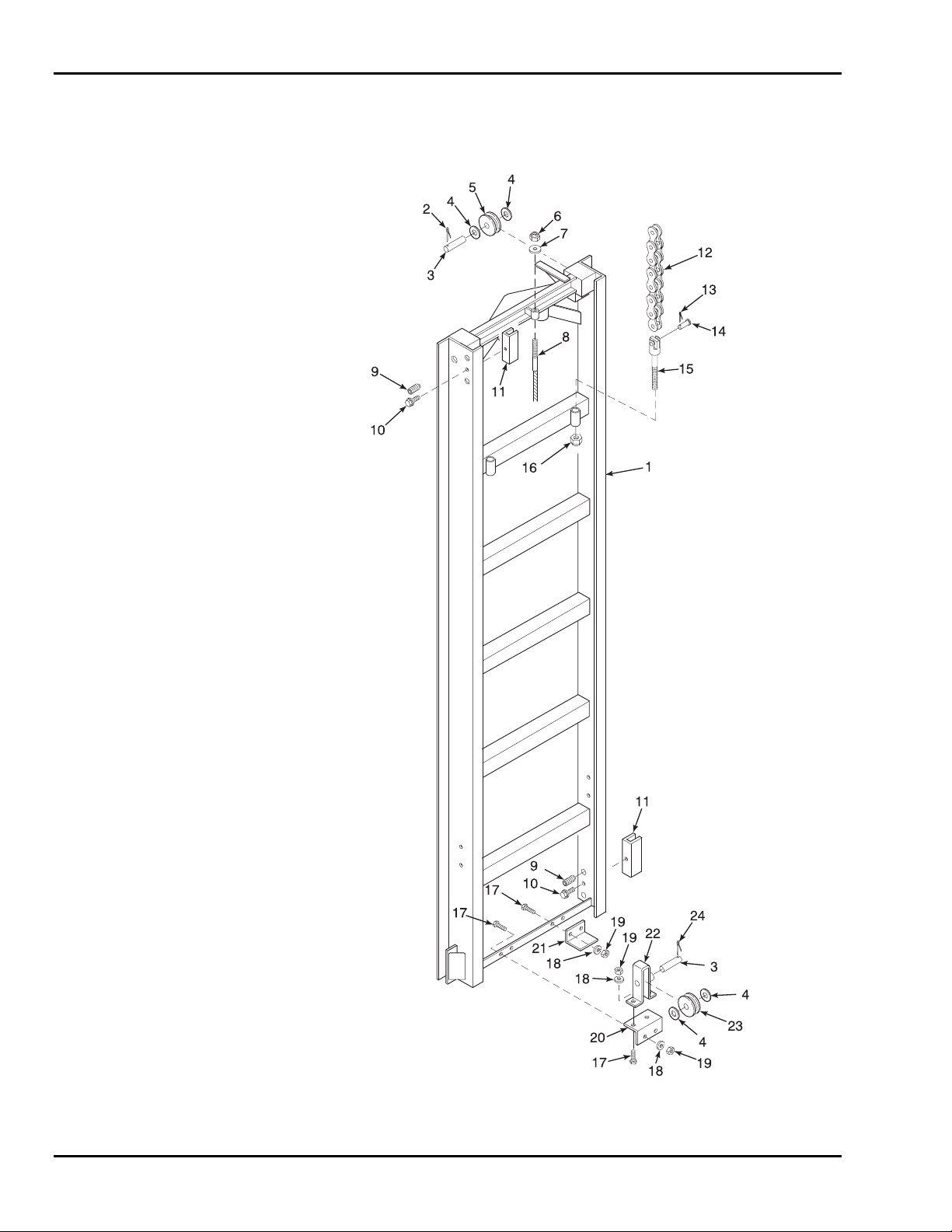

Figure 6-3. Lower Mast ............................................................................................

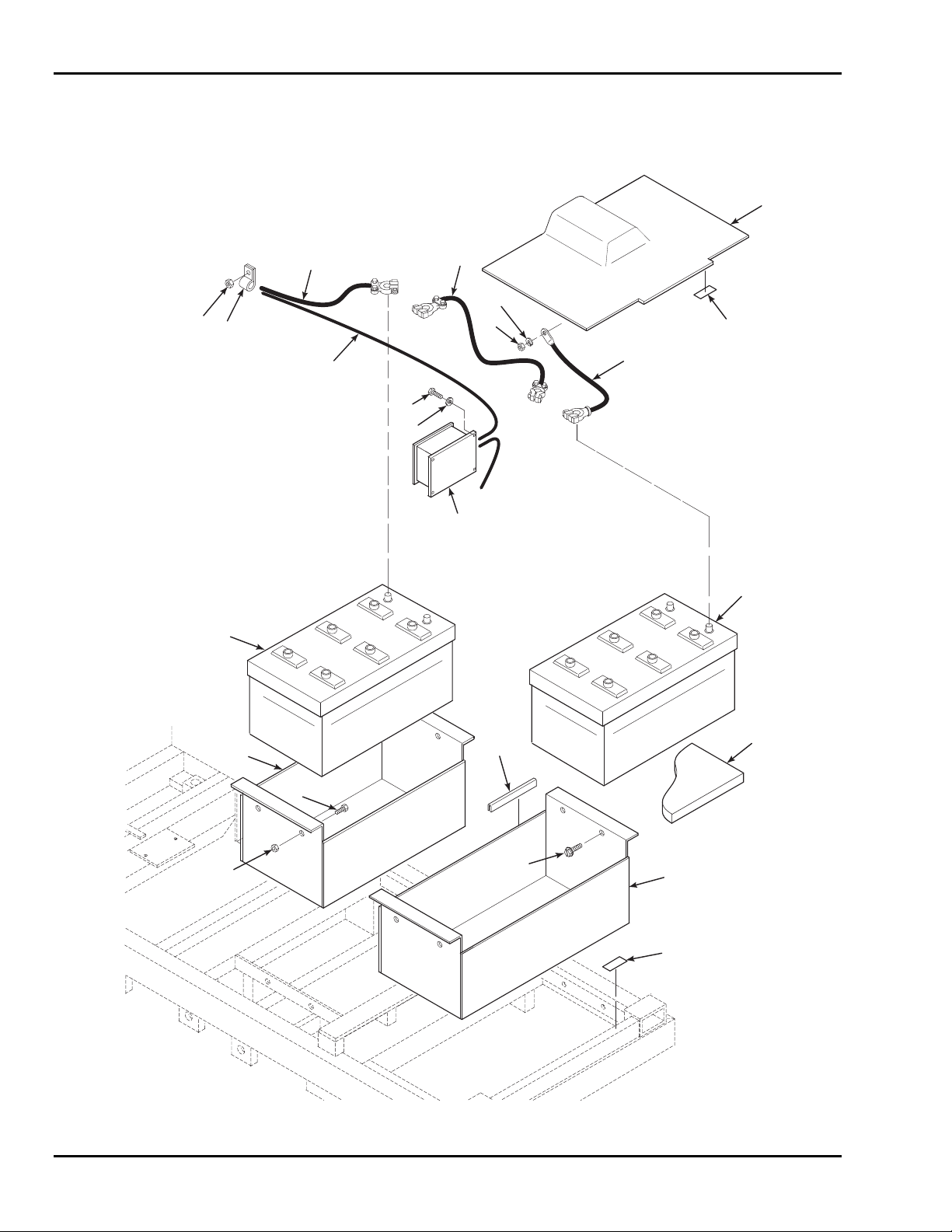

Figure 6-4. Battery Compartment .............................................................................

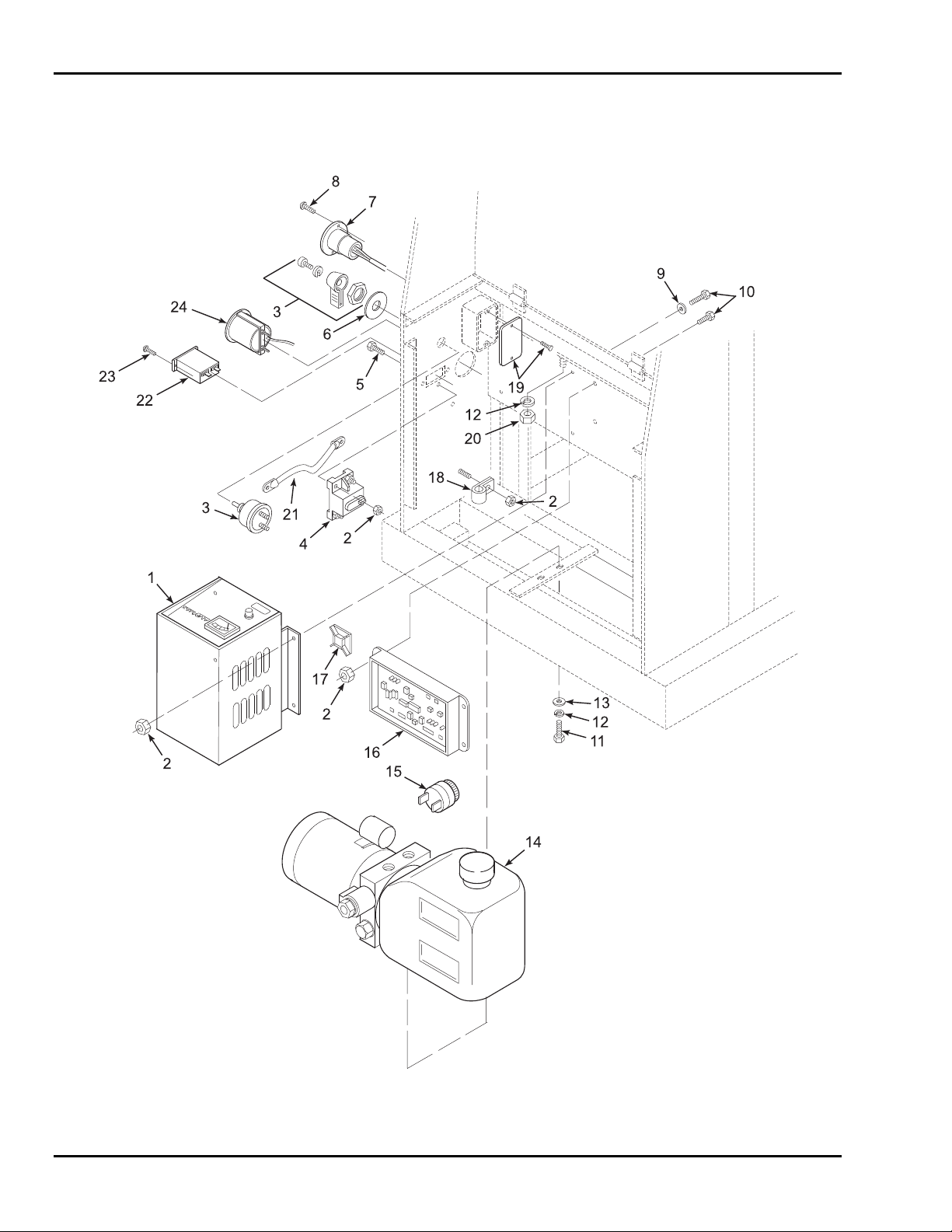

Figure 6-5. Hydraulic Pump Compartment.............................................................

Figure 6-6. Base......................................................................................................

Figure 6-7. Base Mast.............................................................................................

Figure 6-8. Drive Axle and Steering.......................................................................

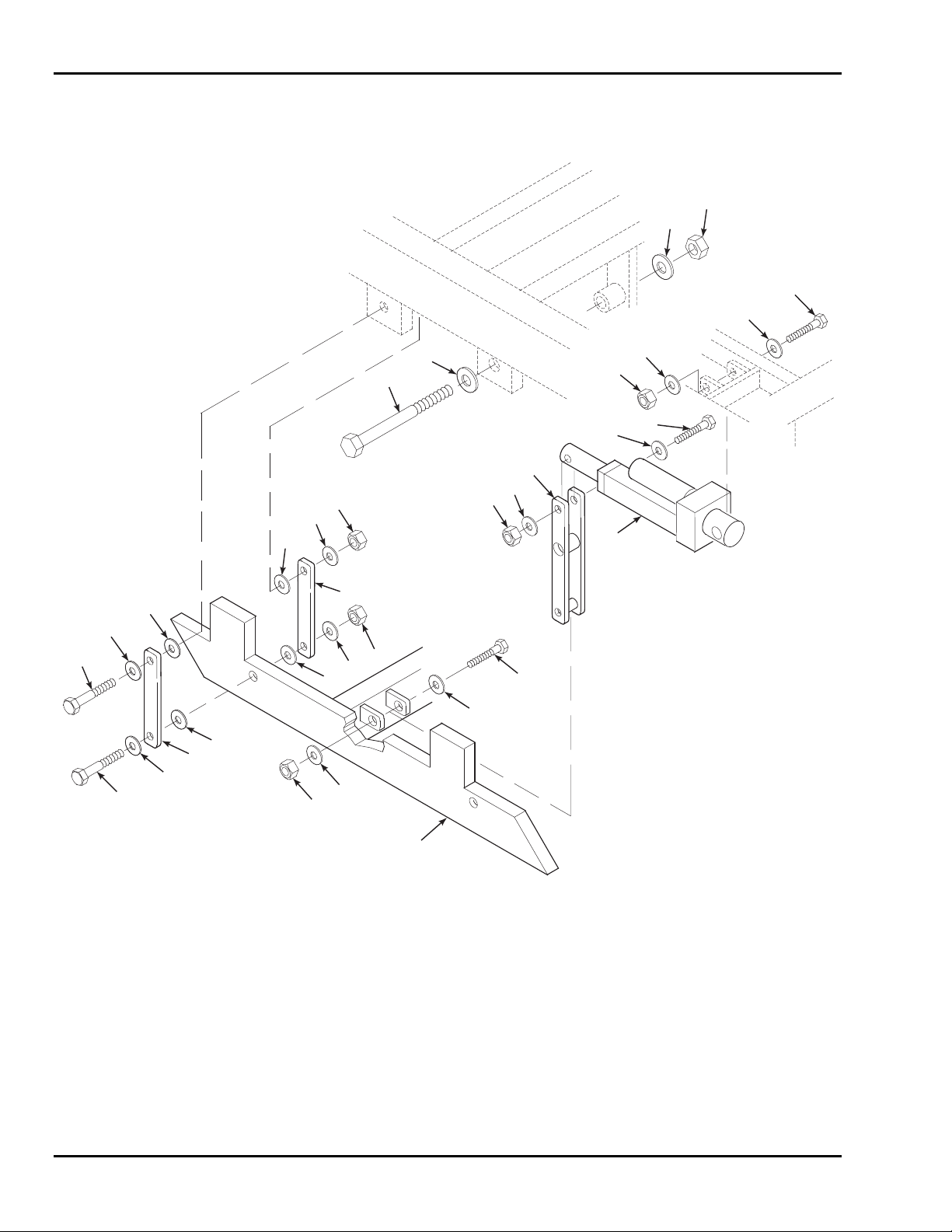

Figure 6-9. Pothole Guard.......................................................................................

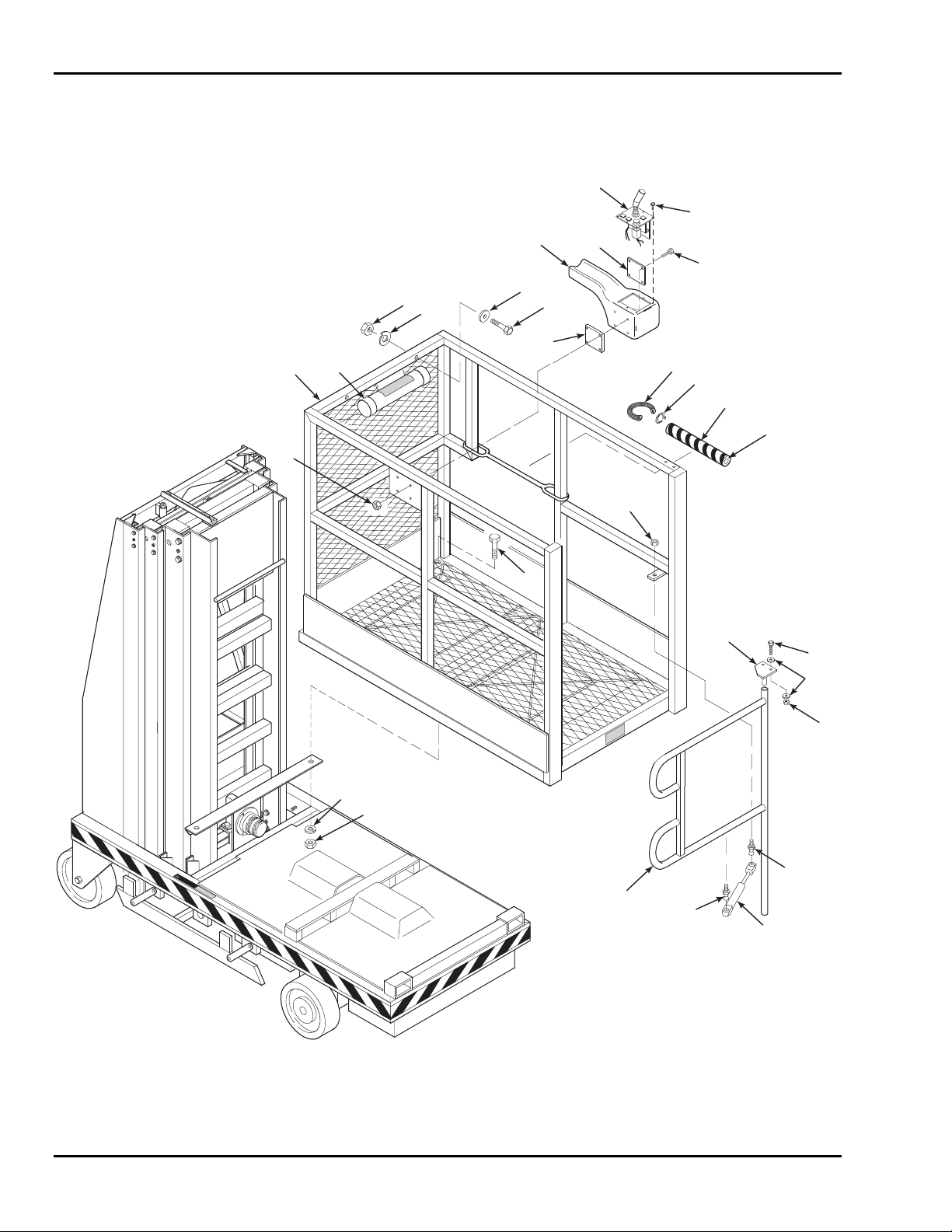

Figure 6-10. Platform................................................................................................

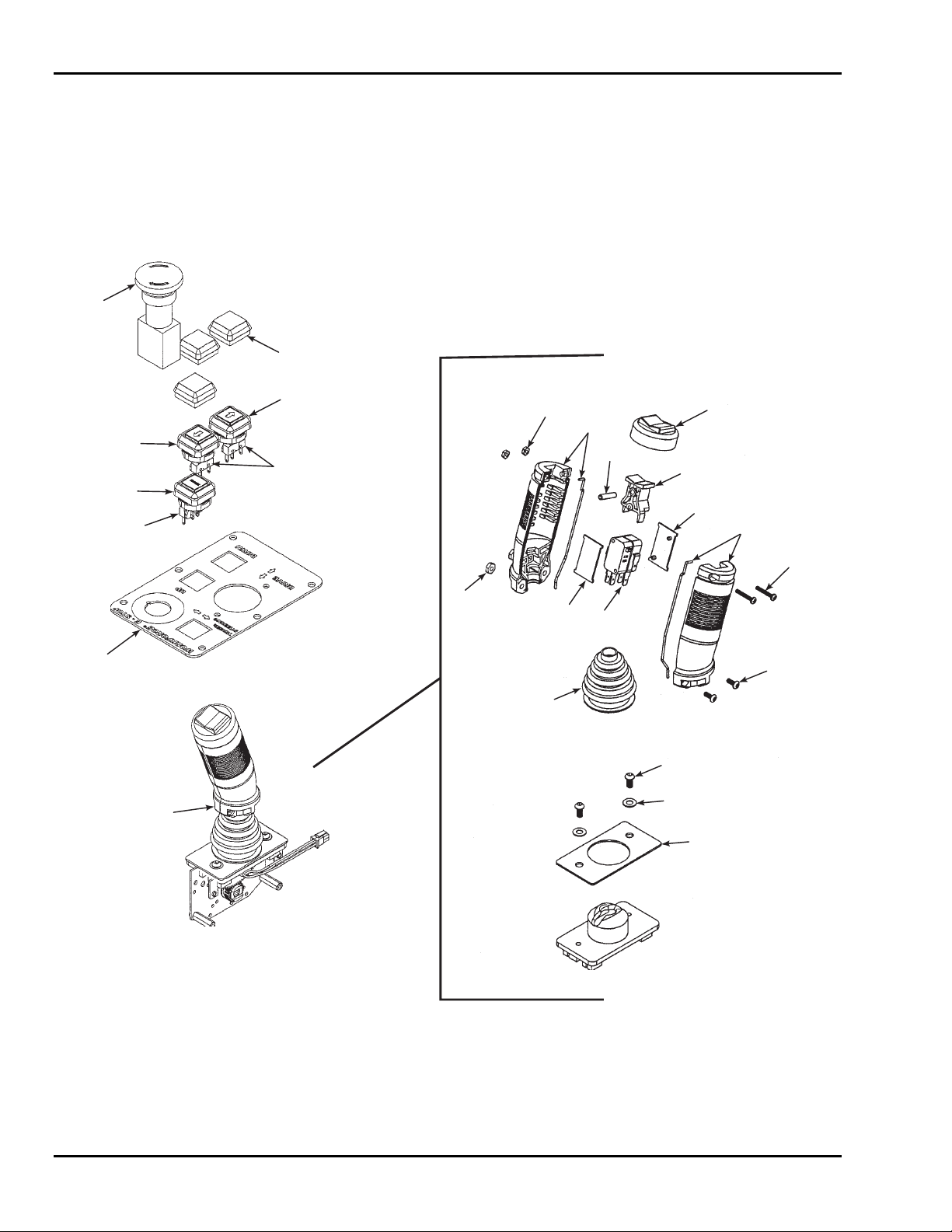

Figure 6-11. Upper Control Box...............................................................................

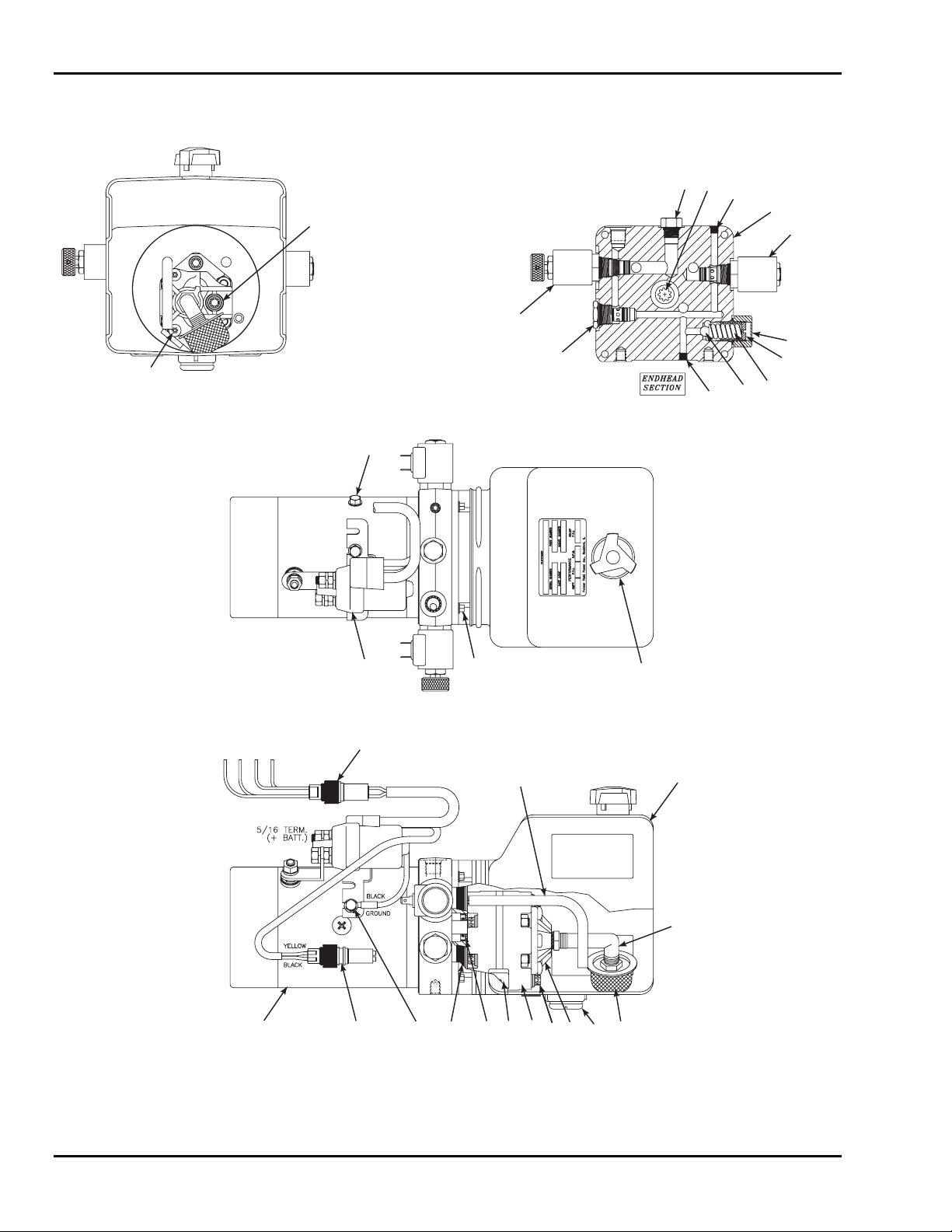

Figure 6-12. Hydraulic Unit Assembly.....................................................................

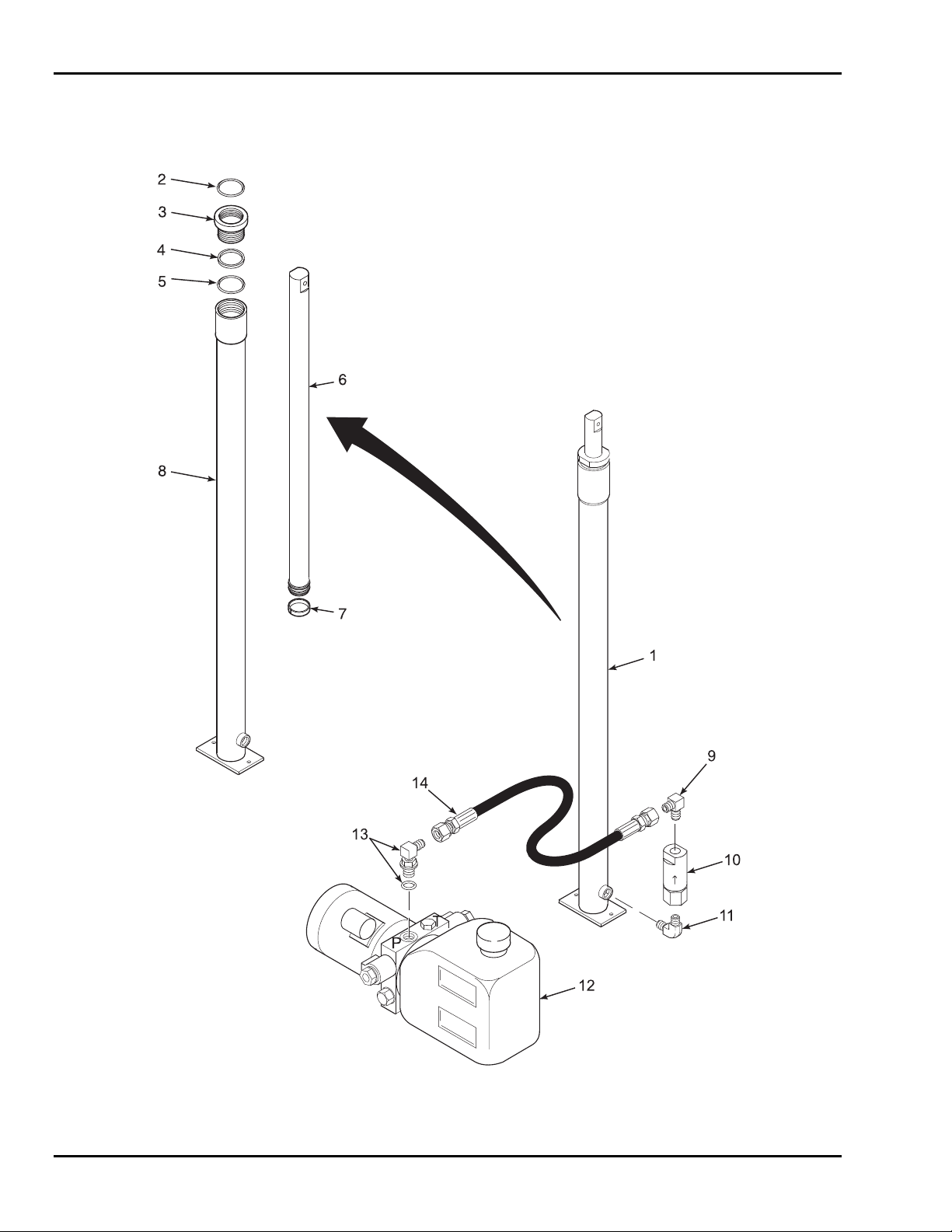

Figure 6-13. Hydraulic Cylinder, Fittings, and Hoses ..............................................

3-2

3-3

3-5

3-6

3-6

4-3

4-3

4-4

4-4

4-6

4-7

4-8

4-10

4-11

4-12

4-13

4-14

4-18

4-20

4-21

4-22

4-23

4-24

5-2

5-3

5-4

6-2

6-4

6-6

6-8

6-10

6-12

6-14

6-16

6-18

6-20

6-22

6-24

6-26

ii

Page 5

List of Tables

Table 1-1. Minimum Safe Approach Distances .......................................................1-4

Table 2-1. Specifications..........................................................................................

Table 4-1. Daily/Weekly Service Checks.................................................................

Table 4-2. Monthly Service Checks.........................................................................

Table 4-3. Troubleshooting Chart ..........................................................................

Table 4-4. Main Controller LED Indicators...........................................................

Table 5-1. Replacement Decals................................................................................

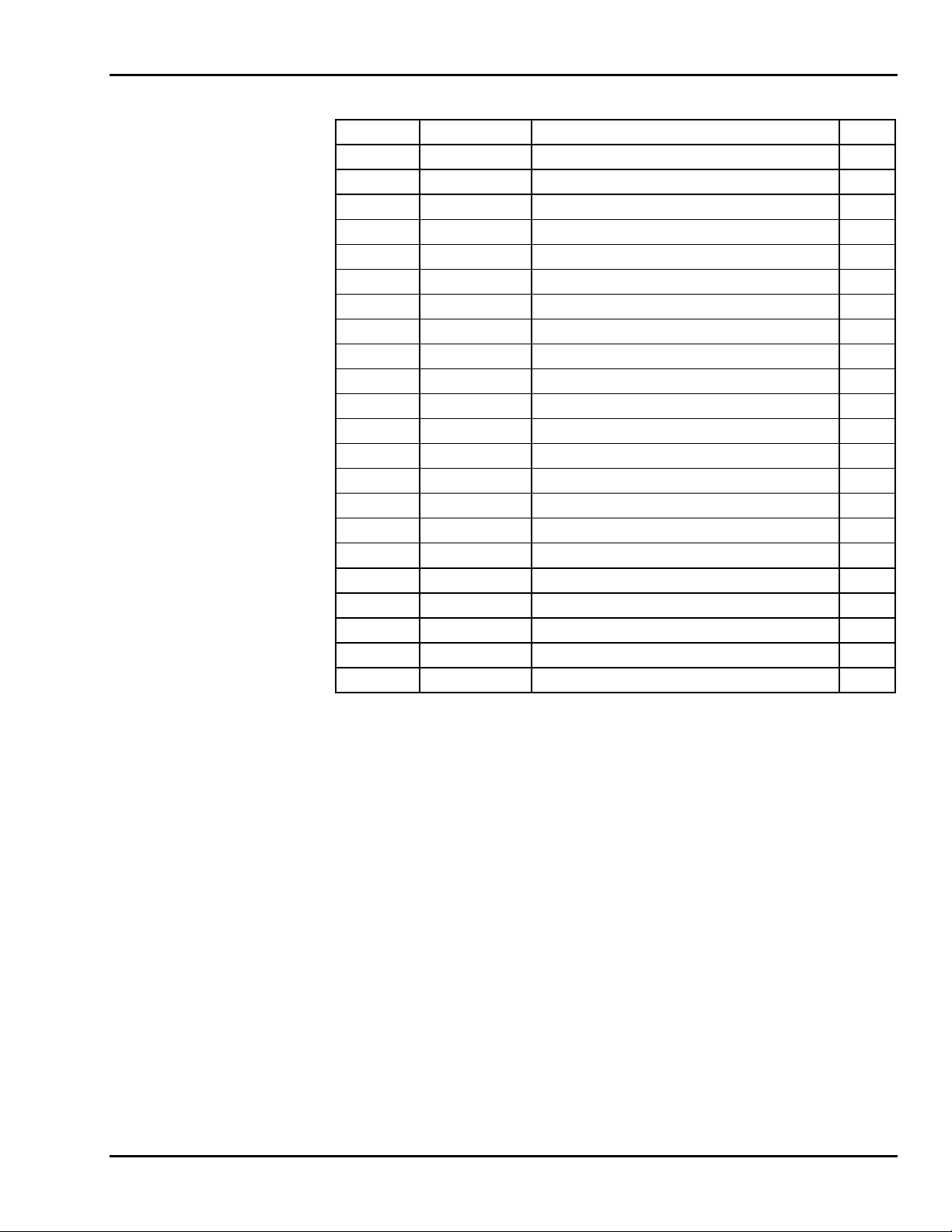

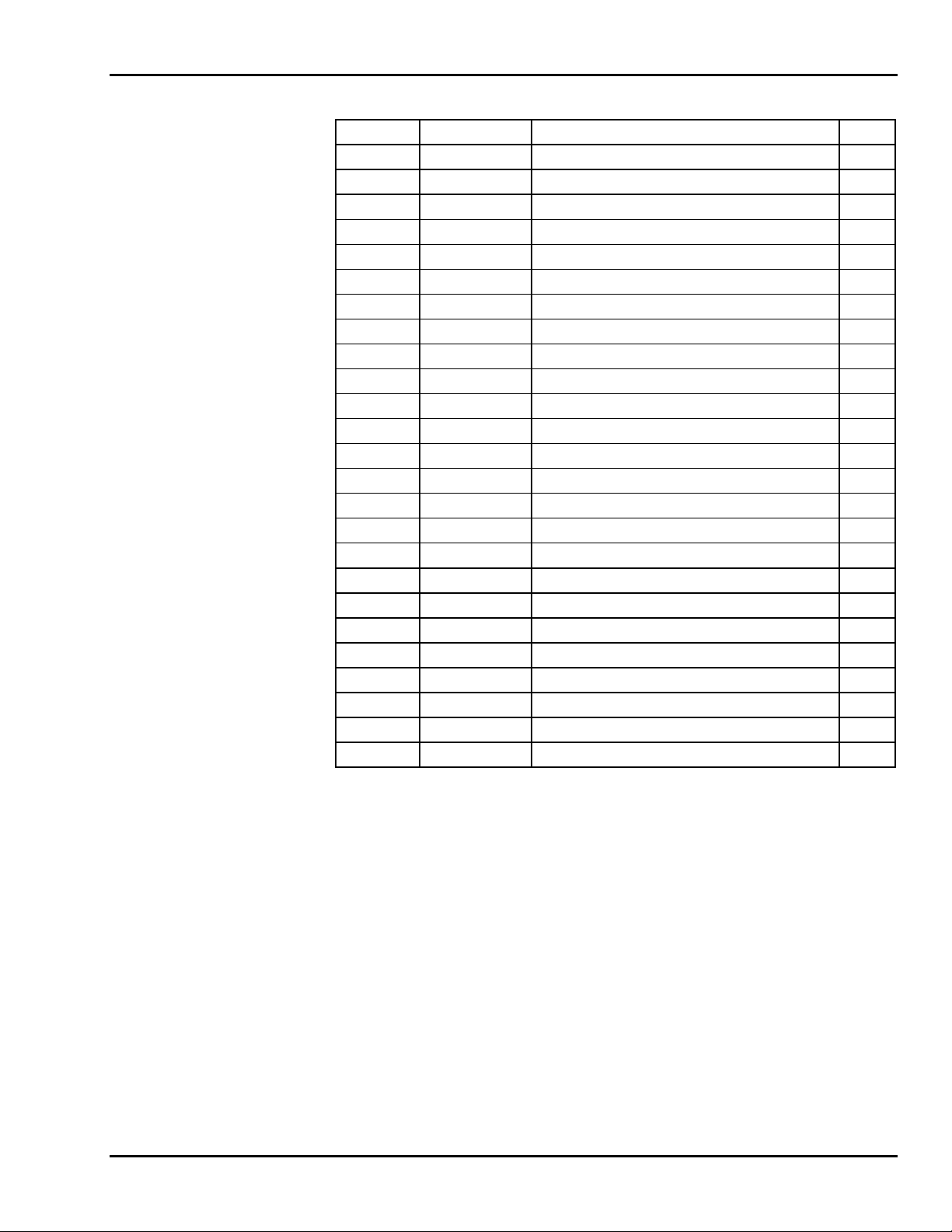

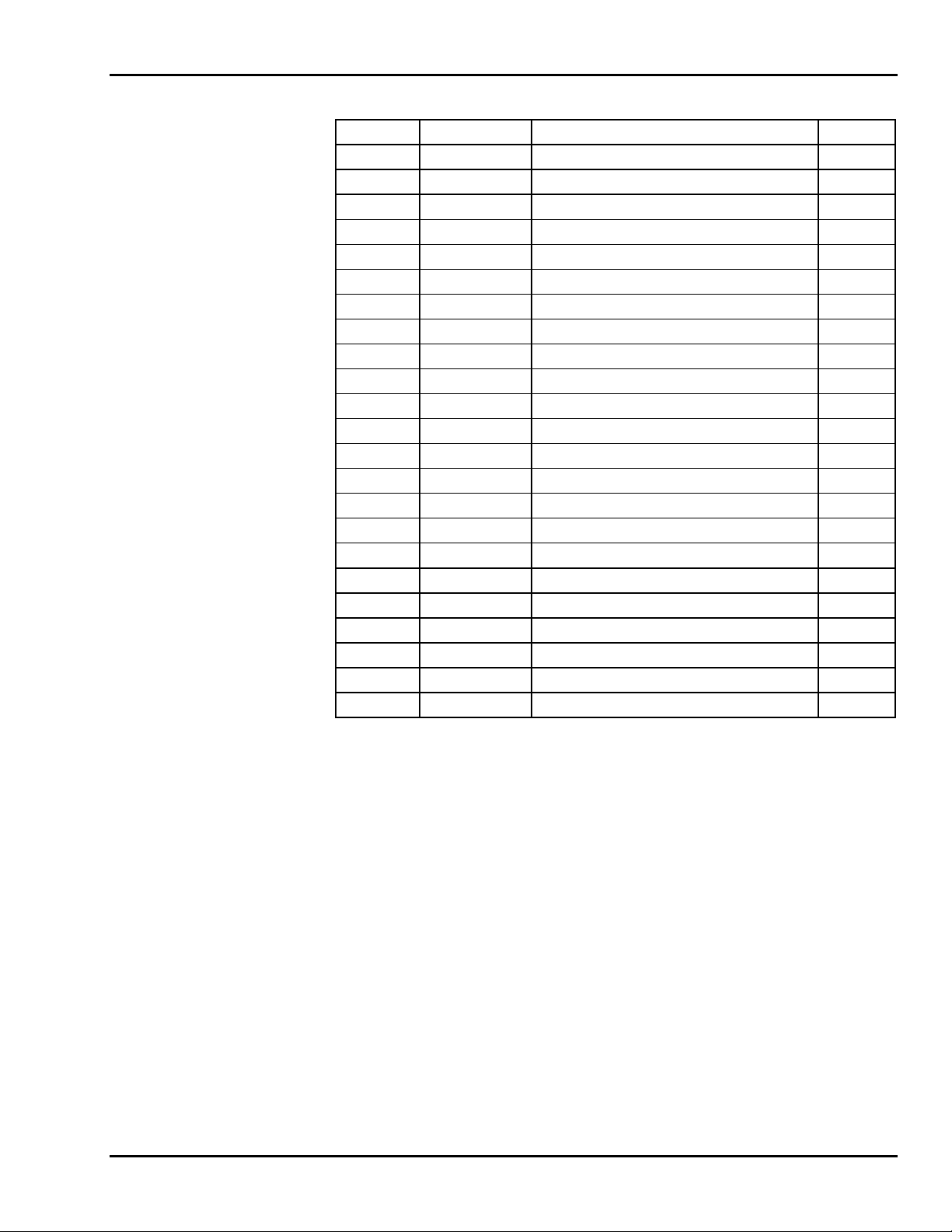

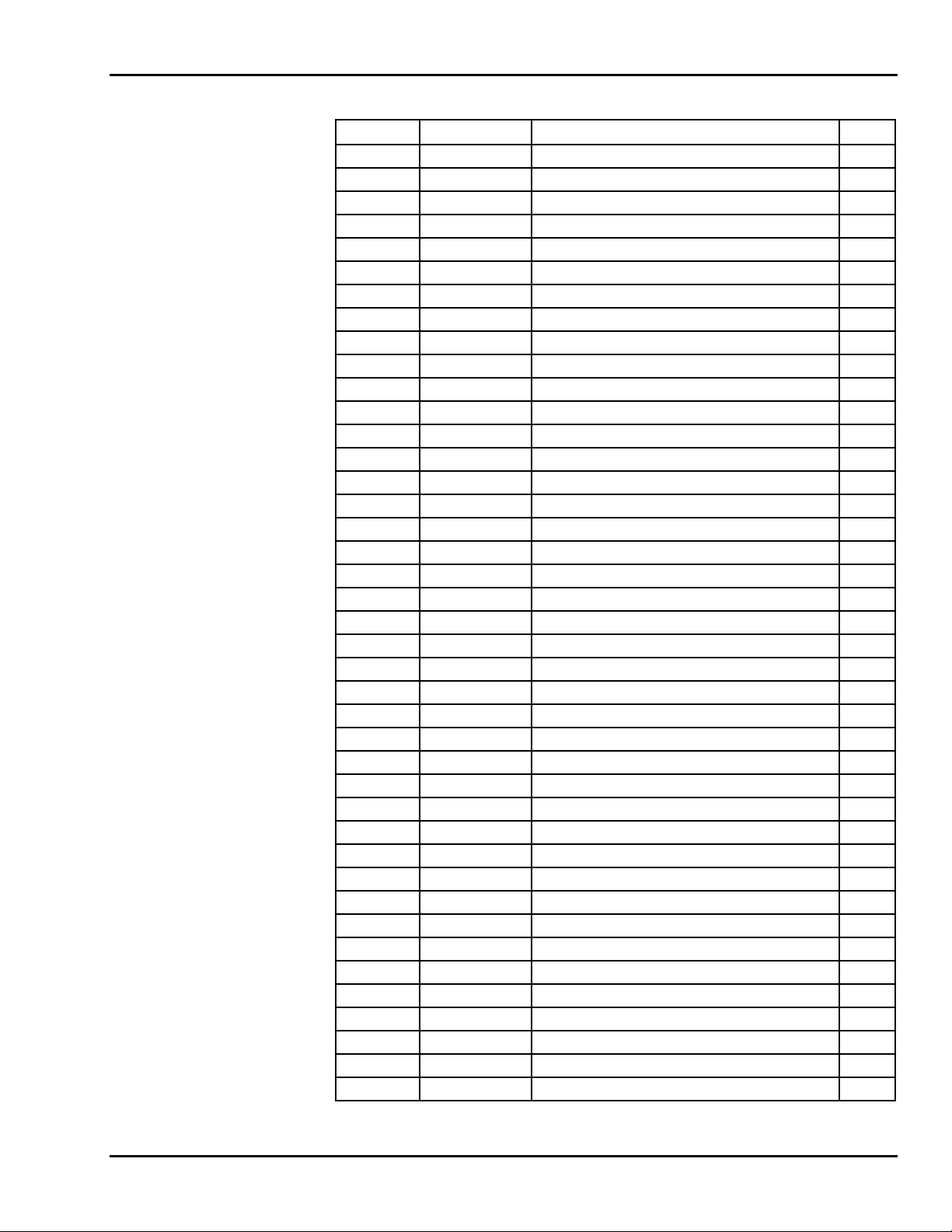

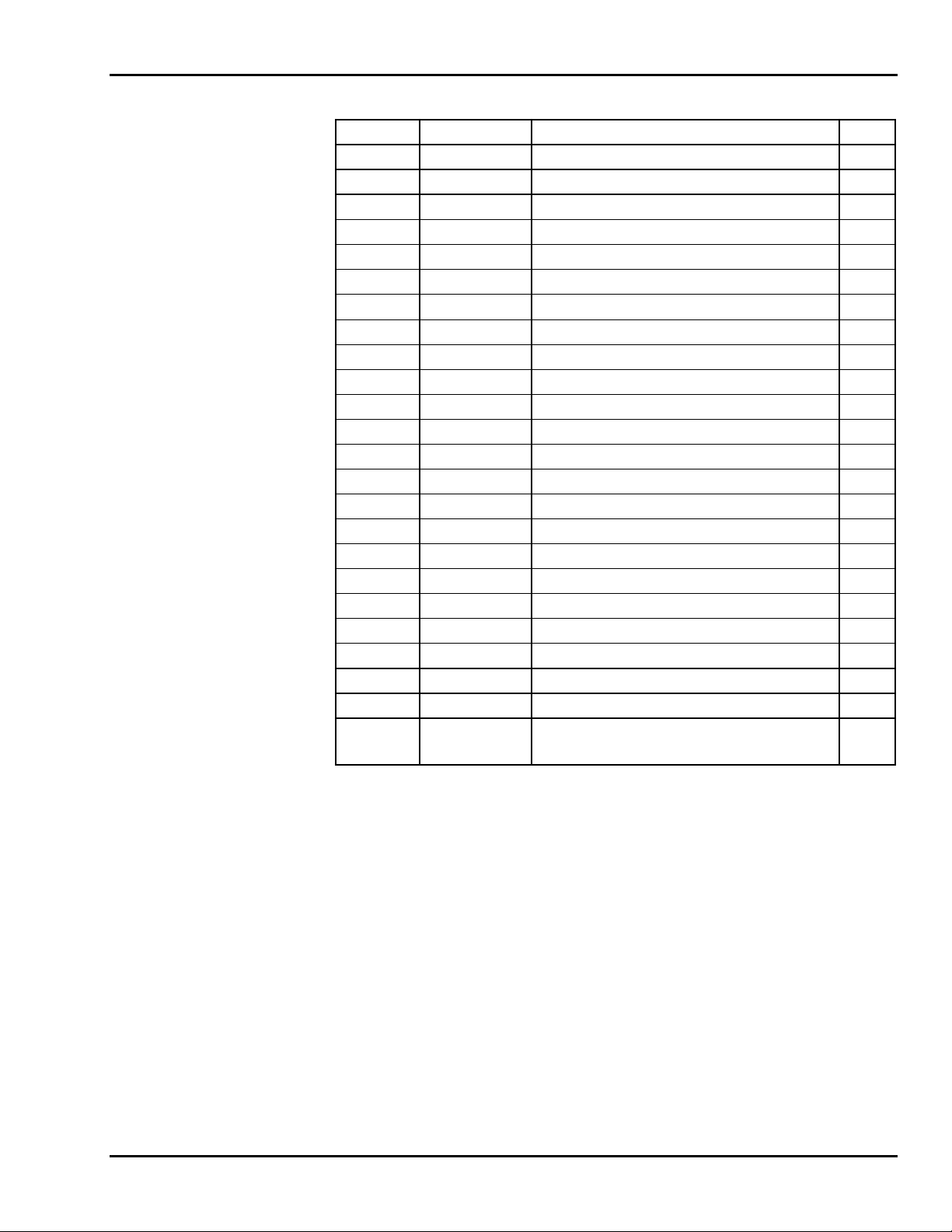

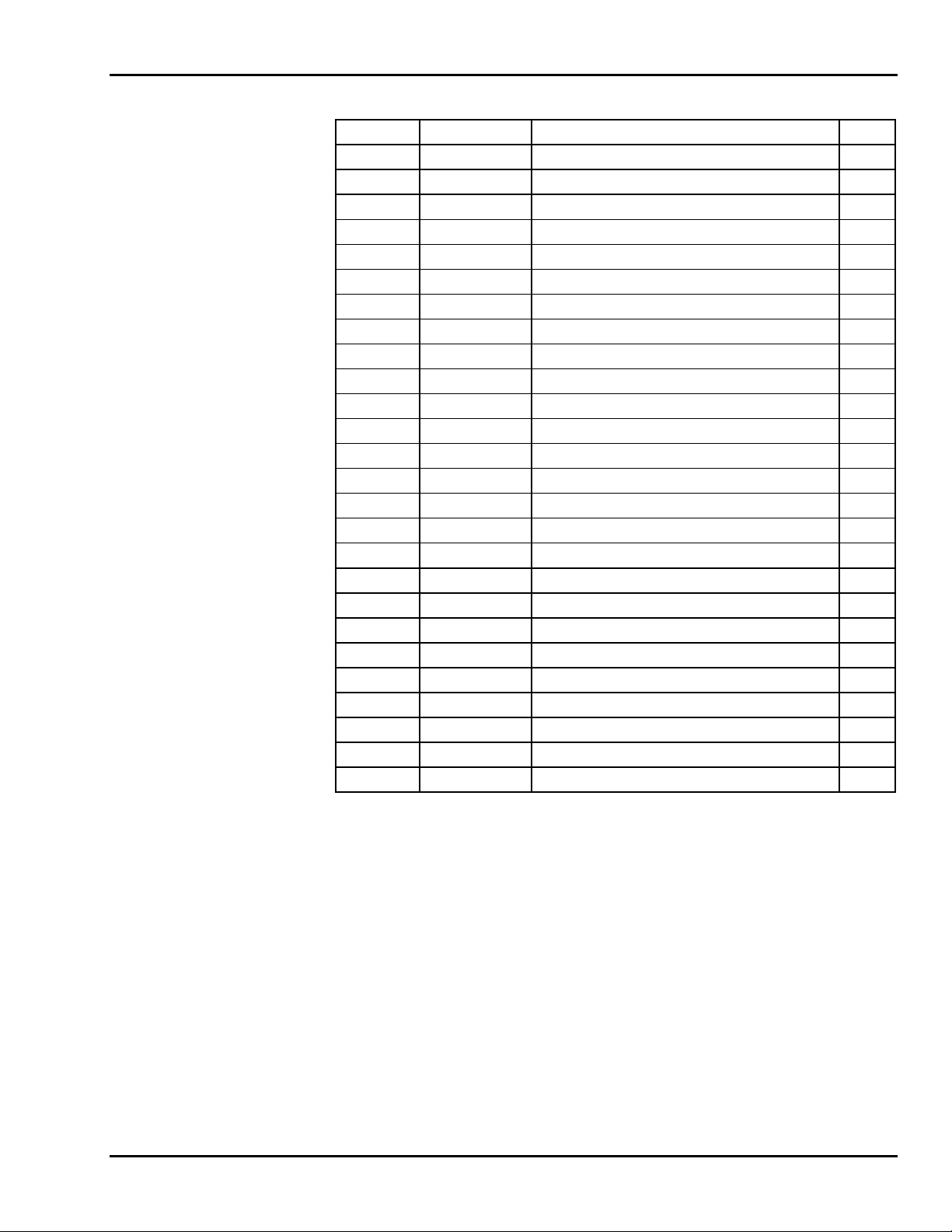

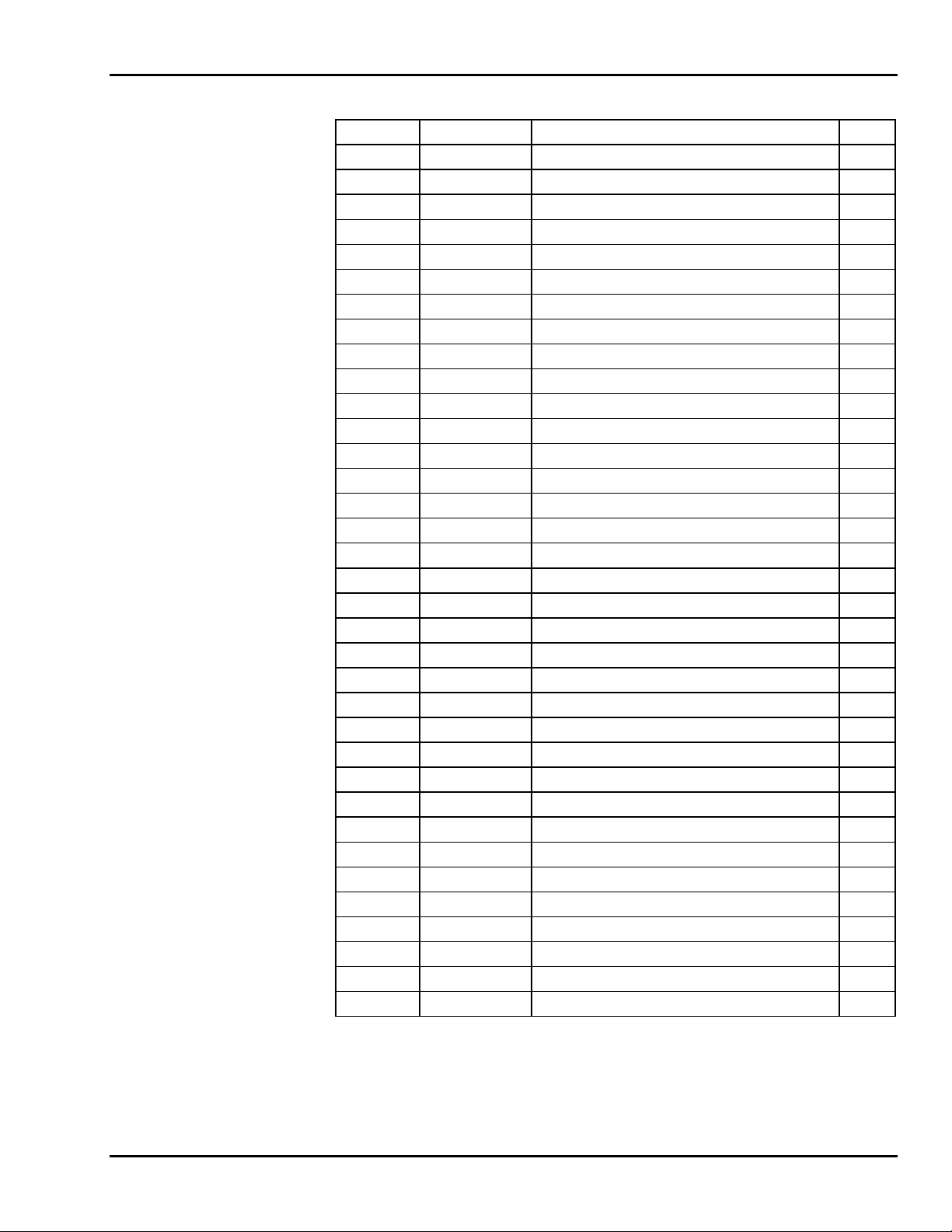

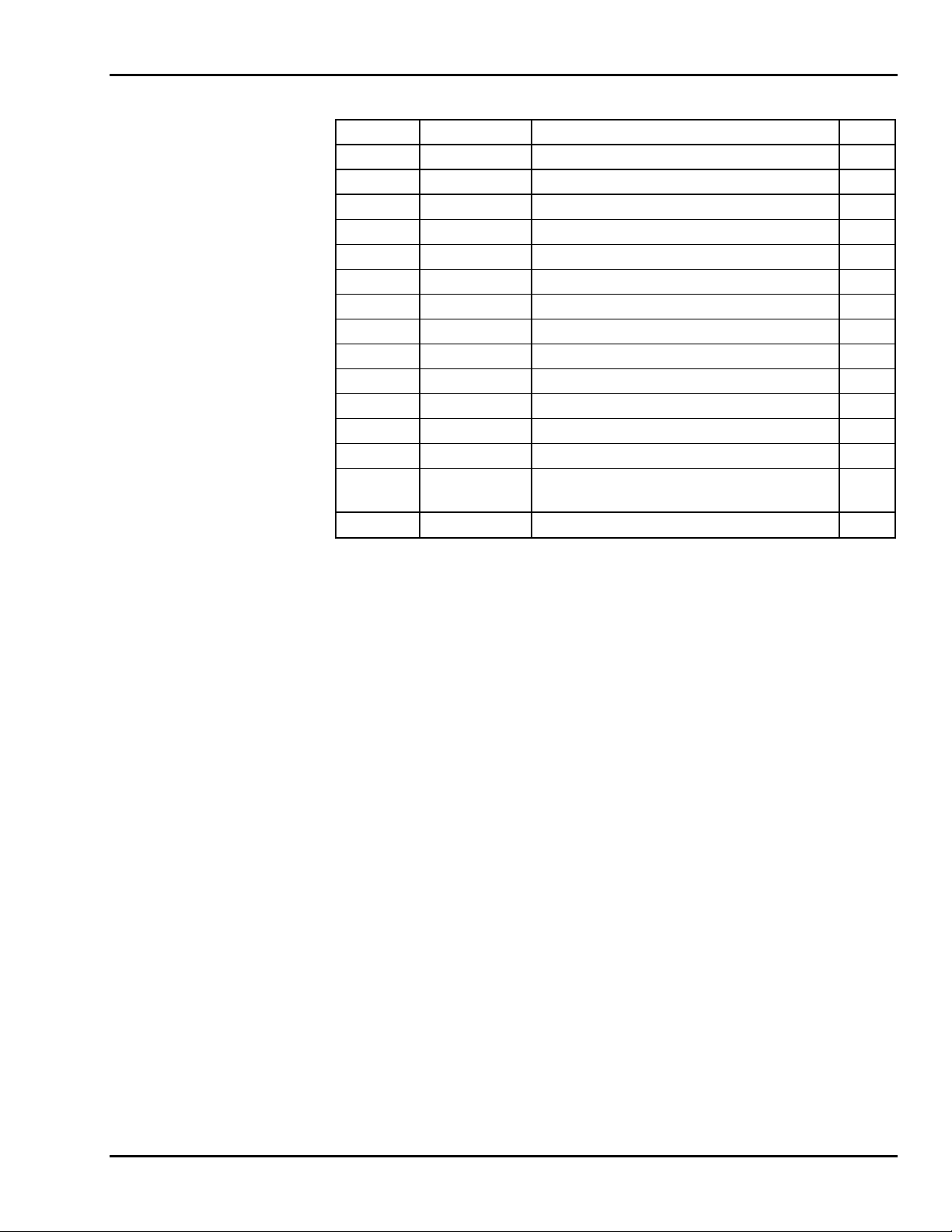

Table 6-1. Top Mast Parts List.................................................................................

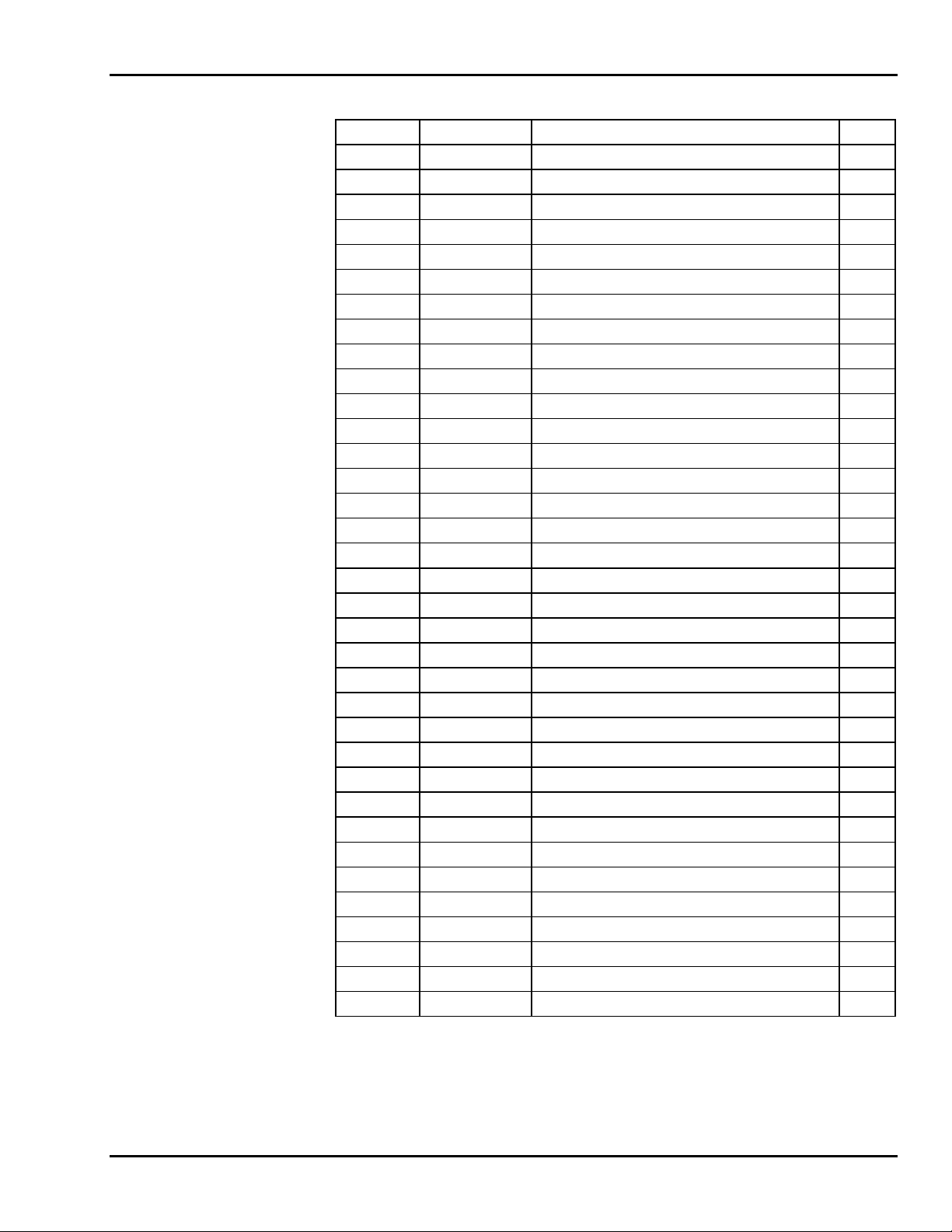

Table 6-2. Center Mast Parts List.............................................................................

Table 6-3. Lower Mast Parts List.............................................................................

Table 6-4. Battery Compartment Parts List..............................................................

Table 6-5. Hydraulic Pump Compartment Parts List .............................................

Table 6-6. Base Parts List.......................................................................................

Table 6-7. Base Mast Parts List..............................................................................

Table 6-8. Drive Axle and Steering Parts List........................................................

Table 6-9. Pothole Guard Parts List.......................................................................

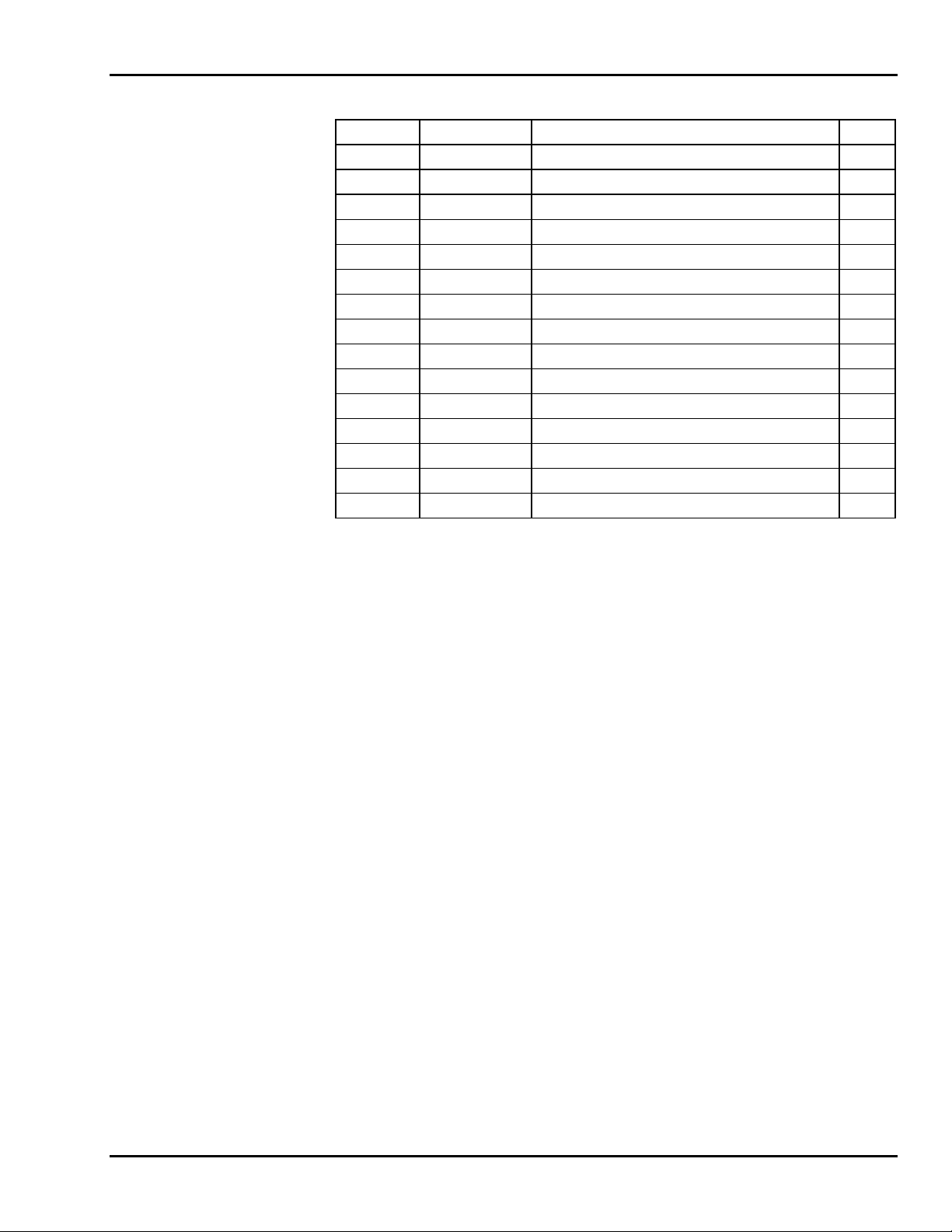

Table 6-10. Platform Parts List.................................................................................

Table 6-11. Upper Control Box Parts List................................................................

Table 6-12. Hydraulic Unit Parts List ......................................................................

Table 6-13. Hydraulic Cylinder, Fittings, and Hoses Parts List...............................

Table 7-1. Minimum Safe Approach Distance (M.S.A.D.) to energized

(exposed or insulated) power lines and parts........................................

2-2

4-1

4-2

4-15

4-19

5-1

6-3

6-5

6-7

6-9

6-11

6-13

6-15

6-17

6-19

6-21

6-23

6-25

6-27

7-15

iii

Page 6

iv

Page 7

1

Safety

1-1 INTRODUCTION

Familiarity and proper training are required for the safe operation of mechanical equipment. Equipment operated improperly or by untrained personnel can be dangerous. Read

the operating instructions in this manual and become familiar with the location and

proper use of all controls. Inexperienced operators should receive instruction from persons who are familiar with the equipment before operating the machine. The use of intelligence and common sense in the operation of mechanical equipment is the best practice

in any safety policy. Be professional and always observe the safety procedures set forth

in this manual.

All OSHA, ANSI, state and local codes and regulations pertaining to this equipment

should be obtained, read, and thoroughly understood before attempting to operate this

equipment. Persons under the influence of drugs, alcohol, or prescription medication

should not be on or near this equipment. Common sense should be implemented at all

times during the use of this equipment. Do not operate this equipment in areas where

equipment or user may come in contact with live power source.

The information contained herein is not to be considered as legal advice and is intended

for informational purposes only. This information is offered to alert Workforce customers to procedures that may be of concern to them.

This information is not intended to be all-inclusive and is to b e followed in the use of

Workforce equipment only.

For any questions concerning the safe use of this equipment, call 419.445.9675 before

operating.

1-1

Page 8

SkyRider 15

Safety Notes

This manual contains DANGERS, WARNINGS, CAUTIONS, and NOTES that must be

followed to prevent the possibility of improper service, damage to the equipment, or personal injury.

DANGER

Dangers warn of equipment operation near electrical power lines that could lead

to personal injury or death.

WARNING

Warnings describe conditions or practices that could lead to personal injury or

death.

CAUTION

Cautions provide information important to prevent errors that could damage machine or components.

NOTE: Notes contain additional information important to a procedure.

1-2

Page 9

1 — SAFETY

1-2 BEFORE OPERATION

Read and observe the following general safety precautions before operating the SkyRider 15.

• ALWAYS survey the usage area for potential hazards such as untampered earth

fills, unlevel surfaces, overhead obstructions, and electrically charged conductors or wires. Be aware of any potential hazards and always consider what could

happen. Watch for moving vehicles in the operating area.

• ALWAYS read, understand, and follow the procedures in this manual before attempting to operate equipment.

• ALWAYS inspect the equipment for damaged or worn parts. Check for cracked

welds, hydraulic leaks, damaged wiring, loose wire connectors, damaged casters, and damaged pothole guards. Also check for any improper operation.

NEVER operate equipment if damaged in any way. Improperly operating

equipment must be repaired before using.

• ALWAYS wear proper clothing for the job. Wear protective equipment as required by federal, state, or local regulations.

• ALWAYS locate, read, and follow all directions and warnings displayed on the

equipment.

• ALWAYS inspect the equipment for “DO NOT USE” tags installed by maintenance personnel. NEVER use tagged equipment until repairs are made and all

tags are removed by authorized maintenance personnel.

• ALWAYS make sure the platform is free of mud, grease, or other foreign material. This will reduce the possibility of slipping.

• NEVER allow improperly trained personnel to operate this equipment. Only

trained and authorized personnel shall be allowed to operate this equipment.

• NEVER operate this equipment if you are under the influence of alcohol or

drugs or if you feel ill, dizzy, or unsteady in any way. Operators must be physically fit, thoroughly trained, and not easily excitable.

• NEVER modify, alter, or change the equipment in any way that would affect its

original design or operation in any way.

• NEVER operate this equipment in ways for which it is not intended.

1-3

Page 10

SkyRider 15

1-3 DURING OPERATION

Read and observe the following general safety precautions at all times during operation

of the SkyRider 15.

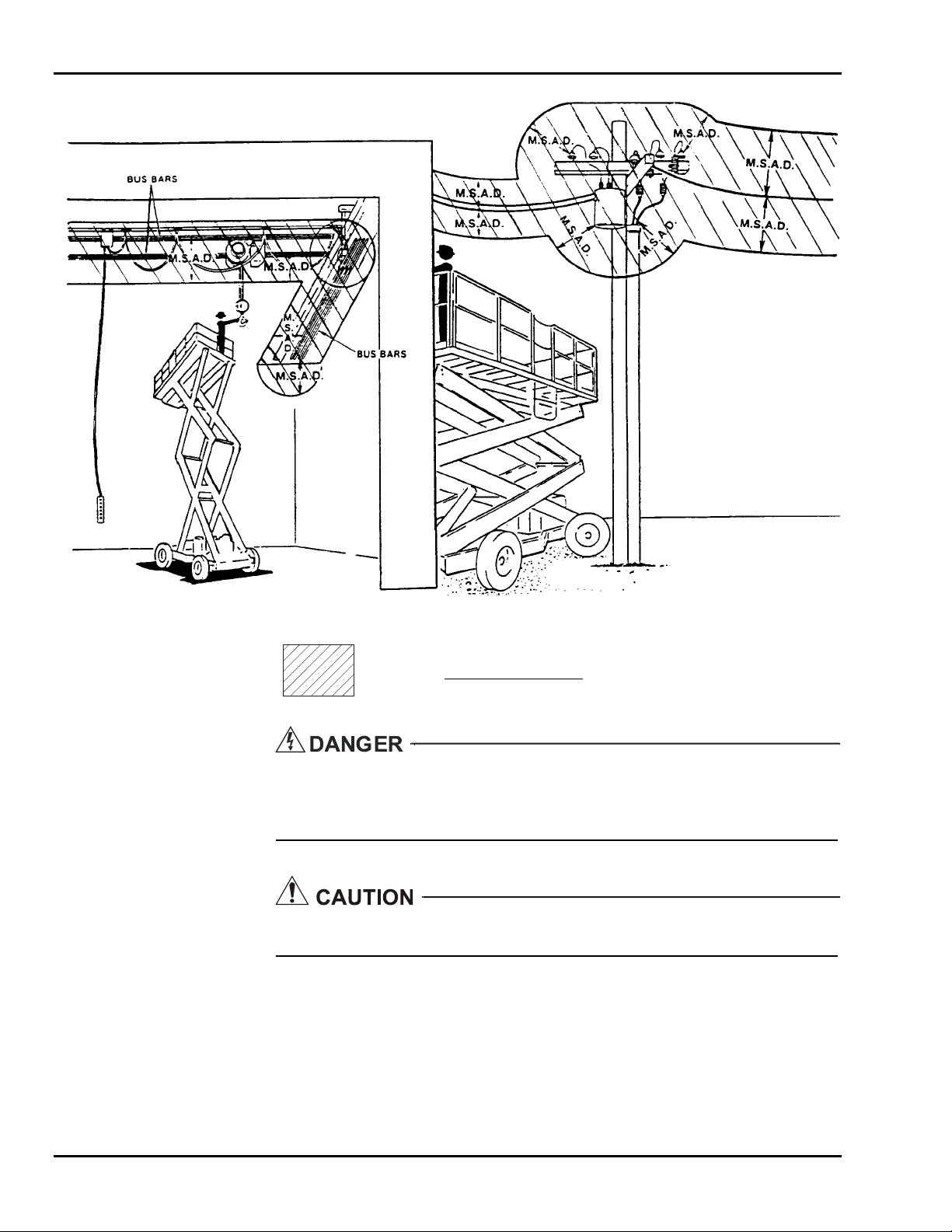

DANGER

This machine is not insulated for use near electrical power lines and DOES NOT

provide protection from contact with or close proximity to any electrically

charged conductor. Operator must maintain safe clearances at all times (10 feet

minimum) and always allow for platform movement such as wind induced sway.

Always contact the power company before performing work near power lines. Assume every line is hot. Remember, power lines can be blown by the wind.

Refer to Table 1-1 for minimum safe approach distances between machine and electrical

power lines.

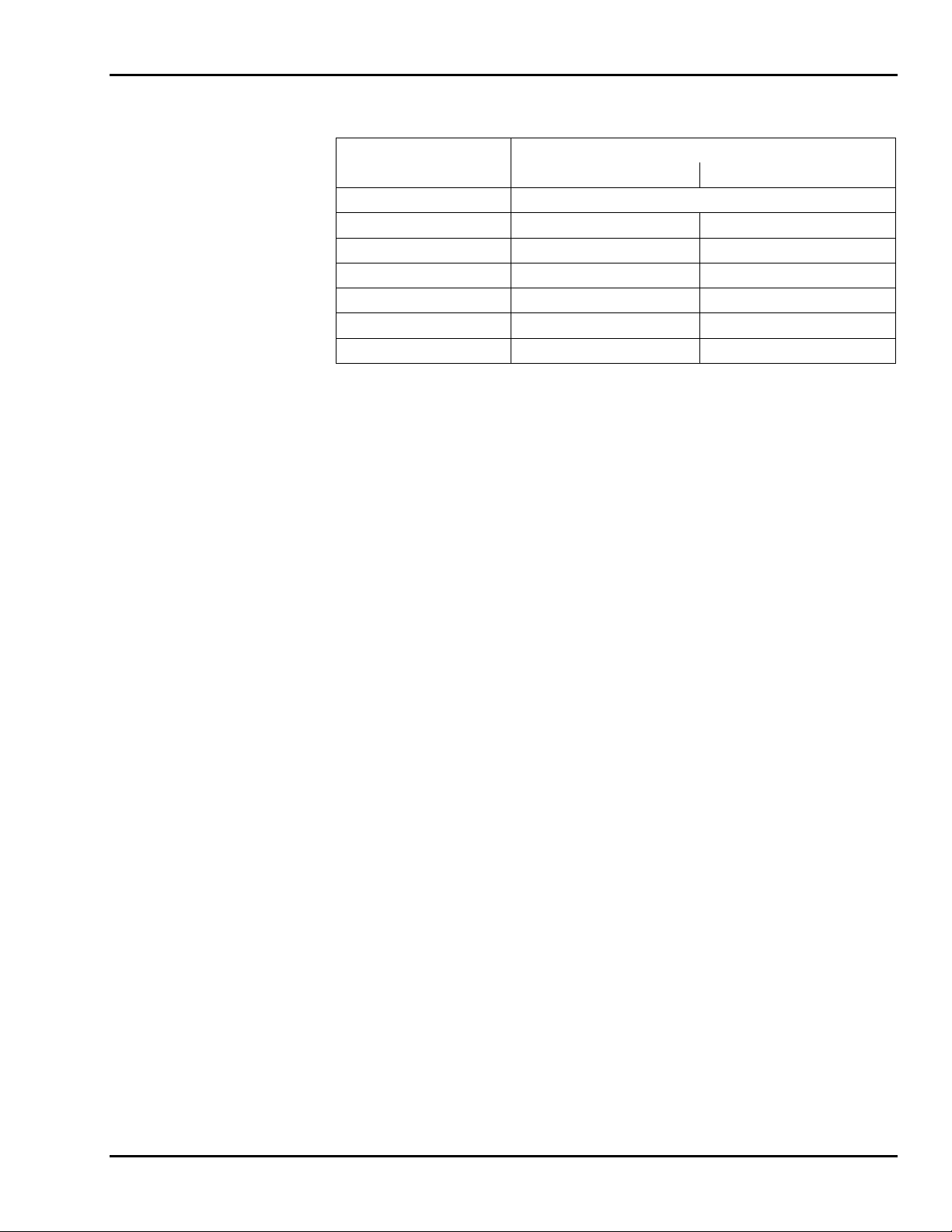

Table 1-1. Minimum Safe Approach Distances

Voltage Range

(Phase to Phase)

0 to 300V Avoid Contact

Over 300V to 50KV 10 3.05

Over 50KV to 200KV 15 4.60

Over 200KV to 350KV 20 6.10

Over 350KV to 500KV 25 7.62

Over 500KV to 750KV 35 10.67

Over 750KV to 1000KV 45 13.72

Minimum Safe Approach Distance

(Feet) (Meters)

• ALWAYS position lift far enough away from power sources to ensure that no

part of the lift can accidentally reach into an unsafe area.

• ALWAYS operate only on a firm and level surface. NEVER use on surfaces

that do not support the weight of the equipment and its rated load capacity.

• ALWAYS keep yourself and all personnel away from potential pinch or shear

points.

• ALWAYS report any misuse of equipment to the proper authorities. Horseplay

is prohibited.

• ALWAYS maintain good footing on the platform. NEVER wear slippery soled

shoes.

• ALWAYS make certain all personnel are clear and there are no obstructions before repositioning platform.

• ALWAYS cordon off area around the base to keep personnel and other equipment away from it while in use.

• ALWAYS stay clear of wires, cables, and other overhead obstructions.

• ALWAYS disconnect power at the batteries when not in use to guard against

unauthorized use.

1-4

Page 11

1 — SAFETY

• NEVER allow electrode contact with any part of the platform if welding is being performed from the platform.

• NEVER override or by-pass manufacturer's safety devices.

• NEVER release the travel brake or tow the lift vehicle while a person or materi-

als are on board.

• NEVER stand or sit on guard rails. Work only within the platform guard rail

area and do not lean out over guard rails to perform work.

• NEVER attempt to increase working height with boxes, ladders, or other means.

• NEVER operate this equipment when exposed to high winds, thunderstorms,

ice, or any other weather conditions that would compromise the safety of the

operator.

• NEVER climb up or down masts.

• NEVER allow ropes, electric cords, hoses, etc. to become entangled in the

equipment when the platform is being raised or lowered.

• NEVER exceed manufacturer's platform load limits and make sure all materials

are evenly distributed over the entire platform.

• NEVER exceed platform load ratings by transferring loads to platform at elevated heights.

• NEVER use guard rails to carry materials and never allow overhang of materials

when raising or lowering platform.

1-5

Page 12

SkyRider 15

1-4 MAINTENANCE SAFETY

Read and observe the following general safety precautions when performing maintenance

on the SkyRider 15.

• ALWAYS perform maintenance procedures according to manufacturer's requirements. NEVER short change maintenance procedures.

• ALWAYS check hydraulic system. Make sure all lines, connectors, and fittings

are tight and in good condition.

• ALWAYS keep all mechanisms properly adjusted and lubricated according to

maintenance schedule and manufacturers specifications.

• ALWAYS perform a function check of operating controls before each use and

after repairs have been made.

• ALWAYS locate and protect against possible pinch points prior to performing

maintenance and repairs.

• ALWAYS use only factory-approved parts to repair or maintain this equipment.

If this equipment is rebuilt, retesting is required in accordance with factory instructions.

• NEVER add unauthorized fluids to the hydraulic system or battery. Check

manufacturers specifications.

• NEVER exceed the manufacturer's recommended relief valve settings.

• NEVER attempt repairs you do not understand. Consult manufacturer if you

have any questions regarding proper maintenance, specifications, or repair.

Battery Maintenance

Read and observe the following general safety precautions when performing battery

maintenance on the SkyRider 15.

• ALWAYS check battery acid level daily. Check battery charge indicator for

proper state of charge on maintenance free batteries before using lift.

• ALWAYS wear safety glasses when working near battery.

• ALWAYS avoid contact with battery acid. Battery acid causes serious burns.

Avoid contact with skin or eyes. If accidental contact occurs, flush with water

and consult a physician immediately.

• ALWAYS disconnect ground cable first when removing battery.

• ALWAYS connect ground cable last when installing battery.

• ALWAYS charge batteries in open, well-ventilated areas.

• NEVER smoke when servicing battery.

• NEVER allow batteries to overcharge and boil.

• NEVER short across battery posts to check for current. NEVER break a live cir-

cuit at battery.

• NEVER jump start other vehicles using lift battery.

1-6

Page 13

1 — SAFETY

1-5 DAMAGED EQUIPMENT POLICY

Safety Statement

At Workforce, we are dedicated to the safety of all users of our products. Therefore, all

Workforce lifts are designed, manufactured, and tested to comply with current applicable

Federal OSHA and ANSI codes and regulations.

Damage Policy

There may be occasions when a Workforce lift is involved in an incident that results in

structural damage to the lift. This can seriously compromise the ability of the lift to perform in a safe manner. Therefore, whenever a Workforce lift is damaged structurally or

when there is the possibility of structural damage (this damage may be internal and is not

always visible to the naked eye), Workforce requires that the lift be returned to our facility at 125 Taylor Parkway, Archbold, Ohio, for reconditioning. If you have any questions

concerning what constitutes structural damage, please call the Workforce Service Department at 419.445.9675.

Damage Repair Notice

There may be occasions when a Workforce lift is involved in an incident resulting in

non-structural damage. When this occurs and repairs are made by the owner or area distributor, please notify Workforce of these non-maintenance repairs and request a repair

form to be filled out and returned to Workforce.

1-7

Page 14

SkyRider 15

1-8

Page 15

2

Introduction

2-1 GENERAL DESCRIPTION

The SkyRider 15 hydraulic lift is designed and manufactured for use as a warehouse

stocking and order picking vehicle. Its guard rail design permits the operator to ride on

the platform with the load, while transferring parts to and from multiple overhead storage

locations. The maximum platform load is limited to 500 lbs.

All SkyRider operations are powered by a 24-Volt DC battery package. A 20-amp battery charger and plug-in receptacle are included in the system for recharging the batteries

at the end of each work period. A charge level indicator displays the battery charge

status.

The platform lift function is hydraulic, including a hydraulic cylinder, reservoir, and

pump. The hydraulic pump motor is driven by a 24-Volt DC electric motor. Elevation is

by a 1-1/2 inch linear-displacement hydraulic cylinder and three telescoping mast sections. The lower mast section is raised by hydraulic cylinder. The upper two mast sections are raised mechanically by two connecting sets of chains and sheaves (pulleys). The

lift platform rises three inches for each inch of hydraulic cylinder extension.

Other electrically powered functions include a two-wheel drive transaxle for floor travel,

pushbutton steering, and automatic deployment of stabilizer rails to protect against potholes when traveling with the platform raised. The maximum travel speed is enabled only

when the lift platform is down. When the platform is raised, the travel speed is limited.

The transaxle includes an electric brake that slows and locks the drive wheels whenever

forward or reverse travel is halted. The electric brake is normally applied; the brake disengages when froward or reverse travel is enabled with the joystick. In case of a loss of

battery power, a manual free wheel lever can be used to disengage the electric brake, allowing the lift vehicle to be towed.

Floor travel and platform lift functions are controlled from an upper control box located

on the lift platform. Floor travel is by joystick control with pushbutton steering. Lift

functions are by pushbutton control. Platform lift can also be controlled from a lower

control box mounted on the vehicle base. An electronic level sensor disables all lift and

travel functions except platform lowering if the lift vehicle base is more than one degree

out of level. While out of level, travel can be resumed after the lift platform is fully lowered.

With equipment power on or off, turning an emergency lowering valve knob lowers the

lift platform at a controlled, safe speed. The lowering valve knob is visible and readily

accessible from floor level.

Proper lift vehicle operation and safety are assured by performing the scheduled inspection and maintenance procedures set forth in this manual. The risk of platform free-fall is

eliminated by proper maintenance of the chains, sheaves and sheave pins, a properly installed flow restrictor valve, and a clean mast. The restrictor valve (non-adjustable) fixes

the maximum rate of platform descent to approximately 0.6 feet per second, whether the

platform is empty or fully loaded. With the restrictor valve properly installed, a hydraulic

hose failure will result in the same maximum rate of descent.

Carefully read and understand all of the safety instructions in Section 1 and all operating

instructions in Section 3 of this manual before operating the lift vehicle.

2-1

Page 16

SkyRider 15

2-2 SPECIFICATIONS

SkyRider 15 Electric Hydraulic Lift Platform

Model Number 15 Serial Number ________________

Manufactured by: bil-jax, Inc.

WORKFORCE AERIAL WORK PLATFORMS

125 Taylor Parkway

Archbold, Ohio 43502

419.445.8915

Table 2-1. Specifications

Rated Platform Load 500 lbs (227 kg) total including operator

[1 person + materials not to exceed 500 lbs (227 kg)]

Extended Platform Height 14 ft 10 in (4.5 m)

Retracted Platform Height 19 -1/4 in. (48.9 cm)

Platform Dimensions 29 in. W x 50 in. L x 42 in. H

(0.74 m x 1.27 m x 1.07 m)

Base Dimensions 30-1/2 in. W x 71 in. L x 78-1/2 in. H

(0.77 m x 1.8 m x 1.99 m)

Gross Shipping Weight 1025 lbs (465 kg)

Platform Lift Time 20 seconds empty, 32 seconds loaded

Platform Retraction Time 22 seconds empty, 22 seconds loaded

Platform Lift Rate Lift platform empty: 0.66 ft (0.3 m)/sec.

Lift platform loaded: 0.42 ft (0.19 m)/sec.

Hydraulic System Pressure 1200 psi empty, 2100 psi loaded

Travel Speeds (Maximum) Lift platform lowered: 2.5 mph

Lift platform raised: 0.5 mph

Power Source DC – two in-series 12 volt deep cycle batteries

2-3 WARRANTY

Workforce warrants its telescopic lifts for one year from the date of delivery against all

defects of material and workmanship, provided the unit is operated and maintained in

compliance with Workforce’s operating and maintenance instructions; structural components are warranted for three years. Workforce will, at its option, repair or replace any

unit or component part which fails to function properly in normal use.

This warranty does not apply if the lift and/or its component parts have been altered,

changed, or repaired without the consent of Workforce or by anyone other than Workforce or its factory trained personnel, nor if the lift and/or its components have been subjected to misuse, negligence, accident or any conditions deemed other than those considered as occurring during normal use.

Components not manufactured by Workforce are covered by their respective manufacturer’s warranties. A list of those components and their warranties is available upon written request to Workforce.

Workforce shall not in any event be liable for the cost of any special, indirect, or consequential damages to anyone, product, or thing. This warranty is in lieu of all other warranties expressed or implied. We neither assume nor authorize any representative, or

other person, to assume for us any other liability in connection with the sale, rental, or

use of this product.

2-2

Page 17

3

Operation

3-1 OPERATOR CONTROLS

Most of the operator controls for the SkyRider 15 are located on the upper and lower

control boxes. Other operator controls include the

gency lowering valve.

base, is the main power disconnect switch for the lift vehicle. The location and operation

of the emergency lowering valve is described in paragraph 3-3.

The BATTERY ON/OFF switch, located on the left side of the lift

Lower Control Box

The lower control box, Figure 3-1, is located on the lift base and contains three controls:

UP/DOWN, EMERGENCY STOP, and UPPER CONTROL/OFF/LOWER CONTROL. The lower con-

trol box enables lift operations from floor level.

UPPER CONTROL/OFF/LOWER CONTROL key switch selects the active (upper or lower)

The

control location. To enable an

key switch in the

vation from the upper control box, turn the key switch to the

To disable lift vehicle operations, turn the key switch to the

key.

LOWER CONTROL position. To enable lift vehicle travel or platform ele-

UP or DOWN lift motion from the floor, turn and hold the

BATTERY ON/OFF switch and the emer-

UPPER CONTROL position.

OFF position and remove the

Turn the

DOWN position to lower the platform. (The key switch must be held in the LOWER

CONTROL

Press the

moving forward or back, pressing the

causing travel to stop quickly. To resume lift vehicle operation, turn the

STOP

UP/DOWN selector switch to the UP position to raise the lift platform or to the

position to enable the UP/DOWN selector switch).

EMERGENCY STOP button to stop all equipment motion. If the lift vehicle is

EMERGENCY STOP button engages the travel brake

EMERGENCY

button clockwise.

Figure 3-1. Lower Control Box

3-1

Page 18

SkyRider 15

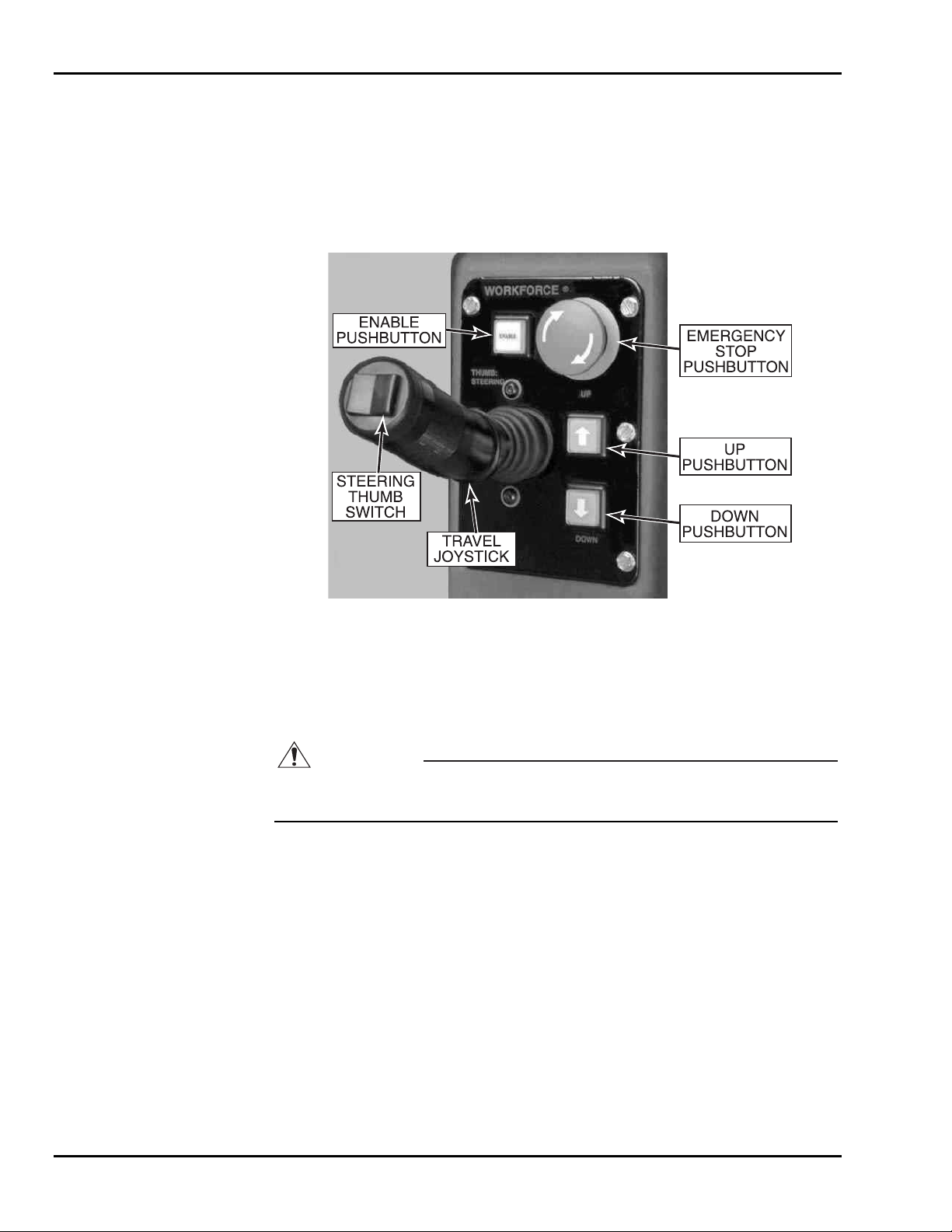

Upper Control Box

The upper control box, Figure 3-2, is in the lift cage. The upper control box enables lift

and travel operations whenever the

lower control box key switch is in the

Upper control box controls include four pushbuttons and a forward/reverse floor-travel

joystick with thumb-switch steering.

BATTERY ON/OFF switch is in the ON position and the

UPPER CONTROL position.

Figure 3-2. Upper Control Box

Press and hold the

ENABLE pushbutton down to enable the control functions. The ENABLE

pushbutton must always be pressed first to enable the lift, steering, and travel functions.

ENABLE pushbutton must be held down to continue the equipment function.

The

CAUTION

The pothole guard actuator will not lift the weight of the SkyRider. Using the pothole guard actuator to lift the vehicle will permanently damage the actuator.

With the ENABLE pushbutton depressed, press the UP [] pushbutton to raise the plat-

form or press the

DOWN [

starts to rise, the pothole guard extends down to near floor level. When extended, the

pothole guard will prevent the lift vehicle from tipping in case a wheel d rops into a hole

during travel. When the lift platform is fully lowered, the pothole guard rises.

With the

ENABLE pushbutton depressed, move the travel joystick forward or back to

move the lift vehicle in the forward or reverse direction. For slow speeds, move the joystick forward or back just a little. For faster speeds, move the joystick more.

With the

ENABLE pushbutton depressed, press the left or right side of the thumb switch to

steer the rear wheels to the left or right. The steering can be adjusted before or during

floor travel.

] pushbutton to lower the platform. When the lift platform

Press the

EMERGENCY STOP button to stop all equipment motion. If the lift vehicle is

moving forward or back, a travel brake is applied causing travel to stop. To resume lift

vehicle operations, turn

3-2

EMERGENCY STOP button clockwise.

Page 19

3 — OPERATION

3-2 NORMAL OPERATING PROCEDURE

Perform the following procedures to operate the SkyRider 15 platform lift vehicle.

1. Read and follow all safety precautions contained in Section 1 and all responsibilities outlined in the ANSI A92.3 reprint in Section 7 of this manual.

2. Position the lift vehicle at the work area. Make sure the vehicle is on a firm and

level surface and that there are no potential hazards such as speed bumps, open

floor drains, potholes, overhead obstructions or electrically charged conductors.

Do not operate the lift vehicle if such hazards exist in the immediate area.

3. Check the lift vehicle for damage or worn parts. If damage or part wear is

found, do not operate the vehicle until the problem is corrected.

4. Turn the

BATTERY ON/OFF switch, Figure 3-3, to the ON position.

Figure 3-3. Battery On/Off Switch

5. Observe the battery charge level indicator. An LED will be lit to indicate the

battery charge level. Verify that the battery charge level is 3/4 or more.

6. Turn the

UPPER CONTROL position.

UPPER CONTROL/OFF/LOWER CONTROL key switch, Figure 3-1, to the

7. Enter the platform cage and close the entry gate. If the gate will be closed when

the lift platform is elevated, you do not have to wear the safety harness. If the

gate will be open while the lift platform is raised, put on the safety harness and

hook it to the

SAFETY HARNESS ATTACHMENT POINT.

8. Use the upper control box controls to operate the lift vehicle.

NOTE: The lift vehicle is equipped with a level sensor. When the vehicle is on a

slope greater than 1 degree, the level sensor disables all functions other

than platform lowering and sounds an alarm beeper. Once the platform

is lowered, floor travel is again enabled to allow travel to a level area.

3-3

Page 20

SkyRider 15

9. During floor travel and lift operations, the alarm beeper should sound. If the

alarm beeper does not work properly, do not operate the lift vehicle.

10. During lift platform descent, the amber caution light should blink on and off. If

the caution light does not blink on and off, do not use the lift vehicle.

11. If any equipment motion continues after the pushbutton, joystick, or selector

switch is released, press the

EMERGENCY STOP pushbutton, Figure 3-2. All

equipment motion should stop immediately.

12. At the end of each workday and whenever a low battery charge level is indicated, transport the lift vehicle to the recharge site and plug in the charge cord.

Verify that the

ON-CHARGING indicator lights up on the battery charger.

NOTE: For more information on battery charging operations, refer to the bat-

tery charging procedure in paragraph 4-4.

13. To shut down the equipment, turn the

switch and the

BATTERY ON/OFF switch to OFF. Remove the key to prevent unau-

thorized equipment operation.

UPPER CONTROL/OFF/LOWER CONTROL key

3-4

Page 21

3 — OPERATION

3-3 EMERGENCY LOWERING PROCEDURES

In an emergency, a person at floor level can lower the platform by holding the UPPER

CONTROL/OFF/LOWER CONTROL

UP/DOWN selector switch to the DOWN position. (If the upper control box emergency

the

stop pushbutton is depressed, the platform will not lower.)

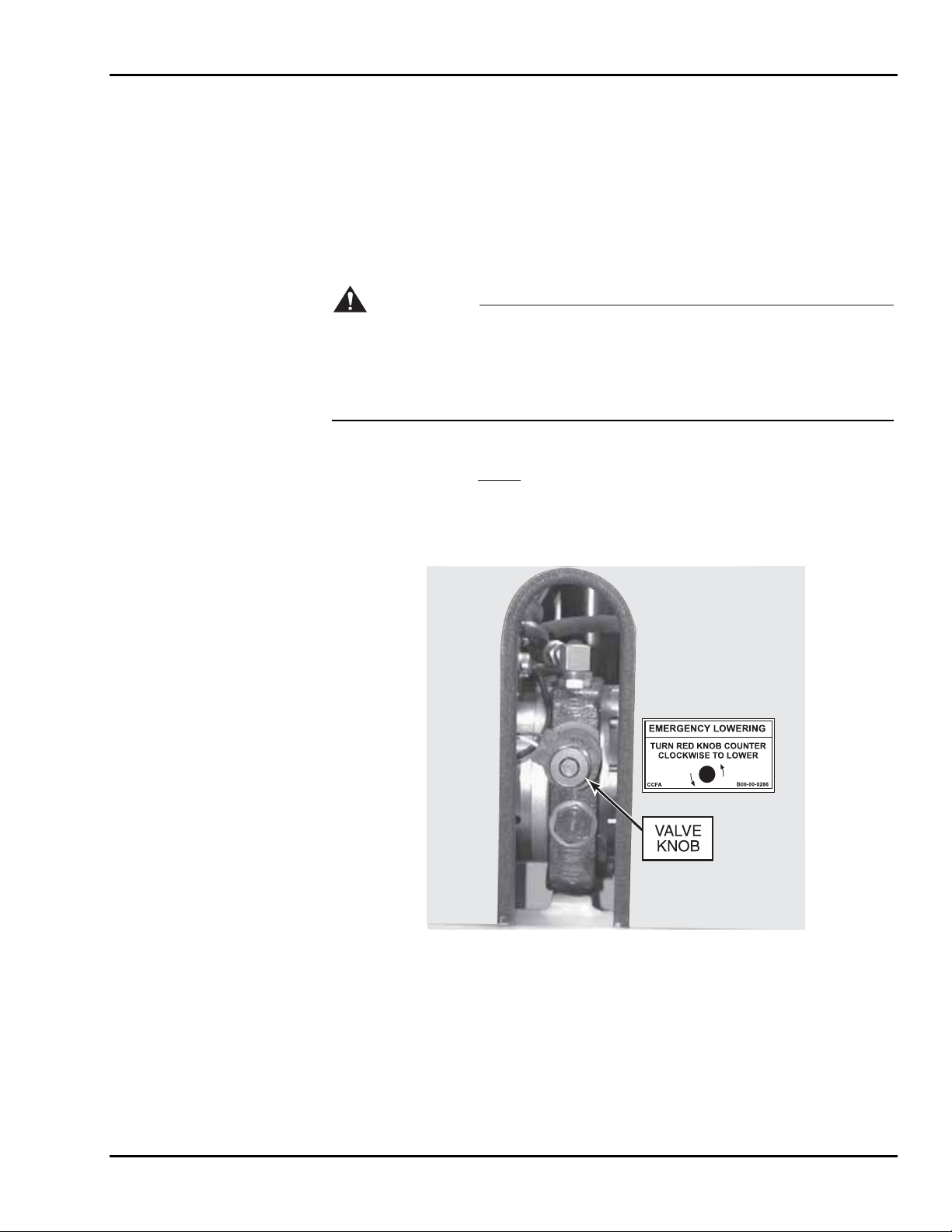

An emergency lowering valve is shown in Figure 3-4. In case of a total loss of battery

power, a person at floor level can safely lower the platform by opening the emergency

lowering valve.

key switch in the LOWER CONTROL position and turning

WARNING

Do not climb out of the lift cage while the lift platform is elevated. The lift mast

cannot be climbed safely. An elevated lift platform has a high center of gravity

and can be tipped easily. Standing on or leaning out from the outside of a cage rail

may cause the lift vehicle to tip over. Tipping the lift vehicle over can cause severe

injury or death and equipment damage.

If you lose power while elevated in the cage, instruct someone else to open the emergency lowering valve. Do not

shelves.

To lower the platform, turn the red valve knob counterclockwise until the platform starts

to descend. When the platform is lowered, turn the valve knob clockwise until closed.

leave the cage to climb down the lift mast or storage

Figure 3-4. Emergency Lowering Valve

3-5

Page 22

SkyRider 15

3-4 LIFT VEHICLE TRANSPORT

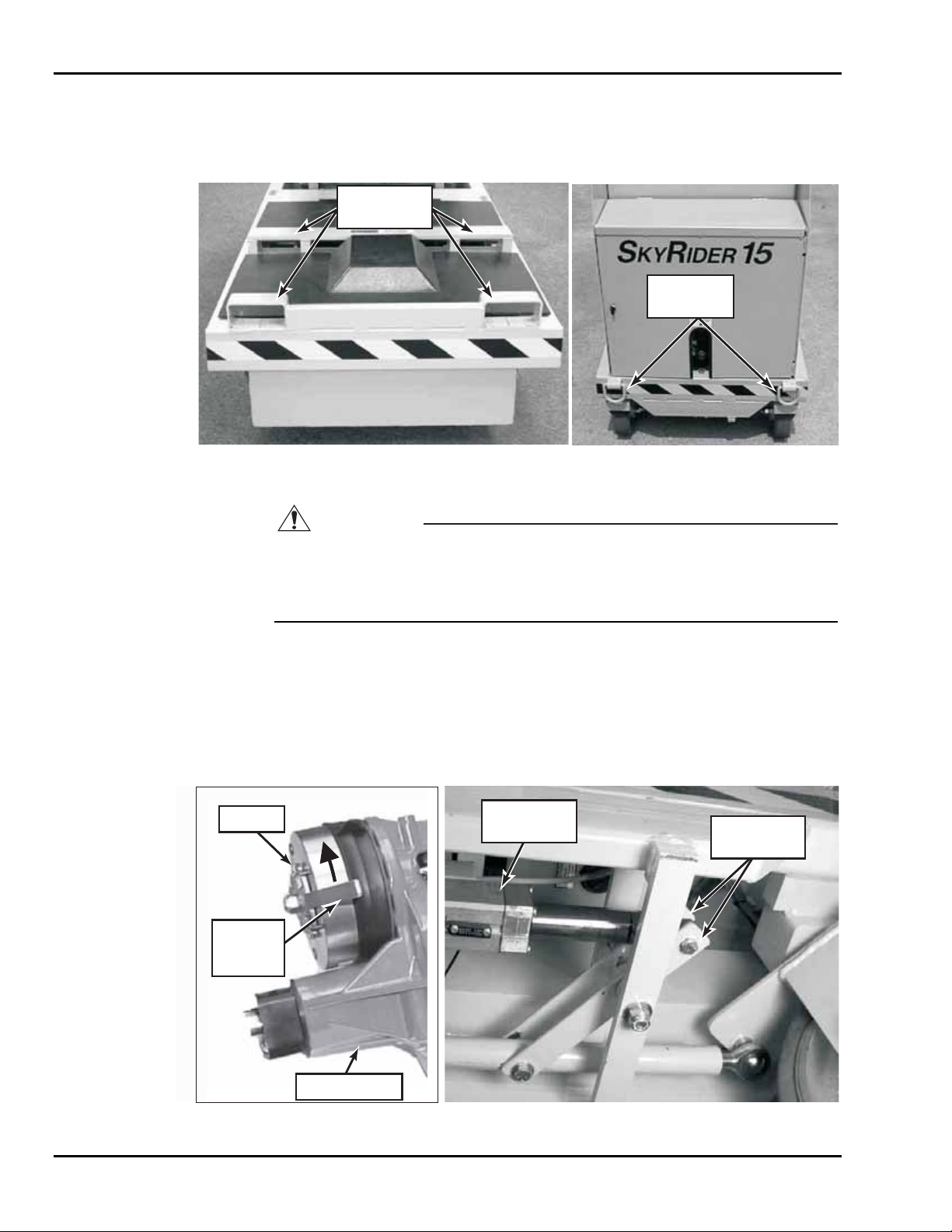

The platform vehicle is equipped with tie down rings, lifting, and tow features, Figure

3-5. Read the following instructions before using these features to lift or tow the vehicle.

LIFTING

BRACKETS

TIE DOWN

RINGS

Figure 3-5. Lifting Brackets and Tie Down Rings

BRAKE

FREE

WHEEL

LEVER

CAUTION

In the event of power failure, the platform lift vehicle can be towed using the tie

down rings. Do not attempt to push the lift vehicle or use the lift vehicle to pull

another vehicle or object. Pushing the lift vehicle or using the vehicle for towing

may cause serious equipment damage.

The forks of a lift truck (2-ton minimum capacity) can be used to raise the SkyRider for

loading onto a trailer or for blocking up the lift vehicle for maintenance. In case of a battery power failure, the tow clevis can be used to pull the lift vehicle to a service area.

Before towing the SkyRider lift vehicle, you must manually disengage the travel brake

and disconnect the steering linkage. Refer to the illustrations in Figure 3-6.

STEERING

ACTUATOR

STEERING

LINKAGE

TRANSAXLE

Figure 3-6. Travel Brake and Steering Linkage

3-6

Page 23

4

Maintenance

4-1 SCHEDULED SERVICE CHECKS

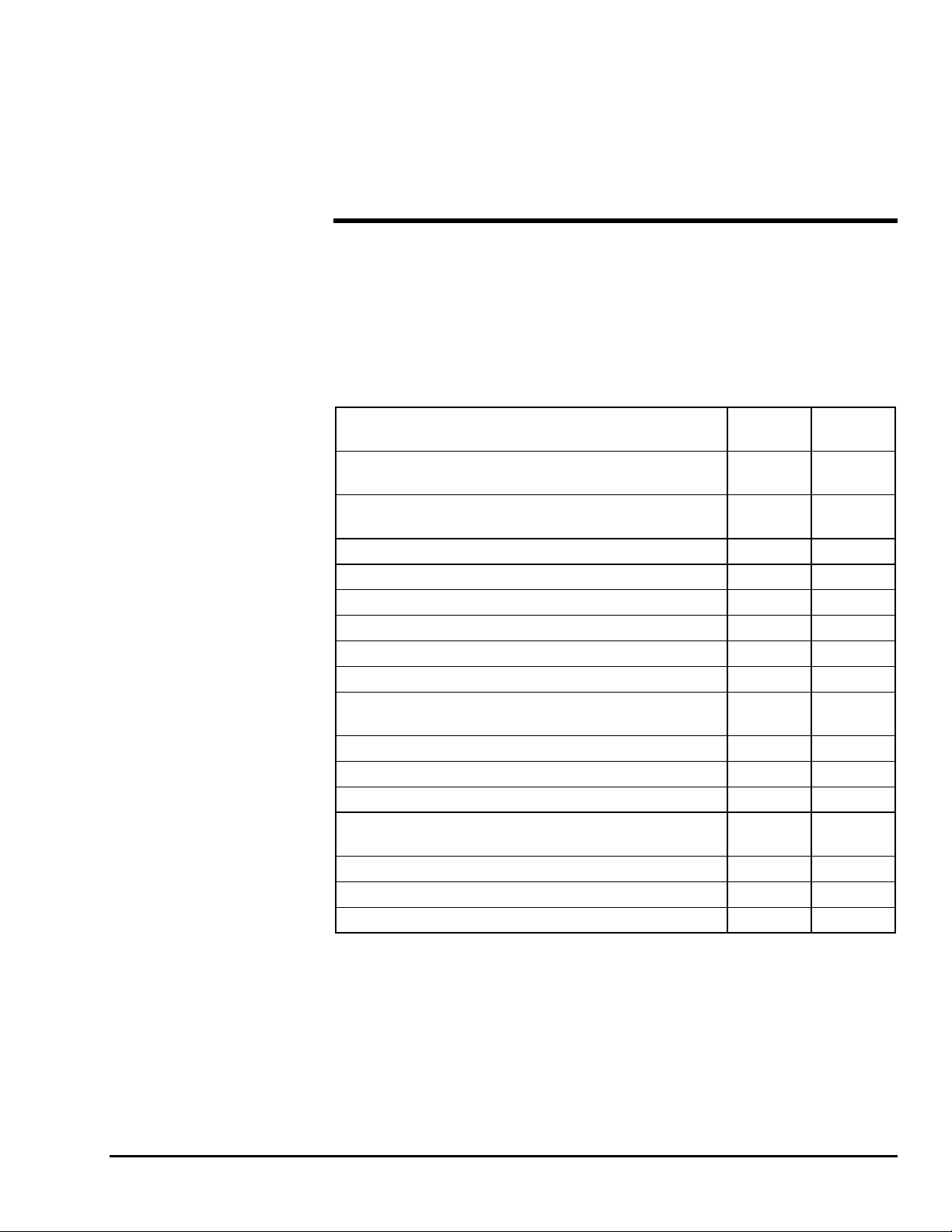

Daily/Weekly Service Checks

Perform the daily and weekly service checks listed in Table 4-1.

Table 4-1. Daily/Weekly Service Checks

Daily

Service Check

Check that all upper and lower control box controls work

properly.

Check chain assemblies for split leaves, loose pins,

excessive wear, or elongation.

Check for hydraulic oil leaks.

Check for loose or missing parts.

Check for and retighten loose nuts and bolts.

Check that cage gate is secure.

Check that safety harness is in good condition

Verify that cage is securely bolted to lift mast.

Check that slide blocks and their paths are clean and lightly

lubricated with a dry silicone lubricant.

Verify that all safety decals are present and legible.

Ensure Operation Manual is in manual tube.

Check battery electrolyte level.

Check for wear on chain sheaves, sheave axles, and

bearings.

Check caster axle and swivel bolts for wear.

Check casters for cracks or excessive wear.

Lubricate lift chains with 40-weight oil.

before use Weekly

4-1

Page 24

SkyRider 15

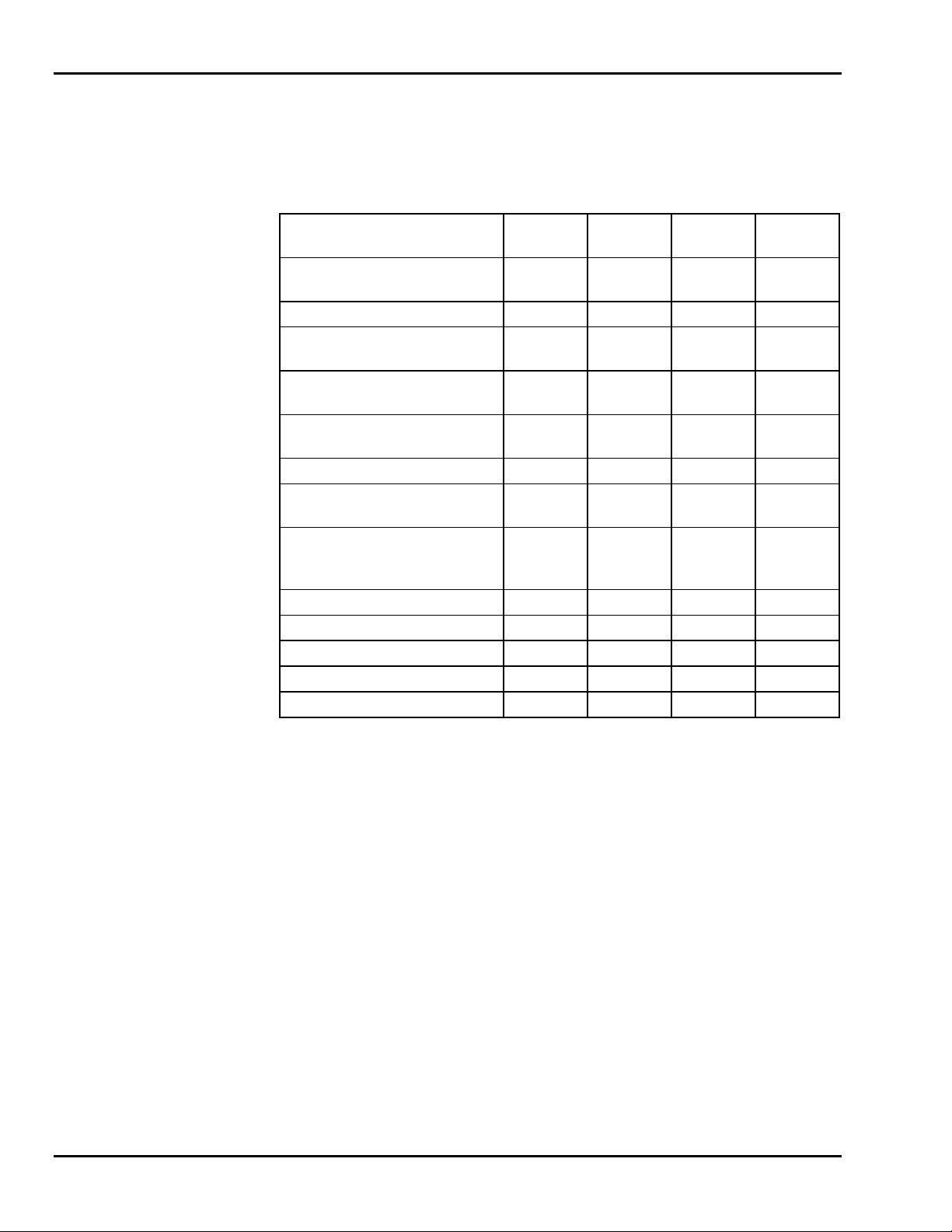

Monthly Service Checks

Perform the service checks in Table 4-2 every month, every 6 months, every 12 months,

or every 48 months, as indicated.

Table 4-2. Monthly Service Checks

Service Check

Check hydraulic UP and DOWN

valves operation.

Clean battery terminals.

Check operation of emergency

lowering valve.

Grease rear caster swivel bolts

and axles.

Grease steering linkage pivot

bolts.

Grease front caster pillow blocks.

Grease pivot bolts of pothole

guard actuator linkage.

Every

month

6 months

Every

Every

12 months

Check battery cables and wiring

for loose connections and

damaged wires.

Replace hydraulic oil.

Check slide blocks for wear.

Check for mast sway.

Load test with 500 pounds.

Replace lift chains.

Every

48 months

4-2

Page 25

4 — MAINTENANCE

4-2 LUBRICATION

Lubrication makes operation of the SkyRider 15 more efficient and extends the life of the

lift vehicle. Perform the following lubrication procedures.

1. Lubricate lift chains with clean 40-weight oil. Refer to Figure 4-1.

LIFT

CHAINS

LIFT

CHAINS

Figure 4-1. Lift Chains Lubrication

2. Clean the mast slide ways, Figure 4-2, and lightly spray the slide ways with a

dry silicone lubricant.

NOTE: The slide blocks have a high level of lubricity and need only be kept

clean. To reduce wear and extend service life, the slide ways should be

cleaned and lightly lubricated with a dry type silicon lubricant.

Figure 4-2. Mast Slide Ways Lubrication

4-3

Page 26

SkyRider 15

Figure 4-3. Rear Casters Lubrication

3. See Figure 4-3. Grease rear caster axles and swivel bolts at the grease fittings

provided. Add about 1/2 ounce of clean #2 NGLI grease to each fitting.

4. Remove, clean, and lubricate steering linkage and pothole guard linkage bolts

with wheel bearing grease.

5. Apply about 1/2 ounce of clean #2 NGLI grease to the fitting on each front

wheel pillow block, Figure 4-4. Do not over-grease the pillow block bearings.

Figure 4-4. Front Caster Pillow Blocks Lubrication

4-4

Page 27

4 — MAINTENANCE

4-3 HYDRAULIC SYSTEM

Hydraulic system maintenance varies by the amount of use and the environment in which

the lift vehicle is used. Keeping the hydraulic oil clean and th e reservoir properly filled

will help prevent possible damage to the system.

Hydraulic System Inspection

Check all hydraulic hose and fittings for leaks and damage daily. Tighten or replace as

necessary to prevent hydraulic oil loss.

Fluid Check and Replacement

With the platform in its lowest position, the hydraulic oil level should be at the MAXIMUM

level mark (1-1/2 in. from top of reservoir).

The reservoir is initially filled with Energol HLP-HD46 (BP Oil); a high grade, nonfoaming hydraulic oil. This oil is recommended for use in climatic temperatures as low as

-20°F/-29°C. Dextron Automatic Transmission Fluid Type A is recommended for use in

temperatures as low as -40°F/-40°C.

If either of these oils is not available, a good grade SAE 10W hydraulic oil may be used

where the minimum climatic temperature is above 32°F/0°C. An SAE 5W hydraulic oil

may be used where temperatures are as low as 0°F/-18°C.

Do not mix different hydraulic oils. Clean the reservoir and sump strainer and replace the

hydraulic oil at least once a year. Clean the reservoir and sump strainer and replace the

oil whenever contamination is suspected.

Hydraulic System Air Bleeding Procedure

Delayed response or uneven movement of the hydraulic cylinder may indicate trapped air

in the hydraulic oil.

NOTE: Whenever the upper control box emergency stop pushbutton is engaged,

lift operation remains enabled at the lower control box. However, the

DOWN lift motion will be intermittent. Intermittent lift motion should

or

not be mistaken as trapped air in the hydraulic system.

Perform the following procedure to bleed trapped air from the hydraulic system.

1. Fill the reservoir to the

2. Fully raise the lift platform.

3. Lower the lift platform to allow oil with entrapped air to return to the reservoir.

Be careful not to overflow the hydraulic reservoir.

4. Leave the lift platform down and the lift vehicle at rest for 10 to 15 minutes

while air escapes the hydraulic oil.

5. Repeat steps 2 through 4 as needed. Each time the platform is lowered, refill the

reservoir to prevent pumping more air into the hydraulic cylinder.

MAXIMUM level with the proper hydraulic fluid.

UP

4-5

Page 28

SkyRider 15

Pressure Relief Valve Adjustment

Perform the following procedure to adjust the pressure relief valve. Refer to Figure 4-5.

1. Move the SkyRider lift platform to the fully

DOWN position.

2. Center 500 pounds of weight on the lift platform.

3. Remove the hex cover from the pressure relief valve. The pressure relief valve

is on the back side of the pump.

th

4. Turn the pressure relief valve adjust screw 1/8

turn counterclockwise. This will

adjust the relief valve bypass pressure setting for less than 500 pounds of lift.

5. Place the key switch in the

LOWER CONTROL position and press the UP pushbut-

ton. The pump should run, bypassing oil to the hydraulic reservoir.

CAUTION

Do not adjust the pressure relief valve for a bypass pressure higher than needed to

raise the 500 pound load. Hydraulic system overload may occur at a higher bypass

pressure, causing hydraulic failures or damage to the equipment.

6. With the platform lift function enabled (pump running), turn the pressure relief

valve adjust screw clockwise just enough to smoothly raise the platform without

bypassing oil to the hydraulic reservoir.

7. Reinstall the hex cover over the pressure relief valve.

Figure 4-5. Pressure Relief Valve Adjustment

4-6

Page 29

4 — MAINTENANCE

Flow Restrictor Valve Replacement

WARNING

Closely read and adhere to the following instructions whenever you remove and

install the flow restrictor valve. Failure to properly install the flow restrictor valve

can result in serious injury or death to personnel or damage to the equipment.

If the flow restrictor valve, Figure 4-6, needs to be removed or replaced, it is important

that it be properly reinstalled. The valve will be marked either with an arrow or with the

word “IN”.

If marked with an arrow, the arrow must point away from the hydraulic cylinder port. If

marked with the word “IN”, the end of the valve marked “IN” must be toward the hydraulic cylinder port.

Only a 1/4 inch NPT hydraulic elbow fitting should be connected between the hydraulic

cylinder port and the flow restrictor valve. Improper installation of the flow restrictor

valve or use of the wrong size hydraulic elbow fitting will allow varying rates of descent

and may result in near free-fall in case of hydraulic hose failure.

Figure 4-6. Flow Restrictor Valve

4-7

Page 30

SkyRider 15

Up Valve Operation Check

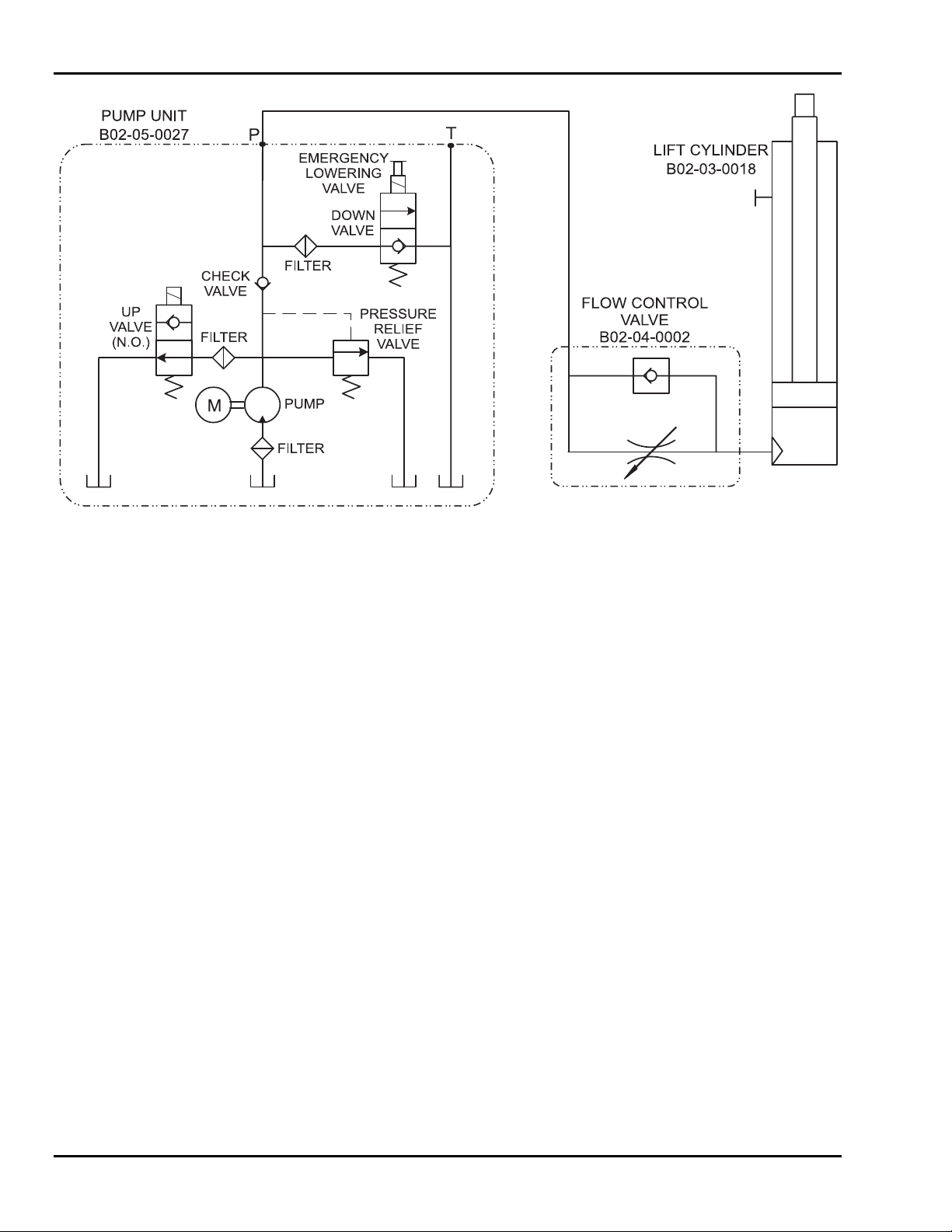

Refer to the hydraulic diagram in Figure 4-14. The normally-open Up valve routes oil

flow from the hydraulic pump to the reservoir. Pressing the

energizes the Up valve. Oil flow to the reservoir is shut off, causing the lift cylinder to

extend. Releasing the

ENABLE or UP pushbutton causes the Up valve to open, routing all

hydraulic oil to the reservoir. Even if the hydraulic pump motor should continue to run,

the lift platform will not rise when the

ENABLE or UP pushbutton is released.

This fail-safe operation is defeated only if the Up valve sticks in the closed position . A

sticking valve and fused pump-start relay contacts would cause the lift platform to rise,

even after the

UP pushbutton is released. This would be an unsafe operating condition.

The following operation check indicates whether or not the Up valve is sticking:

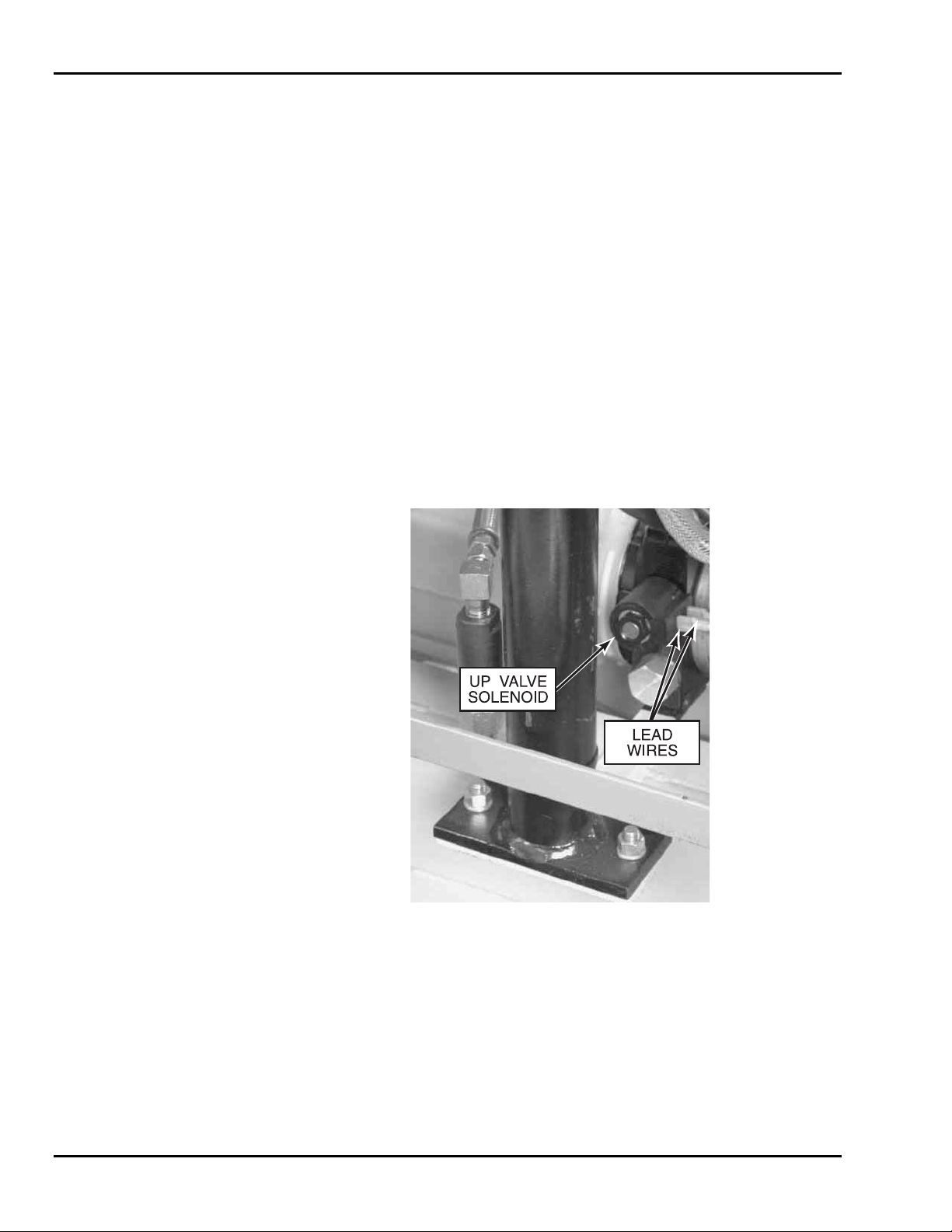

1. Disconnect the lead wires from the Up valve solenoid, Figure 4-7.

ENABLE and UP pushbuttons

2. At the lower control box, hold the key switch in the

and press the

UP pushbutton. The hydraulic pump motor should run without rais-

LOWER CONTROL position

ing the lift platform.

3. If the lift platform rises, the Up valve is sticking closed. Remove and clean or

replace the sticky valve.

4. Reconnect the lead wires to the Up valve solenoid.

Figure 4-7. Up Valve Operation Check

4-8

Page 31

4 — MAINTENANCE

Hydraulic Cylinder Repair

CAUTION

Hydraulic cylinder removal requires extensive disassembly of the SkyRider 15 lift

vehicle. Contact Workforce for assistance before removing the hydraulic cylinder.

Hydraulic Cylinder Removal

It is recommended that Workforce be contacted for assistance before removing the hydraulic cylinder.

1. Make sure hydraulic cylinder is completely retracted and pressure is released

from the system. Place a pan underneath the cylinder to catch the hydraulic oil.

2. Disconnect the hydraulic hose from the flow restrictor valve and drain the hydraulic oil from the cylinder. Remove the two bolts, washers, and nuts securing

the hydraulic cylinder to the base.

3. Remove the plexiglass cover from the base.

4. Remove the mounting bolt, washer, and nut securing hydraulic cylinder to the

lower mast.

5. Disconnect the two lift chains from the base mast.

6. Using a crane with at least one ton of lifting capacity, lift the lower mast section

high enough to remove the clamp securing the cylinder to the base. Remove the

clamp and cylinder from the unit.

7. After hydraulic cylinder maintenance is completed, reinstall the cylinder in the

reverse order of removal.

4-9

Page 32

SkyRider 15

Hydraulic Cylinder Repair Procedure

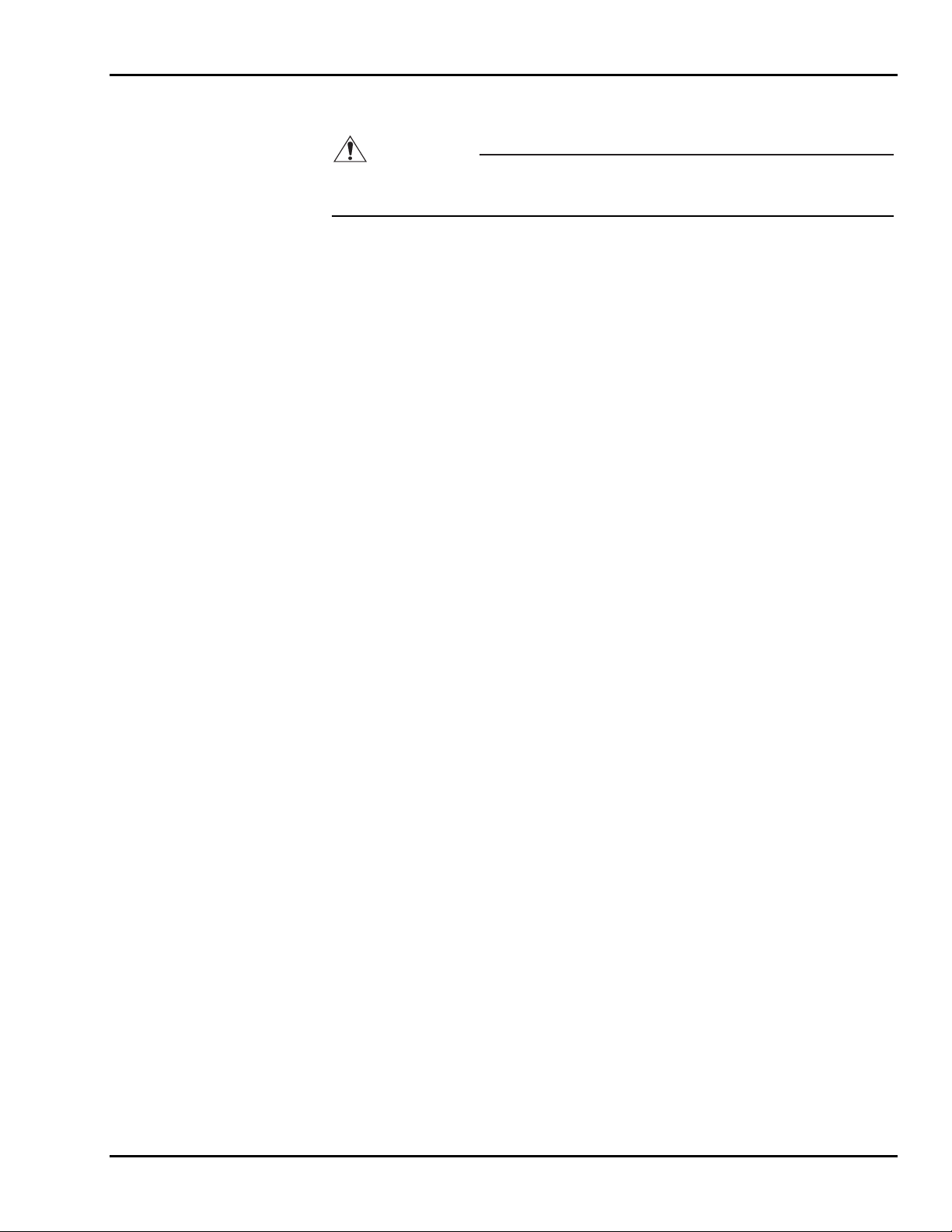

Perform the following procedure to repair the hydraulic lift cylinder. Refer to Figure 4-8.

1. Remove gland nut (1) from cylinder jacket (2). If worn, replace gland nut (1),

o-ring (3), packing ring (4), and rod wiper (5) with a new gland nut assembly.

2. Remove piston rod (6) and wear ring (7).

3. Inspect piston rod (6) and wear ring (7) for gouges, scratches, and wear. Replace worn or damaged components.

4. Thoroughly clean the inside surface of cylinder jacket (2).

5. Lubricate wear ring (7) with clean hydraulic oil or petrolatum. Slide piston rod

(6) with wear ring (7) into cylinder jacket (2).

6. Lubricate o-ring (3), packing ring (4), and rod wiper (5) with clean hydraulic oil

or petrolatum.

7. Slide gland nut (1) onto piston rod (6). Fully thread the gland nut into cylinder

jacket (2).

8. Reinstall the hydraulic cylinder in the lift vehicle and reconnect the hydraulic

hose.

9. Refill the hydraulic reservoir.

10. Stroke the cylinder to seat and align packing ring (4) and wear ring (7).

11. Bleed all trapped air from the hydraulic system.

1. Gland Nut

2. Cylinder Jacket

3. O-ring

4. Packing Ring

5. Rod Wiper

6. Piston Rod

7. Wear Ring

Figure 4-8. Hydraulic Cylinder Disassembly

4-10

Page 33

4 — MAINTENANCE

4-4 ELECTRICAL SYSTEM

Regular maintenance is necessary to keep the electrical system in proper working order.

Check daily all electrical wires for cuts, broken wires, potential short circuits, and any

other damage.

Battery Care and Charging

The electric system is designed to provide power for a normal work shift. However, the

charge life of the battery pack depends on machine usage. Plan your work to prevent unnecessary use of electrical power.

Since the power source for the machine is a battery pack, proper battery care is important. Recharge the batteries after each work shift. When the machine is not being used,

the batteries should be charged at least once a week. Normal battery charging time

should be 10 to 12 hours. If the battery is extremely low, charging time may be as long as

24 hours.

Clean the battery terminals monthly. Remove the cables from the battery posts, clean the

battery posts and cable ends to shiny metal, and replace the cables. Always connect the

insulated cable from the starter solenoid to the most positive post. Lubricate the outside

of the battery post connections with petroleum jelly or grease.

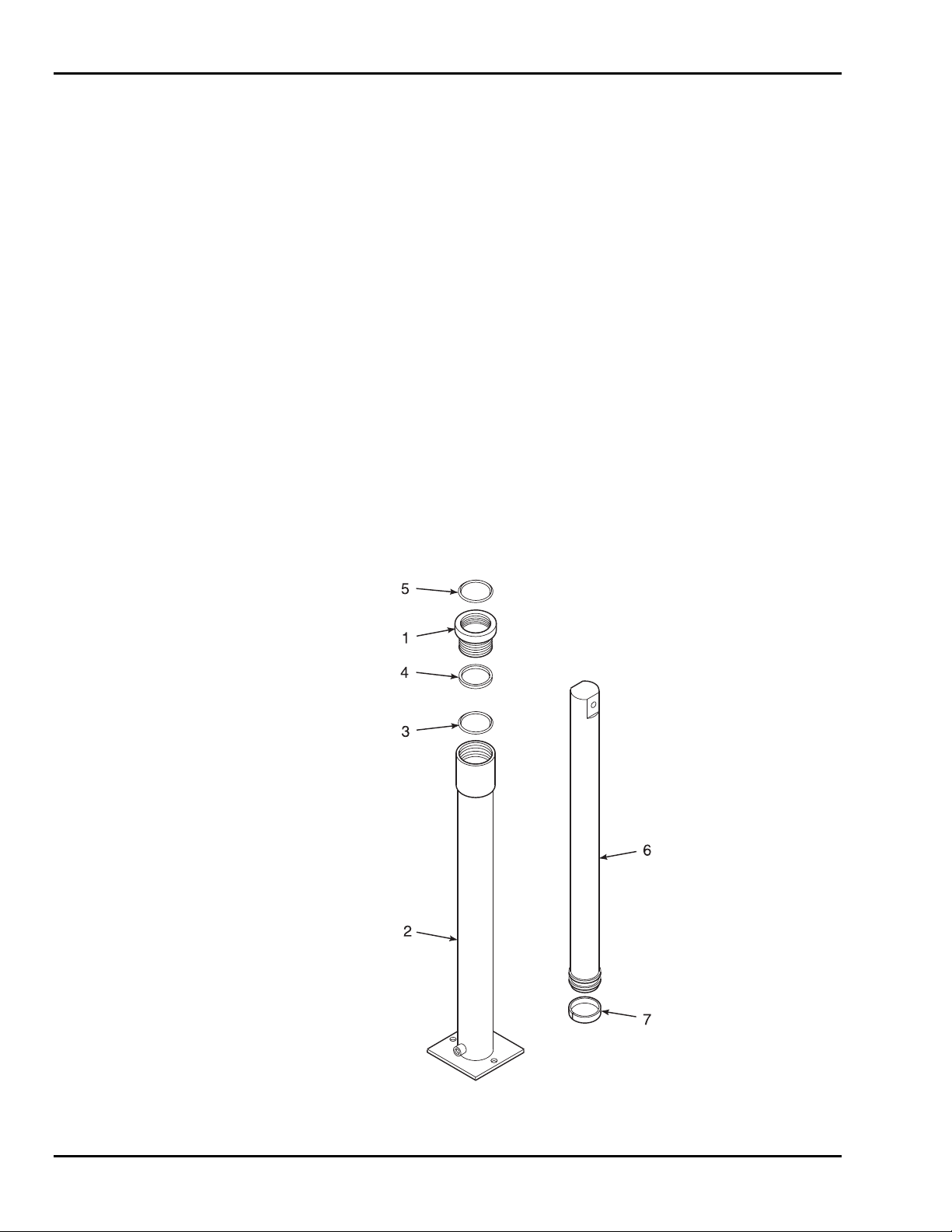

Battery Charging Procedure

1. Connect a heavy-duty extension cord (10AWG, minimum) from a 110V AC,

60 Hz outlet to the battery charger receptacle, Figure 4-9. The extension cord

should be as short as possible to reduce voltage drop.

Figure 4-9. Battery Charger Receptacle

4-11

Page 34

SkyRider 15

2. When there is power to the battery charger, a red “ON-CHARGING” LED on

the charger will be lit and the ammeter will display the rate of charge.

3. Once the battery voltage reaches a predetermined level programmed in the electronic control, the yellow “80% CHARGE” LED will illuminate.

4. The charge will be completed 3-1/2 hours after the yellow “80% CHARGE”

LED is lit. The charger and all LED’s will automatically shut off. The battery

charge level indicator, Figure 4-9, should indicate at least 3/4 charge.

NOTE: If the battery voltage does not reach the 80% level within 14 hours, the

charger will shut off and the “CHECK BATTERY” LED will light up.

CAUTION

Before making or breaking connections between charger and battery, always remove the power cord from the 110 volt AC outlet. Always check the battery electrolyte level and add water after charging the battery. For more information, refer to the instructions supplied with the battery charger.

5. Unplug the extension cord from the battery charger receptacle.

4-5 LIFT CHAINS AND SLIDE BLOCKS

WARNING

Do not operate a unit on which any chain assembly is damaged or in need of replacement. Operating a unit with a damaged chain can cause severe injury or

death to personnel and damage to equipment.

Inspect all lift chains daily. Inspect for signs of wear, split leaves, loose pins, clevis damage, and elongation. Replace any chain that is damaged in any way. Chain assemblies

may be ordered from your dealer or direct from the factory. Do not operate a unit on

which any chain assembly is damaged and in need of replacement.

Chain Elongation Inspection

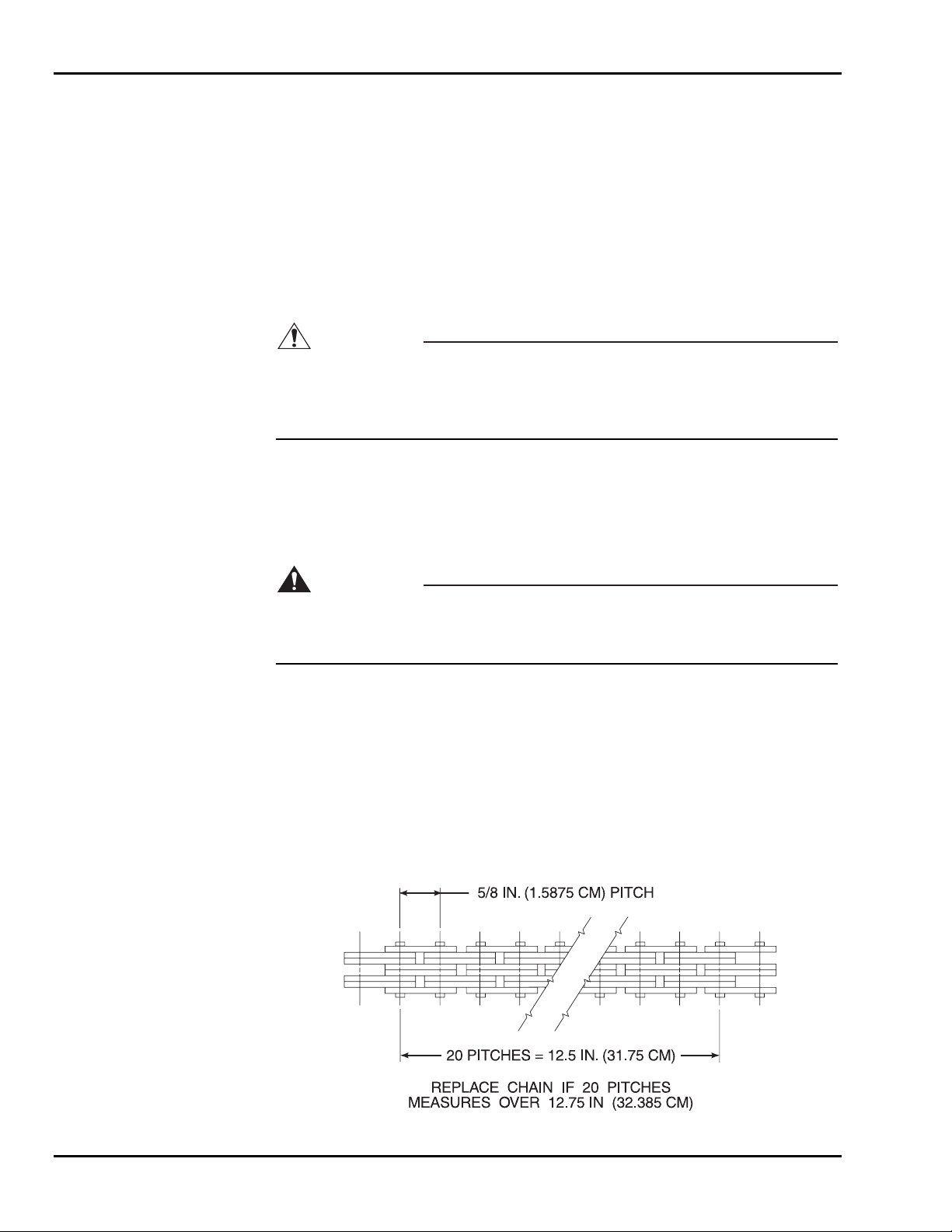

Refer to Figure 4-10. Measure 20 pitches of chain. Twenty pitches of new chain should

measure 12.5 in. (31.75 cm). Replace the chain if a 20-pitch length measures over 12.75

in. (32.385 cm).

Figure 4-10. Chain Elongation Inspection

4-12

Page 35

4 — MAINTENANCE

NOTE: The lift chains should be replaced every four years unless damage or

wear requires earlier replacement.

Lift Chain Adjustment

1. Raise the platform to the maximum height. Then, lower the platform while

someone verifies that all sheaves (pulleys) are turning and that the chains are not

visibly damaged or worn.

2. Remove the plexiglass cover from the base.

3. When the platform is fully lowered, the lift chains should be equally tight.

Check each lift chain at mid-span. The lift chains should flex about 1/2 to 3/4

inch (12 to 19 mm), but there should be no loose play.

4. If a lift chain is loose, tighten the related clevis, Figure 4-11. Tighten the clevis

lock nut until the lift chain just becomes snug. Do not over-tighten any lift

chain. (An over-tightened lift chain will raise the platform from its rest position

at the bottom of the base slide ways).

5. After making a lift chain adjustment, verify that at least 1/8 in. (3 mm) of the

threaded clevis rod extends beyond the lock nut. Also recheck the slack of all

lift chains at mid-span; verify that all lift chains are equally snug.

6. If a single lift chain requires frequent adjustment, the clevis lock nut is probably

worn. Replace any clevis lock nut that does not hold position during use.

7. Replace the plexiglass cover.

LIFT

CHAINS

CLEVIS

LOCK

NUT

Figure 4-11. Lift Chains Adjustment

LIFT

CHAINS

CLEVIS

LOCK

NUT

4-13

Page 36

SkyRider 15

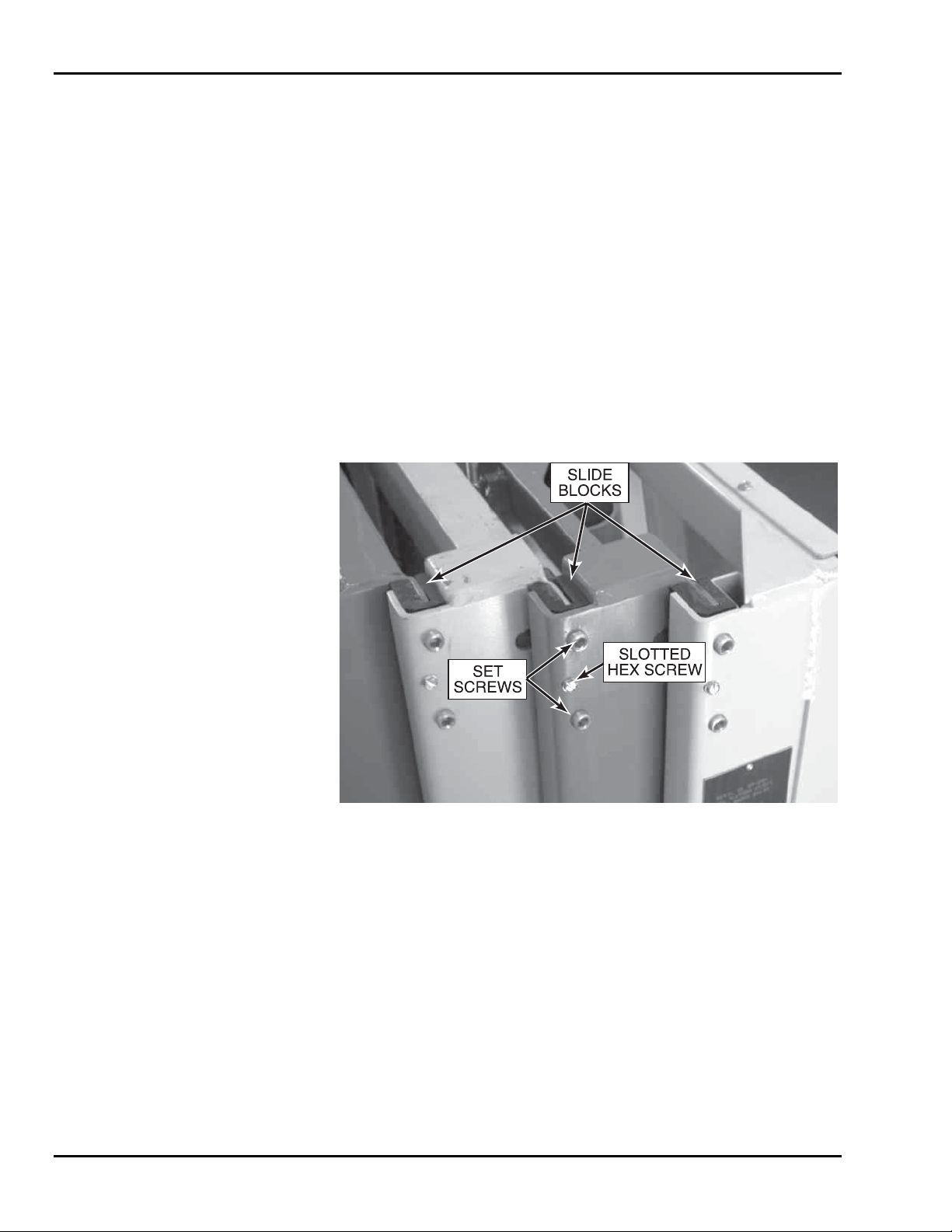

Slide Block Adjustment

Annually check for wear on the slide blocks and replace or retighten as necessary. If the

lift exhibits excessive mast sway, it is probable that the slide blocks need adjustment. The

slide blocks should be adjusted so that there is no air gap between the slide block and the

mast the slide block is moving against. There are 12 slide blocks, - 6 upper and 6 lower.

Three upper slide blocks are shown in Figure 4-12.

Start with the slide blocks on one side of the inner mast. Adjust the upper and lower slide

blocks on one side, followed by the upper and lower slide blocks on the opposite side.

Repeat the adjustments for the center mast slide blocks, followed by the outer mast slide

blocks. The adjustment procedure is the same for all slide blocks:

1. Loosen, but do not remove the slotted hex screw securing the slide block.

2. Use an Allen wrench to turn the set screws clockwise. This will push the block

in against the next mast. Do not overtighten. Tighten the slotted hex head screw

to secure the slide block in position.

3. After all adjustments are made, fully extend the lift. If the platform can be raised

and lowered without hesitation or stopping, the blocks are properly adjusted.

Figure 4-12. Slide Blocks Adjustment

NOTE: The plastic slide blocks in the mast are made of a bearing material which

has a high degree of lubricity and need only be kept clean. However,

precautions should be taken to ensure that the paths along which the

blocks move are kept clean and lightly lubricated with a dry type silicon

lubricant.

4-14

Page 37

4 — MAINTENANCE

4-6 TROUBLESHOOTING

Table 4-3. Troubleshooting Chart

Problem Cause Correction

1. Lift vehicle controls do not

work at upper or lower control box.

a. Master power switch turned off.

b. Low battery power or faulty battery

circuit.

c. Emergency stop button engaged

(pushed in).

d. Battery ground or in-series battery

cable loose.

e. Circuit breaker tripped.

f. Battery cable or equipment ground

lead loose or corroded.

a. Turn on master power switch.

b. Recharge batteries per paragraph 4-4.

Check for faulty battery or cables if

red battery charger LED is lit.

c. Rotate emergency stop buttons clock-

wise to disengage.

d. Check for and repair loose battery

connections or ground fault.

e. Reset breaker. If breaker trips again,

locate and correct short to ground in

power circuit wiring.

f. Clean and reconnect loose or cor-

roded battery cable or ground lead.

2. Lift vehicle controls do not

work at upper control box,

but do work at lower control

box.

3. When UP function is se-

lected, pump motor runs but

will not raise the platform.

a. Emergency stop button engaged

(pushed in) on upper control box.

b. Upper control box cable connectors

unplugged.

c. Upper control box cable connectors

plugged into wrong receptacles.

d. Enable pushbutton switch or wiring

faulty.

a. Hydraulic oil level low in reservoir.

b. More than 500 lbs. on lift platform.

c. Emergency lowering valve open.

d. Up valve solenoid or solenoid wiring

faulty.

e. Down valve sticking open or leaking.

f. UP switch or UP switch wiring faulty.

g. Mast sections dirty; slide blocks

binding.

h. Internal leakage in hydraulic cylinder.

a. Rotate emergency stop buttons clock-

wise to disengage.

b. Plug in cable connectors at front of

upper control box.

c. Plug in cable connectors in opposite

receptacles at upper control box.

d. Repair wire break or replace faulty

switch.

a. Check reservoir level. If low, check

for oil system leakage. Refill reservoir

and bleed air from hydraulic system

per instructions in paragraph 4-3.

b. Ensure load is 500 lbs. or less.

c. Close emergency lowering valve.

d. Check voltage at up valve solenoid. If

no voltage, check wiring. If voltage,

exchange solenoids and recheck func-

tion; replace solenoid if faulty.

e. Repair or replace down valve.

f. Check for lighted UP LED when up

switch is engaged. If LED does not

light, signal is not reaching main con-

troller; repair wire break or replace

faulty switch.

g. Clean and lubricate masts with dry

silicone. If needed, adjust slide bocks

per paragraph 4-5.

h. Check cylinder housing for heat

buildup due to leakage. If leakage is

indicated, repair or replace hydraulic

cylinder.

4-15

Page 38

SkyRider 15

Table 4-3. Troubleshooting Chart (Continued)

Problem Cause Correction

4. ENABLE pushbutton blinks

when pressed.

a. ENABLE pushbutton has been

pressed down for longer than 5

a. Release ENABLE pushbutton and

press again.

seconds without a function being

selected.

b. Joystick potentiometer out of adjust-

ment (will not return to center).

b. Adjust joystick forward/reverse travel

potentiometer for null drive signal

with joystick at center.

c. Did not press ENABLE pushbutton

first before moving joystick to for-

c. Release ENABLE pushbutton and

press again before moving joystick.

ward or reverse drive.

5. When DOWN function is

selected, lift platform will

not descend.

d. Tried to drive forward or reverse and

raise or lower the platform at the

same time.

a. Down valve solenoid or solenoid

wiring faulty.

b. Down valve sticking; does not open.

c. DOWN switch or DOWN switch

wiring faulty.

d. Release ENABLE pushbutton and run

only one function (drive or lift) at a

time.

a. Check voltage at down valve sole-

noid. If no voltage, check wiring. If

voltage, exchange solenoids and recheck function; replace solenoid if

faulty.

b. Repair or replace down valve.

c. Check for lighted DOWN LED when

down switch is engaged. If LED does

not light, signal is not reaching main

controller; repair wire break or re-

place faulty switch.

6. Alarm is sounding; lift UP

and travel functions stopped

a. Lift vehicle more than 1 degree out of

level.

a. Lower lift platform and drive lift

vehicle to level area.

working.

7. When joystick is moved, lift

vehicle will not travel.

a. Wheels blocked.

b. Free wheel lever in free wheel (tow)

position.

c. Joystick or joystick wiring faulty.

d. Main controller or main controller

signal wiring faulty.

e. Motor controller 24-volt power cable

disconnected.

a. Check wheels for blocking; remove

travel obstacle.

b. Move free wheel lever back to drive

position.

c. Check for lighted travel LED when

joystick is engaged. If travel LED

does not light, travel signal is not

reaching main controller; repair wire

break or replace faulty joystick.

d. Check for output voltage to motor

controller when joystick is engaged.

If travel signal is not present at main

controller, contact Workforce for assistance. If travel signal is not present

at motor controller, repair wire break.

e. Check connection of 24-volt power

cable to motor controller; repair faulty

power cable connection.

4-16

Page 39

4 — MAINTENANCE

Table 4-3. Troubleshooting Chart (Continued)

Problem Cause Correction

7. When joystick is moved, lift

vehicle will not travel. (cont)

f. Motor controller, motor controller

output wiring, or transaxle drive motor faulty.

g. Transaxle drive train damaged.

f. Check for output voltage to drive

motor when joystick is engaged. If

drive voltage is not present at motor

controller, replace motor controller. If

drive voltage does not reach drive

motor, repair wire break. If drive voltage is present at drive motor, replace

drive motor.

g. If transaxle drive motor runs, inspect

drive train components for damage.

Repair or replace transaxle gearhouse,

if damaged.

8. Wh en steering thumb switch

is pressed, steering wheels

do not swivel.

9. Pothole guard does not

deploy when lift platform is

raised via upper control box.

a. Wheels turned to steering limit.

b. 10 Amp Motors fuse burned out on

main controller board.

c. Internal steering actuator fuse.

d. Thumb switch or thumb switch wiring

faulty.

e. Actuator or actuator wiring faulty.

f. Steering linkage failed.

g. Main controller faulty.

a. 10 Amp Motors fuse burned out on

main controller board.

b. Internal steering actuator fuse.

c. Actuator or actuator wiring faulty.

d. Down limit switch or limit switch

wiring faulty.

e. Pothole guard linkage failed.

f. Main controller faulty.

a. Turn wheels in opposite direction.

b. Replace 10 Amp Motors fuse.

c. Replace steering actuator fuse.

d. Check for lighted steering LED when

thumb switch is engaged. If LED does

not light, signal is not reaching main

controller; repair wire break or replace faulty joystick.

e. Check actuator wiring for operating

voltage. If voltage is present, replace

faulty actuator. If voltage is not present, check actuator wiring for continuity; repair wire breaks.

f. Check steering linkage for damage;

replace damaged parts.

g. Contact W orkforce for assistance.

a. Replace 10 Amp Motors fuse.

b. Replace steering actuator fuse.

c. Check actuator wiring for operating

voltage while platform is rising. If

voltage is present, replace faulty ac-

tuator. If voltage is not present, check

actuator wiring for continuity; repair

wire breaks.

d. Check limit switch operation and

wiring. Replace damaged limit switch

or repair wiring.

e. Check pothole guard linkage for

damage; replace damaged parts.

f. Contact Workforce for assistance.

4-17

Page 40

SkyRider 15

Table 4-3. Troubleshooting Chart (Continued)

Problem Cause Correction

10. Pothole guard does not rise

when lift platform is lowered

via upper control box.

11. When BATTERY ON/OFF

switch is turned ON, hydrau-

a. 10 Amp Motors fuse burned out on

main controller board.

b. Internal steering actuator fuse.

c. Actuator or actuator wiring faulty.

d. Pothole guard linkage failed.

e. Main controller faulty.

a. Motor start relay failure; relay con-

tacts fused shut.

a. Replace 10 Amp Motors fuse.

b. Replace steering actuator fuse.

c. Check actuator wiring for operating

voltage when platform reaches lower

travel limit. If voltage is present, replace faulty actuator. If voltage is not

present, check actuator wiring for

continuity; repair wire breaks.

d. Check pothole guard linkage for

damage; replace damaged parts.

e. Contact Workforce for assistance.

a. Replace motor start relay.

lic pump starts up.

Troubleshooting Aids

EASI-0

EASI-TXD

Pothole Up

Motor

EASI-24

EASI-RXD

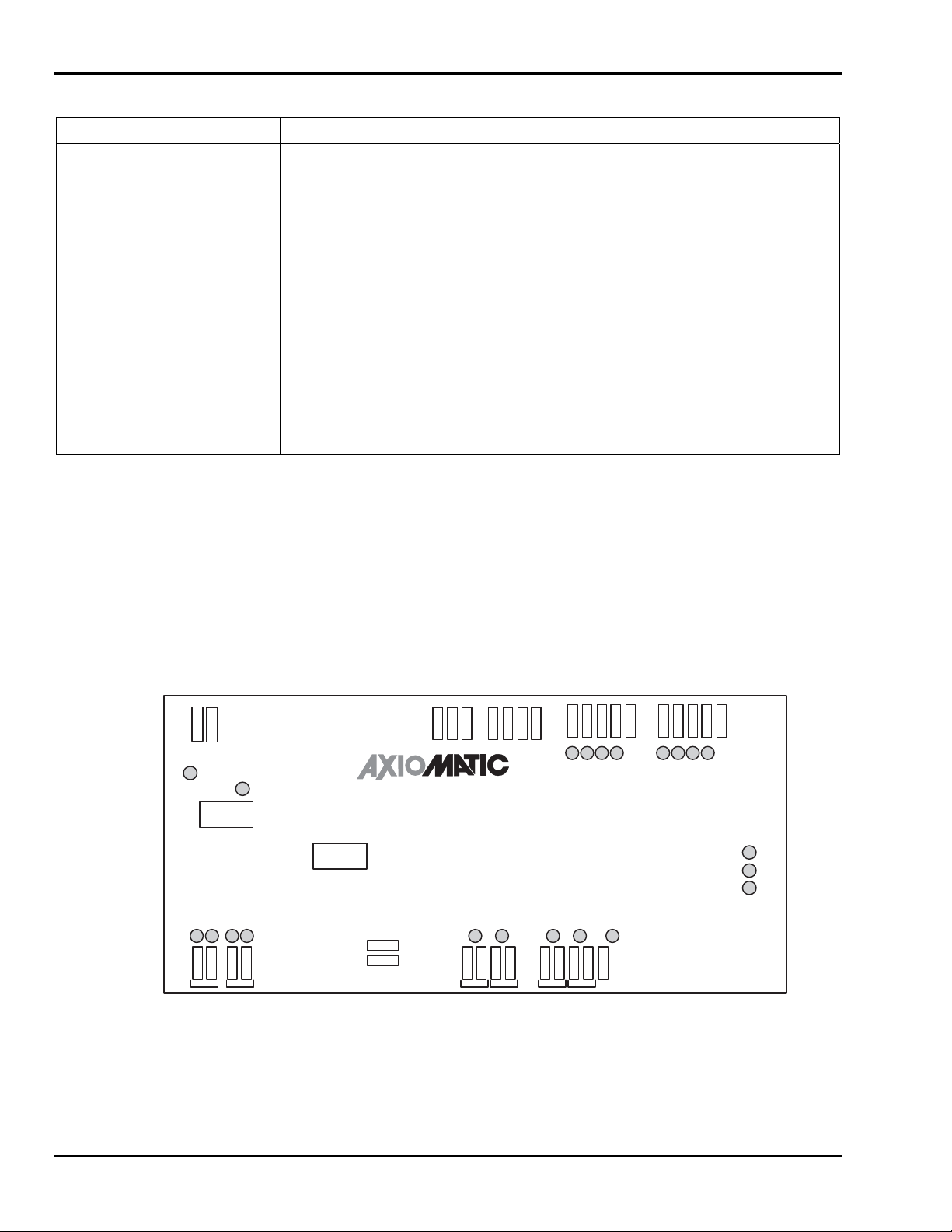

F1 2AMP

Pothole Down

Steer Left

Pothole

Motor

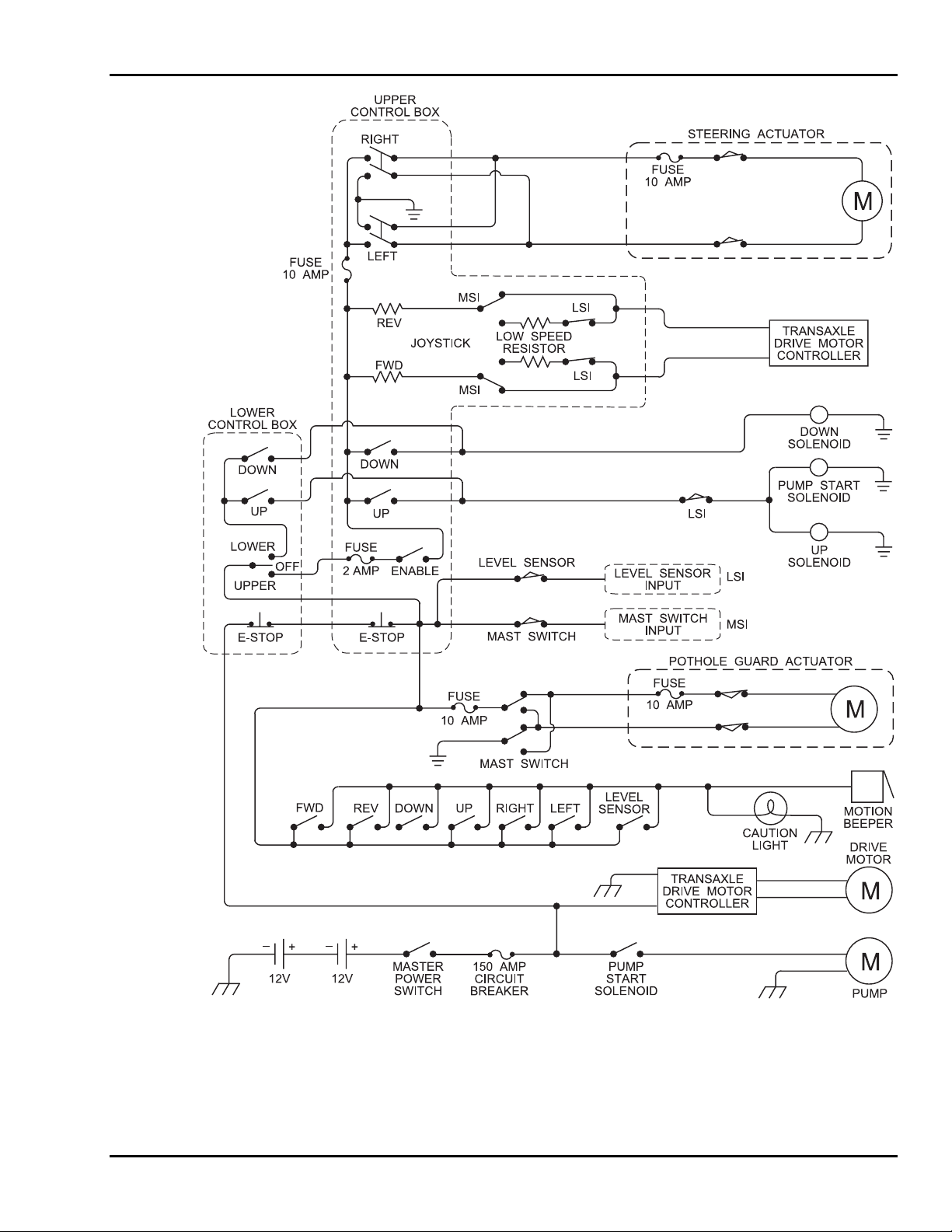

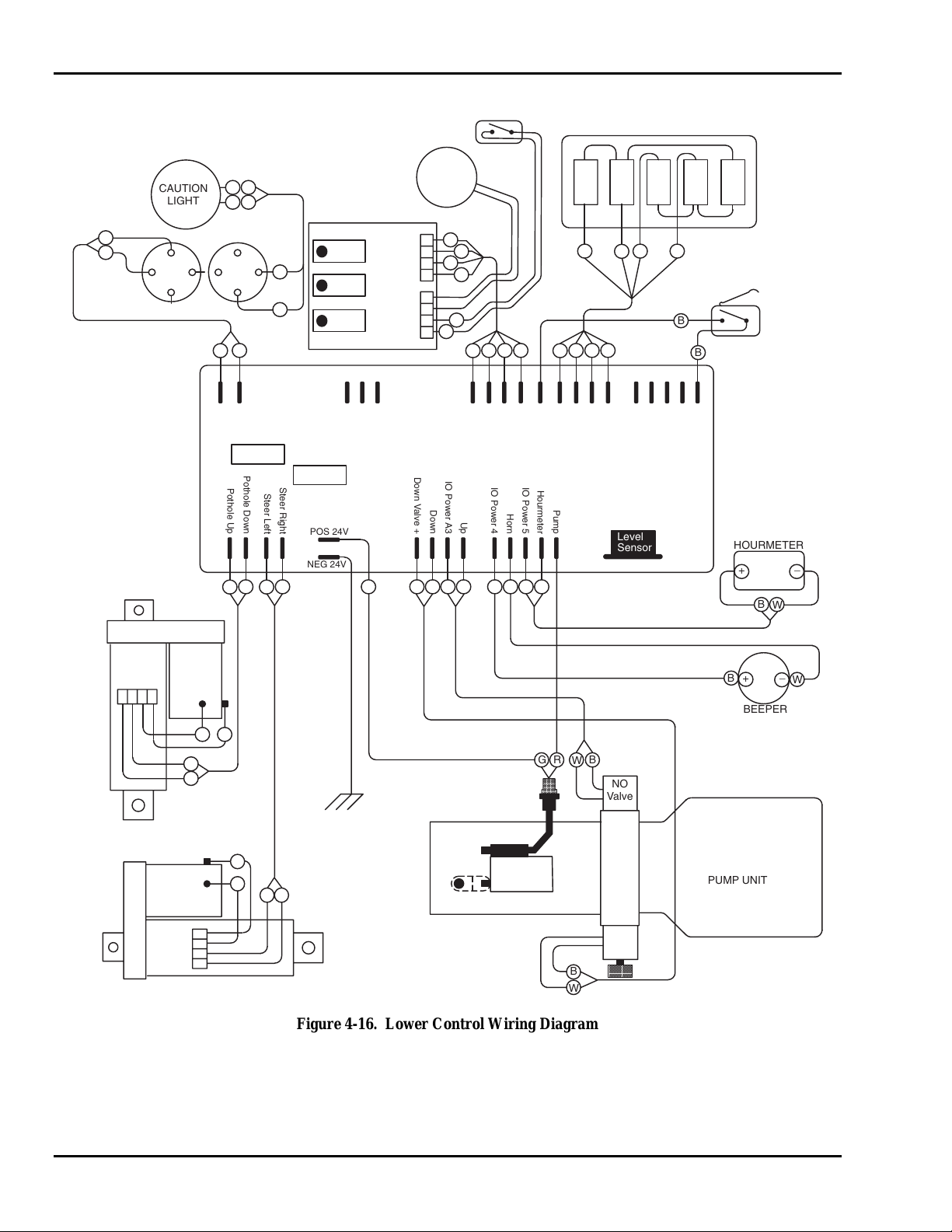

See Table 4-4 for interpreting LED indicators located on the main controller board

shown in Figure 4-13. Hydraulic and PC logic diagrams are shown in Figures 4-14 and

4-15. An electrical wiring diagram is shown in Figure 4-16.

Upper Controls

Lower Down

Steer Right

Steering

F2 10AMP

GND

TXD

TECHNOLOGIES CORPPORATION

P/N: EASI-WFC-02

MAIN CONTROLLER

POS 24V

NEG 24V

CAN L

RXD

Down Valve

Down

ValveUpValve

CAN H

Up Valve

CAN GND

CAN P5V

Mast Switch

Horn ON

Horn

Lower Down

Mast Down

Hour Meter

Hour

Meter

Lower Up

Lower Raise

Pump ON

Pump

IO Power 1

IN-4

Upper Controls

IN-5

IN-6

IN-7

A0/CLK

A1/DATA

IO Power 2

TILT

Figure 4-13. Main Controller Board

4-18

Page 41

4 — MAINTENANCE

Table 4-4. Main Controller LED Indicators

Indicator Function Color

TILT Watch Dog/Tilt CPU (Error Codes)

Red

Flashes 1: Watch Dog/Tilt OK

Flashes 2: Tilt Limit Exceeded

Flashes 3: Watch Dog/Tilt Code Sum Error

Flashes 4: Watch Dog/Tilt Nonvolatile Memory Error

Flashes 5: Unable to confirm Joystick Communications

A0/CLK Main CPU (Error Codes)

Green

Flashes 1: Main Controller OK

Flashes 2: Transaxle Brake Override Open (Free Wheel

Switch)

Flashes 3: Main CPU Code Check Sum Error

Flashes 4: Unable to Communicate with Motor Controller

Flashes 5: Unable to Communicate with Joystick

A1/Data Watch Dog/Tilt CPU (Error Codes)

Green

ON: High Side Safety Lockout = OK to Run

OFF: High Side Safety Lockout = Active E-Stop

EASI-TXD Upper Control Transmitting Green

EASI-RXD Upper Control Receiving Green

Mast Down Mast Down Switch Output Green

Lower Down Lower Mast Down Output Green

Lower Raise Lower Mast Up Output Green

Upper Controls Upper Controls Activated Green

Pothole Up Pothole Up Output Green

Pothole Down Pothole Down Output Green

Steer Left Steer Left Output Green

Steer Right Steer Right Output Green

Down Valve Platform Down Output Green

Up Valve Platform Up Output Green

Horn ON Horn Output Green

Hourmeter Hourmeter On Output Green

Pump ON Pump Motor Running Output Green

IN-4, IN-5, IN-6, IN-7 (Spare Inputs) Green

4-19

Page 42

SkyRider 15

Figure 4-14. Hydraulic Diagram

4-20

Page 43

4 — MAINTENANCE

Figure 4-15. PC Logic Diagram

4-21

Page 44

SkyRider 15

FREE WHEEL

SWITCH NO

LOWER CONTROL BOX

E-

BRAKE

CAN P5V

CAN-HI

CAN-L0

Brake

+24V

IN 0

+24V

RXD

SOLENOID

R

1

G

2

B

3

4

W

1

2

2

3

1

4

CAN L

CAN H

CAN GND

CAN P5V

CAUTION

LIGHT

W

B

1

32

4

B

R B

W

EASI-0

W

1

32

4

B

EASI-24

MOTOR CONTROLLER

Motor

(-)

W

(+)

B

Motor

(+)

GND

CAN GND

TAD

UPNODN

B G

Mast Down

Lower Down

Lower Raise

GBWRGBWR

Upper Controls

IO Power-1

NO

W

R

IN-4

F1 2AMP

Pothole Down

Pothole Up

Steer Left

F2 10AMP

Steer Right

POS 24V

NEG 24V

2

2

1

1

G BWB

Down Valve +

IO Power A3

IO Power 4

IO Power 5

Hourmeter

Down

Horn

Up

BWB

W

Pump

Level

Sensor

W

Stop

NC

IN-5

IN-6

B

IN-7

Up

Low

Cntl

Cntl

NO

NO

MAST SWITCH

B

IO Power 2

NO

HOURMETER

+

B

W

_

POTHOLE

STEERING

B R

2

1

B

W

_

+

BEEPER

G RWB

NO

Valve

R

B

2

1

B

W

PUMP UNIT

Figure 4-16. Lower Control Wiring Diagram

4-22

Page 45

4 — MAINTENANCE

_

BATTERY

+

MOTOR CONTROLLER

_

BATTERY

+

Motor

(-)

(+)

Motor

(+)

CAN P5V

CAN GND

CAN-HI

CAN-L0

Brake

+24V

IN 0

+24V

R

1

G

2

B

3

4

W

1

2

2

3

1

4

120”

18-4

TRANSAXLE

BRAKE

FREEWHEEL

SWITCH

1

C

NO

2

NC

BATTERY

GAUGE

MASTER

R

B

POWER

SWITCH

BAT

CIRCUIT

BREAKER

AUX

R

B

24 VOLT

BATTERY

CHARGER

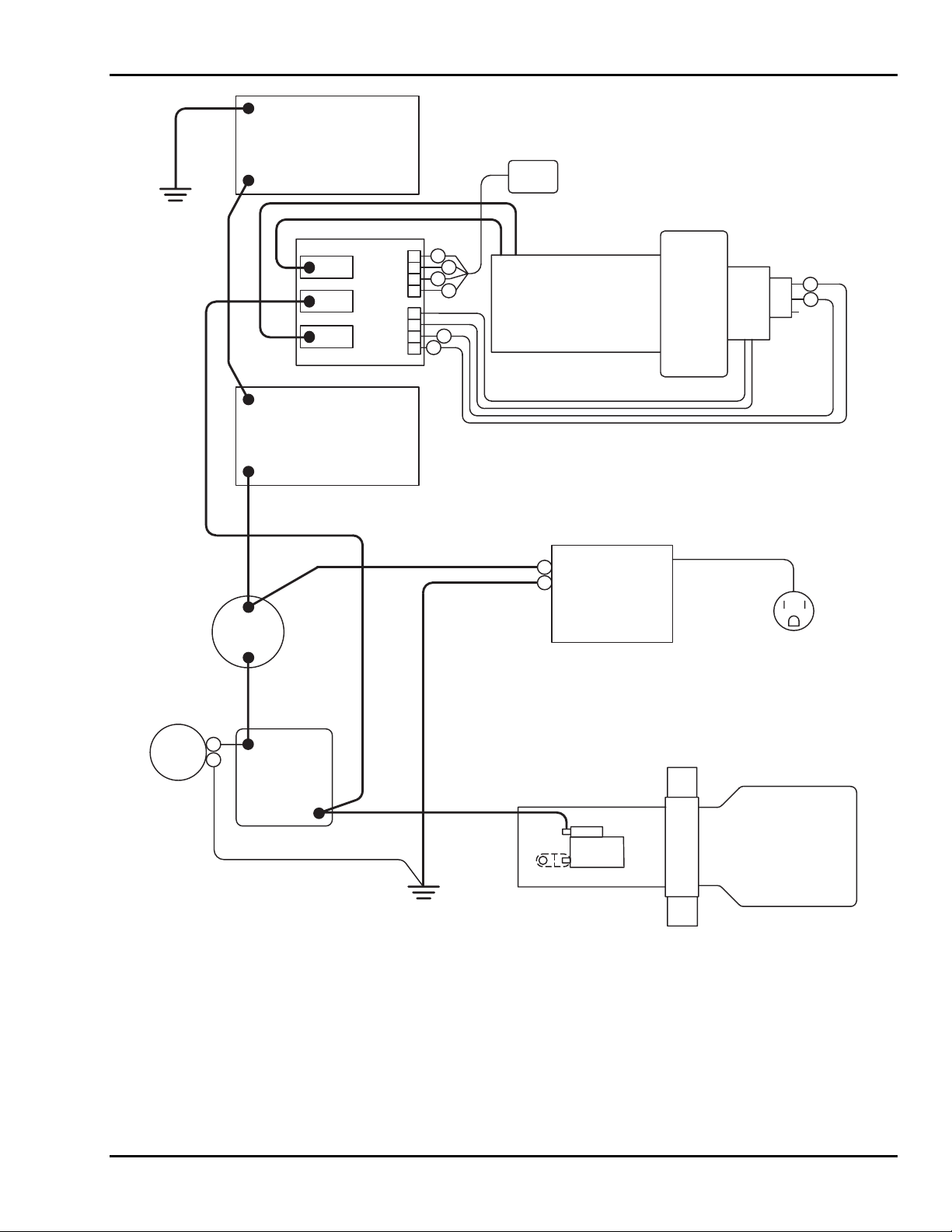

Figure 4-17. Drive Wiring Diagram

110 VOLT

CHARGING

RECEPTACLE

PUMP UNIT

4-23

Page 46

SkyRider 15

E-STOP

GR GR

MAST

UP

GY

BK

GR

MAST

DOWN

PL

BK

GR

RD

GR

PL

BK

YL

BK

YL

ENABLE

GY

RD

RIGHT

TURN

BL

RD

STEERING

COM

NCN

O

RD

W

COM

NON

BL

W

RD GR

BK

C

LEFT

TURN

YL

GR

BK

1

4

YL

1

23

4

23

RD

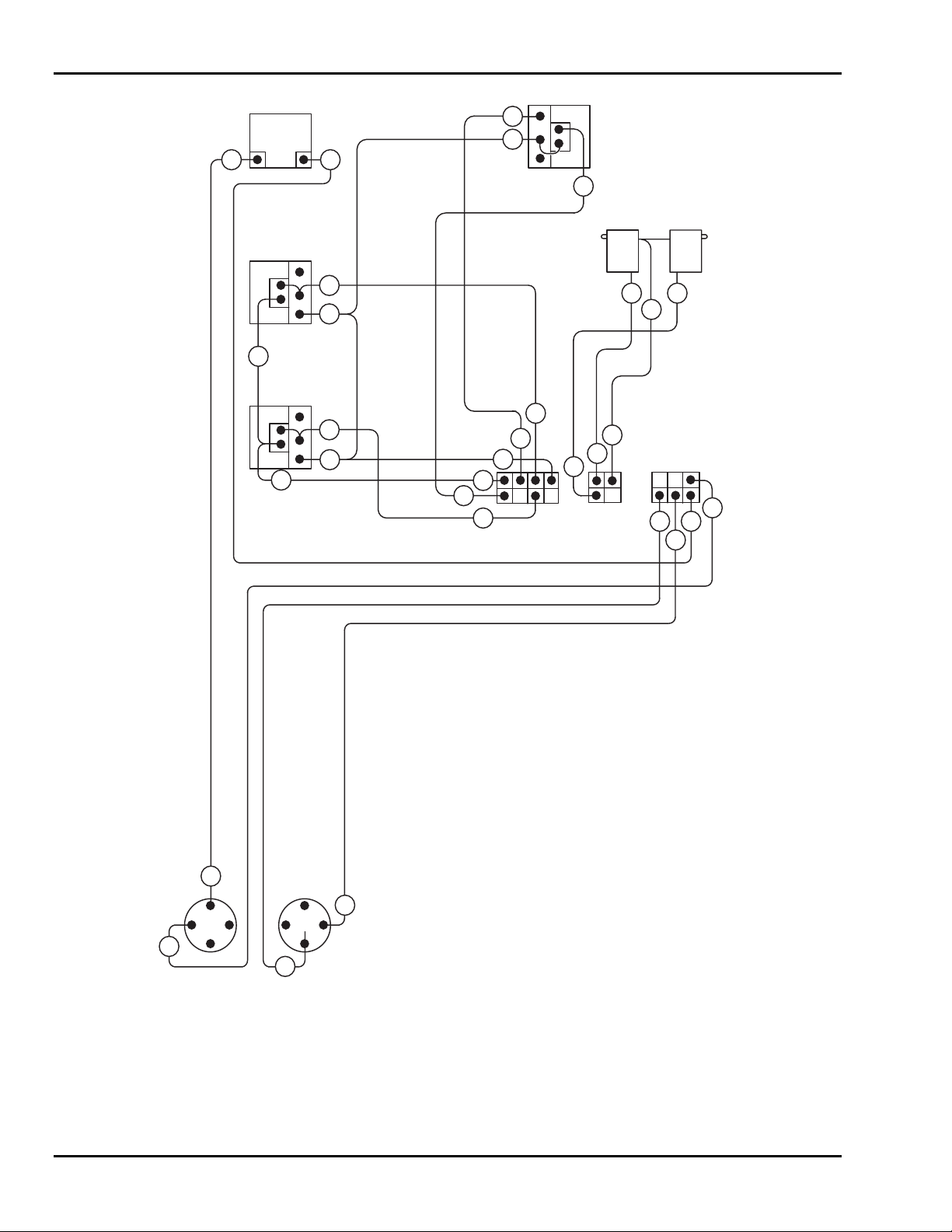

Figure 4-18. Upper Control Wiring Diagram

4-24

Page 47

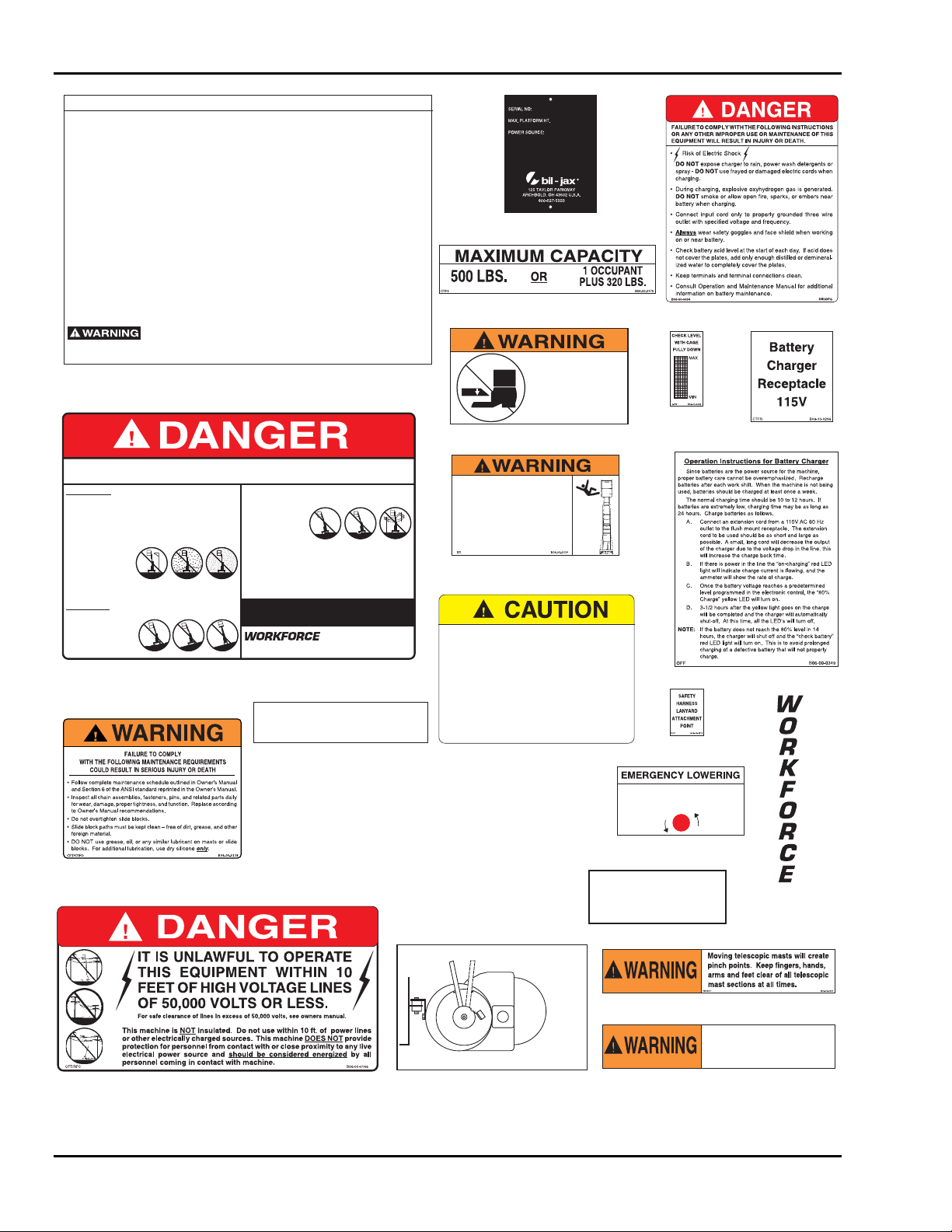

5

Replacement Decals

Refer to Table 5-1, and Figures 5-1, 5-2, and 5-3 for descriptions and locations of decals

on the SkyRider 15.

Table 5-1. Replacement Decals

Decal No. Description of Decal

B06-00-0009 Warning...Moving telescopic masts will create... 2

B06-00-0034 Danger...During charging, explosive oxyhydrogen gas... 1

B06-00-0137 Workforce (Vertical transfer type decal) 2

B06-00-0138 Warning...(Maintenance decal) 1

B06-00-0146 Danger...(High voltage line warning) 1

B06-00-0167 Striped Safety Tape - On all four sides (per roll only) 28 Ft.

B06-00-0170 Maximum Capacity...500 lb. Or... 3

B06-00-0173 Safety harness lanyard attachment point 2

B06-00-0192 Operation and service manual inside 1

B06-00-0225 Warning...Stay clear when raising or lowering 2

B06-00-0286 Emergency Lowering 1

B06-00-0289 Check level with cage fully down 1

B06-00-0296 Battery Charger Receptacle 1

B06-00-0385 Warning...Full Body Harness and Lanyard... 1

B06-00-0349 Operation Instructions for Battery Charger 1

B06-00-0359 Serial Number Tag (Not available as replacement part) 1

B06-00-0382 Caution...This machine designed and manufactured... 1

B06-00-0383 Danger...Failure To Comply With The Following... 1

B06-00-0384 Warning...Stand clear when raising or lowering lift. 2

B06-00-0386 Operation Instructions for SkyRider 15 2

B06-00-0387 SkyRider 15, Yellow (Transfer type decal) 2

B06-00-0388 SkyRider 15, Black (Transfer type decal) 1

B06-00-0390 Trans Axle Instruction 2

B06-00-0130 Lubricate Monthly 6

Qty

5-1

Page 48

SkyRider 15

OPERATION INSTRUCTIONS FOR SKYRIDER 15

1. Read and follow safety precautions and all responsibilities sections set forth in the operators manual