Page 1

AERIAL WORK PLATFORMS

AERIAL WORK PLATFORMS

AERIAL WORK PLATFORMSAERIAL WORK PLATFORMS

ODYSSEY 34

Electric Hydraulic Lift Platform

Operation and

Maintenance Manual

ENABLEENABLE

WA

WORKFORCEWORKFORCE

R

E-STOP

N

IN

G

WA

R

N

IN

G

UPUP

D

DOWN

O

W

N

b

bil-jax

il-ja

x

O

O

D

D

Y

Y

S

S

S

S

E

E

Y

Y

34

34

B33-01-0071

Page 2

TELESCOPIC PERSONNEL LIFT

This equipment is designed and manufactured in compliance with the duties, responsibilities, and standards set forth for manufacturers in the ANSI 92.3 standard

in effect at the time of manufacture.

This equipment will meet or exceed applicable OSHA codes and ANSI A92.3 standards when used in accordance with sections 5, 6, 7, 8, 9 & 10 of ANSI A92.3 and all

other manufacturer’s recommendations.

It is the responsibility of the user of this equipment to follow all applicable ANSI,

OSHA, Federal, State, and local codes and regulations that govern the safe operation of this equipment.

Page 3

Table of Contents

1 Safety ............................................................................................................... 1-1

1-1 Introduction........................................................................................ 1-1

1-2 Before Operation............................................................................... 1-3

1-3 During Operation............................................................................... 1-4

1-4 Maintenance Safety........................................................................... 1-6

1-5 Damaged Equipment Policy............................................................. 1-7

2 Introduction.................................................................................................... 2-1

2-1 General Description........................................................................... 2-1

2-2 Specifications..................................................................................... 2-2

2-3 Warranty............................................................................................. 2-2

3 Operation ........................................................................................................ 3-1

3-1 Operator Controls.............................................................................. 3-1

3-2 Normal Operating Procedure............................................................ 3-4

3-3 Emergency Lowering Procedure...................................................... 3-5

4 Maintenance.................................................................................................... 4-1

4-1 Scheduled Service Checks................................................................ 4-1

4-2 Lubrication......................................................................................... 4-3

4-3 Hydraulic System.............................................................................. 4-5

4-4 Electrical System............................................................................. 4-10

4-5 Lift Chains and Slide Blocks........................................................ 4-11

4-6 Troubleshooting ............................................................................... 4-15

5 Replacement Decals........................................................................................ 5-1

6 Parts List ......................................................................................................... 6-1

6-1 Aluminum Masts Parts List............................................................. 6-2

6-2 Main (Welded) Mast Parts List...................................................... 6-6

6-3 Mast Cylinder and Slide Blocks Parts List................................... 6-8

6-4 Power Unit and Controls Parts List............................................. 6-10

6-5 Main Frame and Outriggers Parts List......................................... 6-12

6-6 Platform Parts List.......................................................................... 6-14

6-7 Covers Parts List............................................................................ 6-16

6-8 Jack Assembly Parts List............................................................... 6-18

6-9 Upper Control (B01-10-0169) Parts List...................................... 6-20

6-10 Lower Control (B01-10-0170) Parts List..................................... 6-21

6-11 Hydraulic Unit Parts List............................................................... 6-22

6-12 Hydraulic System Schematic Diagram.......................................... 6-24

6-13 ElectricaL Schematic....................................................................... 6-25

6-14 Electrical Layout............................................................................. 6-26

7 ANSI Reprint................................................................................................. 7-1

i

Page 4

List of Illustrations

Figure 3-1. Receiver.................................................................................................. 3-1

Figure 3-2. Transmitter.............................................................................................. 3-2

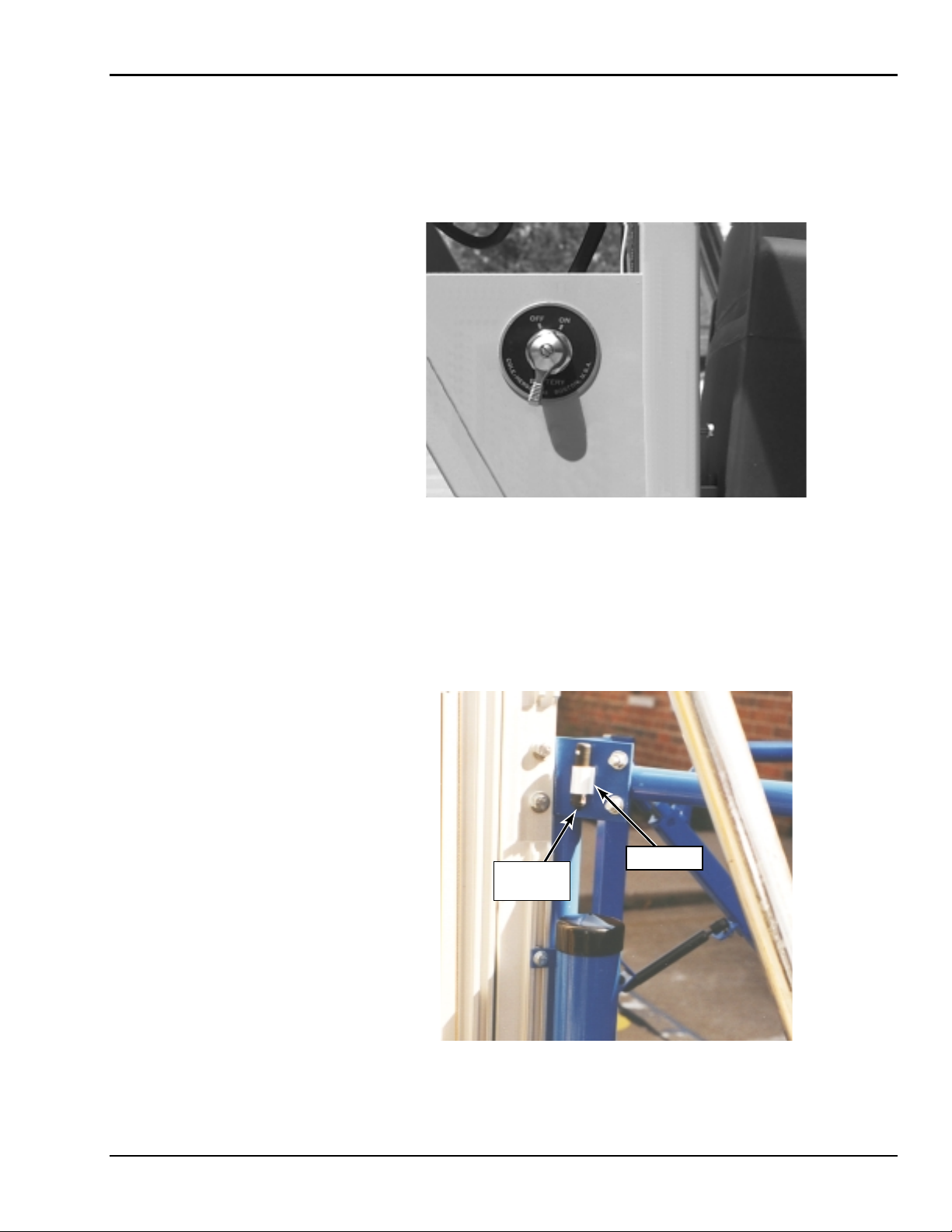

Figure 3-3. ON/OFF Switch...................................................................................... 3-3

Figure 3-4. Laser Pointer...........................................................................................3-3

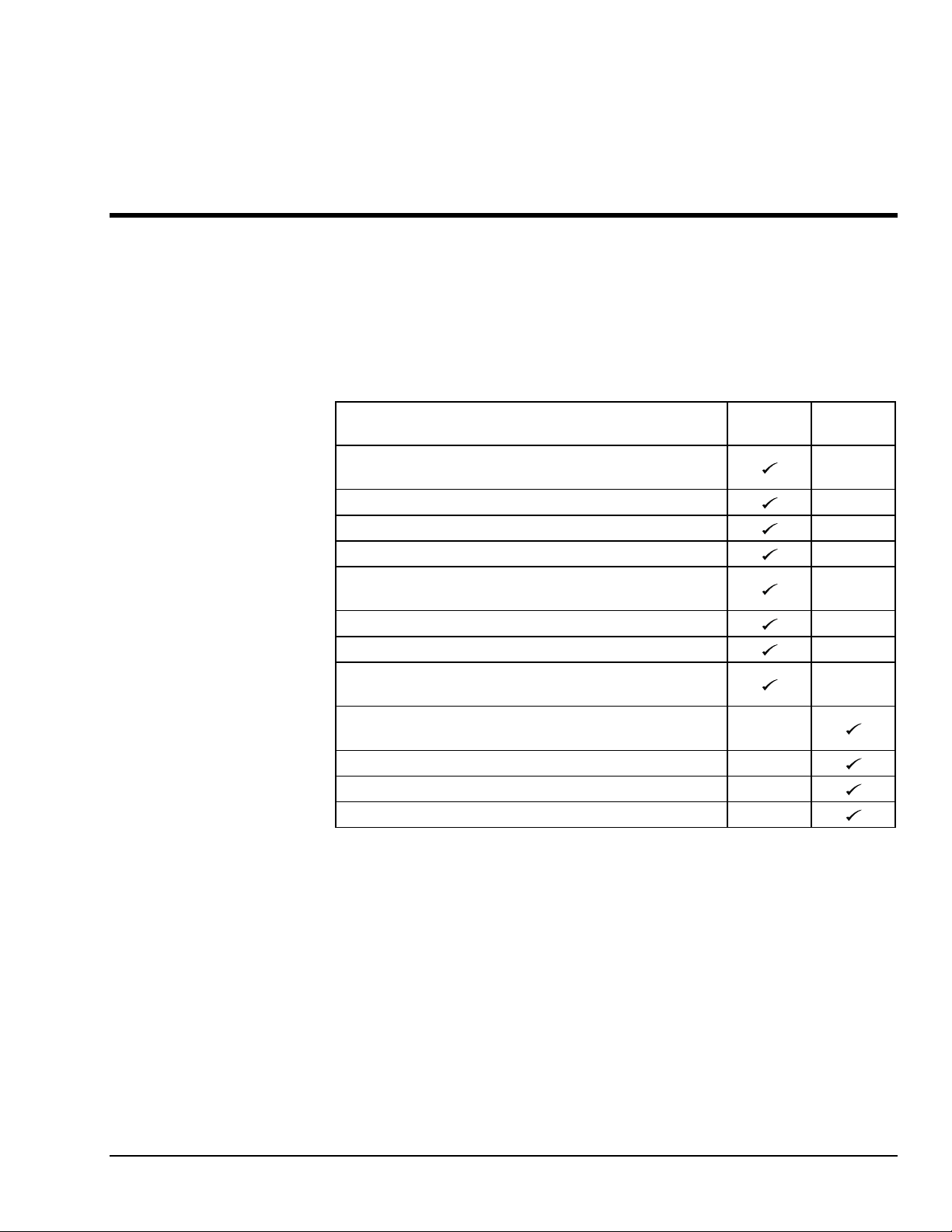

Figure 3-5. Outrigger LEDs on Main Frame .............................................................3-4

Figure 3-6. Emergency Lowering Valve....................................................................3-5

Figure 4-1. Lift Chain Lubrication.............................................................................4-3

Figure 4-2. Wheel and Axle Lubrication...................................................................4-4

Figure 4-3. Steel Mast Slide Lubrication................................................................... 4-4

Figure 4-4. Pressure Relief Valve Adjustment ..........................................................4-6

Figure 4-5. Hydraulic Cylinder Exploded View........................................................4-9

Figure 4-6. BL-566 Chain Elongation Inspection....................................................4-11

Figure 4-7. BL-466 Chain Elongation Inspection....................................................4-11

Figure 4-8. Slide Block Adjustment........................................................................4-13

Figure 4-9. Guide Peg Adjustment ..........................................................................4-14

Figure 5-1. Replacement Decals................................................................................ 5-2

Figure 5-2. Decal Locations, Carriage and Base....................................................... 5-3

Figure 5-3. Decal Locations, Continued.................................................................... 5-4

Figure 6-1. Aluminum Masts Exploded View...........................................................6-2

Figure 6-2. Main (Welded) Mast Exploded View.....................................................6-6

Figure 6-3. Mast Cylinder and Slide Blocks Exploded View....................................6-8

Figure 6-4. Power Unit and Controls Exploded View.............................................6-10

Figure 6-5. Main Frame and Outriggers Exploded View.........................................6-12

Figure 6-6. Platform Exploded View.......................................................................6-14

Figure 6-7. Covers Exploded View......................................................................... 6-16

Figure 6-8. Jack Assembly Exploded View............................................................. 6-18

Figure 6-9. Upper Control Exploded View.............................................................6-20

Figure 6-10. Lower Control (Receiver) Exploded View ...........................................6-21

Figure 6-11. Hydraulic Unit Assembly...................................................................... 6-22

Figure 6-12. Hydraulic System Schematic Diagram..................................................6-24

Figure 6-13. Electrical Schematic..............................................................................6-25

Figure 6-14. Electrical Layout................................................................................... 6-26

ii

Page 5

List of Tables

Table 1-1. Minimum Safe Approach Distances....................................................... 1-4

Table 2-1. Specifications.......................................................................................... 2-2

Table 4-1. Daily/Weekly Service Checks ................................................................ 4-1

Table 4-2. Monthly Service Checks......................................................................... 4-2

Table 4-3. Troubleshooting Chart.......................................................................... 4-15

Table 5-1. Replacement Decals................................................................................ 5-1

Table 6-1. Aluminum Mast Parts List...................................................................... 6-3

Table 6-2. Main (Welded) Mast Parts List............................................................... 6-7

Table 6-3. Mast Cylinder and Slide Blocks Parts List ............................................. 6-9

Table 6-4. Power Unit and Controls Parts List ...................................................... 6-11

Table 6-5. Main Frame and Outriggers Parts List.................................................. 6-13

Table 6-6. Platform Parts List................................................................................ 6-15

Table 6-7. Covers Parts List................................................................................... 6-17

Table 6-8. Jack Assembly Parts List...................................................................... 6-19

Table 6-9. Upper Control (Transmitter) Parts List................................................. 6-20

Table 6-10. Lower Control (Receiver) Parts List..................................................... 6-21

Table 6-11. Hydraulic Unit Parts List...................................................................... 6-23

Table 7-1. Minimum Safe Approach Distance (M.S.A.D.) to energized

(exposed or insulated) power lines and parts.................................... 7-11

iii

Page 6

iv

Page 7

1

Safety

1-1 INTRODUCTION

Familiarity and proper training are required for the safe operation of mechanical equipment. Equipment operated improperly or by untrained personnel can be dangerous. Read

the operating instructions in this manual and become familiar with the location and proper

use of all controls. Inexperienced operators should receive instruction from someone familiar with the equipment before being allowed to operate the machine. The use of intelligence and common sense in the operation of mechanical equipment is the best practice in

any safety policy. Be professional and always observe the safety procedures set forth in

this manual.

All OSHA, ANSI, state and local codes and regulations pertaining to this equipment

should be ob tained, read, a nd thoroughly understood before attempting to operate this

equipment. Persons under the influence of drugs, alcohol, or prescription medication

should not be on or near this equipment. Common sense should be implemented at all

times during the use of this equipment. Do not operate this equipment in areas where

equipment or user may come in contact with live power source.

The information contained herein is not to be considered as legal advice and is intended

for informational purposes only. This information is offered to alert Bil-Jax customers to

procedures that may be of concern to them.

This information is not intended to be all inclusive and is to be followed in the use of

Bil-Jax equipment only.

For any questions concerning the safe use of this equipment, call 419.445.9675 before

operating.

1-1

Page 8

ODYSSEY 34

Safety Notes

This manual contains DANGERS, WARNINGS, CAUTIONS, and NOTES that must be

followed to prevent the possibility of improper service, damage to the equipment, or personal injury.

DANGER

Dangers warn of equipment operation near electrical power lines that could lead

to personal injury or death.

WARNING

Warnings describe conditions or practices that could lead to personal injury or

death.

CAUTION

Cautions provide information important to prevent errors that could damage machine or components.

NOTE: Notes contain additional information important to a pro cedure.

1-2

Page 9

1 — SAFETY

1-2 BEFORE OPERATION

Ensure the following general safety precautions are followed before operating the

Odyssey 34 lift.

• ALWAYS survey the usage area for potential hazards such as untampered earth

fills, unlevel surfaces, overhead obstructions, and electrically charged conductors

or wires. Be aware of any potential hazards and always consider what could happen. Watch for moving vehicles in the o perating area.

• ALWAYS read, understand, and follow the procedures in this manual before at-

tempting to operate equipment.

• ALWAYS inspect the equipment for damaged or worn parts. Check for cracked

welds, hydraulic leaks, damaged wiring, loose wire connectors, damaged casters,

and damaged outriggers. Also check for any improper operation. NEVER operate equipment if damaged in any way. Improperly operating equipment must be

repaired before using.

• ALWAYS wear proper clothing for the job. Wear protective equipment as re-

quired by federal, state, or local regulations.

• ALWAYS locate, read, and follow all directions and warnings displayed on the

equipment.

• ALWAYS inspect the equipment for any “DO NOT USE” tags placed on the

equipment by maintenance personnel. NEVER use any equipment tagged in this

way until repairs are made and all tags are removed by authorized maintenance

personnel.

• ALWAYS make sure the cage platform and outrigger shoes are free of mud,

grease, or other foreign material. This will reduce the possibility of slipping.

• NEVER allow improperly trained personnel to operate this equipment. Only

trained and authorized personnel shall be allowed to operate this equipment.

• NEVER operate this equipment if you are under the influence of alcohol or

drugs or if you feel ill, dizzy, or unsteady in any way. Operators must be physically fit, thoroughly trained, and no t easily excitable.

• NEVER modify, alter, or change the equipment in any way that would affect its

original design or operation in any way.

• NEVER operate this equipment in ways for which it is not intended.

1-3

Page 10

ODYSSEY 34

1-3 DURING OPERATION

Ensure the following general safety precautions are followed during the operation of the

Odyssey 34 lift.

DANGER

This machine is not insulated for use near electrical power lines and DOES NOT

provide protection from contact with or close proximity to any electrically charged

conductor. Operator must maintain safe clearances at all times (10 feet minimum)

and always allow for platform movement such as wind induced sway. Always contact the power company before performing work near power lines. Assume every

line is hot. Remember, power lines can be blown by the wind.

Refer to Table 1-1 for minimum safe approach distances between machine and electrical

power lines.

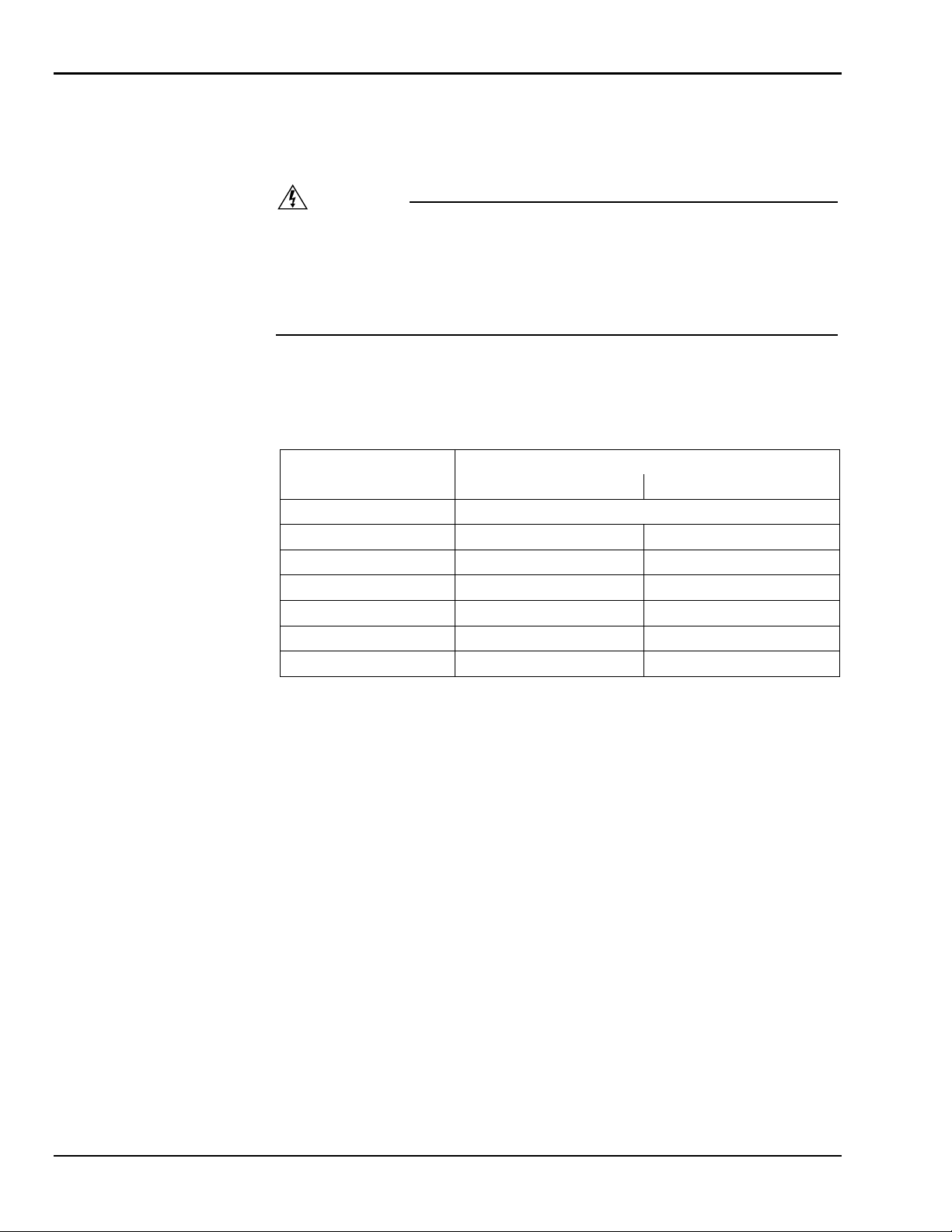

Table 1-1. Minimum Safe Approach Distances

Voltage Range

(Phase to Phase)

0 to 300V Avoid Contact

Over 300V to 50KV 10 3.05

Over 50KV to 200KV 15 4.60

Over 200KV to 350KV 20 6.10

Over 350KV to 500KV 25 7.62

Over 500KV to 750KV 35 10.67

Over 750KV to 1000KV 45 13.72

Minimum Safe Approach Distance

(Feet) (Meters)

• ALWAYS position lift far enough away from power sources to ensure that no

part of the lift can accidentally reach into an unsafe area.

• ALWAYS operate only on a firm and level surface. NEVER use on surfaces that

do not support the weight of the equipment and its rated load capacity.

• ALWAYS keep yourself and all personnel away from potential pinch or shear

points.

• ALWAYS report any misuse of equipment to the proper authorities. Horseplay is

prohibited.

• ALWAYS maintain good footing on the cage platform. NEVER wear slippery

soled shoes.

• ALWAYS make certain all personnel are clear and there are no obstructions be-

fore repositioning cage platform.

• ALWAYS cordon off area around the outriggers to keep personnel and other

equipment away from it while in use.

• ALWAYS stay clear of wires, cables, and other overhead obstructions.

• ALWAYS disconnect power at the batteries when not in use to guard against un-

authorized use.

1-4

Page 11

1 — SAFETY

• NEVER allow electrode contact with any part of the cage platform if welding is

being performed by a worker from the cage platform.

• NEVER use without the outriggers fully based on the floor.

• NEVER override or by-pass manufacturer's safety devices.

• NEVER release outrigger locks or move unit with a person or materials on

board.

• NEVER stand or sit on cage bars. Work only within the cage platform area and

do not lean out over cage platform to perform work.

• NEVER attempt to increase working height with boxes, ladders, or other means.

• NEVER operate this equipment when exposed to high winds, thunderstorms, ice,

or any other weather conditions that would compromise the safety of the

operator.

• NEVER climb up or down masts.

• NEVER allow ropes, electric cords, hoses, etc. to become entangled in the

equipment when the cage platform is being raised or lowered.

• NEVER exceed manufacturer's load limits.

• NEVER exceed load ratings by transferring loads to cage platform at elevated

heights.

• NEVER use cage to carry materials and never allow overhang of materials when

raising or lowering cage platform.

1-5

Page 12

ODYSSEY 34

1-4 MAINTENANCE SAFETY

Ensure the following general safety precautions are observed when maintenance is performed on the Odyssey 34 lift.

• ALWAYS perform maintenance procedures according to manufacturer's re-

quirements. NEVER short change maintenance procedures.

• ALWAYS check hydraulic system. Make sure all lines, connectors, and fittings

are tight and in good condition.

• ALWAYS keep all mechanisms properly adjusted and lubricated according to

maintenance schedule and manufacturers specifications.

• ALWAYS perform a function check of operating controls before each use and

after repairs have been made.

• ALWAYS locate and protect against possible pinch points prior to performing

maintenance and repairs.

• ALWAYS use only factory approved parts to repair or maintain this equipment.

If this equipment is rebuilt, retesting is required in accordance with factory instructions.

• NEVER add unauthorize d fluids to the hydraulic system or battery. Check manu-

facturers specifications.

• NEVER exceed the manufacturer's recommended relief valve settings.

• NEVER attempt repairs you do not understand. Consult manufacturer if you

have any questions regarding proper maintenance, specific ations, or repa ir.

Battery Maintenance

Ensure the following general safety precautions are followed when battery maintenance is

being performed on the Odyssey 34 lift.

• ALWAYS check battery acid level daily. Check battery test indicator for proper

state of charge on maintenance free batteries before using lift.

• ALWAYS wear safety glasses when working near battery.

• ALWAYS avoid contact with battery acid. Battery acid causes serious burns.

Avoid contact with skin or eyes. If accidental contact occurs, flush with water

and consult a physician immediately.

• ALWAYS disconnect ground cable first when removing battery.

• ALWAYS connect ground cable last when installing battery.

• ALWAYS charge batteries in open, well ventilated areas.

• NEVER smoke when servicing battery.

• NEVER allow batteries to overcharge and boil.

• NEVER short across battery posts to check for current. NEVER break a live cir-

cuit at battery.

• NEVER jump start other vehi cles using lift battery.

1-6

Page 13

1 — SAFETY

1-5 DAMAGED EQUIPMENT POLICY

Safety Statement

At Bil-Jax, we are dedicated to the safety of all users of our products. Therefore, all

Bil-Jax lifts are designed, manufactured and tested to comply with current applicable

Federal OSHA and ANSI codes and regulations.

Damage Policy

There may be occasions when a Bil-Jax lift is involved in an incident that results in structural damage to the lift. This can seriously compromise the ability of the lift to perform in

a safe manner. Therefore, whenever a Bil-Jax lift is damaged structurally or when there is

the possibility of structural damage (this damage may be internal and is not always visible

to the naked eye), Bil-Jax requires that the lift be returned to our facility at 125 Taylor

Parkway, Archbold, Ohio, for reconditioning. If you have any questions concerning what

constitutes structural damage, please call the Bil-Jax Service Department at

419.445.9675.

Damage Repair Notice

There may be occasions when a Bil-Jax lift is involved in an incident resulting in nonstructural damage. When this occurs and repairs are made by the owner or area distributor, please notify Bil-Jax of these non-maintenance repairs and request a repair form to be

filled out and returned to Bil-Jax.

1-7

Page 14

ODYSSEY 34

1-8

Page 15

2

Introduction

2-1 GENERAL DESCRIPTION

The Odyssey 34 lift is designed and manufactured for use as a telescoping personnel lift.

The maximum platform load is limited to 350 lbs. The electric pump motor is powered by

a 12VDC battery. A 20 amp automatic battery charger is included for recharging the battery at the end of each work period.

Platform elevation is accomplished by means of a 2-1/4 inch displacement type hydraulic

cylinder. The lower telescoping section is pushed vertically upward by the cylinder while

the upper sections are raised by a mechanical motion advantage accomplished through

two sets of chains and sheaves. Platform elevation and descent is controlled by pushbuttons on the main control box located on the back of the machine, or the transmitter

mounted on the cage platform.

Safety of operation is assured by proper inspection and maintenance procedures as set

forth in this manual. The possibility of platform free-fall is eliminated by proper maintenance and replacement of the chains, sheaves and sheave pins, a properly installed flow

restrictor valve, and a clean mast. The adjustable restrictor valve controls and fixes the

rate of platform descent whether empty or fully loaded to approximately 0.6 feet per second. A hydraulic hose failure will result in the same rate of descent, eliminating free-fall,

when the restrictor valve is installed properly.

Emergency lowering of the platform is accomplished by means of a manual control valve

located on the pump/motor unit.

The Odyssey 34 lift features a displacement type of cylinder that will not rust or corrode

during storage since the cylinder rod is immersed in oil. It is important that the cylinder

rod be kept clean and undamaged for the protection of the cylinder head packing.

The outrigger lock safety switches prevent the Odyssey 34 from raising until the four outriggers have been properly positioned and engaged. This helps to make the Odyssey 34

lift a safe, dependable machine.

Carefully read all the safety instructions contained in Section 1 of this manual before operating the Odyssey 34 lift.

2-1

Page 16

ODYSSEY 34

2-2 SPECIFICATIONS

Odyssey Lift Electric Hydraulic Lift Platform

Model Number Odyssey 34 Serial Number ________________

Manufactured by: Bil-Jax, Inc.

125 Taylor Parkway

Archbold, Ohio 43502

419.445.8915

Table 2-1. Specifications

Rated Platform Load 350 lbs (158.8 kg) total including operator

Extended Platform Height 34 ft (10.36 m)

Retracted Platform Height 6 in. (15 cm)

Platform Dimensions 28 in. x 30 in. (71 cm x 76 cm)

Base Dimensions

(Outriggers Extended)

Retracted Dimensions 29 in. wide x 74 i n. long x 79 in. high

Gross Shipping Weight 1350 lbs (614 kg)

Full Extension Time 45 seconds empty, 50 seconds loaded

Complete Retraction Time 55 seconds empty, 45 seconds loaded

Platform Extension Rate 0.86 ft/sec (0.26 m/sec) empty

Hydraulic System Pressure 1200 psi empty, 2000 psi loaded

Power Source DC - 12 volt deep cycle battery

66 in. x 72 in. (168 cm x 183 cm)

(74 cm wide x 190 cm long x 201 cm high)

0.59 ft/sec (0.18 m/sec) loaded

2-3 WARRANTY

Bil-Jax warrants its telescopic lifts for one year from the date of delivery against all defects of material and workmanship, provided the unit is operated and maintained in compliance with Bil-Jax’s operating and maintenance instructions; structural components are

warranted for three years. Bil-Jax will, at its option, repair or replace any unit or component part which fails to function prop erly in normal use.

This warranty does not apply if the lift and/or its component parts have been altered,

changed, or repaired without the consent of Bil-Jax or by anyone other than Bil-Jax or its

factory trained personnel, nor if the lift and/or its components have been subjected to

misuse, negligence, accident or any conditions deemed other than those considered as occurring during normal use.

Components not manufactured by Bil-Jax are covered by their respective manufacturers

warranties. A list of those components and their warranties is available upon written request to Bil-Jax.

Bil-Jax shall not in any event be liable for the cost of any special, indirect or consequential damages to anyone, product, or thing. This warranty is in lieu of all other warranties

expressed or implied. We neither assume nor authorize any representative, or other person, to assume for us any other liability in connection with the sale, rental, or use of this

product.

2-2

Page 17

3

Operation

3-1 OPERATOR CONTROLS

The Odyssey 34 lift is equipped with several operator controls; a transmitter mounted in

the cage platform to control the lift; a receiver mounted on the base to monitor and control the lift; an

the lift before raising the platform.

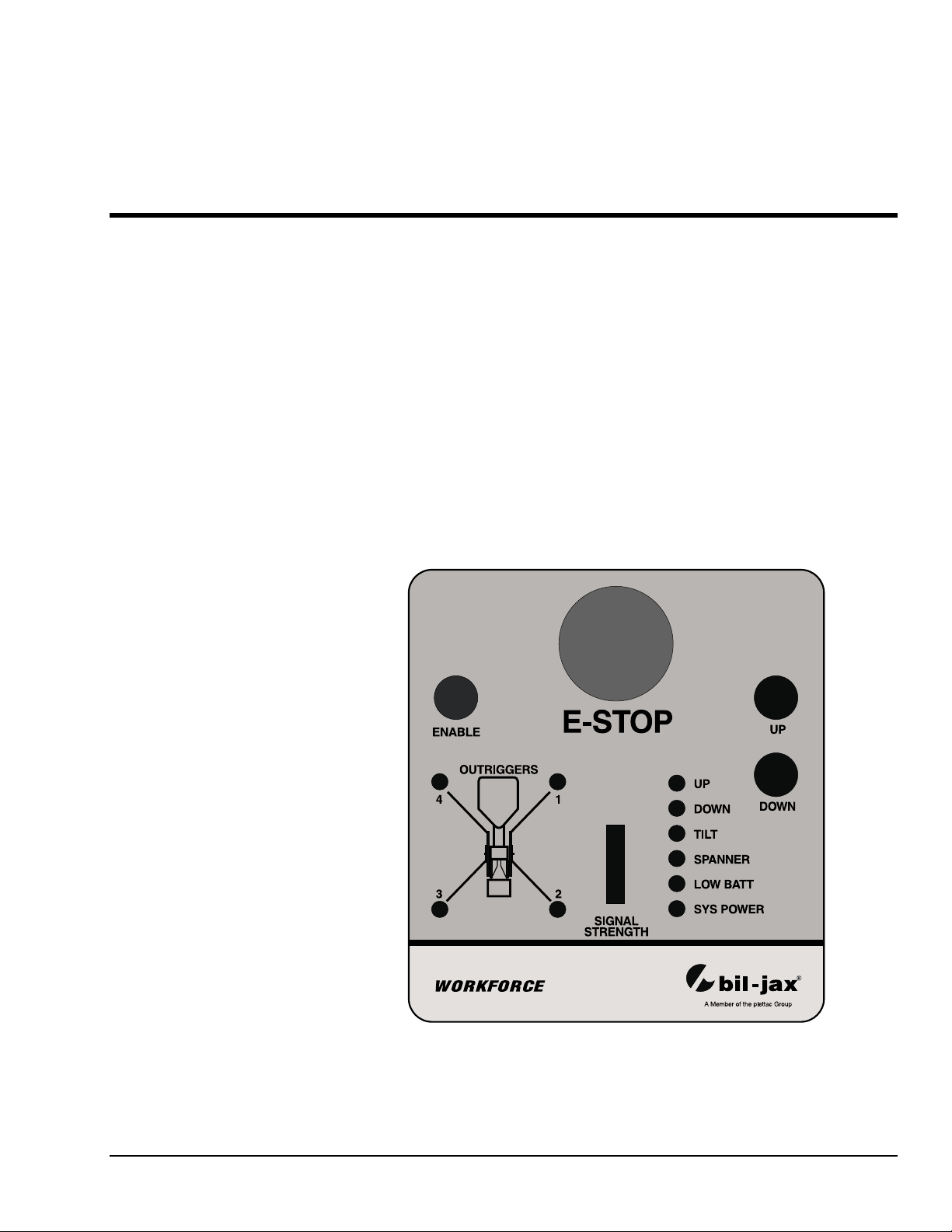

Receiver

The receiver is located on the back of the base frame and contains four controls, UP and

DOWN pushbuttons, an ENABLE pushbutton, and an EMERGENCY STOP pushbutton. The re-

ceiver also contains LEDs to monitor the operation of the lift and a signal strength indicator to monitor the strength of the signal being sent from the platform transmitter. While

the operator normally does not raise or lower the lift from the receiver, the receiver does

control the operation of the Odyssey 34 lift. When the operator pushes a pushbutton on

the platform transmitter, the transmitter sends a signal to the receiver, the receiver processes that signal and controls the various lift functions. Refer to Figure 3-1.

ON/OFF switch to turn power on or off; and a laser pointer to help position

Figure 3-1. Receiver

3-1

Page 18

ODYSSEY 34

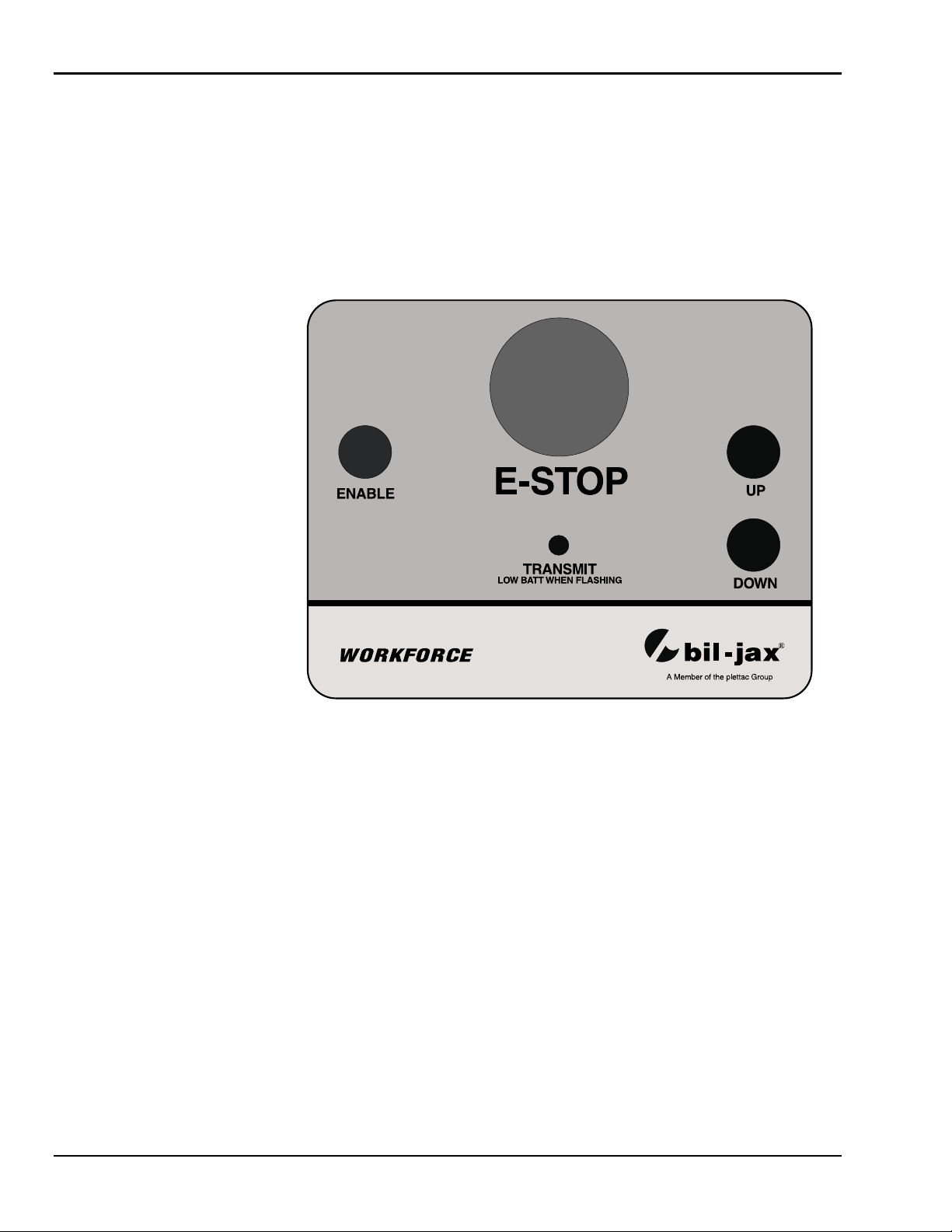

Transmitter

The transmitter is located on the mast directly above the platform. The transmitter contains four controls,

EMERGENCY STOP pushbutton. The controls on the upper control box are used to raise and

lower the unit. There are no electrical connections between the transmitter and the receiver, or between the transmitter and the lift power supply. The transmitter operates from

a 9-Volt battery installed in the transmitter control box. An LED monitors operation of

the transmitter — a flashing LED indicates a low battery. The battery should be replaced

with a new battery when the LED flashes. The LED will light with a steady glow when

any control is activated and a signal is being sent to the receiver. Refer to Figure 3-2.

UP and DOWN pushbuttons, an ENABLE pushbutton, and an

Figure 3-2. Transmitter

3-2

Page 19

3 — OPERATION

ON/OFF Switch

The ON/OFF switch is used to turn the battery power on or off to the lift. Turning the

switch to the

To conserve battery power, the switch should be in the

being used. Refer to Figure 3-3.

ON position activates the Audio Program ‘Hal’ and turns power on to the lift.

OFF position when the lift is not

Figure 3-3. ON/OFF Switch

Laser Pointer

The laser pointer is used to help position the lift before it is raised. It is mounted on the

side of the cage. To help position the lift before setting outriggers, turn the laser pointer

ON and place it in its holder in an upright position. When the red dot from laser pointer is

in the area where you want to work, this is the position you want the Odyssey 34 lift to be

located before setting the outriggers. Refer to Figure 3-4.

LASER

POINTER

HOLDER

Figure 3-4. Laser Pointer

3-3

Page 20

ODYSSEY 34

3-2 NORMAL OPERATING PROCEDURE

Perform the following procedures to operate the Odyssey 34 lift.

1. Read and follow all safety precautions contained in Section 1 and all responsibilities outlined in the ANSI A92.3 reprint contained in Section 7 of this manual.

2. Position the lift at the work area. Make sure the lift is on a firm and level surface

and that there are no potential hazards such as overhead obstructions or electrically charged conductors. Do not operate the lift if such hazards exist.

3. Check the lift for damaged or worn parts and repair or replace as necessary.

4. Check to be sure that the cage platform is properly attached to the lift.

5. Pull the four outriggers away from the base. The spring-loaded pin on the jack

should lock in place. If the spring-loaded pin does not lock in, unwind the jack

until the pin snaps in place. Adjust each outrigger so that its footpad is firmly set.

For best performance, assure that the wheels are off the ground.

6. Turn the

ON/OFF switch to ON. Ensure that the E-STOP pushbutton is not enga ged.

The controller’s audio program ‘Hal’ will start. Hal will instruct you how to proceed. Hal will tell you the lift is ready to operate or what outrigger needs to be

adjusted; the corresponding LED will also be lit.

7. Adjust the outriggers until all LEDs are lit. When all outriggers are set properly

and the unit is level, Hal will tell you the lift is ready to operate and the tilt LED

will be off. To enable you to monitor the setting of the outriggers, LEDs for the

corresponding outriggers are located on the sides of the main frame, Figure 3-5.

When the outriggers are set properly the LEDs will be ON.

NOTE: The lift is equipped with a level sensor that will prevent the lift from rais-

ing if the lift is at a slope greater than 1.5 degree. The TILT LED on the

receiver will light and the audio program will tell you that the lift is not

level. Adjust the outriggers until the lift is level and the TILT LED is

OFF.

MAST

MOUNTED

LEDs

Figure 3-5. Outrigger LEDs on Main Frame

3-4

Page 21

3 — OPERATION

8. Enter the cage platform. Ensure that the cage gate is closed and engaged properly. A proximity switch in the gate will prevent operation of the lift if the gate is

not properly closed.

9. The lift is now ready for operation. While depressing the

lect the

lower respectively. The

UP or DOWN pushbutton on the transmitter. The platform will raise or

EMERGENCY STOP pushbutton deactivates the control

ENABLE pushbutton, se-

circuit.

3-3 EMERGENCY LOWERI NG PROCEDURE

The Odyssey 34 lift is equipped with a manual lowering valve in case of emergency situations to lower the platform. The emergency lowering valve is located on the hydraulic

pump. The valve may be accessed through the opening on the side of the machine. To

lower the platform, turn the red knob on the valve counterclockwise. Refer to Figure 3-6.

EMERGENCY

LOWERING

VALVE

Figure 3-6. Emergency Lowering Valve

3-5

Page 22

ODYSSEY 34

3-6

Page 23

4

Maintenance

4-1 SCHEDULED SERVICE CHECKS

Daily/Weekly Service Checks

Perform the following daily/weekly service checks as listed in Table 4-1.

Check chain assemblies for split leaves, loose pins,

excessive wear, or elongation.

Check battery electrolyte level.

Check and retighten all nuts and bolts.

Check cage gate is secure.

Check to be sure slide blocks and their path are clean and

lightly lubricated with a silicone lubricant.

Check level sensor.

Check to see that all decals are present.

Check that all functions on transmitter and receiver are

operating properly.

Check for wear on chain sheaves, sheave axles, and

bearings.

Lubricate chains with 40W oil.

Check wheels for wear on axles.

Check surface of casters for cracks or excessive wear.

Table 4-1. Daily/Weekly Service Checks

Service Check

before use Weekly

Daily

4-1

Page 24

ODYSSEY 34

Monthly Service Checks

Perform the following monthly service checks as listed in Table 4-2.

Table 4-2. Monthly Service Checks

Service Check

Clean battery terminals.

Check operation of manual

emergency lowering valve.

Lubricate wheels and axles.

Lubricate steel mast with dry

silicone spray.

Every

month

Every

6 months

Every

12 months

Check battery cables and wiring

for loose connections and

damaged wires.

Replace hydraulic oil.

Check slide blocks for wear.

Check for mast sway.

Load test with 350 pounds.

Replace lift chains.

Every

48 months

4-2

Page 25

4 — MAINTENANCE

4-2 LUBRICATION

Lubrication makes operation of the Odyssey 34 lift more efficient and extends the life of

the unit. Perform the following lubrication procedures.

1. Oil lift chains with clean 40W oil weekly or as needed. Refer to Figure 4-1.

LIFT

CHAINS

LIFT

CHAINS

Figure 4-1. Lift Chain Lubrication

4-3

Page 26

ODYSSEY 34

2. Grease both wheels and axles at the grease fittings on each wheel semiannually

with wheel bearing grease. Refer to Figure 4-2.

Figure 4-2. Wheel and Axle Lubrication

3. Lubricate the steel mast slides with dry silicone spray semiannually. Apply a

light spray coating to the slide surfaces as shown in Figure 4-3.

Figure 4-3. Steel Mast Slide Lubrication

NOTE: The plastic slide blocks in the mast are made of a bearing material which

has a high degree of lubricity and need only be kept clean. However,

precautions should be taken to ensure that the paths along which the

blocks move are kept clean and lightly lubricated with a dry type silicon

lubricant.

4-4

Page 27

4 — MAINTENANCE

4-3 HYDRAULIC SYSTEM

Hydraulic system maintenance varies by the amount of use and the environment in which

the lift is used. Constant attention to keep the oil clean and the reservoir properly filled

will help prevent possible damage to the system.

Hydraulic System Inspection

Check the hydraulic hose and fittings for leaks and damage daily. Tighten or replace as

necessary to prevent hydraulic oil loss. Refer to the hydraulic schematic diagram in Section 6 for general reference.

Fluid Check and Replacement

The reservoir should be filled to within 1/2 inch of the top with the platform in its lowest

position. The lift is shipped from the factory with Energol HLP-HD46 (BP Oil), a high

grade, non-foaming hydraulic oil designed for temperatures as low as -20°F/-29°C. Use

Dextron Automatic Transmission Fluid Type A for temperatures as low as -40°F/-40°C.

If either oil is not available, a good grade SAE 10W hydraulic oil may be used where the

minimum climatic temperature is above 32°F/0°C. SAE 5W hydraulic oil may be used

where temperatures are as low as 0°F/-18°C. Do not mix different hydraulic oils. Clean

the reservoir sump strainer and replace the hydraulic oil at least once a year or whenever

it becomes contaminated.

Hydraulic System Air Bleeding Procedure

Delayed response or sporadic action in the unit may indicate a presence of air in the cylinder. Perform the following procedure to bleed air from the system.

1. Fill the reservoir with the proper hydraulic fluid.

2. Fully extend the lift.

3. Lower the unit to allow the oil with entrapped air to return to the reservoir, being

careful not to overflow it.

4. Let the unit set while the air escapes the fluid and then repeat if necessary. Each

time the platform is lowered, refill the reservoir to prevent pumping more air into

the cylinder.

4-5

Page 28

ODYSSEY 34

Pressure Relief Valve Reset

Perform the following procedure to reset the pressure relief valve. Refer to Figure 4-4.

1. Disconnect the hydraulic hose from the main pressure port.

2. Install a 4000 psi gage into the main pressure port in the pump unit.

CAUTION

Do not adjust the pressure relief valve higher than 2300 psi. Overloading may

occur at pressures greater than 2300 psi.

3. Remove the hex cover from the pressure relief valve.

4. While depressing the

the screw until maximum pressure of 2300 psi is obtained.

5. After adjusting the pressure relief valve, replace the hex cover, remove the 4000

psi gage, and reconnect the hydraulic hose to the main pressure port.

6. If a gage is unavailable, place 400 pounds on the platform and adjust the pressure relief valve screw so that the load can just be lifted without bypassing oil

through the pressure relief valve.

ENABLE and UP pushbutton on the lower control box, adjust

RELIEF VALVE

(LOCATED OPPOSITE

OF EMERGENCY

LOWERING VALVE)

MAIN

EMERGENCY

LOWERING

VALVE

PRESSURE

PORT

Figure 4-4. Pressure Relief Valve Adjustment

4-6

Page 29

4 — MAINTENANCE

Down Valve Operation Check and Adjustment

The adjustable down valve (13, Figure 4-5) is located in the base of the hydraulic cylinder. When properly adjusted, the down valve will allow the cylinder to fully retract in 35

to 39 seconds.

Adjust the down valve with the cylinder fully retracted. Loosen the lock nut and turn the

adjusting screw in to extend the retract time and out to shorten the retract time. Extend the

cylinder and note the time it takes to retract. Adjust as necessary to extend or shorten the

retract time. When the cylinder is retracting properly, hold the adjusting screw and tighten

the lock nut.

Hydraulic Cylinder Repair

CAUTION

Removing the hydraulic cylinder from the Odyssey Lift requires major disassembly of the unit. Contact Bil-Jax for assistance before removing the hydraulic cylinder from the unit.

Hydraulic Cylinder Removal

It is recommended that Bil-Jax be contacted for assistance before removing the hydraulic

cylinder.

WARNING

Keep hands and feet away from elevated masts at all times.

1. Raise lift far enough to place scrap 4 x 4 wood block(s) under the main (welded)

mast. Lower lift down onto the block(s) and turn off the main power.

2. Remove mounting bol t (10), washers (9), and nut (8) securing the top of the hydraulic cylinder rod to the main (welded) mast.

3. Open the emergency lowering valve (See Figure 3-6) and use a pry bar to lower

the cylinder rod down from the main (welded) mast connection.

4. Be sure cylinder is retracted and pressure is released from the system. Place a

pan underneath the hydraulic cylinder to catch the hydraulic oil.

5. Disconnect the hydraulic hose from the bottom of the cylinder and drain the remaining hydraulic oil.

6. Remove four bolts (2, Figure 6-3), lock washes (3), and two cylinder brackets

(4) securing cylinder (7) to the base. Lift the cylinder to remove it from the

mounts on the base unit.

7. After maintenance has been performed on the hydraulic cylinder, reinstall the

cylinder in the mounts on the base unit, reconnect the hydraulic hose, and close

the emergency lowering valve. Turn on the main power, raise the lift until the

cylinder rod slides back into the main (welded) mast connection, and reinstall the

mounting bolt, washers, and nut.

Hydraulic Cylinder Repair Procedure

Perform the following procedure to repair and maintain the hydraulic lift cylinder. Refer

to Figure 4-5. It is recommend that whenever the hydraulic cylinder is disassembled that

all seals be replaced; order seal kit B02-13-0099.

4-7

Page 30

ODYSSEY 34

Disassemble and inspect the hydraulic cylinder as follows:

1. Remove retaining ring (14, Figure 4-5) by rotating cylinder head (5) clockwise

until the edge of the retaining ring appears in the milled opening of cylinder tube

(12).

2. Pull cylinder head (5) assembly off the end of cylinder rod (1) and from cylinder

tube (12).

3. Pull assembled cylinder rod (1) and piston (8) from the cylinder tube.

4. Remove piston nut (11) and remove piston (8) assembly from the end of the rod.

5. Remove wiper (3), u-cup seal (4), static o-ring (7), and back-up ring (6) from

cylinder head (5). Discard all parts.

6. Remove u-cup seals (9 and 10) from piston (8). Discard the u-cup seals.

7. Inspect rod (1) for any scratches or pits. Pits that go into the base metal are unacceptable. Scratches that catch the fingernail, but are not through the base metal

or less than 1/2 inch long and are around the rod, are acceptable providing they

are not sharp enough to cut the seal. The rod surface should not have any of the

chrome worn through. Replace the rod if any of these conditions are not met.

8. Inspect cylinder head (5). Check the inside bore of the cylinder head for

scratches; deep scratches are unacceptable. Check the bore for polishing —

polishing indicates uneven loading. The bore should be checked for out-ofroundness; if the bore is more than 0.007 inch out-of-round, the head should be

replaced. Damage to any of the seal grooves is unacceptable. Replace the head if

any of these conditions are not met.

9. Inspect piston (8). Check the outside surface of piston for scratches; deep

scratches are unacceptable. Check the outside surface for polishing. If polishing

is noticed, the piston should be checked for out-of-roundness. If out-of roundness exceeds 0.007 inch, the piston should be replaced. Damage to any of the

seal grooves is unacceptable. Replace the piston if any of these conditions are

not met.

10. Inspect cylinder tube (12) for any scratches or pits. Pits or scratches that are

deep enough to catch the fingernail are not acceptable. Scratches that catch the

fingernail, but are less than 1/2 inch long and are around the tube, are acceptable

providing they are not sharp enough to cut the seal. Replace the cylinder tub e if

any of these conditions are not met.

Assemble the hydraulic cylinder as follows:

11. Lubricate piston (8) and u-cup seals (9 and 10) with hydraulic fluid.

12. Stretch u-cup seals (9 and 10) into the grooves. The sealing lips of the u-cup

seals should face toward the outside face of the piston. Be careful to avoid damaging the seal grooves during installation; scratching the grooves may cause bypass leakage. Allow the assembled piston to sit 1 hour to allow the seals to return

to shape.

13. Lubricate cylinder head (5), wiper (3), u-cup seal (4), static back-up ring (6), and

static o-ring (7) with hydraulic fluid.

14. Twist dual lip u-cup seal (4) into a ‘C’ shape and allow it to snap into the lower

groove.

15. Twist wiper (3) into a ‘C’ shape and allow it to snap into the outer groove.

4-8

Page 31

4 — MAINTENANCE

16. Install static back-up ring (6) and static o-ring (7) into the static seal groove in

the head. Make sure the back-up ring is installed closest to the retaining ring

groove. Allow the assembled head to sit 1 hour to allow the seals to return to

shape.

17. Thoroughly rinse the inside of cylinder tube (12) with a high-pressure rinse and

wipe with a lint free cloth.

18. Install the head assembly followed by the piston assembly onto the rod. Torque

piston nut (11) to 100-120 ft. lbs.

1.

B02-13-0099 Seal Kit

includes 2, 3, 4, 6, 7,

9, 10, and 14.

2.

B02-03-0019 is the

Complete Cylinder

Assembly.

Rod, Cylinder

1.

O-Ring

2.

Wiper

3.

Seal, U-Cup

4.

Head, Cylinder

5.

Static Back-Up Ring

6.

Static O-Ring

7.

Piston

8.

Seal, U-Cup

9.

Seal, U-Cup

10.

Nut, Piston

11.

Tube, Cylinder

12.

Valve, Adjustable Down

13.

Ring, Retaining

14.

14

NOTE:

1

2

3

4

(B02-14-0040)

(B02-13-0100)

5

12

6

7

8

(B02-13-0101)

9

10

13

11

Figure 4-5. Hydraulic Cylinder Exploded View

19. Apply anti-seize to the head outer surface, especially static o-ring (7).

20. Coat the entire rod assembly with hydraulic fluid and insert the rod into the cylinder tube. When inserting cylinder head (5), make sure that static o-ring (7)

does not extrude into the retaining ring slot in the cylinder tube. Be careful not to

nick the seals as they enter the cylinder tube.

21. Rotate the cylinder he a d until the retaining ring hole is visible through the slot

milled into the tube. Insert retaining ring (14) hook into the hole and rotate the

head 1-1/4 turns until the retaining ring is completely pulled into the cylinder

tube and the ends are covered.

22. Reinstall the hydraulic cylinder into the unit and reconnect the hydraulic hose.

Refill hydraulic fluid reservoir.

23. Pressurize the cylinder and extend one full stroke to fill it with hydraulic fluid

and remove any trapped air.

4-9

Page 32

ODYSSEY 34

4-4 ELECTRICAL SYSTEM

Regular maintenance is necessary to keep the electrical system in proper working order.

Check daily all electrical wires for cuts, broken wires, potential short circuits, and any

other damage.

Battery Care and Charging

The electric system is designed to provide power for a normal work shift. However, the

charge life of the battery pack depends on machine usage. Plan your work to prevent unnecessary use of electrical power.

Since the power source for the machine is a battery, proper battery care is important. Recharge the battery after each work shift. When the machine is not being used, batteries

should be charged at least once a week. Normal battery charging time should be 10 to 12

hours. If the battery is extremely low, charging time may be as long as 24 hours.

Clean battery terminals monthly. Remove the cables from the battery, clean the battery

posts and cable ends to shiny metal, and replace. Always connect the insulated cable from

the starter solenoid to the positive post. Lubricate the outside of the connections with petroleum jelly or grease.

Battery Charging Procedure

1. Connect an extension cord from a 110V AC 60 Hz outlet to the flush mount receptacle on the side of the Odyssey Lift. The extension cord should be kept as

short and as large as possible to reduce voltage drop.

2. When there is power to the battery charger the ammeter will display the rate of

charge.

CAUTION

Before making or breaking connections between charger and battery, always remove the power cord from the 110 volt AC outlet. Always check the battery electrolyte level and add water after charging the battery. For more information, refer

to the instructions supplied with the battery charger.

3. Unplug the extension cord from the flush mount receptacle on the side of the

Odyssey Lift.

4-10

Page 33

4 — MAINTENANCE

4-5 LIFT CHAINS AND SLIDE BLOCKS

WARNING

Do not operate a unit on which any chain assembly is damaged or in need of replacement. Operating a unit with a damaged chain can cause severe injury or

death to personnel and damage to equipment.

Inspect all lift chains daily. Inspect for signs of wear, split leaves, loose pins, clevis damage, and elongation. Replace any chain which is damaged in any way. Chain assemblies

may be ordered from your dealer or direct from the factory. Do not operate a unit on

which any chain assembly is damaged and in need of replacement.

Chain Elongation Inspection

First Mast Chain (BL-566 Chain)

One pitch of chain should measure 5/8 in. (1,5875 cm). Measure 20 pitches of chain. The

ideal measurement for 20 pitches of chain should be 12.5 in. (31,75 cm). Replace the

chain if 20 pitches measure over 12.75 in. (32,385 cm). Refer to Figure 4-6.

NOTE: It is recommended that

chains be replaced every four

years unless damage or wear

requires replacement at a lesser

interval.

Figure 4-6. BL-566 Chain Elongation Inspection

Second through Sixth Mast Chain (BL-466 Chain)

One pitch of chain should measure 1/2 in. (1,2700 cm). Measure 20 pitches of chain. The

ideal measurement for 20 pitches of chain should be 10.0 in. (25,40 cm). Replace the

chain if 20 pitches measure over 10.25 in. (26,035 cm). Refer to Figure 4-7.

Figure 4-7. BL-466 Chain Elongation Inspection

4-11

Page 34

ODYSSEY 34

Lift Chain Adjustment

1. Raise the platform to the maximum extended height and then lower it while

someone checks to see that all sheaves are turning, and checks for chain damage

or wear.

2. Chains should be tight to the touch with no loose play. Check all lift chains for

snugness. If a chain is loose, it will need to be adjusted.

3. After the platform is completely lowered, raise the complete Odyssey 34 lift with

a fork lift. Insert the forks into the fork lift openings in the base from the lower

control box end.

4. Loosen lock nut (48, Figure 6-1) attaching clevis pin (50) to lifting bar (47).

Tighten hex nut (49) until the chain just becomes snug. Do not overtighten any

chain so that the mast is raised from its resting position.

5. Make sure lock nuts (48) are turned onto the threaded clevis ends with at least

1/8 in. of the clevis end extending through the nut. Replace any lock nut which

does not stay in position during use.

4-12

Page 35

4 — MAINTENANCE

Slide Block Adjustment

Annually check for wear on the slide blocks and replace or retighten as necessary. If the

lift exhibits excessive mast sway, it is probable that the slide blocks need adjustment. The

slide blocks should be adjusted so that there is no air gap between the slide block and the

mast the slide block is moving against. There are 4 adjustable slide blocks. The adjustment procedure is the same for all slide blocks. Refer to Figure 4-8.

1. Loosen, do not remove, the slotted hex head screw securing the slide block to be

adjusted.

2. Using an allen wrench, turn the set screws in (clockwise). This will push the

block in against the mast. Do not overtighten. Tighten the slotted hex head screw

to secure the slide block in position.

3. Check all slide blocks and make adjustments as necessary.

4. After all adjustments are made, fully extend the lift. If the platform can be lowered without stopping then the blocks are properly adjusted.

SLIDE

BLOCKS

SET

SCREW

SLOTTED

HEX HEAD

SCREW

Figure 4-8. Slide Block Adjustment

NOTE: The plastic slide blocks in the mast are made of a bearing material which

has a high degree of lubricity and need only be kept clean. However,

precautions should be taken to ensure that the paths along which the

blocks move are kept clean and lightly lubricated with a dry type silicon

lubricant.

4-13

Page 36

ODYSSEY 34

Guide Peg Adjustment

Annually check for wear on guide pegs (9, Figure 6-1 and 1, Figure 6-2) and replace or

retighten as necessary. If any of the masts exhibit excessive side sway, it is probable that

the guide pegs need adjustment. The guide pegs should be adjusted so that there is no air

gap between the guide peg and the mast. There are 8 adjustable guide pegs per aluminum

mast and 12 adjustable guide pegs on the steel mast. The adjustment procedure is the

same for all guide pegs. Refer to Figure 4 -9.

1. Using an allen wrench, turn the set screws in (clockwise). This will push the

guide peg in against the mast. Do not overti ght en.

2. Check all guide pegs and make adjustments as necessary.

3. After all adjustments are made, fully extend the lift. If the platform can be lowered without stopping, then the guide pegs are properly adjusted.

ALUMINUM

MAST

STEEL

MAST

SET

SCREWS

Figure 4-9. Guide Peg Adjustment

NOTE: The plastic guide pegs in the mast are made of a bearing material which

has a high degree of lubricity and need only be kept clean. However,

precautions should be taken to ensure that the paths along which the

guide pegs move are kept clean and lightly lubricated with a dry type

silicon lubricant.

4-14

Page 37

4 — MAINTENANCE

4-6 TROUBLESHOOTING

Table 4-3. Troubleshooting Chart

Problem Cause Correction

1. Control panel LEDs will not

light and audio program

‘Hal’ will not respond.

2. Control Panel LEDs will not

turn off.

3. When UP switch is selected,

motor runs but unit will not

lift a load.

4. Masts have excessive sway

when fully extended.

a. Low voltage*.

b. Master power switch turned off.

c. Emergency stop button is activated

(pushed in).

d. Burned out LED.

e. Two parts of battery connector plug

not mated together.

a. Lift is out of level.

b. Broken or loose wire.

a. More than 350 lbs. on platform.

b. NO (Normally Open) valve is not

being energized.

c. Emergency lowering valve is open.

d. Mast sections are dirty.

a. Plastic slide blocks are out of adjus-

ment.

b. Plastic guide pegs are out of adjust-

ment.

a. Recharge battery or replace if dam-

aged.

b. Turn on master power switch.

c. Pull out on emergency stop button.

d. Replace LED board.

e. Mate battery connector plug parts

together.

a. Level lift with outrigger jacks or

relocate lift to level surface.

b. Repair or replace wire.

a. Ensure load is 350 lbs. or less.

b. Check voltage at NO valve. If no

voltage, check for loose or broken

wire. If voltage, ensure at least 9 volts

for start solenoid operation. Check

battery and start solenoid. Repair or

replace as needed.

c. Close emergency lowering valve.

d. Clean and lubricate masts with dry

silicone.

a. Refer to Slide Block Adjustment in

Section 4-5.

b. Refer to Guide Peg Adjustment in

Section 4-5.

*NOTE: Smart start solenoid will not engage if battery charge drops below 9 volts.

4-15

Page 38

ODYSSEY 34

Table 4-3. Troubleshooting Cha rt, Continued

Problem Cause Correction

5. Pump/motor will not run

when

UP is selected.

6. When two parts of battery

connector plug are mated together, the motor runs without

UP switch being selected.

7. Hydraulic cylinder leaks at

gland nut.

EMERGENCY STOP button is activated

a.

(pushed in).

b. Motor start relay is not activating.

c. Motor start relay is activating, but

motor does not run.

d. Low voltage*.

e. Outrigger is not set.

f. Level sensor is out of level.

a. Short in electrical system.

b. Motor start relay is stuck in “

ON”

a. Turn EMERGENCY STOP button coun-

terclockwise to deactivate.

b. Check voltage at white wire on motor

start relay. If voltage, replace defective motor start relay. If no voltage,

check for loose or broken wire. Repair

or replace wire.

c. Check hydraulic gear pump for sei-

zure. If seized, replace pump. If not,

check motor. Motor may need re-

placement.

d. Recharge or replace the battery.

e. Set all outriggers.

f. Level machine.

a. Repair or replace any loose or broken

wires.

b. Replace defective motor start relay.

position.

a. Defective seals. a. Replace seals in hydraulic cylinder.

Refer to Hydraulic Cylinder Repair in

Section 4-3.

8. Outrigger will not set after

extensive winding of jack

handle.

a. Spring-loaded pin on outrigger jack

failed to engage due to over extension

of the jack.

a. Unwind jack handle, retr acting foot

pad, until the spring-loaded pin snaps

into place. Then, wind jack down until

foot pad is firmly set and outrigger

LED is lit.

*NOTE: Smart start solenoid will not engage if battery charge drops below 9 volts.

4-16

Page 39

5

Replacement Decals

Refer to Table 5-1, and Figures 5-1, 5-2, and 5-3 for descriptions and locations of decals

on the Odyssey Lift.

Decal No. Description of Decal Qty

B06-00-0009 Warning….Moving telescopic masts… 1

B06-00-0034 Danger….Failure to comply with instructions… 1

B06-00-0135 Danger….Failure to comply with safety instructions… 1

B06-00-0139 Danger….Before using… 1

B06-00-0146 Danger….(High voltage line warning) 1

B06-00-0151 Danger….110 Volt 1

B06-00-0189 Warning….Level machine… 1

B06-00-0192 Operation Instructions 1

B06-00-0286 Emergency Lowering 1

B06-00-0289 Hydraulic Fluid Level 1

B06-00-0293 Maximum Capacity….350 Lbs. 1

B06-00-0360 Warning….Tip Over Hazard 1

B06-00-0361 Warning….(Various) 1

B06-00-0362 Warning….(Odyssey™ Instructions) 1

B06-00-0363Y Bil-Jax (Both sides of toe board) 2

B06-00-0364 Odyssey 34 (Vertical transfer decal) 2

B06-00-0365 Danger….Swing down outriggers… 2

B06-00-0366 Caution….Always secure outriggers… 2

B06-00-0367 Warning….Pinch Point 1

B06-00-0359 Serial Number Plate (not available as replacement part) 1

Table 5-1. Replacement Decals

5-1

Page 40

ODYSSEY 34

B06-00-0363Y

Figure 5-1. Replacement Decals

5-2

Page 41

5 — REPLACEMENT DECALS

0361

WA

R

N

E

ENABLE

N

A

B

L

E

WORKFORCE

IN

E

E-STOP

-S

G

WA

R

N

IN

G

TO

P

UP

D

DOWN

O

W

N

bil-jax

O

O

D

D

Y

Y

S

S

0365

0366

0364

0362

0151

0367

0192

S

S

E

E

Y

Y

34

34

0363Y

Figure 5-2. Decal Locations, Carriage and Base

SERIAL NO.

PLATE

5-3

Page 42

ODYSSEY 34

0009

O

D

Y

S

E

L

B

A

G

N

E

ENABLE

IG

R

T

U

O

OUTRIGGERS

WORKFORCE

ING

WARN

WARNING

DANGER

ER

DANG

UPUP

N

W

O

D

DOWN

UPUP

E-STOP

N

W

O

D

DOWN

TTILT

L

I

T

T

T

A

B

BATT

S

W

R

E

R

E

LO

LOW

W

O

P

POWER

S

Y

R

S

SYS

E

N

N

A

P

S

SPANNER

L

A

N

IG

H

S

SIGNAL

T

G

N

E

R

T

STRENGTH

S

- jax

bil - jaxbil

DA

DANGER

R

E

G

N

0146

0139

0034

0286

(BELOW ACCESS

HOLE IN SIDE COVER)

0360

0189

G

IN

RN

WA

IM

X

A

M

ITY

AC

P

A

C

M

U

DANGER

0293

0135

0289

(ON HYDRAULIC

FLUID TANK)

R

O

OR

TS

L

PS

VO

VOLTS

AM

AMPS

50

00-125

1

100-125

1.4

1.4

0-2

HERTZ

HERTZ

R

200-250

20

O

OR

60

60

.8

R

INPUT:

2.8

2

O

OR

TS

L

50

50

A.C.INPUT:A.C.

VO

VOLTS

PS

M

12

12

A

AMPS

:D.C.

10

10

TPUT

U

OUTPUT:

.:MODEL

O

D.C.O

r

NO.:

LN

be

DE

m

O

number

M

Lnu

IA

SER

SERIAL

2

9

1

12

C

E

A

AC

G

TA

L

O

V

VOLTAGE

-1

0

1

1

110-125

0

2

200-250

INPUT

INPUT

P

POWER

AC

AC

FUSES

FUSES

ONLY

USEONLY

USE

250V

2A250V

2A

DELAY

DELAY

:

N

IO

T

N

U

O

A

CONTINUED

C

C

CAUTION:

T

R

S

O

IN

FOR

F

M

A

A

G

SAME

S

AGAINST

A

H

IT

WITH

W

6

DC

DC

s

3

e

r

e

CIRCUIT

CIRCUIT

0

p

m

BREAKER

BREAKER

A

Amperes

.

C

D.

D.C.

5

2

TO

PRESSTO

PRESS

RESET

RESET

0

5

-2

0

R

E

O

T

W

U

O

A

AUTO

F

F

O

OFF

Y

L

.

N

E

N

ONLY

O

S

U

E

TIO

FUSE.

F

C

C

F

A

L

TE

OF

O

P

O

S

E

R

REPLACE

R

G

PROTECTION

P

,

IN

E

D

T

E

IR

A

FIRE,

F

U

RATINGS

R

F

IN

D

T

OF

O

N

K

AND

A

IS

E

RISK

R

P

TYPE

TY

E

S

Figure 5-3. Decal Locations, Continued

5-4

Page 43

6

Parts List

6-1

Page 44

ODYSSEY 34

6-1 ALUMINUM MASTS PARTS LIST

Refer to Table 6-1 for the parts list for the aluminum masts.

15

16

17

12

14

13

11

19

18

10

2

E

W

O

R

K

F

O

R

C

1

3

7

8

5

9

6

29

60

4

21

20

59

21

22

23

24

26

25

27

36

28

55

56

57

58

54

53

51

52

50

42

45

41

4849

38

44

46

47

37

34

31

30

32

33

35

39

40

43

Figure 6-1. Aluminum Masts Exploded View

6-2

Page 45

6 — PARTS LIST

Table 6-1. Aluminum Mast Parts List

Item No. Part No. Description Qty Qty Qty Qty Qty Qty

6

5

4

3

2

1

th

Mast Assembly, Carriage

th

Mast Assembly

th

Mast Assembly

rd

Mast Assembly

nd

Mast Assembly

st

Mast Assembly

X

X

X

X

X

X

1 B18-00-0139 Cover, Mast 1 1 1 1 1 1

2 0090-0344 Screw, 10-24 x 1/2 in. Threadcutting 2 2 2 2 2

3 B26-00-0021 Sheave with Bushing, 2 in. 2 2 2 2 2

4 B36-01-0025 Axle, 5/8 in., Sheave 2 2 2 2 2

5 B07-06-5407 Plate, End, Axle 2 2 2 2 2

6 0090-0924 Screw, 10-24 x 3/8 in., Threadcutting 4 4 4 4 4

7 B45-00-0010 Bracket, Sheave Mounting 1 1 1 1 1

8 B04-07-0113 Pin, Clevis 2 2 2 2 2

9 B31-00-0030 Guide Peg 8 8 8 8 8

10 B04-07-0108 Axle Bolt, Roller 8 8 8 8 8

11 B05-05-0006 Roller 8 8 8 8 8

12 B07-06-5386 Plate, Clamping, Roller 4 4 4 4 4

13 B07-06-5387 Plate, Mounting, Roller 4 4 4 4 4

14 0090-0363 Screw, Set, 1/4-20 x 3/4 in. 8 8 8 8 8

15 0090-0688 Bolt, 1/4-20 x 1 in. 1 1

16 0090-0419 Washer, Flat, 1/4 in. 2 2

17 B26-00-0019 Sheave, Cable 1 1

18 B25-00-0066 Spacer 1 1

19 B04-02-0002 T-Nut, 1/4-20 1 1

20 0090-0001 Screw, 1/4-20 x 1/2 in. 2 2 2 2

21 0090-0419 Washer, Flat, 1/4 in. 3 3 3 3

22 B07-06-5437 Bracket, Cable 1 1 1 1

23 B40-00-0024 Cable 1 1 1 1

24 B04-02-0002 T-Nut, 1/4-20 2 2 2 2

25 B29-00-0136 Bracket, Cover 1 1 1 1 1

26 B29-00-0142 Bracket, Cover 1

27 B24-00-0005-074 Mast Extrusion 1 1 1 1 1

28 B24-00-0006-074 Mast Extrusion, Carriage 1

29 0090-0921 Screw, Skt. Hd., Ctsk., 5/16-18 x 2-1/8 in. 1 1 1 1 1

30 0090-0001 Screw, 1/4-20 x 1/2 2 2 2 2 2 2

31 B40-00-0024 Cable 1 1 1 1 1 1

32 0090-0419 Washer, Flat, 1/4 in. 2 2 2 2 2 2

6-3

Page 46

ODYSSEY 34

15

16

17

12

14

13

11

19

18

10

2

C

E

W

O

R

K

F

O

R

1

3

7

8

5

9

6

29

60

4

21

20

59

21

22

23

24

26

25

27

36

28

55

56

57

58

54

31

30

38

34

37

32

33

41

42

35

39

40

43

53

52

51

50

45

44

46

47

4849

Figure 6-1. Aluminum Masts Exploded View, Continued

6-4

Page 47

6 — PARTS LIST

Table 6-1. Aluminum Masts Parts List, Continued

Item No. Part No. Description Qty Qty Qty Qty Qty Qty

6

5

4

3

2

1

th

Mast Assembly, Carriage

th

Mast Assembly

th

Mast Assembly

rd

Mast Assembly

nd

Mast Assembly

st

Mast Assembly

X

X

X

X

X

X

33 B07-06-5437 Bracket, Cable 1 1 1 1 1 1

34 0090-0927 Screw, Socket Head, 1/4-20 x 1 in. 1 1 1 1 1

35 B26-00-0020 Sheave, Cable 1 1 1 1 1

36 0090-0472 Screw, 10-24 x 1/2 in., Sheetmetal 3

37 0090-0419 Washer, Flat, 1/4 in. 2 2 2 2 2

38 B04-02-0002 T-Nut, 1/4-20 2 3 3 3 3 3

39 B07-10-1091 Bushing, Sleeve 1 1 1 1 1 1

40 B05-05-0007 Roller, Lower (includes item 39) 1 1 1 1 1 1

41 0090-0185 Nut, Nylon Lock, 5/16-18 1 1 1 1 1 1

42 0090-0922 Screw, Skt. Hd., Ctsk., 5/16-18 x 2-1/4 in. 1 1 1 1 1 1

43 0090-0185 Nut, Nylon Lock, 5/16-18 1 1 1 1 1

44 0090-0420 Washer, Flat, 5/16 1 1 1 1 1

45 B31-00-0031 Block, Slide 1 1 1 1 1

46 B30-00-0045 Plate, Shim 1 1 1 1 1 1

47 B11-00-0043 Bar, Lifting 1 1 1 1 1 1

48 0090-0192 Nut, Nylon Lock, 1/2-13 2 2 2 2 2 2

49 0090-0169 Nut, Hex 1/2-13 2 2 2 2 2 2

50 B04-07-0109 Clevis, BL-466 Chain 2 2 2 2 2

50 B04-07-0110 Clevis, BL-566 Chain 2

51 B04-07-0112 Pin, Clevis, with Cotter Pin, BL-466 Chain 2 2 2 2 2

51 B04-07-0111 Pin, Clevis, with Cotter Pin, BL-566 Chain 2

52 B40-00-0022 Chain, BL-466 2 2 2 2 2

52 B40-00-0023 Chain, BL-566 2

53 B04-02-0002 T-Nut, 1/4-20 1 1 1

54 0090-0419 Washer, Flat, 1/4 2 2 2

55 0090-0688 Bolt, 1/4-20 x 1 in. 1 1 1

56 B26-00-0019 Sheave, Cable 1 1 1

57 B25-00-0066 Spacer 1 1 1

58 0090-0921 Screw, Skt. Hd., Ctsk., 5/16-18 x 2-1/8 in. 1 1 1 1 1

59 0089-158 Spring 1 1 1 1

60 0090-0183 Nut, Nylon Lock, 1/4-20 1 1 1 1

NOTE: Chain parts must be purchased as an assembly. Chain Assembly (Part Number B03-00-0142) for aluminum masts

include: sheave mounting bracket, two BL-466 chains, two clevises, four clevis pins, four cotter pins, two hex nuts,

and two lock nuts.

6-5

Page 48

ODYSSEY 34

6-2 MAIN (WELDED) MAST PARTS LIST

Refer to Table 6-2 for the parts list for the main (welded) mast.

23 24

22

21

20

25

19

31

18

17

32

18

26

16

30

28

15

27

29

1

2

3

4

5

6

4

7

6

8

9

10

8

11

12

13

13

14

Figure 6-2. Main (Welded) Mast Exploded View

6-6

Page 49

6 — PARTS LIST

Table 6-2. Main (Welded) Mast Parts List

Item No. Part No. Description Qty

1 B31-00-0030 Guide Peg 12

2 B04-07-0108 Axle Bolt, Roller 12

3 B05-05-0006 Roller 12

4 B07-06-5386 Plate, Clamping, Roller 8

5 B07-06-5387 Plate, Mounting, Roller 4

6 0090-0363 Screw, Set, 1/4-20 x 3/4 in. 12

7 B29-00-0138 Plate, Mounting, Bracket 2

8 0090-0419 Washer, Flat, 1/4 in. 2

9 B25-00-0066 Spacer 1

10 B26-00-0019 Sheave, Cable 1

11 0090-0688 Bolt, 1/4-20 x 1 in. 1

12 B16-00-0003 Mast, Welded 1

13 B31-00-0033 Block, Slide 4

14 0090-0472 Screw, 10 x 1/2 in. Sheetmetal 16

15 0089-158 Spring 1

16 B07-06-5437 Bracket, Cable 1

17 B40-00-0024 Cable 1

18 0090-0419 Washer, Flat, 1/4 in. 5

19 0090-0001 Screw, 1/4-20 x 1/2 in. 2

20 0090-0702 Bolt, 10-24 x 2 in., Machine 2

21 B36-01-0026 Axle, 3/4 in., Sheave 2

22 0090-0182 Nut, Nylon Lock, 10-24 2

23 0090-0066 Bolt, 1/2-13 x 1-1/4 in. 4

24 0090-0212 Washer, Lock, 1/2 in. 4

25 B11-00-0044 Bracket, Right Side 1

25 B11-00-0045 Bracket, Left Side 1

26 B26-00-0022 Sheave with Bushing, 3 in. 2

27 0090-0183 Nut, Nylon Lock, 1/4-20 1

28 B04-07-0109 Clevis, BL-466 Chain 2

29 B04-07-0112 Pin, Clevis, with Cotter Pin, BL-466 Chain 2

30 B40-00-0022 Chain, BL-466 2

31 0090-0169 Nut, Hex, 1/2-13 2

32 0090-0192 Nut, Nylon Lock, 1/2-13 2

NOTE: Chain parts must be purchased as an assembly. Chain Assembly (Part Number

B03-00-0141) for main (welded) mast includes: BL-466 chain, clevises on both

ends, two clevis pins, two cotter pins, two hex nuts, and two lock nuts.

6-7

Page 50

ODYSSEY 34

6-3 MAST CYLINDER AND SLIDE BLOCKS PARTS LIST

Refer to Table 6-3 for the parts list for the mast cylinder and slide blocks.

2

10

1

9

8

3

4

1

5

6

7

O

D

Y

S

S

E

Y

34

Figure 6-3. Mast Cylinder and Slide Blocks Exploded View

6-8

Page 51

6 — PARTS LIST

Table 6-3. Mast Cylinder and Slide Blocks Parts List

Item No. Part No. Description Qty

1 B31-00-0032 Block, Slide 4

2 0090-0042 Bolt, 3/8-16 x 1 in. 4

3 0090-0210 Washer, Lock, 3/8 in. 4

4 B07-06-5414 Bracket, Cylinder 2

5 0090-0389 Screw, Set, 1/4-20 x 1/2 in. 8

6 0090-0403 Screw, 10 x 1 in. Sheetmetal 12

7 B02-03-0019 Cylinder, Hydraulic 1

8 0090-0192 Nut, Nylon Lock, 1/2-13 1

9 0090-0574 Washer, Flat, 1/2 in. 2

10 0090-0080 Bolt, 1/2-13 x 4-1/2 in. 1

6-9

Page 52

ODYSSEY 34

6-4 POWER UNIT AND CONTROLS PARTS LIST

Refer to Table 6-4 for the parts list for power unit and controls.

1

29

UPUP

N

W

O

D

DOWN

UPUP

E-STOP

N

W

O

D

DOWN

TTILT

T

IL

T

T

A

BATT

B

S

E

L

R

R

W

B

E

E

O

A

G

L

LOW

W

N

IG

E

ENABLE

O

R

POWER

P

T

S

U

Y

R

O

OUTRIGGERS

S

SYS

E

N

N

A

P

S

SPANNER

L

A

N

H

IG

T

S

SIGNAL

G

x

N

E

R

jax

ja

T

STRENGTH

O

F

K

R

O

W

WORKFORCE

S

il b

bil -

E

C

R

27

26

30

5

6

2

3

4

28

24

25

24

21

16

20

18

12

23

19

22

13

12

35

8

11

32

34

WORKFORCE

7

31

9

7

R

S

T

OR

O

L

S

5

P

O

2

VOLTS

V

1

M

Z

AMPS

A

0

0

T

5

0

4

R

.

2

1

100-125

-

1.4

1

E

0

:

HERTZ

H

T

0

R

200-250

2

0

U

OR

O

60

6

P

8

.

N

R

INPUT:

I

2.8

2

.

OR

O

S

C

0

T

.

L

50

5

A

A.C.

O

S

VOLTS

V

P

2

M

1

12

AMPS

A

:

T

0

U

1

10

P

T

U

OUTPUT:

O

.

:

.

C

.

O

r

D

D.C.

N

e

L

b

E

m

u

D

n

O

L

M

MODELNO.:

A

I

R

E

S

SERIALnumber

2

9

1

12

C

6

T

C

D

DC

I

E

A

AC

U

s

G

3

R

C

e

E

r

R

I

TA

e

K

C

CIRCUIT

L

p

0

A

E

O

m

R

Amperes

A

V

VOLTAGE

B

BREAKER

.

C

.

D

D.C.

5

2

1

-

O

0

T

TO

S

11

110-125

S

T

E

E

R

S

P

PRESS

E

R

RESET

0

5

2

0

0

2

200-250

R

OAUTO

E

T

T

U

W

U

P

O

N

A

I

INPUT

S

P

POWER

E

C

Y

S

A

AC

L

F

Y

U

.

N

F

L

F

FUSES

E

O

ONLY

N

O

OFF

S

V

ONLY

O