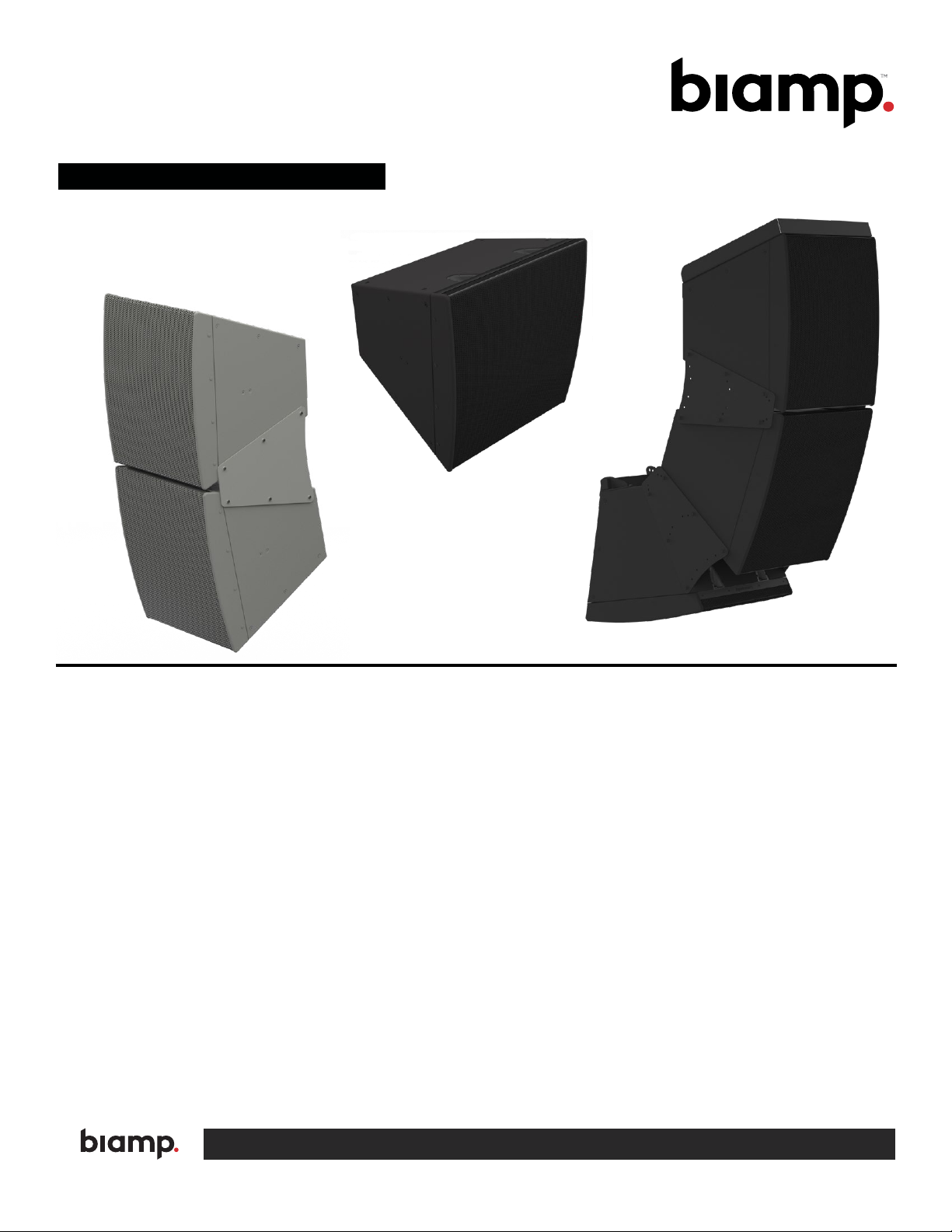

Community L Series

LVH-900 Beamforming Venue Horn

Installation & Operation Guide

Models

LVH-906/AS

LVH-909/AS

LVH-906/AP

LVH-909/AP

PRODUCT DESCRIPTION

Biamp's Community L SERIES LVH-900 Beamforming Venue

Horn, combined with the Community Amplified Loudspeaker

Controllers (ALCs), precisely tailor the directivity of each

loudspeaker, or array of loudspeakers, to meet the sound

requirements in any application.

Designed for exceptional performance in large venues,

each LVH-900 model consists of four 12-inch LF drivers,

three Community M200E midrange compression drivers

and four 1.5-inch HF compression drivers. Using patentpending techniques, all drivers integrate into a single triaxial

waveguide that fills the entire 36 x 31-inch face of the

enclosure, providing pattern control to below 400 Hz. The

LVH-900 models offer 60 or 90 degrees of fixed horizontal

dispersion.

The LVH-900 Active Standard (AS) models allow DSP

settings and control of individual driver pairs to provide

uniform sound to the audience areas. The LVH-900/AS

models have presets for vertical dispersion beamforming in

60°, 40°, 20° configurations.

The LVH-900 Active-Plus (AP) models use advanced

FIR techniques to seamlessly combine the output of two

loudspeakers into one coherent wavefront, providing higher

output or wider coverage patterns. LVH-900/AP models

have presets for vertical dispersion beamforming in 100°,

80°, 20° configurations.

Typical applications include music and speech reinforcement

for large houses of worship, stadiums, theaters, and much

more. Possessing advanced features, highly-focused

dispersion patterns, weather-resistant construction, and

most importantly sonic excellence, LVH-900 loudspeakers

make installations not only fast and simple, but as functionally

effective as possible.

FEATURES

• Designed for extraordinary performance in large

venues

• Large format, horn-loaded triaxial design maintains

pattern control to below 400Hz

• Co-linear manifold for HF and MF beamforming

• Indoor or Outdoor weather-resistant (WR) models

A: 9300 S.W. Gemini Drive Beaverton, OR 97008 USA W: www.biamp.com

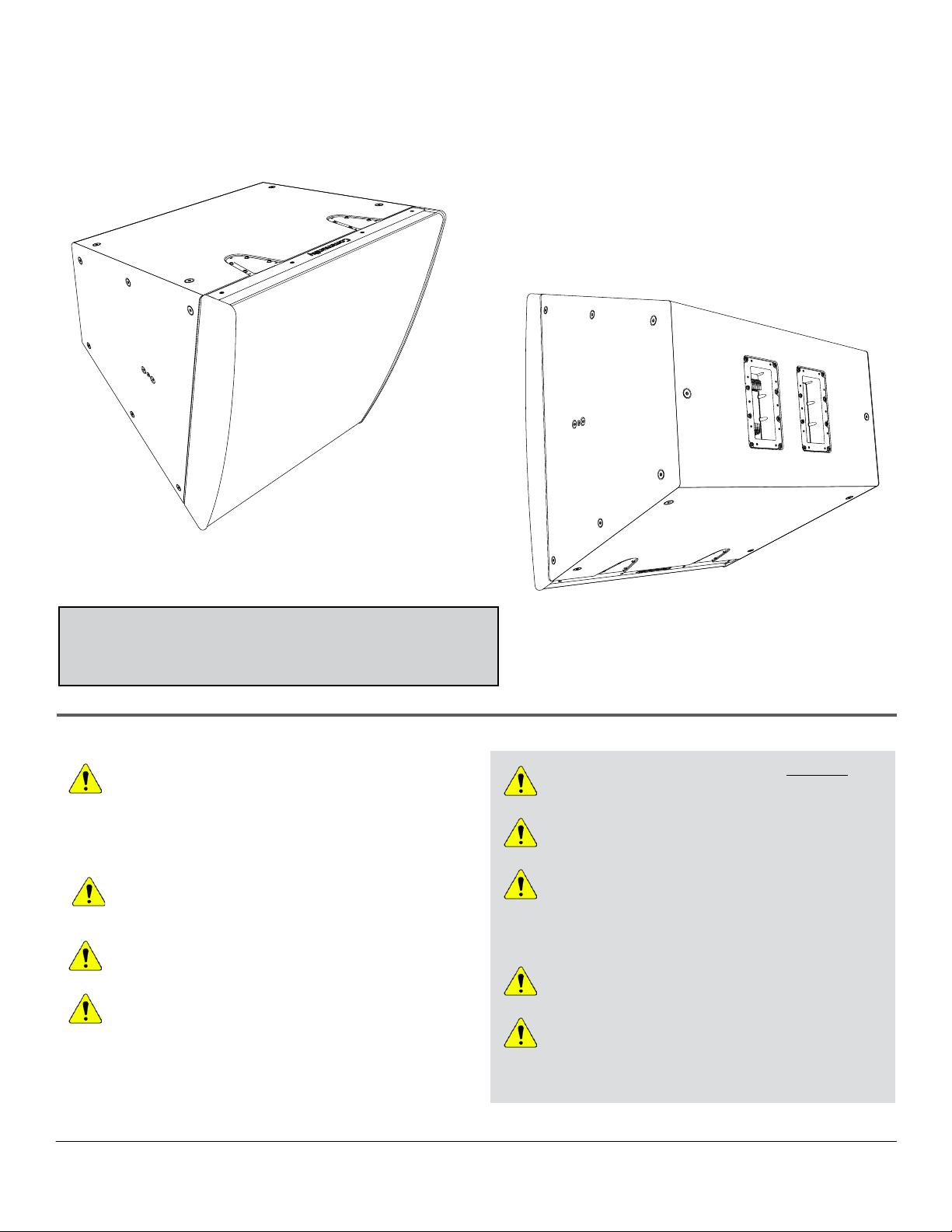

PRODUCT REPRESENTATION

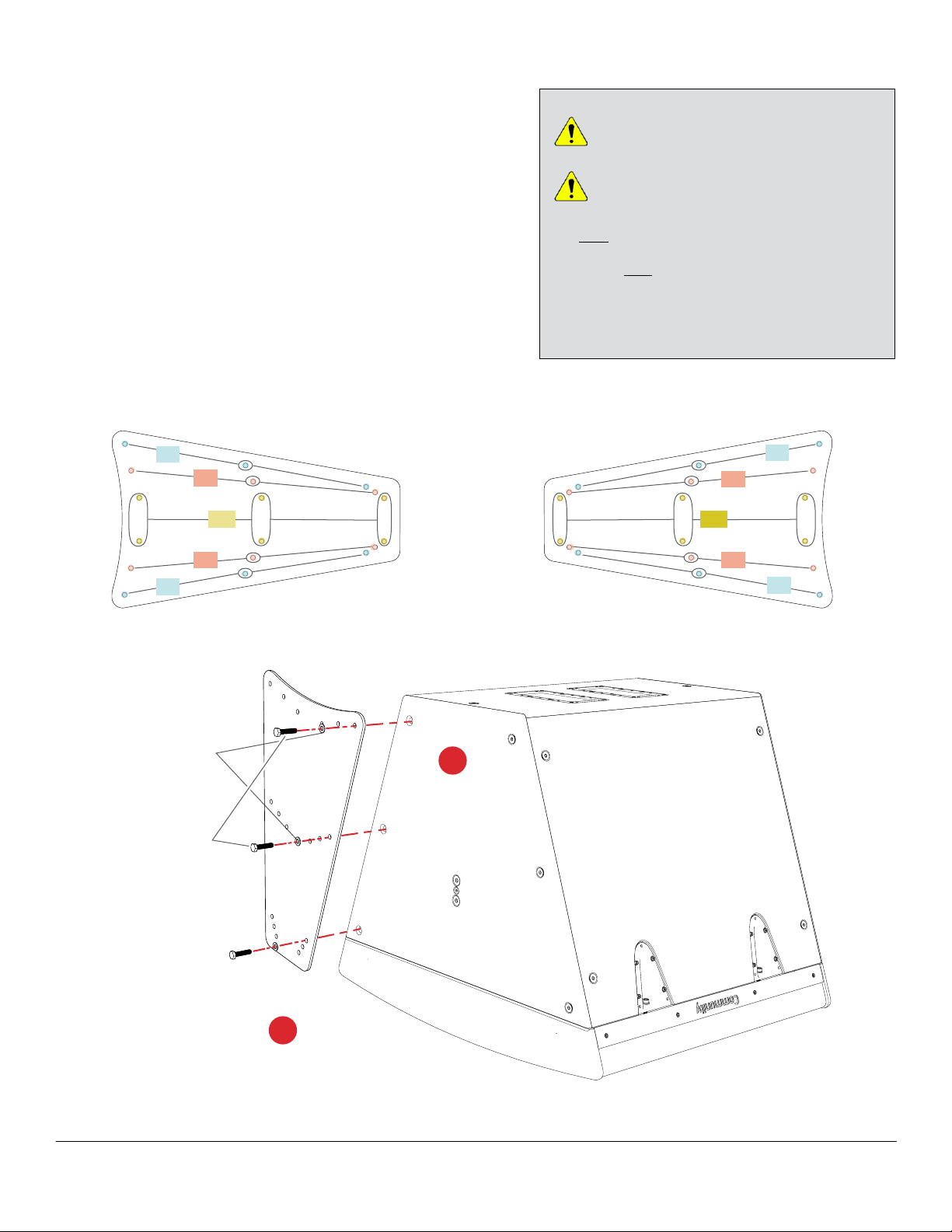

LVH-900 Loudspeaker

Models: LVH-906/AS, LVH-909/AS, LVH-906/AP, LVH-909/AP

Front

IMPORTANT: Please note any application restrictions (Indoor vs

Outdoor) on the rigging accessories shown in this installation guide.

Contact Biamp for information regarding mounting options for multicabinet WR (outdoor) LVH loudspeakers.

RIGGING AND ELECTRICAL SAFETY

IMPORTANT: The loudspeakers described in this manual are

designed and intended to be mounted to diering building

surfaces using a variety of rigging hardware, means and

methods. Installation of loudspeakers should only be performed

by trained and qualied personnel. All electrical connections

must conform to applicable city, county, state, and national

electrical codes or standards.

. DANGER: It is possible to experience severe electrical shock

from a power amplier. Always make sure that all power

ampliers are in the "OFF" position and unplugged from an AC

Mains supply before performing electrical work.

IMPORTANT: Refer to the sections on installation and

connections later in this manual for additional information on

rigging and electrical safety.

IMPORTANT: Any open threaded inserts in the sides of each

enclosure must have threaded fasteners inserted to seal the

enclosure from air leaks. If the threaded ttings do not remain

sealed, air leaks will occur in the enclosure that may

compromise the low-frequency performance with distortion,

reduced output, and premature driver failure.

(LVH-900/AS model shown)

Rear

WARNING: This LVH-900 loudspeaker is very heavy

(250 lbs, 113.4kg). Use of a rated lifting device and the

appropriate hardware is strongly recommended.

IMPORTANT: Please review the safety guide

accompanying this product and these installation

instructions prior to installing this loudspeaker.

CAUTION: Installation of Biamp loudspeakers should only

be performed by trained and qualied personnel. It is

strongly recommended that a licensed and certied

professional structural engineer approve the mounting.

Severe injury and/or loss of life may occur if this product is

improperly installed.

IMPORTANT: When installing speakers outdoors, use a

support system with enough wind-load strength to comply

with applicable codes and standards.

IMPORTANT: (Applicable for outdoor (WR) systems with

input panel covers installed) - If electrical and signal

connections are made to a non-rigid wiring system (without

conduit), then connections shall not be made with rigid

conduit, but with exible conduit or wiring only.

page 2 Installation and Operation Guide L SERIES LVH-900

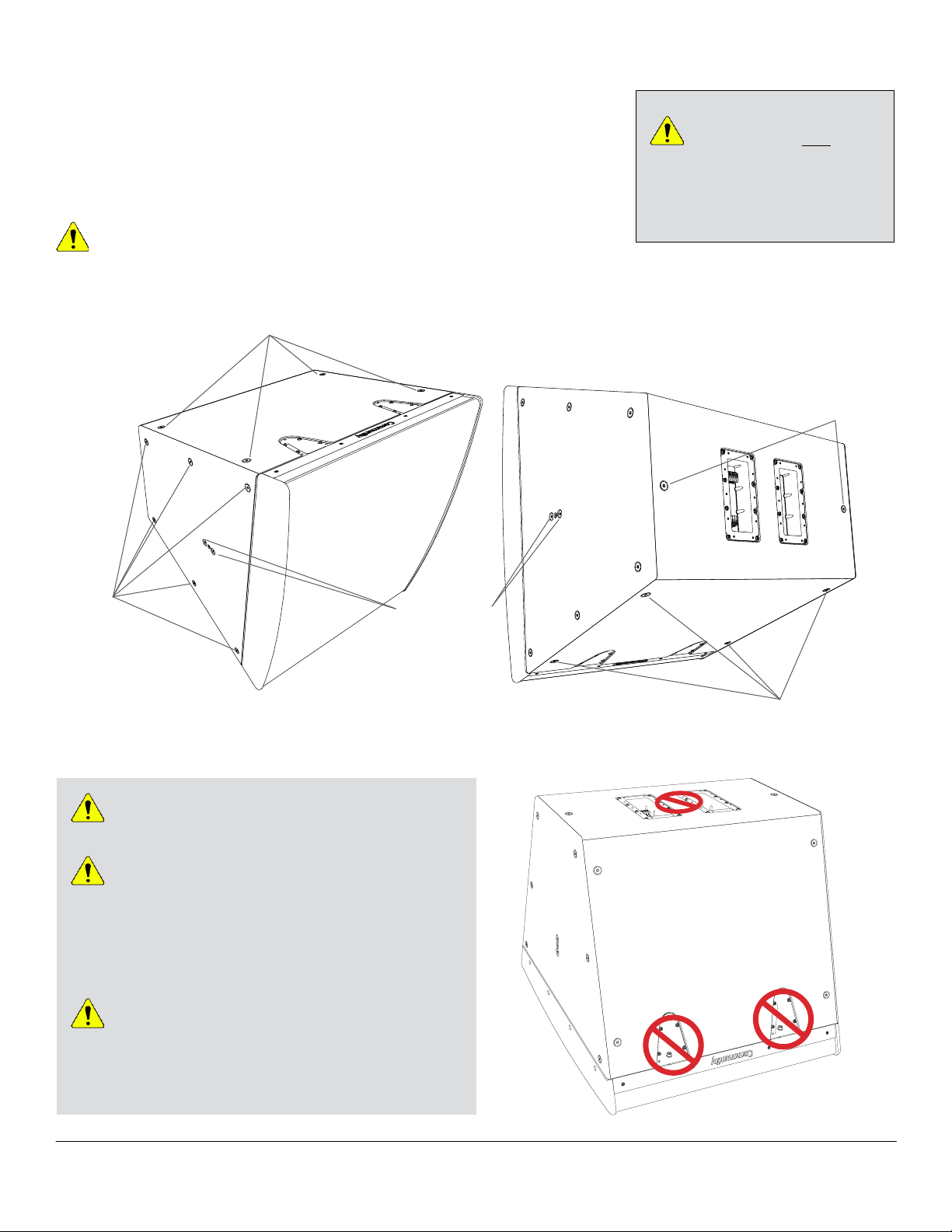

INSTALLATION

Installation preparation

The LVH-900 is securely packed one to a carton on a pallet.

1. Move the pallets to the assembly area.

2. Remove strapping and wrap to expose the carton.

3. Remove the carton top and cardboard sleeve. The

speaker is positioned face (grille) down in the bottom

tray.

4. Review the safety information enclosed and reserve the

hardware packet for later use.

5. See page 4 for mounting / suspension points.

The LVH-900 models explained:

There are functional differences between the /AS (Active

Standard) and /AP (Active Plus) models described below. It is

important to order the appropriate models for your application.

Your system designer should have modeled the system using

EASE® Focus3 (EF3) software (available free from AFMG®

here)*. The latest LVH-900 GLL (loudspeaker file) is available

on the Biamp website (here) The report generated will

dictate the models, splay plate types and quantities needed.

The WR (weather-resistant) models are designed to comply

with, and pass IEC 60068-2-5 Solar Radiation, IEC 60068-2-11

Salt Mist, IEC 600682-42 SO2, IEC 60068-2-60 Chlorine, and

IEC 60529 IP56 test conditions

LVH-900/AS (Active Standard) models

• Are always used as single cabinet point sources.

• Internally the HF & MF drivers are wired in pairs –

outside pairs and inside pairs – each driver pair is driven

by different FIR settings, manipulating the phase to

create the single cabinet beamformed patterns.

Note: Since there are only 3 MF drivers they are

wired to the input panel as MF1&3, and MF2.

• Recommend a total of 6 amplifier channels to drive each

cabinet.

*EASE® and AFMG® are registered trademarks of

AFMG Technologies GmbH.

LVH-900/AP (Active Plus) models

• Must be ordered as two (2) /AP cabinets in order to

create one dual array.

• Are always deployed in pairs. Two ‘/AP’ cabinets are

arrayed together to create one single, larger LVH

loudspeaker. The proper mechanical splay between

cabinets must be paired with matching FIR settings.

• Provide additional output and/or wider coverage patterns

than are available from single ‘/AS’ models.

• The input panels provide wiring access to each HF & MF

driver individually. Mirrored FIR settings are sent to the

upper and lower cabinets in the pairs, allowing the two

cabinets to act as one large loudspeaker.

• Like the ‘/AS’ version, the HF & MF drivers are driven as

pairs but in the ‘/AP’ version the drivers in each pair are

located in two different cabinets. There are four (4) HF

pairs and three (3) MF pairs of drivers driven across the

dual ‘/AP’ loudspeaker array.

• '/AP' arrays recommend a total of 11 amplifier channels

for each array.

• Use of a single '/AP' speaker is not currently supported.

L SERIES LVH-900 Installation and Operation Guide page 3

INSTALLATION

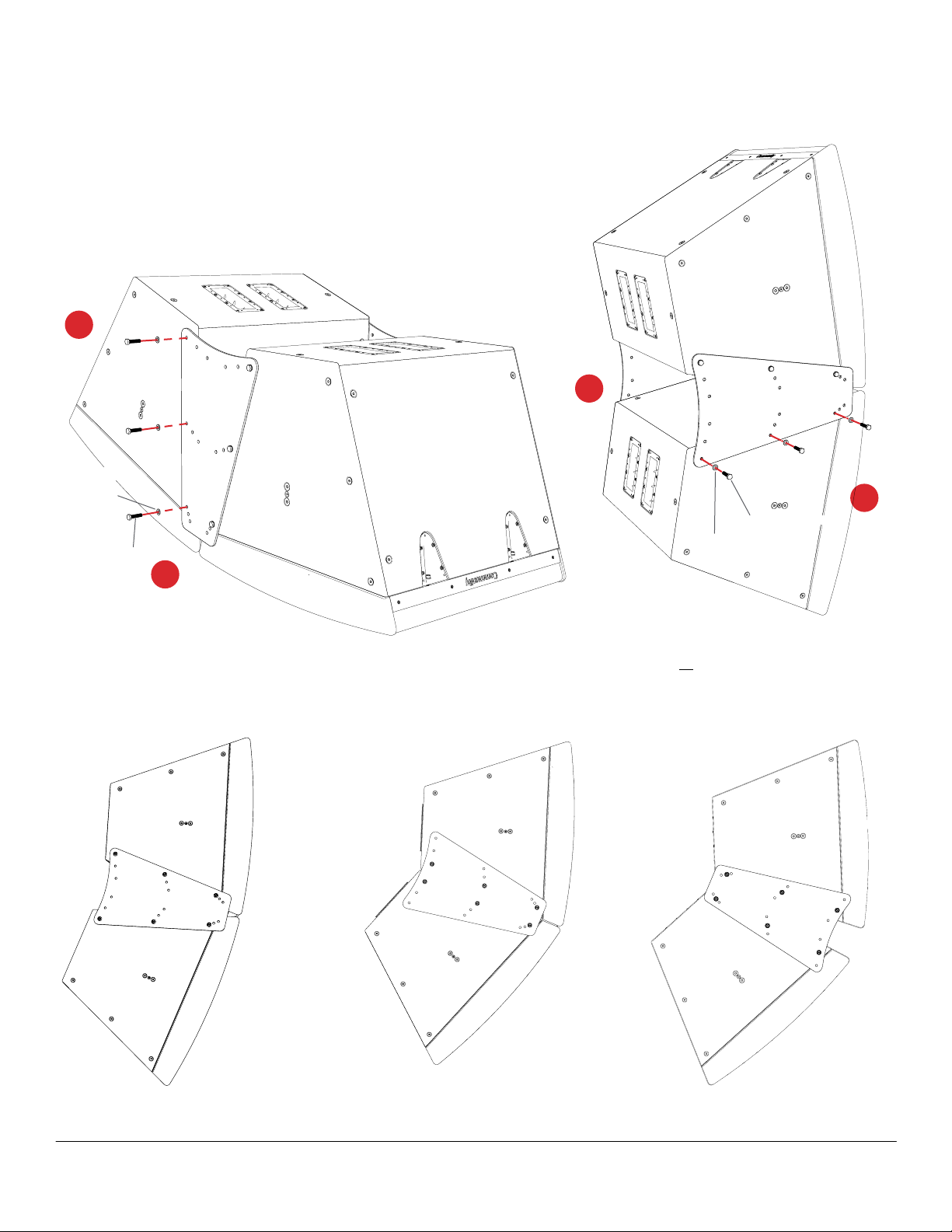

Mounting Points

There are at least four mounting points on each side, top and bottom that may be

used for rated eyebolts, splay brackets, or rigging frames. The existing (M10) flat

head bolts may be removed and replaced with M10 mounting hardware (thread

length between 35-45mm). Please note that the center larger holes in the side panel

take M12 size hardware and represent the center of gravity (CoG) of the cabinets.

IMPORTANT - Rigging point WLL:

M10 rigging point is 200 lbs (10:1 Safety rating) - recommend 4 suspension points;

M12 rigging point is 250 lbs (10:1 Safety rating) - recommend 2 suspension points

M10 Mounting points

CAUTION: Each LVH

loudspeaker is very heavy

(~250 lbs, 113.4 kg).

Please use caution, rated

hardware and a lifting

device when moving it.

M10

Mounting

points

(rear)

M10

Mounting

points

M12 CoG

U-Bracket

Mounting Points

Front

WARNING: Do not use any hardware connection points

other than the M10s or M12s as indicated for lifting,

suspension, mounting, or secondary safety points.

IMPORTANT: Any open threaded inserts in the sides of

each enclosure must have threaded fasteners inserted

to maintain structural integrity and seal the enclosure

from air leaks which may compromise LF performance.

Additionally, weather-resistant (WR) models must have

hardware fully threaded in all of the holes to prevent

moisture from entering and interfering with

performance.

CAUTION: Do not disconnect or utilize any hardware in

the plastic cups, grille or input panels unless specically

instructed. They are not rigging points and are

necessary for cabinet integrity. For the same reason, do

not remove the plugs on the curved side panels or the

bolts in the Community trim bars.

M10 Mounting

points

Rear

page 4 Installation and Operation Guide L SERIES LVH-900

INSTALLATION (continued)

Installation and Assembly Tips

• Test all cabinets before hanging (see expected values at right). Because each

cabinet has multiple LF, MF & HF drivers, it can be difficult to confirm all drivers

are operating properly by simply passing signal through and listening. We

recommend measuring the D.C. Resistance (DCR) of each driver, or driver

pairs, via the input panel(s) using a standard, calibrated Ohmmeter.

• Arrange cabinets in the order that they will hang, and loosely attach appropriate

splay brackets to the bottom of each cabinet.

• Use cardboard or packing blankets to protect grilles and enclosure finish while

units are on the ground .

• Orient cabinets with input panels aligned for ease of wiring; input label text

indicates orientation.

• Leave splay bracket connections slightly loose until all cabinet connections are

made, then tighten evenly according to indicated torque values.

• Have padded wooden materials to support cabinet splay angles if assembling

the array (or parts of the array) on the ground.

• Tools needed: Allen/hex key wrenches (5, 6, 8 mm); #2 Phillips screwdriver.

• Gland nuts are not provided for WR panel covers, holes = 1" (25mm)

- recommended size - 3/4" NPT. Typical 3/4" NPT gland nuts will accept wire

sizes up to 0.875" (22.2mm).

• Pallet jack, fork lift and/or portable lifting equipment are recommended to

facilitate safe assembly.

• When attaching rigging or replacing hardware, please tighten the hardware to

the following torque values: 10mm bolts: 50Nm (36.88 ft-lbs);

12mm bolts: 85Nm (62.69 ft-lbs); 8mm bolts: 25Nm (18.44 ft-lbs).

Do NOT overtighten.

Expected DCR Values (testing)

For LVH900/AS models the DCR for

each input should read approximately:

HF 1+4: ~6 Ohms

HF 2+3: ~6 Ohms

MF 1+3: ~3 Ohms

MF 2: ~6 Ohms

LF 1: ~7 Ohms

LF 2: ~7 Ohms

For LVH900/AP models the DCR on

each cabinet individually should read

approximately:

HF 1, 2, 3, 4: ~12 Ohms each

MF 1, 2 ,3: ~6 Ohms each

LF 1: ~7 Ohms

LF 2: ~7 Ohms

Safety Cable

The safety cable and associated

hardware are not included. Consult all

applicable codes for your application.

Confer with a structural engineer for the

appropriate cable/hardware for the load,

application and locale.

If required, a safety cable(s) must be

secured to a suitable load-bearing point

separate from the array mounting point,

with as little slack as possible, so as

not to develop undue kinetic force if the

primary array mount were to fail.

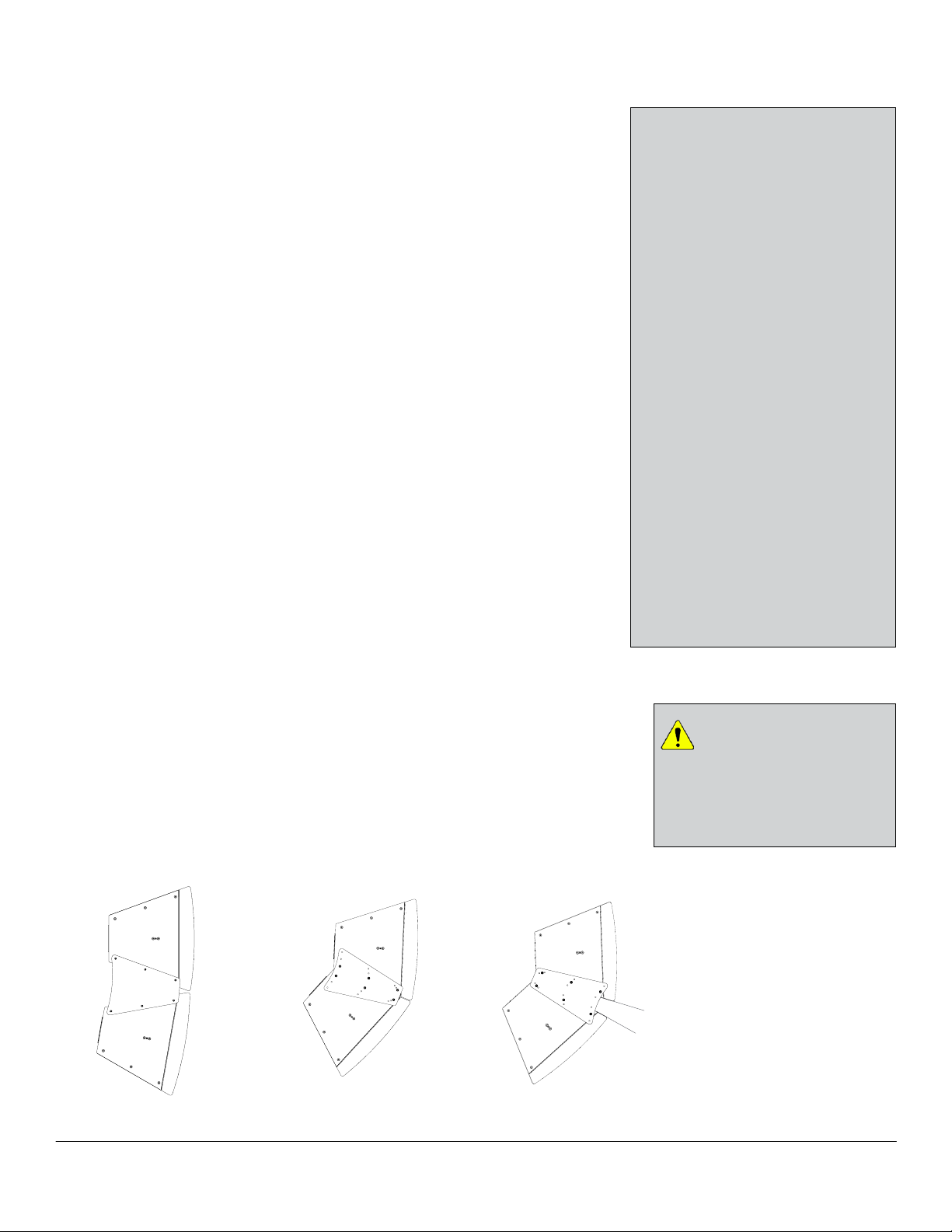

Splay Brackets, Cabinet Angles and Beamformed Patterns in LVH-900/AP Dual Cabinet Arrays

It is important to remember the beamformed patterns that dual cabinet arrays

can make are distinct and will dictate the splay between two cabinets. The

LVH-900/AP dual-cabinet beamformed patterns require both proper physical

splay between cabinets and appropriate FIR filters applied in the DSP. Two

LVH-900/AP loudspeakers and appropriate splay brackets* are required for each

dual-cabinet array to function properly.

The EASE® Focus report will define any cabinet splay angles in an array.

LVH-900/AP Dual cabinet arrays should be configured using the following splay

plates and hole sets.

LVH-900/AP 20°

SP2 - 30° Back Splay

LVH-900/AP 80°

SP1 - 0° Back Splay

LVH-900/AP 100°

SP1 - 10° Front Splay

installations), splay brackets may

not be necessary, but the exact

cabinet splay geometry must be

duplicated in that frame.

10°

*IMPORTANT: If a custom

rigging frame is being used

(especially with outdoor

L SERIES LVH-900 Installation and Operation Guide page 5

INSTALLATION (continued)

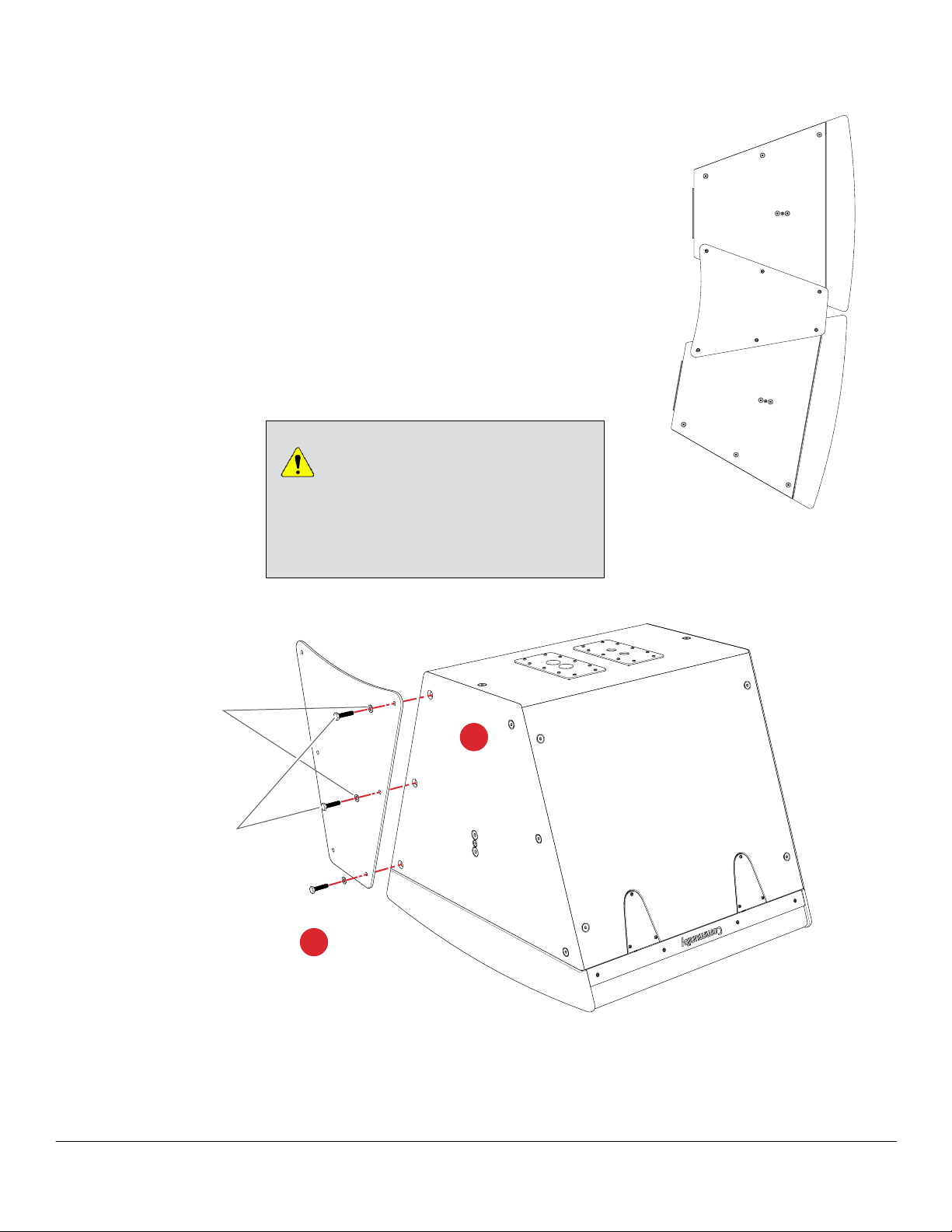

Splay Bracket Connections (LVH-900SP1)

The angle of the splay brackets should be determined using

EF3 modeling software prior to installation. The report detailing

the positioning of each cabinet in a multi-cabinet array should

be provided by your system designer or integrator. The report

will detail splay angles and bracket types for each of the

cabinets. Refer to Figure 1 for which holes to use to achieve

those angles.

1. Remove at head M10 bolts from the holes where the

splay bracket will attach to the cabinet.

2. Attach the splay brackets to what will be the upper

cabinet - Keep the connections loose so that the next

cabinet can be moved between them. (Figure 2)

IMPORTANT: Do not use power tools to

tighten the bracket hardware - Do NOT

cross-thread or strip these bolts.

IMPORTANT: Splay bracket to cabinet

connections should be symmetrical

Splay Bracket Orientation:

For back splay angles 0-20° the smaller end of the

splay bracket should be at the front of the LVH

For 10-20° front splay angles, ip the bracket so the

larger end is at the front of the LVH.

SP1 Pair Weight: 15.6 lbs (7.1 kg

WLL: 1760 lbs (798.3 kg) per pair of brackets

Cabinet

Rear

20°

10°

10°

20°

Figure 1. Cabinet to Splay Bracket attachment points to achieve splay angles suggested in EF3

M10 Flat

Washer

M10 Hex Bolt

Back Splay

(gap between the

back of the cabinets)

0°

Cabinet

Front

1

Cabinet

Rear

Front Splay

(gap between the front

of the cabinets)

10°

0°

10°

20°

Cabinet

Front

20°

2

Figure 2. Attach splay bracket to each side of the loudspeaker

Use correct holes to attain desired angle - keep connections loose

page 6 Installation and Operation Guide L SERIES LVH-900

INSTALLATION (continued)

3. With the appropriate M10 screws removed, move the

second cabinet into position behind the rst and attach

the splay bracket.

4. Thread bolts into all splay bracket connections before

tightening them. (Figure 3)

5. Fully tighten all splay bracket connections on both

sides of the cabinet.

3

M10 Flat

Washer

M10 Hex Bolt

4

3

4

M10 Hex Bolt

M10 Flat Washer

Cabinets face-down on protected surface

Figure 3. Attach the side plate to the next cabinet - keep all connections loose until all bolts are started.

Support the second cabinet until all connections are made and tightened

Back Splay

20° hole set

Back Splay

0° hole set

Lower cabinet lifted into place

Front Splay

10° hole set

Figure 4. Typical splay bracket orientation - cabinet connection locations are symmetrical on the splay bracket

L SERIES LVH-900 Installation and Operation Guide page 7

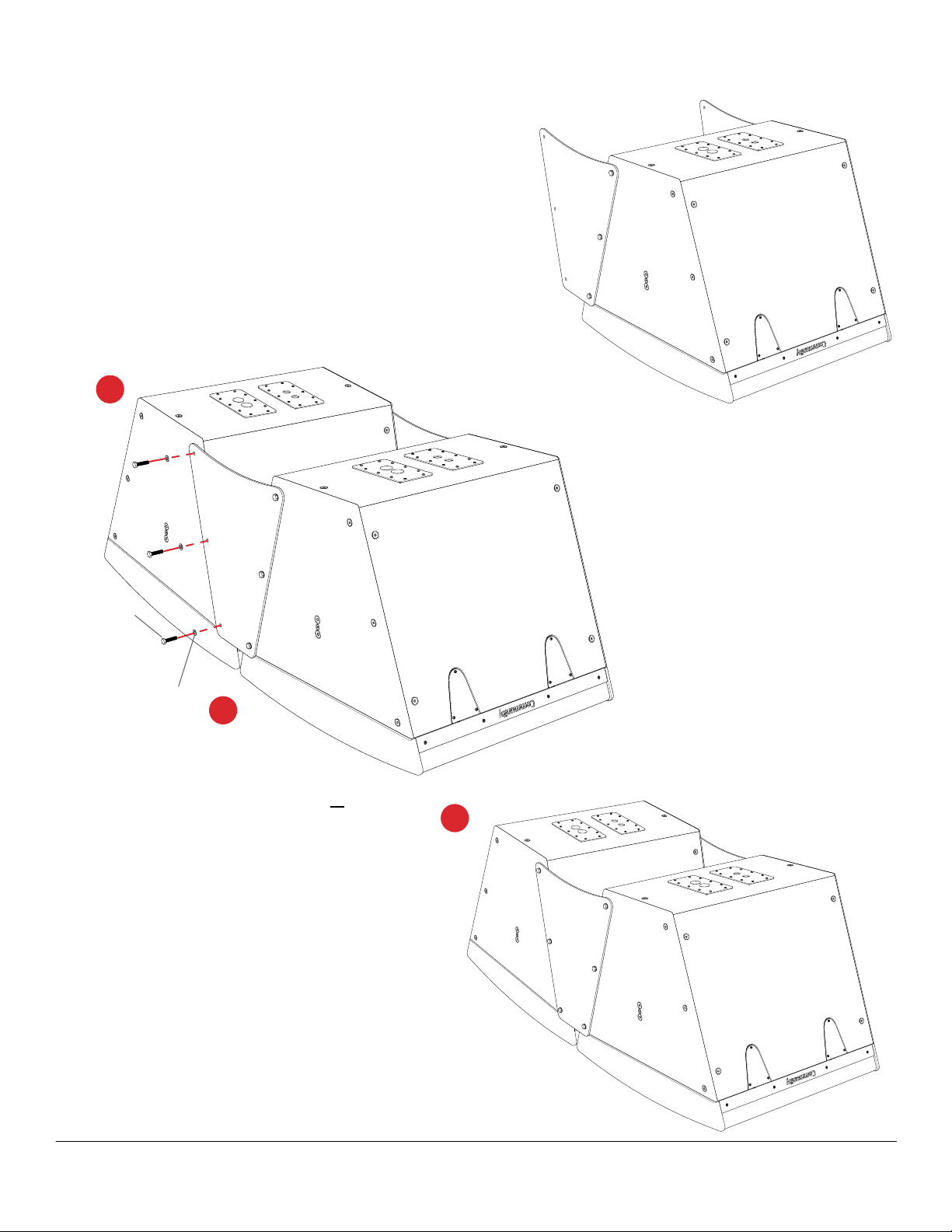

INSTALLATION (continued)

Splay Bracket Connections (LVH-900SP2)

LVH-900SP2 is used for creating a 30° splay between

cabinets. Most commonly, it is used as the joining plate in an

LVH-900/AP 20° cabinet, creating the proper rear splay angle.

Or it can also be used to create a wide splay at the front of an

array when separation between adjacent cabinets is required.

Please keep cardboard or other cushioning material under the

grilles to protect them from any damage.

1. Remove at head M10 bolts from the holes where the

splay bracket will attach to the cabinet.

2. Attach the splay brackets to what will be the upper

cabinet - Keep the connections loose so that the

bracket can be moved slightly. (Figure 5)

Important: Do not use power tools to

tighten the bracket hardware - you do

not want to cross-thread or strip these

bolts.

SP2 Pair Weight: 18.3 lbs (8.3 kg)

WLL: 1760 lbs (798.3 kg) per pair of brackets

LVH-900/AP Dual 20° Array

M10 Flat

Washer

M10 Hex Bolt

1

2

Figure 5. Loosely attach splay bracket

page 8 Installation and Operation Guide L SERIES LVH-900

INSTALLATION (continued)

3. With the appropriate M10 screws removed, move the

second cabinet into position behind the rst and attach

the splay bracket.

4. Thread bolts into all splay bracket connections before

tightening them. (Figure 6)

5. Fully tighten all splay bracket connections on both sides

of the cabinet.

3

Cabinet with splay brackets attached

M10 Hex Bolt

M10 Flat Washer

4

Figure 6. Attach the side plate to the next cabinet

- keep all connections LOOSE until all bolts are

started. Support the second cabinet until all

connections are made and tightened

Hardware Torque Setting

10mm bolts: 50Nm (36.88 ft-lbs)

5

L SERIES LVH-900 Installation and Operation Guide page 9

INSTALLATION (continued)

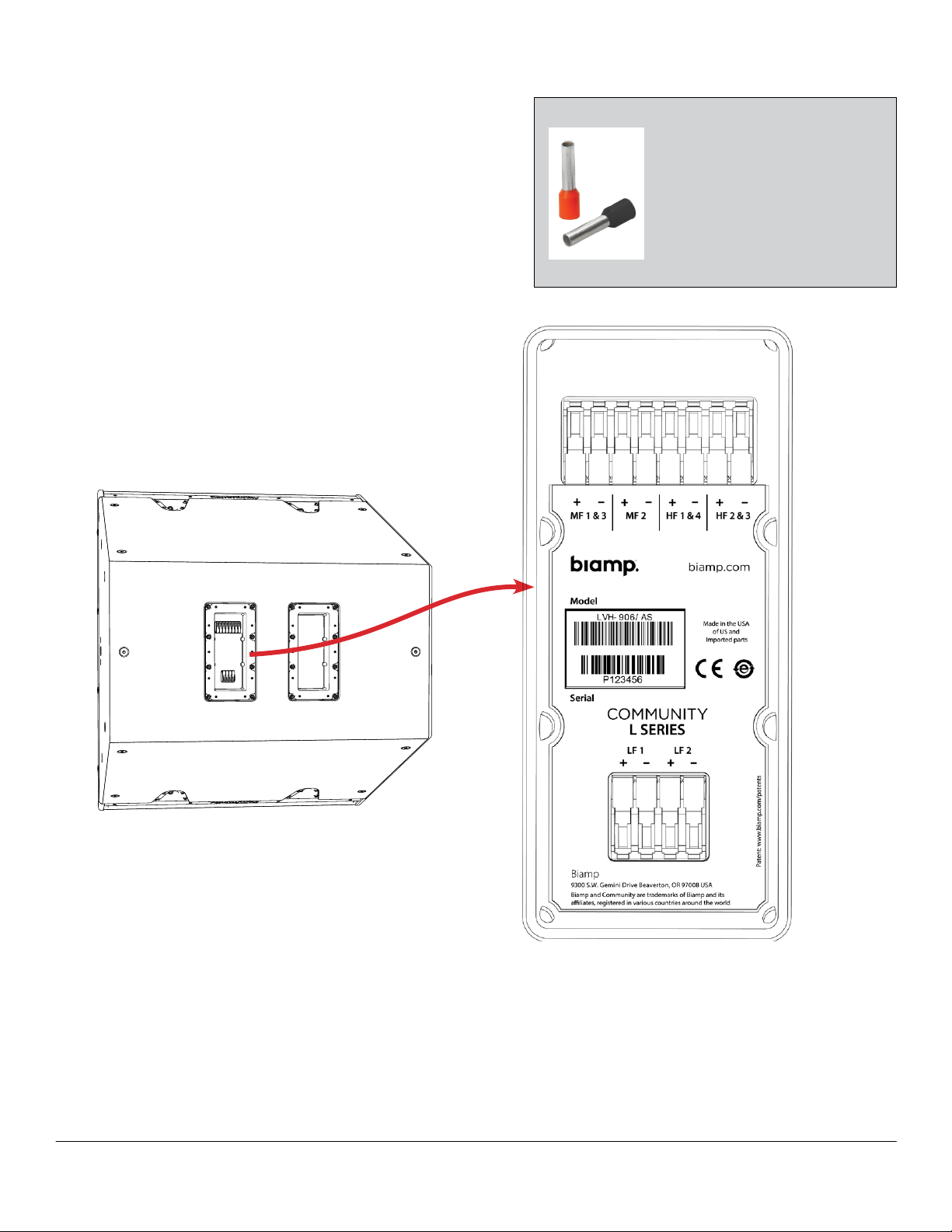

Electrical Connections LVH-900AS (Active Standard)

The input panels are fitted with lever-action terminals to make

electrical connections to the drivers. Strip the insulation 0.5"

(13mm) from the end of each wire. Lift a lever up and insert the

wire fully into the slot. Press the lever back down on the wire to

secure the connection. Ensure the lever is fully snapped down

and each wire is tight and can't be pulled out. Stranded wire

should be twisted or crimp-on wire ferrules used to ensure all

strands are captured.

Note: The levers are sti: take care when lifting or pressing them

down.

Wire Ferrules

Note: It is strongly recommended to use

wire ferrules with stranded wire.

Recommended wire size:

0.5 mm2 - 2.5mm2

(AWG 20 ga - 10 ga)

Use the appropriate gauge and length

of wire to avoid appreciable signal loss

based on the number of devices per run.

example

Input Panel LVH-900/AS

page 10 Installation and Operation Guide L SERIES LVH-900

INSTALLATION (continued)

Electrical Connections LVH-900AS (continued)

IMPORTANT: Make sure that all cables and conductors are

labeled to prevent problems.

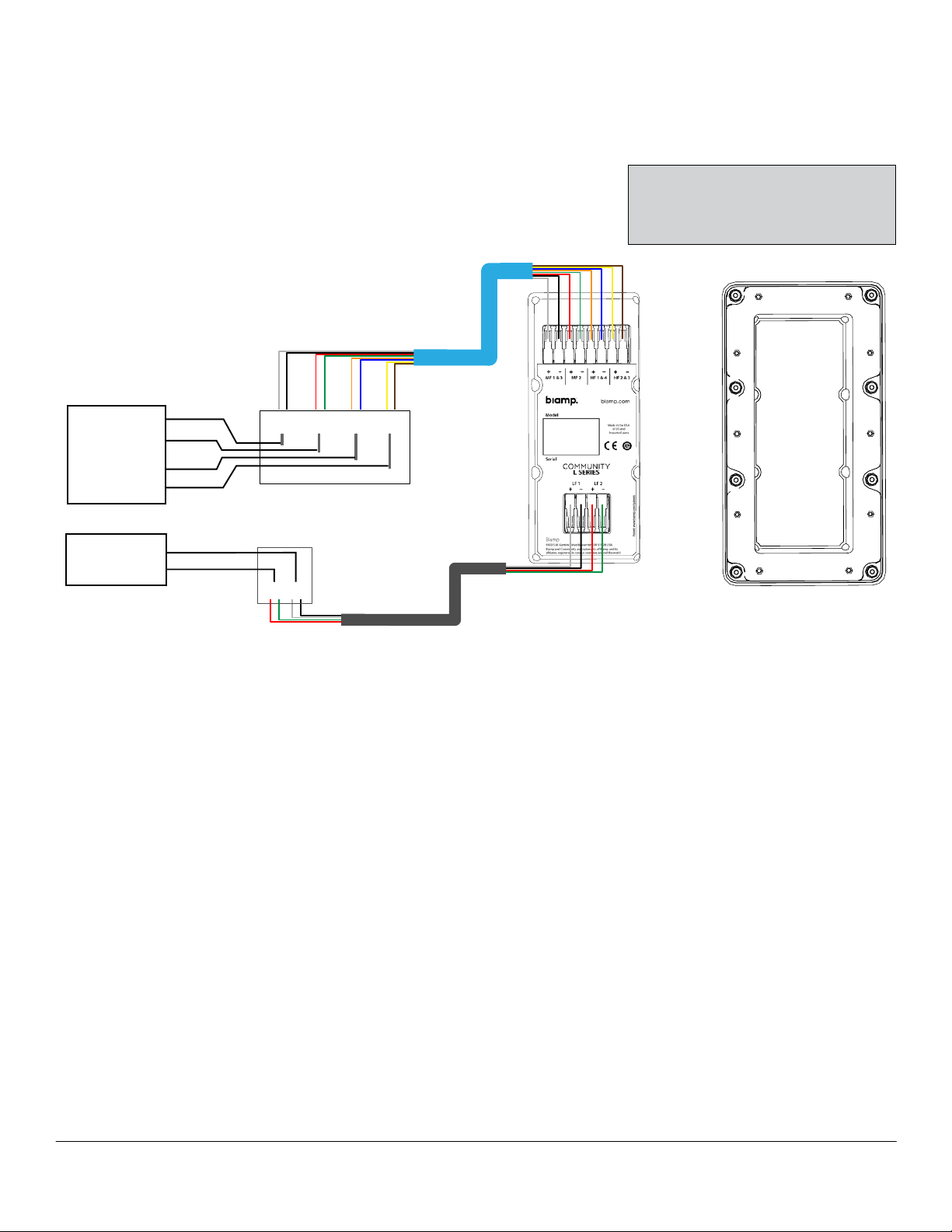

1. Wire the Active Standard (LVH900/AS) models as

shown below. Six (6) channels recommended.

8-conductor

NOTE: Bold identiers (H#, M#, L#) on each

channel correspond to the channel DSP

settings called out in the Armonia+ software

for the ALCs.

ALC-404D

ALC-1604D

(bridged)

Ch 1 (M1)

Ch 2 (M2)

Ch 3 (H1)

Ch 4 (H2)

Ch 1 & 2 bridged

(L1)

Ch 3 & 4 bridged

(L2)

+ –

MF 1&3

+ –

Junction box

+ –

+ –

LF 2

LF 1

+ –

+ –

+ –

+ –

HF 1&4

+ –

+ –

HF 2&3

+ –

4-conductor

MF 2

+ –

Junction box

Figure 7. Wiring for LVH-900/AS Input Panel

L SERIES LVH-900 Installation and Operation Guide page 11

Loading...

Loading...