Page 1

EN

CONTROL UNIT pag. 10

INSTALLATION AND OPERATION MANUAL

LOG-BC

035393-B_03_10/09/12

Page 2

Index

Page

1. INTRODUCTION 11

2. MAIN FEATURES 11

3. TECHNICAL SPECIFICATIONS 11

4. SAFE INSTALLATION 12

5. POWER 12

5.1 M3 MOTOR + POWER SUPPLY 24 Vac 12

6. INPUT AND OUTPUT CONNECTIONS AND FUNCTIONS 12

6.1 M1 POWER TERMINAL BLOCK 12

6.2 M2 INPUTS CONTROL TERMINAL BLOCK 13

7. DIP-SWITCH CONFIGURATION 13

8. PROGRAMMING 13

8.1 PRELIMINARY CHECKS 13

8.2 CHAIN HEIGHT ADJUSTMENT 13

9. SETTING THE TRIMMERS 14

10. RADIO RECEIVER 14

10.1 RECEIVER TECHNICAL SPECIFICATIONS 14

10.2 RADIO CHANNEL FUNCTIONALITY 14

10.3 ANTENNA INSTALLATION 14

10.4 MANUAL PROGRAMMING 14

10.5 SELF-LEARNING MODE PROGRAMMING 14

11. WORKING WITH A BUFFER BATTERY 16

12. TROUBLESHOOTING GUIDE 16

13. ATTENTION 16

- 10 -

Page 3

EN

LOG-BC

Installation and operation manual

1. INTRODUCTION

The control unit denominated LOG-BC is designed to manage the PRIVEE automation and is equipped with encoder input for

learning the stroke and recognising the obstacle.

Thanks to the considerable amount of logic available even very particular operating conditions on sytems can be met.

2. MAIN FEATURES

- Microprocessor logic

- Green LEDS displaying the status of the N.O. control inputs and red LEDS for the status of the N.C. safety ones

- Pull out terminal blocks

- Output for a ashing light and gate open indicator or for a red and green trafc light

- Integrated radio receiver 433Mhz; 2048 codes

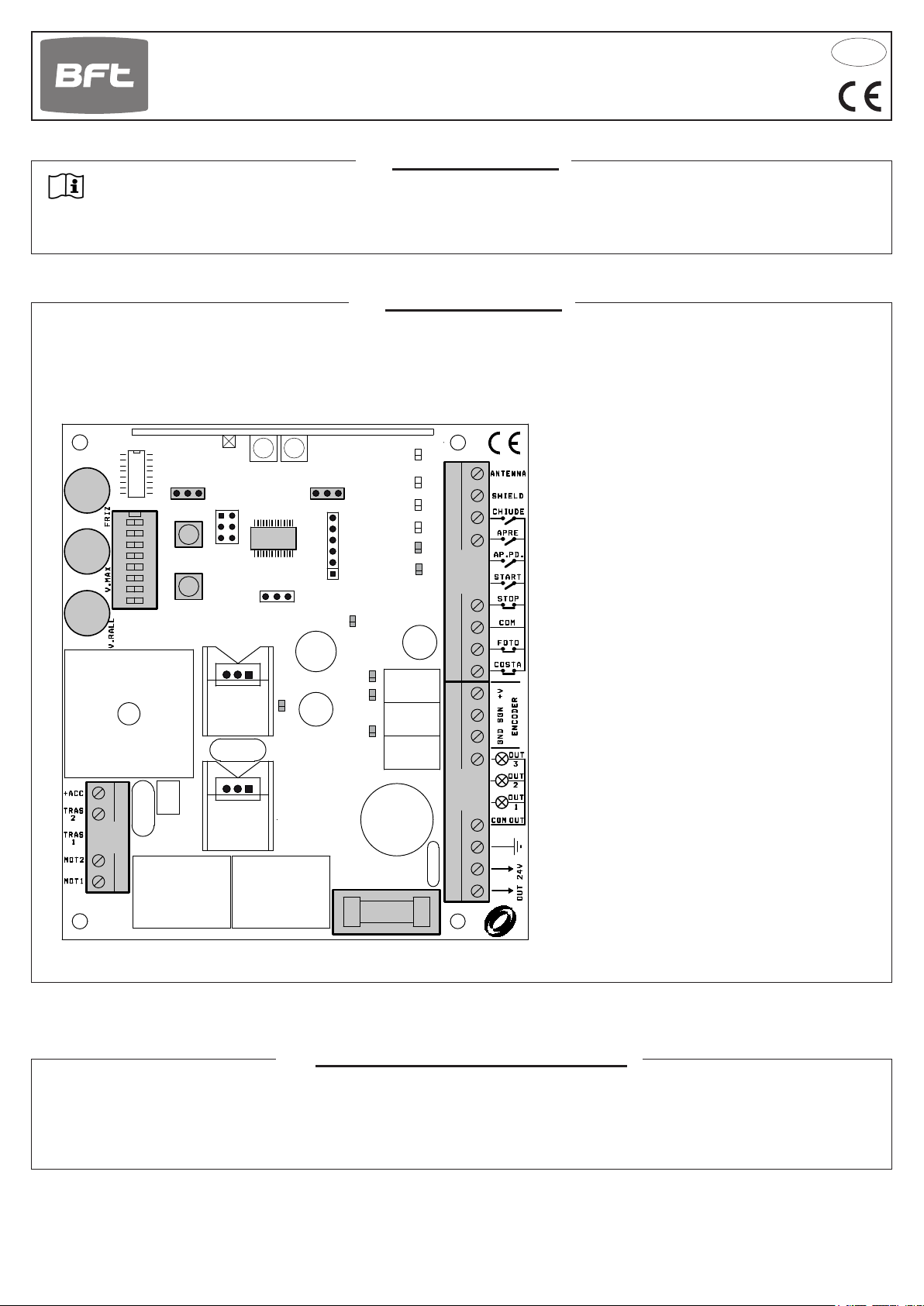

PM1

PM2

PM3

M3

1

2 3 4 5 6 7 8

SW3

ON

START

AP.PD

DL1

μP

PWR

PR1PR2

CHIUDE

APRE

AP.PD.

START

STOP

FOTO

M2

M1: Power terminal board

ENC

M2: Controls and safety devices terminal board

M3: Motor terminal, transformer, +acc

SW3: 8-way Dip Switch

COSTA

OUT 2

F2: Power fuse 500mA 5x20

AP.PD: Semi-automatic opening cycle

START: Start and programming

OUT 1

PM1: Pre-manoeuvre warning lamp ash time

PM2: Chain dip

PM3: Pause time

µP: Microprocessor with ash memory

M1

F2

3. TECHNICAL SPECIFICATIONS

- Power: 230Vac ±10% 50/60 Hz 100W

- SCA output: 24Vac 3 W

- Flashing lamp output 24Vac 25Wmax

- Power supply output for 20 ÷ 26 Vac 12W max.

accessories

- 11 -

Page 4

4. SAFE INSTALLATION

In order to reach the level of safety required by current standards, read the following prescriptions carefully.

Do all the connections on the terminal block, reading the instructions given in this manual carefully and observing the general code of

1)

practice regulating the execution of electrical installations.

Install a four-pole circuit breaker upstream from the installation with a minimum contact opening distance of 3 mm.

2)

Install, wherever it is not foreseen, a differential switch with a 30 mA threshold.

3)

Check effectiveness of the earthing system and connect to it all parts of the automation that have a terminal or earth wire.

4)

There must be at least one signalling device outside, either a trafc light type or a ashing light, together with either a danger or

5)

warning sign.

Apply all the safety devices required by the type of installation, considering the risks it can cause.

6)

Separate the power lines (min. 1,5 mm2 cross section) from the low voltage signal lines (min. 0,5 mm2 cross section) in the ducts.

7)

Jumper the unused NC inputs.

8)

Arrange in series any contacts to be connected to the same NC input.

9)

Arrange in parallel the inputs connected to the same NO input.

10)

Keep radio control or other control devices out of children’s reach, in order to avoid any unintentional automation activation.

11)

5. POWER

(230V)

F N

+ACC

TRAS 2

TRAS 1

MOT2

MOT1

F

230 V ~

N

230V LINE

- Transformer input at 230V 50/60Hz

- Connect the earthing pole in the relevant terminal.

- Power the gear motor via the 3-way terminal

protected by 1A fuse (5x20).

- Utilise an H07RN-F 2x1.5+T min type cable

1A

TRANSFORMER

5.1

MOT1 - MOT2

Motor output 24Vdc. After a power failure, the rst action performed is an opening cycle.

If it fails, stop the automation, take the motor connector out and put it back in the other way around.

TRAS1 - TRAS2

24 Vac input for transformer. Connection to the control unit

is shown in the gure here

+ACC

Do not use

MOTOR + POWER SUPPLY 24 Vac

M3

6. INPUT AND OUTPUT CONNECTIONS AND FUNCTIONS

+

OUT 24V

OUT 1

OUT 2

OUT 3

6.1

OUT 24V

-

Accessories power supply (max 12 W):

24 Vac operations with mains power on.

24 Vdc (out+, 24V-) operation with no main power and optional buffer battery kit. KIT-BATT-SC

SCA 24Vac 3W max

Carriageway open LED that ashes slowly during opening, rapidly during closing, remains lit steady during the stop and

pause phase and switches off when the barrier is closed.

N.B.: The indicator lamp ashes twice to indicate that the automation system has detected an obstacle three consecutive

times while closing. Automatic closing is temporarily disabled and is enabled again only after a subsequent successful

closing cycle.

YELLOW FLASHING LAMP (SL-R-24V-AI) 24Vac 25W max.

Flashing output for self-ashing blinker

NOT USED

POWER TERMINAL BLOCK

M1

- 12 -

Page 5

START

AP. PD

FOTO

STOP

6.2

INPUTS CONTROL TERMINAL BLOCK

M2

FOTO

Safety input with NC contact. During closure, when the photocell ray is interrupted, it immediately opens the gate again.

COM

If this input is kept open by a clock or weekly timer, the automation system closes again after the pause time, if programmed,

and only once the entrance is clear.

STOP

NC safety input. When this is activated it stops the automation instantly and when a start command is then given the gate

COM

will always open. If a stop command is given during pause time it eliminates automatic re-closing, waiting for a command.

START

NO input, allowing the open and close signals to be sent to the automation system. This input is ignored during the opening cycle.

COM

If this input is commanded continuously, the automation system performs the opening cycle and, if the pause time is programmed and only once the entrance is clear, the automatic closing cycle.

AP.PD.

The command is accepted only if the barrier is completely closed, and automatic closing is temporarily disabled during the

COM

opening cycle. Use in accordance with the automatic logic of the start command (DIP 1-2 ON).

APRE

COM

Encoder input SGN-2.

CHIUDE

APRE

COM

CHIUDE

NO input for closing. To close the automation only if the safety devices have not triggered.

7. DIP SWITCH CONFIGURATION

Dip switches 1 and 2: They select the functioning logic

Off-Off: Hold-to-run logic.

The automation works by keeping the commands pressed, acting on the open or close inputs.

The start command opens once and closes once.

On-Off: SEMI-AUTOMATIC (Logic for pulse type collective control)

Open command only. To close after opening, press start or close. Pressing during closing cycle reopens

On-On: AUTOMATIC (Logic for pulse type collective control)

Open command only. Pressing start when paused closes barrier, pressing while barrier is closing opens

Dip switch 3: Selects pre-ashing function.

Off: The pre-ashing function is disabled: the ashing unit is commanded during the manoeuvre.

On: The warning lamp ashes for a period from 2 to 10 seconds (settable from trimmer PM1) before all mano-

Commands via radio in the hold-to-run logic are forbidden by law.

the barrier.

barrier. Barrier is closed after pause time.

euvres except barrier inversion triggered by the safety devices.

8. PROGRAMMING

8.1 PRELIMINARY CHECKS

To guarantee the safety of the system, remember that the automation must be checked according to the risk analysis, therefore the

installer must install any safety accessories needed and resolve all residue risks and dangers that the machine may cause when it

works automatically via the remote controls.

8.2 CHAIN HEIGHT ADJUSTMENT

1) Switch automation system off and on.

2) Set trimmer PM2 (chain dip setting) to the middle setting.

3) Press start and wait. The automation system performs the reset procedure.

4) At the end of the reset procedure, press START again and wait for the closing cycle to conclude.

5) Adjust trimmer PM2 to set the desired chain height and perform an open cycle and a close cycle to check that the height is correct.

- 13 -

Page 6

9. SETTING THE TRIMMERS

PM1: PRE-MANOEUVRE WARNING LAMP FLASH TIME. Sets the pre-manoeuvre warning ash time between 2 and 10 sec.

PM2: CHAIN DIP. Sets chain height. Turn clockwise to increase height.

PM3: PAUSE TIME. Sets the pause time between 2 and 120 sec.

10. RADIO RECEIVER

10.1 RECEIVER TECHNICAL SPECIFICATIONS

- Max. n° of radio transmitters that can be memorized: 64

- Frequency: 433.92MHz

- Code by means of: Rolling-code algorithm

- N° of combinations: 4 billion

10.2 RADIO CHANNEL FUNCTIONALITY

Channel 1: START command

Channel 2: AP.PD command (Semi-automatic opening cycle)

10.3 ANTENNA INSTALLATION

Use an antenna tuned to 433MHz. Connect the tuned antenna to the antenna terminals using RG58 coaxial cable .

antenna cable RG58

ANTENNA

SHIELD

10.4 MANUAL PROGRAMMING

In the case of standard installations where no advanced functions are required, it is possible to proceed to

manual storage of the transmitters, making reference to programming table A and to the example for basic

programming.

1) If you wish the transmitter to activate output 1, press pushbutton PR1, otherwise if you wish the

transmitter to activate output 2, press pushbutton PR2.

2) When LED DL1 starts blinking, press hidden key on the transmitter, LED DL1 will remain continuously lit.

3) Press the key of the transmitter to be memorized, LED DL1 will ash quickly to indicate that it has been

memorized successfully. Flashing as normal will then be resumed.

4) To memorize another transmitter, repeat steps 2) and 3).

5) To exit memorizing mode, wait for the LED to go off completely or press the key of a remote control that

has just been memorized.

IMPORTANT NOTE: ATTACH THE ADHESIVE KEY LABEL TO THE FIRST MEMORISED TRANSMITTER

(MASTER).

In the case of manual programming, the rst transmitter assigns the key code to the receiver; this code is

necessary in order to carry out subsequent cloning of the radio transmitters.

Hidden key

10.5 SELF-LEARNING MODE PROGRAMMING

This mode is used to copy the keys of a transmitter already stored in the receiver memory, without accessing the receiver.

The rst transmitter is to be memorised in manual mode (see paragraph 10.4).

a) Press hidden key on the transmitter already memorised.

b) Press key T on the transmitter already memorised, which is also to be attributed to the new transmitter.

c) Within 10 s., press hidden key on the new transmitter to be memorised.

d) Press key T to be attributed to the new transmitter.

e) To memorise another transmitter, repeat the procedure from step (c) within a maximum time of 10

seconds, otherwise the receiver exits the programming mode.

f ) To copy another key, repeat from step (a), having waited for the receiver to exit the programming mode

(or after disconnecting the receiver from the power supply).

- 14 -

Hidden key

T1

T3

T2

T4

Page 7

- 15 -

Page 8

11. WORKING WITH A BUFFER BATTERY

KIT-BATT-SC allows the automation system to operate even when the mains power supply is disconnected for a short time.

Consult the KIT-BATT-SC installation manual.

12. TROUBLESHOOTING GUIDE

1) The chain drops by a few centimetres at the end of the close cycle.

At the end of the rst close cycle, the control unit determines the force necessary to be applied with the electronic brake and the

excessive dip will be compensated when subsequent close cycles are performed.

2) The barrier is reopened by the automation system during a close cycle, even though there are no obstacles and the photocell beams

are not interrupted.

The chain height setting is too high. Reduce the setting with trimmer PM2.

13. ATTENTION

You are recommended to full an installation that includes all the accessories required to guarantee operation according to current

standards and always using original devices.

These devices must be used and installed in strict compliance with the instructions supplied by the manufacturer, who cannot be held

liable for any damages deriving from improper or unreasonable use.

The manufacturer declines all forms of liability with regard to any errors possibly written in this handbook and reserves the right to add

any modications considered necessary at any time without notice.

- 16 -

Page 9

NOTE

NOTES

REMARQUES

ANMERKUNGEN

NOTAS

INSTALLATORE

INSTALLER

INSTALLATEUR

INSTALLATEUR

INSTALATOR

035393BFT_03_10/09/12

Loading...

Loading...