Page 1

INTRIC 1-2

TRC 1-2-4

MITTO 2-4

433.92 Mhz

D811249 20-10-01 Vers. 06

SELF-LEARNING

ROLLING-CODE

RADIO CONTROLS

433.92 MHZ

FREQUENCY

Page 2

353

D811249_06

RADIO CONTROLS

RADIO CONTROLS

INTRIC 1-2/TRC 1-2-4/MITTO 2-4 433.92 MHZ

INTRIC 1-2/TRC 1-2-4/MITTO 2-4 433.92 MHZ

1) GENERAL OUTLINE

Thank you for buying this product, our company is sure that you will be more

than satisfied with the performance of the product. Read the “Instruction

Manual” supplied with this product carefully, as it provides important

information about safety, installation, operation and maintenance.This

product conforms to recognised technical standards and safety regulations.

It complies with the 89/336/EEC, 1999/5/CEE, European Directive and

subsequent amendments. This product complies with recognised technical

standards and safety regulations. Self-learning rolling-code radio receiver

system. This is used to configure impulse or bistable or timed outputs. It can

also memorize TEO 1-2-4 series (non rolling-code) transmitters. The

INTRIC/TRC-MITTO system is compatible with the EElink protocol for fast

installation and maintenance.

2) GENERAL SAFETY

WARNING! An incorrect installation or improper use of the product

can cause damage to persons, animals or things.

• The “Warnings” leaflet and “Instruction booklet” supplied with this

product should be read carefully as they provide important information

about safety, installation, use and maintenance.

• Scrap packing materials (plastic, cardboard, polystyrene etc) according

to the provisions set out by current standards. Keep nylon or polystyrene

bags out of children’s reach.

• Keep the instructions together with the technical brochure for future

reference.

• This product was exclusively designed and manufactured for the use

specified in the present documentation. Any other use not specified in

this documentation could damage the product and be dangerous.

• The Company declines all responsibility for any consequences resulting

from improper use of the product, or use which is different from that

expected and specified in the present documentation.

• Do not install the product in explosive atmosphere.

• The construction components of this product must comply with the

following European Directives:It complies with the 89/336/EEC, 1999/

5/CEE, European Directive and subsequent amendments. As for all

non-EEC countries, the above-mentioned standards as well as the

current national standards should be respected in order to achieve a

good safety level.

• The Company declines all responsibility for any consequences resulting

from failure to observe Good Technical Practice when constructing

closing structures (door, gates etc.), as well as from any deformation

which might occur during use.

• The installation must comply with the provisions set out by the following

European Directives:It complies with the 89/336/EEC, 1999/5/CEE,

European Directive and subsequent amendments.

• Disconnect the electrical power supply before carrying out any work on

the installation. Also disconnect any buffer batteries, if fitted.

• Fit an omnipolar or magnetothermal switch on the mains power supply,

having a contact opening distance equal to or greater than 3mm.

• Check that a differential switch with a 0.03A threshold is fitted just

before the power supply mains.

• Check that earthing is carried out correctly: connect all metal parts for

closure (doors, gates etc.) and all system components provided with an

earth terminal.

• Fit all the safety devices (photocells, electric edges etc.) which are

needed to protect the area from any danger caused by squashing,

conveying and shearing.

• Position at least one luminous signal indication device (blinker) where

it can be easily seen, and fix a Warning sign to the structure.

• The Company declines all responsibility with respect to the automation safety

and correct operation when other manufacturers’ components are used.

• Only use original parts for any maintenance or repair operation.

• Do not modify the automation components, unless explicitly authorised

by the company.

• Instruct the product user about the control systems provided and the

manual opening operation in case of emergency.

• Do not allow persons or children to remain in the automation

operation area.

• Keep radio control or other control devices out of children’s reach, in

order to avoid unintentional automation activation.

• The user must avoid any attempt to carry out work or repair on the

automation system, and always request the assistance of qualified

personnel.

• Anything which is not expressly provided for in the present instructions,

is not allowed.

3) TECHNICAL SPECIFICATIONS

Frequency: .............................................................................. 433.92MHz

Operating temperature: .......................................................... -20 / +55°C

Coded by means of: .............................................. Rolling-code Algorithm

No. combinations: ........................................................................ 4 million

Dimensions: ................................................................................. see fig.1

3.1) Receiver

Power supply: .................................. from 12 to 28Vdc, from 16 to 28Vac

Antenna impedance: ........................................................ 50Ohm (RG58)

Relay contact: ........................................................ 1A - 33Vac, 1A 24Vdc

Max No. radio control to be memorised: ............................................ 128

Receiver versions: INTRIC1 -single-channel, INTRIC2 - double-channel.

3.2) Transmitter MITTO

Keys: ............................................................................................... Yellow

Power supply: ............................. Two 3V lithium batteries (type CR2016)

Range: ............................................................................. 50 / 100 metres

Transmitter versions: MITTO2 - double-channel, MITTO4 - four-channel.

3.3) Transmitter TRC

Keys: ................................................................................................... Red

Power supply: ........................................................... 12V Alkaline battery

Range: ............................................................................. 50 / 100 metres

Transmitter versions:TRC1-single-channel, TRC2-double-channel, TRC4-four-channel.

4) ANTENNA INSTALLATION

Use an antenna tuned to 433MHz. For Antenna-Receiver connection, use

an RG58 coaxial cable. The presence of metallic masses close by the

antenna can interfere with radio reception. In case of poor transmitting

range, move the antenna to a more suitable site.

5) PROGRAMMING

The receivers are provided with a “JP5” jumper (fig.2) which is used to

enable the transmitters to be memorized, in MANUAL or SELF-LEARNING

mode by radio. Having inserted the receiver in the connector provided with

the control unit, enter the programming mode by pressing the SW1 button

for INTRIC 1 or, in case of INTRIC 2, the SW1 button for the CH1 output and

SW2 button for CH2 output. This condition is signalled by constant blinking

of the DL1 LED. The DL1 LED blinker packs (fig.2), which range from 1 to

6 blinks interrupted by a pause of about 1 second, indicate the different

learning functions (see table). The receiver comes out of the programming

mode if no operations take place during the subsequent 90 seconds.

5.1) Transmitter memory storage in manual mode (JP5 closed)

Select the required function from the table. When the operating method has

been understood, proceed as follows:

a) Preset the receiver to the required function (see table) and check the

DL1 LED blinker packs.

b) Send the transmitter secret code. In the case of TRC1-2/MITTO2-4,

press the P1 hidden button (fig.2). In the case of TRC4, the P1 button

function corresponds to pressing the 4 transmitter buttons simultaneously

or, after opening the battery compartment, bridging the two P1 points with

a screwdriver (fig.2).

Note: For the TEO 1-2-4 series, enter the personal code with the 10-way

Dip-switch provided with the transmitter and press the T key of the

transmitter which is to be memorised.

c) Press the T key of the transmitter which is to be memorised. The key of

that transmitter is now stored.

d) To memorise other transmitters, repeat the sequence from point (b)

within a maximum time of about 10 seconds, otherwise the receiver will

come out of the programming mode.

5.2) Transmitter memory storage in self-learning mode by radio (JP5 open)

This procedure permits to copy the keys of a transmitter previously stored

to a receiver without having to operate on the receiver inside the box.

NOTE: The transmitters belonging to the TEO 1-2-4 series (without

rolling-code) can only be stored MANUALLY.

The first transmitter must be memorized in manual mode (see paragraph

5.1). Note: with JP5 open, you can also carry out memory storage in manual

mode. Leaving the JP5 bridge open, and having a MITTO transmitter

already memorized in the receiver, you can also memorize other transmitters

by radio, as explained below:

a) Send the secret code of the transmitter already memorised. In the case

of TRC1-2/MITTO2-4 transmitters, press the hidden P1 button (fig.2). In the

case of TRC4, the P1 button function corresponds to pressing the 4

transmitter buttons simultaneously or, after opening the battery compartment,

bridging the two P1 points with a screwdriver (fig.2).

b) Press the T key which is also to be assigned to the new transmitter.

c) Transmit the secret code of the new transmitter to be memorized.

d) Press the T key which is to be assigned to the new transmitter.

e) To memorise another transmitter, repeat the sequence from step (c)

N° radio control

Receiver versions

Intric

Intric 512

Intric 2048

128

512

2048

Page 3

354

D811249_06

within a maximum time of 10-15 seconds, otherwise the receiver will come

out of the programming mode.

f) To copy another key, repeat the sequence from step (a) and wait for the receiver to

come out of the programming mode (or disconnect the receiver from the power supply).

Note: Maximum protection from memory storage of foreign codes is

obtained by presetting the JP5 jumper closed and programming in

MANUAL mode or by means of the UNIPRO mod. programmer.

5.3) UNIPRO mod. Universal programmer (Fig.4-Fig.5)

To use the programmer, see the respective instructions. Transmitter -

Connect the UNIPRO programmer to the transmitter by means of the

UNITRC/UNIMITTO and UNIFLAT accessories supplied. Receiver Connect the UNIPRO programmer to the INTRIC receiver by means of the

UNIDA and UNIFLAT accessories supplied. The system will not support

the power input of the UNIPRO programer.

6) MAINTENANCE

The maintenance of the system should only be carried out by qualified

personnel regularly. The MITTO transmitters are supplied by two 3V

lithium battiers (type CR2016).The TRC transmitters are powered by a 12V

alkaline battery.When replacing the batteries type CR2016 do not touch the

poles with thehands.

Any reduction in the transmitter capacity may be due to the batteries getting

flat. When the led of the transmitter flashes, it means that the batteries are

flat and must be replaced.

7) DISPOSAL

ATTENTION: disposal should only be carried out by qualified personnel.

Materials must be disposed of in conformity with the current regulations.

In case of disposal, the system components do not entail any particular

risks or danger. In case of recovered materials, these should be sorted out

by type (electrical components, copper, aluminium, plastic etc.).

For battery disposal, refer to the current regulations.

The descriptions and illustrations contained in the present manual

are not binding. The Company reserves the right to make any

alterations deemed appropriate for the technical, manufacturing

and commercial improvement of the product, while leaving its

essential features unchanged, at any time and without undertaking

to update the present publication.

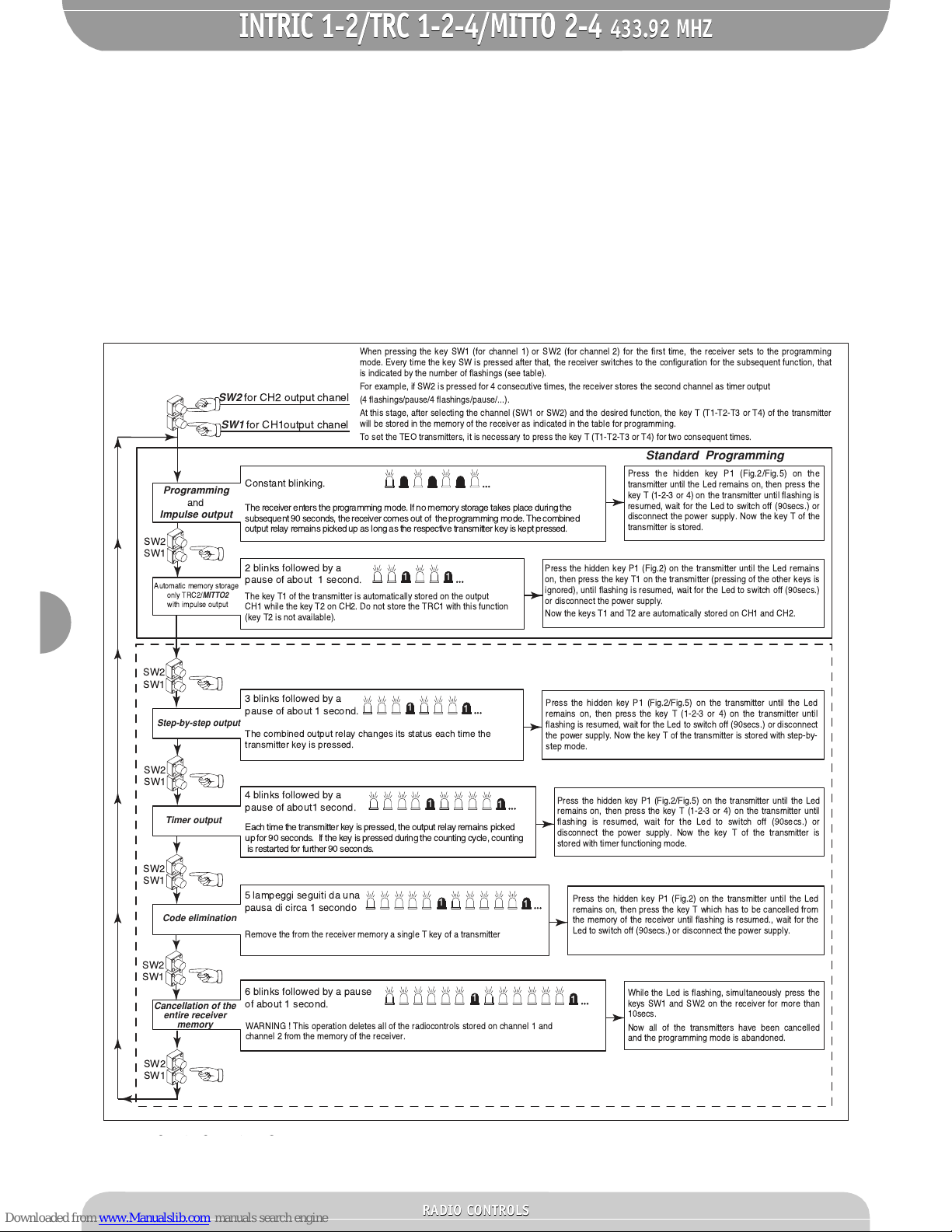

Advanced Programming

When pressing the key SW1 (for channel 1) or SW2 (for channel 2) for the first time, the receiver sets to the programming

mode. Every time the key SW is pressed after that, the receiver switches to the configuration for the subsequent function, that

is indicated by the number of flashings (see table).

For example, if SW2 is pressed for 4 consecutive times, the receiver stores the second channel as timer output

(4 flashings/pause/4 flashings/pause/...).

At this stage, after selecting the channel (SW1 or SW2) and the desired function, the key T (T1-T2-T3 or T4) of the transmitter

will be stored in the memory of the receiver as indicated in the table for programming.

To set the TEO transmitters, it is necessary to press the key T (T1-T2-T3 or T4) for two consequent times.

The receiver enters the programming mode. If no memory storage takes place during the

subsequent 90 seconds, the receiver comes out of the programming mode. The combined

output relay remains picked up as long as the respective transmitter key is kept pressed.

Constant blinking.

Standard Programming

Press the hidden key P1 (Fig.2/Fig.5) on the

transmitter until the Led remains on, then press the

key T (1-2-3 or 4) on the transmitter until flashing is

resumed, wait for the Led to switch off (90secs.) or

disconnect the power supply. Now the key T of the

transmitter is stored.

Press the hidden key P1 (Fig.2) on the transmitter until the Led remains

on, then press the key T1 on the transmitter (pressing of the other keys is

ignored), until flashing is resumed, wait for the Led to switch off (90secs.)

or disconnect the power supply.

Now the keys T1 and T2 are automatically stored on CH1 and CH2.

Press the hidden key P1 (Fig.2/Fig.5) on the transmitter until the Led

remains on, then press the key T (1-2-3 or 4) on the transmitter until

flashing is resumed, wait for the Led to switch off (90secs.) or disconnect

the power supply. Now the key T of the transmitter is stored with step-by-

step mode.

Press the hidden key P1 (Fig.2/Fig.5) on the transmitter until the Led

remains on, then press the key T (1-2-3 or 4) on the transmitter until

flashing is resumed, wait for the Led to switch off (90secs.) or

disconnect the power supply. Now the key T of the transmitter is

stored with timer functioning mode.

Press the hidden key P1 (Fig.2) on the transmitter until the Led

remains on, then press the key T which has to be cancelled from

the memory of the receiver until flashing is resumed., wait for the

Led to switch off (90secs.) or disconnect the power supply.

While the Led is flashing, simultaneously press the

keys SW1 and SW2 on the receiver for more than

10secs.

Now all of the transmitters have been cancelled

and the programming mode is abandoned.

SW2

for CH2 output chanel

SW2

SW1

The combined output relay changes its status each time the

transmitter key is pressed.

3 blinks followed by a

pause of about 1 second.

SW2

SW1

Each time the transmitter key is pressed, the output relay remains picked

up for 90 seconds. If the key is pressed during the counting cycle, counting

is restarted for further 90 seconds.

4 blinks followed by a

pause of about1 second.

SW2

SW1

Remove the from the receiver memory a single T key of a transmitter

5 lampeggi seguiti da una

pausa di circa 1 secondo

SW2

SW1

WARNING ! This operation deletes all of the radiocontrols stored on channel 1 and

channel 2 from the memory of the receiver.

1

1

1

1

1

1

6 blinks followed by a pause

of about 1 second.

SW2

SW1

1

1

SW1

for CH1output chanel

SW2

SW1

2 blinks followed by a

pause of about 1 second.

1

1

The key T1 of the transmitter is automatically stored on the output

CH1 while the key T2 on CH2. Do not store the TRC1 with this function

(key T2 is not available).

Programming

and

Impulse output

Automatic memory storage

only TRC2/

MITTO2

with impulse output

Step-by-step output

Timer output

Code elimination

Cancellation of the

entire receiver

memory

RADIO CONTROLS

RADIO CONTROLS

INTRIC 1-2/TRC 1-2-4/MITTO 2-4 433.92 MHZ

INTRIC 1-2/TRC 1-2-4/MITTO 2-4 433.92 MHZ

Page 4

355

D811249_06

PROGRAMMAZIONE BASE - BASIC PROGRAMMING - PROGRAMMATION DE BASE - BASIS-PROGRAMMIERUNG - PROGRAMACIÓN BASE - PROGRAMAÇÃO BASE

Premere una volta il tasto SW1

Press the key SW1 once

Appuyer une fois sur la touche SW1

Einmal die Taste SW1 drücken.

Presione una vez la tecla SW1

Pressionar uma vez a tecla SW1

1

Premere una volta il tasto SW2

Press the SW2 once

Appuyer une fois sur la touche SW2

Die Taste SW2 einmal drücken.

Presione una vez la tecla SW2

Pressionar uma vez a tecla SW2

6

IL Led comincia a lampeggiare

The Led begins to flash

La led commence clignoter

Die Led beginnt zu blinken.

El led empieza a parpadear

O led começa a piscar

Premere il tasto P1 fino a che il Led del ricevitore resta acceso

Press the key P1 until the Led of the receiver stays on

Appuyer sur la touche P1 jusqu' ce que la Led du rcepteur reste allume

Die Taste P1 drücken, bis die Led des Empfängers eingeschaltet bleibt.

Presione la tecla P1 hasta que el led del receptor se encienda

Pressionar a tecla P1 até que o Led do receptor fica aceso

2

IL Led comincia a lampeggiare

The Led begins to flash

La led commence clignoter

Die Led beginnt zu blinken.

El led empieza a parpadear

O led comea a piscar

7

Attendere che il led si spenga

Wait for the Led to switch off

Attendre que la led s'teint

Warten, bis die Led erlischt.

Espere a que el led se apague

Aguardar que o led se apague

5

3

Premere il tasto P1 fino a che il Led del ricevitore resta acceso

Press the key P1 until the Led of the receiver stays on

Appuyer sur la touche P1 jusqu' ce que la Led du rcepteur reste allume

Die Taste P1 drücken, bis die Led des Empfängers eingeschaltet bleibt.

Presione la tecla P1 hasta que el led del receptor se encienda

Pressionar a tecla P1 até que o Led do receptor fica aceso

8

Premere il tasto T1 fino a che il LED del ricevitore riprende a lampeggiare

Press the key T1 until the Led of the receiver begins to flash again

Appuyer sur la touche T1 jusqu' ce que la LED du rcepteur recommence clignoter

Die Taste T1 drücken, bis die Led des Empfängers wieder zu blinken beginnt.

Presione la tecla T1 hasta que el led del receptor vuelva a parpadear

Pressionar a tecla T1 até que o LED do receptor recomeça a piscar

4

Attendere che il led si spenga

Wait for the Led to switch off

Attendre que la led s'teint

Warten, bis die Led erlischt.

Espere a que el led se apague

Aguardar que o led se apague

10

Premere il tasto T2 fino a che il LED del ricevitore riprende a lampeggiare

Press the key T2 until the Led of the receiver begins to flash again

Appuyer sur la touche T2 jusqu' ce que la LED du rcepteur recommence clignoter

Die Taste T2 drücken, bis die Led des Empfängers wieder zu blinken beginnt.

Presione la tecla T2 hasta que el led del receptor vuelva a parpadear

Pressionar a tecla T2 até que o LED do receptor recomeça a piscar

9

PROGRAMMAZIONE BASE INTRIC2

Uscita impulsiva1e2(per comandare ad esempio lo

start di una centrale di comando e l'apertura pedonale

della stessa)

BASIC PROGRAMMING OF INTRIC2

Impulsive output 1 and 2 (to activate, for example, a

control unit and its

pedestrian opening)

PROGRAMMATION DE BASE INTRIC2

Sortie impulsive 1 et 2 (pour commander par exemple

le start d'une unit de commande et l'ouverture

pitonne de l'unit)

BASIS-PROGRAMMIERUNG INTRIC2

Impuls-Ausgang 1 und 2 (um zum Beispiel den Start

einer Steuerzentrale und deren Fußgängeröffnung zu

befehligen)

PROGRAMACIîN BASE INTRIC2

Salida impulsiva 1 y 2 (para activar, por ejemplo, el

start de una central de mando y la apertura peatonal

de la misma)

PROGRAMAÇÃO BASE INTRIC2

Saída impulsiva 1 e 2 (para comandar por exemplo o

start de uma central de comando e a função abertura

do postigo da mesma)

TRC MITTO

TRC MITTO

TRC MITTO

TRC

MITTO

I

GB

F

D

E

P

RADIO CONTROLS

RADIO CONTROLS

INTRIC 1-2/TRC 1-2-4/MITTO 2-4 433.92 MHZ

INTRIC 1-2/TRC 1-2-4/MITTO 2-4 433.92 MHZ

Page 5

356

D811249_06

Fig. 2

Fig. 1

T1 T2

T3 T4

T1 T2

SW2

DL1

JP5

SW1

75.00

75.00

45.00

16.00

45.00

16.00

MITTO 2

MITTO 4 TRC 1-2 TRC4

P1

Contatti

Contacts

Contacts

Kontakte

Contactos

Contatos

CH1

CH2

+

24vac/12vdc

P1

T1

Led

T2

P1

P1

TRC4

T1

T2

T3

T4

44

18.5

82

T3

T2

T4

T1

16

12.5

65

35

T2

T1

OK!

MITTO 2-4

TRC 1-2

RADIO CONTROLS

RADIO CONTROLS

INTRIC 1-2/TRC 1-2-4/MITTO 2-4 433.92 MHZ

INTRIC 1-2/TRC 1-2-4/MITTO 2-4 433.92 MHZ

Page 6

357

D811249_06

Fig. 3

TEO 4

T4

T4

T3

T3

T2

T2

T1

T1

T1

T1

T2

T2

12V

ALKALINE BATTERY

-

+

ON

10987654321

TEO 2

TRC1-2

TRC4

UNIDA

UNIFLAT

UNITRC

UNITRC

UNIFLAT

UNIPRO

UNIFLAT

Contatti

Contacts

Contacts

Kontakte

Contactos

Contatos

JP2

TRC1-2

INTRIC 1-2

Contatti

Contacts

Contacts

Kontakte

Contactos

Contatos

UNITRC

1

3

4

12

3

4

Fig. 4

TRC 4

RADIO CONTROLS

RADIO CONTROLS

INTRIC 1-2/TRC 1-2-4/MITTO 2-4 433.92 MHZ

INTRIC 1-2/TRC 1-2-4/MITTO 2-4 433.92 MHZ

Page 7

358

D811249_06

Fig. 5

UNIDA

UNIFLAT

UNIMITTO

MITTO 2-4

UNIPRO

UNIFLAT

Contatti

Contacts

Contacts

Kontakte

Contactos

Contatos

JP2

INTRIC 1-2

UNIMITTO

P1

RADIO CONTROLS

RADIO CONTROLS

INTRIC 1-2/TRC 1-2-4/MITTO 2-4 433.92 MHZ

INTRIC 1-2/TRC 1-2-4/MITTO 2-4 433.92 MHZ

Loading...

Loading...