Page 1

Phone: (888) 845-9800 Fax: (800) 253-5168 Website: www.beverageair.com

REFRIGERATOR & FREEZER

UCR/WTR/SPE – UCF/WTF

(Under Counter, Work Top and Sandwich Prep Models)

Installation, Operation and Troubleshooting Manual

R290 VERSION

1

809-112A Rev C 2017-03-15

Page 2

THANK YOU!

Thank you for purchasing a Beverage-Air cabinet. This series has passed our strict quality control

inspection and meets the high standards set by Beverage-Air Refrigeration! You have made a quality

investment that with proper maintenance will give you many years of reliable service!

Please read the following installation and maintenance instructions before installing or using your unit. If

you have any questions, Please call our Technical Service Department at (800) 684-1195.

Important Information, Please Read

* PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLING OR USING, IF

RECOMMENDED PROCEDURES ARE NOT FOLLOWED, WARRANTY CLAIMS MAY BE DENIED.

* Your warranty registration information is located on the next page of this manual. Please complete he

card and submit it to Beverage-Air Refrigeration within TEN days of installation. Failure to properly

register equipment may limit or void the warranty.

* Beverage-Air Refrigeration reserves the right to change specifications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes, improvements, additions, or

replacements for previously purchased equipment.

REMEMBER, SAFETY FIRST. PLEASE BE SAFE AT ALL TIMES

When using electrical appliances, basic safety measures should always be taken. These include, but are

NOT limited to:

-following manufacturers installation instructions

-not allowing children to climb on or around equipment

-having service done only by qualified technicians

IMPORTANT – HC MODELS

Please use care when moving or handling this equipment. It is

equipped with flammable refrigerant and damage to refrigerant

tubing will increase the risk of a leak.

When service is required, seek factory authorized technicians

trained to safely maintain and service systems that utilize

flammable refrigerants, such as R290. RSES offers such

training and certification.

Use factory authorized replacement parts to minimize the risk of

possible ignition.

2

809-112A Rev C 2017-03-15

Page 3

IMPORTANT

You may mail this completed page to Beverage-Air or register on line at www.beverage-

air.com

NOTE: The mail-in form must be filled out and forwarded to Beverage-Air by the

installer or customer within 10 days after start-up. Failure to do this may

invalidate the warranties. Retain this information for your records.

3779 Champion Blvd,

Winston-Salem, NC 27105

TEL: (888) 845-9800

FAX: (800) 253-5168

Cabinet Model No.____________

Cabinet Serial No.____________

WARRANTIES NOT VALID UNLESS REGISTERED AT FACTORY

WITHIN 10 DAYS AFTER START-UP DATE.

ORIGINAL DATE OF

INSTALLATION________________________________________________________

CUSTOMER

NAME______________________________________________PHONE____________________

STREET_______________________________________STATE_______ZIP CODE__________

DEALER’S

NAME____________________________________PHONE____________________________

STREET________________________________________STATE_______ZIP CODE________

INFORMATION

This cooler has passed all Quality Control Inspections

and meets the high standards of Beverage-Air Refrigeration.

This inspection includes complete refrigeration system, cabinet construction, and finish

IMPORTANT

PLEASE RETAIN FOR YOUR RECORDS

You may mail this completed page to Beverage-Air Refrigeration or register on line at

www.Beverage-Airrefrigeration.com

NOTE: The mail-in form must be filled out and forwarded to Beverage-Air by the

installer or customer within 10 days after start-up. Failure to do this may

invalidate the warranties. Retain this information for your records.

809-112A Rev C 2017-03-15

3

Page 4

LIMITED WARRANTY

(Continental US Only)

The Seller warrants to the original purchaser, equipment manufactured by the Seller shall be free from

defects in material or workmanship for which it is responsible. The Seller’s obligation under this warranty

shall be limited to replacing or repairing at Seller’s option, without charge, F.O.B. Seller’s factory, any part

found to be defective and any labor and material expense incurred by Seller in replacing or repairing such

part, such warranty to be limited to a period of twelve (12) months from the date of installation, provided,

however, installation occurs within three (3) months of date of purchase and equipment is in normal use

and service and is installed in accordance with manufacturer’s recommendations and provided terms of

payment have been fully met. All labor shall be performed during regular working hours. Overtime

premium charges shall be at the Buyers expense.

Proof of purchase must be provided to the Seller to validate warranty. This warranty is valid only if

equipment is properly installed, started-up, and inspected by the dealer or authorized Beverage-Air

Service agent.

Removal or alteration of the serial/data plate from any equipment shall be deemed to release Seller from

all warranty obligations, expressed or implied.

This warranty does not cover Thermostat, Controller, Thermometer, or Defrost Timer calibration and/or

adjustment, freight damage, normal maintenance items outlined in the Owner’s Manual, adjustment of

door mechanisms, or replacement or door gaskets, light bulbs, fuses, or batteries. The warranty does not

cover installation, start-up, normal maintenance, food loss or other consequential damage.

Any repairs or replacement of defective parts shall be performed by Seller’s authorized service personnel.

Seller shall not be responsible for any costs if the work is performed by other than Seller’s authorized

personnel. Reimbursement claims for part(s) or labor service costs must be made in writing. Model,

cabinet serial numbers and installation location must be shown on the claim. A receipted bill from the

servicing agency must accompany the claim, together with full details of the service problems, diagnosis

and work performed. Beverage-Air will determine at its sole discretion whether further documentation on

a claim is to be submitted.

Seller shall not be liable for consequential damages of any kind which occur during the course of

installation of equipment or which result from the use or misuse by Buyer, it’s employees or others of the

equipment supplied. Hereunder, and Buyers sole and exclusive remedy against seller for any breach of

the foregoing warranty or otherwise shall be for the repair or replacement of the equipment or parts

thereof affected by such breach.

The foregoing warranty shall be valid and binding upon Seller if, and only if, Buyer loads operates and

maintains the equipment supplied hereunder in accordance with the instruction manual provided to Buyer.

Seller does not guarantee the process of manufacture by Buyer or the quality of the product to be

produced by the equipment supplied hereunder and Seller shall not be liable for any prospective lost

products or profits of Buyer.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND

IMPLIED WARRANTIES WHATSOEVER. SPECIFICALLY THERE ARE NO IMPLIED WARRANTIES OF

MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE. The foregoing shall be sellers

sole and exclusive obligation and Buyers sole and exclusive remedy for any action, whether in breach of

contract or negligence. In no event shall Seller be liable for a sum in excess of the purchase price of the

item.

4

809-112A Rev C 2017-03-15

Page 5

TABLE of CONTENTS

1. Introduction

1.1 Beverage-Air Refrigeration / Freezer 7

1.2 Glossary of Terms 7

2 Installation

2.1 Receiving and Inspection 9

2.2 Uncrating 9

2.3 Placement 9

2.4 Set-up 10

A. Roll In 10

B. Reach In 10

2.5 Leveling, Shelves and Bumper Install 10

2.6 Cleaning 12

2.7 Power Supply 12

2.8 Controller 12

2.9 Installation Checklist 12

3 Unit Start-up

3.1 Sequence of Operations 13

3.1.1 Refrigerator 13

3.1.2 Freezer 14

3.2 Electronic Controller 15

3.2.1 Control Panel Display 15

3.2.2 Control Panel Connections 15

3.2.3 Keyboard Functions 16

3.2.4 Changing the Set point 17

3.2.5 Viewing the current Probe Temperature 18

3.2.6 Electronic Controller Parameters 19

3.2.7 How To View Alarms 20

3.2.8 Entering StandBy Mode 21

3.2.9 Exiting StandBy Mode 21

4 Preventative Maintenance

4.1 Daily Exterior 22

4.2 Weekly Interior 22

4.3 Monthly Condenser 22

4.4 Periodic Gaskets 22

4.5 Drawers 23

4.6 Effectively Cleaning Stainless Steel 24

5 Trouble Shooting Chart

5.1 General 26

5.2 Refrigerator Ladder Diagram 27

5.3 Freezer Ladder Diagram 28

5

809-112A Rev C 2017-03-15

Page 6

INTRODUCTION

1.1 Description

Beverage-Air Refrigeration products, refrigerators and freezers, are distinctly designed to accommodate a

wide variety of food service needs and situations. Beverage-Air products are designed to keep

refrigerated products at 38 F, while frozen products are kept at 0 F for maximum safety and freshness.

1.2 Glossary of Terms

Compressor - The compressor is the heart of the system. The compressor does just what it’s name

states. It compresses the low pressure refrigerant vapor from the evaporator and compresses it into a

high pressure vapor. The inlet to the compressor is called the “Suction Line”. It brings the low pressure

vapor into the compressor. After the compressor compresses the refrigerant into a high pressure Vapor,

the vapor is pumped into the “Discharge Line”.

Condenser Coil - The “Discharge Line” leaves the compressor and runs to the inlet of the condenser coil

located on top of the cabinet. Because the refrigerant is compressed, it is a hot high pressure vapor (as

pressure goes up – temperature goes up). The hot vapor enters the condenser coil and starts to flow

through the tubes. Cool air is blown across the outside of the finned tubes of the condenser coil (usually

by a fan or water with a pump). Since air is cooler than the refrigerant, heat moves from the refrigerant to

the cooler air (energy goes from hot to cold – “latent heat”). As the heat is removed from the refrigerant, it

reaches it’s “saturated temperature” and starts to condense (change states), into a high pressure liquid.

The high pressure liquid leaves the condenser coil through the “liquid line” and travels to the “metering

device”. Sometimes running through a filter dryer first, removes any dirt or foreign particles.

Defrost - The term is used to identify the function of a refrigerator or freezer to remove frost or ice from

the internal evaporator coil.

Differential - An increment between where the compressor turns on and off.

Setpoint - This is the refrigerator or freezer cut out temperature set by the operator. Prior to shipping,

refrigerators are factory preset at 35°F and freezers are factory preset at -4°F.

6

809-112A Rev C 2017-03-15

Page 7

INSTALLATION

I

WARNING: If it is necessary to move the cooler after removal from the skid,

remove all doors and carefully push the unit at a point of no more than 36” from

the bottom to avoid damage. It is an NSF requirement that all rollin-in/roll-thru units

be sealed to the floor upon installation.

WARNING: UNIT MUST BE BLOCKED AND SECURED WHEN

REMOVING SKID

2.1 Receiving and Inspecting

Prior to shipping, all Beverage-Air products are factory tested for performance and thoroughly inspected

to ensure they are free of any defects. Upon receipt, carefully examine the unit for any damage that may

have occurred during shipping and delivery. Any damage, discrepancies, overages, or shortages should

be noted on the carrier’s Bill of Lading and a freight claim must be immediately filed with the carrier. If

damage is noted after receipt, contact the carrier’s local terminal and file a freight claim. In either case, IT

IS IMPORTANT THAT ALL ORIGINAL CARTONS, CRATES, AND INTERIOR PACKAGING MATERIAL

ARE SAVED UNTIL INSPECTION HAS BEEN MADE BY THE DELIVERING CARRIER

NOTE: If the unit is laid down for any reason, the fluids in the compressor will drain out. To

prevent damage to the unit it MUST be allowed to sit upright for a minimum of One (1) hour prior

to starting up unit.

2.2 Uncrating

* Tools Needed: ¾” box wrench, adjustable wrench, level, flat head screw driver, and box cutter.

1. First, remove the cardboard top capping, all clear tape, and all staples including those at the b

bottom of the cardboard carton and skid.

2. Next, start from the top of the carton. Using the box cutter, carefully make one continuous

cut to the bottom of the skid. Remove cardboard carton and discard.

*Note: additional clear plastic protective wrap is applied directly to any product with a glass door.

3. Then, move unit as close to final position as possible before removing the skid.

4. Finally, tip the unit forward and remove the skid. Remove the shipping bolts using the ¾” box

wrench while cabinet is held in one direction. Then repeat the process while the cabinet is held in

the opposite direction.

2.3 Placement

Consider the following when selecting a location for your cooler:

1. Clearance:

2. Floor Load: the floor on which the cooler is located must be even and level, free from

vibrations, and strong enough to support the combined weights of the unit and maximum

product load.

3. Ventilation

4. Power Outlet: Dedicated power outlet is located within 8 feet of length of cord.

809-112A Rev C 2017-03-15

7

Page 8

INSTALLATION

WARNING: unit must be blocked and secured prior to installing casters

2.4 Cooler Set-up for Reach In units

With Legs or Casters

1. Legs and casters must be screwed in by hand. Use the threaded holes located on the bottom

of the cabinet. None of the threads on the leg or caster stem should be visible once

screwed in. Once the caster cannot be turned any further, use the ¾’ box wrench to

tighten the nut in between the mounting plate and the wheel of the caster until snug.

2. Tilt the cabinet in one direction approximately 8” and block it securely with pieces of 2x4

lumber or other suitable material.

3. Screw in the two accessible legs/casters

4. Repeat this procedure with unit secured in the opposite direction so as to access the

remaining legs/casters

2.5 Leveling, Bumpers and Shelves

2.5.1 Leveling:

Cabinets must be leveled when installed. Level should be measured on the headrail.

Failure to level your cabinet may result in door not sealing, closing correctly, or

condensed water draining not draining properly.

For cabinets with legs, rotate the foot of the leg with an adjustable wrench to achieve

desired height for leveling.

For cabinets with casters, leveling can be achieved by placing large washers in between

the ½’ stud and the holes located on the bottom of the case.

2.5.2 Bumpers:

Bumpers and screws are included in the zip lock bag.

Remove one screw frome each end of the top rear and discard screws. Attach the

bumpers in the same locations, using the longer screws provided.

8

809-112A Rev C 2017-03-15

Page 9

INSTALLATION

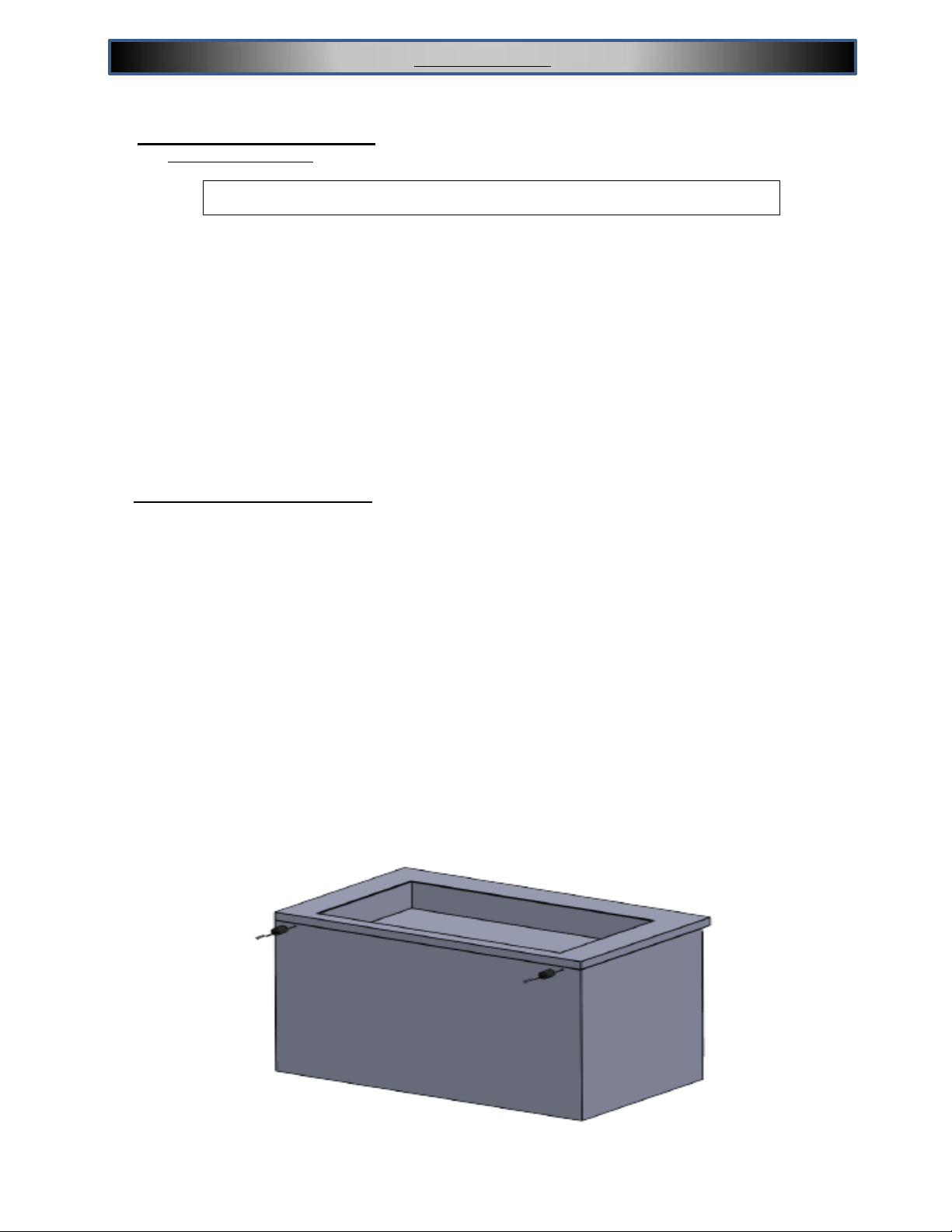

2.5 Leveling, Bumpers and Shelves

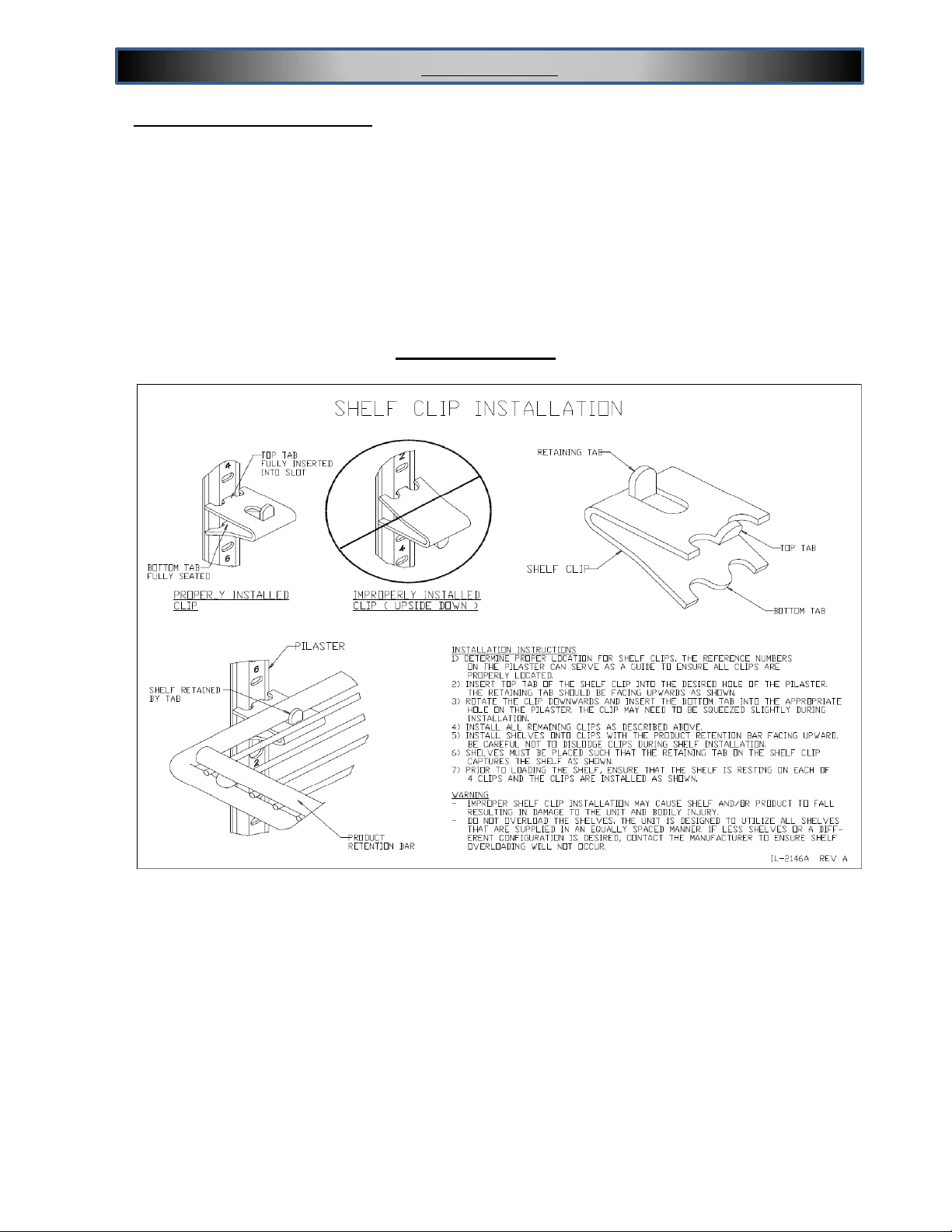

2.5.3 Shelves:

All cabinets with shelves are supplied with pilasters and shelf clip supports. Shelves are

easily installed by inserting the shelf support clips into the pilasters so that they fit

tightly.

Adjust the shelf so that the smaller fill wires run from front to rear and the shelf frame

wire rest the shelf on the clips.

SHELVING ASEMBLY

9

809-112A Rev C 2017-03-15

Page 10

INSTALLATION

Warning: Cabinet MUST NOT SHARE A RECEPTACLE with another piece of equipment

WARNING: DO NOT clean with any product containing bleach or ammonia. Rinse

with clean water before drying with clean cloth.

2.6 Cabinet Cleaning

Prior to use, the interior and exterior surfaces of the cabinet should be cleaned thoroughly with warm

water, mild detergent, and a soft cloth. Apply with a dampened cloth and wipe in the direction of the metal

grain. Then allow to air dry with the doors open. Only use a clean soft cloth. See detailed cleaning

instructions in the Preventative Maintenance section below.

2.7 Electrical supply

115 volt self-contained units are provided with a 15 or 20 amp power chord with plug that is shipped

coiled on top of the cabinet. The power cord is equipped with a three prong (grounding) plug which is to

be used in an appropriately rated and dedicated three prong (grounding) receptacle.

*NOTE: have a wall outlet checked by a qualified electrician for polarity and proper grounding

prior to plugging in the power cord.

For units not provided with a power cord, the electrical connection should be made by a qualified

electrician and in accordance with local electrical codes. The electrical requirements are located on the

rating (or data plate) located on the left hand side of the interior of the cabinet. Use of a dedicated circuit

with separate grounding wire is required.

2.8 Controller

The controls are designed for the refrigeration units to maintain a product temperature of 38 F and the

freezers to maintain a product temperature of 0 F. See section 3.1 for control display information.

2.9 Installation Checklist

After the cabinet has been installed, leveled, and cleaned as described above, refer to the following check

list:

Check for proper electrical hook-up.

Check that all clearances are in line with the aforementioned guidelines.

Check that cabinet is level.

* NOTE: Once the unit has been started and reaches proper storage temperatures, it may be

loaded with product. For proper energy efficiency and airflow we recommend a minimum1”

clearance between product and side walls, 4” clearance between product and ceiling, and 1”

clearance from the bottom of the unit.

10

809-112A Rev C 2017-03-15

Page 11

UNIT STARTUP

ON

OFF

COMPONENT

OPERATION

CONTROLLER

ACTION

OPERATION

CONTROLLER

ACTION

COMPRESSOR

Compressor turns

on when the air

temperature at the

probe is above the

sum of the set point

and the dead band

The Compressor

Contact is energized

Compressor turns off

when the air

temperature at probe is

equal to or less than

the set point

The Compressor

Contact is de-

energized

(nEW974 - Terminal

#4)

(nEW974 - Terminal

#4)

CONDENSER

FAN

The Condenser Fan

turns on when the

Compressor is

running

The Condenser Fan is

wired to the

Compressor Contact

The Condenser Fan

turns off when the

Compressor is not

running

The Condenser Fan

is wired to the

Compressor Contact

(nEW974 - Terminal

#4)

(nEW974 - Terminal

#4)

EVAPORATOR

FAN

The Evaporator Fan

runs continuously.

When the unit is

plugged in, the

Evaporator Fan will

run.

The Evaporator Fan is

connected directly to

incoming power, not

through the controller.

The Evaporator Fan

runs continuously.

When the unit is

plugged in, The

Evaporator Fan will run.

The Evaporator Fan

is connected directly

to incoming power,

not through the

controller.

LIGHT

The light will turn on

when the is

pressed

The Light Contact is

energized

The light will turn off

when the

is pressed

The Light Contact is

de-energized

(nEW974 - Terminal

#3)

(nEW974 - Terminal

#3)

PROBE IS LOCATED

BEHIND EVAPORATOR

COVER

3.1 Sequence of Operations

3.1.1 Refrigerator

The refrigerator operates based on the air temperature measured by the probe located at the

return air.

809-112A Rev C 2017-03-15

11

Page 12

UNIT STARTUP

PROBE IS LOCATED

BEHIND EVAPORATOR

COVER

Condition

Compressor

Condenser

Fan

Evaporator

Fan

Lights

Cabinet Temp > Setpoint + Deadband

ON

ON

ON

ON or OFF

Cabinet Temperature <= Sepoint

OFF

OFF

ON

ON or OFF

Defrost

OFF

OFF

ON

ON or OFF

3.1.2 Freezer

The freezer operates based on the air temperature measured by the probe located at the return

air.

809-112A Rev C 2017-03-15

12

Page 13

UNIT START UP

ON

OFF

COMPONENT

OPERATION

CONTROLLER

ACTION

OPERATION

CONTROLLER

ACTION

COMPRESSOR

Compressor turns

on when the air

temperature at the

probe is above the

sum of the set point

The Compressor

Contact is energized

Compressor turns

off when the air

temperature at

probe is equal to or

less than the set

point

The Compressor

Contact is de-energized

(nEW974 - Terminal #4)

(nEW974 - Terminal #4)

CONDENSER

FAN

The Condenser Fan

turns on when the

Compressor is

running

The Condenser Fan is

wired to the

Compressor Contact

The Condenser

Fan turns off when

the Compressor is

not running

The Condenser Fan is

wired to the

Compressor Contact

(nEW974 - Terminal #4)

(nEW974 - Terminal #4)

EVAPORATOR

FAN

The Evaporator Fan

turns on when the

Compressor is

running

The Evaporator Fan is

wired to the

Compressor Contact

The Evaporator

Fan turns off when

the Compressor is

not running

The Evaporator Fan is

wired to the

Compressor Contact

(nEW974 - Terminal #4)

(nEW974 - Terminal #4)

DEFROST

HEATER

The Defrost Heater

is on a timer; set at

4 to 6 equally

spaced defrost

periods each day

The Defrost Heater

Contact is energized

When either the

defrost is not

scheduled or the

temperature at

defrost probe has

reached the defrost

termination

temperature.

The Defrost Heater

Contact is de-energized

(nEW974 - Terminal #2)

(nEW974 - Terminal #2)

FACE/DOOR

HEATERS

The Face & Door

Heaters turn on

when the

Compressor is

running

The Door/Face Heater

are wired to the

Compressor Contact

The Face & Door

Heaters turn off

when the

Compressor is not

running

The Door/Face Heater

are wired to the

Compressor Contact

(nEW974 - Terminal #4)

(nEW974 - Terminal #4)

LIGHT

The light will turn on

when the is

pressed

The Light Contact is

energized

The light will turn

off when the

is pressed

The Light Contact is de-

energized

(nEW974 - Terminal #3)

(nEW974 - Terminal #3)

Condition

Compressor

Condenser

Fan

Evaporator

Fan

Defrost

Heater

Face/Door

Heater

Drain Heater

Lights

Cabinet Temp > Setpoint + Deadband

ON

ON

ON

OFF

ON

ON

ON or OFF

Cabinet Temperature <= Sepoint

OFF

OFF

OFF

OFF

OFF

ON

ON or OFF

Defrost

OFF

OFF

OFF

ON

OFF

ON

ON or OFF

809-112A Rev C 2017-03-15

13

Page 14

UNIT STARTUP

Defrost LED

Alarm LED

On fixed:

Automatic defrost active

On fixed:

ALARM Present

Flashing:

Manual defrost active

Flashing:

ALARM Silenced

Off:

Defrost is off

Off:

No Alarm

Aux LED

Compressor LED

On fixed:

AUX output active

On fixed:

Compressor active

Off:

AUX output Off

Flashing:

Delay, protection or activation blocked

Off:

No Alarm

UP

Press and release

•

Scrolls the menu items

•

Increases the values

DOWN

Press and release

•

Scrolls the menu items

•

Decreases the values

STAND-BY (ESC)

Press and release

•

Returns up one level with respect to

the

current menu

•

Confirms the parameter value

SET (ENTER)

Press and release

•

Accesses the machine status menu

and

displays any alarms (if present)

STAND-BY (ESC)

SET (ENTER)

MANUAL DEFROST

(FREEZER)

LIGHT ON/OFF

NOTE: When switched on, the instrument panel performs a lamp test and for a few seconds, the display and LEDs flash to verify

their condition and proper operation.

3.2 Electronic Controller

3.2.1 Control Panel Display

3.2.2 Keyboard Functions

3.2.3 Control Panel Connections

809-112A Rev C 2017-03-15

14

Page 15

UNIT START UP

3.2.4 Changing the Setpoint

Press and release the button to enter the machine status menu.

The screen will display SP

Press and release the button again to see the current set point value (see image

below).

To adjust to a different value press and release the and buttons.

Press and release the button to accept the value.

Press and release the button to exit out of the machine status menu.

15

809-112A Rev C 2017-03-15

Page 16

UNIT START UP

3.2.5 Viewing the current Probe Temperature

Press and release the button to enter the machine status menu.

The screen will display SP

Use the and buttons to change the display to S1

Press and release the button to view the current sensor value.

16

809-112A Rev C 2017-03-15

Page 17

UNIT START UP

Label

Descripti

Cause

Effects

Troubleshooting

E1

Pb1probe

error (cell)

• Reading of values outside the

operating range

• Probe is inoperable /short

circuit/open

• Display of label E1

• Fixed alarm icon

• Disabling of the max/min

alarm regulator

• Compressor operation

based on the

parameters P0 and P1

• Check the type of

probe (NTC)

• Check the probe wiring

• Replace the probe

E2

Pb2 probe

error

(defrosting)

• Reading of values outside the

operating range

• Probe is inoperable/short

circuit/open

• Display of label E2

• Fixed alarm icon

• Defrosting ends due to time

out (d3)

• The evaporator fans are

disabled

• Check the type of

probe (NTC)

• Check the probe wiring

• Replace the probe

Ht

HIGH alarm

Pb1

temperature

Value read by Pb1 > A2 after

time equal to A7.

(see ‘TEMP. ALARMS

MAX/MIN’)

• Recording of label Ht in the AL

folder

• Fixed alarm icon

• No effect on regulation

Wait for the value ready

by Pb1 to return below

A2-A1

Lt

LOW alarm

Pb1

temperature

Value read by Pb1 < A3 after

time equal to A7.

(see ‘TEMP. ALARMS

MAX/MIN’)

• Recording of label Lt in the AL

folder

• Fixed alarm icon

• No effect on regulation

Wait for the value ready

by Pb1 to return above

A3+A1.

EA

External

alarm

Activation of the digital

input (i3 = 6)

• Recording of label EA in the

AL folder

• Fixed alarm icon

Check and remove

the external cause

that caused the

alarm on D.I.

ES

Energy

Saving +

reduced set

point

• Activation of the digital

input (i3 = 1,5, 8)

• Activation from key if H1...3=2

(see paragraph Key

Functions)

• Display of label ES

alternating with the

setpoint value

• Regulation to the value set at

C5 parameter.

• D.I. Open

• Press associated with

the function key

OP

Alarm

Door

open

Activation of the digital input

(i3 = 4) (for a time greater than

r1)

• Recording of label OP in the

AL folder

• Fixed alarm icon

• Close the door

• Delayed function

defined by A6

3.2.6 Electronic Controller Alarms

The alarm condition is always signaled by the alarm icon . To turn off the relative icon will continue

flashing.

NOTE: If alarm exclusion times are in progress (AL folder of the parameter table), the alarm is not

signaled.

809-112A Rev C 2017-03-15

17

Page 18

UNIT START UP

3.2.7 How to View Alarms

Press and release the button to enter the machine status menu.

The screen will display SP

Use the and buttons to change the display to AL

Press and release the button to view the alarm(s)

If more than one alarm is present, use the and buttons to scroll through them.

18

809-112A Rev C 2017-03-15

Page 19

UNIT START UP

3.2.8 How to Enter the StandBy Mode

The Stand By Mode is used to remove power from the condensing unit (Compressor &

Condensing Fan) so the coil can be cleaned or the unit defrosted without having to disconnect the power

from the unit)

In Refrigerator models the Evaporator Fan will continue to run

In Freezer models, power is disconnected from the Evaporator Fan, so it does not run.

Press and release the button for 5 seconds until St is displayed

Press and hold the button to confirm. OF will be displayed, the unit is now in

Standby mode.

3.2.9 How to Exit the StandBy Mode

Press and release the button for 5 seconds until St is displayed

Press and hold the button to confirm. The cabinet temperature will be displayed, the

unit is now in Normal Operation

19

809-112A Rev C 2017-03-15

Page 20

PREVENTATIVE MAINTENANCE

4.1 Daily, Exterior

1 - Clean the surface with a sponge and dilute mild detergent. Use a non-abrasive cleaner that

does NOT contain chlorine.

2 - Rinse with clean water before drying with clean soft cloth.

3 - Polish with a soft cloth, wiping with the grain of the metal.

4 - Once a week wipe with a film cutting agent or stainless steel polish to maintain finish.

4.2 Weekly, Interior

1 - Remove all food, food related items, and shelves.

2 - Disconnect power to the cabinet at the main power supply circuit breaker

3 - Remove loose food particles from interior floors, walls, and ceiling

4 - Scrub all interior surfaces and door gaskets with a warm (100-120F) detergent solution

and a soft nylon bristle brush

5 - Rinse with clean water and allow to air dry

6 - Re-install the shelves

7 - Restore power to the cabinet by resetting main power supply circuit breaker

8 - Return food to the cabinet when temperature indicator displays safe food temperature

4.3 Monthly, Condenser

The condenser coil is located right behind the front grille on top of the cabinet. It should be

inspected once a month and cleaned as required. Vacuum clean all surfaces of the condenser.

Make sure no fins are bent or damaged in the process. If there are bent fins, carefully straighten

them so that air can flow through the coils. Failure to keep the condenser coil clean will lead to

poor performance, excessive power consumption and compressor failure and may result in loss

of property. Failure to keep the condenser coil clean may void the limited warranty.

4.4 Periodic, Gaskets

1 Visually inspect the door gaskets for a tight seal on all four sides. Inspect for any type of

damage such as rips, tears, stiffness, or cracks.

2 If any such condition exists, the magnet will not seal and the gasket will need replaced.

3 Cleaning the gasket requires the use of mild dish detergent and warm water.

4 Next, thoroughly rinse and dry the gasket.

20

809-112A Rev C 2017-03-15

Page 21

PREVENTATIVE MAINTENANCE

Drawers and slides can be removed from a cabinet for cleaning purposes. To remove a drawer from a

cabinet follow these instructions:

1 - Open the drawer to full extension

2 - Push the white locking tabs forward on both sides of the drawer

3 - Press down the back of the tabs

4 - Slide the drawer out of the cabinet

5 - To remove the sliding member (Middle slide), press the metal tab up and slide it

6 - To reinstall the sliding member, press the metal tab up and slide it in

7 - To reinstall drawer, push the locking tab forward and press the back of the tab down

8 - Align the drawer slide members and moving slide members

9 - Slide the drawer in and lock the slide by pushing the front of the locking tab down and in

4.5 Drawer Maintenance

Drawer models are shipped with the drawers already installed in the cabinets. Drawers are designed with

slides which have locking mechanisms to prevent drawers from coming off cabinets during normal

opening and closing operations.

See Illustration below:

21

809-112A Rev C 2017-03-15

Page 22

PREVENTATIVE MAINTENANCE

Type of Cleaning

Cleaning

Agent

Method of

Application

Effective

Finish

Routine Cleaning

Soap or ammonia, or

detergent and water.

Sponge with cloth, then

rinse with clear water and

wipe dry

Satisfactory for use on all

finishes.

Smears and Fingerprints

Arcal 20, Lac-O-NU, Lumin

Wash O'Cedar Cream

Polish, Stainless Shine.

Rub with cloth as directed

on the package.

Satisfactory for use on all

finishes. Provides barrier

film to minimize prints.

Stubborn Spots and Stains,

Baked-On Splatter, and

Other Light Discolorations

Allchem Concentrated

Cleaner.

Apply with damp sponge

or cloth

Satisfactory for use on all

finishes.

Samae, Twinkle or Cameo

Copper Cleaner.

Rub with damp cloth.

Satisfactory for use on all

finishes if rubbing is light.

Grade FFF Italian pumice,

whit- ing, or talc.

Rub with damp cloth.

Use in direction of polish

lines on No. 4 (polished)

finish. May scratch No. 2

(mill) and Nos. 7 and 8

(polished) finishes.

Liquid NuSteal.

Rub with dry cloth. Use

small amount of cleaner.

Paste NuSteal or DuBois

Temp.

Rub with dry cloth using a

small amount of cleaner.

Copper's Stainless Steel

Apply with damp sponge

or cloth.

Cleaner Revere Stainless

Household cleansers, such

as Old Dutch, Lighthouse,

Sun- brite, Wyandotte,

Bab-O, Gold Dust, Sapolio,

Bon Ami, Ajax, or Comet.

Rub with a damp cloth.

May contain chlorine

bleaches. Rinse

thoroughly after use.

Grade F Italian pumice,

Steel Bright, Lumin

Cleaner, Zud, Restoro, Sta-

Clean, or Highlite.

Rub with a damp cloth.

Penny-Brite or Copper-

Brite.

Rub with a dry cloth

using a small amount of

cleaner.

4.6 Effective Methods for Cleaning Stainless Steel

809-112A Rev C 2017-03-15

22

Page 23

PREVENTATIVE MAINTENANCE

Type

of Cleaning

Cleaning

Agent

Method of

Application

Effective

Finish

Heat Tint or Heavy

Discoloration

Penny-Brite or Copper-

Brite.

Rub with a dry cloth.

Use in direction of

polish lines on No. 4

(polished) finish. May

scratch No. 2 (mill) and

Nos. 7 and 8 (polished)

finishes.

Past NuSteel, DuBois

Temp, or Tarnite.

Rub with a dry cloth or

stainless steel wool.

Revere Stainless Steel

Cleaner. Allen Polish,

Steel Bright, Wyan- dotte,

Bab-O, or Zud.

Rub with a damp cloth.

Revere Stainless Steel

Cleaner.

Apply with damp sponge or

cloth.

Burnt-On Foods and

grease

Fatty Acids, Milkstone

(where swabbing or

rubbing is not practical)

Easy-Off, De-Grease-It,

4 to 6% hot solution of

such agents as

trisodium phosphate or

sodium tripolyphosphate

or 5 to 15% caustic

soda solution.

Apply generous coating.

Allow to stand for 10-15

minutes. Rinse.

Repeated application

may be necessary.

Excellent removal,

satisfactory for use on

all finishes.

Tenacious Deposits,

Rusty Discolorations,

Industrial Atmospheric

Stains

Oakite No. 33, Dilac

Texo 12, Texo N. Y.,

Flash-Klenz, Caddy

Cleaner, Turco Scale

4368 or Permag 57.

Swab and soak with

clean cloth. Let stand 15

minutes or more

according to directions

on package, then rinse

and dry.

Satisfactory for use on

all finishes.

Hard Water Spots and

Scale

Vinegar.

Swab or wipe with cloth.

Rinse with water and

dry.

Satisfactory for all

finishes.

5% oxalic acid, 5%

sulfamic acid, 5 to 10%

phosphoric acid, or

Dilac, Oakite No. 33,

Texo 12, Texo N. Y.

Swab or soak with cloth.

Let stand 10-15

minutes. Always follow

with neutralizer rinse,

and dry.

Satisfactory for all

finishes. Effective on

tenacious deposits or

where scale has built

up.

4.6 Effective Methods for Cleaning Stainless Steel

809-112A Rev C 2017-03-15

23

Page 24

TROUBLE SHOOTING

SERVICE AND REFRIGERATION SYSTEM CHART ANALYSIS

Malfunction

Possible Cause

Solution

Compressor will not start –

no hum

Line cord not plugged in

Plug cord in

Compressor starts and runs

but unit does not begin to

cool on initial start-up (MT

Bare Tube Condenser

Models only)

Ambient is below 60°F

Warm unit to above 60°F prior to initial

start-up.

Unit runs OK, but short

cycles

Overload protector.

Check wiring diagram for correct

wiring

Cold control.

Differential set too close

Overcharge.

Reduce refrigerant charge.

Air in system.

Recover and recharge.

Undercharge.

Fix leak and recharge with refrigerant.

Unit operates long or

continuously

Dirty condenser

Clean condenser

Shortage of refrigerant.

Fix leak, add charge, correct charge

Temp control contacts stuck or

frozen

Replace Temp control

Evaporator coil iced.

Defrost

Restriction in refrigeration system.

Determine location and remove.

Start capacitor open,

shorted or blown.

Relay contacts not opening properly.

Replace relay

Low voltage to unit.

Determine reason and correct.

Improper relay.

Replace.

Run capacitor open,

shorted or blown.

Improper capacitor.

Determine correct size and replace.

Excessively high line voltage (110%

of rated max).

Determine reason and correct.

Relay defective or burned

out.

Line voltage too high or too low.

Determine reason and replace.

Relay being influenced by loose

vibrating mounting.

Remount rigidly.

Space temperature too

high.

Control setting too high.

Reset control.

Overcharged with refrigerant

Recover refrigerant and recharge with

Proper charge specified on data plate

Inadequate air circulation.

Improve air movement

Cooler freezing beverage

Temperature control

Reset control

Unit noisy

Loose parts or mountings

Find and tighten

Tubing rattle

Reform to be free of contact

Bent fan blade causing vibration

Replace blade

Fan motor bearings worn

Replace motor

WARNING: ALL SERVICING MUST COMPLY WITH STATE AND FEDERAL EGULATIONS

5.1 General

809-112A Rev C 2017-03-15

24

Page 25

TROUBLE SHOOTING

LEGEND

RC – Run Capacitor

SC – Start Capacitor

OL – Overload

- Eliwell Controller Terminal

- Connection Point

ICR – Control Relay

SPE Models Only

5.2 Refrigerator Ladder Diagram

809-112A Rev C 2017-03-15

25

Page 26

TROUBLE SHOOTING

LEGEND

RC – Run Capacitor

SC – Start Capacitor

OL – Overload

- Eliwell Controller Terminal

- Connection Point

ICR – Control Relay

5.3 Freezer Ladder Diagram

809-112A Rev C 2017-03-15

26

Page 27

APPENDIX

SERVICE RECORD

27

809-112A Rev C 2017-03-15

Loading...

Loading...