Beverage Air SPE27 Installation Manual

IMPORTANT

INFORMATION

for

SPE SERIES

This cooler has passed the

QUALITY CONTROL INSPECTION

and meets the high standards at

Beverage-Air. This inspection includes

complete refrigeration system,

cabinet construction & finish.

809-084A

Rev. A

IMPORTANT

PLEASE RETAIN FOR YOUR RECORDS

SALES OFFICE: 3779 CHAMPION BLVD. • WINSTON-SALEM, NC 27105

PHONE: 336-245-6400 TOLL FREE: 800-845-9800

TECHNICAL SERVICE: 800-684-1199 PARTS ORDER FAX: 800-262-9381

PLANT: BROOKVILLE, PENNSYLVANIA

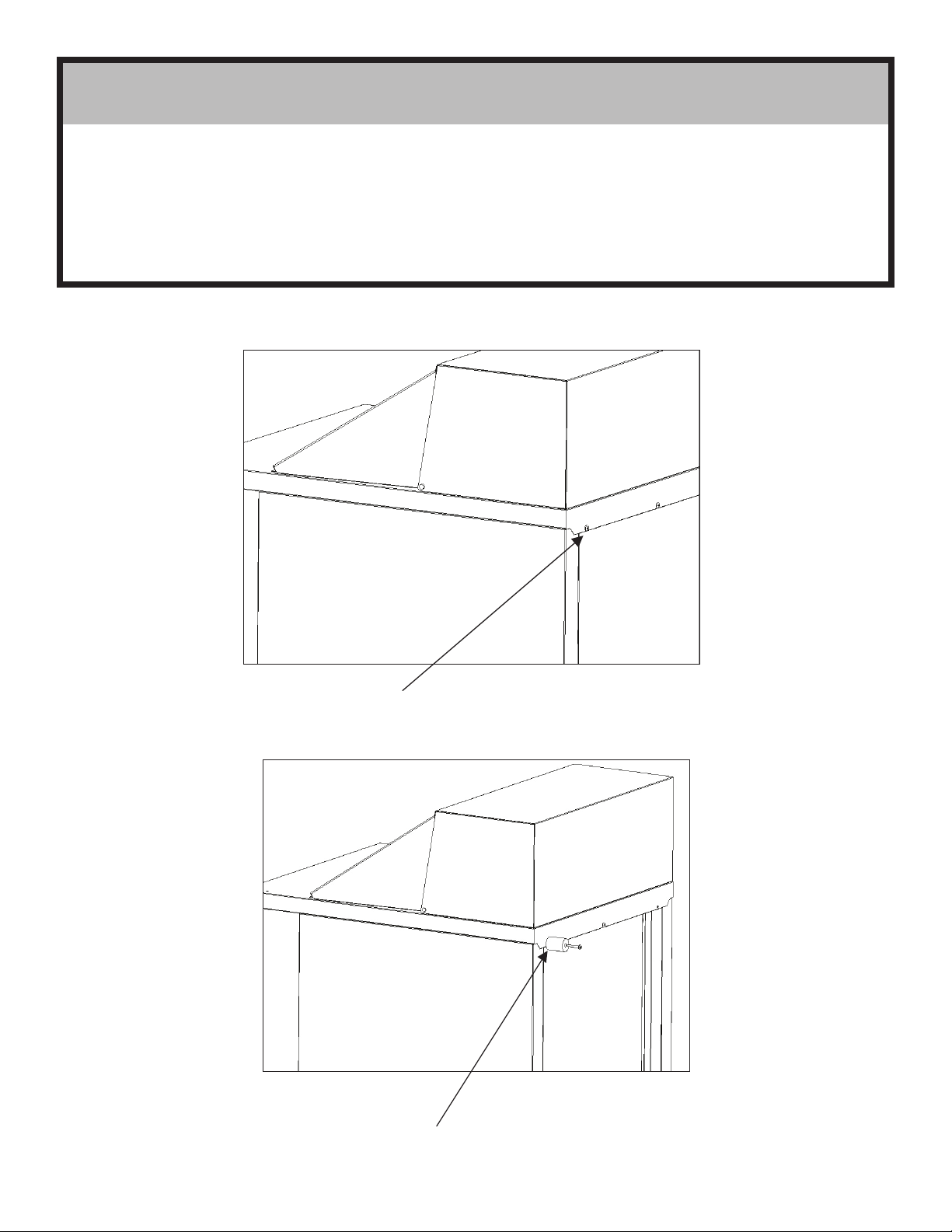

IMPORTANT

INSTALL BUMPERS ON THE REAR OF UNIT

PRIOR TO USE. FAILURE TO DO SO

WILL VOID THE WARRANTY.

BACK BUMPER INSTALLATION INSTRUCTION

• Remove the screw from the back of the unit.

• Install the bumpers at both ends with the provided screws.

INSTALLATION AND OPERATING INSTRUCTIONS

REFRIGERATORS — SPE: 27, 48, 60, 72

FREEZERS — UCF/WTF27A, UCF/WTF48A

ILA-0800-REV. B

• INSTALLATION

— RECEIVING INSPECTION: Upon receipt, check all packages for accessories or optional components, including

legs, casters and shelves.

— DOOR HANDLES: Remove door handle from bag inside cabinet and install on outside of door. The screw heads

must be lled with NSF listed RTV.

— SHELVES: Shipped inside each cabinet are plastic wrapped shelves and a bag of shelf supports. Shelf spacing is

adjustable to suit requirements.

— PILASTERS (SP/WTR/UCR: 27, 48, 60, 72): The pilasters can be removed, without the use of tools, for cleaning.

— LEGS & CASTERS: Each cabinet is provided with 4 legs or casters shipped inside the cabinet.

The legs or casters screw directly into an adapter nut provided in each corner of the base.

— LOCATING COOLER: Provide at least 2 inches of space between cabinet rear and adjacent wall.

• OPERATION

— ELECTRICAL SUPPLY & CONNECTIONS: Plug all standard models into a 115 volts A.C. 60 Hz. outlet. Low line

voltage is often the cause of service complaints. Check to see that the line voltage is 110 volts or more with the

unit running. Other motors or heavy appliances should not be used on the same circuit with the cooler. When

working on the inside of the cooler, disconnect from electrical circuit for safety reasons. CAUTION: If an

extension cord is necessary, use only a 3-wire grounding type of wire, size 16 AWG or larger. DO NOT

exceed 20 feet in length. The use of ungrounded cords or overload circuit voids compressor warranty.

— INITIAL START-UP: Turn power on and check to verify that the condenser fan is running.

— TEMPERATURE CONTROL: Factory setting of temperature control is at No. 5 position (normal) on control dial

which will maintain the product at about 38°F. For colder temperatures, turn knob clockwise one number at a time.

Excessive tampering with the control could lead to service difculties. For operation above 3000 feet altitude,

have thermostat adjusted by a qualied service technician.

— CONDENSATE DISPOSAL:

The aluminum pan below the evaporator serves to collect and direct the

condensate to the evaporator pan located just below the unit. Airow over the pan hastens the evaporation

process so that external plumbing is not required.

— FREEZER DEFROST SYSTEM:

Defrost timers are factory set for (6) twenty minute defrosts per 24-hour period.

The start time for defrosting should be set to occur during lightest usage of the cabinet. Choose defrost time

desired and turn adjusting cam until defrost is activated. Defrost will then occur every four hours. The adjusting

cam is located on the face of the evaporator housing.

• CLEANING

—

CLEANING CABINET EXTERIOR:

Cabinets should be cleaned with a solution of mild soap and water. Do not

use caustic soap or abrasive cleaners, since these might damage the cabinet nish. If stainless steel surface

becomes discolored, scrub by rubbing only in the direction of the nish grain. Do not use steel wool.

—

CLEANING INTERIOR SURFACES:

The inside of the cabinet is Anodized Aluminum. To clean, use mild soapy

water and cloth or sponge.

—

CONDENSER:

For efcient operation, it is recommended that the condenser coil and fans be cleaned every 3 to 6

months. Remove rear grille for access. Vacuum clean front surface of coil thoroughly or direct forced air through

condenser ns. Failure to clean condenser can cause compressor malfunction and will void warranty.

—

CONDENSATE PAN:

Condensate pan should be cleaned periodically to prevent odors and to maintain

evaporating efciency.

Loading...

Loading...