Page 1

SERVICE &

INSTALLATION

MANUAL

MEDIUM

TEMPERATURE

VERTICAL

REFRIGERATORS

51-1337-02

01/03

CARRIER COMMERCIAL REFRIGERATION, INC.

Providing BEVERAGE-AIR • FRIGIDAIRE • KELVINATOR • UNIVERSAL NOLIN Products/Services

Page 2

If additional information is necessary, call the factory.

Our toll free number is 1-800-684-1199.Technical assis-

tance engineers are willing to assist you in any way possible. Office hours are from 8:00 a.m. to 5:30 p.m., Eastern

Standard Time.

Important information is contained in this manual which should

be retained in a convenient location for future reference.

All data and information in this manual is subject to change without notice.

Manual effective for models produced January, 2003.

Starting serial number .

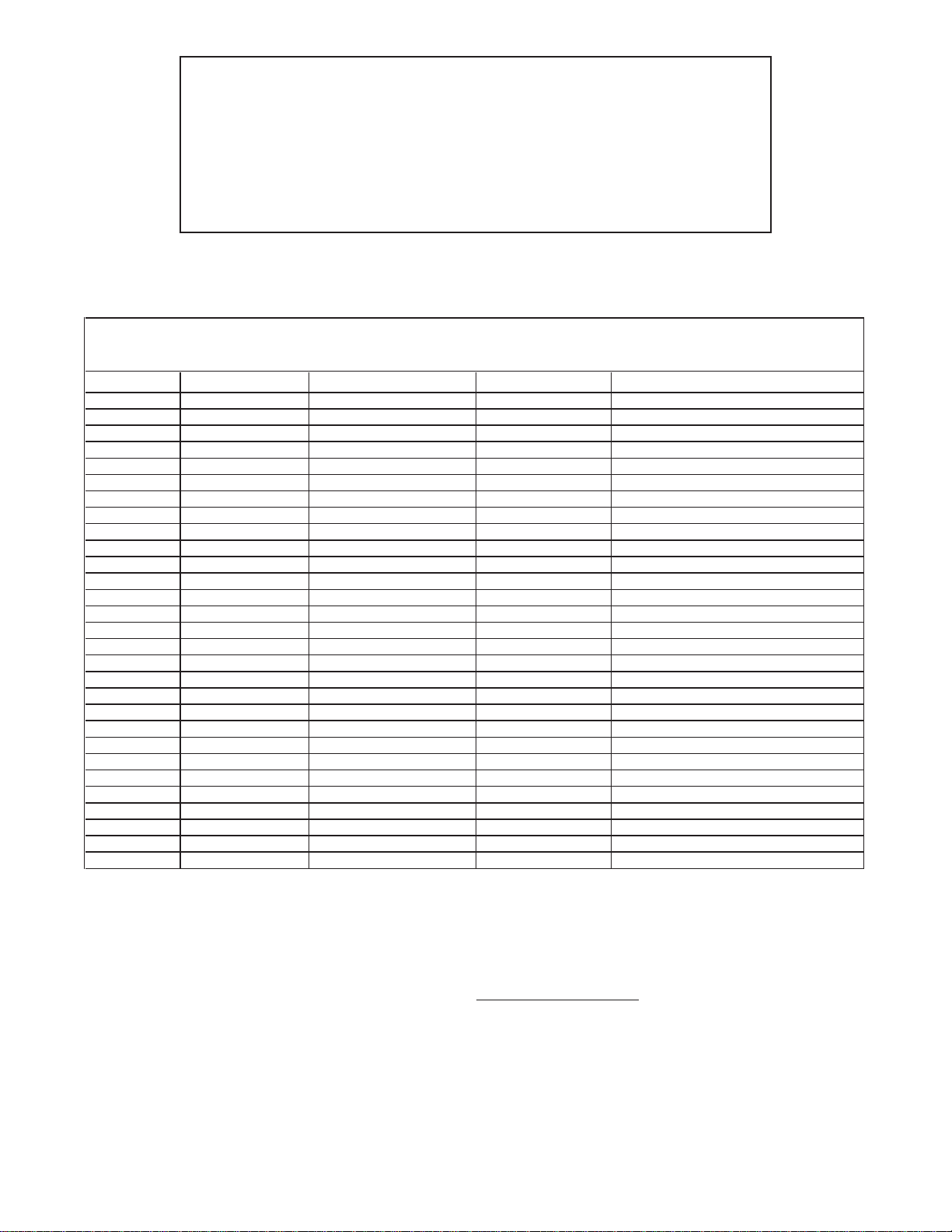

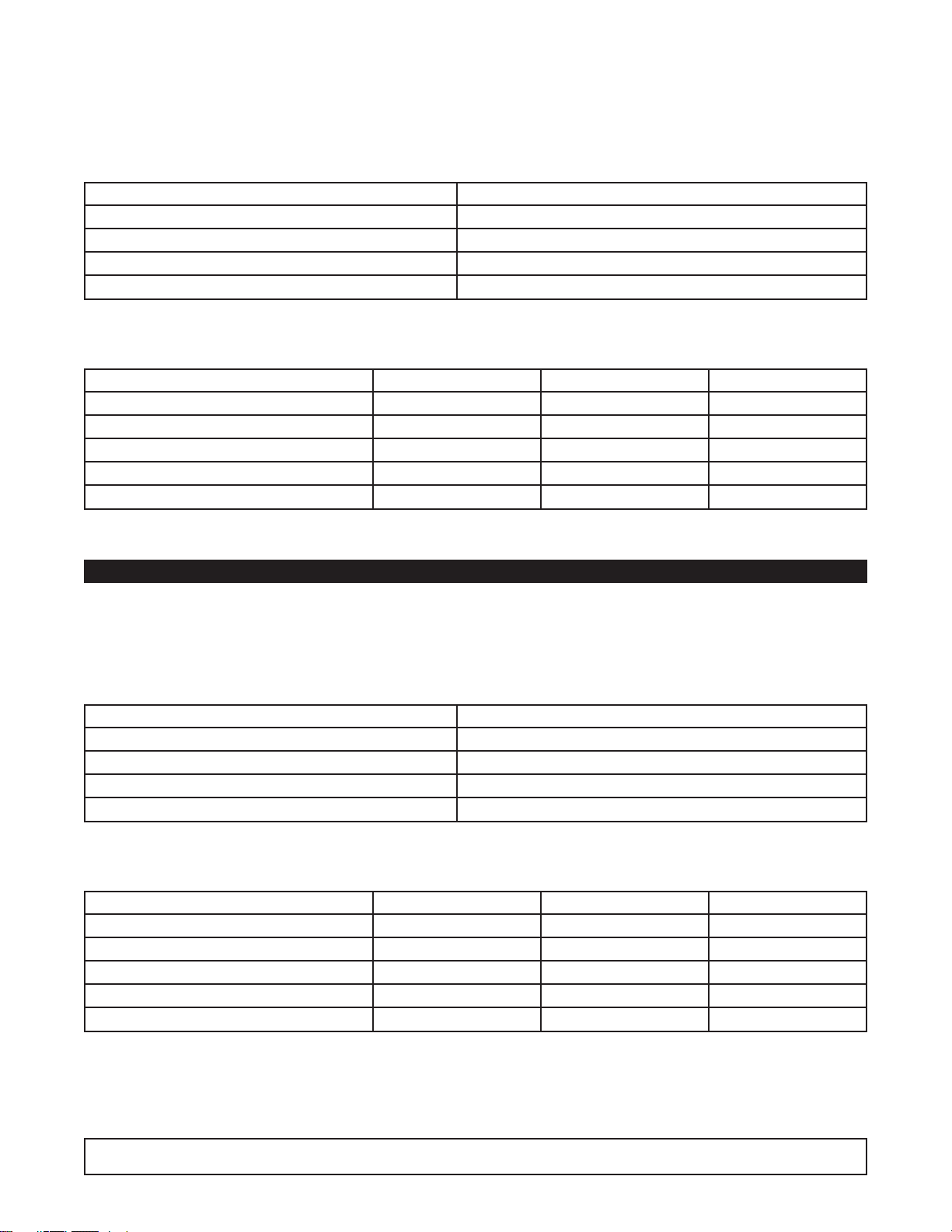

MODEL DESIGNATION INFORMATION

PART NO. MODELS STYLE CONDENSER SPECIAL USE

52-1923-01 BT30RF- EXPR SOLID ONE DOOR TOP MOUNT EXPLOSION PROOF

52-1958-02 BT30RF-FMS SOLID ONE DOOR TOP MOUNT FLAMMABLE MAT'L STORAGE

52-1993-33 BT30RG-4.1 GLASS ONE DOOR TOP MOUNT SCIENTIFIC GENERAL PURPOSE

52-1993-34 BT30RGCH-4.1 GLASS ONE DOOR TOP MOUNT CHROMATOGRAPHY

52-1993-35 BT30RS-4.1 SOLID ONE DOOR TOP MOUNT SCIENTIFIC GENERAL PURPOSE

52-1993-29 BT30RSFMS-4.1 SOLID ONE DOOR TOP MOUNT FLAMMABLE MAT'L STORAGE

52-1993-36 BT50RG-4.1 GLASS TWO DOOR TOP MOUNT SCIENTIFIC GENERAL PURPOSE

52-1993-37 BT50RGCH-4.1 GLASS TWO DOOR TOP MOUNT CHROMATOGRAPHY

52-1993-38 BT50RS-4.1 SOLID TWO DOOR TOP MOUNT SCIENTIFIC GENERAL PURPOSE

52-1993-30 BT50RSFMS-4.1 SOLID TWO DOOR TOP MOUNT FLAMMABLE MAT'L STORAGE

52-1993-39 BT80RG-4.1 GLASS THREE DOOR TOP MOUNT SCIENTIFIC GENERAL PURPOSE

52-1993-32 ST260RIR-4.1 SOLID ONE DOOR TOP MOUNT INCUBATOR

52-1993-41 ST30RGBB-4.1 GLASS ONE DOOR TOP MOUNT BLOOD STORAGE

52-1993-42 ST50RGBB-4.1 GLASS TWO DOOR TOP MOUNT BLOOD STORAGE

52-1991-64 T30MGP-4.1 GLASS ONE DOOR TOP MOUNT

52-1991-65 T30MSP-4.1 SOLID ONE DOOR TOP MOUNT

52-1991-66 T50MGP-4.1 GLASS TWO DOOR TOP MOUNT

52-1997-36 T50MGPR-4.1 GLASS TWO DOOR TOP MOUNT

52-1991-67 T50MSP-4.1 SOLID TWO DOOR TOP MOUNT

52-1991-68 T80MGP-4.1 GLASS THREE DOOR TOP MOUNT

52-1997-37 T80MGPR-4.1 GLASS THREE DOOR TOP MOUNT

52-1992-32 UMG30BS-4.1 GLASS ONE DOOR BOTTOM MOUNT

52-1992-33 UMG50BS-4.1 GLASS TWO DOOR BOTTOM MOUNT

52-1997-34 UMG50RS-4.1 GLASS TWO DOOR BOTTOM MOUNT

52-1992-34 UMG80BS-4.1 GLASS THREE DOOR BOTTOM MOUNT

52-1997-35 UMG80RS-4.1 GLASS THREE DOOR BOTTOM MOUNT

52-1992-35 UMH30BS-4.1 GLASS ONE DOOR BOTTOM MOUNT HEATED DOORS

52-1992-36 UMH50BS-4.1 GLASS TWO DOOR BOTTOM MOUNT HEATED DOORS

52-1992-37 UMH80BS-4.1 GLASS THREE DOOR BOTTOM MOUNT HEATED DOORS

Page 3

TABLE OF CONTENTS-MED. TEMP. VERTICAL

MODEL CODES EXAMPLES..................................................2

HANDLING & INSTALLATION ..............................................4

TOP MOUNT, GLASS PULL DOOR (1-,2-,& 3-DR MODELS)

Dimensional Drawings..........................................................6

Refrigerator Specifications....................................................7

BOTTOM MOUNT, GLASS PULL DOOR (1-, 2-, 3-DR MODELS)

Dimensional Drawings..........................................................8

Refrigerator Specifications....................................................9

TOP MOUNT, SOLID PULL DOOR (1 & 2-DR MODELS)

Dimensional Drawings & Specifications ............................10

MAINTENANCE & REPAIR ......................................37

ELECTRICAL & REFRIGERATION INFORMATION

Medium Temperature Glass & Solid 1 Door ......................15

Medium Temperature Glass & Solid 2 Door ......................16

Medium Temperature Glass 3 Door ....................................17

Medium Temperature Solid 1 & 2 Door FMS......................17

ELECTRICAL & REFRIGERATION INFORMATION

BT30RF-FMS

Medium Temperature Solid 1 Door ....................................65

ELECTRICAL & REFRIGERATION INFORMATION

BT30RF-EXPR

Medium Temperature Solid 1 Door Refrigerator/Freezer ....69

ELECTRICAL & REFRIGERATION INFORMATION

ST260RI, ST260RIR

Incubator ............................................................................81

TROUBLESHOOTING ................................................93

COMPONENT IDENTIFICATION ........................100

PA RT S LIST ....................................................................109

TABLE OF CONTENTS 1

Page 4

Medium Temperature Vertical Refrigerators

Introduction

These refrigerators have been designed to maintain a medium temperature environment. These multi-purpose refrigerators are available in one, two, and three-door solid or glass

door models.

Except for routine cleaning, these medium temperature cabinets will require little maintenance. In the unusual event that

repair should be necessary, this manual presents information

that is helpful in maintaining, diagnosing, and repairing these

cabinets.

2 INTRODUCTION

Page 5

MODEL CODES – KELVINATOR & KELVINATOR SCIENTIFIC 3

MODEL CODES

Kelvinator Model Example: T30LGPR-4

T30LGP R-4

T = Top Mount

B = Bottom Mount

FS = Food Service

30, 50, 80 - Cubic Feet

L = Low Temp

M - Medium Temp

H = Hardening Cabinet

G= Glass Door

S = Solid Door

P = Pull Door

S = Sliding Door

Q = Quadrant Pull Door

R = Remote

E = Export

ET = Export Transformer

Customer Variations:

BR = Baskin Robbins

DQ = Dairy Queen

DQL = Dairy Queen Light Duty

4 = Revision Level

Kelvinator Scientific Model Example: ESTL50RSFMS-4

ESTL50RSFMS -4

E = Export

ET = Export (Transformer)

S = Scientific

B = Base Scientific

T = Top Mount

B = Bottom Mount

C = Chest

L = Hardening Cabinet

30, 50, 80 =

Cubic Feet

F = Freezer

R = Refrigerator

G = Glass Door

S = Solid Door

I = Incubator (Solid Door)

FMS = Flammable Material Storage

CH = Chromatography

BB = Blood Bank

EXPR = Explosion Proof

R = Recorder on Incubator

Customer Variations:

XXX

4 = Revision Level

Page 6

4 MODEL CODES – UN

MODEL CODES

Universal Nolin Model Example: UMG50BS-4

UMG50B S-4

U = Upright

S = Scientific (upright)

L = Low Temp.

M = Med Temp.

H = Heated Glass (medium temp.)

G = Glass

S = Solid

O = Open

T = Sliding Glass Door (track)

30, 50, 80 =

Cubic Feet

R = Remote on Bottom Mounted Upright

U - Remote on Top Mounted Upright

T = Top Mounted Compressor

B = Bottom Mounted Compressor

S = Single Facing (sliders)

D = Double Facing

S = 115V / 60 Hz.

D = 208/230V / 60 Hz. / 1 Ph.

P = 208V / 60 Hz. / 3 Ph.

T = Transformer

F = 220V / 50 Hz.

4 = Revision Level

Page 7

SECTION I – HANDLING & INSTALLATION

HANDLING & INSTALLATION 5

FREIGHT DAMAGES & SHORTAGES

The cabinet was inspected and

packaged at the factory, and should

arrive in excellent condition.The transportation company or other parties involv ed in the shipment are responsible for loss and/or damage.Always make an inspection before and after uncrating. Inspect the crated

unit(s) before locating (preferably at the point of

unloading by the transportation company).

INSPECTING FOR DAMAGES

Always use care when removing shipping

tape, blocks, pads, hardware or other material until you are satisfied that the unit is completely

operational.Contact the factory if technical assistance

is required.

Check the cartons or containers.If these are damaged

in any way, open them and inspect the contents in the

driver’s presence. If damage is detected:

1. Have the driver note the nature and extent of the

damage on the freight bill.

2. Notify the transpor tation company at once to request

an inspection. Carrier claim policies usually require

inspections to be made within 15 days of delivery.

3. If damage is noticed, file a claim with the transpor ta-

tion company.

FILING A CLAIM

File a claim for loss at once with the transportation company for:

A. A cash adjustment; B.Repairs; or C. Replacement.

When filing your claim, retain all packaging materials

and receipts.

HANDLING THE CABINET

The refrigeration system of the cabinet is

designed to operate with the cabinet located

on a level surface. Do not tilt the cabinet more than

10° to any side. If the cabinet must be tilted on an

angle for handling or moving purposes, allow it to sit in

an upright position 30 minutes prior to starting.

CHOOSING A LOCATION

This model cabinet should be situated to allow proper air

circulation. These cabinets require a 2" minimum clearance behind for proper air circulation.

The cabinet must be installed on sturdy, solid, level floor.

The cabinet must be located so it can be plugged into a

properly grounded three-prong electrical outlet of 115

volt, 60 hz.The electrical outlet should not be controlled

by a wall switch which might be turned off accidentally.

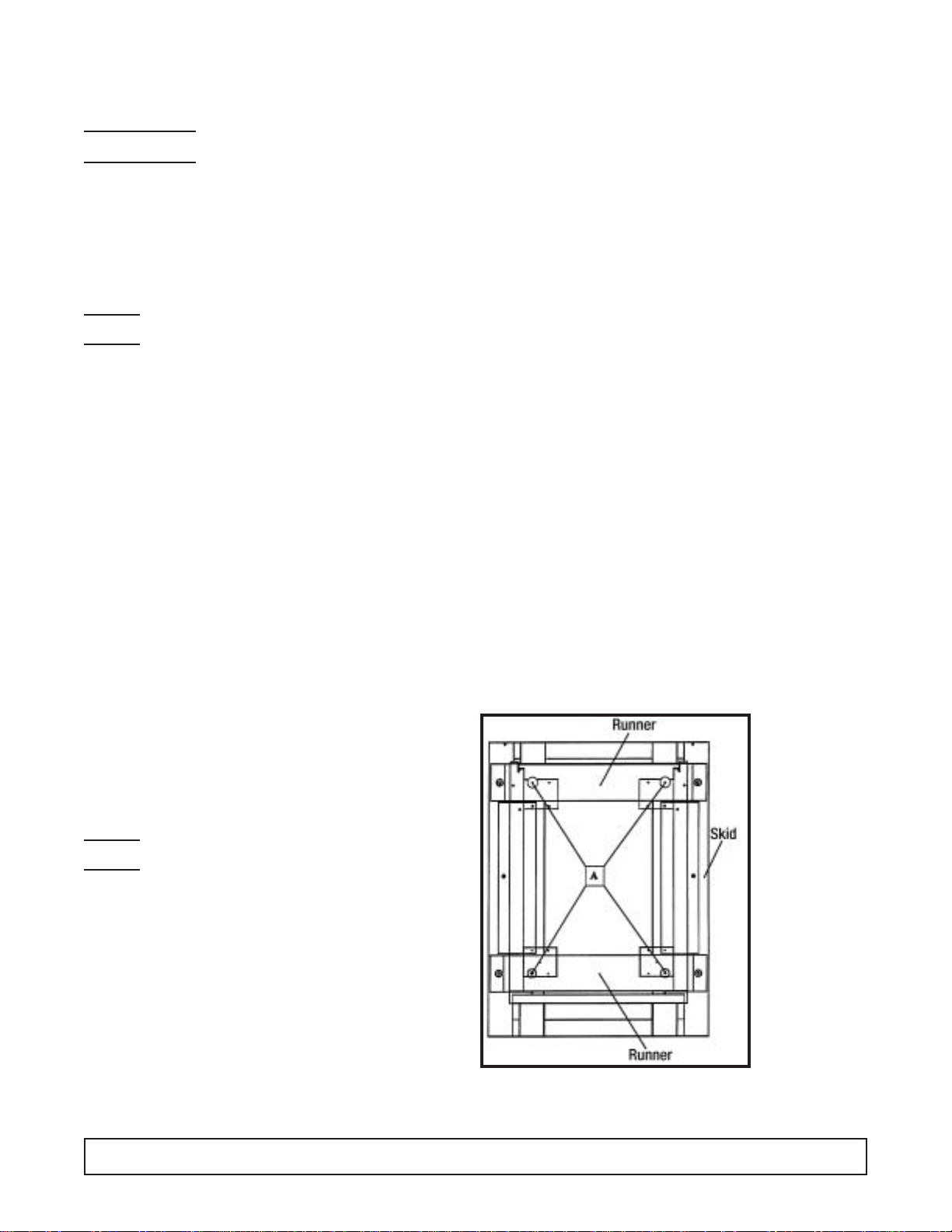

UNCRATING THE CABINET

The cabinet should be moved as close as possible to the

operating location before removing crate base. Be sure

to follow the steps in the “INSPECTING FOR DAM-

AGES ”instructions.

INSTALLING THE CABINET

(Models with Top Mounted Compressor)

Whenever possible leave the crate base on the cabinet

until it is moved close to the final position.When it is necessary to move the cabinet through a doorway, it may be

necessary to remove the crate base.

Wood runners are provided on the underside of the cabinet for ease in sliding. These runners should be left

attached to the cabinet when the crate base is removed

and should remain attached until after the legs are

installed.The cabinet can then be pushed around more

easily without scratching the floor.The runners also prevent damage to the electrical receptacle and condensate pan hardware on the cabinet bottom.

After the cabinet has been moved to the approximate

final location, remove the package containing the legs

from the cabinet interior. Tape the doors to prevent

accidental opening when handling. Raise the sides of

the cabinet high enough to mount the legs at the locations provided on the bottom of the cabinet.

IMPORTANT:

AFTER REMOVAL

OF WOOD RUNNER, REPLACE

BOLT “A” INTO

LEG MOUNTING

BRACKETS. THIS

IS EXTREMELY

IMPORTANT TO

THE SECURE

ATTACHMENT OF

THE CABINET

LEG. THERE

MUST BE FOUR

(4) BOLTS

SECURING EACH

LEG.

Level the cabinet by means of the leg adjustments.

Cabinet doors are self-closing, and the cabinet must be

level to operate properly.

NOTE:

IMPORTANT:

NOTE:

Page 8

6 HANDLING & INSTALLATION

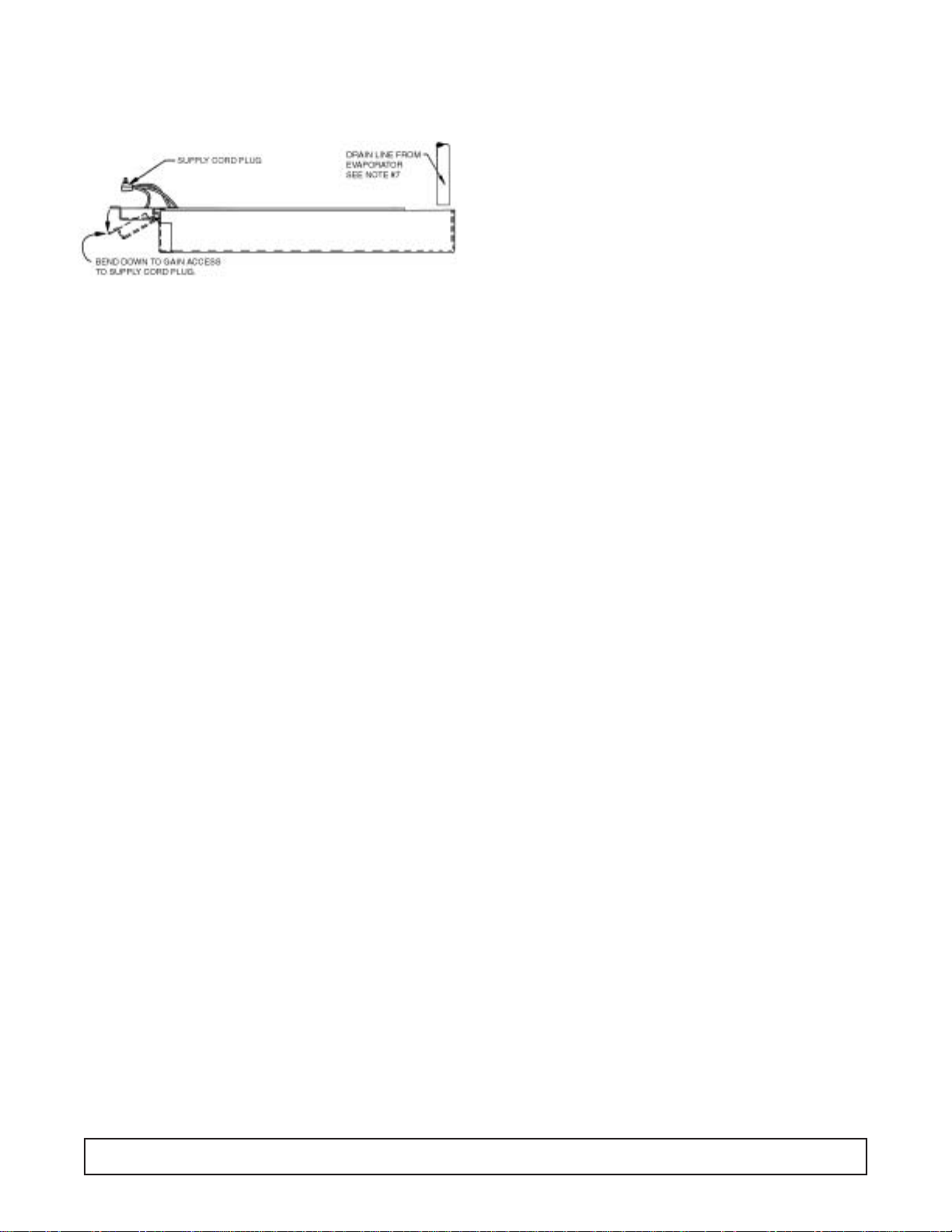

CONDENSATE PAN

INSTALLATION INSTRUCTIONS

MAKE SURE THE CABINET IS DISCONNECTED

FROM ITS POWER SOURCE

1. Remove and discard protective cover over electrical

receptacle on bottom of cabinet

2. Bend down front part of housing. (See above.)

3. Insert condensate evaporator pan assembly into the slide

supports on the underside of the cabinet by pushing

toward back of cabinet until it stops.

4. Plug supply cord into receptacle in underside of cabinet.

5. Bend up front part of housing. Line up slot with rivnut in

cabinet bottom and insert thumbscrew through slot onto

rivnut in cabinet bottom. Insert thumb screw through slot

onto rivnut and tighten.

6. The assembly will now operate when power is supplied to

the cabinet.

7. Inspect rear of cabinet to ensure that the drain line from

the evaporator is properly positioned over the condensate pan.

On top mount models, allow a minimum of twelve (12) inches between the top of the cabinet and ceiling and two (2)

inches from the back of the cabinet to the wall.

(Models with Bottom Mounted Compressor)

Remove the crate base mounting clips located behind the

front grill.Slide the cabinet forward on the crate base to clear

the rear mounting clips.

After removing the crate base, move the cabinet into location.Make sure the cabinet is lev el to ensure operation of the

“self-closing” doors.

Allow a minimum of two (2) inches between the back of the

cabinet and the wall for proper air circulation through the

condensing unit.

CABINET STARTUP

Once the cabinet has been located in its permanent location

and the proper power and grounding have been provided,

the following items must be checked or completed:

1. Cut and remove the compressor hold-down band (if

applicable) so the compressor “floats” freely.

2. Check for traces of oil on the compressor pan which could

mean a broken or leaking refrigeration line.

2. UNDER NO CIRCUMSTANCE SHOULD THE COM-

PRESSOR BE STARTED WHEN OIL IS PRESENT

UNTIL INSPECTED BY A SERVICE TECHNICIAN.

3. INSPECT THE FACTORY WIRING FOR TERMINALS

THAT MIGHT HAVE VIBRATED LOOSE IN SHIPPING.

TIGHTEN ALL SCREW-TYPE TERMINALS.

4. Check the refrigeration lines to see that they are “free”

and no damage was done during shipping.

5. Check fan blade(s) for “free” operation.

6. Turn on the main power switch. Once the compressor

starts, the voltage should be checked at the compressor

terminals to determine if there is proper voltage to the

compressor.The voltage should not exceed 10% abov e or

below the rated compressor voltage.

EXAMPLE: If the voltage reads 115 volts with no load and it

drops below 103 volts when the compressor starts, it

may indicate that the supply wiring is too small or that

the wire run is too long.

7. Make sure that the drain line has not been dislodged or

broken during shipping and that the drain trap terminates properly in the condensate pan or floor drain.

(See Condensate Pan on top mounted compressor.)

8. Listen for any unusual noise such as lines vibrating, etc.

Correct problem by tightening screws, slightly bending

tubing, etc.

9. Check proper tension on doors. (See Door Torque

Adjustment.)

10. Cabinet should not be loaded with product until cabinet

has operated for 24 hours and reached desirable storage temperature.

THERMOSTAT SETTINGS

The refrigerator is shipped from the factory with a thermostat

setting of approximately the mid-point of the operating

range. Final thermostat setting must be made in the field.

Allow the cabinet to operate until the compressor cycles on

the thermostat. The normal operating temperature range for

the refrigerator is:

32°F to 55°F (0°C to 13°C)

NOTE:DO NOT OPERATE THE CABINET WITH THERMO-

STAT SETTINGS BELOW 32°F (0°C).

The thermostat is easily adjusted with a standard screwdriv-

er. The thermostat has settings 1 through 7, tur n the thermostat to a higher number to lower the cabinet temperature.

The thermostat is located behind the evaporator front grill

and can be adjusted through the grill. On some models the

thermostat is located in the electrical box at the top of the

cabinet.

SCIENTIFIC CONTROL AND

ANNUNCIATOR PANELS

Cabinets for Scientific use may be equipped with a v ariety of

optional control, alarm, and recorder devices. Each cabinet

is shipped with the appropriate operators manual for the

device installed on the cabinet.These operator manuals pertain to the set-up and basic operation of the control panel

devices. For more comprehensive operation, repair, and

maintenance information refer to the control panel service

manual part number 51-0170-01.

FIGURE 2

Page 9

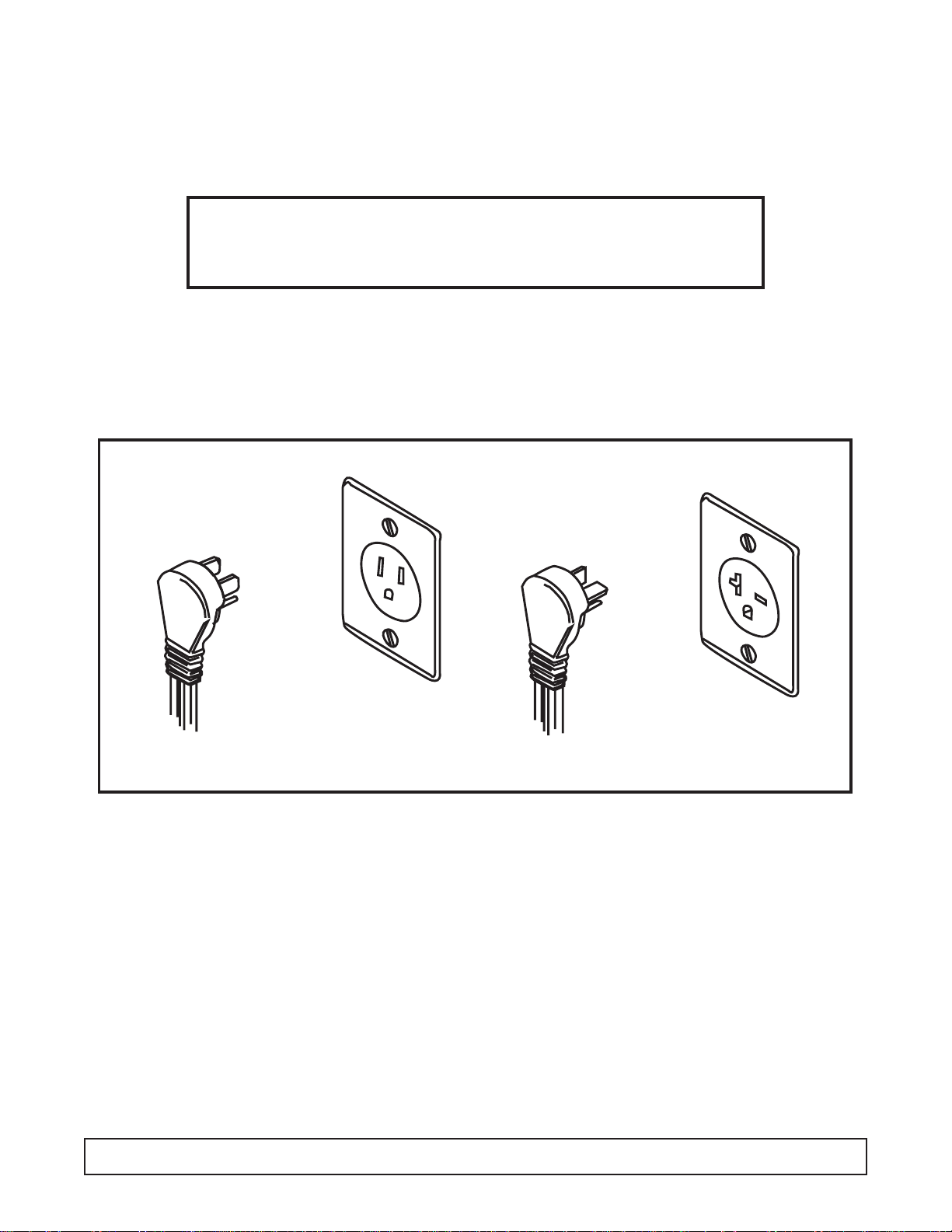

GROUNDING INSTRUCTIONS/SERIAL RATING PLATES 7

GROUNDING INSTRUCTIONS

This appliance is equipped with a three-prong

(grounding) plug for your protection against shock

hazards.The appliance should be plugged directly into

a properly grounded three-prong receptacle.

Where a two-prong wall receptacle is encountered, it

must be replaced with a properly grounded three

prong receptacle in accordance with the National

Electrical Code and local codes and ordinances. The

work must be done by a licensed electrician.

IMPORTANT

Do not under any circumstances cut or remove

the round grounding prong from the equipment plug.

WARNING

Consult a licensed electrician if you have any doubt about the grounding

of your wall receptacle. Only a licensed electrician can determine the

polarization of your wall receptacle. Only a properly installed three-pronged

wall receptacle assures the proper polarization with the equipment plug.

SERIAL RATING PLATES

Serial Number Rating Plates on each vertical cabinet

are located on the inside upper left hand corner.This

plate contains all technical data necessary to the oper-

ation of the cabinet. Warranty administration is based

on the serial number as printed on the rating plate.

15 Amp

20 Amp

Page 10

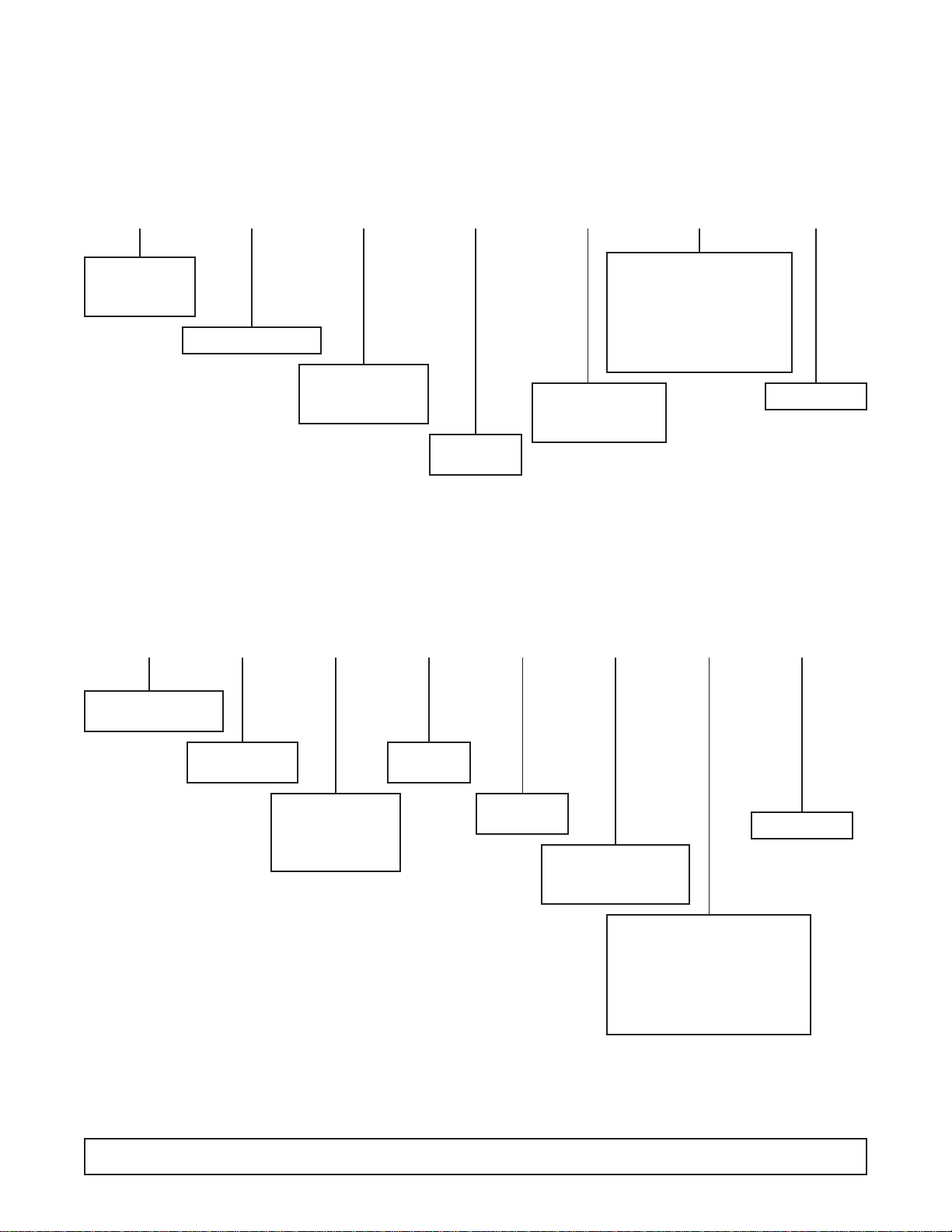

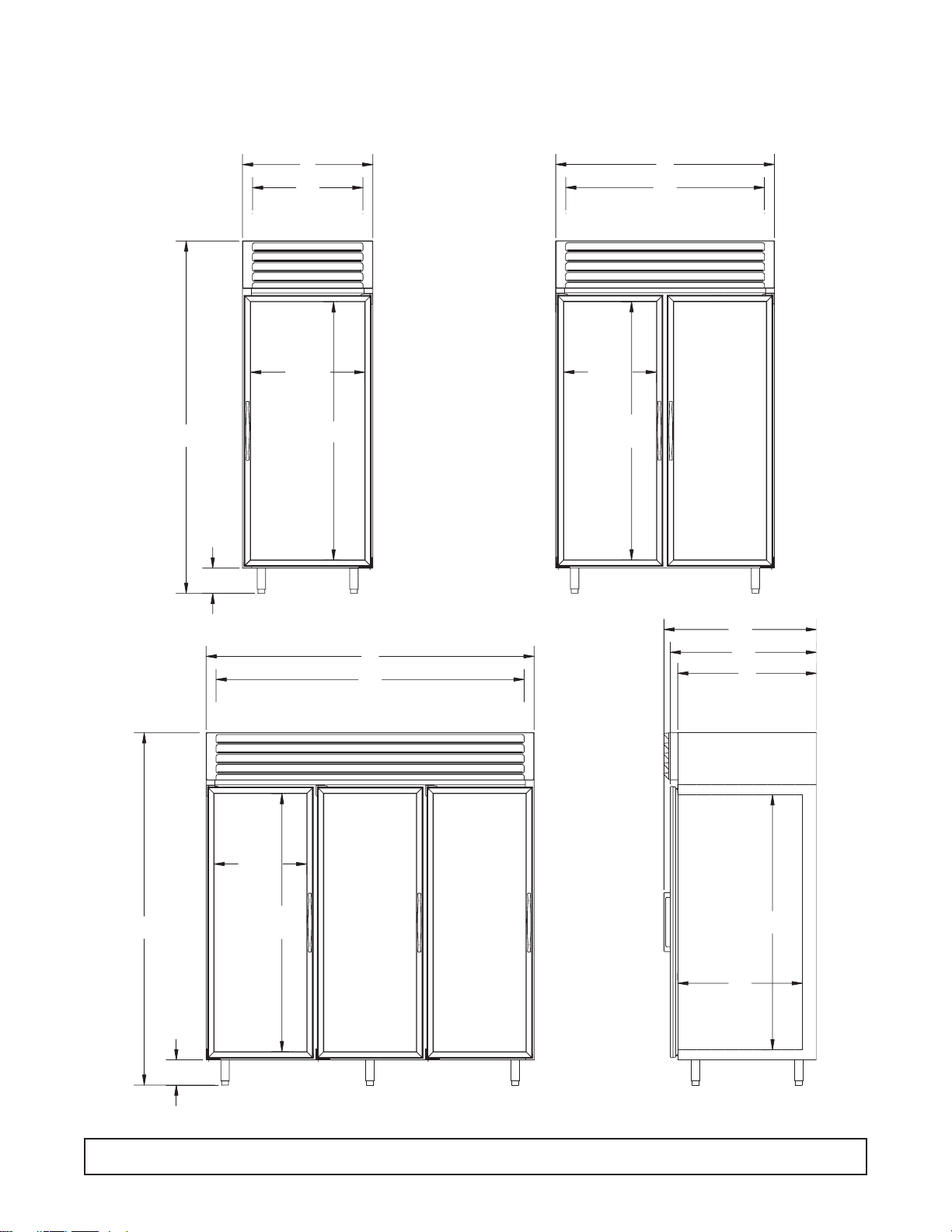

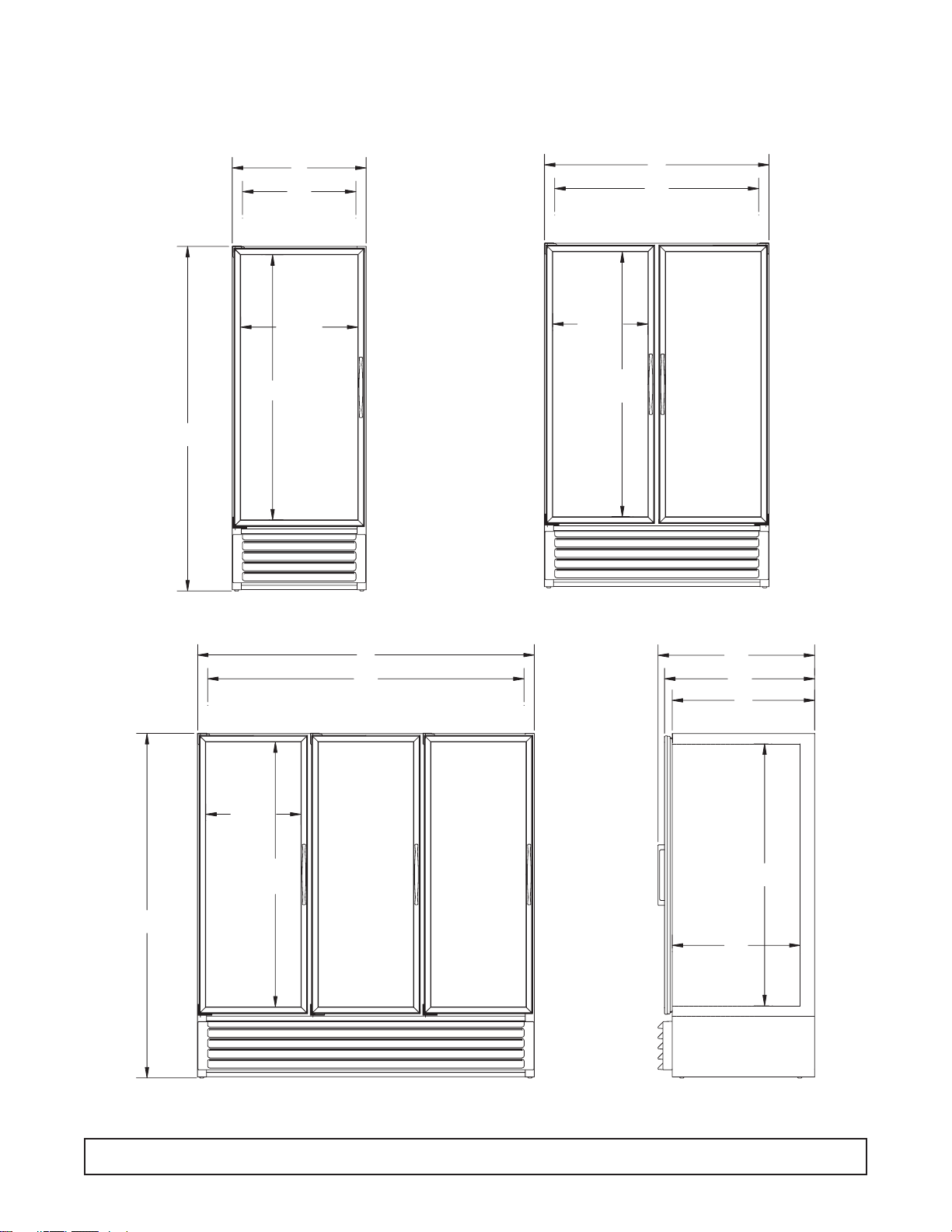

Medium Temperature, Top Mount, Glass Pull Door

Refrigerators Dimensional Drawings

8TOP MOUNT GLASS PULL DOOR DIMENSIONAL DRAWINGS

833/4

61

GLASS

TYP.

52

1

/4

47

INTERIOR

31

261/4

INTERIOR

3

/4

26

GLASS

61

GLASS

6

5

21

GLASS

TYP.

/8

1

/4

36

78

1

/4

73

INTERIOR

5

21

/8

GLASS

TYP.

61

3

83

/4

6

GLASS

TYP.

343/4

33

INTERIOR

295/8

INTERIOR

605/8

SIDE VIEW

Page 11

Medium Temperature, Top Mount, Glass Pull Door

Refrigerators Specifications

TOP MOUNT GLASS DOOR REFRIGERATOR SPECIFICATIONS 9

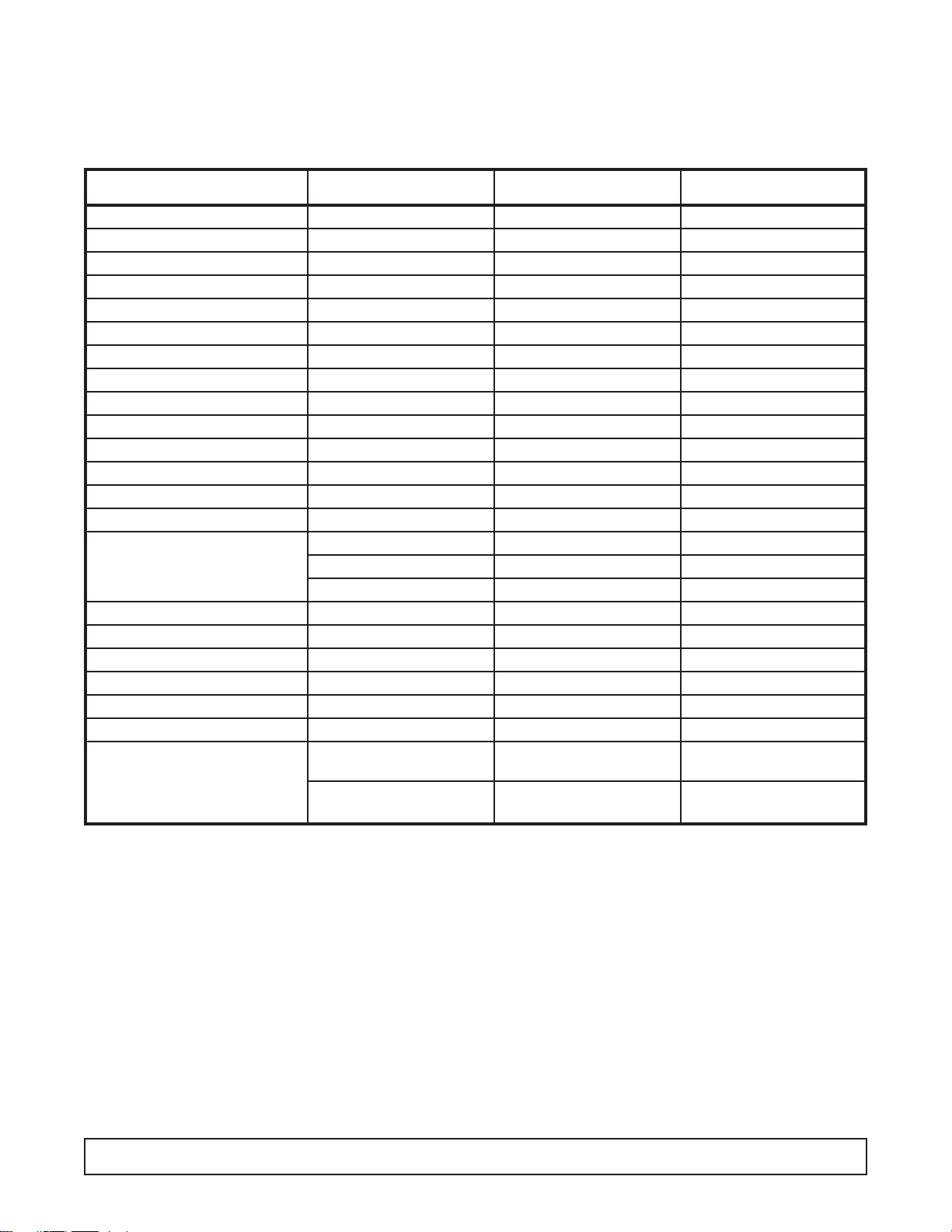

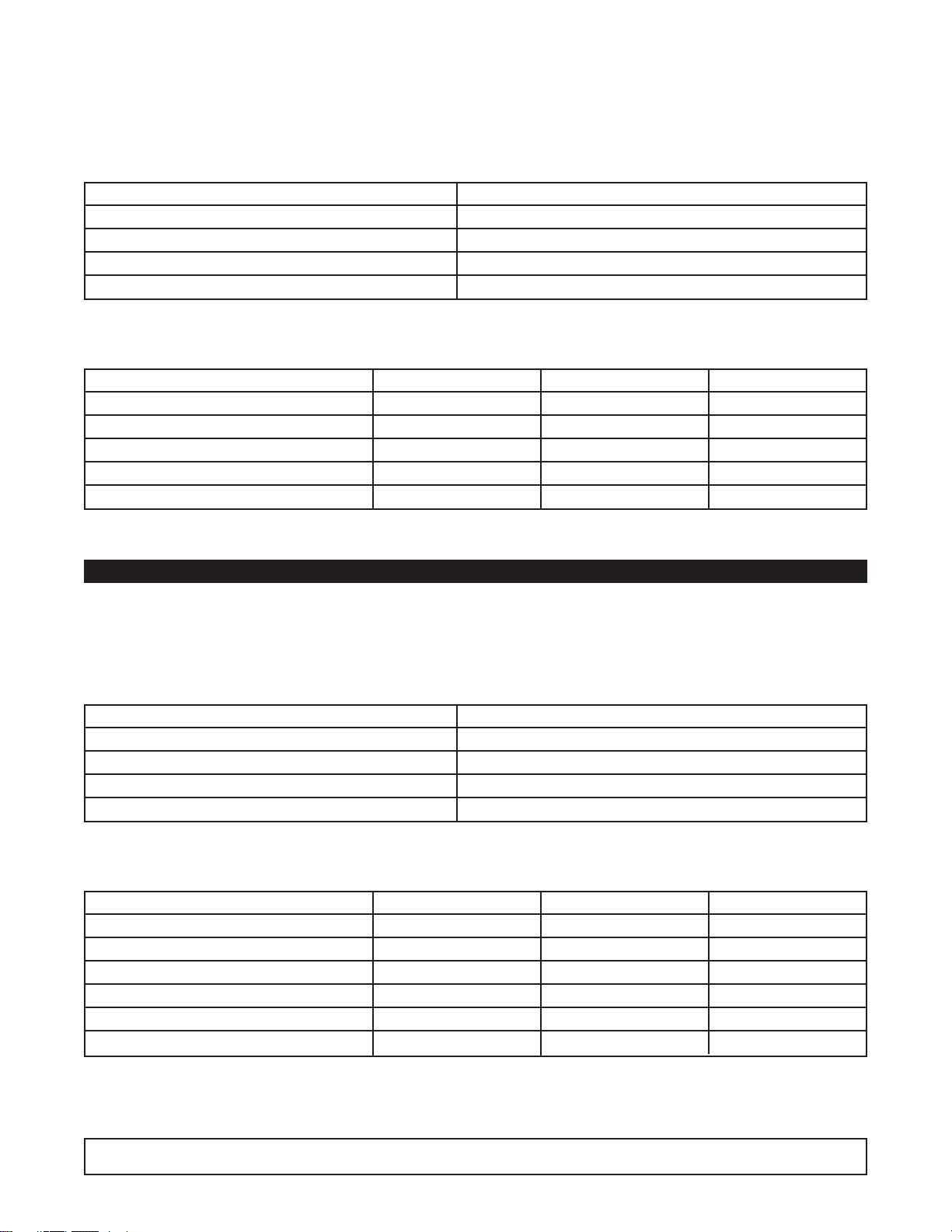

Specification 1-Door 2-Door 3-Door

Compressor Mount Top Top Top

Temperature Range 32° to 55° (0° to 13°C) 32° to 55° (0° to 13°C) 32° to 55° (0° to 13°C)

Number of Doors 1 2 3

Door Construction Double Pane Double Pane Double Pane

Hinge Type Torsion Bar Torsion Bar Torsion Bar

Insulation - CFC-Free Foam-in-Place Urethane Foam-in-Place Urethane Foam-in-Place Urethane

Wall Thickness 2 3/8" 2 3/8" 2 3/8"

Capacity - Gross 27.3 ft.

3

49.1 ft.

3

76.2 ft.

3

Shipping Weight (Approx.) 470 lbs. 640 lbs. 870 lbs.

Compressor BTUH/-10°F Evap. 2400 5400 5400

Condenser Type Fin & Tube Forced Air Fin & Tube Forced Air Fin & Tube Forced Air

Evaporator Type Fin & Tube Forced Air Fin & Tube Forced Air Fin & Tube Forced Air

Refrigerant Type R-404A R-404A R-404A

Refrigerant Control Expansion Valv e Expansion Valve Expansion Valv e

Amp Rating 9.5 12.1 14.5

11.2 BT30RG & ST30RGBB 13.8 BT50RG & ST50RGBB 16.0BG80RG

13.2 BT30RGCH 15.8 BT50RGCH

Electrical Specs. (V / Hz / Ph) 115 / 60 / 1 115 / 60 / 1 115 / 60 / 1

NSF NSF7 NSF7 NSF7

UL & CSA Listed Yes Yes Yes

Interior Finish Baked Enamel, Coved Corners Baked Enamel, Coved Corners Baked Enamel, Coved Corners

Exterior Finish Baked Enamel Baked Enamel Baked Enamel

Lighting

2 Insul. 1500 Milliamp Fluor. Lamps 3 Insul. 1500 Milliamp Fluor. Lamps 4 Insul. 1500 Milliamp Fluor. Lamps

Electrical Information 15 Amp Service Cord 20 Amp Ser vice Cord 20 Amp Ser vice Cord

w/NEMA 5-15P Plug w/NEMA 5-20 Plug w/NEMA 5-20P Plug

20 Amp Cord BT30RGCH

w/NEMA 5-20P Plug

Page 12

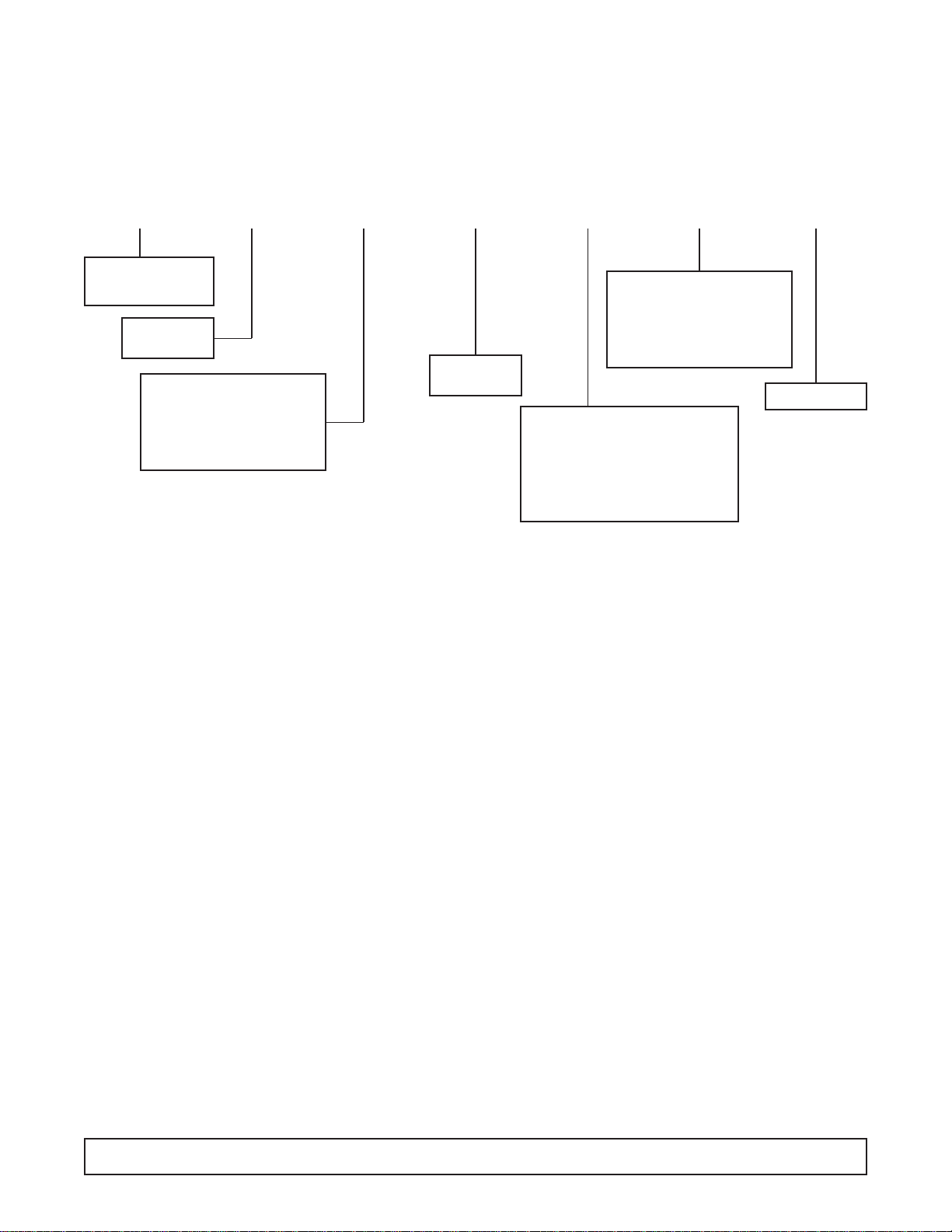

Medium Temperature, Bottom Mount, Glass

Pull Door Refrigerators Dimensional Drawings

10 BOTTOM MOUNT DIMENSIONAL DRAWINGS

61

GLASS

TYP.

52

1

47

/4

INTERIOR

31

1

26

/4

INTERIOR

5

21

263/4

GLASS

61

GLASS

3

/4

79

GLASS

TYP.

/8

78

1

/4

73

INTERIOR

5

/8

21

GLASS

TYP.

61

GLASS

TYP.

3

/4

79

1

36

/4

343/4

33

295/8

INTERIOR

SIDE VIEW

5

/8

60

INTERIOR

Page 13

Medium Temperature, Bottom Mount, Glass

Pull Door Refrigerators Specifications

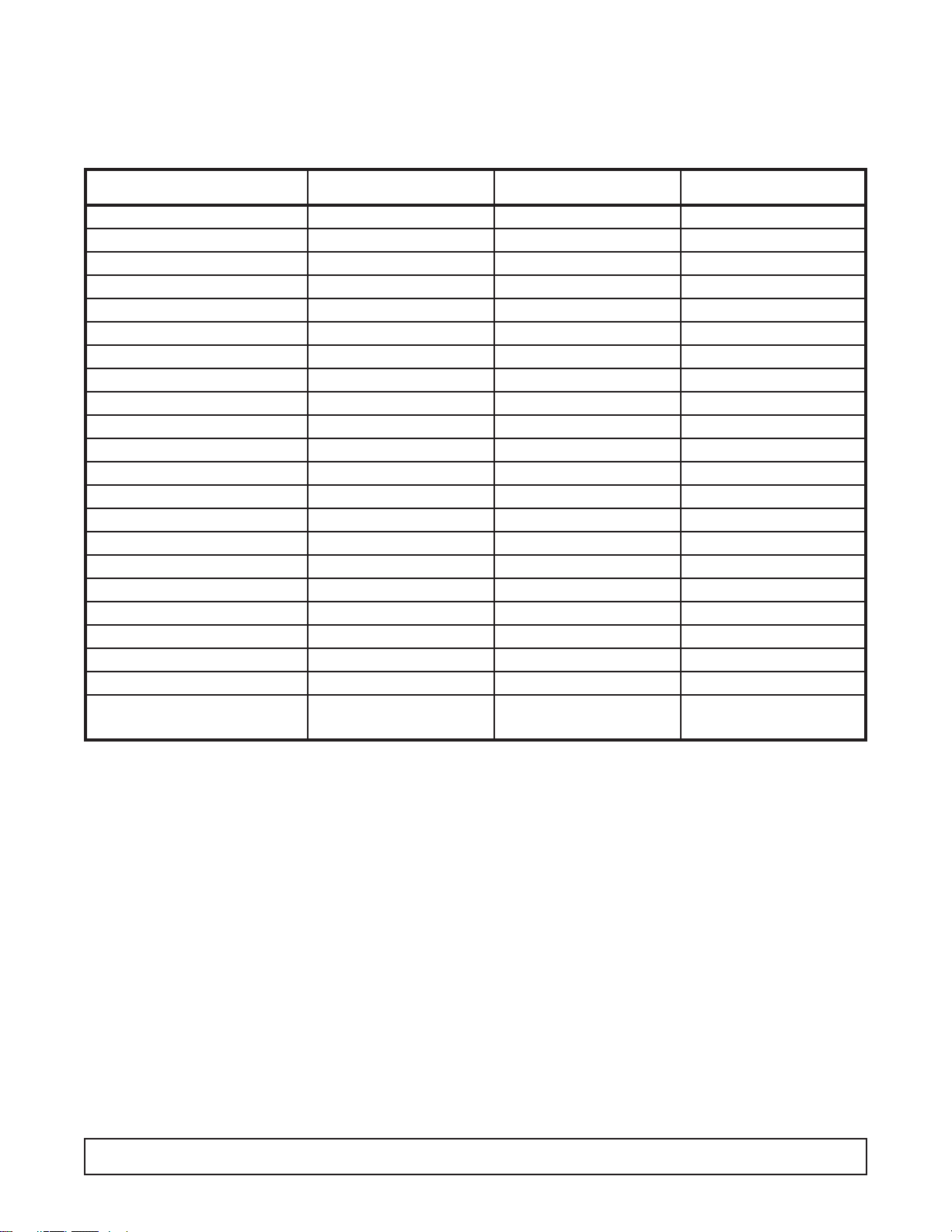

BOTTOM MOUNT REFRIGERATOR SPECIFICATIONS 11

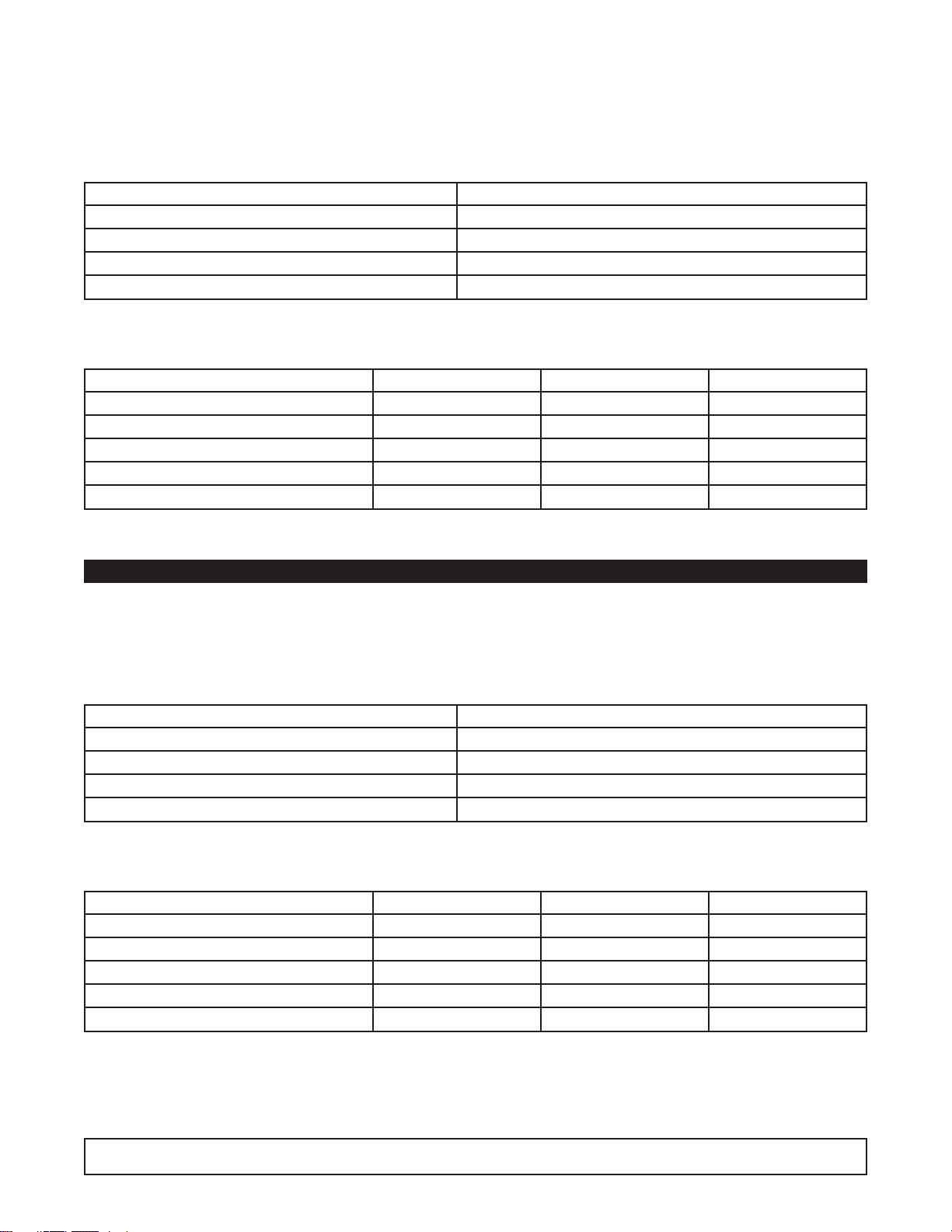

Specification 1-Door 2-Door 3-Door

Compressor Mount Bottom Bottom Bottom

Temperature Range 32° to 55° (0° to 13°C) 32° to 55° (0° to 13°C) 32° to 55° (0° to 13°C)

Number of Doors 1 2 3

Door Construction Double Pane Double Pane Double Pane

Hinge Type Torsion Bar Torsion Bar Torsion Bar

Insulation - CFC-Free Foam-in-Place Urethane Foam-in-Place Urethane Foam-in-Place Urethane

Wall Thickness 2 3/8" 2 3/8" 2 3/8"

Capacity - Gross 27.3 ft.

3

49.1 ft.

3

76.2 ft.

3

Shipping Weight (Approx.) 488 lbs. 640 lbs. 724 lbs.

Compressor BTUH/-10°F Evap. 2400 5400 5400

Condenser Type Fin & Tube Forced Air Fin & Tube Forced Air Fin & Tube Forced Air

Evaporator Type Fin & Tube Forced Air Fin & Tube Forced Air Fin & Tube Forced Air

Refrigerant Type R-404A R-404A R-404A

Refrigerant Control Expansion Valv e Expansion Valve Expansion Valv e

Amp Rating 9.5 12.1 14.5

Electrical Specs. (V / Hz / Ph) 115 / 60 / 1 115 / 60 / 1 115 / 60 / 1

NSF NSF7 NSF7 NSF7

UL & CSA Listed Yes Yes Yes

Interior Finish Baked Enamel, Coved Corners Baked Enamel, Coved Corners Baked Enamel, Coved Corners

Exterior Finish Baked Enamel Baked Enamel Baked Enamel

Lighting

2 Insul. 1500 Milliamp Fluor. Lamps 3 Insul. 1500 Milliamp Fluor. Lamps 4 Insul. 1500 Milliamp Fluor. Lamps

Electrical Information 15 Amp Service Cord 20 Amp Ser vice Cord 20 Amp Ser vice Cord

w/NEMA 5-15P Plug w/NEMA 5-20P Plug w/NEMA 5-20P Plug

Page 14

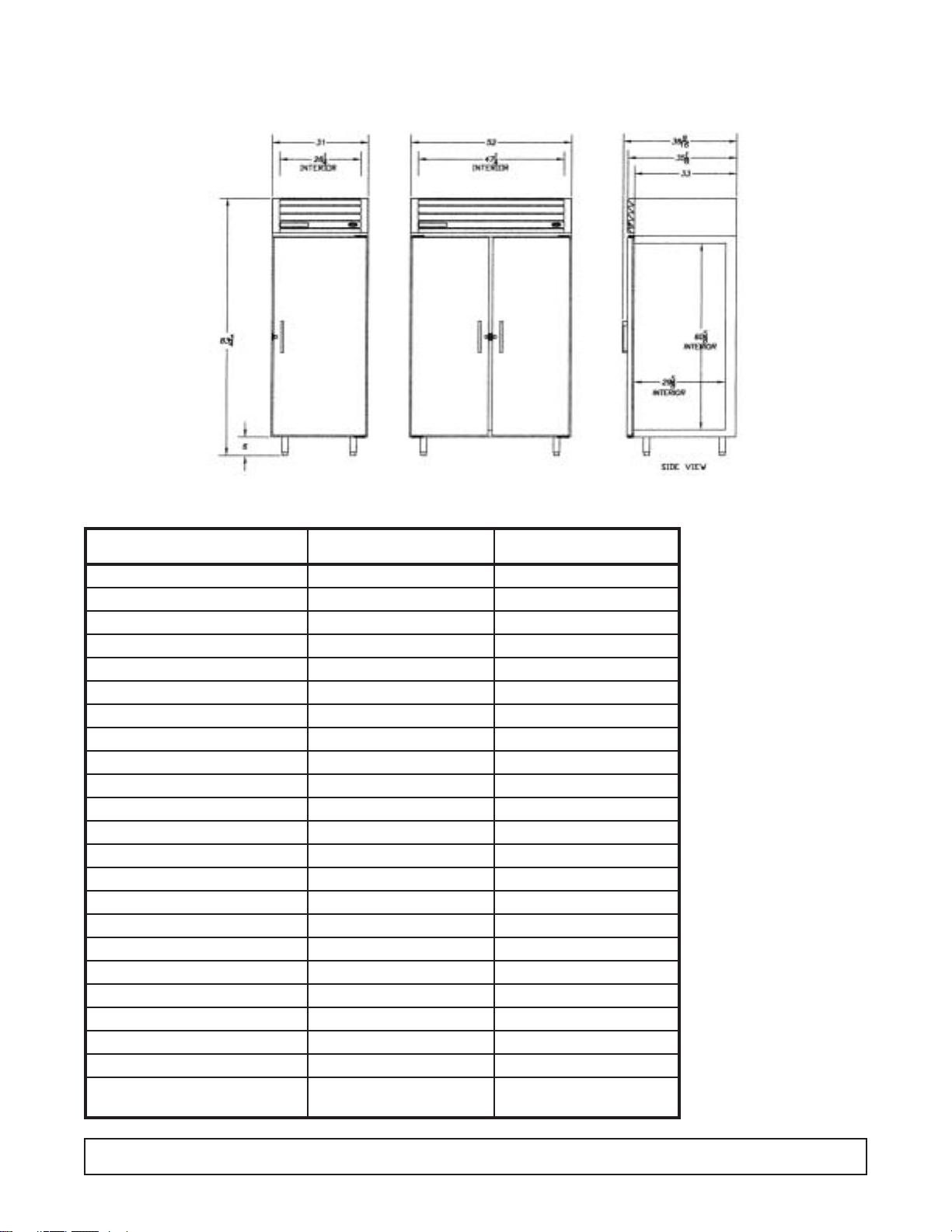

12 TOP MOUNT SOLID DOOR DRAWINGS & SPECIFICATIONS

Medium Temperature, Top Mount, Solid Pull Door

Dimensional Drawings

Specification 1-Door 2-Door

Compressor Mount Top Top

Temperature Range 32° to 55° (0° to 13°C) 32° to 55° (0° to 13°C)

Number of Doors 1 2

Door Construction Foam-In-Place Foam-In-Place

Hinge Type Camlift Camlift

Insulation Foam-in-Place Urethane Foam-in-Place Urethane

Wall Thickness 2 3/8" 2 3/8"

Capacity - Gross 27.3 ft.

3

49.1 ft.

3

Shipping Weight (Approx.) 440 lbs. 604 lbs.

Compressor BTUH/-10°F Evap. 2126 2126

Condenser Type Fin & Tube Forced Air Fin & Tube Forced Air

Evaporator Type Fin & Tube Forced Air Fin & Tube Forced Air

Refrigerant Type R-404A R-404A

Refrigerant Control Expansion Valv e Expansion Valvee

Amp Rating (80° Running) 8.7 8.7

8.9 BT30RS 8.9 BT50RS

Electrical Specs. (V / Hz / Ph) 115 / 60 / 1 115 / 60 / 1

NSF NSF7 NSF7

UL Listed Yes Yes

Interior Finish Baked Enamel, Coved Corners Baked Enamel, Coved Cornerss

Exterior Finish Baked Enamel Baked Enamel

Compressor Make Tecumseh Tecumseh

Electrical Information 15 Amp Service Cord 15 Amp Ser vice Cord

w/NEMA 5-15P Plug w/NEMA 5-15P Plug

Refrigerator Specifications

Page 15

Compressor Model Number Copeland ASE24C3E-IAA

Recommended Operating Temp. Range 32°F to 55°F (0°C to 13°C)

Cabinet V olts 115

Expansion Device Sporlan FBS 1/4C BP40

Charge Refrig.Type / Oz. / Grams R404A / 23 / 652.0

ELECTRICAL & REFRIGERATION SPECIFICATIONS

Medium Temp., Glass, 1-Door Refrigerators

SYSTEM COMPONENTS

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) 40 / 4 40 / 4 41 / 5

Suction Pressure (PSIG / Kpa) 44 / 303 45 / 317 49 / 338

Discharge Pressure (PSIG / Kpa) 211 / 1455 237 / 1634 269 / 1855

Compressor Amps 6.3 6.3 6.5

Total Refrigeration Amps 8.7 8.8 9.0

SYSTEM PERFORMANCE

NOTE: REFER TO SERIAL DATA PLATE FOR REFRIGERANT TYPE & CHARGE.

Compressor Model Number Americold HP121-1-3087

Recommended Operating Temp. Range (F/C) 32°F to 55°F (0°C to 13°C)

Cabinet V olts 115

Expansion Device Capillary .054 x 7"

Charge Refrig.Type / Oz. / Grams R404A / 15 / 425.2

SYSTEM COMPONENTS

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) 38 / 3 38 / 3 37 / 3

Suction Pressure (PSIG / Kpa) 39 / 268 41 / 283 45 / 310

Discharge Pressure (PSIG / Kpa) 192 / 1324 217 / 1496 247 / 1703

Compressor Amps 3.9 4.0 4.2

Total Refrigeration Amps 5.7 5.8 6.0

SYSTEM PERFORMANCE

Medium Temp., Solid, 1-Door Refrigerators

1 DOOR (GLASS & SOLID) ELECTRICAL / REFRIGERATION SPECS 15

Page 16

ELECTRICAL & REFRIGERATION SPECIFICATIONS

Medium Temp., Glass, 2-Door Refrigerators

Compressor Model Number Copeland AST54CIE-CAA

Recommended Operating Temp. Range 32°F to 55°F (0°C to 13°C)

Cabinet V olts 115

Expansion Device Sporlan FBS 1/4C BP405

Charge Refrig.Type / Oz. / Grams R404A / 23 / 652.0

SYSTEM COMPONENTS

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) 49 / 9 50 / 10 50 / 10

Suction Pressure (PSIG / Kpa) 48 / 331 49 / 332 50 / 345

Discharge Pressure (PSIG / Kpa) 238 / 1641 271 / 1868 306 / 2110

Compressor Amps 11.0 11.4 11.2

Total Refrigeration Amps 14.2 14.7 14.6

SYSTEM PERFORMANCE

NOTE: REFER TO SERIAL DATA PLATE FOR REFRIGERANT TYPE & CHARGE.

Compressor Model Number Americold HP121-1-3087

Recommended Operating Temp. Range (F/C) 32°F to 55°F (0°C to 13°C)

Cabinet V olts 115

Expansion Device Capillary .054 x 7"

Charge Refrig.Type / Oz. / Grams R404A / 15 / 425.2

SYSTEM COMPONENTS

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) 40 / 4 40 / 4 39 / 4

Suction Pressure (PSIG / Kpa) 38 / 262 42 / 289 45 / 310

Discharge Pressure (PSIG / Kpa) 196 / 1351 231 / 1593 264 / 1820

Compressor Amps 3.9 4.2 4.4

Total Refrigeration Amps 5.8 6.0 6.2

Center Mullion Heater 2.5 watt / foot 529 OHMS 115V

SYSTEM PERFORMANCE

Medium Temp., Solid, 2-Door Refrigerators

16 2 DOOR (GLASS & SOLID) ELECTRICAL / REFRIGERATION SPECS

Page 17

ELECTRICAL & REFRIGERATION SPECIFICATIONS

Medium Temp., Glass, 3-Door Refrigerators

Compressor Model Number Copeland AST54CIE-CAA

Recommended Operating Temp. Range 32°F to 55°F (0°C to 13°C)

Cabinet V olts 115

Expansion Device Sporlan FBS 1/2CP BP40

Charge Refrig.Type / Oz. / Grams R404A / 24 / 680.4

SYSTEM COMPONENTS

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) 36 / 2 37 / 3 35 / 2

Suction Pressure (PSIG / Kpa) 43 / 296 42 / 289 43 / 296

Discharge Pressure (PSIG / Kpa) 205 / 1413 234 / 1648 271 / 1868

Compressor Amps 10.0 9.6 9.8

Total Refrigeration Amps 14.4 14.1 14.2

SYSTEM PERFORMANCE

NOTE: REFER TO SERIAL DATA PLATE FOR REFRIGERANT TYPE & CHARGE.

Compressor Model Number Americold HP110-1-3083

Recommended Operating Temp. Range (F/C) 32°F to 55°F (0°C to 13°C)

Cabinet V olts 115

Expansion Device Capillary .049 x 5"

Charge Refrig.Type / Oz. / Grams R404A / 15 / 425.2

SYSTEM COMPONENTS

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) 41 / 5 40 / 4 38 / 3

Suction Pressure (PSIG / Kpa) 39 / 268 42 / 290 46 / 317

Discharge Pressure (PSIG / Kpa) 172 / 1186 196 / 1351 229 / 1579

Compressor Amps 1.8 1.9 2.1

Total Refrigeration Amps 3.3 3.4 3.5

SYSTEM PERFORMANCE

Medium Temp., Solid, 1 & 2 Door FMS

3 DOOR (GLASS) & FMS ELECTRICAL / REFRIGERATION SPECS 17

Page 18

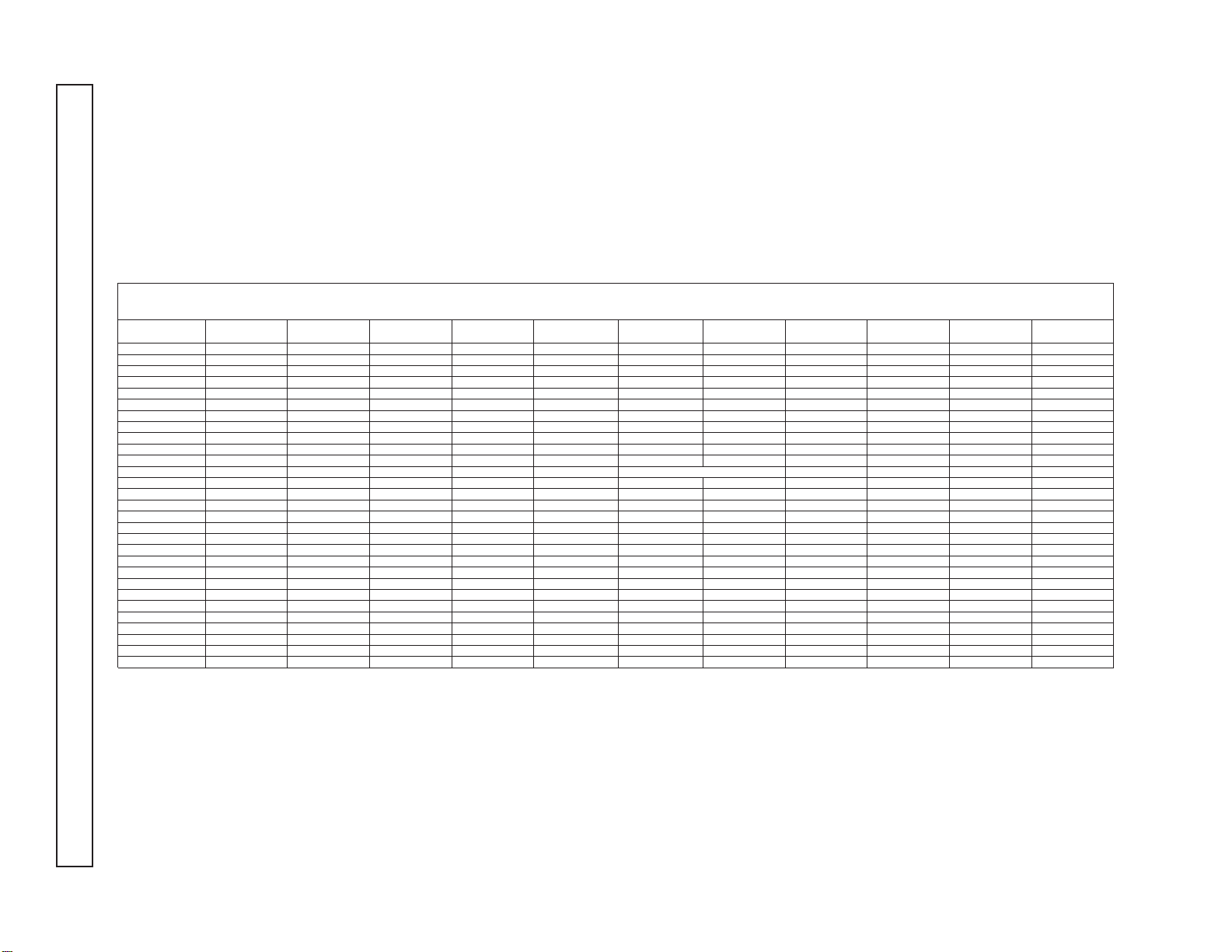

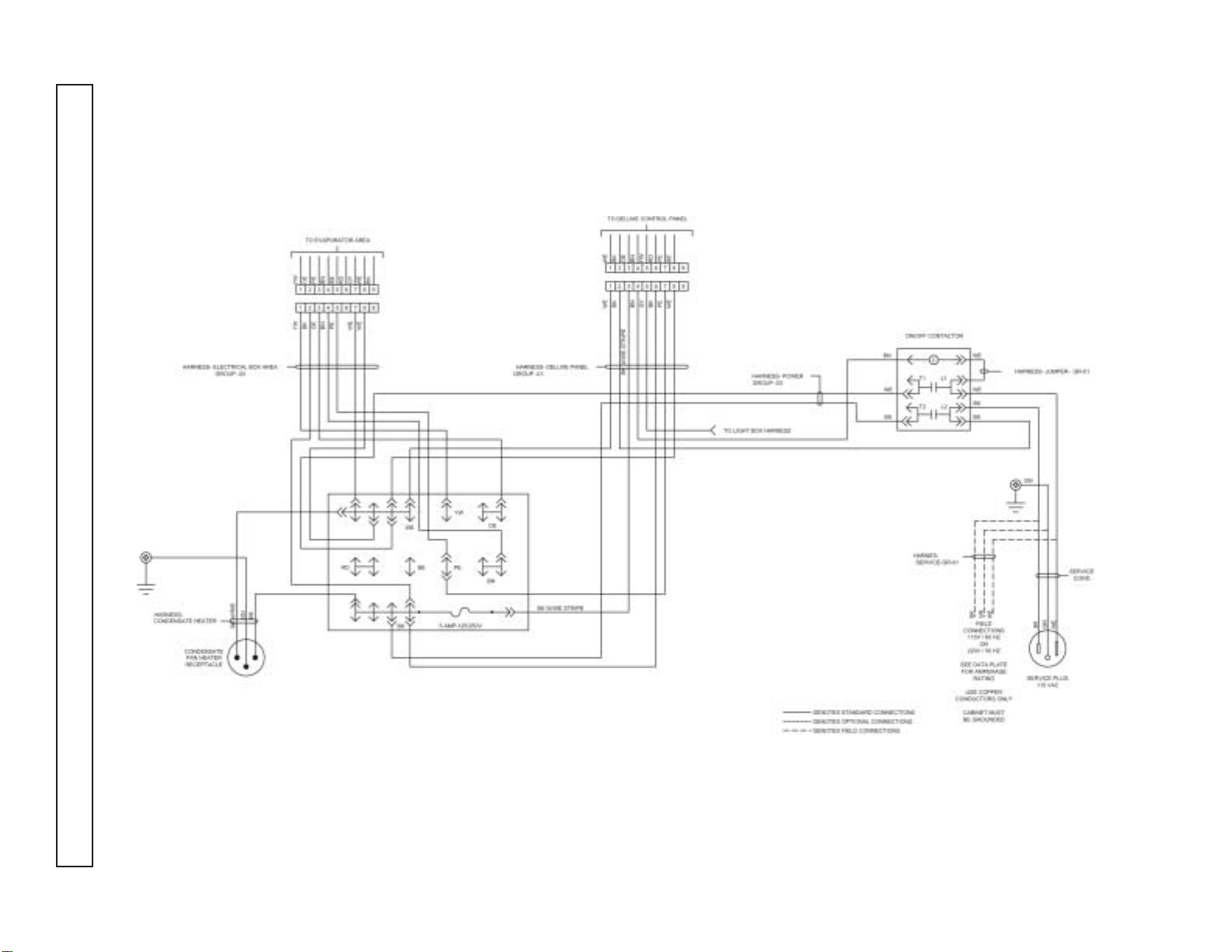

WIRING DIAGRAM REFERENCE

18 WIRING DIAGRAM REFERENCE

MODELS LADDER COMPRESSOR ELECT BOX

BT30RF- EXPR 26-0983-00

BT30RF-FMS 00-0428-00

BT30RG-4.1 00-0052-00 00-0137-00 00-0056-00 00-0050-01 00-0067-01 00-0058-01/02

BT30RGCH-4.1 00-0052-00 00-0137-00 00-0056-00 00-0059-00 00-0050-01 00-0067-01 00-0058-01/02

BT30RS-4.1 00-0052-00 00-0071-00 00-0056-00 00-0061-01 00-0061-05 00-0050-01 00-0058-01

BT30RSFMS-4.1 00-0055-00 00-0071-00 00-0057-00 00-0050-04 00-0058-01

BT50RG-4.1 00-0052-00 00-0084-00 00-0056-00 00-0061-04 00-0050-01 00-0067-02 00-0058-01/02

BT50RGCH-4.1 00-0052-00 00-0084-00 00-0056-00 00-0061-04 00-0059-00 00-0050-01 00-0067-02 00-0058-01/02

BT50RS-4.1 00-0052-00 00-0071-00 00-0056-00 00-0061-02 00-0061-04 00-0061-05 00-0050-01 00-0058-01

BT50RSFMS-4.1 00-0055-00 00-0071-00 00-0057-00 00-0050-04 00-0058-01

BT80RG-4.1 00-0052-00 00-0084-00 00-0056-00 00-0061-04 00-0050-01 00-0067-03 00-0058-01/02

ST260RIR-4.1 00-0053-00 00-0071-00 00-0064-00 00-0061-01 00-0061-04 00-0065-00 00-0050-03 00-0065-00 00-0017-12

ST30RGBB-4.1 00-0052-00 00-0137-00 00-0056-00 00-0061-01 00-0050-01 00-0067-01 00-0017-10

ST50RGBB-4.1 00-0052-00 00-0084-00 00-0056-00 00-0061-04 00-0050-01 00-0067-02 00-0017-10

T30MGP-4.1 00-0052-00 00-0137-00 00-0056-00 00-0050-01 00-0067-01

T30MSP-4.1 00-0052-00 00-0071-00 00-0056-00 00-0050-01

T50MGP-4.1 00-0052-00 00-0084-00 00-0056-00 00-0061-04 00-0050-01 00-0067-02

T50MGPR-4.1 00-0052-00 00-0056-00 00-0061-04 00-0050-01 00-0067-02 00-0060-00

T50MSP-4.1 00-0052-00 00-0071-00 00-0056-00 00-0061-04 00-0050-01

T80MGP-4.1 00-0052-00 00-0084-00 00-0056-00 00-0061-04 00-0050-01 00-0067-03

T80MGPR-4.1 00-0052-00 00-0056-00 00-0061-04 00-0050-01 00-0067-03 00-0060-00

UMG30BS-4.1 00-0052-00 00-0137-00 00-0056-00 00-0050-01 00-0067-01

UMG50BS-4.1 00-0052-00 00-0084-00 00-0056-00 00-0061-04 00-0050-01 00-0067-02

UMG50RS-4.1 00-0052-00 00-0056-00 00-0061-04 00-0050-01 00-0067-02 00-0060-00

UMG80BS-4.1 00-0052-00 00-0084-00 00-0056-00 00-0061-04 00-0050-01 00-0067-03

UMG80RS-4.1 00-0052-00 00-0056-00 00-0061-04 00-0050-01 00-0067-03 00-0060-00

UMH30BS-4.1 00-0052-00 00-0137-00 00-0056-00 00-0050-01 00-0067-01

UMH50BS-4.1 00-0052-00 00-0084-00 00-0056-00 00-0061-04 00-0050-01 00-0067-02

UMH80BS-4.1 00-0052-00 00-0084-00 00-0056-00 00-0061-04 00-0050-01 00-0067-03

DOOR SWITCH,

RACEWAY

WIRING DIAGRAM REFERENCE

ANTI-SWEAT

HTR, RACEWAY

INCAND LIGHT,

RACEWAY

RECEPTACLE

BOX / LIGHT EVAPORATOR

LIGHTS,

FLUORESCENT SOLENOID

CONTROL

PANEL

Page 19

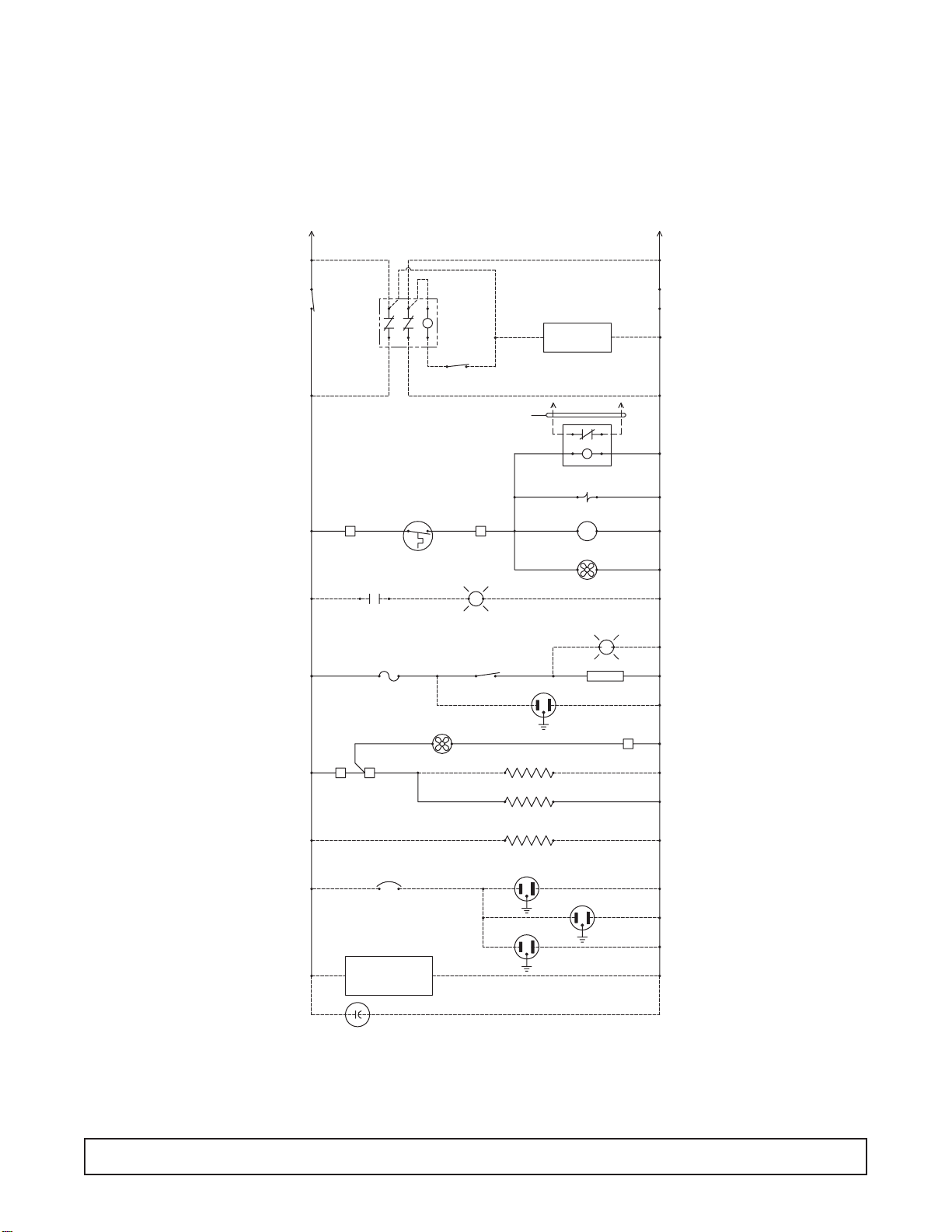

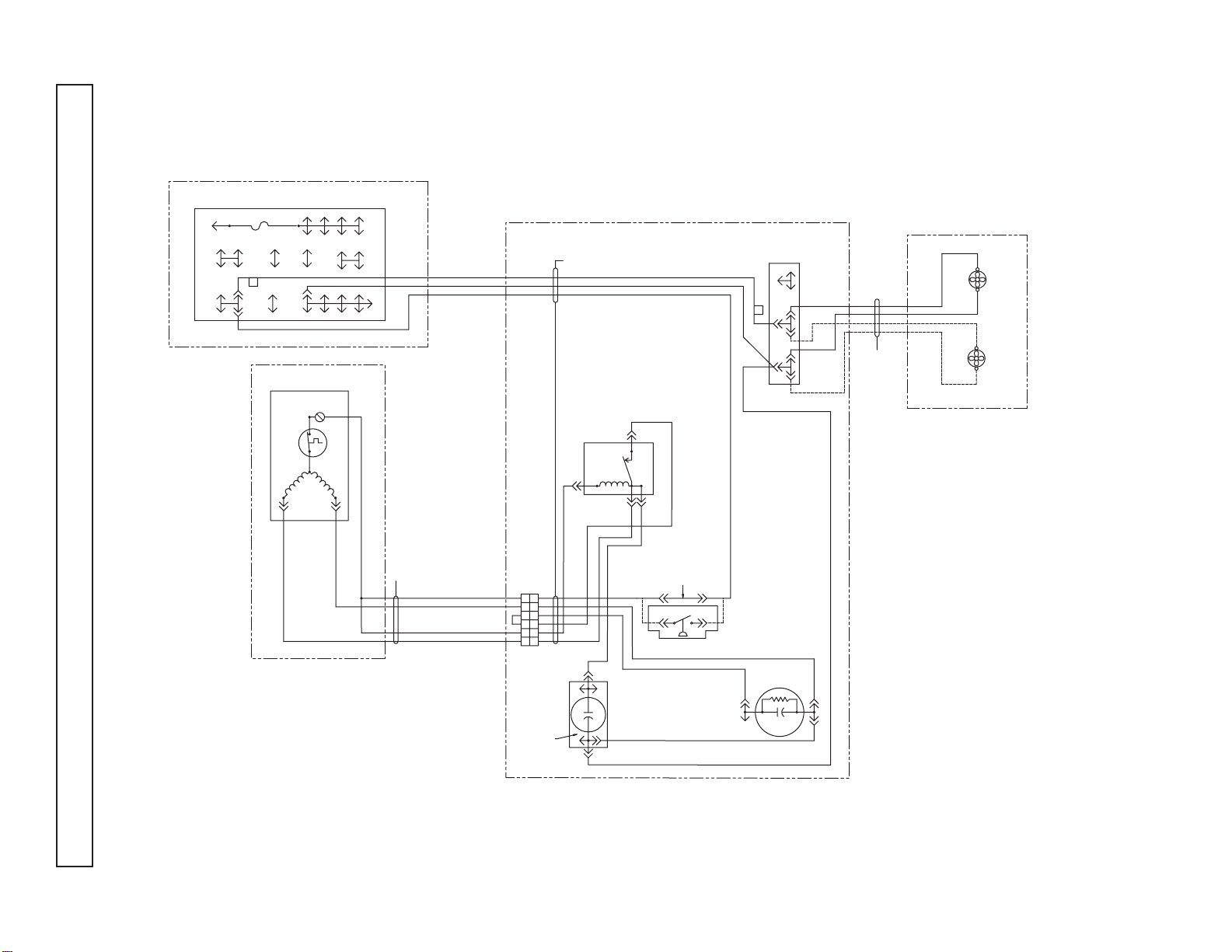

LADDER WIRING DIAGRAM – 00-0052-00

WIRING DIAGRAM 19

MED TEMP

115V, 60 HZ

220V, 50 HZ

ALL CONTROLS SHOWN IN OPERATING MODE

L1 N

CABINET MUST BE GROUNDED

DENOTES PIN NUMBER OF 9 PIN CONNECTOR

*

BK

SEE DATA PLATE FOR AMPERAGE RATING

USE COPPER CONDUCTORS ONLY

WE

C

M

OPTIONAL

INDICATOR

BALLAST/SLIGHT SWITCH

WE

L

DPSTDPST

ON/OFF

SWITCH

WE

POWER POWER

ON/OFF

SWITCH

BK OE

BK RD WE

OPTIONAL DOOR

(MODELS WITH FLUORESCENT LIGHTING SYSTEM)

BK

BK

WE

WE

OPTIONAL

ON/OFF

SWITCH

C

AND

CONTACTOR

BK

BN

WE

FIELD WIRED TO CONDENSING UNIT

USE COPPER CONDUCTORS ONLY

CAVITY T'STAT

OE OE OE WE

2

CNC

SWITCH/S

OPTIONAL INCANDESCENT

FUSE

INTERIOR LIGHT

OR DOOR AJAR

INDICATOR

BK/WE

BK

BK

COMP. CONTROL CONTACTOR

LIQUID LINE SOLENOID VALVE

3

(SELF CONTAINED MODELS)

L

(SELF CONTAINED MODELS)

BK WE

OPTIONAL DELUXE

CONTROL PANEL

BLOOD BANK MODELS

OE

(REMOTE MODELS)

OE

(REMOTE MODELS)

COMPRESSOR

OE WE

COND FAN/S

GY

RECEPTACLEOPTIONAL LIGHTED SIGN KIT

GY

WE

WE

WE

BK

94

BK

OPTIONAL CIRCUIT BREAKER

BK WE

OPTIONAL POWER

FACTOR CORRECTION

CAPACITOR 55 MFD

BN WE WE

BN

BK BK WE

EVAP FAN/S

BN

OPTIONAL RECEPTACLES

OPTIONAL

CHART RECORDER

WEBK

BN

OPTIONAL HEATED GLASS DOOR/S

BN WE

MULLION HEATERS/S

(SOLID 2 & 3 DOOR MODELS)

BK BK W/RIB

CONDENSATE PAN HEATER

OPTIONAL

BK

BK

WE

WE

WE

WE

BK

P/N 00-0052-00 Rev A

8

Page 20

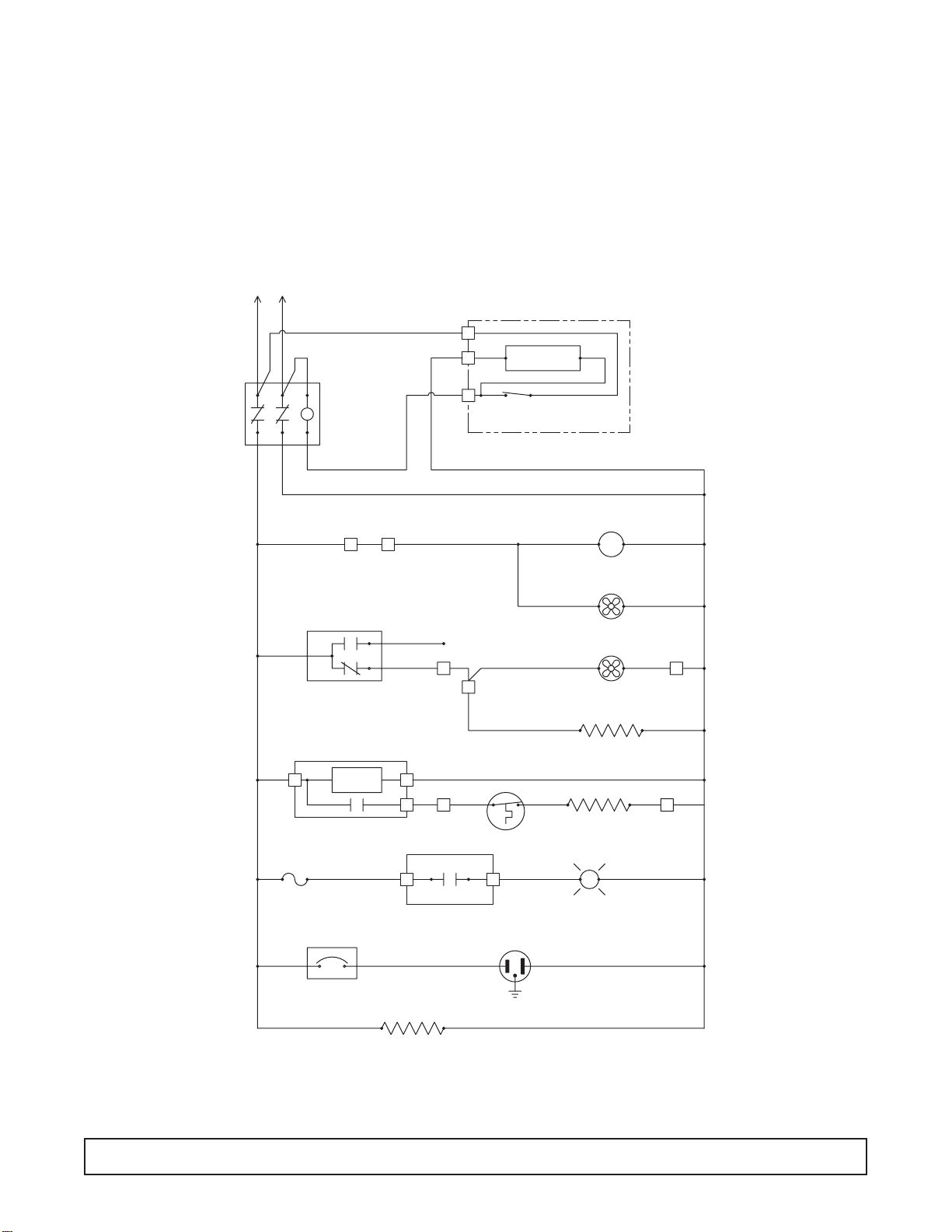

LADDER WIRING DIAGRAM – 00-0053-00

20 WIRING DIAGRAM

INCUBATOR

115V, 60 HZ

220V, 50 HZ

ALL CONTROLS SHOWN IN OPERATING MODE

CABINET MUST BE GROUNDED

*

DENOTES PIN NUMBER OF 9 PIN CONNECTOR

L1 N

BK

WE

BK

WE

WE

ON/OFF

C

CONTACTOR

BK

BN

WE

BK

DOOR SWITCH

BK OE

OE

23

NC

NO

SEE DATA PLATE FOR AMPERAGE RATING

USE COPPER CONDUCTORS ONLY

BK

2

WEBKWE

1

BN

4

RD

YW

YW BN

1

4EVAP FAN

BN

BN

ON/OFF

SWITCH

CONTROL PANEL

TEMPERATURE

MONITOR

DELUXE

PERIMETER HEATER

BN

BK

OE WE

M

COMPRESSOR

CONDENSOR FAN

BN WE

BN WE

WEOE

8

BK WE

RD

DELUXE

CONTROL PANEL

FUSE

BK

CIRCUIT BREAKER

CONDENSATE PAN HEATER

BK/WE OE

BE

TEMP

CONTROL

86

PE

PE

7

HIGH TEMP SAFETY

LIGHT SWITCH

DELUXE

CONTROL PANEL

BK

BK BK W/RIB

RD BK

5

T'STAT

53

RECEPTACLE

BK WE

GYYW

CAL-ROD

INCANDESCENT

INTERIOR LIGHT

P/N 00-0053-00

GY WE

7

L

Page 21

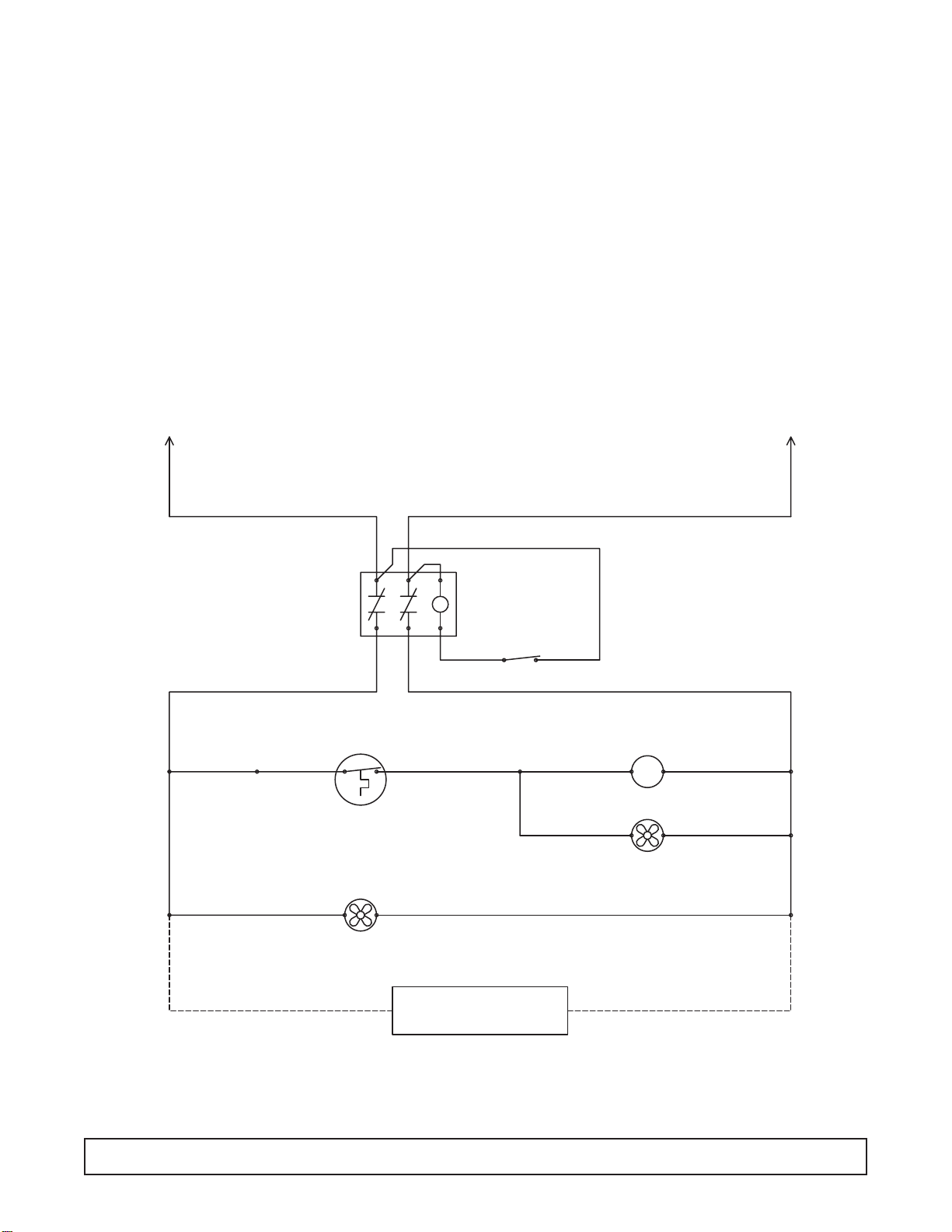

LADDER WIRING DIAGRAM – 00-0055-00

WIRING DIAGRAM 21

MEDIUM TEMP SCIENTIFIC

115V, 60 HZ

220V, 50 HZ

ALL CONTROLS SHOWN IN OPERATING MODE.

SEE DATA PLATE FOR AMPERAGE RATING

USE COPPER CONDUCTORS ONLY

CABINET MUST BE GROUNDED

L1 N

BK

BK

OE

BK WE

CAVITY

T'STAT

BK

BK W/RIB

OE

BK

WE

ON/OFF

C

SWITCH

& CONTACTOR

BN

BK

COMPRESSOR

OE WE

CONDENSOR FAN/S

WE

WEOE

M

EVAPORATOR FAN/S

OPTIONAL

CHART RECORDER

WEBK

P/N 00-0055-00

Page 22

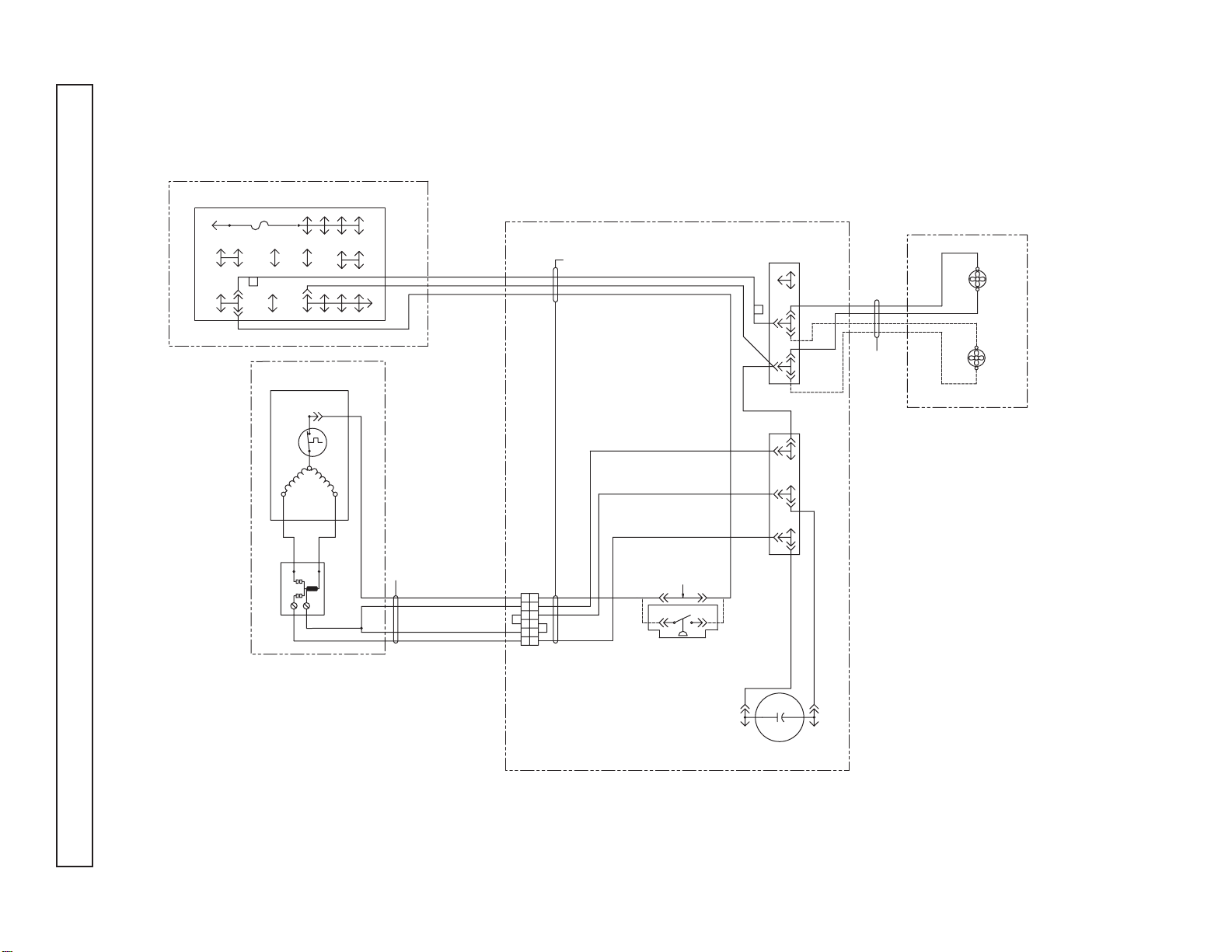

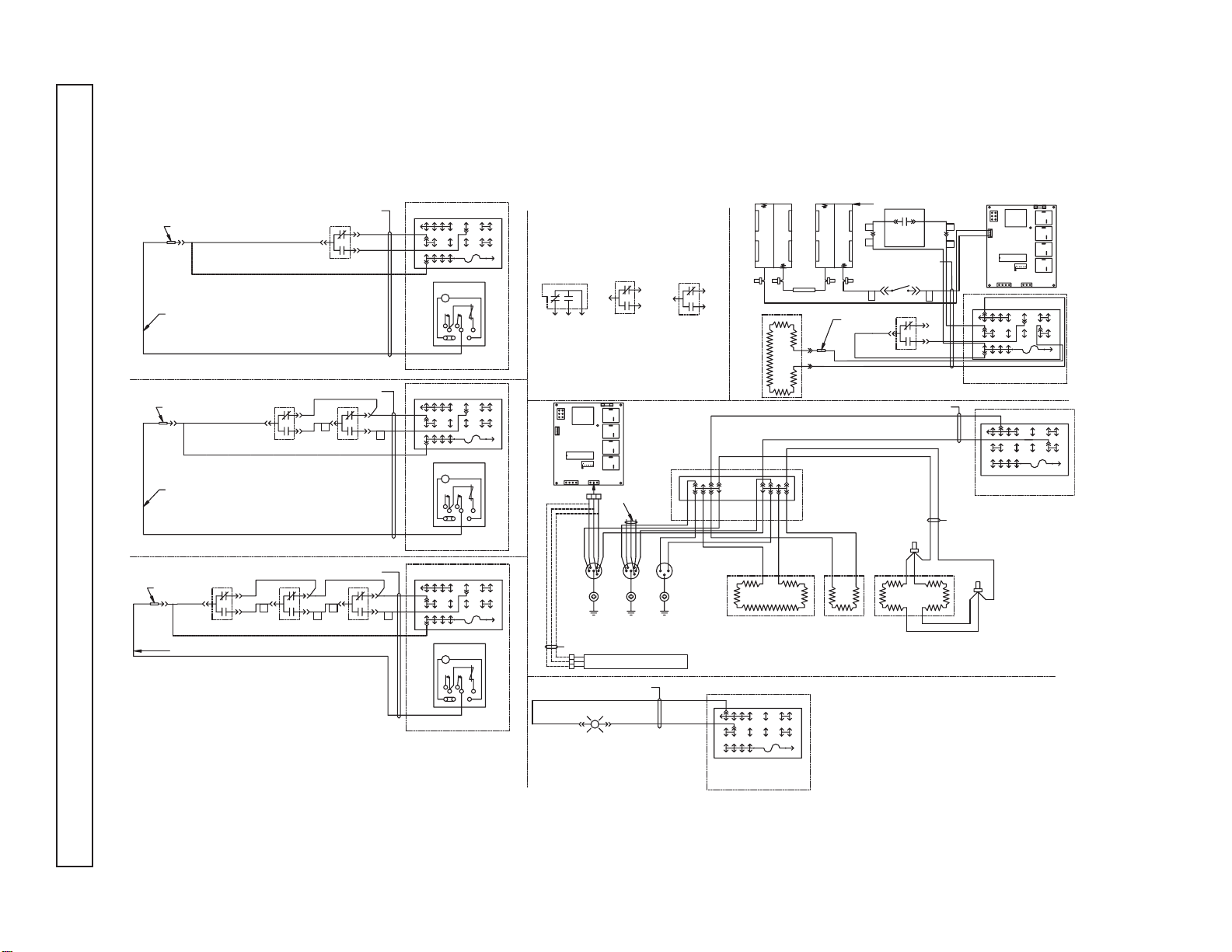

COMPRESSOR WIRING DIAGRAM – 00-0071-00

22 WIRING DIAGRAM

ELECTRICAL BOX ASSY

5 AMP-125/250V

BN

F

OE

TERMINAL BLOCK

AMERICOLD COMPRESSOR ASSY

O.L.

S

PIN

BE

RD

BEPE

WEYW

COMPRESSOR

C

RELAY

3

2

1

4

BK

START BOX ASSY

TERM

I

NAL BOAR

RD

R

PIN

WE

HARNESS- COMPRESSOR GR-01

OE

HARNESS- START

GR-01

6

6

5

5

4

4

3

3

2

2

1

1

115V, 60 HZ

220V, 50 HZ

JUMPER (REMOVE WHEN

INSTALLING PRESSURE SWITCH)

OE

PRESSURE SWITCH

(OPTIONAL)

E

O

F

OE

E

W

WE

WE

RD

D

BK

B

K

B

K

OR

WE

CONDENSOR

FAN LEADS

B

K

R

O

W

E

B

K

B

K

BE

NOTES-

1) STANDARD CONNECTIONS SHOWN WITH SOLID LINES;

OPTIONAL CONNECTIONS SHOWN WITH DASHED LINES.

K

B

K

B

2) F FORWARD ROTATION CONDENSOR FAN

(NORMAL OPERATION)

F

CONDENSOR

FAN #1

F

CONDENSOR

FAN #2

(OPTIONAL)

CONDENSOR FAN ASSY

B

B

K

RUN CAP

K

START CAP

Page 23

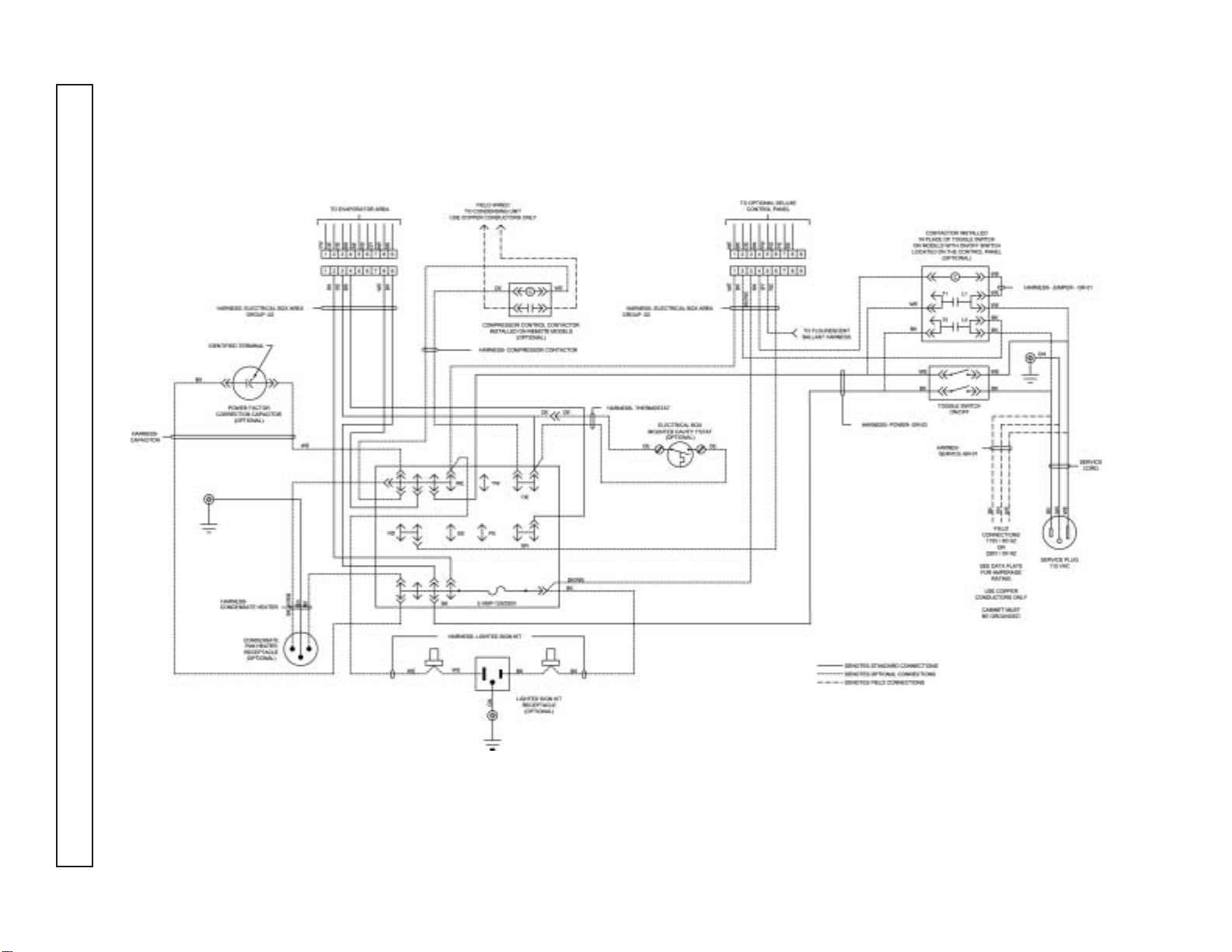

COMPRESSOR WIRING DIAGRAM – 00-0084-00

WIRING DIAGRAM 23

ELECTRICAL BOX ASSY

5 AMP-125/250V

BN

F

OE

TERMINAL BLOCK

BK

BEPE

WEYW

COPELAND AST54

COMPRESSOR ASSY

COMPRESSOR

START BOX ASSY

TERMINAL BOA

R

RD

HARNESS- START

GR-02

115V, 60 HZ

220V, 50 HZ

E

O

F

OE

E

W

WE

D

BK

B

K

B

K

R

O

W

E

CONDENSOR

FAN LEADS

B

K

OR

WE

F

CONDENSOR

FAN #1

F

CONDENSOR

FAN #2

(OPTIONAL)

CONDENSOR FAN ASSY

O.L.

C

S

BE

R

115V, 60 HZ

220V, 50 HZ

OE

WE

HARNESS- COMPRESSOR GR-05

6

5

4

3

2

1

6

5

4

3

2

1

RUN CAP

IDENTIF

TERMIN

OE

WE

BN

YW

RD

BE

IED

AL

RELAY

5

OE

BE

WE

WE

1

Z

JUMPER (REMOVE WHEN

INSTALLING PRESSURE SWITCH)

PRESSURE SWITCH

(OPTIONAL)

NOTES-

1) STANDARD CONNECTIONS SHOWN WITH SOLID LINES;

OPTIONAL CONNECTIONS SHOWN WITH DASHED LINES.

2) F FORWARD ROTATION CONDENSOR FAN

(NORMAL OPERATION)

BN

WE

START CAP

Page 24

COMPRESSOR WIRING DIAGRAM – 00-0137-00

24 WIRING DIAGRAM

ELECTRICAL BOX ASSY

5 AMP-125/250V

BN

F

OE

TERMINAL BLOCK

BK

BEPE

WEYW

COPELAND ASE24

COMPRESSOR ASSY

COMPRESSOR

START BOX ASSY

TERMINAL BOAR

RD

HARNESS- START

GR-01

115V, 60 HZ

220V, 50 HZ

E

O

F

OE

E

W

WE

D

BK

B

K

B

K

O

R

WE

CONDENSOR

FAN LEADS

B

K

R

O

W

E

F

CONDENSOR

FAN #1

F

CONDENSOR

FAN #2

(OPTIONAL)

CONDENSOR FAN ASSY

S

RELAY

O.L.

C

R

115V, 60 HZ

S

M

1

WE

BE

OE

2

220V, 50 HZ

HARNESS- COMPRESSOR GR-01

WE

RD

JUMPER (REMOVE WHEN

INSTALLING PRESSURE SWITCH)

6

6

5

5

4

4

3

3

2

2

1

1

OE

PRESSURE SWITCH

(OPTIONAL)

WE

RD

BE

START CAP

B

K

NOTES-

1) STANDARD CONNECTIONS SHOWN WITH SOLID LINES;

OPTIONAL CONNECTIONS SHOWN WITH DASHED LINES.

2) F FORWARD ROTATION CONDENSOR FAN

(NORMAL OPERATION)

K

B

Page 25

ELECTRICAL BOX WIRING DIAGRAM – 00-0056-00

WIRING DIAGRAM 25

Page 26

ELECTRICAL BOX WIRING DIAGRAM – 00-0057-00

26 WIRING DIAGRAM

Page 27

ELECTRICAL BOX WIRING DIAGRAM – 00-0064-00

WIRING DIAGRAM 27

Page 28

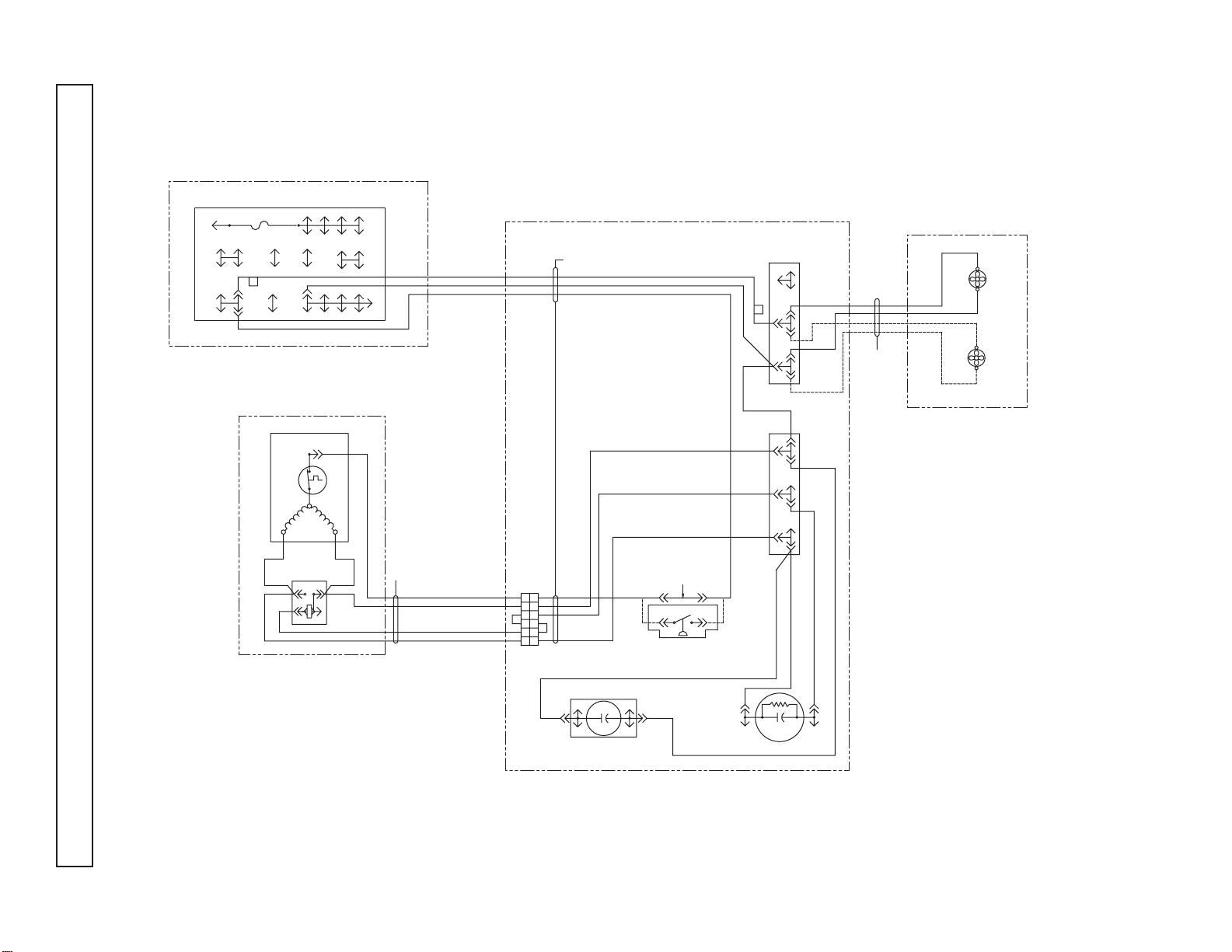

RACEWAY WIRING DIAGRAM – 00-0061-*

28 WIRING DIAGRAM

BLACK TAPE

OE

MED. TEMP & INCUBATOR MODELS

LOW TEMP "PULSE" MODELS

REMOVE "OE" WIRE ON MED. TEMP & INCUBATOR MODELS

LOW TEMP MODELS

*GR-01

OE

BLACK TAPE

1 DOOR

OPTIONAL DOOR SWITCH

MED. TEMP MODELS

LOW TEMP "PULSE" MODELS

REMOVE "OE" WIRE ON MED. TEMP MODELS

LOW TEMP MODELS

*GR-02

BLACK TAPE

OE

REMOVE "OE" WIRE ON MED. TEMP MODELS

*GR-03

2 DOOR

OPTIONAL DOOR SWITCHES

BK

DOOR 1

MED. TEMP MODELS

LOW TEMP "PULSE" MODELS

3 DOOR

VERTICAL MODELS

VERTICAL MODELS

BK

VERTICAL MODELS

RD

C

YW

LOW TEMP MODELS

HARNESS- DOOR SWITCH GROUP -01

BK

DOOR 1

HARNESS- DOOR SWITCH GROUP -02

RD

C

YW

DOOR 1

DOOR 2

HARNESS- DOOR SWITCH GROUP -03

RD

C

YW

NO

DOOR 2

OPTIONAL DOOR SWITCHES

DOOR 3

TERMINAL BLOCK

RD

YW

RD

ELECTRICAL BOX ASSY

WE

BE

BK

TIME CLOCK

T

12 N

OE

YW

PE BN

5 AMP-125/250V

X34

OE

ARCOELECTRIC

3

NC

NO

(RED)

12

C

DOOR SWITCH TERMINAL NUMBERS

McGILL

2

CARLINGSWITCH

1

3

2

3

1

+

-

-

+

RD

BK

BK

RECTIFIER

BK

WE

+

RD

RD

WE

*GR-06

RD

YW

NO

RD

YW

NO

TERMINAL BLOCK

YW

WE

RD

BE

PE

BK

5 AMP-125/250V

TIME CLOCK

T

43

X

1

N

2

OE

ELECTRICAL BOX ASSY

TERMINAL BLOCK

YW

WE

RD

BE

PE

5 AMP-125/250V

BK

TIME CLOCK

T

34

X

N

12

OE

ELECTRICAL BOX ASSY

34

OE

2

651

"PULSE"

(OPTIONAL)

BN

1 2 3 4 5 6 7 8

O

N

DISPLAY

1 324 213

3

12

CUT

WIRES

BK

RD

GN

BK

BN

BN

RD

GN

WE

WE

GN

OE

BN

HARNESS- DISPLAY

321

HARNESS- INCANDESCENT LIGHT

HARNESS- HARDENING CABINET LIGHT

WE RD

INCANDESCENT LIGHT

(OPTIONAL)

ALL SOLID DOOR VERTICAL MODELS

OPTIONAL INCANDESCENT INTERIOR LIGHT

GN

PULSE

PULSE

MODELS

MODELS

DOOR DOOR

W/0 DISPLAY

W/DISPLAY

PULSE DISPLAY IN SOLID DR FRT PANEL

OR

L

*GR-05

NON-PULSE

MODELS

GLASS HEAT

DOOR RECEPTACLE

GN

WE

(OPTIONAL)

WE

WE

WE

PERIMETER HEATER

BN

WE

TERMINAL BLOCK

RACEWAY

BNBNBN

BN

WE

PERIMETER HEATER

(OPTIONAL)

TERMINAL BLOCK

YW

WE

RD

BE

PEOEBN

BK

5 AMP-125/250V

ELECTRICAL BOX ASSY

BN

MULLION HEATER

2 & 3 DOOR MODELS

BATTERY BACKUP

BK

02

02

HARNESS- DOOR SWITCH

-

BK

01

BLACK TAPE

BK

BN

UNDER COUNTER MODELS

HARNESS- ANTI-SWEAT HEATER

(OPTIONAL)

RD

PUSHBUTTON

SWITCH

GROUP- 04

01

RD

YW

DOOR SWITCH

BN

BK

BK

SHORT MULLION HEATER

(QUAD-DOOR HARDENING

CABINETS ONLY)

4

3

2

5

1

6

03

03

1 2 3 4 5 6 7 8

O

N

DISPLAY

1423 123

TERMINAL BLOCK

RDWEBE

BK

5 AMP-125/250V

ELECTRICAL BOX ASSY

WEBEYWPEOE

RD

BK

ELECTRICAL BOX ASSY

HARNESS- SHORT MULLION HEATER

WE

WE

WE

ALL VERTICAL MODELS

OPTIONAL ANTI-SWEAT HTRS

OPTIONAL HEATED DOOR

*GR-04

YW

5 AMP-125/250V

OE

BNPE

BN

Page 29

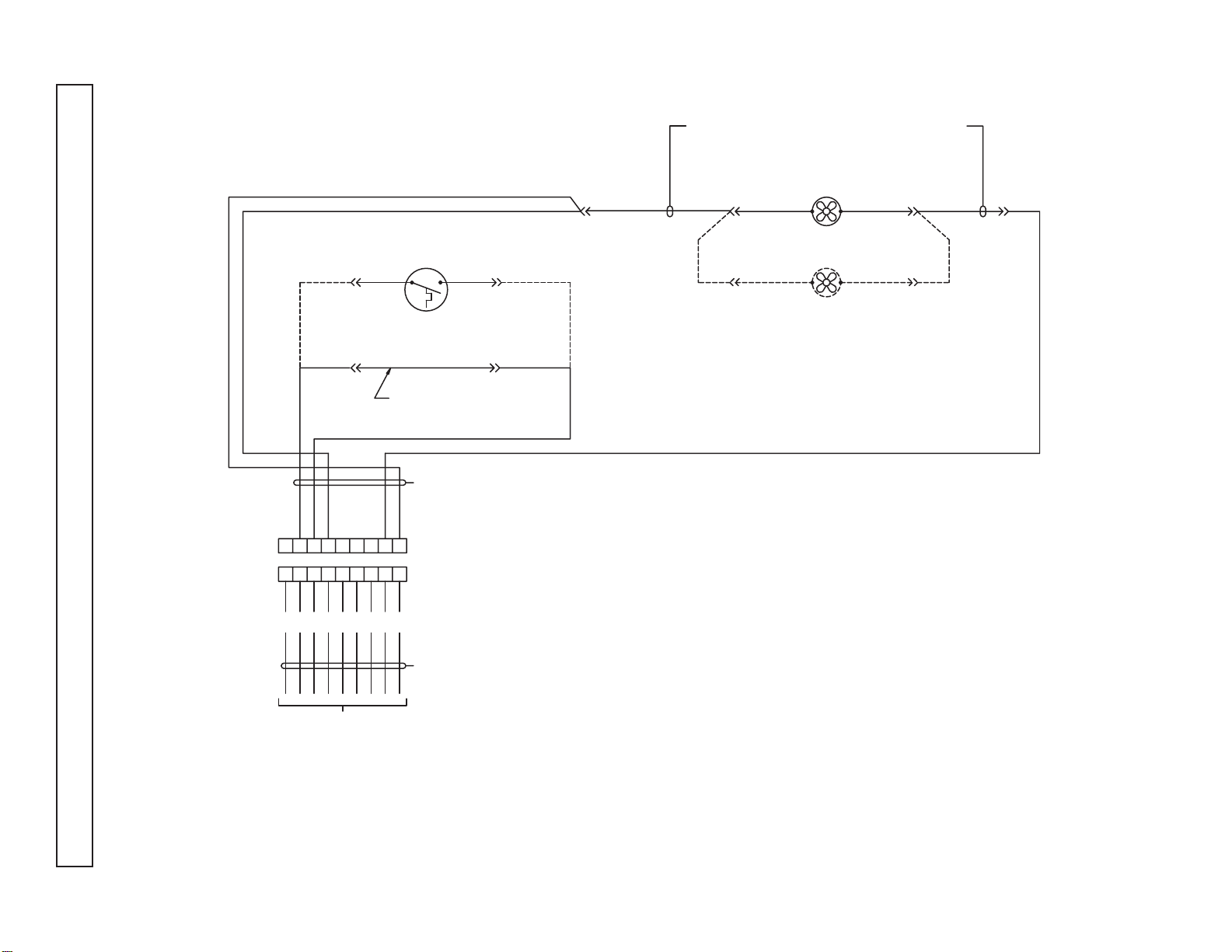

EVAPORATOR WIRING DIAGRAM – 00-0050-*

WIRING DIAGRAM 29

HARNESS- EVAPORATOR FAN EXTENSION

GROUP -01; 1 DOOR

GROUP -02; 2 DOOR/3 DOOR

EVAPORATOR AREA

MOUNTED

CAVITY T'STAT

OE

OE OE

OE

OE

BN

123456789

1432765

YW

OE

PEBNBE

RD

OE

(REMOVE JUMPER WHEN

INSTALLING THERMOSTAT)

HARNESS- EVAPORATOR AREA

GROUP -02

WE

BK

98

GY

WE

BK

BK

BN

SPADESPADE

OE

BN

USE WITH

REMOTE

MOUNTED

CAVITY

T' STAT

BN

BN BK BK WE

EVAP FAN/S

1 FAN

2 FANS

BKBK

WEWE

TO ELECTRICAL BOX

*GR.-01

MED. TEMP MODELS

HARNESS- MAIN CABINET

(EXIT EVAPORATOR AREA)

Page 30

FLUORESCENT LIGHT WIRING DIAGRAM – 00-0067-*

30 WIRING DIAGRAM

YW

YW

YW

BE

BE

RD

RD

BK

WE WE

YW

BE

BE

RD

RD

GY

BALLAST

BLK

LINE

WHT

BE

L2

RD

L1

YW

LAMP 1

C

C

LAMP 2

YW

RD

L1

BE

L2

TWO LAMP WIRING

YW

WE

BNOEBE PE

RD

BK

5 AMP-125/250V

ELECTRICAL BOX

BK/WE GY

ROCKER OR

PUSHBUTTON

LIGHT SWITCH

OPTIONAL

CONTROL PANEL

(1) DOOR CABINET- (1- BALLAST / 2- BULBS) *GR-01

YW

YW

BE

BE

RD

RD

GY GY

WE

SEC

WE

YW OE

BE

BNPE

RD

BK

5 AMP-125/250V

ELECTRICAL BOX

WE

HARNESS-

BALLAST TRANS.

INPUT/PRIMARY

OUTPUT/SECONDARY

BALLAST TRANFORMER

TYPICAL EXPORT TRANSFORMER CONNECTIONS *GR-04

GY

EXPORT

BK

HARNESS-

LIGHT SWITCH

BK/WE

SEC

RACEWAY

BK GYBKBK/WE

(OPTIONAL)

LIGHT SWITCH

CAVITY SIDEWALL

CAVITY LIGHT CHANNELS

RACEWAY

(OPTIONAL)

LIGHT SWITCH

CAVITY SIDEWALL

BK/WE BK BK GY

CAVITY LIGHT CHANNELS

BKBK GY

BK/WE

RACEWAY

RD

WE

(OPTIONAL)

LIGHT SWITCH

CAVITY SIDEWALL

WE

YW

CAVITY LIGHT CHANNELS

HARNESS-

BE

BEBEBE

RD

RD

RD

YW

YWYW

WE

BE

YWYWWEWEYWWEWEYWYW

WE

BE

WE

WE

YW

FLOURESCENT LIGHT, GR-02

YW

YW

HARNESS-

LAMP FIXTURE EXTENSION

WE

WE

YW

YW

ONE LAMP WIRING

BALLAST

CAP

BLK

LAMP 1

LINE

BE

YW

YW

YWYWWEWEYW

FLOURESCENT LIGHT, GR-01

HARNESS-

LAMP FIXTURE EXTENSION

BE

RD

RD

YWYW

YW

WE

WE

HARNESS-

WHT

CAP

BALLAST

BLK

LAMP 1

LINE

LAMP 2

WHT

TWO LAMP WIRING

WE

WE

WE

YW

YW

YW

YW WE

TWO LAMP WIRING

BALLAST

BLK

LAMP 1

LINE

LAMP 2

WHT

BALLAST

BLK

LAMP 1

LINE

LAMP 2

WHT

TWO LAMP WIRING

BE

L2

RD

L1

YW

C

C

YW

RD

L1

BE

L2

BE

L2

RD

L1

YW

C

C

YW

RD

L1

BE

L2

WE

BEOEBN

RD

BK

ELECTRICAL BOX

YW

PE

5 AMP-125/250V

YW

YW

BE

BE

RD

BK

WE

YW

YW

BE

BE

RD

RD

BK

WE

YW

YW

BE

BE

RDRD

RD

GY

WE

YW

YW

BE

BE

RD

RD

GYWEGY

BK/WE

ROCKER OR

PUSHBUTTON

LIGHT SWITCH

OPTIONAL

CONTROL PANEL

RD

RD

WEWEWE

YW YW

HARNESS-

LIGHT SWITCH

BKBK GY

(OPTIONAL)

LIGHT SWITCH

CAVITY SIDEWALL

GY

BK/WE

WEYW

YW WE

YW

L2

RD

L1

BE

C

BE

C

RD

L1

YW

L2

BE

L2

RD

L1

YW

C

C

YW

RD

L1

BE

L2

YWPEOE

WE

BN

BE

RD

BK

5 AMP-125/250V

ELECTRICAL BOX

RACEWAY

BE

BE

WE

YW YW

YW YW

YW YW

WE

WEYW

CAVITY LIGHT CHANNELS

YW

YW

BE

BE

RD RD

RD

BK

WE

YW

YW

BE

BE

RD

BK

WE

BK/WE GY

RD

RD

WE

WE

WEYW

WEYW

BE

BE

RD

GY

WE

YW

YW

BE

BE

RDRD

RD

GY

GY

WE

HARNESSLIGHT SWITCH

ROCKER OR

PUSHBUTTON

LIGHT SWITCH

OPTIONAL

CONTROL PANEL

(2) DOOR CABINET- (2- BALLAST / 3- BULBS) *GR-02

HARNESS-

BE

WE BE

YW YW

YW YW

WE

WE WE

YW

YW

FLOURESCENT LIGHT, GR-03

YW YW

YW YW

HARNESS-

LAMP FIXTURE EXTENSION

(3) DOOR CABINET- (2- BALLAST / 4- BULBS) *GR-03

Page 31

SOLENOID WIRING DIAGRAM – 00-0060-00

WIRING DIAGRAM 31

HARNESS- SOLENOID VALVE

WE

BK BK OE

LIQUID LINE

SOLENOID VALVE

INSTALL ON REMOTE

MODELS

RD

BK

WE

BE

YW

OE

PE

BN

5 AMP-125/250V

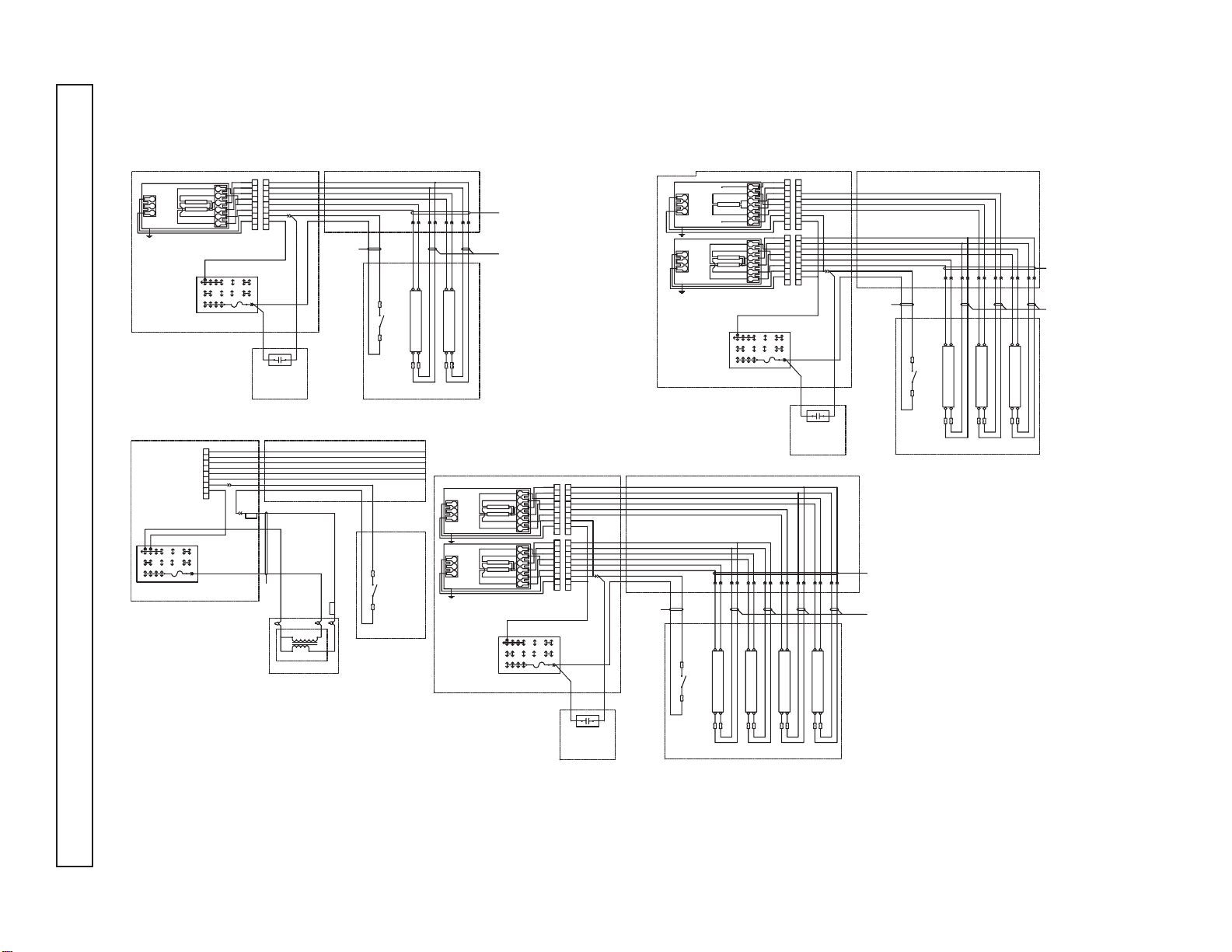

Page 32

RECEPTACLE BOX/LIGHT WIRING DIAGRAM – 00-0059-00

32 WIRING DIAGRAM

HARNESS- RECEPTACLE BOX SUPPLY

BK BK

CIRCUIT BREAKER

RECEPTACLE BOX- BACK OF CAVITY

TERMINAL BLOCK

BKWE

BK

BK

WE

WE

GN

WE BK

TERMINAL BLOCK

GN

BKBKBKWE WE WE

GN

WE

RD BE

BK

YW OE

PE BN

5 AMP-125/250V

ELECTRICAL BOX

Page 33

RECEPTACLE BOX/LIGHT WIRING DIAGRAM – 00-0065-00

WIRING DIAGRAM 33

GY GY

WE

L

C

WE

RD

BK

BE

YW OE

PE

BN

BK/WE

5 AMP-125/250V

TERMINAL BLOCK

ELECTRICAL BOX

1

BK

2

BK/WE

3

BN

4

GY

5

BK

6

PE

7

WE

8

9

DELUXE CONTROL

PANEL CONNECTOR

HARNESS- LIGHT BOX SUPPLY

INCANDESCENT LIGHT

WE

WEGY BK BK

CIRCUIT BREAKER

GN

LIGHT BOX- BACK OF CAVITY

Page 34

CONTROL PANEL WIRING DIAGRAM – 00-0017-10

34 WIRING DIAGRAM

58

TERMINAL

STRIP

SENSOR

44

44

58

GROUND

TO MATING PLUG

ON ELECTRICAL

BOX SEE DIAGRAM

GROUND

SHIELDED CABLE ASSEMBLY

P/N 19-A-1151-00

47K

RESISTOR

15

15

L

INTERIOR

LIGHT

SWITCH

DIGIT DISPLAY

MODULE #1

WE

BK

OE

BN

YW

RD

PE

BE

69

68

BATTERY

-

+

LOW VOLTAGE

RACEWAY

5

3

PINK

RED

CONTROLLER/MONITOR

1

J4

3

J5

4

J3

1

J2

J1

52

19-1004-00

19

51

67

66

WE

YW

TERMINAL

BOARD

OE BK

WE

65

64

62

19

19-1009-00

RESISTOR

47K

53

ON/OFF

POWER

SWITCH

2

6

1

6

1

6

1

6

55

56

BN

8

7

3

5

1

4

6

2

6V ALARM

61

54

63

39

8

4

70

FUSE 1.0 AMP

38

12

18

POWER

RELAY

9

9

115V

33

13

TERMINAL STRIP

13

4

3

2

1

7

ALARM SYSTEM

MODULE #2

RELAY

6

8

C

35

59

INDICATOR

5

10

RED

RED

L

LOW

POWER

FAILURE

TEMP.

INDICATOR

12

17

16

20

33

ALARM

25

-

SONALERT

29

34

THESE CONNECTIONS ARE MADE IN THE RACEWAY

ON PANELS W/ALARM MODULE OPTION.

6

860

L

WE BK

INDICATOR

36

11

RED

L

HIGH

TEMP.

23

+

28

30

OE

TERM. BOARD

27

7

3

4

TIME DELAY

32

AUDIO SILENCE

+

1

RELAY

1

1

5

V

A

C

NO

BUTTON

2

NO

NC

C

PUSH TO TEST

NO

BUTTON

NC

C

15

19

RESISTOR

GY

PK

PE

2

8

-

C

INPUT

R

E

C

E

P

T

A

C

L

E

C

19-0998-00

1

14

4

21

24

C

1

H

2

-

A

V

R

D

G

+

C

E

26

7

15

RD

TERMINAL

BOARD

YW

36

BN

22

28

31

37

41

CIRCUIT BOARD

ALARM

NO

COM

NC

TRANSFORMER

230V

CHART

MODULE #4

115V

DOOR AJAR

MODULE

ORANGE

L

DOOR AJAR

TERM. BOARD

RD

RECORDER

4-20mA(+)

GND(-)

#3

BE

RTD

71

72

71

72

39

38

40

PE

*SHIELDED CABLE

19-A-1151-00

72

BLACK 19-A-1054-05

71

WHITE 19-A-1054-04

70 FUSE 1AMP 19-A-1049-00

GREEN LEAD

69

BLUE LEAD

68

PURPLE LEAD

67

RED LEAD

66

YELLOW LEAD

65

ORANGE LEAD

64

BROWN LEAD

63

BLACK LEAD

62

WHITE LEAD

61

18GY008GX2A

60

18PK008GX2A

59

18PE008GS2A

58

57

18WE008GS2A

56

18BN008GS2A

55

18BN008GX2A

54

18BK004GX2A

53

18WE004GG2A

52

18OE008GR2A

51

50

49

48

47

46

45

18RD008GS2A

44

43

42

18OE032SS2A

41

40

18RD008GR2A

18WE036GG2A

39

18BK036GG2A

38

18GY032SS2A

37

18BN004GR2A

36

18WE024GG2A

35

18BK024GG2A

34

18BE008GQ2A

33

WHITE LEAD

32

BLACK LEAD

31

18BK008GQ2A

30

18WE008GQ2A

29

18OE008GG2A

28

18OE004GR2A

27

18PE008GR2A

26

18GY012DG2A

25

18GY008GG2A

24

18YW004GR2A

23

18PE008DG2A

22

18PE008GG2A

21

18PE008GQ2A

20

RESISTOR W/LEADS

19

18RD004QQ2A

18

18GY004GQ2A

17

18YW008GQ2A

16

18YW008GR2A

15

18BN008GR2A

14

18YW008QR2A

13

18RD004GQ2A

12

18BE020RS2A

11

18PE020RS2A

10

18YW020QS2A

9

18GY016GL2A

8

18RD020GS2A

7

18PK016GL2A

6

18PK054GQ2A

5

BLACK LEAD

4

18RD054GQ2A

3

18RD008GR2A

2

BLACK & WHITE LEAD

1

ITEM NO

XX

PART NO.

DATE

CHKD

RD = RED

BK = BLACK

BE = BLUE

BN = BROWN

WE = WHITE

OE = ORANGE

GA

CLR

XX

:

2-26-96

DATE

COLOR CODE

LTH

IN

XXX

00-C-0017-10

(60)

(59)

(58)

(56)

(55)

(54)

(53)

(52)

(51)

(44)

(41)

(40)

(37)

(36)

(35)

(34)

(33)

(30)

(29)

(28)

(27)

(26)

(25)

(24)

(23)

(22)

(21)

(20)

(18)

(17)

(16)

(15)

(14)

(13)

(12)

(11)

(10)

(09)

(08)

(07)

(06)

(05)

(03)

(02)

WIRE CODE

WIRE

TERM

XX

DRAWN

APPR

HARNESS

19-1020-00

*

*

GN = GREEN

PE = PURPLE

PK = PINK

GY = GRAY

TN = TAN

YW=YELLOW

IN

THK

(64)

X

:

DATE

WIRE

WIRE

TYPE

CODE

DETAIL

X

RM

REV

D

HIGH VOLTAGE

RACEWAY

Page 35

CONTROL PANEL WIRING DIAGRAM – 00-0017-12

WIRING DIAGRAM 35

TERMINAL

STRIP

SENSOR

58

58

TO MATING PLUG

ON ELECTRICAL

BOX SEE DIAGRAM

GROUND

44

GROUND

44

SHIELDED CABLE ASSEMBLY

15

15

INTERIOR

LIGHT

SWITCH

DIGIT DISPLAY

MODULE #1

69

P/N 19-A-1151-00

47K

RESISTOR

L

WE

BK

OE

BN

YW

RD

PE

BE

68

7

15

36

22

28

NOTE: WHEN CHART RECORDER IS NOT

PRESENT WIRE #48 IS CONNECTED

TO J4/pin3 ON CONTROLLER/MONITOR

AND WIRE #37 IS NOT USED.

7

NO

NC

NO

NC

15

RESISTOR

RD

GY

TERMINAL

BOARD

YW

PK

BN

PE

14

3

4

+

-

128

C

TIME DELAY

RELAY

R

E

C

1

1

E

5

P

31

V

T

A

A

C

C

L

32

E

NO

C

AUDIO SILENCE

BUTTON

37

49

48

CHART RECORDER

CIRCUIT BOARD

ALARM

2

C

PUSH TO TEST

BUTTON

C

19

19-0998-00

DOOR AJAR

MODULE

POTENTIOMETER

1

4

21

24

C

1

H

2

-

A

V

R

D

G

+

C

E

26

12

13

TEMPERATURE

CONTROLLER

1

2

47

46

45

44

TERMINAL

BOARD

NO

COM

NC

TRANSFORMER

230V

#3

11

10

3

4

1

-

4

RD

115V

RED

9

5

BE PE

WHITE

8

7

6

SOLID STATE

RELAY

2

+

3

4-20mA(+)

BLACK

22

GND(-)

RTD

71

72

71

72

39

38

50

*SHIELDED CABLE

19-A-1151-00

72

BLACK 19-A-1054-05

71

WHITE 19-A-1054-04

70 FUSE 1AMP 19-A-1049-00

GREEN LEAD

69

BLUE LEAD

68

PURPLE LEAD

67

RED LEAD

66

YELLOW LEAD

65

ORANGE LEAD

64

BROWN LEAD

63

BLACK LEAD

62

WHITE LEAD

61

18GY008GX2A

60

18PK008GX2A

59

18PE008GS2A

58

57

18WE008GS2A

56

18BN008GS2A

55

18BN008GX2A

54

18BK004GX2A

53

18WE004GG2A

52

18OE008GR2A

51

18RD008DG2A

50

18PK024SS2A

49

18OE024SS2A

48

47

18YW008AD2A

18BN008AD2A

46

18BE008AG2A

45

18RD008GS2A

44

43

42

41

40

18WE036GG2A

39

18BK036GG2A

38

18GY032SS2A

37

18BN004GR2A

36

18WE024GG2A

35

18BK024GG2A

34

18BE008GQ2A

33

WHITE LEAD

32

BLACK LEAD

31

18BK008GQ2A

30

18WE008GQ2A

29

18OE008GG2A

28

18OE004GR2A

27

18PE008GR2A

26

18GY012DG2A

25

18GY008GG2A

24

18YW004GR2A

23

18PE008DG2A

22

18PE008GG2A

21

18PE008GQ2A

20

RESISTOR W/LEADS

19

18RD004QQ2A

18

18GY004GQ2A

17

18YW008GQ2A

16

18YW008GR2A

15

18BN008GR2A

14

18YW008QR2A

13

18RD004GQ2A

12

18BE020RS2A

11

18PE020RS2A

10

18YW020QS2A

9

18GY016GL2A

8

18RD020GS2A

7

18PK016GL2A

6

18PK054GQ2A

5

BLACK LEAD

4

18RD054GQ2A

3

18RD008GR2A

2

BLACK & WHITE LEAD

1

ITEM NO

PART NO.

DATE

CHKD

RD = RED

BK = BLACK

BE = BLUE

BN = BROWN

WE = WHITE

OE = ORANGE

GA

CLR

XX

XX

:

2-26-96

DATE

COLOR CODE

LTH

IN

XXX

00-C-0017-12

(60)

(59)

(58)

(56)

(55)

(54)

(53)

(52)

(51)

(50)

(49)

(48)

(47)

(46)

(45)

(44)

(37)

(36)

(35)

(34)

(33)

(30)

(29)

(28)

(27)

(26)

(25)

(24)

(23)

(22)

(21)

(20)

(18)

(17)

(16)

(15)

(14)

(13)

(12)

(11)

(10)

(09)

(08)

(07)

(06)

(05)

(03)

(02)

WIRE CODE

WIRE

TERM

XX

DRAWN

APPR

HARNESS

19-1020-00

*

*

GN = GREEN

PE = PURPLE

PK = PINK

GY = GRAY

TN = TAN

YW=YELLOW

IN

THK

(64)

X

RM

:

DATE

WIRE

WIRE

TYPE

CODE

DETAIL

X

REV

BATTERY

-

+

5

3

PINK

RED

CONTROLLER/MONITOR

1

J4

3

J5

4

J3

1

J2

J1

52

BN

19-1004-00

19

51

67

66

WE

YW

TERMINAL

BOARD

WE

OE BK

65

64

62

53

ON/OFF

POWER

SWITCH

2

6

1

6

1

6

1

6

55

61

54

63

70

FUSE 1.0 AMP

38

39

8

4

LOW VOLTAGE

RACEWAY

10

11

RED

RED

RED

LL

L

LOW

TEMP.

INDICATOR

25

-

SONALERT

29

HIGH

TEMP.

INDICATOR

23

36

+

28

30

BK OE

WE

TERM. BOARD

27

THESE CONNECTIONS ARE MADE IN THE RACEWAY

ON PANELS W/ALARM MODULE OPTION.

7

3

1

4

2

6V ALARM

RELAY

33

TERMINAL STRIP

4

3

2

1

7

MODULE #2

POWER

FAILURE

INDICATOR

12

17

8

16

5

20

6

33

ALARM

6

5

8

C

35

34

59

6

860

56

9

13

9

13

12

18

115V

POWER

RELAY

ALARM SYSTEM

D

DESCRIPTION

HIGH VOLTAGE

RACEWAY

WIRING DIAGRAM (CONTROL PANEL)

Page 36

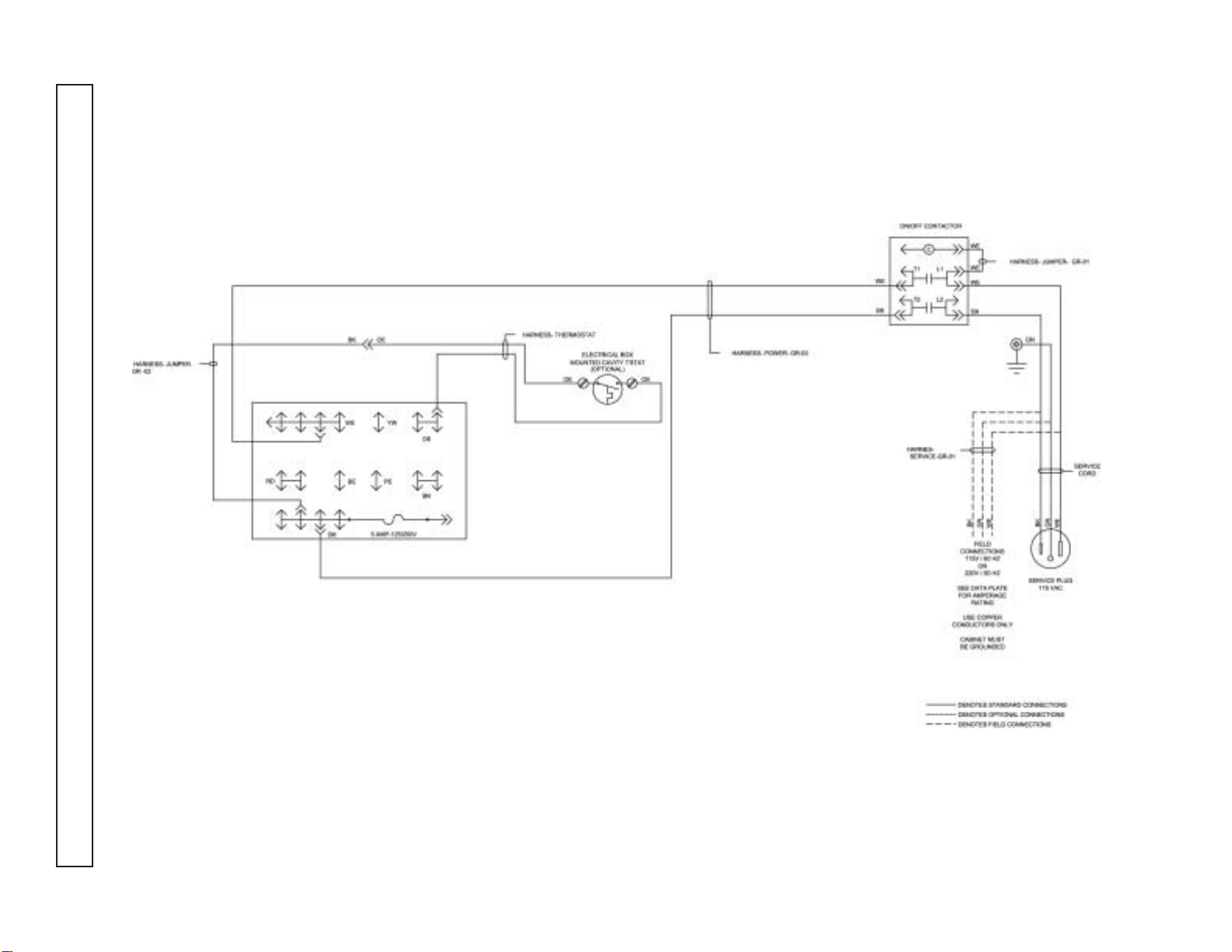

CONTROL PANEL WIRING DIAGRAM – 00-0058-*

36 WIRING DIAGRAM

OPTIONAL CONTROL PANEL MOUNTED LIGHT SWITCH

BALLAST

CONNECTOR/S

WE

GY GY

YW OE

BEWERDBKPE

5 AMP-125/250V

TERMINAL BOARD

GY

BN

BK/WE

HARNESS- PANEL, PUSHBUTTON LIGHT

ELECTRICAL BOX

OPTION #1- PUSHBUTTON LIGHT SWITCH WITH INDICATOR *GR-02

BALLAST

CONNECTOR/S

WE

RD PE

YW OE

WE

BE BN

5 AMP-125/250V

BK

TERMINAL BOARD

GY

GY

BK/WE

HARNESS- PANEL, ROCKER LIGHT

ELECTRICAL BOX

OPTION #2- ROCKER LIGHT SWITCH *GR-04

47 K

BK/WE

GY

BK/WE

L

PUSHBUTTON

LIGHT SWITCH

WITH

INDICATOR

CONTROL PANEL

12

ROCKER

LIGHT SWITCH

CONTROL PANEL

OPTIONAL CONTROL PANEL MOUNTED ON/OFF POWER SWITCH

HARNESS- PANEL, KEYED ON/OFF

BN

BN WE

C

C

T1 L1

L2T2

CONTACTOR

TYP FOR 115/60 OR 220/50

SEE ELECTRICAL BOX

DIAGRAM FOR 230/60

ELECTRICAL BOX

GN

WE

SERVICE PLUG

GND LEAD

BK

L

BK

BK

WE

WE

POWER CORD

BK

872

643

KEYED

ON/OFF SWITCH

CONTROL PANEL

OPTION #1- KEYED ON/OFF SWITCH *GR-01

HARNESS- PANEL, ROCKER ON/OFF

BN

BN WE

C

C

T1 L1

54

T2 L2

CONTACTOR

TYP FOR 115/60 OR 220/50

SEE ELECTRICAL BOX

DIAGRAM FOR 230/60

L

BK

BK

WE

WE

GND LEAD

BK

CONTROL PANEL

415

ROCKER

ON/OFF SWITCH

2

ELECTRICAL BOX

POWER CORD

GN

WE

SERVICE PLUG

BK

OPTION #2- ROCKER ON/OFF SWITCH *GR-03

Page 37

WARNING

To avoid the possibility of an electrical shock, turn

OFF the thermostat and unplug the power cord of

the cabinet before cleaning or touching electrical

connections or parts.

Page 38

MAINTENANCE & REPAIR

PRE-SERVICE CHECK LIST

You may avoid the cost and inconvenience of an unnecessary product call by first reviewing this check list of the

most frequently encountered situations that are not the

result of defective workmanship or materials.

COMPRESSOR RUNS TOO MUCH

1. A refrigerated cabinet automatically compensates for

product loading by running longer and more often.

Before calling for service, check running time for at

least one hour the first thing in the morning (before

store traffic starts).

2. Be sure the doors seal.A faulty gasket seal will cause

increased running time.

3. Check the room temperature.The warmer the room,

the more the compressor will run.

4. Check the condenser to be sure the face is clean.Dirt

and lint will raise pressures and increase running

time.Use a brush or vacuum to clean the condenser.

5. Be sure condenser fan operates.

6. Check to see that evaporator fans are running.

7. If product is too hard (cold), try setting the

Temperature Control (thermostat) warmer. This will

result in warmer cabinet temperature and reduced

running time.

8. Check insufficient ventilation to condenser.

CABINET DOES NOT OPERATE

1. Be sure cabinet is plugged in.

2. Check that breakers or fuses are good and all switches in the supply line are ON.

3. Be sure that cabinet Master Power Supply Switch is

ON.

4. If you are in an area with voltage problems, try shutting off all non-essential electrical equipment.

LIGHT IS OFF

1. If the cabinet is operating, be sure the lamp is properly seated in sockets.

2. If cabinet is not running, check that Master Power

Supply Switch and Light Switch are ON, fuses are

okay, no switch in the supply is OFF, and that the cabinet is plugged in.

CUSTOMER COMPLAINT ON STORED

PRODUCT

1. Check cleaning solutions used inside cabinet.

2. Check cleaning solutions, paint, or other contaminants used in store maintenance.

3. Sometimes the ingredients used in some products or

containers will contaminate other products.

4. Be sure to follow a weekly schedule for cleaning cabinet interior.

SERVICE

In the event of a malfunction, damage to the cabinet,

or if the cabinet requires service beyond the items in

the “Pre-Service Checklist,” contact your local service

company or the dealer from whom the cabinet was

purchased.

POWER FAILURE

Do not open the cabinet doors unnecessarily if power is

cut off due to electrical failure.The cabinet will start up if

the power supply returns, but will require sufficient time

to reach maximum cold storage performance.

CABINET FAILURE

1. If the cabinet has stopped operating, check that the

cabinet is securely plugged in and turned on.Contact

a licensed electrician to locate and correct any power

supply problems.

2. Do not open the cabinet doors unnecessarily.

3. Provisions for other storage of the product may be

required to prevent spoilage.

If you call for service, describe your problem and giv e the

following information to the service representative:

Cabinet Model No. ____________________________

Part No. ____________________________________

Serial No. __________________________________

(These numbers are located on a silver serial number

rating plate in the upper left side of the cabinet interior.)

MAINTENANCE & REPAIR 39

Page 39

TOOLS:

To provide full service diagnostics and repairs on these

cabinets, the following tools are needed:

A Multimeter

An Electronic Leak Detector

An Electronic Micron Gauge

A Vacuum Pump capable of pulling to 50 microns

Four Hand Valves

A Compound Gauge Set

A cylinder of nitrogen with a regulator capable of 10 to

400 pounds.

Standard refrigeration hand tools, e.g.: wrenches, tube

cutter, swage and flare tools, wire strippers, wire crimp.

ers, wire cutters, slot and phillips head screwdrivers.

PRODUCT HISTORY

The first rule in servicing a refrigeration system is to

determine if the problem is an electrical or mechanical

failure.

First, try to obtain the product’s history of operation

from the customer.This will help identify the source of

the problem.

Good facts from the cabinet user can help identify

whether the problem is electrical, within the refrigeration system, or a “misapplication by the user”.Get the

history of operation and failure by asking these questions:

1) Were there any brown-outs or power outages that

they are aware of?

2) Is the cabinet on a dedicated circuit?

3) Has any other equipment in this area had operational problems?

4) When was the last time the cabinet’s operation was

confirmed as working properly?

5) When was a problem noticed?

6) How long has the equipment run without this problem? (Years? Weeks? Days? Hours?)

7) Was anything tried prior to your arrival?

The refrigeration system should only be entered if it is

absolutely necessary. It is critical that a clean, uncontaminated system be maintained.

If a system is unable to reach the proper operating

temperature, a test of the unit’s mechanical refrigeration components is required.

COMPRESSOR EFFICIENCY TEST

To test the compressor, place compound gauge on the

compressor’s suction port.

While the compressor is running, close off the suction

line so that only the port and valve are part of the compressor’s low side.

When the valve is closed and vacuum has started, time

how long it takes to pull the compressor’s low side to its

lowest possible vacuum.

Compressors used on these cabinets should be capable

of pulling at least 20 to 22 inches of vacuum in less than

40 seconds.

Next, shut off the compressor and watch the gauge. A

one or two inch rise in pressure is acceptable, since a

small amount of freon may remain on the low side of the

compressor, after which the reading should stabilize.

If the pressure continues to rise, the discharge reeds in

the valve head ha ve f ailed, allowing high pressure gas to

return to the compressor.

If the compressor pulls less than 20 inches, the suction

reeds have failed.

If the compressor takes longer than 40 seconds to pull

to its ultimate low vacuum, one or both cylinders are not

functioning as they should. Any reading less than these

will require replacement of the compressor.

ENTERING THE SYSTEM

Entering the system should only be done as a last

resort. Extreme care must be used no matter what the

reason for entering the system. Of course there are

times when it cannot be avoided, such as component or

compressor replacement, or a leak within the system.

The system must also be entered any time you need to

obtain the operating pressures.Again, use extreme caution to avoid any possible contamination.

Cabinets that use hermetic compressors typically do not

have valve ports, so therefore process stubs for both

suction and discharge sides of the system were added.

Line taps should only be used to obtain pressure readings, and not for the reprocessing of the system. The

opening of a line tap is too restrictive for the pressure of

vacuum procedures.

On a hermetic compressor system, once you have

determined that reprocessing a system is required,

recover refrigerant and remove the line taps.

40 MAINTENANCE & REPAIR

Page 40

Install hand valves at the process stub ends. Hand

valves will be less restrictive to flow because of a larger

opening. They will also be easier to use during repair

procedures.

EVACUATION

Once the system has been cleaned and components

have been replaced, you are ready to initiate the final

servicing procedures necessary to achieve proper cabinet operation. Drier should be replaced prior to system

processing.

Pull an evacuation to approximately 50 microns.

CHARGING

You should use a charging cylinder to measure in the

correct amount of refrigerant.The charging methods are:

1. Add the refr igerant to the system until you reach a

balanced pressure. This will give you an approximate static charge.

2. Weigh in the refrigerant using a scale calibrated in

ounces.

The cabinet’s operation is now ready to be tested. A

final check of the refrigeration lines should be made

before running the cabinet.

Be sure the refrigeration lines are not kinked or rubbing against each other.

Also check that the door seals properly. An air leak will

affect proper operation, and the cabinet’s ability to

reach its coldest temperature.

Run the cabinet at both 100% run, and a cycling temperature for at least 24 hours. If the temperature and

pressures are correct, the system can be considered

repaired.

Hermetic systems should now have their process

stubs pinched off, hand valves removed and the ends

brazed shut.

MAINTENANCE & REPAIR 41

Page 41

COMPRESSOR INSTALLATION & MAINTENANCE

TO CHANGE THE COMPRESSOR:

1. Disconnect the power supply to the cabinet.

2. Disconnect the power supply leads at the

compressor.

3. Disconnect wires to relay and capacitors.

4. Remove relay and starting capacitor and install on

new compressor.

5. Remove defective compressor from condensing

unit base.

6. Set new compressor in place.

7. Reconnect relay and capacitor wires.

8. Reconnect power supply lead.

9. Leak test, evacuate, and weigh in charge.

CHANGING DRIER

If flare connected, make sure flares and faces of fittings on new drier are clean and in good condition

before installing new drier.

If sweat connected, clean tubing close to original

drier before cutting tubing in clean area. Check that

ends of the replacement drier are clean, then make

brazed connection using as little heat as possible.

Cut tubing only with tube cutters, not hacksaws, to

avoid metal filings from entering the system. Driers

must be replaced any time you enter the system,

except when you are obtaining pressures.

SERVICE VALVES

The compressors on some cabinets have service

valves for measuring suction and discharge pressures.

Two types are used. The first type is connected directly to the compressor body or shell and back seats to

connect gauges to the access port. The second is on

the end of a process tube and requires a gauge or

charging line with a depressing pin to open valve when

the connection is made.

This type valve should be tightly

capped except when making the

gauge connection.

TO CHECK FOR OPEN WINDINGS

Use a multimeter. Measure ohms between “C” and “R”

and between “C” and “S.”

If windings are O.K., multimeter will show a resistance

reading between terminals.