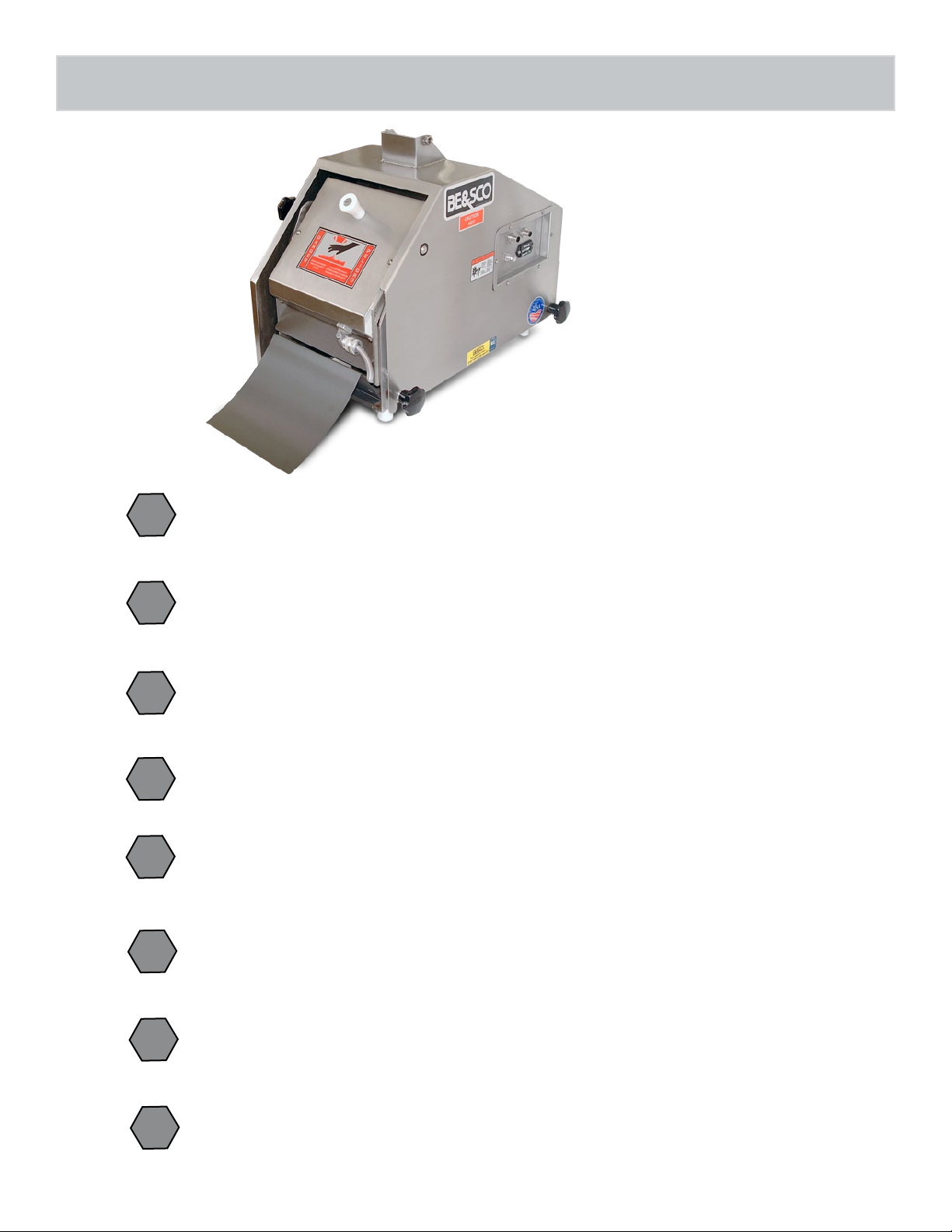

Besco 9A-12, 9AV-12, 9AE-12, 9AEV-12, 9AEV-12SS Installation Manual

!

Precautions

Models: 9A-12, 9AV-12,

9AE-12, 9AEV-12, 9AEV-12SS

BE CAREFUL WHEN OPERATING OR CLEANING MACHINE AS

SURFACES MAY BE HOT!

!

!

!

!

!

!

DISCONNECT ELECTRICAL POWER PRIOR TO MAINTENANCE AND

CLEANING.

ALL MAINTENANCE AND CLEANING MUST BE PERFORMED

ACCORDING TO THIS MANUAL.

NEVER USE ANY SHARP OBJECTS, CAUSTIC OVEN CLEANER, OR

DEGREASER TO CLEAN MACHINE OR PRESS PLATES.

IN CASE OF POWER FAILURE, SHUT DOWN MACHINE.

FOR EMERGENCY SHUT DOWN, PUSH MASTER SWITCH.

READ AND FOLLOW ALL THE DIRECTIONS IN THIS MANUAL. DO NOT

LOSE OR THROW THIS MANUAL AWAY. DO NOT USE STAND ALONE

MIDWEDGE UNLESS YOU HAVE READ THE MANUAL.

DO NOT CONNECT TO A CIRCUIT OPERATING AT MORE THAN 150

VOLTS TO GROUND.

!

1

10-06-14

Table of Contents

Precautions...................................................................................................................................1

Table of Contents..........................................................................................................................2

Policy & Procedure for Returning BE&SCO Parts ........................................................................ 3

Warnings, Storyboard ................................................................................................................... 4

Delivery & Inspection ....................................................................................................................4

Qualied Service Person and Adjustments ..................................................................................5

Specications ...............................................................................................................................6

Components ................................................................................................................................. 7

Control Panel .............................................................................................................................8-9

Operation Instructions ................................................................................................................10

Temperature Controller Instructions ........................................................................................... 11

Operation Troubleshoot .............................................................................................................. 12

Cleaning .....................................................................................................................................13

Maintenance ............................................................................................................................... 17

Dough Making ............................................................................................................................21

Dough Making Troubleshoot.......................................................................................................22

Tortilla Making.............................................................................................................................24

Tortilla Making Troubleshoot ....................................................................................................... 25

Tortilla Recipe ............................................................................................................................. 29

Closing Statement ...................................................................................................................... 31

Parts and Pictures ...................................................................................................................... 32

Warranty .....................................................................................................................................51

Neither this manual nor any part may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying microlming and recording, or by information storage and retrieval system, without

permission in writing from Bakery Equipment & Service Co., Inc.

2

Policy & Procedure for Returning BE&SCO Parts

Returning BE&SCO Parts:

To return any BE&SCO parts you must follow BE&SCO’s procedure for returning. No returns

will be accepted outside of this procedure. BE&SCO warrants parts for 1 year or 3000 hours,

which ever comes rst, for full credit. This does not include wear and tear items as stated in our

manual.

This warranty does not cover any defect due to or resulting from handling, abuse, misuse,

improper maintenance and cleaning, or harsh chemical action, nor shall it extend to any unit

from which the serial number has been removed or altered, or acts of God. Adjustments such as

calibrations, leveling, tightening of fasteners or plumbing connections normally associated with

original installation are the responsibility of the dealer or installer and not of BAKERY EQUIPMENT

& SERVICE CO., INC.

Procedure for Returning BE&SCO Parts:

1. Call BE&SCO Parts Department at 1-800-683-0928 or email parts@bescomfg.com. At this

time you may request a repair and return, advance replacement or a credit of the component. The

Parts Department will then issue you an RA (Return Authorization) number to return the BE&SCO

part. After you are issued an RA number. You have 10 working days to return the old part for full

credit or you will be invoiced for the new part.

2. Package the component and a detailed description of what is wrong with the component. Write

the RA number on the outside of the package in a visible place and send the return to:

BE&SCO - Parts Department

RA#

1623-27 N. San Marcos

San Antonio, TX 78201

To obtain warranty on return parts the customer or the end user will be responsible for that

particular item to be shipped back to BE&SCO. Freight is not covered under warranty, going or

coming. BE&SCO recommends that you insure any parts that are being returned to BE&SCO,

as BE&SCO Inc. is not responsible for any damage or loss that occurs during shipping. If the part

is damaged or lost during shipping, BE&SCO will not be responsible for repair or replacement of

the parts.

3

Warnings

For Emergency Shutdown press the red side of the Master Switch.

In case of power failure, shutdown machine.

Storyboards

The laminated poster included in your shipment is called a Storyboard. A Storyboard shows how to operate

or care for the machine. It should be posted on a wall close by the machine. Both front and back have the

same information but in two different languages - Spanish and English.

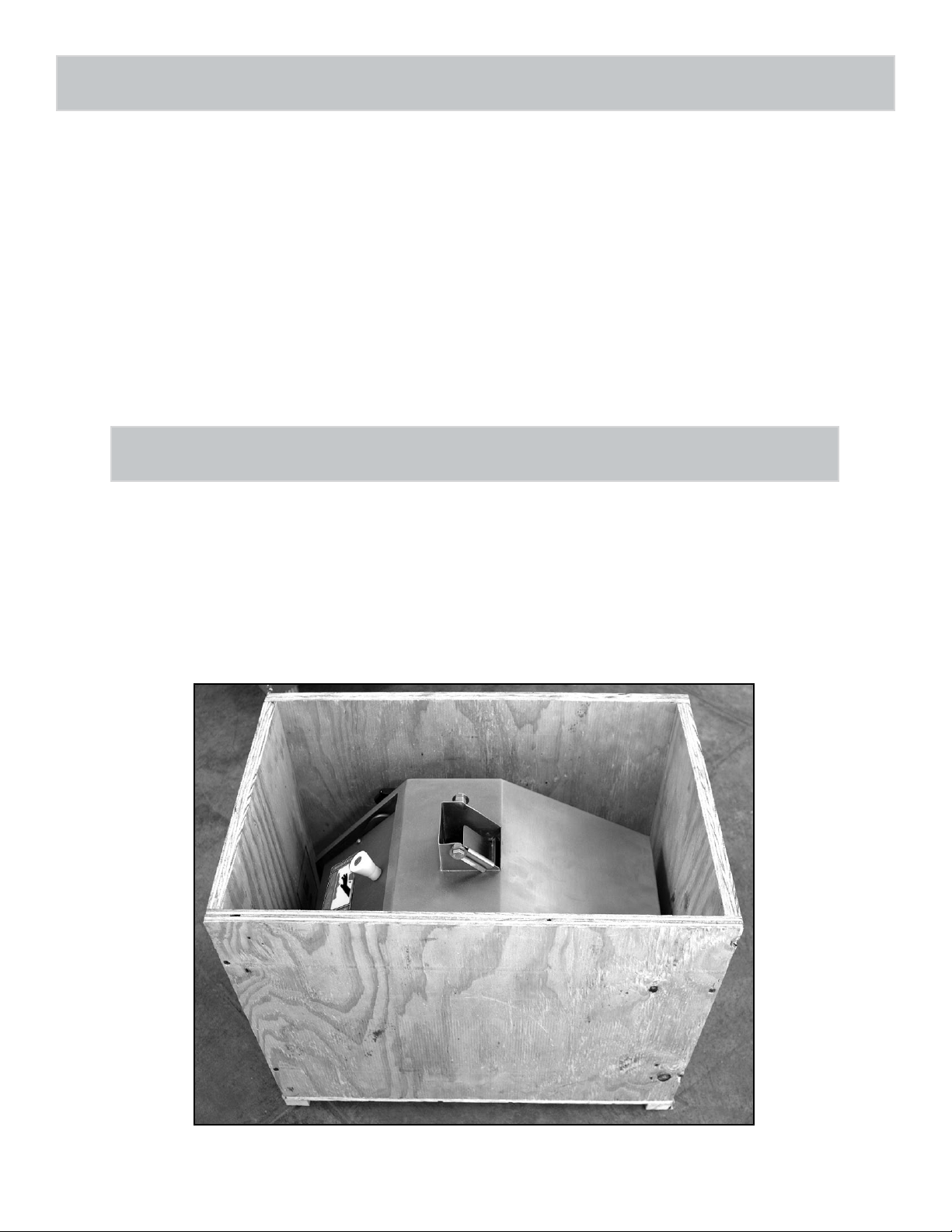

Delivery & Damage

We rmly pack Midwedge Machines in wooden crates before giving them to the shipping company. After we

give the merchandise to the shipping company, they are responsible for delivering your purchase; therefore,

BE&SCO will not be responsible for loss or damage of your shipment. If you nd your purchase damaged,

call the shipping company.

4

Qualied Service Person

A Qualied Service Person is an employee of a rm, a corporation or a company that will:

1. Install, connect, repair, service, and replace parts of the Stand Alone Midwedge 9A either

electrical or mechanical.

2. Follow rules and regulations of the National Electrical Code, ANSI/NFPA 70 or Canada’s

CSA STD. C22.1, or any other local codes.

Adjustments

A Midwedge is shipped in a wooden crate with llings in. Have two people take the Midwedge machine

carefully out of the wooden crate and set it up.

Any further adjustments you think maybe needed must be done by a Qualied Service Person. If you can

not locate a Qualied Service Person, call BE&SCO at (210) 734-5124 for assistance in locating a Service

Representative. Lastly, the warranty does not cover these adjustments.

5

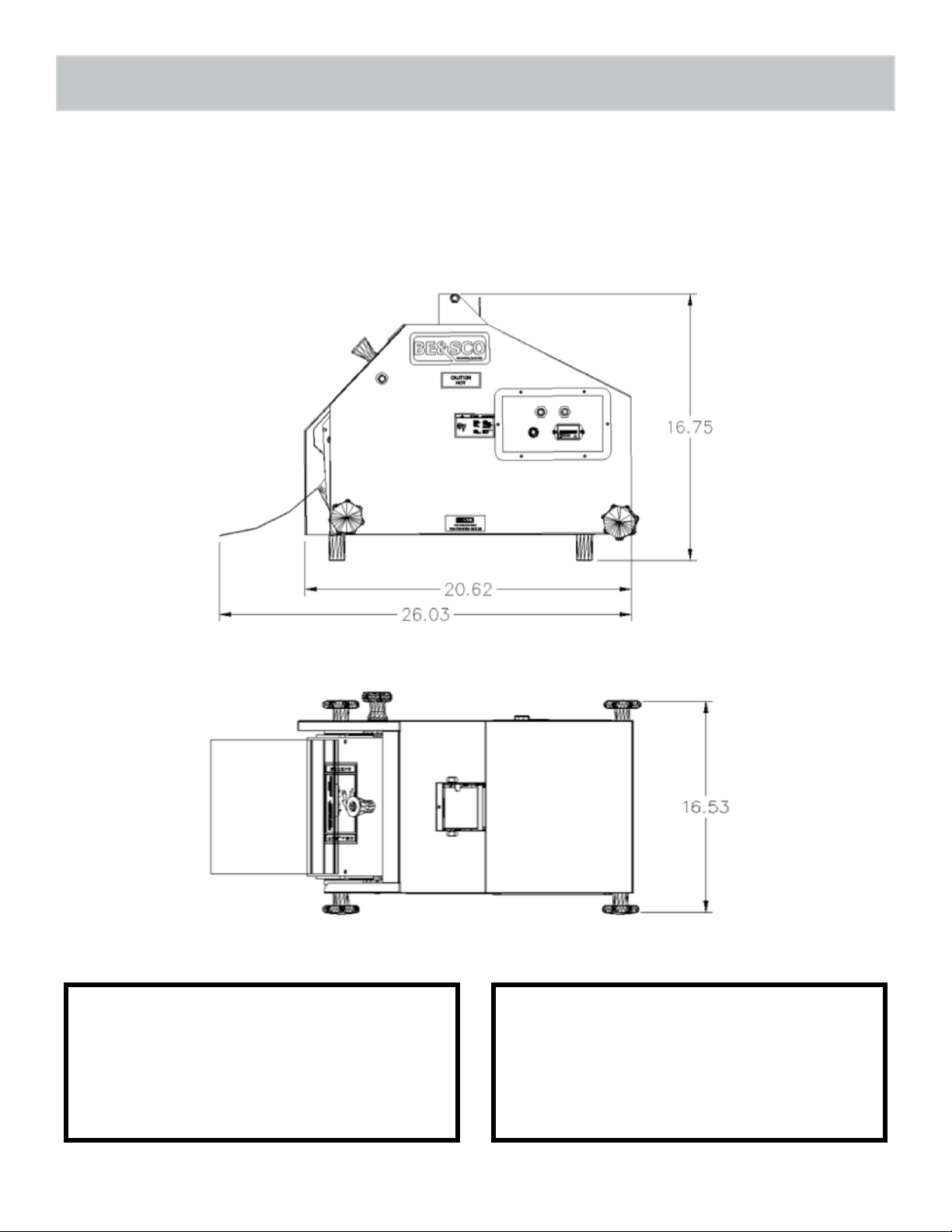

Specications

The Midwedge works on 120 volt or 240 volt grounded circuits. The voltage and phase

must be compatible with the power supply to safely operate. Any installation not matching

the electrical specications for the machine will void your warranty and may damage the unit.

Machine installation must follow rules and regulations of the National Electrical Code, ANSI/

NFPA 70 or Canada’s CSA STD. C22.1, or any other local codes.

Models 9A and 9AE Models 9AV and 9AEV

Voltage...............................................................120V

Cycles ................................................................ 60 Hz

Phase ................................................................ single

Amperage .......................................................... 20

Total Heating Element ....................................... 1800 Watts

Press Motor Size ............................................... 1/15 HP

Press Motor Voltage .......................................... 120 Volts

Press Motor Amperage ...................................... 0.90

Voltage...............................................................240V

Cycles ................................................................ 60 Hz

Phase ................................................................ single

Amperage .......................................................... 14

Total Heating Element ....................................... 3000 Watts

Press Motor Size ............................................... 1/15 HP

Press Motor Voltage .......................................... 240 Volts

Press Motor Amperage ...................................... 0.90

6

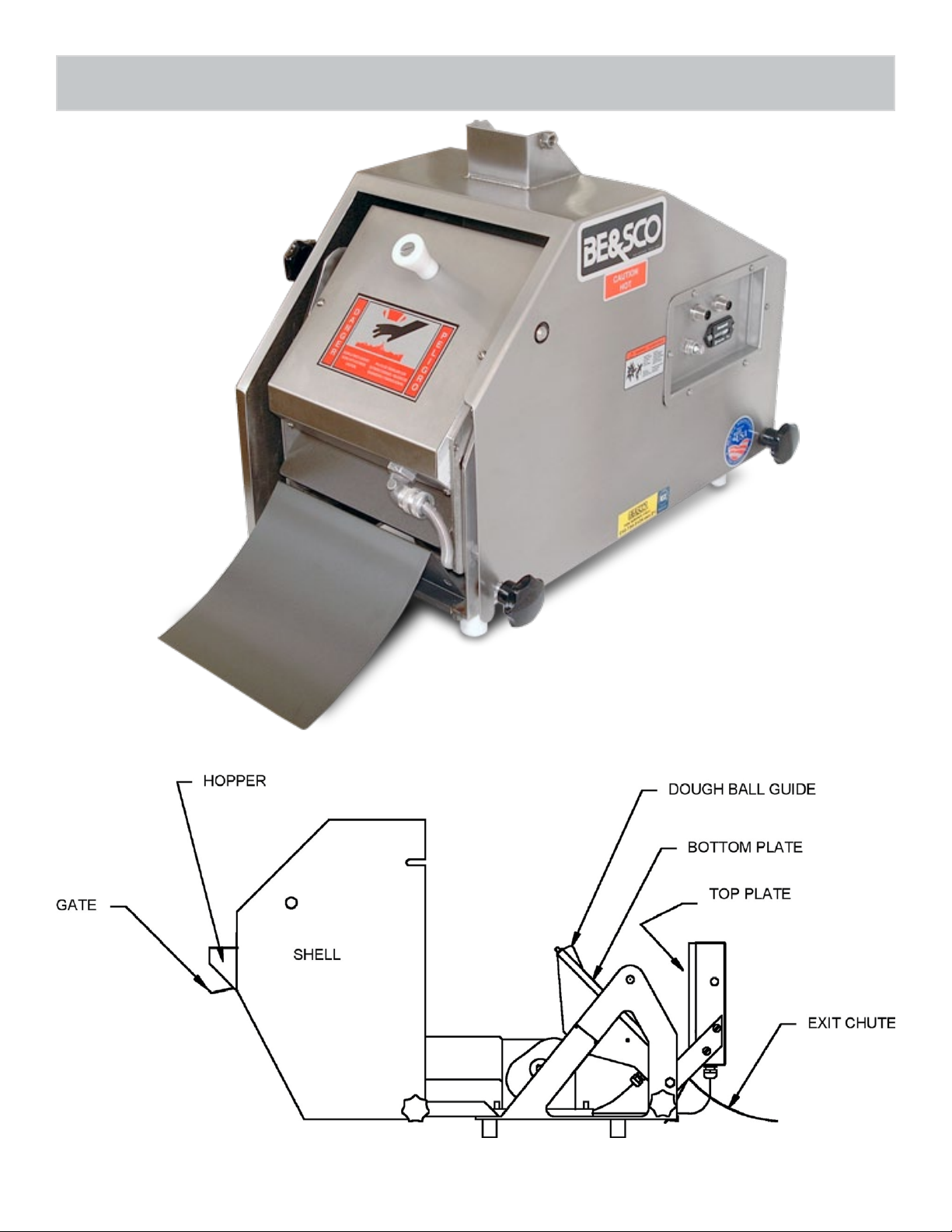

Components

7

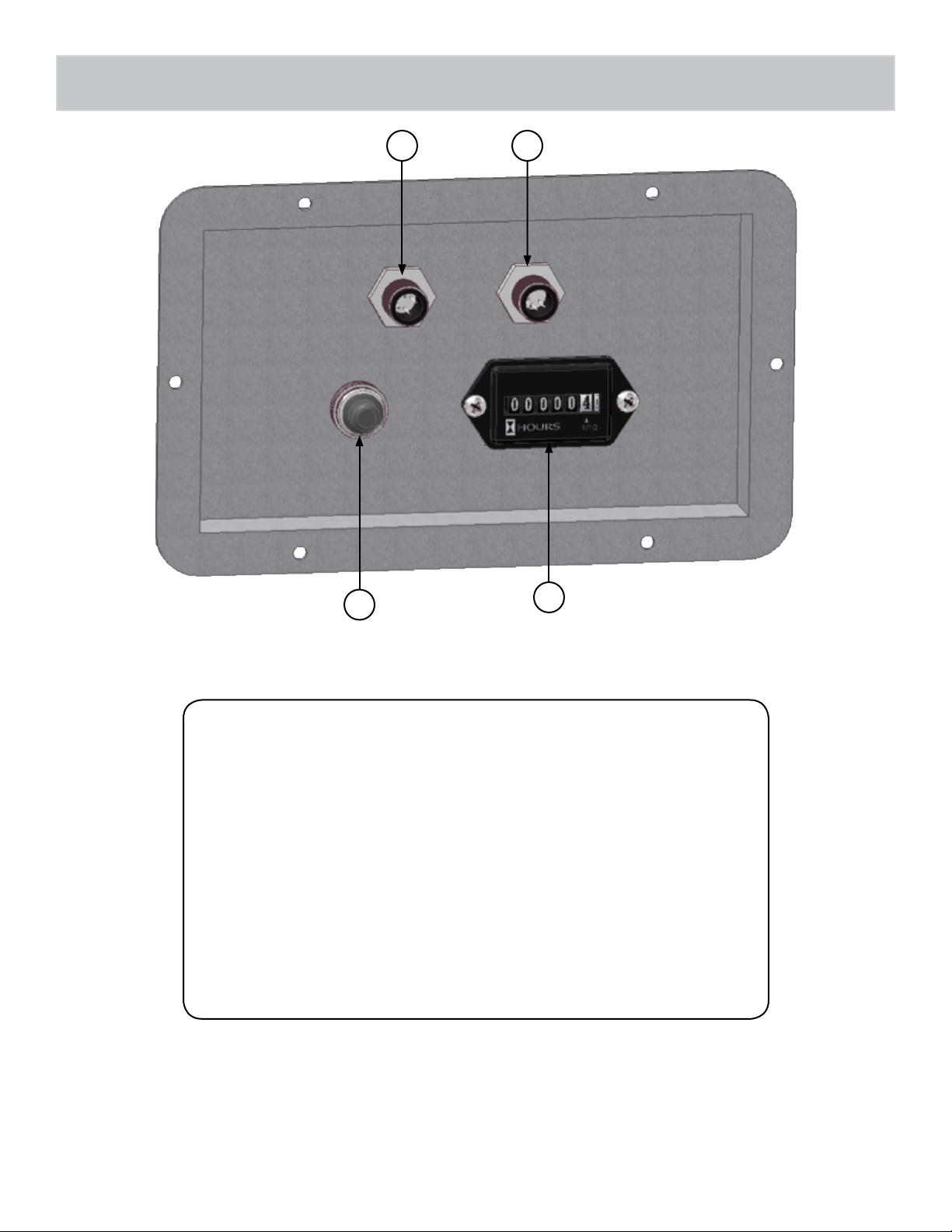

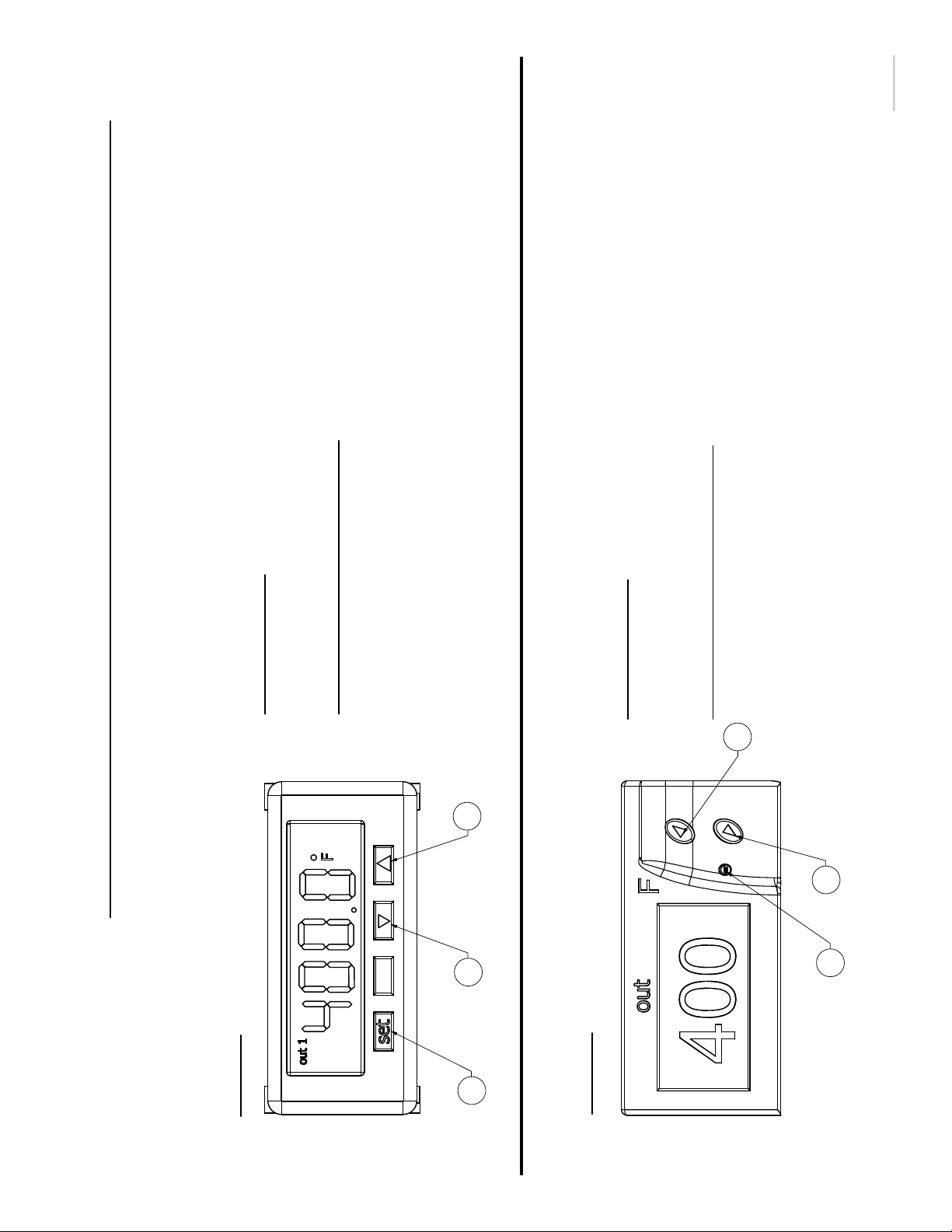

Control Panel Side 1

3

4

1

1. The CONTROL FUSE/ CIRCUIT BREAKER protects the unit

system against an overload in the main power.

2. The HOUR METER tracks hour usage against the motor.

3. The CABLE CONNECTOR on the left is for the cable that controls

the signal to the Dough Trolley Loader.

4. The CABLE CONNECTOR on the right connects the cable that

powers the Dough Trolley Loader.

2

8

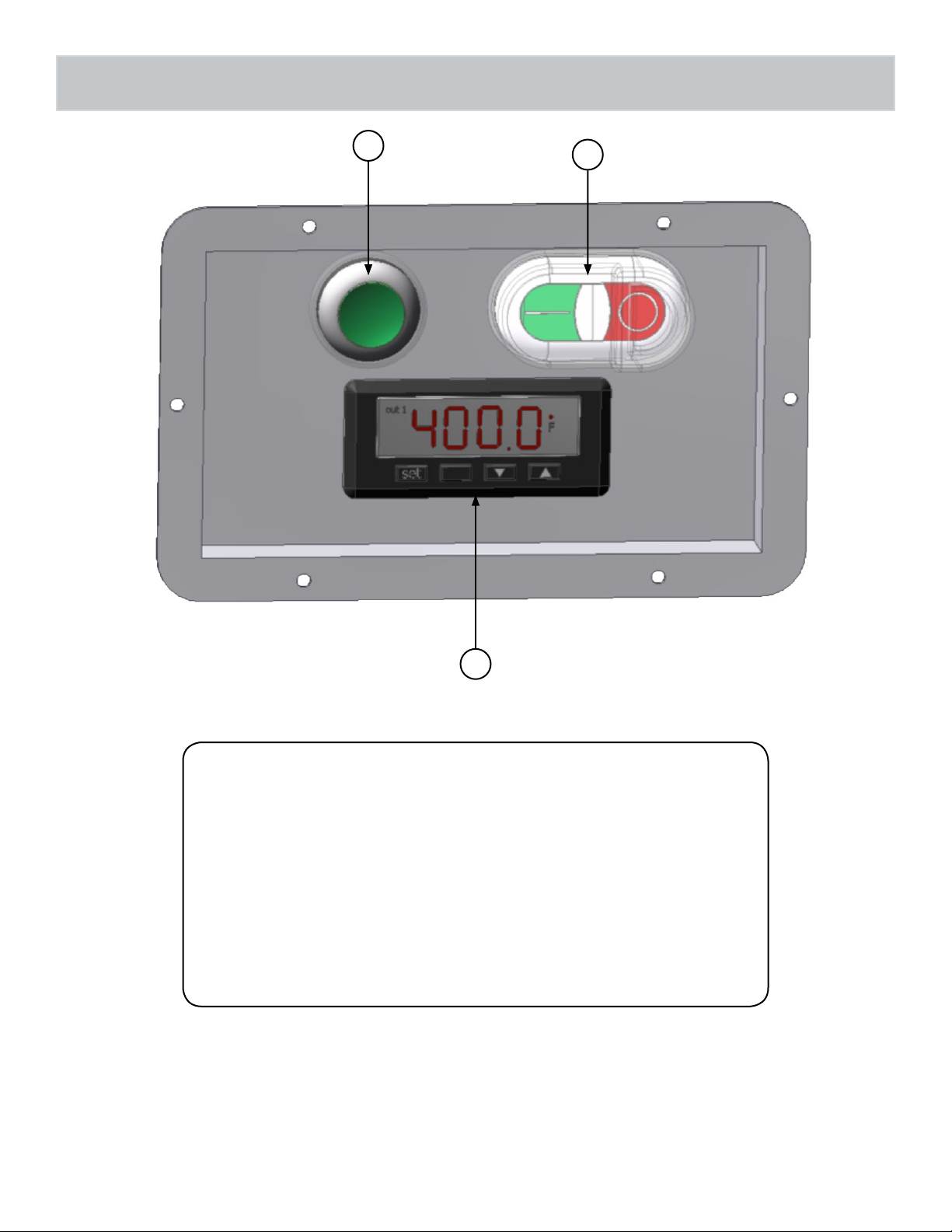

Control Panel Side 2

3

1

2

1. The HEAT ON/OFF SWITCH turns the power on to the machine

and is also the emergency shut down switch.

2. The TEMPERATURE CONTROLLER allows you to set the actual

temperature of the plates.

3. The MOTOR SWITCH starts the press plates. Press the switch

in to Activate/Deactivate the motor.

9

!

Midwedge Operation Instructions

Before Start-up, make sure that the Midwedge press plates

have been well cleaned.

START UP

1. Press the HEAT ON/OFF switch on. Wait for approx. 20-30

minutes to warm up. When the Temperature Controls reaches set

temperature between 380-400°F the press is ready.

2. Press the MOTOR switch on. The press plates will begin to press.

3. Dust the dough ball with our, wait until the hopper gate opens

and drop the dough ball into the hopper: Note: Over dusting of the

rst few dough balls may be necessary to establish a cure on the

Midwedge press plates to prevent sticking.

4. A tortilla is made when the hopper closes and the dough ball drops

between the press plates. When the press plates open again, the

tortilla will slide over the exit slide.

SHUT DOWN

To shut down the Midwedge, simply reverse the previous steps.

1. Press the MOTOR switch to turn off motor.

2. Press the HEAT ON/OFF switch off.

3. Always clean the Midwedge between use.

10

SGR 3-23-12

TEMPERATURE CONTROL INSTRUCTIONS

-PLATE TEMPERATURE IS NOW DISPLAYED

TO CHANGE TEMPERATURE SET POINT:

PLATE TEMPERATURE WILL DISPLAY ONCE FLASHING STOPS

WHEN POWERED UP UNIT WILL FLASH SEVERAL TIMES

INSTRUCTIONS:

-PRESS SET BUTTON (A) ONCE

-PRESS SET BUTTON (A) AGAIN TO EXIT

-USE UP AND DOWN BUTTONS (B) & (C) TO CHANGE SET POINT

-SET TEMPERATURE IS NOW DISPLAYED

INSTRUCTIONS:

TO CHANGE TEMPERATURE SET POINT:

PLATE TEMPERATURE WILL DISPLAY NEXT

WHEN POWERED UP UNIT WILL DISPLAY F

-PRESS SET BUTTON (A) ONCE

-SET TEMPERATURE WILL DISPLAY

-PRESS SET BUTTON (A) A SECOND TIME

-SP (SET POINT) WILL DISPLAY

-PLATE TEMPERATURE IS NOW DISPLAYED

-PRESS SET BUTTON (A) AND DOWN BUTTON (B) AT THE SAME TIME TO EXIT

-USE UP AND DOWN BUTTONS (B) & (C) TO CHANGE SET POINT

C

C

B

B

A

A

PLEASE DETERMINE WHETHER YOU HAVE TYPE A OR TYPE B AND FOLLOW INSTRUCTIONS BELOW

*THERE ARE TWO TYPES OF TEMPERATURE CONTROLLERS THAT WILL COME INSTALLED IN YOUR MACHINE

TYPE A

TYPE B

11

Operation Troubleshooting

PROBLEM CAUSE REMEDY

Stand Alone Midwedge

1

2

3

does not come on.

Temperature Controller

lights up, press plates

heat up. Press motor

light comes on. Press

motor would not run.

Top Press Plate is not

getting hot.

A. No power to machine.

B. Machine not plugged in.

C. Shell is not closed properly.

A. Plug harness not connected.

A. Top Press Plate power harness

disconnected.

B. Top Press Plate thermostat is

not functioning.

A. Check branch line circuit

breaker.

B. Check to see if machine is

plugged into electrical outlet.

C. Make sure safety shell is

placed in properly with knobs

tightened.

A. Check if motor plug harness

is connected to the female

receptacle.

A. Call the service company.

B. Call the service company.

Bottom Press Plate is

4

not getting hot.

A. Bottom Press Plate power

harness disconnected.

B. Bottom Press Plate thermostat

is not functioning.

12

A. Call the service company.

B. Call the service company.

How to remove a stuck tortilla during production

Introduction:

Build up of small amounts of dirt and our stick to the press plates during tortilla

production over time which cause tortilla jams to occur. This section will show

you how to remove a tortilla jam. Be very careful while removing the jam. If you

touch the machine without a mitt, the heated metal can easily burn. Follow the

instructions below exactly.

Items needed:

A. Cleaning Stick

B. Oven Mitt

Item Description QTY Part Number

A Cleaning Stick 1 949912005

B Oven Mitt 1 949952010

If you do not have these materials call BE&SCO’s Parts Department @ 210-734-5124.

Precautions:

• Do not wash Press Plates in water.

• Wear oven mitts for protection.

• Do not clean press plates with any brand name cleaners, degreasers, and/or sharp objects, such as:

13

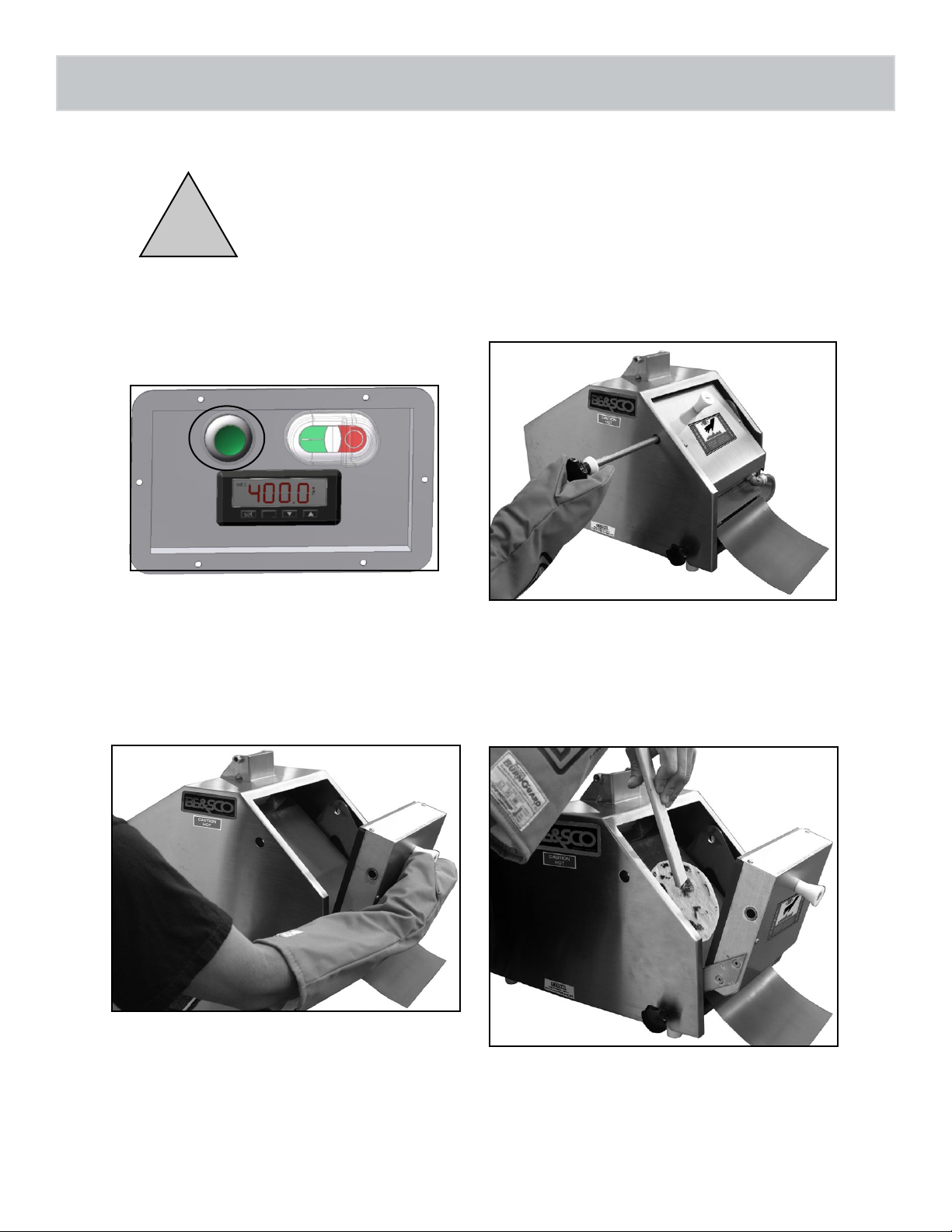

!

How to remove a stuck tortilla during production

CAUTIONS HOT: When cleaning the press plates while in production always

use the oven mitt and cleaning stick to keep a safe distance between you and

the hot surface. Make sure to always turn off the press motor before you start

cleaning the press plates.

1. Turn off the Press Motor by

depressing the green push button.

3. Pull the white knob opening the top plate.

2. Pull the locking pin and place it under the machine.

CAUTION: LOCKING PIN EXTREMELY HOT.

4. Use the BE&SCO Oven Mitt and Cleaning

Stick to remove the tortilla jam.

14

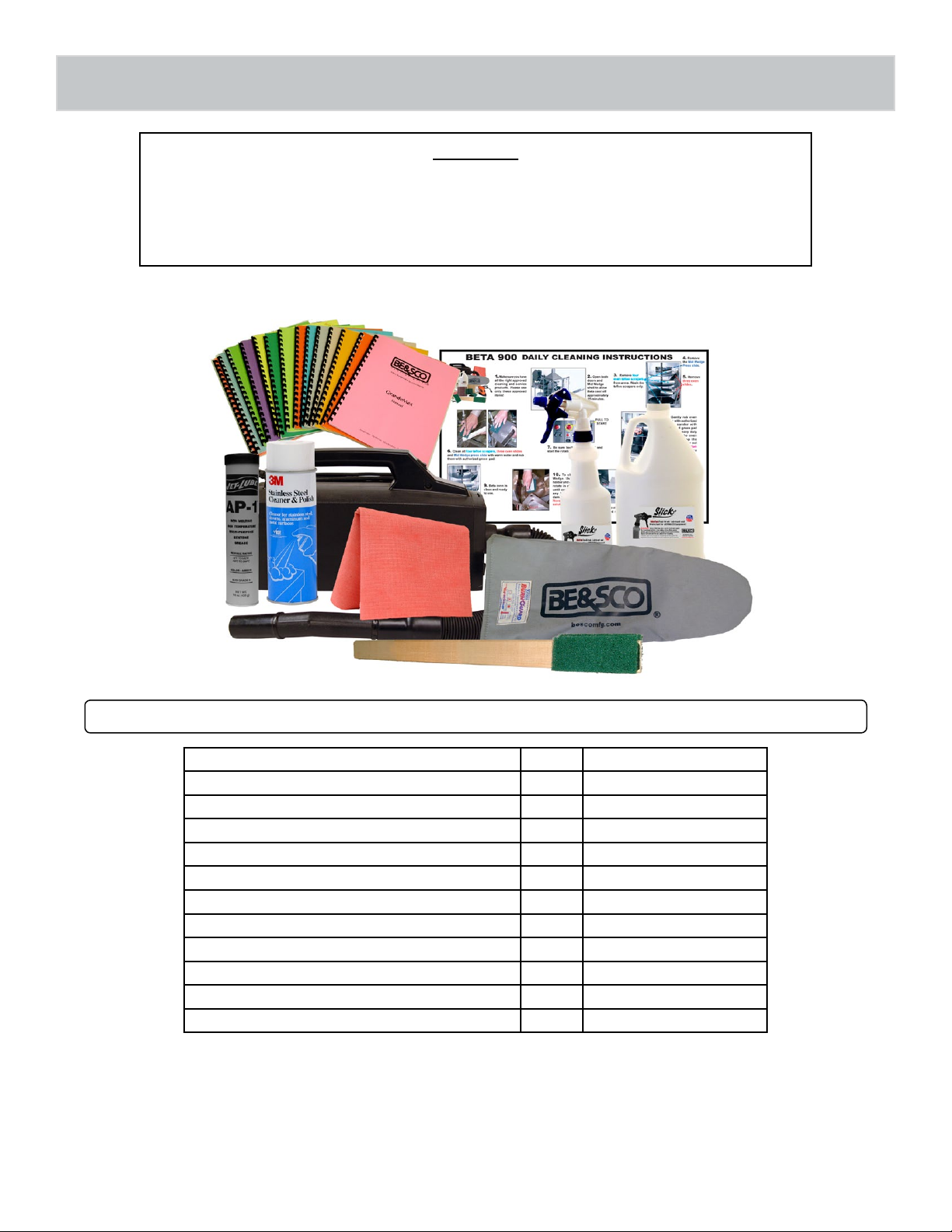

Cleaning the Stand Alone Midwedge Press

Introduction:

Cleaning keeps the inside and outside of the machine free from dust, our, or any other

build-up. If the machine remains unclean for along period of time, the oil and build-up clog

the moving parts and could slow or halt production and damage the unit. This section will

show you how to clean the machine.

Order these materials as needed through the BE&SCO’s Parts Department @ 210-734-5124.

Description QTY Part Number

BE&SCO Manuals 1 Machine Manual

BE&SCO Storyboards 1 Machine Storyboard

Cleaning Stick 20” 1 949912005

Cleaning Stick 26” 1 949912006

BE&SCO Oven Mitt 1 949952010

Grade Slick’em Gallon 1 911522101

Grade Slick’em Qt. 1 911522100

Stainless Steel Cleaner & Polish 1 911512016

Grease, Ultra Hi Temp 1 911211003

Vacuum Cleaner with Hose Attachment n/a n/a

Soft Dry & Damp Cloth n/a n/a

15

Cleaning the Stand Alone Midwedge Press

1. Make sure you have all the

approved cleaning supplies

and service products. Please

use only these approved items.

2. Before cleaning make

sure you turn off the machine

and allow to completely cool

approx. 20-30 minutes.

3.To clean the press plates, pull

the locking pin out, pull out the

exit slide and pull the white knob

to open the top plate.

4. Loosen the two

front black knobs to

loosen the shell.

7. Spray Slick’em on a

cloth. Apply to both top and

bottom plates.

5. Pull the shell back to

expose the plates and motor

compartment.

8. Use a compact vacuum to

vacuum up the debris in the motor

compartment.

6. Clean the plates with the

Green Scrub pad. Use Brown

pad for heavy build-up.

9. Clean the exterior with

Stainless Steel Cleaner. The

press is clean and ready to use.

16

Loading...

Loading...