Bernina Industrial 950 Instruction Manual

-=

=-L--

- ~=

-

-

--

~-.- '"': ==

~§§§- -

- .: §.

==

-~

-~

---

-

----

--

-

-

.=---~

-

-

./=

"=

-

-

-

-

--

-

---'

._-'

'-

-----_

.•.

_-

_.-

~-----

--

--

----

--

'-

'-

-

-

-

-

-

~

",-

./

""

..-

..--

,..-

~

-"

-"

-"

./

./

..r

,/

-<

---

./

""

-~

--.-

-

-

-

Industrial

950

Instruction Manual

Bedienungsanleitung

Manual

d'

instructions

Manuale

d'

instruzione

Manual de instrucciones

Safety instructions

IMPORTANT! SAFETY INSTRUCTIONS

The following safety instructions should always be

followed:

Before using the machine, read the safety instructions

and the instruction manual carefully.

Please follow the instructions below very carefully when

setting up, operating and cleaning the appliance:

Use this appliance only for its intended use as descri-

bed in this manual.

Never operate the appliance if parts are defective or

missing.

The appliance may only be operated when all protec-

tive covers are correctly fitted.

The motor voltage mentioned on the specification

plate must correspond with the electrical voltage of

the place where the appliance is used. Do not use the

machine if this is not the case.

.

-",

Use only attachments recommended by the manu-

facturer as contained in this manual.

Never operate the machine where aerosol (spray pro-

ducts) are being used or where oxygen is being admi-

nistered.

-.

Keep flammable and volatile liquids well away from

the appliance.

Switch the machine off or remove the plug from the

power supply when making any adjustments in the

needle area.

Always unplug the machine from the electrical supply

when cleaning or lubricating or when work is comple-

ted. In addition wait until the machine has come to a

complete standstill when using a clutch motor.

Always unplug by grasping the plug and not the cable.

Do not press the foot control when switching the

appliance on .

.

,......,.

The needle and other moving parts (thread take-up,

hook and handwheel) are sources of injury (injury to

fingers). It is therefore important to keep your eyes on

to work.

Always use the prescribed needle system. Do not use

blunt or damaged needles.

Keep ventilation openings of the motor and foot con-

trol free from the accumulation of lint, dust and loose

cloth.

Before tilting the machine, turn the power switch to

,,0", remove the plug from the power supply and let

the machine come to a complete standstill. Be careful

of sharp, protruding parts and when tilting the machi-

ne back again, make sure that your fingers do not get

trapped between the machine and the sewing table.

Keep these instructions carefully for your own safety .

Contents

<:»

"

1

Safety Instructions

'../

C!:

2

Content

2

3

Details of the machine

Setting up the machine

4

Removing and inserting the bobbin case

"-'

Winding the bobbin

5

Inserting the bobbin

Selecting needle and thread

Inserting the needle

6

Changing the presserfoot

'-'

Threading the upper thread

Bringing up the lower thread

'-"

7

Thread tension

Lowering the feed-dog

Presserfoot lifter (FHS-FreeHand System)

-'

Sewing tips

Standard Accessories

8

Presserfeet

9

Presserfeet

'-'

Practical sewing ~

10

Practical stitches

Decorative stitches

Y.".f'-

-::»

Basic settings

11

Straight stitch, zig-zag

12

Practical stitches, decorative stitches

'-"

Practical sewing

13

Sewing with decorative stitches

14

Buttonhole

--../

15

Buttonhole with gimp

Buttonhole foot with slide

<::»

16

Blind hem

Vari-Overlock

17

Sewing in zips

'--

Darning

Maintenance

18

Cleaning, Lubricating

<::»

19

Solving problems

"-

-

20

Index

<:»

'-./

->,

<:»

<:»

'-'

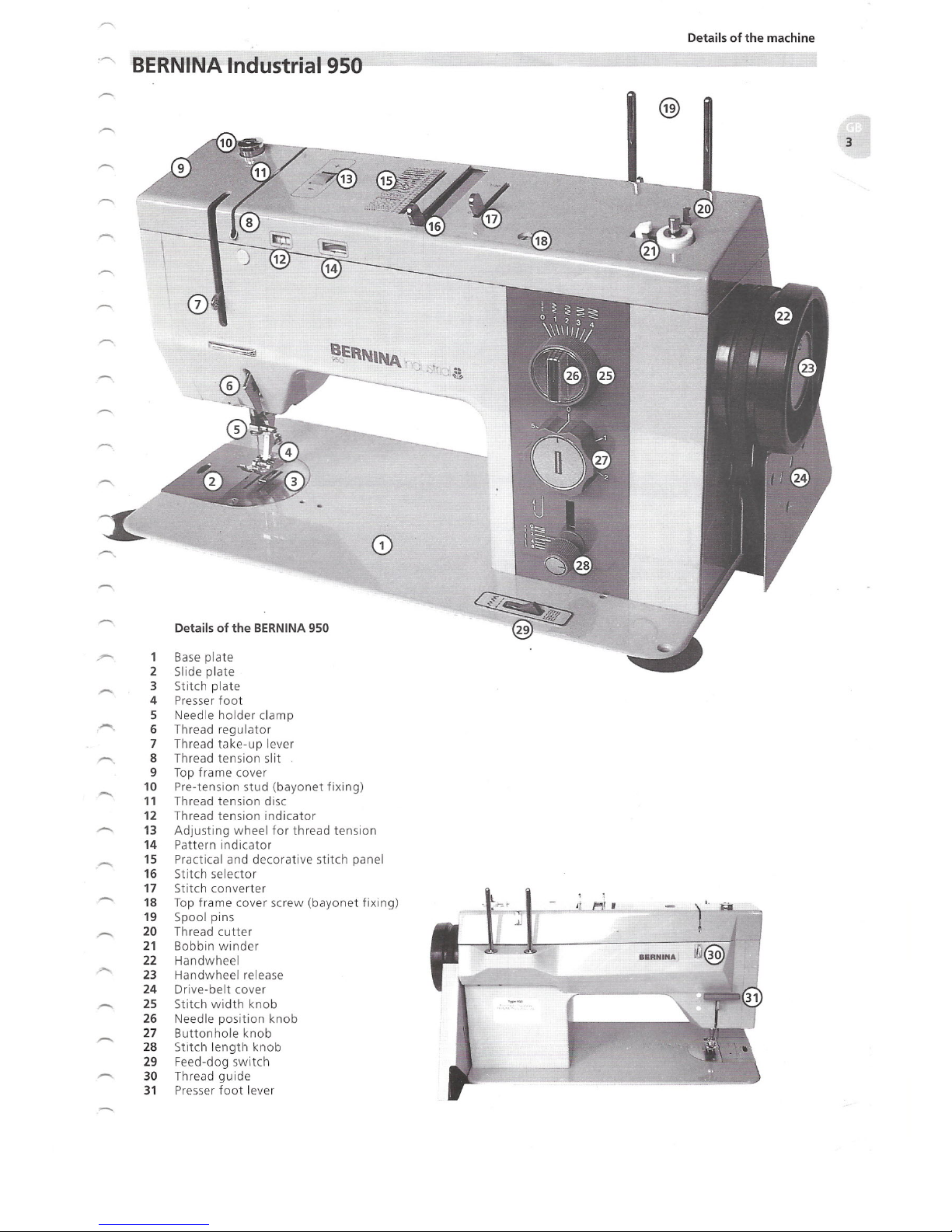

BERNINA Industrial 950

Details of the machine

Details of the BERNINA 950

1 Base plate

2 Slide plate

3 Stitch plate

4 Presser foot

5 Needle holder clamp

6 Thread regulator

7 Thread take-up lever

8 Thread tension slit

9 Top frame cover

10 Pre-tension stud (bayonet fixing)

11 Thread tension disc

12 Thread tension indicator

13 Adjusting wheel for thread tension

14 Pattern indicator

15 Practical and decorative stitch panel

16 Stitch selector

17 Stitch converter

18 Top frame cover screw (bayonet fixing)

19 Spool pins

20 Thread cutter

21 Bobbin winder

22 Handwheel

23 Handwheel release

24 Drive-belt cover

25 Stitch width knob

26 Needle position knob

27 Buttonhole knob

28

Stitch length knob

29 Feed-dog switch

30 Thread guide

31 Presser foot lever

3

Setting up the machine

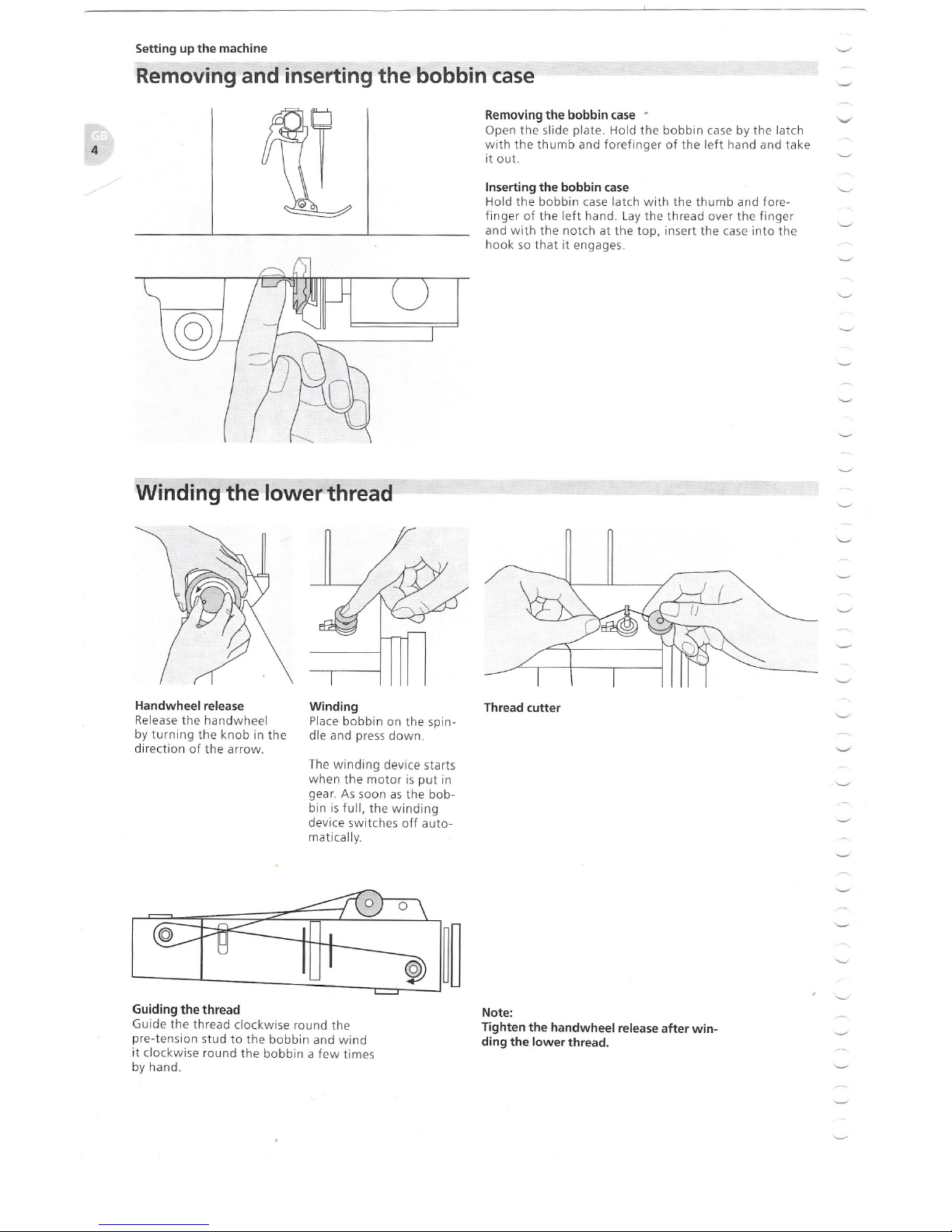

Removing and inserting the bobbin case

4

Winding the lower-thread

Handwheel release

Release the handwheel

by turning the knob in the

direction of the arrow.

Winding

Place bobbin on the spin-

dle and press down.

The winding device starts

when the motor is put in

gear. As soon as the bob-

bin is full, the winding

device switches off auto-

matically.

Guiding the thread

Guide the thread clockwise round the

pre-tension stud to the bobbin and wind

it clockwise round the bobbin a few times

by hand.

Removing the bobbin case •

Open the slide plate. Hold the bobbin case by the latch

with the thumb and forefinger of the left hand and take

it out.

Inserting the bobbin case

Hold the bobbin case latch with the thumb and fore-

finger of the left hand. Lay the thread over the finger

and with the notch at the top, insert the case into the

hook so that it engages.

Thread cutter

Note:

Tighten the handwheel release after win-

ding the lower thread.

Inserting the bobbin

Inserting

Insert the bobbin with the

thread running in an anti-

clockwise direction.

:

••....•..

Threading

Draw the thread through

the slot and below the

spring until it lies in the

T-shaped slot at the end of

the spring.

Selecting needle and thread

Selecting needle and

thread

Use only left-twisted

th read. The correct size of

needle allows the thread

to pass easily through the

eye and the long groove.

Left or Z twisted.

Special needles

»<

We recommend the use of special needles which are

designed for specific fabrics and materials.

.-'

»

2:>

287 WH SES

- fine ballpoint for fine

knits and synthetics

287WH SUK

- medium ballpoint for

thick knits

287WH L

- cutting point for leather,

suede, imitation leather

and plastic

Inserting the needle

Needle system 287 WH

Insert the needle fully with

the long groove to the

front.

The direction of the eye

should be between the 6

and 7 on a clock.

,.......

'"'

.....•.

,I

,

-

-

>'"'.

-9

I

3-

-

,~/;

-

,

c-...

I' ,

Lower thread tension

Normal tension

Sharp hand movement

=

bobbi n case tu rns

Hand still=bobbin case

stiII.

Needle

70

Thread

Darning thread

o

Embroidery

thread No. 30

Mercerised cotton

Polyester

Thick mercerised

cotton,

Polyester

Buttonhole thread

(cordonnet) for

decorative seams

Setting up the machine

5

Adjustment

Adjusting the bobbin

thread tension:

+ tighter tension

- looser tension

80

90

100 110-120

o

o

o o

o o

o o

o

o

Use the screwdriver from

the accessory box to loo-

sen and tighten the needle

clamp screw.

Loading...

Loading...