Page 1

Page 2

Retyped by Mastersewusa.co

m

Important

Dear customer

Congratulations on your choice!

Your Bernette Funlock 004D/004 is made to the highest standards. It will cut, sew and neaten for you in one smooth

operation giving a professional look to anything you make.

The 4 thread Bernette Funlock is particularly suited to sewing stretch fabrics. Let your wardrobe and home benefit

from the Bernette’s superb sewing qualities. Our comprehensive Instruction Manual introduces you step by step to

the joys of overlocking and also gives you some useful sewing tips.

We wish you many happy hours of overlocking pleasure.

Safety Regulations

The following safety regulations must be observed without fail: It is important to pay attention to the needle and knife

while sewing as these are potential sources of injury to fingers. Movements within the area of the needle, knife or

looper such as threading, changing needles or presser feet, or raising the knife, may only be done with the machine

switched off (power switch at “O”). When cleaning or lubricating the machine replacing the bulb or when sewing is

finished, machine should be disconnected from the electricity supply. All repair work, especially electrical repairs

(e.g. renewing the cable connection out by one of our authorized service agencies.

Please note:

Funlock 004 is not equipped with differential feed. All points relating exclusively to Funlock 004D are marked with

the symbol. ✱

1

Page 3

Retyped by Mastersewusa.co

m

Contents

Safety regulations 1

Contents 2

Details of the machine 3

● Accessories 4

Preparing the machine 5

● Foot control 5

● Assembling the thread stand 5

● Thread, cones, spools 6

Using the machine 7

● Main switch 7

● Handwheel 7

● Looper cover, cloth plate 7

● Presser foot lifter 8

● Changing the presser foot 8

● Inserting the needles 9

● Raising the upper knife 9

Threading 10

● Preparations 10

● Upper and lower looper 11/12

● Right-hand and left-hand needle 13/14

Threading/trial sewing 15

● 3 thread Overlock 15

● Sewing test/tension 15/16

● Adjusting tension 17

Adjustments and settings 18

● Stitch length 18

● Cutting width 18

● Differential feed ✱ 19/20

● Gathering ✻ 20

Setting/Practical sewing 21

● Presser foot pressure 21

● Roll hemming 22

● Sewing in tape 23

● Thread breakage, unpicking seams 23

Maintenance 24

● Changing knifes and light bulb 24

● Cleaning and lubricating 24

Trouble shooting guide 25

Technical data 26

2

Page 4

Retyped by Mastersewusa.co

m

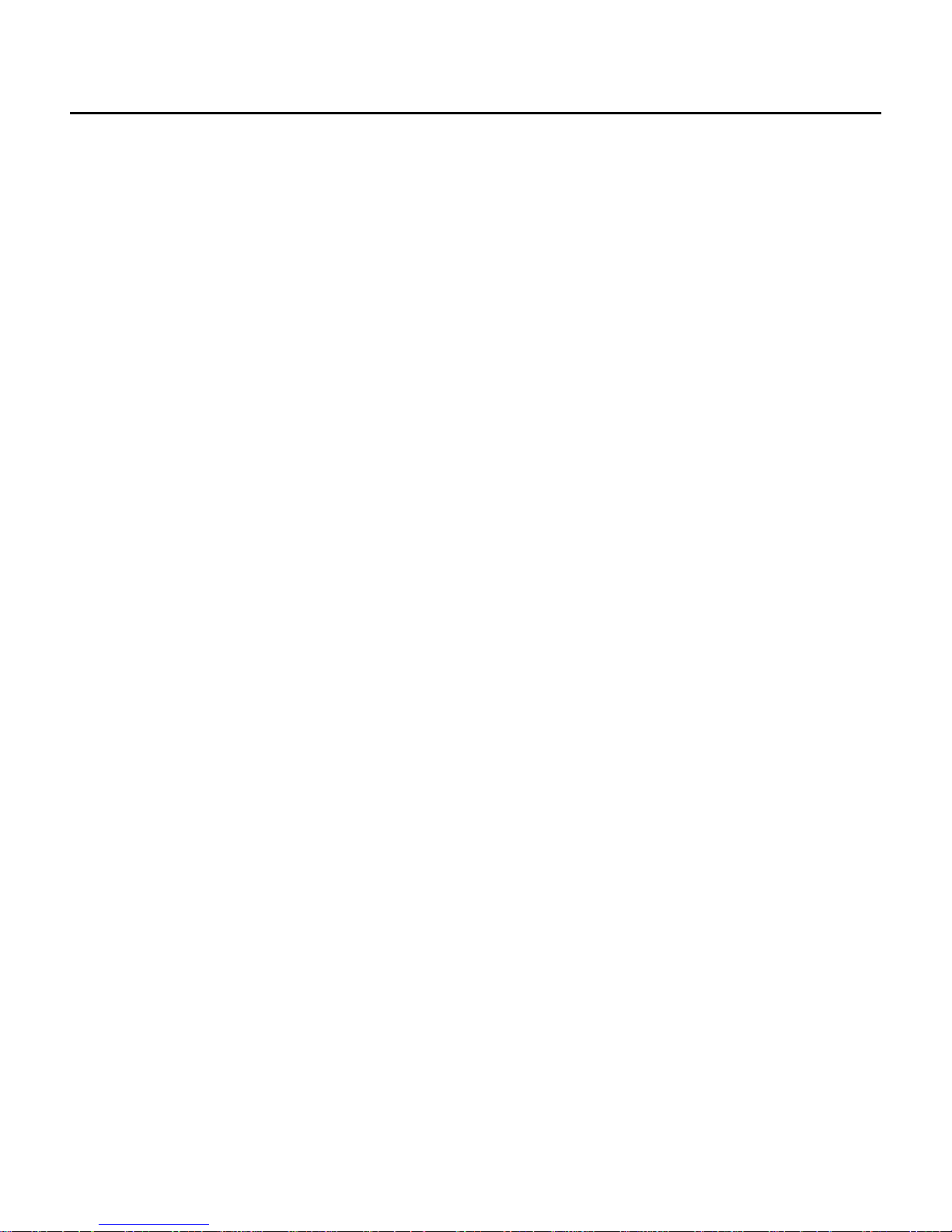

Details of the machine

Details of the machine

1. Looper cover

2. Looper cover opening indent

3. Knife guard

4. Cloth plate opening lever

5. Cloth plate

6. Stitch plate

7. Presser foot

8. Lower looper thread tension dial

9. Upper looper thread tension dial

10. Right needle thread tension dial

11. Left needle thread tension dial

12. Thread take-up cover

13. Thread guide plate

14. Presser foot adjusting screw

15. Sewing light

16. Power/light switch

17. Handwheel

18. Machine socket

19. Thread stand

20. Anti-vibration cone

21. Spool holder pin

22. Retractable support rod

23. Thread guide

24. Open thread guide

25. Presser foot lifter

26. Foam pad

27. Stitch length adjustment knob

28. Differential feed adjustment knob

3

21

20

19

Page 5

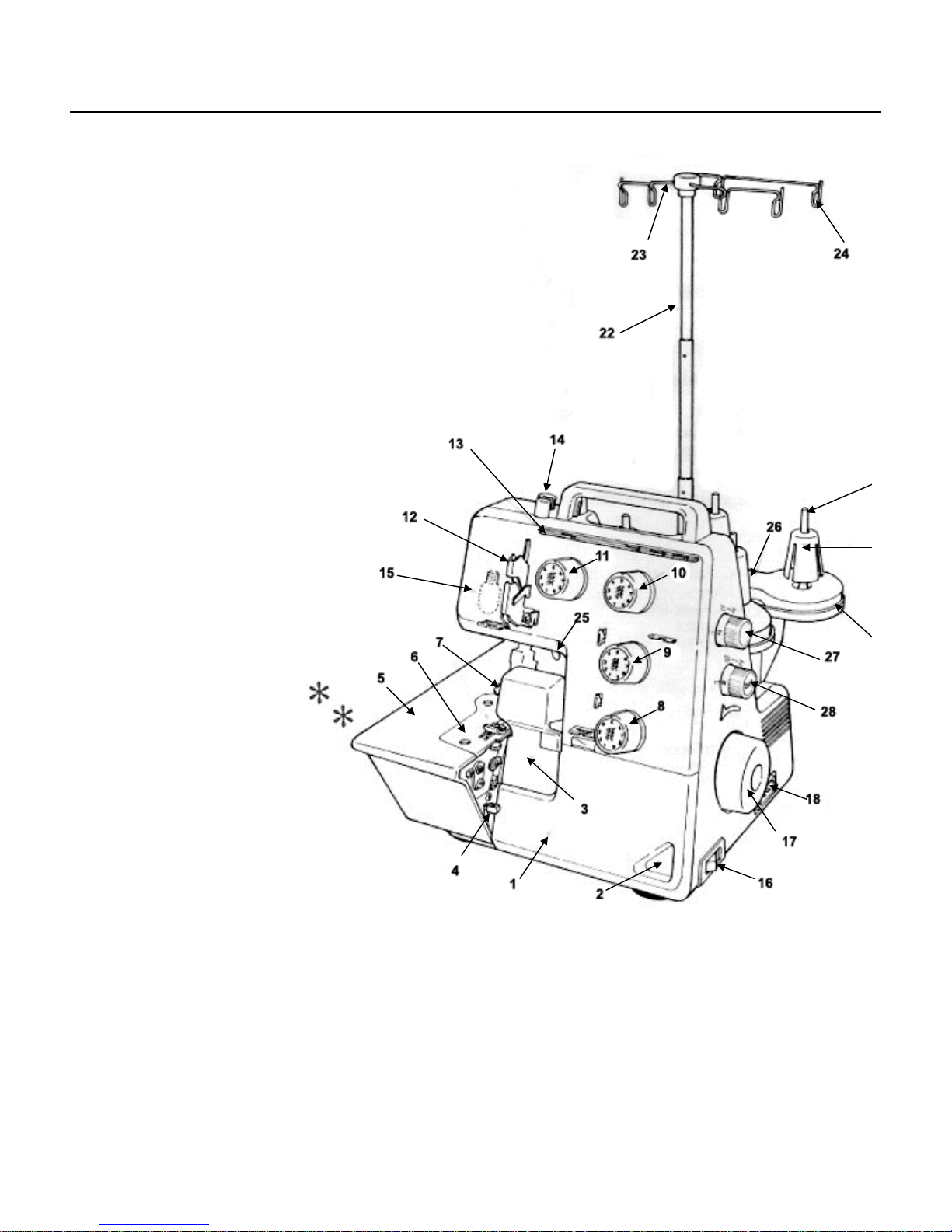

Details of the machine

View with looper cover open

1. Upper looper

2. Upper knife

3. Lower knife

4. Selection lever for overlocking or roll hemming

5. Lower looper

6. Lower knife setscrew

View with cloth plate open

1. Cutting with adjustment knob

2. Stitch length adjustment knob (004)

Accessories

1. Electronic foot control

2. Lower knife

3. Net

4. Spool caps

5. Tweezers

6. Cleaning brush

7. Looper threader

8. Needle threader

9. Set of household needles

10. Small screwdriver

11. Large screwdriver

12. Oiler

13. Accessory bag

14. Dust cover

4

Page 6

Preparing the machine

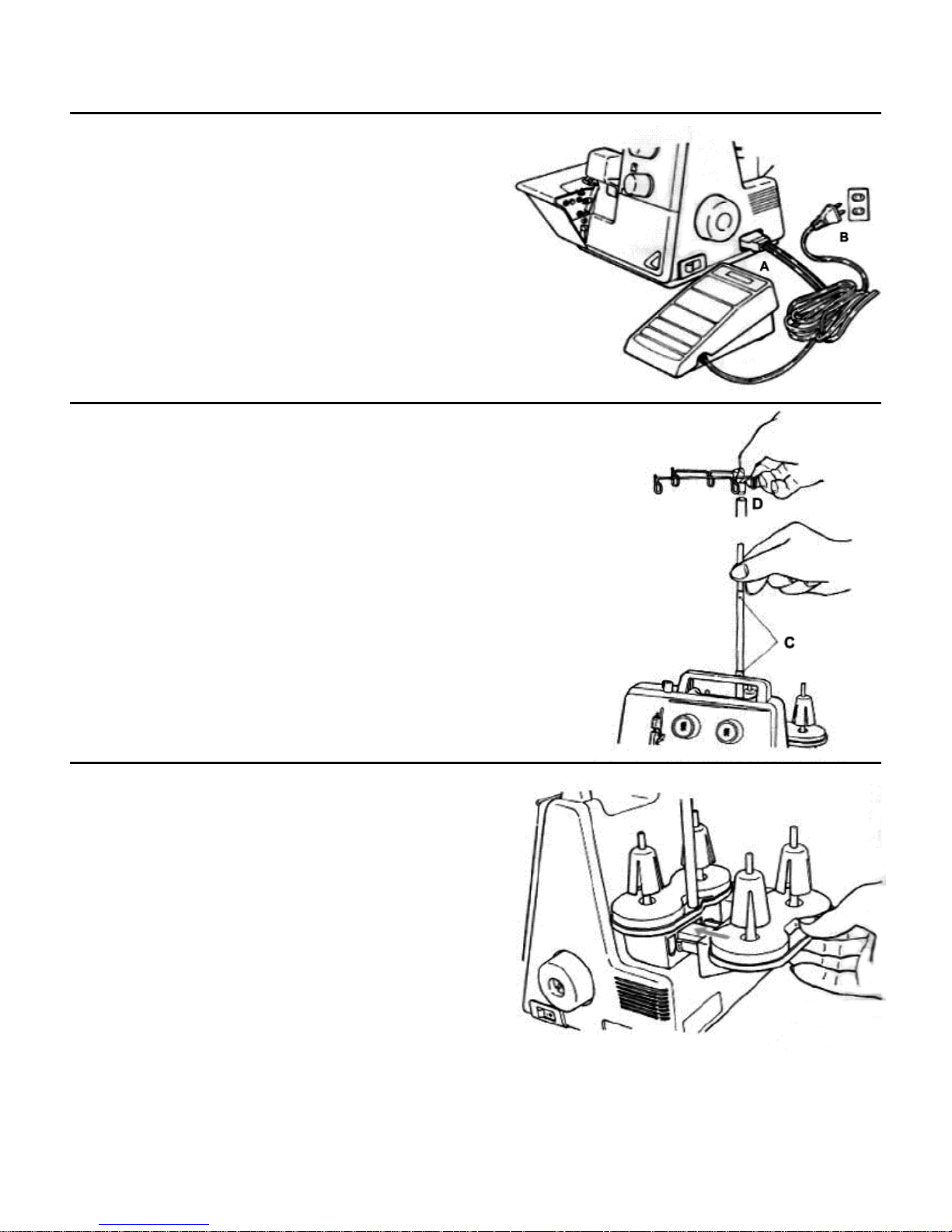

Attaching the foot control

Plug foot control into machine socket (A) and then into main

socket (B). The foot control regulates the sewing speed. The

sewing speed can be adjusted by increasing or decreasing the

pressure on the foot control.

Thread guide

Raise, the support rod fully, turning slightly until the

positioning catches engage (C). Position the thread guide on

the thread stand so that the arrow is to the front (D).

Thread Stand

Attach the separately packed spool holder to the fixed spool

holder.

5

Page 7

Preparing the machine

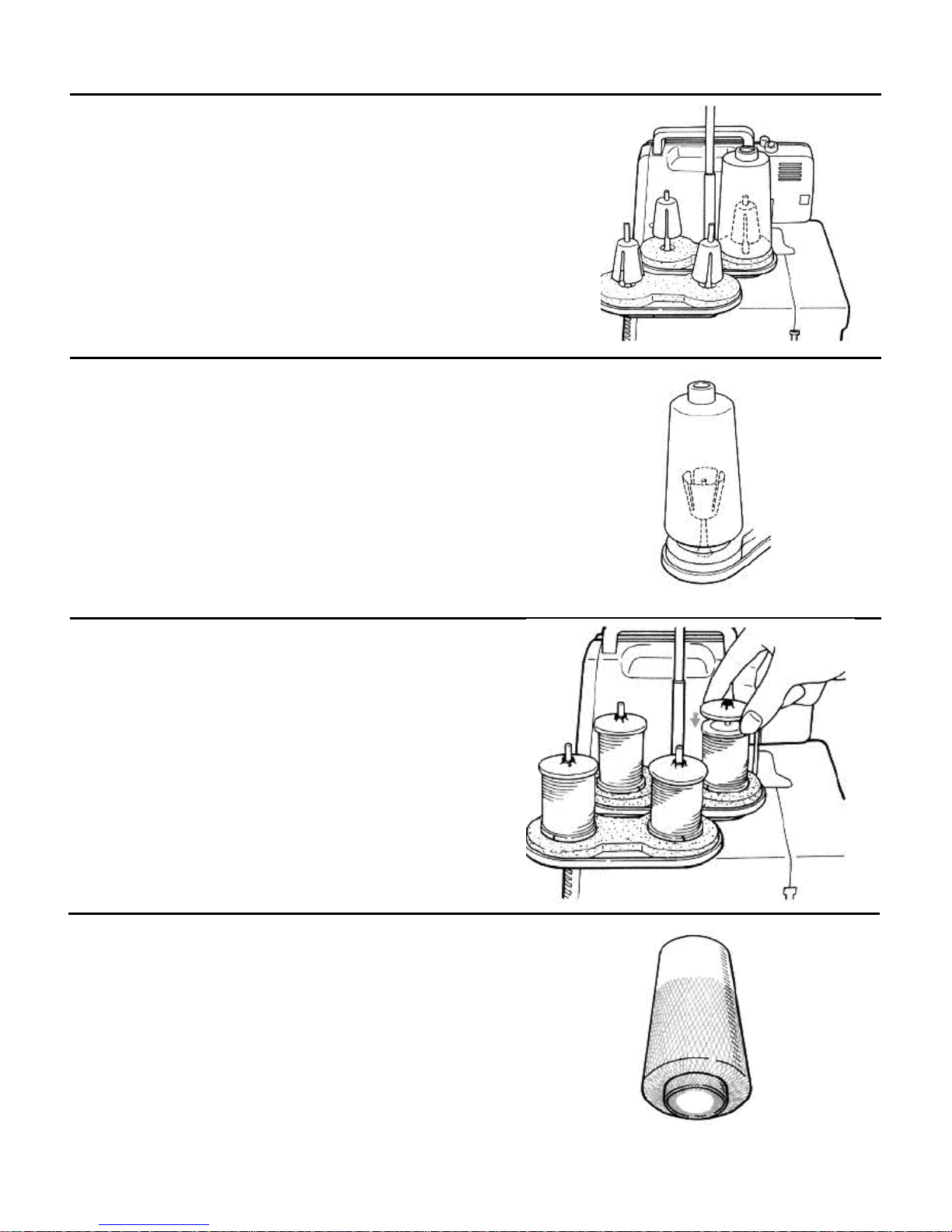

Thread cones/spools

The anti-vibration cone should be used with the wider edge

at the bottom on the spool holder pin when sewing with

cones.

Large spools

If large industrial spools are used, position the anti-vibration

cone upside down on the spool holder pin, i.e. with the wider

edge at the top.

Household spools

Remove the anti-vibration cones. Place spools on spool

holder pins and push the spool capon with the rounded side

downwards.

Thread net

If threading slip and get twisted, cover the spools of upper

and lower looper with the nets supplies in the accessory bag.

6

Page 8

Using the machine

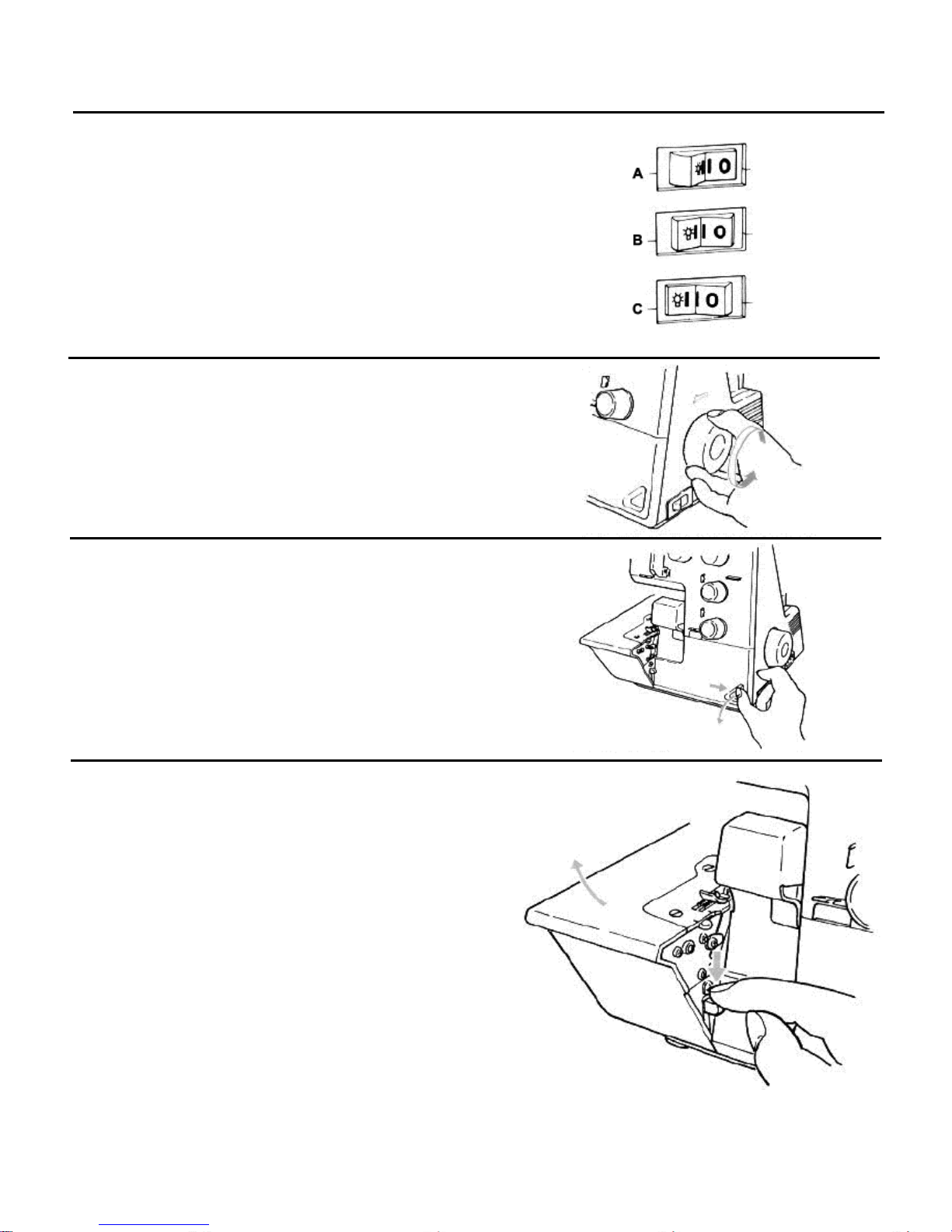

Power/light switch

The power/light switch is conveniently placed on the handwheel side of the machine in front of the socket.

• Off (A)

• On without light (B)

• On with light (C)

Handwheel

The handwheel turns forward, i.e. in the same direction as on

a household sewing machine.

Looper cover

To open press to the right with your thumb in the indent

provided and tilt the cover towards you. To close, push it up

and press lightly to the right. The cover engages

automatically.

Cloth plate

The cloth plate opens automatically by pushing the lever

downwards. To close the cloth plate, push it towards the

machine and press gently until the cover engages.

7

Page 9

Using the machine

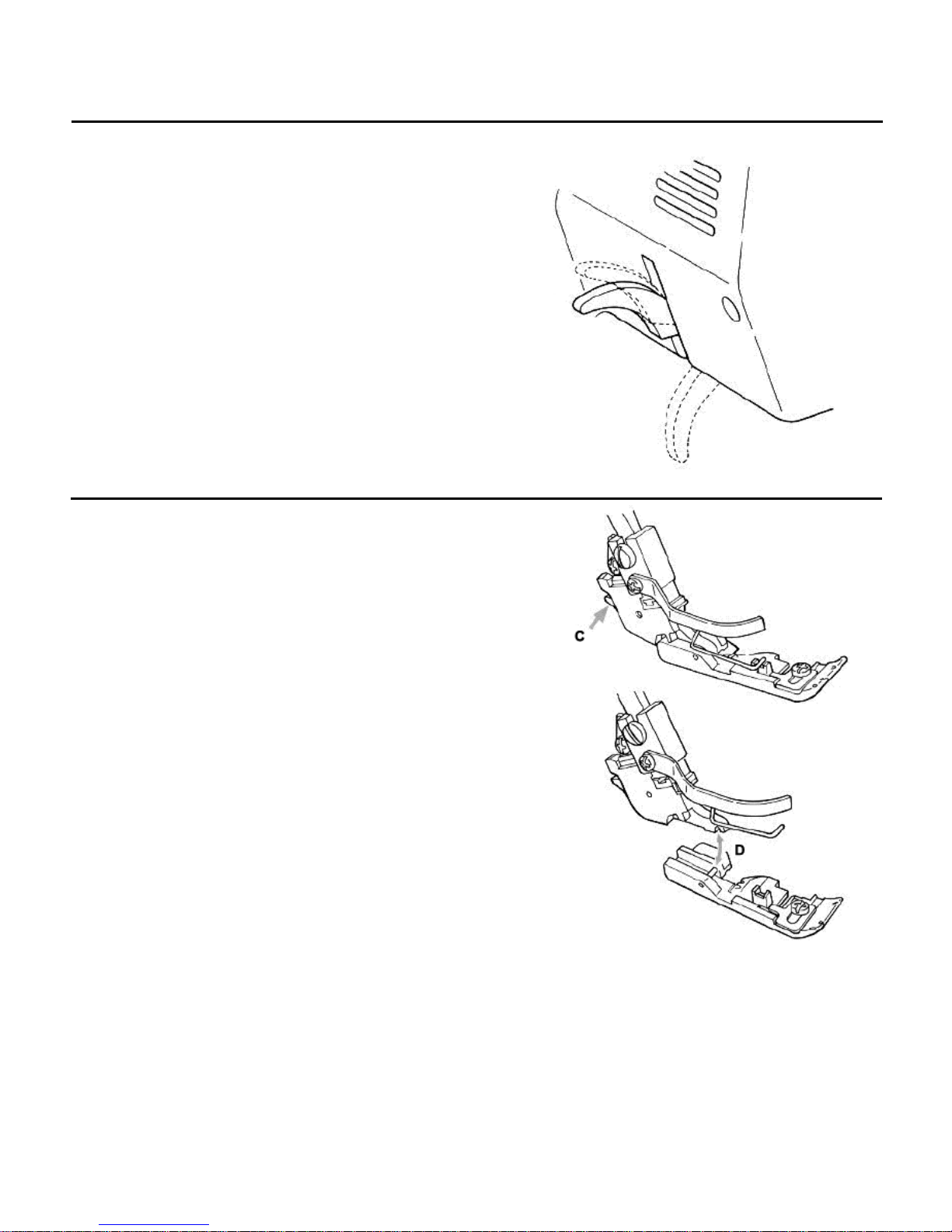

Two-step presser foot lifter

To raise the presser foot, raise the presser foot lever on the

rear of the machine, until it engages (A). It can be raised

again to maximum height and held in this position to provide

more space between presser foot and stitch plate (B).

Changing the presser foot

• Turn power switch to “O”

• Raise the presser foot

• Turn handwheel towards you until needles are fully

raised.

Press the catch (C) to release the presser foot from the

clamp. Raise the presser foot to the highest position (B)

and remove the presser foot to the left. To attach the

presser foot, place it under the shaft. The groove in the

shaft should line up exactly with the presser foot pin

(D). Lower the shank and the presser foot will engage

automatically.

8

Page 10

Using the machine

Inserting the needles

Needles can be inserted quickly and easily with the practical

brush-cum-needle inserter (A).

• Turn power switch to “O”.

• Turn handwheel towards you until needles are fully

raised.

• Lower the presser foot.

Using the small screwdriver, loosen the needle set- screws

and remove the needles (B).

Place right-hand needle, flat sides towards the back, into the

hole of the needle inserter and insert the needle as far as

possible into the needle clamp. Tighten the set-screw lightly

and then insert the left-hand needle in the same way and

tighten both setscrews (C).

Needle and machine

Your Funlock is equipped with needle system 130/705 H

(household needles). These should be purchased when

replacement needles are required. Use needles no. 70 – 90 on

your Bernette.

Raising the upper knife

•

• Turn the handwheel towards you until needles

• Open looper cover.

Press the upper knife holder (D) to the right. Turn the knob

clockwise (E) until the knife is in the position illustrated (F).

9

Turn the power switch to “O”

are fully raised.

Page 11

Threading

Preparation/Tips

• Turn power switch to “O”

• Support rod with thread guide must be fully raised.

• Open the looper cover and cloth plate.

• Turn the handwheel towards you until needles are

fully raised.

• Raise the upper knife.

Thread the machine carefully and in the correct sequence.

Invaluable threading aids simplify threading:

• coloured threading illustration

• colour coded thread path on the machine.

• threading accessories.

Thread guide bar

Slide thread into the two slits to form an S-loop.

Thread tension

The thread must lie correctly between the tension discs for

perfect stitch formation. When a slight resistance is felt on

the thread, it is lying correctly between the tension discs.

Needle threader

Insert thread into threader. Push the rigid end of the threader

through the looper or needle eye and pull it completely

through the eye.

10

Page 12

Threading

1. Upper looper thread, blue markings

Place the spool on the spool holder pin underneath the blue

marking on the thread guide.

(1) Bring thread up from spool and take it through the blue

guide.

(2,3) Make S-loop around thread guide bar.

(4) Thread guide.

(5) Thread tension dial.

(6,7,8,9,10) Thread guides

(11) Turn handwheel towards you until upper looper is in the

position illustrated. Thread looper eye.

(12) Lift presser foot, place thread underneath and lower

presser foot.

11

Page 13

Threading

1. Lower looper thread, red markings

Place the spool on the spool holder pin underneath the red

marking on the thread guide.

(1,2) Bring thread up from spool and take it through the red

guide.

(3,4) Make S-loop around thread guide bar.

(5) Thread guide.

(6) Thread tension dial.

(7,8,9,10,11) Thread guides

(12) Using the looper threader, pass the thread from the right

hand side through to the left hand-side of the machine. Turn

the handwheel towards you until the lower looper is in the

left-most position. Insert the thread into the slit on the lower

looper.

(13) Using the looper threader, pull the thread through to the

right side again. Turn the handwheel towards you until the

lower looper is in the right-most position, and thread the

looper eye so that the thread lies in the long groove on the

lower looper.

(14) Take the thread over the upper looper. Raise the presser

foot, place the thread under it and then lower the presser

foot.

12

Page 14

Threading

3. Right-hand wheel needle, green markings

Place the spool on the spool holder pin underneath the green

marking on the thread guide.

(1,2) Bring thread up from spool and take it through the

green guides.

(3,4) Make S-loop around the thread guide bar.

(5) Thread tension dial.

(6,7,8) Thread guides.

(9) Thread guide on needle clamp.

(10) Turn the handwheel towards you until the needles are

fully raised. Thread the right-hand needle.

(11) Raise the presser foot, place thread underneath it. Lower

presser foot.

13

Page 15

Threading

4. Left-hand needle, yellow markings

Place the spool on the spool holder pin underneath the

yellow marking on the thread guide.

(1) Bring the thread up from the spool and take it through the

yellow guide.

(2,3) Make S-loop around thread guide bar.

(4) Thread tension dial.

(5,6,7) Thread guides

(8) Thread guide on needle clamp

(9) Turn the handwheel towards you until the needles are

fully raised. Thread the left-hand needle.

(10) Raise the presser foot, place the thread underneath it.

Lower presser foot.

When threading is complete, lower the upper knife and close

the looper cover and cloth plate.

Note: If the lower looper has to be re-threaded, cut both

needle threads off at the needle and removes surplus thread

from below. Thread the looper and then re-thread the

needles.

14

Page 16

Threading, Trial sewing

3 thread overlock (right needle)

For a 3-5 mm wide 3 thread overlock stitch, remove the

left-hand needle. Then thread both loopers and the righthand needle. (See Page 11-13).

3 thread overlock (left needle)

For a 5-7 mm wide 3 thread overlock stitch, remove the

right-hand needle. Then thread both loopers and the lefthand needle. (See Page 11,12,14).

Sewing test

After threading make a trial run. Always use a double layer

of fabric in order to be able to check the stitch formation and

thread tension properly.

• Set upper and lower looper tension dials to 4 and needle

tension dials to 4.

• Upper knife in cutting position.

• Presser foot lowered.

• Raise the front of the presser foot slightly with your

thumb and position the fabric under the foot just up to

the knife. Release the presser foot Sew.

• At the end of the seam continue sewing a 5-6 cm (2-2

½”) long thread chain (A).

• Holding the fabric in one hand, pull the thread chain

over the thread cutter on the presser foot shank (B).

15

Page 17

Thread tension

Check your trial run

1. Upper looper thread (blue)

2. Lower looper thread (red)

3. Right-hand needle thread (green)

4. Left-hand needle thread (yellow)

Perfect stitch formation is when both looper threads meet at the

fabric edge. The needle threads form straight stitches for a

stretchy and durable seam.

Thread tension

Thread tension should be properly adjusted to suit the various types

of work.

The ideal tension setting for most fabrics and threads is between 3

and 5. However this can vary quite considerably when special threads

such as filament, wooly nylon, buttonhole twist (cordonnet), perle

yarn or decorative threads are used.

Infinitely variable adjustments can be made from 1-9. Turn to the left

for less tension. Turn to the right for more tension.

16

Page 18

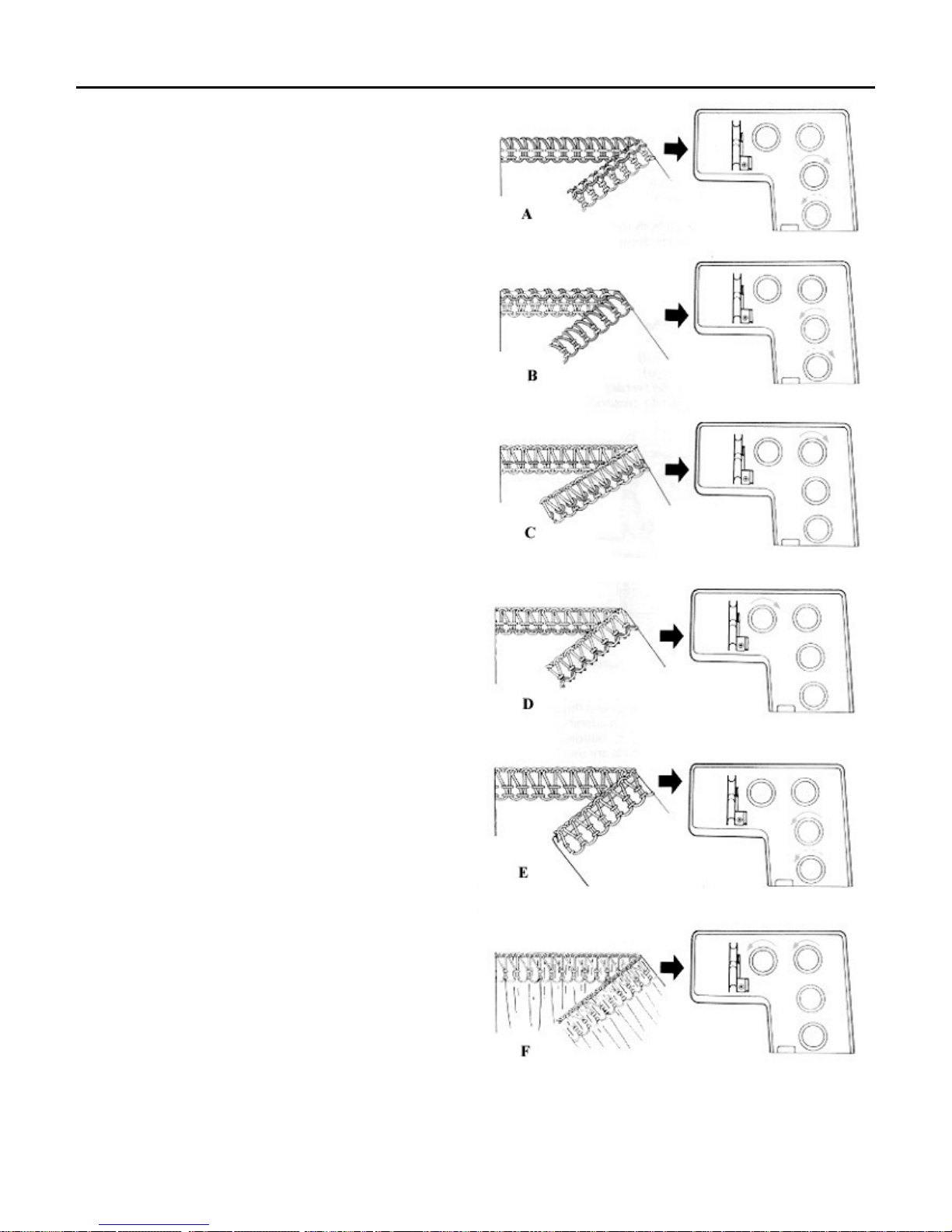

Thread tension

Adjusting the thread tension

Turn tension dials by only half or one number then test

sew again and check the results.

The loops are formed on the underside;

Tighten the upper lower thread tension, blue or loosen

the lower looper tension, red (A).

The loops are formed on the upper side;

Tighten the lower looper thread tension, red or loosen

the lower looper tension, blue (B).

The right-hand needle thread forms loops on the

underside;

Tighten the right-hand needle thread tension, green (C).

The left-hand needle thread forms loops on the

underside;

Tighten the left-hand needle thread tension, yellow (D).

The edge of the fabric curls up; tension of both looper

threads is too tight;

Loosen upper and lower looper thread tension, blue and

red (E).

The fabric puckers during sewing;

Loosen the right or left-hand needle thread tension,

green or yellow (F).

17

Page 19

Adjustments and settings

Stitch length

004:

• Turn power switch to “O”.

• Open cloth plate, loosen knob and adjust to desired

length. Tighten knob and close cloth plate.

004D:

• Turn dial to stitch length desired can be adjusted

while sewing.

The stitch length is infinitely variable from 1-4 mm. Most

overlock work is done with a basic setting of 2-3 mm.

Cutting width

• Turn power switch to “0”.

• Raise the upper knife.

• Open the cloth plate.

• Turn cutting width adjustments knob in the direction

desired.

• Lower upper knife.

• Close cloth plate.

The position of the lower knife determines the width of

the seam.

1=3.5 mm seam width

2=4.5 mm seam width

3=5.7 mm seam width

Reduce the cutting width if the edges of fine fabrics curl up

when being sewn. Adjust the cutting knob to a higher

number (A).

Increase the cutting width knob to a higher number (B).

18

Page 20

Adjustments and settings

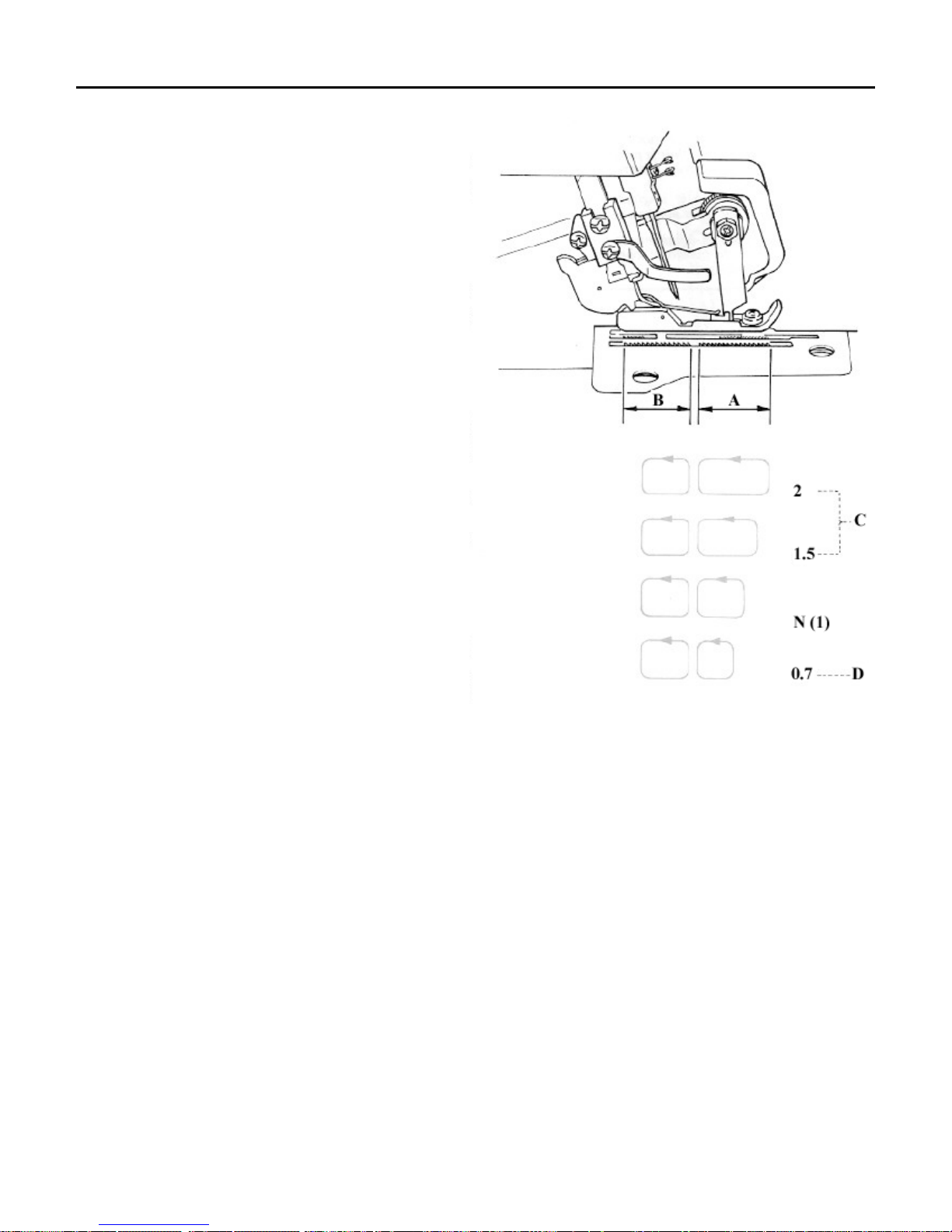

Differential feed

There are two feed dogs one front (A) and one rear

(B).

The two feed dogs move independently and the

distance each feed dog travels during one complete

movement can be adjusted.

The differential feed prevents fluting or waving in

knitted or stretch fabrics and movements between the

layers of fabric.

It also ensures pucker-free seams in smooth fabrics

such as nylon or closely woven fabric (C).

Perfectly flat seams in knits or stretch fabrics.

The distance traveled by the front feed dog should be

greater than that of the rear feed dog. The front feed

dog, therefore, feeds an amount of fabric, which the

rear feed dog, can take up behind the needle without

stretching the fabric.

Pucker-free seams in nylon or closely woven

fabrics.

The distance traveled by the rear feed dog should be

greater than that of the front feed dog. The front feed

dog, therefore, holds the fabric back so that the rear

feed dog can take it up behind the needle without any

puckering (D).

19

Page 21

Adjustments and settings

Adjusting the differential feed

The differential feed can be adjusted by simply turning

the differential feed adjustments knob in the direction

desired.

Always make a trial run. The differential feed is

infinitely variable and can be adjusted while sewing.

2

1.5

N Normal feed (C) Woven fabrics

0.7 No puckering (D)

Effect Fabric

Wave-free seams

(A)

Wave-free seams

(B)

Thick wool knits, and

knitted articles, very

stretchy fabric

Cotton, silk, synthetic

jerseys, sweatshirt fabrics

and fine knits

Fine nylon jersey, closely

woven fabrics, lining fabric

satin, poplin

Gathering

Using the differential feed, a single layer of fabric can

be gathered before sewing it to the garment. For

example, sleeve heads and lower edges, yokes, lace

edging or frills.

djustment:

A

• Stitch: 4 th

• Differential feed: 2 tension (6-8) for a

• Stitch length: 3 –4 tighter gathering

• Cutting width: 2-3

• Thread tension: 4-6

N

ote: When sewing without differential feed, turn the

adjustment knob to “N”.

read overlock Increase the thread

20

Page 22

Settings, practical sewing

Presser foot pressure

he presser foot pressure is factory adjusted to a medium setting.

T

Should you wish to adjust it, simply turn the knob in the direction

desired:

osition of knob for normal pressure (A).

P

M

ore pressure: for thick or stiff fabrics such as denim, tweed, firm

linen (B).

L

ess pressure: for lightweight or sheer fabrics and knits (C).

Roll Hemming

Turn the handwheel towards you until the needle are

•

fully raised.

For roll hemm

• ing, pull the selection lever back to the

red marking on the stitch plate furthest from the

presser foot (D).

• push the selection lever forwards to

For overlocking,

the red marking on the stitch plate nearest the presser

foot (E).

T

he roll hemmer is fully integrated in the machine. The

edges of the fabric will be automatically rolled over

producing a very narrow, fine seam or hem. Roll

hemming is deal for finishing edges on all fine fabrics,

such as evening clothes, lingerie, scarves frills and also

for curtains and napkins.

2

1

Page 23

Settings, practical sewing

Rolled hem

Application: Edge finish

•

•

Stitch: 3 thread overlock, right needle.

• Stitch selection: roll hemming

• Thread: Darning thread, fine polyester thread, wooly nylon thread

(only in upper looper)

• Needle: 70/80

• Stitch length: 1-1.5

• Cutting width: 1-2

• Differential feed: 0.7-2

• Thread tension: Adjust the tension to suit the fabric and thread chosen.

The looper threads meet on the underside of the fabric. Lower looper

tension (red) 6-9, upper looper tension (blue) 2-5 and needle tension

(green) 4-7.

Narrow seam

• Application: Fine seams

• Stitch: 3-thread overlock right-hand needle.

• Stitch selection: roll hemming.

• Thread: Fine polyester thread, wooly stretch nylon in upper and lower

looper.

• Needle: 70/80

• Stitch length: 1,5-2,5

• Cutting width: 1-2

• Differential feed: N-2

• Thread tension: Adjust the tension according to fabric and thread

chosen. The loops formed by the loopers should meet exactly on the

edge of the fabric. Lower looper tension (red) 2-5. Upper looper

tension (blue) 3-6. Right-hand needle tension (green) 4-7.

22

Page 24

Settings, practical sewing

Sewing in tape

The standard presser foot is equipped with a tape guide. A tape can

be sewn into the shoulder or side seams of garments made from

knits or stretch fabrics to prevent stretching.

• Turn the handwheel towards you until needles are fully raised.

• Raise the presser foot.

• Lay the tape under the presser foot and slide it carefully into

the tape slot.

• Lower the presser foot and sew a few stitches until the right-

hand needle catches the left-hand edge of the tape.

• Loosen the setscrew (A) and adjust the tape guide to suit the

width of the tape (B).

• Retighten setscrew.

• Raise the tip of the power foot and place work underneath,

Sew.

Thread breakage during sewing

Sew off immediately at an angle and remove the work. Rethread.

If the lowe

at the needle and remove the thread. First thread the looper and

then the needle. Start sewing again about 2-3 cm in front of

where the thread broke.

npicking seams

U

sing sharp scissors cut the loops (C). Pull the needle thread

U

(D) and the stitches will come undone.

3

2

r looper thread has broken, cut off both needle threads

Page 25

Maintenance

Changing the upper knife

The upper knife (moving knife) is made from special

hardened material. Should it get damaged, it can be replaced

by your local Bernette dealer.

Changing the lower knife

• Disconnect machine from electricity supply.

• Turn handwheel towards you until needles are

fully raised.

• Raise the upper knife

Loosen the setscrew on the lower knife retaining plate.

Remove the lower knife. Fit the replacement knife

(from accessory bag) in the groove so that the sharp is

in line with the stitch plate. Retighten the screws (see

page 1).

Replacing the bulb

• Disconnect machine from electricity supply.

Unscrew the bulb and replace it with a new one: The bulbs

are 15 Watt for 110V/115V machines and 10 Watt for

220V/230V/240V machines. They are available from your

local dealer.

Cleaning and lubricating

• Disconnect machine from electricity supply.

During sewing, dust and fluff collect in and on the machine.

This should be removed regularly. Your Funlock requires

very little lubrication. Now and then, lubricate only the

points illustrated (see page 1).

24

Page 26

Trouble shooting guide

Problem Cause Solution Page

Fabric does not feed……………… Presser foot pressure is too low Adjust the presser foot pressure…………… 21

evenly Lower knife is blunt or wrongly positioned Replace the lower knife 24

Thread breaks…………………….. Thread tensions is too tight for thread Reduce thread tension…………………. 16/17

being used

The machine is not thread correctly Check the threading 11 – 14

Needles are incorrectly inserted Insert needles fully into needle clamp 9

with flat side to the back

Use needle system 130/705 H 9

Needles break……………………. Needles are bent, blunt or points are Replace needles……………………………. 9

damaged

Needles are not inserted correctly Insert needles fully into needle clamp with 9

flat side to the back

Fabric was pulled while sewing Guide fabric gently with both hands

Skipped stitches………………….. Needles are bent or blunt Replace the needles………………………… 9

Wrong needles used Use needles of system 130/705 H 9

Presser foot pressure is too low Increase presser foot pressure……………… 21

Poor stitch information…………… Thread is not wound correctly round Check if thread is lying between………….. 10

tension dials tension discs.

Thread has got caught Check the threading path of each thread 11 – 14

Seams flute or wave……………….Fabric was pulled while sewing Guide fabric gently…………………………….

especially when Presser foot pressure is too tight Reduce presser foot pressure 21

sewing knits

Differential feed is set incorrectly. Adjust differential feed to N – 2 1 9 – 20

Seams pucker…………………….. Thread tension is too tight Reduce thread tension………………….16 - 17

Differential feed is set incorrectly. Adjust differential feed to 0.7 – N 19 – 20

Fabric edges curl…………………. Too much fabrics is in the stitch Reduce cutting width……………………… 18

Thread tension is too tight Reduce thread tension 16 – 17

25

Page 27

Trouble shooting guide

Stitch choice………………….. 2 needles, 4 thread

Overlock with integral safety seam

1 needle, 3 thread Overlock

Needle system………………… 130/705 H

Seam width…………………… 3 – 7 mm (3 thread overlock)

5 – 7 mm (4 thread overlock)

Stitch length…………………... 1 – 4 mm

Differential feed……………… No waving or fluting in knits N – 2

No puckering 0.7 N

Presser foot lift……………….. 5 mm

Handwheel……………………. Rotates forward

Sewing speed…………………. Up to 1500 s.p.m.

Weight………………………… 7.0 kg

Dimension…………………….. 270 (W) x 340 (D) x 295 (H) mm

We reserve the right to make changes in the interests of technical progress.

Blind stitch foot

The blind stitch foot is ideal for stretchy and invisible hems

in knitwear.

Elasticator

The Elasticator will sew on any type of elastic from a width

of 5 mm – 12 mm. The fabric edges are cut off and

overlocked in the normal way producing a lovely neat finish.

The elasticator is of invaluable help when sewing swimwear

or gymnastic wear.

Cording foot

Ideal for fine fabrics. Give frills and flounces a beautiful

wavy finish by sewing cord, wool of fishing line into a rolled

hem.

26

Page 28

“IMPORTANT SAFETY INSTRUCTIONS”

“When using an electrical appliance, basic precautions should always be followed, including the following:”

“Read all instructions before using this sewing machine.”

“DANGER___ To reduce the risk of electric shock:”

1. “An appliance should never be left unattended when plugged in. Always unplug immediately after using

and before cleaning.”

2. Always unplug before relamping. Replace bulb with the same type rated 15 watts.”

“WARNING”___ To reduce the risk of burns, fire, electric shock, or injury to persons.”

1. “Do not allow to be used as a toy. Close attention is necessary when this appliances is used by or near

children.”

2. “Use this appliance only for its intended use as a described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.”

3. “Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water. Return the appliance to the nearest authorized dealer or

service center for examination, repair, electrical or mechanical adjustment.”

4. “Never operate the appliance with any air openings blocked. Keep ventilation openings of the sewing

machine and foot controller free from the accumulation of lint, dust, and loose cloth.”

5. “Keep fingers away from all moving parts. Special care is required around the sewing machine needle.”

6. “Always use the proper needle plate. The wrong plate can cause the needle to break.”

7. “Do not use bent needles.”

8. “Do not pull or push fabric while stitching. It may deflect the needle causing it to break.”

9. “Switch the sewing machine off (“0”) when making any adjustments in the needle area, such as threading

needle, changing needle, threading bobbin, or changing presser foot, and the like.”

10. “Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or when

making any other uses servicing adjustments mentioned in the instruction manual.”

11. “Never drop or insert any object into any opening.”

12. “Do not use outdoors.”

13. “Do not operate where aerosol (spray) produces are being used or when oxygen is being administered.”

14. “To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.”

15. “Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.”

“SAVE THESE INSTRUCTIONS”

“This sewing machine is intended for household use only.”

Page 29

© Copyright by Fritz Gegauf Ltd.

Bernina Sewing Machines

8266 Steckborn, Switzerland

No. 501 661 13 GB/E

Page 30

Replacement Sewing Manuals

From

http://www.mastersewusa.com

Thank you for your purchase.

We try to scan original manuals at the highest DPI settings without

compromising the readability of the manual. We also have a technical

team that has been working over a year retyping hard to find and in

poor shape manuals from many different manufacturers. During he

retype operation the technicians try their best to maintain the wording

and page set up as of the original manual.

If you are satisfied with this product please tell others about us. Many

of our sales are made to people who heard of us by referrals of

customers like you. Many homes have sewing machines but their

manuals became lost or damaged.

We are here 24/7 on the Internet at:

http://www.mastersewusa.com

We have Instructional manuals, service manuals, parts lists, and

instructional videos for many industrial and consumer sewing

machines.

We assist owners of older Singer sewing machines by using their

machines serial number and converting it to their sewing machines

model number. Contact us at:

Mastersewusa is committed to adding manuals to our library to

consistently improve our service in the sewing community.

BERNINA * BROTHER * CONSEW * FEIYUE-YAMATA * ELNA

* GN * PFAFF * JUKI * MORSE * NECCHI * NEW HOME *

SEARS KENMORE * SIMPLICITY * SINGER * WHITE

For Reprints Visit on the web.

sales@mastersewusa.com

Our manuals are:

http://www.mastersewusa.com May 2006

Loading...

Loading...