Page 1

Sergers

Mastering Your

Mastering

Your

BERNINA

®

Serger

Owner’s Workbook

MASTERING YOUR BERNINA®SERGERS 6/2006 1

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 2

Mastering

Sergers

BERNINA

Table of Content s

Class 1 - General Information..................................................... 3

Introduction ..................................................................................................... 4

Presser Feet & Accessories ............................................................................ 5

Needles...........................................................................................................6

Thread............................................................................................................. 8

Balanced 4-Thread Overlock ........................................................................10

Adjusting Tensions ........................................................................................ 12

Stitch Length .................................................................................................18

Cutting Width.................................................................................................2 0

Differential Feed............................................................................................22

mtc - Micro Thread Control...........................................................................28

Securing Ends ............................................................................................... 3 0

Serging a Tube..............................................................................................32

Product Reference List ................................................................................. 34

Class 2 - Four Thread Techniques........................................... 35

Serger Seams...............................................................................................36

Seaming Knits...............................................................................................3 8

Serger Piecing...............................................................................................46

Elasticator .....................................................................................................50

Gathering Foot and Attachment....................................................................5 2

Product Reference List ................................................................................. 58

Class 3 - Three-Thread Techniques......................................... 59

3-Thread Overlock ........................................................................................ 60

3-thread Overlock with mtc........................................................................... 68

3-Thread Flatlock .......................................................................................... 72

Blindstitch Foot..............................................................................................78

3-Thread Rolled Hem.................................................................................... 86

Cording Foot .................................................................................................88

Product Reference List ................................................................................. 92

Class 4 - Miscellaneous Techniques ....................................... 93

3-Thread Super Stretch Stitch.......................................................................94

2-Thread Flatlock .......................................................................................... 98

2-Thread Flatlock with mtc. ........................................................................102

2-Thread Rolled Hem..................................................................................104

2-Thread Wrapped Edge ............................................................................ 106

Multi-Purpose Foot with Guide....................................................................108

Product Reference List ............................................................................... 116

Class 5 - Cover & Chain...........................................................117

Cover Stitch ................................................................................................. 118

Chain Stitch................................................................................................. 130

Combination Stitches (1300MDC only).......................................................136

Product Reference List ............................................................................... 140

Your

®

MASTERING YOUR BERNINA®SERGERS 6/2006 2

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 3

Sergers

Class 1

General Information

Class Overview

Mastering

Your

BERNINA

®

Machine Overview

Parts of the serger

Setting up the serger

Serger Accessories

Tweezers

Lower Looper Threader (700D only)

Needle Threader

(optional for 700D & 800DL)

Brush/Needle Insertion Tool

Spool Caps

Spool Cones

Thread Nets

Thread

Good quality vs. poor quality

Construction/All-Purpose Thread

Decorative Thread

Needles

Types of Needles

Sizes of Needles

Parts of Needles

Matching Needle & Thread

Basic Serging Samples

1 Balanced 4-Thread Overlock

2 Adjusting Tensions - Loopers

3 Adjusting Tensions - Loopers

4 Adjusting Tensions - Needles

5 Stitch Length Adjustment

6 Cutting Width Adjustment

7 Differential Feed - S tretch

8 Differential Feed - Pucker

9 Differential Feed - Gathering & Easing

10 Micro Thread Control - mtc

11 Securing Serged Seams

12 Serging a Tubular Project

Care & Cleaning

Removing Lint from Inside Serger

Oiling

Replacing the Cutting Knives

Yearly “Tune Up”

by Authorized BERNINA

®

technician

Threading for Overlock Serging

The Threading Path

Threading Order

First – Upper Looper (Blue)

Second – Lower Looper (Red)

Third – Right Needle (Green)

Fourth – Left Needle (Yellow)

Test Serging

MASTERING YOUR BERNINA®SERGERS 6/2006 3

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

This class is formatted for owners of

the following models of BERNINA

overlock machines:

• 700D

• 800DL

• 1150MDA

• 1300MDC

®

Page 4

Mastering

Sergers

Your

BERNINA

Introduction

Congratulations on your purchase of a BERNINA® serger!

This workbook is designed to be used in conjunction with the Owners Classes you will take at

your BERNINA® dealership, and contains a series of exercises intended to familiarize you with

®

the features of your new BERNINA

needles, threads, presser feet and accessories, all of which will increase your knowledge of

serging and assist you in achieving success in all of your serging endeavors.

overlock machine. In addition, you will learn about

®

Once you have completed the exercises designated for your BERNINA

attach the sewn samples to the indicated pages and insert the p ages into plastic page protectors and store them in a 3-ring binder . They can then be used as a reference tool in the future

as you use your machine and explore the creative possibilities it affords you.

BERNINA® of America, Inc. strives to provide it s customers not just with quality sewing

and overlock machines, but with informative publications and classes. Along with providing

Owners Classes, your local BERNINA® dealer stocks BERNINA® books and magazines, such

as Feetures, Serger Technique Reference Guide, and Through the Needle. Plus, BERNINA® of

America, Inc. has a website – www.berninausa.com – offering free projects, basic sewing and

serging information, a glossary of sewing terms, inspirational stories, interviews with creative

stitchers, and a variety of articles and postings that appeal to all types of stitchers,

no matter which machines are their favorites.

Learn to use your BERNINA® serger to

its full extent and enjoy being creative

with fabric and thread!

My BERNINA® overlock machine

model is: __________________

I purchased it on: ____________

at ________________________

®

overlock machine,

__________________________

__________________________

MASTERING YOUR BERNINA®SERGERS 6/2006 4

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 5

Mastering

Sergers

Your

BERNINA

®

Presser Feet & Accessories

BERNINA® Presser Feet:

• are precision engineered for specific functions

• are, in some cases, modeled after commercial feet used in factories to increase speed and production

with professional looking results

• do the job intended in relation to all types of sewing (ex. garment-making, quilting, home dec, etc.)

• are supported by the best and most complete educational materials in the industry, such as the Serging

Technique Reference Guide, Feetures, and the BERNINA

®

website at www.berninausa.com

Additional Presser Feet

& Accessories Available for

BERNINA® Sergers:

• Blindhem Foot

• Cording Foot

• Elasticator

• Gathering Attachment

• Multi-Purpose Foot with Guide

• St andard Foot with Tape Guide

• Attachment Base

• Looper/Needle Threader

• Left Seam Guide

• Right Seam Guide

• Upper Looper Converter

• Waste Collector

• Serger Technique Reference Book

• Feet-ures Volume 2 (Unit M)

• Feet-ures Volume 3 (Unit P)

MASTERING YOUR BERNINA®SERGERS 6/2006 5

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 6

Sergers

Needles

Along with thread, needles are very important to stitch formation. Many

“mechanical” problems and damage to fabrics can be traced to a bent,

damaged, or incorrect size or type needle. Approximately 60% of all

needles made are discarded at some stage of production. When selecting the correct needle for any serging project, three things must be

considered:

Needle system – 130/705H

Needle point – to assure stitch formation and avoid fabric damage

Needle size – smaller for lightweight fabrics; larger for heavier ones

If the needle is:

Too small – the thread can’t stay in the groove to form a loop

to be picked up by the looper

Bent – thread loop forms too far away from looper, which can’t

enter loop to form stitch

Blunt – needle won’t pierce fabric so no thread loop forms to make

a stitch

Need To Know

Mastering

Your

BERNINA

Notes

®

• Never use a needle bigger than size 90/14 in your serger; larger

needles can interfere with looper movement and cause damage.

• Needle should be changed every 4-6 hours of sewing. The needle

is the most inexpensive part in your serger but is one of the most

crucial for getting good results and keeping your machine running

well. Don’t let false economy keep you from doing what is best for

your sewing projects and your machine.

• European needles are chrome-plated to glide through fabric easily.

• The selected thread should fit in the groove on the front of the

needle. If it isn’t protected by the groove, a needle with a larger

groove should be used.

• Always make sure needles are fully inserted as high as possible,

with the flat side to the back.

Needle Size Conversion

European vs. Domestic

60 = 8

70 = 10

75 = 11

80 = 12

90 = 14

100 = 16

110 = 18

120 = 19

Regardless of the system, the greater

the number, the larger the diameter

of the needle. Never use a needle

larger than size 90/14 in your serger!

MASTERING YOUR BERNINA®SERGERS 6/2006 6

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 7

Mastering

Sergers

BERNINA

Needle Chart

Never use a needle bigger than size 90/14 in your serger;

larger needles can interfere with looper movement and cause damage.

Your

®

Ball Point

Stretch

Universal

Jeans

Microtex

Sharp

(Schmetz)

70-90

70-90

60-90

70-90

60-90

Has a rounded point. 70 for lingerie, nylon, jersey;

80 for T-shirt; 90 for sweatshirt fleece.

A stretch needle has a more rounded point and

a blue anti-cling coating which helps to prevent

skipped stitches in knits and elastic. Sometimes

used on Ultrasuede

A compromise between a sharp and a ballpoint

needle; can be used on both wovens and knits.

60 – very fine batiste

70 – broadcloth

80 – trigger and gabardine

90 – denim and twill

Has a sharp point and a shaft that is less prone to

flex. The sharpness of the needles makes it better for

use on denim and woven fabrics where a clean stitch

is desired.

A sharp point with a thin shaft. 60-90 corresponds

to the weight of the fabric; as the fabric gets heavier

or denser, the number is higher. Specially designed

for microfiber fabrics.

®

, vinyl, and plastic.

Microfiber

(Lammertz)

Quilting

Topstitch

Embroidery

(Schmetz)

Metafil (Lammertz)

Leather

MASTERING YOUR BERNINA®SERGERS 6/2006 7

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

assort’d

(75 & 90)

80-90

75-90

80-90

The thin, tapered point of this needle causes less

damage to fabric when seaming and cross seaming.

A sharp point with a large eye and deep groove.

Use with heavier fabrics – the large groove cradles

heavy threads.

Sharp needle with a large eye and groove; also has a

coating and a larger scarf. For use with embroidery

thread – prevents shredding of rayon or metallic

threads. Two threads may be used through the eye of

an 80 or 90 needle.

Point is a sharp cutting wedge. Used for leather only.

Not for vinyl or simulated leathers.

©2006 BERNINA® of America, Inc.

Page 8

Sergers

Thread

Poor quality or the wrong type of thread can cause poor stitches on any

machine. Thread passes through the eye of the needle approximately

37 times in a “see-saw” action before it forms a single stitch. Poor

quality thread results in crooked and looped stitches, puckered seams,

frayed thread, and/or needle breakage. To achieve quality stitches, an

overlock machine needs three things: correct thread, correct size

needle, and properly adjusted settings.

Several factors such as the fiber, twist, ply, finish, and size of thread

must be considered for use with today’s fabrics for fine stitches.

Staple – refers to the length of fibers used to twist together to form a

single ply. Domestic thread fiber lengths are usually 1½” to 2½” long

while European threads use 5½” to 6½” lengths.

Mastering

Your

BERNINA

Notes

®

Ply – number of strands twisted together to make a single thread.

Roll – the tendency of thread to roll to the right or left during

stitching, causing the stitch to appear slightly crooked. Poor quality

threads are more likely to roll.

Twist – the crimping of fibers which causes them to interlock firmly into

a single ply . Thread should not untwist during stitching. This will cause

skipped stitches, thread breakage, crooked stitches, and weak spots in

seams.

Right twist – most American

threads are twisted to the right,

causing some rolling. This gives

average stitch quality.

Left twist – Most commercial and

imported threads are twisted to

the left, giving better than average

stitch quality . Lef t twist resists

rolling and makes a larger loop for

the hook point to enter, reducing

skipped stitches.

MASTERING YOUR BERNINA®SERGERS 6/2006 8

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 9

Sergers

Thread

Wearable art embellishment has necessitated the creation and marketing of many new thread types, such as rayons and metallics.

Threads made in West Germany are left twist threads; Mettler and

Isacord threads are also left twist. To test the twist of a thread: while

holding the spool in the left hand, roll the strand of thread towards you

with one thumb. Left twist will tighten, right twist will loosen.

Fiber – refers to the type of material used to produce the thread.

Some commonly used threads:

• Polyester Overlock Thread – such as Mettler Metrocor

Thinner than regular sewing thread, eliminating bulk in serger

stitch formations. An excellent all-purpose serger thread.

• Texturized Nylon Thread – such as YLI Woolly Nylon

and Mettler Metroflock. A very elastic thread with excellent

coverage; perfect for rolled edges and knit seams. Available

in solid and variegated colors, and metallics.

• Polyester Topstitching Thread – such as YLI Jeans Stitch

& Mettler Cordonnet – this heavy thread is used for decorative

stitching, such as flatlocked seams and overcast edges. Also

nice for cover and chain stitching. Available in solid and

variegated colors.

• Rayon Decorative Threads – such as YLI Pearl Crown Rayon

& YLI Designer 6 – shiny threads for decorative applications.

Pearl Crown Rayon is twisted, while Designer 6 is untwisted.

Available in solid and variegated colors.

• Metallic Decorative Threads – such as YLI Candlelight –

adds a bit of glitz to seams and edgings.

• Decorative Sewing Threads – sewing machine threads can

also be used in the serger, and are particularly effective when

several are used together as one thread.

Mastering

Your

BERNINA

Notes

®

Storage of Thread

Thread does wear out and should be stored with care to keep it usable

as long as possible. Extreme moisture may cause thread to swell while

very dry conditions can leave it dry and brittle as it ages. Store thread

in a covered container (thread box with a lid, cabinet with doors, or

drawers that close) if possible to keep it dust-free.

Be wary of old spools of thread recovered from Grandma’s sewing

box. The fibers may be so weak and brittle that even if it sews into a

seam, it may be so unstable that the garment or project will not hold

together and the life of the project may be considerably shortened.

MASTERING YOUR BERNINA®SERGERS 6/2006 9

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 10

Sergers

Balanced 4-Thread Overlock

Fabric ........................................................................... firm fabric, 6” x 6”

Needle............................................................................. 80/12 Universal

Thread............................................................... 4 cones of serger thread

.......................................................................... (yellow, red, green, blue)

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

Thread the serger for a 4 thread overlock stitch using thread colors to

match the color-coded threading path on the serger.

Mastering

Your

BERNINA

Notes

®

Adjust all thread tension settings as indicated.

Fold the fabric in half to 3” x 6”.

To begin stitching, lift the front of the presser foot with your right thumb

and slide the fabric under the presser foot. Release the tip of the presser

foot and begin serging.

Serge to the end of the fabric. Continue stitching off the fabric until you

have a 3”- 4” thread chain. Cut thread chain.

Examine the serger stitch formation and compare it to the balanced

stitch graphic on page__ of your Owner's manual.

Read the information under Adjusting the Thread Tension on page__

of the Owner's manual for information about the stitch formation and

correcting any stitch irregularities.

Make any necessary tension adjustments and serge another row of

stitching.

Trim and mount the sample.

Record your serger’s “personal” tension settings

for a balanced overlock in the chart below:

Balanced 4-Thread Overlock

Left Needle Right Needle Upper Looper Lower Looper

MASTERING YOUR BERNINA®SERGERS 6/2006 10

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 11

Sergers

Balanced 4-Thread Overlock Sample

Mastering

Your

BERNINA

®

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2-3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3-5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

11

Page 12

Sergers

Adjusting T ensions

Fabric ................................................... 6 pieces firm fabric, each 3” x 6”

.........................................................1 piece of lightweight cotton, 3” x 4”

Needle............................................................................. 80/12 Universal

Thread............................................................... 4 cones of serger thread

.......................................................................... (yellow, red, green, blue)

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

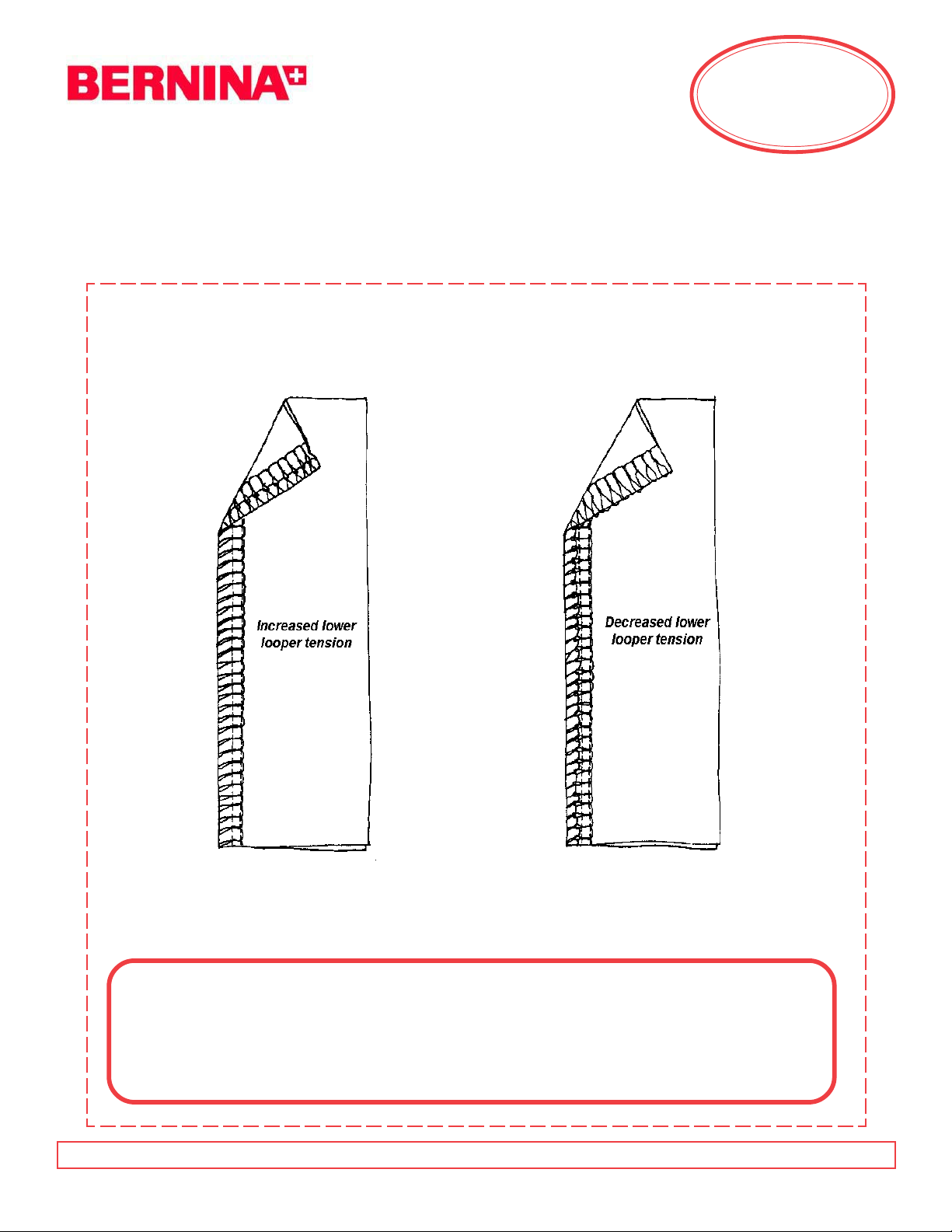

Lower Looper - Increased Tension

Thread the serger for a 4-thread overlock stitch using thread colors

to match the color-coded threading path on the serger.

Mastering

Your

BERNINA

Notes

®

Fold each piece of the firm fabric to 1½” x 4” and set aside.

Locate the thread tension levers on the front of the serger. From left

to right, these levers adjust tension for the Left Needle, Right Needle,

Upper Looper, and the Lower Looper.

Adjust the lower looper thread tension lever to 7 to increase the

tension on the looper thread.

Place the first piece of folded fabric under the presser foot with the

fold to the right and serge to the end of the fabric, cutting off the fold.

Examine the sample. The looper threads do not lock on the edge of

the fabric. The upper looper thread is pulled tightly to the back of the

stitch. The left needle thread may be pulled to the back of the stitch.

Trim, label, and mount the sample.

Lower Looper - Decreased Tension

Change the lower looper thread tension lever to 2 to decrease the

tension on the looper thread.

Serge the second piece of folded fabric, cutting off the fold.

Examine the sample. The looper threads do not lock on the edge of

the fabric. The lower looper thread is visible on the face of the fabric.

The looper threads are very loose.

Label, trim, and mount the sample. Return the thread tension levers

to normal.

MASTERING YOUR BERNINA®SERGERS 6/2006 12

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 13

Sergers

Adjusting Tensions Samples

Mastering

Your

BERNINA

®

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2-3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3-5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

13

Page 14

Sergers

Adjusting Tensions, continued

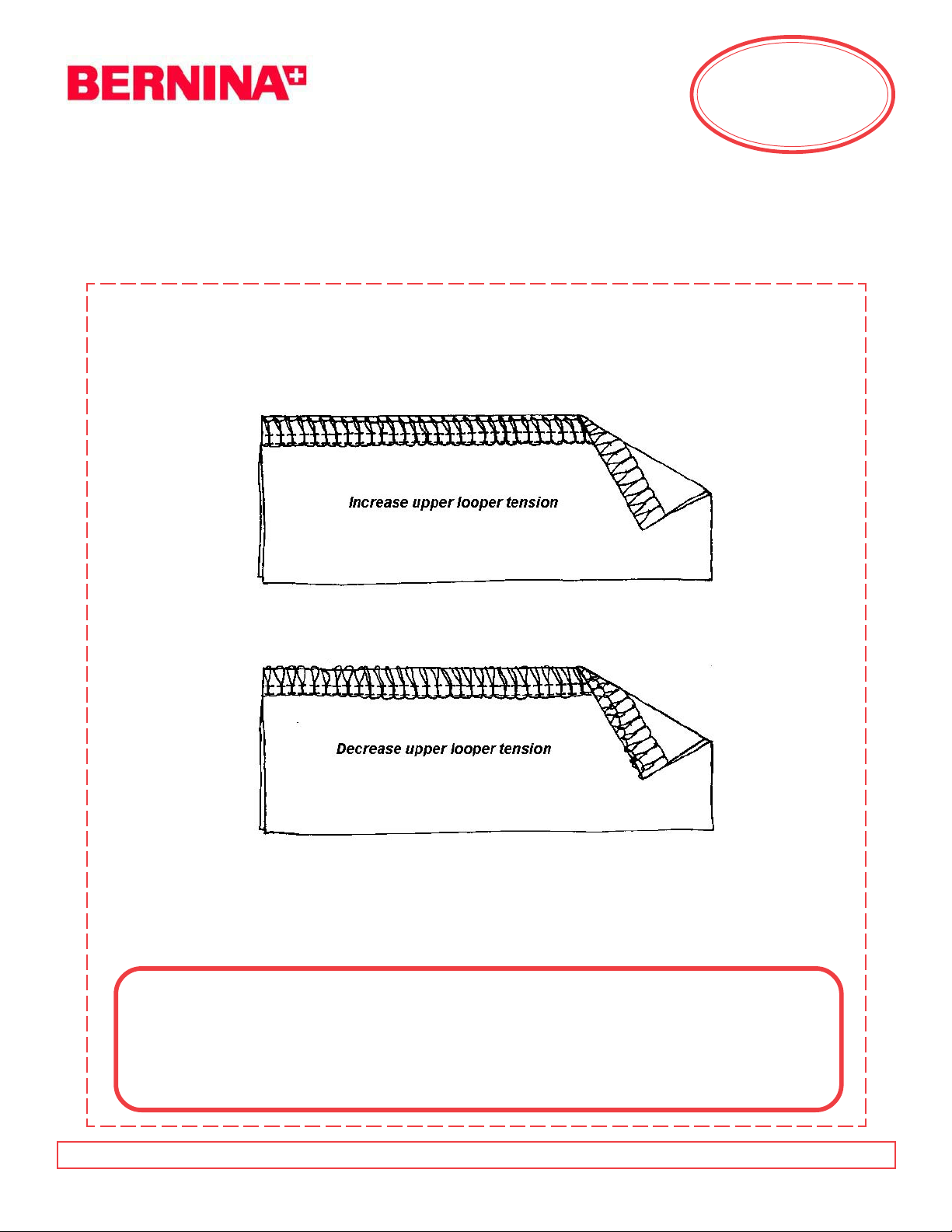

Upper Looper - Increased Tension

Adjust the upper looper thread tension lever to 7 to increase the

tension on the looper thread.

Serge the third piece of folded fabric, cutting off the fold.

Examine the sample. The looper threads do not lock on the edge

of the fabric. The lower looper thread is pulled tightly to the front

of the stitch.

Label, trim, and mount the sample.

Mastering

Your

BERNINA

Notes

®

Upper Looper - Decreased Tension

Change the upper looper thread tension lever to 2 to decrease the

tension on the looper thread.

Serge the fourth piece of folded fabric, cutting off the fold.

Examine the sample. The looper threads do not lock on the edge

of the fabric. The upper looper thread is visible on the back of the

fabric. The looper threads are very loose.

Label, trim, and mount the sample.

Return the thread tension levers to normal.

MASTERING YOUR BERNINA®SERGERS 6/2006 14

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 15

Sergers

Adjusting Tensions Samples

Mastering

Your

BERNINA

®

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2-3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3-5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

15

Page 16

Sergers

Adjusting Tensions, continued

Right Needle - Decreased Tension

Adjust the right needle thread tension lever to 2 (down) to decrease

the tension on the needle thread.

Serge the fifth piece of folded fabric, cutting off the fold.

Examine the sample. The needle thread forms large loops on the

back of the fabric.

Label, trim, and mount the sample.

Mastering

Your

BERNINA

Notes

®

Left Needle - Decreased Tension

Adjust the left needle thread tension lever to 2 to decrease the tension

on the needle thread.

Serge the sixth piece of folded fabric, cutting off the fold.

Examine the sample. The needle thread forms large loops on the back

of the fabric.

Label, trim, and mount the sample.

Both Needles - Increased Tension

Adjust both the left and right needle thread tension levers to 7 to

increase the tension on the needle threads.

Fold the piece of lightweight woven cotton fabric to 1½” x 4”.

Serge the folded fabric, cutting off the fold.

Examine the sample. The lower looper thread is pulled to the front

of the sample and the stitch is puckering the fabric.

Label, trim, and mount the sample.

Return both needle thread tension levers to normal.

MASTERING YOUR BERNINA®SERGERS 6/2006 16

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 17

Sergers

Adjusting Tensions Samples

increased left & right needle tensions

Mastering

Your

BERNINA

®

decreased right needle tension

decreased left needle tension

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2-3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3-5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

17

Page 18

Sergers

Stitch Length Adjustment

Fabric .......................................................................... firm fabric, 6” x 6”

Needle............................................................................. 80/12 Universal

Thread............................................................... 4 cones of serger thread

.......................................................................... (yellow, red, green, blue)

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

Fold fabric in half to 3” x 6”.

Using a fabric marker, divide the fabric into four equal sections along the

folded edge.

Mastering

Your

BERNINA

Notes

®

Thread the serger for a four thread overlock stitch. Fine tune the

settings as needed. Set the cutting width and the differential at their

normal settings.

Adjust the stitch length to 4mm. Serge to the first mark along the

folded edge, trimming the fold slightly .

Adjust the stitch length to 3mm and serge to the second mark.

Adjust the stitch length to 2mm and serge to the third mark.

Adjust the stitch length to 1mm and serge to the end.

Mark the stitch length settings on the fabric sample.

Trim and mount the sample.

Return stitch length to its normal setting, 2.5mm.

MASTERING YOUR BERNINA®SERGERS 6/2006 18

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 19

Sergers

Stitch Length Adjustment Sample

4mm 3mm 2mm 1mm

Mastering

Your

BERNINA

®

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2- 3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3- 5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

19

Page 20

Sergers

Cutting Wid th Adjustment

Fabric .......................................................................... firm fabric, 6” x 6”

Needle............................................................................. 80/12 Universal

Thread............................................................... 4 cones of serger thread

.......................................................................... (yellow, red, green, blue)

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

Fold the fabric in half to 3” x 6”.

Divide and mark the fabric into three equal sections along the folded

edge.

Mastering

Your

BERNINA

Notes

®

Thread the serger for a 4-thread overlock stitch. Fine tune the tensions

for a balanced overlock stitch (3-5).

Rotate the upper knife up. Adjust cutting width to 3. Rotate the upper

knife down into cutting position.

Serge to the first mark on the fabric, stopping when the knife edge

is on the mark.

Adjust cutting width to 2mm and serge to the second mark.

Adjust the cutting width to 1mm and serge to the end of the fabric.

Mark the cutting width settings on the sample.

Rotate the upper knife up. Return the cutting width to its normal setting,

2mm. Rotate the upper knife down into cutting position.

Compare the cutting width sample to the balanced 4-thread sample

to see how cutting width affects the balance of the overlock stitch.

MASTERING YOUR BERNINA®SERGERS 6/2006 20

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 21

Sergers

Cutting Wid th Adjustment Sample

3mm 2mm 1mm

Mastering

Your

BERNINA

®

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2- 3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3- 5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

21

Page 22

Sergers

Differential Feed:

Fabrics that Stretch

Mastering

Your

BERNINA

®

Fabric .................................... 3 pieces of ribbing, each 5” wide x 2” long

Needle............................................................................. 80/12 Universal

Thread............................................................... 4 cones of serger thread

.......................................................................... (yellow, red, green, blue)

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

Thread the serger for a 4-thread overlock stitch. Fine tune the tensions

for a balanced overlock stitch. Set the cutting width as needed and set

the stitch length to 2.5mm.

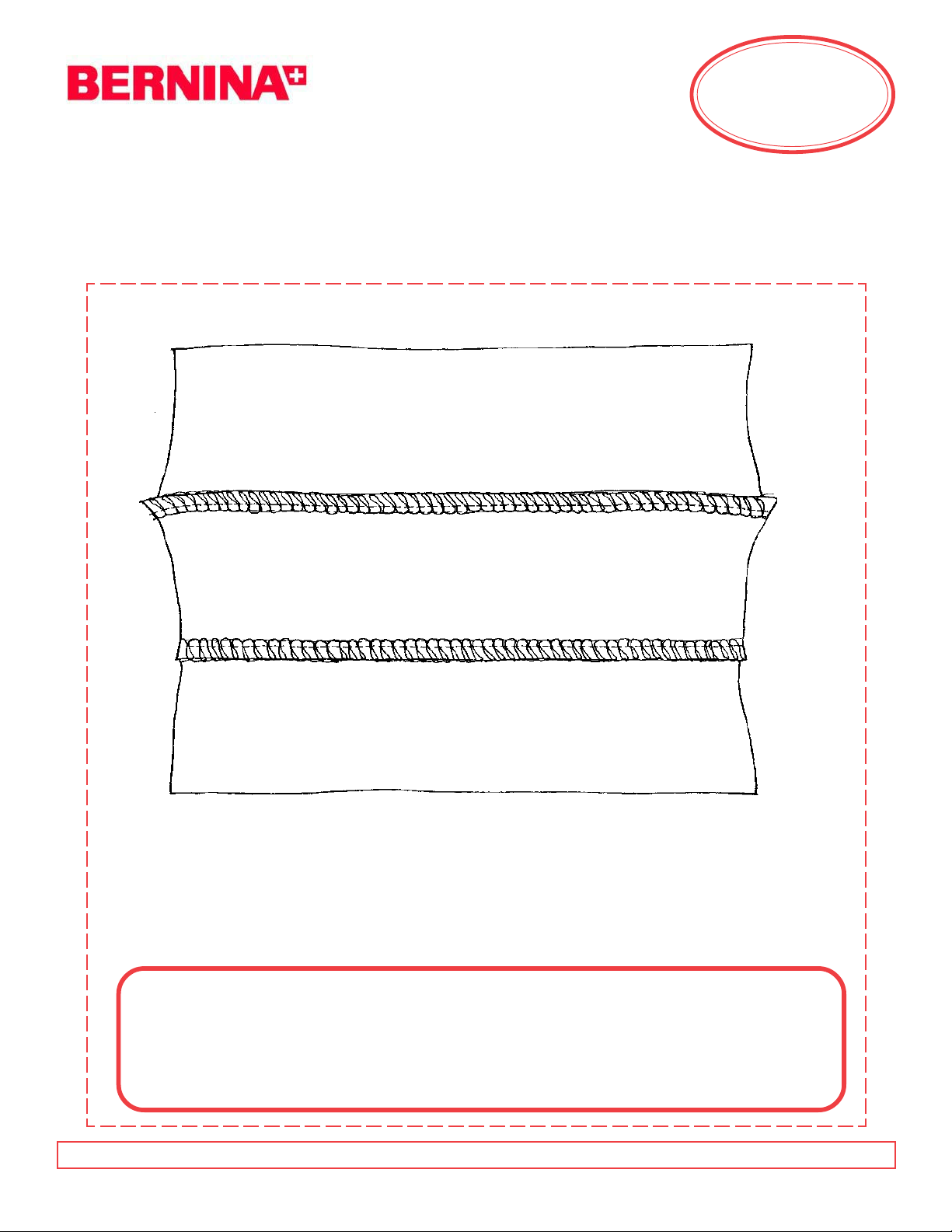

With differential set at N, serge two of the ribbing pieces together along

one 5” edge. If the fabric is stretchy enough you will have a wavy edge.

Adjust the differential to 2.0.

Stitching along the 5” side, serge the remaining ribbing to the other

side of the piece, trimming slightly . W ith differential at a higher setting,

the wavy edge should be eliminated.

Mark the differential settings on the fabric sample.

Notes

Compare the seams to see how the differential settings can affect

stretching.

Trim and mount the sample.

Return the differential feed setting to N (normal).

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

c

MASTERING YOUR BERNINA®SERGERS 6/2006 22

©2006 BERNINA® of America, Inc.

Page 23

Mastering

Sergers

Your

BERNINA

®

Differential Feed: Fabrics that Stretch Sample

N

2.0

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2- 3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3- 5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

23

Page 24

Sergers

Differential Feed:

Fabrics that Pucker

Mastering

Your

BERNINA

®

Fabric ................................................................... 1 piece batiste, 3” x 6”

Needle............................................................................. 80/12 Universal

Thread............................................................... 4 cones of serger thread

.......................................................................... (yellow, red, green, blue)

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

Thread the serger for a four thread overlock stitch. Fine tune tensions for

a balanced overlock stitch. Adjust the stitch length to 2.5mm.

With differential set at N, serge on one 6” edge. If fabric is lightweight

enough you will have a puckered edge.

Adjust the differential to 0.7.

Serge along the other edge, trimming slightly. With a low differential

setting, the puckered edge should be eliminated.

Mark the differential settings on the fabric sample.

Trim and mount the sample.

Notes

Return the differential feed setting to N (normal).

MASTERING YOUR BERNINA®SERGERS 6/2006 24

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 25

Mastering

Sergers

Your

BERNINA

Differential Feed: Fabrics that Pucker Sample

N

®

0.7

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2- 3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3- 5 Differential Feed ............................ N

Right Needle ............................... 3- 5 Stitch SelectionLever...................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

25

Page 26

Sergers

Differential Feed:

Gathering & Easing

Mastering

Your

BERNINA

®

Fabric ..................................................... medium weight cotton, 3” x 12”

Needle............................................................................. 80/12 Universal

Thread............................................................... 4 cones of serger thread

.......................................................................... (yellow, red, green, blue)

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

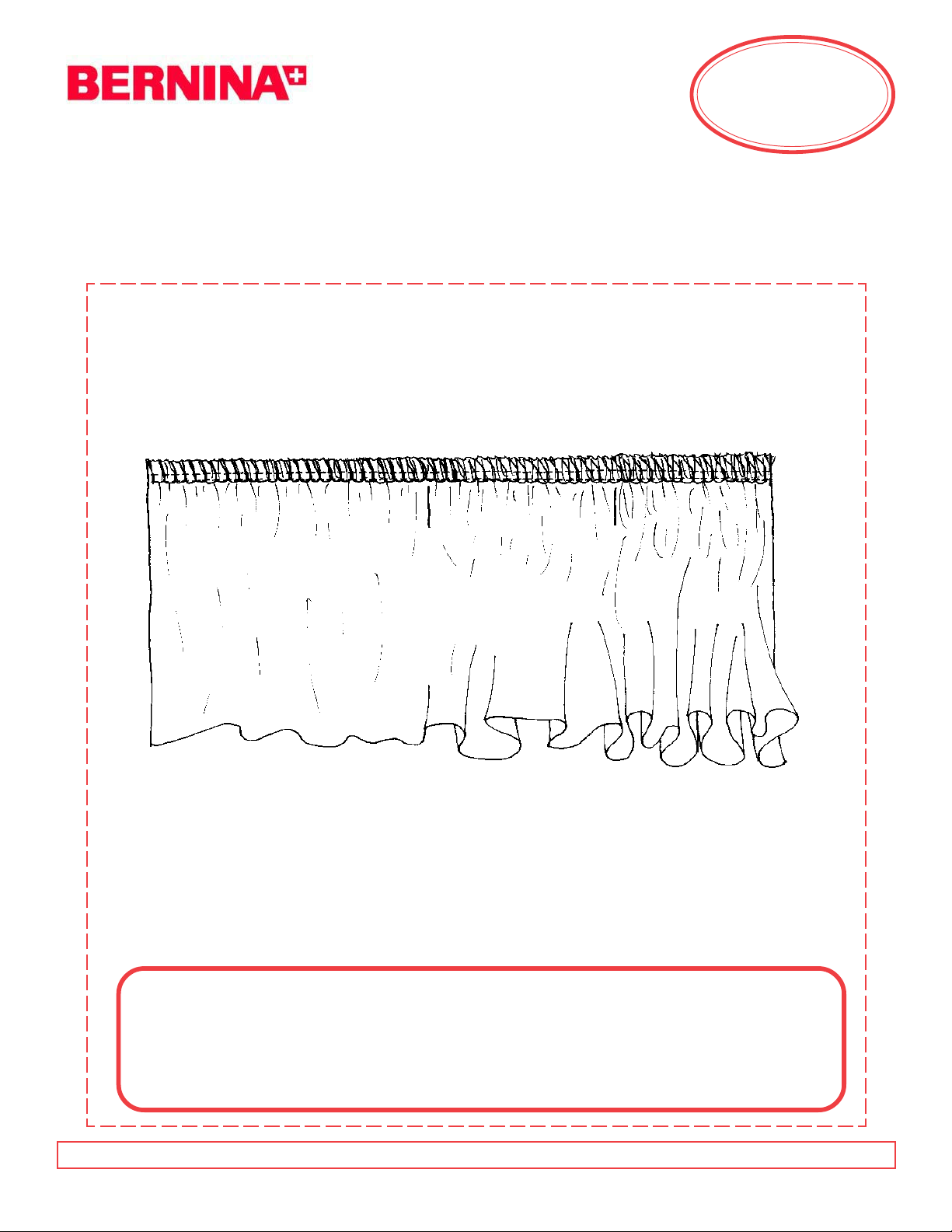

Using a fabric marker divide the fabric into 3 equal sections along the

12” side.

Thread the serger for a 4-thread overlock stitch. Fine tune the tensions

for a balanced overlock stitch.

Turn the differential feed dial to 2. Serge to the first mark.

Adjust stitch length to 4mm and serge to the second mark.

Move the thread tension levers up to 8 to increase the needle thread

tensions. Serge to the end of the fabric.

Return the differential feed to “N” (normal).

Notes

Return the stitch length to 2.5 (normal).

Move the thread tension levers to return tensions to normal (3-5).

Mark the sample:

Differential Feed 2

Differential Feed 2 & Stitch Length 4

Differential Feed 2 & stitch length 4 & increased needle tension.

Trim and mount the sample.

MASTERING YOUR BERNINA®SERGERS 6/2006 26

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 27

Mastering

Sergers

Your

BERNINA

Differential Feed: Gathering & Easing Sample

Increased needle tensions

Diff. Feed 2

SL 4mm

Diff. Feed 2

SL 4mm

Diff. Feed 2

®

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2- 3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3- 5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

27

Page 28

Sergers

Micro Thread Control - mtc

(for 1300MDC/1150MDA models only)

Mastering

Your

BERNINA

®

Fabric ....................................................... medium weight cotton, 6” x 8”

Needle............................................................................. 80/12 Universal

Thread............................................................... 4 cones of serger thread

.......................................................................... (yellow, red, green, blue)

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

Divide the fabric into 4 equal sections along the 8” side, finger press

creases into place.

Thread the serger for a 4-thread overlock stitch. Set the tensions and

cutting width according to the manual for a balanced overlock stitch.

Set the mtc lever to the maximum setting, serge on the first fold.

Move the mtc lever to the normal setting, serge on the second fold.

Move the mtc lever to the minimum setting, serge on the third fold.

Mark the sample:

mtc - maximum -

Notes

mtc - normal -

mtc - minimum -

Trim and mount the sample.

MASTERING YOUR BERNINA®SERGERS 6/2006 28

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 29

Sergers

Micro Thread Control - mtc - Sample

Mastering

Your

BERNINA

®

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

29

Page 30

Sergers

Securing Serged Seams

Fabric ....................................................... medium weight cotton, 4” x 6”

Needle............................................................................. 80/12 Universal

Thread............................................................... 4 cones of serger thread

.......................................................................... (yellow, red, green, blue)

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

Thread the serger for a 4-thread overlock stitch. Fine tune the tensions

for a balanced overlock stitch.

Fold fabric in half to 2” x “6” and place under the presser foot. Note:

If you are using a Wavy Rotary Cutter or Pinking Shears to trim the

samples, do all trimming before beginning to sew this sample.

Mastering

Your

BERNINA

Notes

®

Take 2-3 stitches on the fabric. Lower the needles into the fabric.

Raise the presser foot and with your left hand gently pull the thread chain

around the needles to the knife.

Lower the presser foot and continue serging (cutting off the excess

thread chain) until you are one stitch off the end of the fabric.

Locate the Stitch Selection lever on the right side of the cloth plate; pull

it towards you, releasing the thread chain from the stitch tongue.

Raise the presser foot and carefully flip the fabric over so that the

lower looper side of the previously serged seam will be overstitched.

Place the fabric under the presser foot so that the first stitch will

enter the fabric when you begin stitching.

Slide the Stitch Selection lever towards the body of the serger.

Serge for about 1”, overstitching the previous stitching. Guide the fabric

so as not to cut the previous stitching. Option: Rotate upper knife up.

Raise the toe of the presser foot and rotate the fabric 90° clockwise.

Serge off the edge of the fabric.

If the upper knife is up, rotate it down into the cutting position.

Trim and mount the sample

MASTERING YOUR BERNINA®SERGERS 6/2006 30

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 31

Sergers

Securing Serged Seams Sample

Mastering

Your

BERNINA

®

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2- 3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3- 5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

31

Page 32

Sergers

Serging a Tube

Fabric ..................................................... medium weight cotton, 3” x 12”

Needle............................................................................. 80/12 Universal

Thread............................................................... 4 cones of serger thread

.......................................................................... (yellow, red, green, blue)

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

Thread the serger for a 4-thread overlock stitch.

With right sides together, seam the fabric into a tube along the 3” side.

Mastering

Your

BERNINA

Notes

®

Press the seam to one side. (The upper looper thread is the right side

of the seam.)

On one 12” side of the tube, cut away a 2” x ¼” section of fabric.

Lower the presser foot and serge around the tube, cutting off ¼”.

Stop serging when the knife enters the cutout; rotate the knife up.

Continue serging to complete the circle, overlapping the previous stitch-

ing by 1”.

Raise the presser foot and rotate the fabric clockwise.

Lower the presser foot and serge off the edge of the fabric.

Return the knife to the normal cutting position.

Trim and mount the sample.

MASTERING YOUR BERNINA®SERGERS 6/2006 32

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 33

Sergers

Serging a Tube Sample

Mastering

Your

BERNINA

®

cut out

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2- 3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3- 5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

33

Page 34

Sergers

Class 1

General Information

Product Reference List

Feet-ures, Volume 2 (Unit M)

Feet-ures, V olume 3 (Unit P)

Serger Technique Reference Book

Carrying Case

Serger Cone Thread (Mettler Metrocor , YLI Success)

color________

color________

color________

color________

Mastering

Your

BERNINA

®

Needles

size____ and type___

size____ and type____

size____ and type____

size____ and type____

Seam Sealant

Fabric Marking Pen

Rotary Cutter

Wavy Cutting Blade

Clear Quilters’ Ruler

Cutting Mat

Fabric Glue Stick

Large Eye Tapestry/Darning Needles

V acuum Cleaner Attachment

1” Wide Cosmetic Brush or Mini-Duster

BERNINA® Thread Storage Box (clear)

BERNINA® Deluxe Accessory Box

Bernette® IS 60 Professional Iron

S tandard Serger Foot with Tape Guide

Serger Needle/Looper Threader

Waste Collector

MASTERING YOUR BERNINA®SERGERS 6/2006 34

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 35

Sergers

Four Thread Techniques

Class Overview

General Construction Seaming

1 4-Thread Overlock Seam

Serging Knits

2 Seaming Knit Fabrics: Presser Foot Pressure

3 Seaming Knit Fabrics: Differential Feed

4 Seaming Knit Fabrics: Presser Foot Tape Guide

5 Attaching Ribbing

Class 2

Mastering

Your

BERNINA

®

Serging Wovens

6 Serger Piecing

7 Reversible Piecing

Using Optional Accessories: Elasticator & Gathering Attachment

8 Elasticator

9 Gathering Attachment: Gathering Fabric

10 Gathering Attachment: Gathering Fabric to Fabric

11 Gathering Attachment: with Elasticator

Optional Presser Feet & Accessories (used in this unit)

Standard Presser Foot with Tape Guide

Holds narrow twill tape, elastic, and ribbon to be serged into seam

Elasticator

For attaching elastic from 5mm -12mm (¼” to ½”) wide.

Attachment Base (700D and 800DL only)

Needed to attach some accessories to serger

Seam Guides

Right Seam Guide

Multi-Purpose Foot Guide

Gathering Attachment or Foot

For gathering one layer, or gathering to a flat piece

This class is formatted for owners of

the following models of BERNINA

overlock machines:

• 700D

• 800DL

• 1150MDA

• 1300MDC

®

MASTERING YOUR BERNINA®SERGERS 6/2006 35

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 36

Sergers

4-Thread Overlock Seam

Fabric ....................................................... medium weight cotton, 5” x 6”

Needle............................................................................. 80/12 Universal

Thread............................................................... 4 cones of serger thread

.......................................................................... (yellow, red, green, blue)

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

Thread the serger for a 4-thread overlock stitch. Adjust settings as

indicated. Fine tune as needed.

Mastering

Your

BERNINA

Notes

®

Locate the seam guide markings on the knife guard. Measurements

shown are distances from the right needle. When using the left needle,

add 1/8” to measurements.

Tip: Use a permanent marker to highlight the raised markings; this is

particularly useful for those with “mature” eyesight.

Fold fabric in half to 2½” x 6”.

Align the fold of the fabric with the ½” mark on the knife guard (the left

needle is being used). Serge the seam, cutting off exactly 3/8”.

Trim and mount the sample.

MASTERING YOUR BERNINA®SERGERS 6/2006 36

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 37

Sergers

4-Thread Overlock Seam Sample

Mastering

Your

BERNINA

®

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2- 3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3- 5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

37

Page 38

Sergers

Seaming Knit Fabrics:

Presser Foot Pressure

Mastering

Your

BERNINA

®

Fabric .................................................. 2 pieces cotton single knit jersey,

................................................... each 3” x 6” with stretch across 3” side

Needle.............................................................. 75/11 Stretch or Ballpoint

Thread...............................................2 cones of serger thread (needles)

......................................................... 2 cones YLI Woolly Nylon (loopers)

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

Thread the serger for a 4-thread overlock stitch, using regular serger

thread in the needles and Woolly Nylon in the loopers.

Set all thread tensions at usual 4-thread overlock settings.

Using a fabric marker, divide the fabric in half along a 6” side.

With right sides together and a ¼” seam allowance, serge to the mark on

the fabric.

Without removing the fabric from under the presser foot, notice the

“ripple” effect where the fabric has stretched.

Reduce the presser foot pressure to low.

Notes

Seam the jersey to the end of the fabric.

Remove the fabric from under the presser foot and observe the de-

creased “rippling”.

Return the presser foot pressure adjusting lever its normal setting.

Trim and mount the sample.

Record settings in chart below:

MASTERING YOUR BERNINA®SERGERS 6/2006 38

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 39

Mastering

Sergers

Your

BERNINA

®

Seaming Knits: Presser Foot Pressure Sample

N

L

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2-3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3-5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

39

Page 40

Sergers

Seaming Knit Fabrics:

Differential Feed

Mastering

Your

BERNINA

®

Fabric .................................................. 2 pieces cotton single knit jersey,

................................................... each 3” x 6” with stretch across 3” side

Needle.............................................................. 75/11 Stretch or Ballpoint

Thread............................................................... 2 cones of serger thread

........................................................................ 2 cones YLI Woolly Nylon

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

Thread the serger for a 4-thread overlock stitch, using regular serger

thread in the needles and Woolly Nylon in the loopers.

Set all thread tensions at usual 4-thread overlock settings.

Using a fabric marker, divide the fabric in half along a 6” side.

With right sides together and a ¼” seam allowance, serge to the mark on

the fabric.

Without removing the fabric from under the presser foot, notice the

“ripple” effect where the fabric has stretched.

Notes

Locate the differential feed dial on the serger. Adjust to 1.5.

Seam the jersey to the end of the fabric.

Remove the fabric from under the presser foot and observe the

decreased “rippling”.

Return the differential feed dial to normal setting (N).

Trim and mount the sample.

MASTERING YOUR BERNINA®SERGERS 6/2006 40

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 41

Mastering

Sergers

Your

BERNINA

®

Seaming Knit Fabrics: Differential Feed Sample

N

1.5

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2-3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3-5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

41

Page 42

Sergers

Seaming Knit Fabrics:

Presser Foot Tape Guide

Mastering

Your

BERNINA

®

Fabric .................................................. 2 pieces cotton single knit jersey,

................................................... each 3” x 6” with stretch across 3” side

............................................................ 8” length of ¼” twill tape or ribbon

Needle.............................................................. 75/11 Stretch or Ballpoint

Thread............................................................... 2 cones of serger thread

........................................................................ 2 cones YLI Woolly Nylon

Presser Foot ........................................... Standard Foot with Tape Guide

Stitch ............................................................................ 4-thread overlock

Thread the serger for a 4-thread overlock stitch. Adjust tension settings

for a balanced 4-thread overlock.

Locate the tape guide on the presser foot.

Using the small screwdriver from the accessory pouch, loosen the fixing

screw and slide the tape guide all the way to the left. Snug the screw.

Slip the twill tape or ribbon into the slot on the presser foot.

Lower the presser foot and lower the needles into the tape or ribbon.

Loosen the fixing screw and adjust the tape guide to the width of the

tape or ribbon. Retighten the screw.

Notes

Seam the jersey together along the 6” side, catching the tape or ribbon

in the serged edge.

Remove the fabric from under the presser foot and examine the seam. It

will not stretch. The tape or ribbon has stabilized the seam.

Trim and mount the sample.

MASTERING YOUR BERNINA®SERGERS 6/2006 42

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 43

Mastering

Sergers

Your

BERNINA

®

Seaming Knit s: Presser Foot Tape Guide Sample

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2-3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3-5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

43

Page 44

Sergers

Attaching Ribbing

Fabric ............................................................... sweatshirt fleece, 4” x 6”

....................................................................... ribbing, 6” wide x 2½” long

Needle.............................................................. 75/11 Stretch or Ballpoint

Thread............................................................... 2 cones of serger thread

........................................................................ 2 cones YLI Woolly Nylon

Presser Foot ........................................... Standard Foot with Tape Guide

Stitch ............................................................................ 4-thread overlock

Thread the serger for a 4-thread overlock stitch using Woolly Nylon

in both loopers. Set tensions for a balanced 4-thread overlock.

Mastering

Your

BERNINA

Notes

®

Cut a mock neckline on the corner of the fleece (quarter circle).

Fold the ribbing in half (wrong sides together) to 1¾” x 6”.

Matching raw edges, place the ribbing to the neckline on the right

side of the fleece.

Serge the ribbing to the fleece, stretching the ribbing to meet the

fleece neckline.

Trim and mount the sample.

MASTERING YOUR BERNINA®SERGERS 6/2006 44

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 45

Sergers

Att aching Ribbing Sample

Mastering

Your

BERNINA

®

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2-3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3-5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

45

Page 46

Sergers

Serger Piecing

Fabric ............................. 3 strips medium weight cotton 1 3/4” x 4” each

.............................................. 3 strips contrasting cotton, 13/4” x 4” each

Needle..............................................80/12 Universal, Sharp, or Microtex

Thread................................................................... 4 cones serger thread

........................................................................ 2 cones YLI Woolly Nylon

Presser Foot .............................................................................. standard

Stitch ............................................................................ 4-thread overlock

Thread the serger for a 4-thread overlock stitch, with regular serger

thread in the needles and the loopers. Set all tensions for a balanced

4-thread overlock.

Mastering

Your

BERNINA

Notes

®

Create two strip sets, each with three alternating strips of fabric.

Strip #1 is light-dark-light; strip #2 is dark-light-dark. Serge strips

together without trimming any fabric. Press seam allowances toward

dark strips.

Using a rotary cutter, mat and ruler, cut the strip sets into 1¾” block sets.

Use 1 block set from the light/dark/light strip set and 2 block sets from

the dark/light/dark strip set. Discard the excess fabric.

Serge 1 dark/light/dark strip to the light/dark/light strip, matching seam

allowances. The opposing seams will “nest” into each other.

Serge the remaining dark/light/dark strip to the light/dark/light strip.

Press the seam allowances to the dark/light/dark strips.

Trim thread tails and mount the sample on the following page.

MASTERING YOUR BERNINA®SERGERS 6/2006 46

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 47

Sergers

Serger Piecing Sample

Mastering

Your

BERNINA

®

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2-3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3-5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

47

Page 48

Sergers

Reversible Piecing

Fabric ......................................................... 3 pieces cotton prints, 2” x 4”

.................................................................... 1 piece cotton print, 2” x 5½”

.............................................................................3 pieces muslin, 2” x 4”

........................................................................... 1 piece muslin, 2” x 5½”

............................................................................ 3 pieces batting, 2” x 4”

........................................................................... 1 piece batting, 2” x 5½”

Needle.............................................. 80/12 Universal, Sharp, or Microtex

Thread................................................................... 4 cones serger thread

Presser Foot ............................................................................... standard

Stitch .............................................................................4-thread overlock

Mastering

Your

BERNINA

Notes

®

Thread the serger for a 4-thread overlock stitch. Set all tensions for a

balanced 4-thread overlock.

Optional: Increase the presser foot pressure for thick fabrics.

Create a quilt sandwich, layering the 4” fabrics as follows: 2 layers of

muslin (right sides together), one layer of batting, 2 layers of printed

fabric (right sides together) and a layer of batting on top.

Raise the presser foot and position the fabrics under it with the right

edges of the fabric and batting even with the left edge of the knife.

Serge the 6 layers together, stopping as necessary to keep the right

edges of the fabrics even. Open the layers (1 muslin, 1 quilt top, 1

batting) to the right and left of the serged seam and press.

To serge the third section into place, layer the remaining 4” fabrics as

follows: muslin to muslin, right sides together; print to print, right sides

together; batting on top.

Serge through all 6 layers. Open the last 3 layers; press.

Add the last section to the top edge of the 3-paneled quilt. Layer the 5½”

fabrics as follows: muslin to muslin, right sides together; print to print,

right sides together; batting on top.

Serge, open the layers to the top of the square, and press.

Trim and mount the sample on the following page.

MASTERING YOUR BERNINA®SERGERS 6/2006 48

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 49

Sergers

Reversible Piecing Sample

Mastering

Your

BERNINA

®

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2-3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3-5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch Selection Lever..................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

49

Page 50

Sergers

Elasticator

Fabric ....................................................... mediumweight cotton, 3” x 12”

............................................12” length of ½” nylon or cotton braid elastic

Needle...............................................................75/11 Stretch or Ballpoint

Thread................................................................... 2 cones serger thread

.........................................................................2 cones YLI Woolly Nylon

Presser Foot ............................................................................Elasticator

Stitch .............................................................................4-thread overlock

Thread the serger for a 4-thread overlock stitch. Set tensions for a

balanced stitch. Attach the Elasticator to the serger.

Mastering

Your

BERNINA

Notes

®

Adjust stitch length to 4mm.

Increase the presser foot pressure.

Locate and raise the roller guide in the front of the presser foot. Turn the

handwheel to lower the needles. (This also lowers the feed dog.) Raise

the presser foot and insert the elastic through the slot and under the

presser foot until it touches the needles.

Lower the presser foot and serge a few stitches to catch and straighten

the elastic along the right edge of the slot. Turn the handwheel to lower

the needles.

Lower the roller guide. Using the small screwdriver, adjust the guide

plate on the presser foot to the width of the elastic.

Locate the pressure adjustment set screw (on the top of the roller guide)

and turn the screw counterclockwise to completely loosen the pressure

on the roller .

Place the fabric under the presser foot and begin serging. Slowly tighten

the pressure adjustment set screw to increase the pressure on the roller

and stretch the elastic. Note: Do not over tighten the screw. Excessive

pressure on the elastic will bind the fabric. Serge the elastic onto the

fabric letting the presser foot stretch the elastic for you.

Trim and mount the sample.

Return all settings to normal.

MASTERING YOUR BERNINA®SERGERS 6/2006 50

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Page 51

Sergers

Elasticator Sample

Mastering

Your

BERNINA

®

Balanced 4-Thread Overlock

Upper Looper .............................. 3-5 Cutting Width...............................2-3

Lower Looper .............................. 3-5 Stitch Length..........................2.5mm

Left Needle.................................. 3-5 Differential Feed ............................ N

Right Needle ............................... 3-5 Stitch SelectionLever...................

MASTERING YOUR BERNINA®SERGERS 6/2006

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

51

Page 52

Sergers

Gathering Attachment:

Gathering Fabric

Mastering

Your

BERNINA

®

Fabric ....................................................... mediumweight cotton, 3” x 12”

Needle............................................................................. 80/12 Universal

Thread................................................................... 4 cones serger thread

Presser Foot ............................................................................... standard

Other ......................................................................Gathering Attachment

Stitch .............................................................................4-thread overlock

If necessary, install the attachment base on your serger (700D and

800DL only).

Raise the cutting knife and adjust cutting width to 3mm. Slip Gathering

Attachment on to the fixing screw and metal post directly behind the

fixing screw. Hint: Place the horseshoe-shaped slot over the screw, then

rotate the attachment to lock over the metal post. Tighten fixing screw.

Set cutting width at 2mm (normal) and lower the upper knife into cutting

position. Locate and adjust the differential feed dial to 2. Using a fabric

marker, divide fabric into 3 sections along one 12” edge.

Turn the handwheel to lower the needles. (This also lowers the feed

dog.) Raise the presser foot and insert the fabric under the Gathering

Attachment, up against the needles. The fabric is lying against the stitch

plate.

Notes

Lower the presser foot and serge to the first mark.

Adjust the stitch length to 4mm and serge to the second mark.

Increase the tension on both needles to 7. Serge to the end of the fabric.

Mark the sample: with Differential Feed; with Differential Feed & SL4;

with Differential Feed, SL4 and tightened needle tensions.

Mount the sample on the following page.

Return all settings to normal.

The attachment base can remain on the machine.

MASTERING YOUR BERNINA®SERGERS 6/2006 52

©2006 BERNINA® of America, Inc.

Permission to copy and distribute in printed and electronic formats granted only to Authorized BERNINA® Dealers

Gathers Plus

For even more gathers,

tighten needle tensions

slightly and increase stitch

length to 4mm.

Page 53

Mastering

Sergers

Your

BERNINA

®

Gathering Att achment: Gathering Fabric Sample

Balanced 4-Thread Overlock