Page 1

BERNINA

Service

manual

1230

(Supplement

to

service

manual

1130/20)

*

FRITZ

GEGAUF

LTD.

Manufacturers

of

BERNINA

Sewing-Machines

8266

Steckborn

Switzerland

88/10

GB

006

807

50

02

Page 2

Impressum

Authers:

P.

Kenyon

T.

Kalberer

Graphics:

F.

Rapold

Typeset

and

printed:

by

Bodan

AG,

Kreuzlingen

2

1230

Page 3

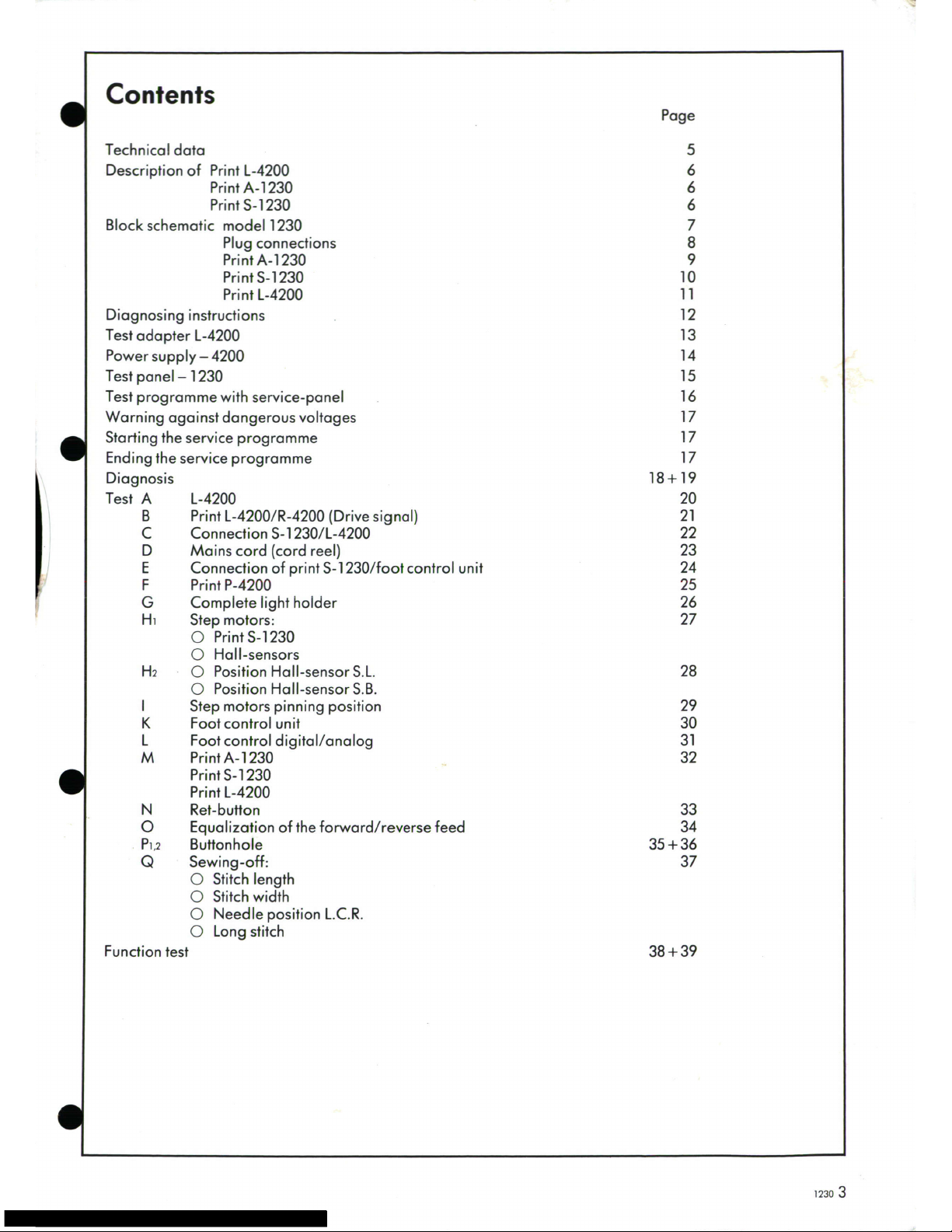

Contents

Page

Technical

data

5

Description

of

Print

L-4200

6

Print

A-1230

6

Print

S-1230

6

Block

schematic

model

1230

7

Plug

connections

8

Print

A-1230

9

Print

S-1230

10

Print

L-4200

11

Diagnosing

instructions

12

Test

adapter

L-4200

13

Power

supply

-

4200

14

Test

panel -1230

15

Test

programme

with

service-panel

16

Warning

against

dangerous

voltages

17

Starting

the

service

programme

17

Ending

the

service

programme

17

Diagnosis

18+19

Test

A

L-4200

20

B

Print

L-4200/R-4200

(Drive

signal)

21

C

Connection

S-1

230/L-4200

22

D

Mains

cord

(cord

reel)

23

E

Connection

of

print

S-1

230/foot

control

unit

24

F

Print P-4200

25

G

Complete

light

holder

26

Hi

Step

motors:

27

o

PrintS-1230

o

Hall-sensors

H2

0

Position

Hall-sensorS.L.

28

o

Position

Hall-sensor

S.B.

I

Step

motors

pinning

position

29

K

Foot

control

unit

30

L

Foot

control

digital/analog

31

M

Print

A-1230

32

Print S-1230

Print

L-4200

N

Ret-button

33

0

Equalization

of

the

forward/reverse

feed

34

P1,2

Buttonhole

35+36

Q

Sewing-off:

37

o

Stitch

length

o

Stitch

width

o

Needle

position

L.C.R.

o

Long

stitch

Function

test

38

+

39

1230

3

Page 4

Important:

A

comparison

ot

the

models

1230

and

1130

is

not

made

as

from

a

technical

point

of

view.

They

are

identical.

All

gauges,

instruments,

adjustments

etc,

which

are

applicable

to

model

1130

are

also

valid

here.

BERNINA

has

only

changed

the

test

programme

which

also simplifies

things

for

you.

These

instructions

are

to

be used

in

conjunction with

the

service

manual

cl.

1130.

This

manual

remains

the

property

of

our

company,

repro-

duction,

publication

or information

to

a

third

party

without

our

written

approval

is

forbidden.

FRITZ

GEGAUF

LTD.,

Manufacturers

of

BERNINA

Sewing-Machines

Steckborn

(TG)

Switzerland

4

1230

Page 5

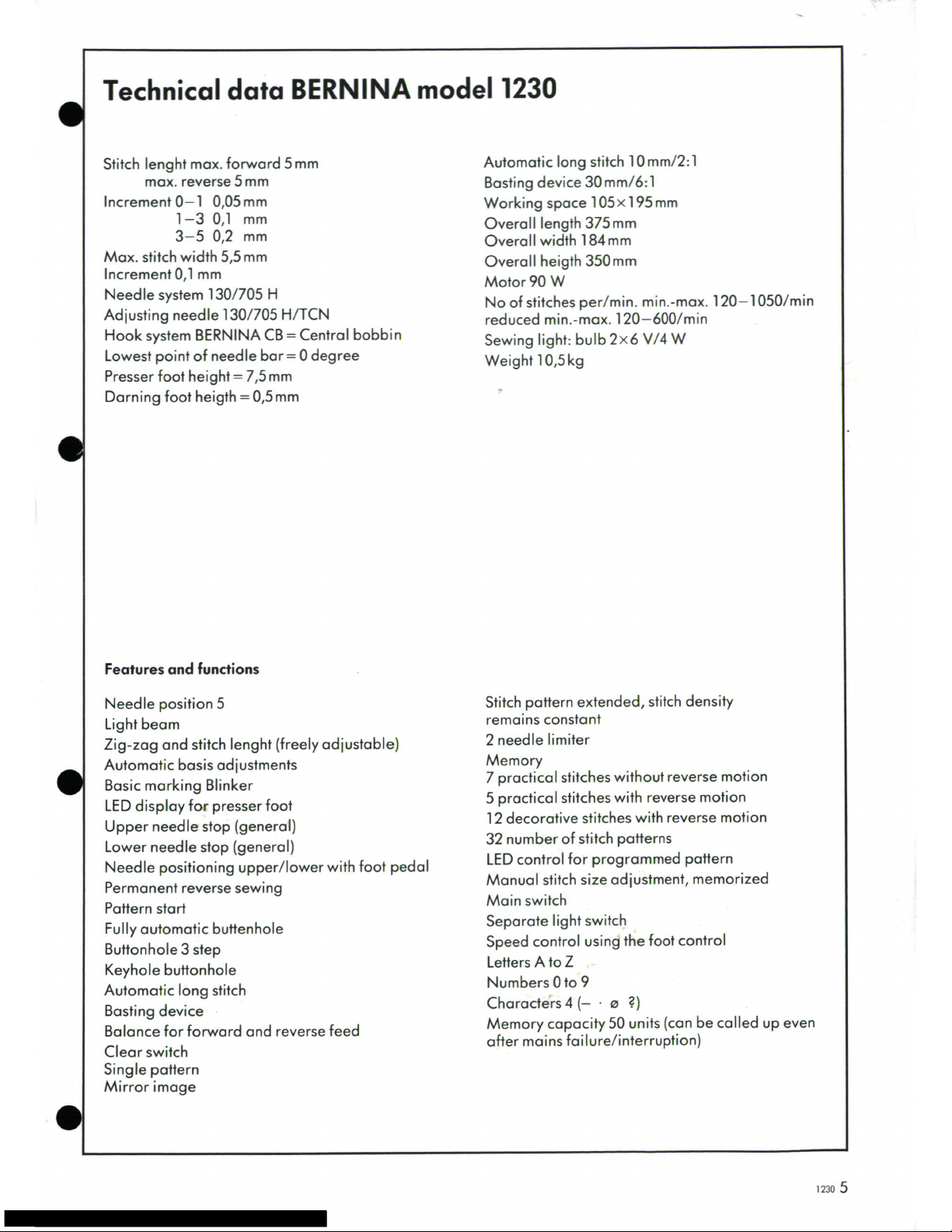

Technical

data

BERNINA

model

1230

Stitch

lenght

max.

forward

5 mm

Automatic

long

stitch

10

mm/2:1

max.

reverse

5 mm

Basting

device

30mm/6:1

Increment

0-1

0,05mm

Working

space

105x195mm

1-3

0,1

mm

Overall

length

375mm

3-5

0,2

mm

Overallwidth

184mm

Max.

stitch

width

5,5

mm

Overall

heigth

350

mm

Increment

0,1

mm

Motor

90

W

Needle

system

130/705

H

No

of

stitches

per/min.

min.-max.

120-1050/min

Adjusting

needle

130/705

H/TCN

reduced

min.-max.

120-600/min

Hook

system

BERNINA

CB

=

Central

bobbin

Sewing

light:

bulb

2x6

V/4

W

Lowest

point

of

needle

bar

=

0

degree

Weight

10,5kg

Presser

foot

height = 7,5

mm

Darning

foot

heigth

=

0,5

mm

Features

and

functions

Needle

position

5

Stitch

pattern

extended,

stitch

density

Light

beam

remains

constant

Zig-zag

and

stitch

lenght

(freely

adjustable)

2

needle

limiter

Automatic

basis

adjustments

Memory

Basic

marking

Blinker

7

practical

stitches

without

reverse

motion

LED

display

for

presser

foot

5

practical

stitches

with

reverse

motion

Upper

needle

stop

(general)

12

decorative

stitches

with

reverse

motion

Lower

needle

stop

(general)

32

number

of

stitch

patterns

Needle

positioning

upper/lower

with

foot

pedal

LED

control

for

programmed

pattern

Permanent

reverse

sewing

Manual

stitch

size

adjustment,

memorized

Pattern

start

Main

switch

Fully

automatic

buttenhole

Separate

light

switch

Buttonhole

3

step

Speed

control

using

the

foot

control

Keyhole

buttonhole

Letters

A

to

Z

Automatic

long

stitch

Numbers

0

to

9

Basting

device

Characters

4

(-

-

o

?)

Balance

for

forward

and

reverse

feed

Memory

capacity

50

units

(can

be

called

up

even

Clear

switch

after

mains

failure/interruption)

Single

pattern

Mirror

image

1230

5

Page 6

Description

The

electronics

of

the

model

1230

sewing

S-1230

control

print

machine

is

essentially

located

on

three

large

The

complete

sewing

machine

control

is

located

printed

circuit

boards;

the

power

print

L-4200,

the

on

the

S-1230

control

print.

The

S-1

230

control

control

print

S-1230

and

the

display

print

A-1

230

print

is

located

on

the

A-1

230

print

from

the

rear.

(compare

to

the

block

schematic

diagram).

The

The

most

important

control

elements

are

the

tasks

of

the

3

units

correspond

to

the

known

microcomputer,

and

the

power

drive

for

the

step

functions

of

L-4200,

S-4200

and

A-4200

prints

motors.

A

new

feature

over

model

1130

is

that

the

from

the

model

1130.

bobbin

winder

motor

is

also

controlled

by

the

microprocessor.

The

bobbin winder

motor

speed

1-4200

powerprint

can

now

be

controlled

from

the

foot

control.

The

L-4200

power

print

is

mounted

above

the

The

S220

service

switch

on

print

S-1

230

is a

motor

on

the

rear

side

of

sewing

machine.

The

service

aid.

This

switch

has

two

positions:

normal

circuit

components

on

the

L-4200

have

the

follow-

sewing

operation,

and

service

position.

In

the

ing

functions:

service

position,

several

buttons

and

diodes

on

-the

display

panel

are

assigned

other

functions.

- Motor

control:

This

allows

the

service

technician

to

execute

The

main

motor

control

operates

with

the

mains

necessary

adjustment

and

testing

functions

using

voltage.

The

main

motor

is

a

DC

motor

with

the

display

panel (refer

to

the

special

section

pulse-width

modulated

speed

control.

The

service

programme).

The

service

switch

must

closed

loop

control

circuit

on the

small

R-4200

always

be

set

into

the

sewing

position

for

normal

print

is

located

on

the

power

print.

sewing

operations.

All

circuit

components

for

the

motor

control

The

microcomputer

on

print

S-1

230

receives

an

operate

at dangerous

voltage

levels,

analog

signal

from

the

foot

control,

which it

then

The

safety

regulations

must

be

adhered

to.

converts

into

a

digital

signal

and

transmits

to

print

R-4200

as

setpoint

for

the

motor

speed.

The

-

Power

supply:

R-4200

print

controls

the

motor

speed

to

the

Generates

the

following

D.C.

voltages:

speed

specified

by

the

S-print,

using

a

setpoint

-

-

30V

for

the

step

motors

actual

value

comparison.

When

the

foot

control

is

-

5V

for

the

logic

circuitry

on

the

S-1

230

and

released,

the

setpoint

goes

to

zero,

the

brake

is

A-1230

prints

actuated

from

the

microcomputer

on

the

S-print

-

6V

for

the

sewing

light

via

the

R-4200

print,

and

the

motor

is

rapidly

-

30V

for

the

bobbin

winder

motor

braked.

Components

are

protected

from

overload,

in

Signal

transfer

between

the

S-1230

and

R-4200

the

case

of

faults,

by

three

fuses

F

150,

F

151

print

is

realised

using

a

4-pole

cable.

Signal

and

F

152. If

a

fuse

blows

only

original

replace-

transfer

is

realised

through

an

opto-coupler

ment fuses,

with

the

correct

rating

may

be

used.

providing

electrical

isolation

and

thus

eliminating

dangerous

voltage

levels

from

the

foot

control

A-1230

display

print

and

the

S-1230

control

print.

The

display

section

is

mounted

directly

behind

the

The

step

motors

are

in

random

positions

when

operating

control

panel.

The

display

and

ope-

sewing

machine

is

switched

on.

Random

values

rating

control

elements

are

soldered

onto

the

L-

can

also

be

in

the

microcomputer

control

shaped

printed

circuit.

memory.

In

order

to

have

a

defined

state, the

step

A

time

multiplex

control

allows

the

numerous

motors

are

rotated

into

their

calibrated

position

LEDs

and

control

elements

to

be

connected

to

the

by

a

microcomputer

command,

and

the

position

open

loop

control

on

the

S-1

230

control

print

value

is

set

to

zero

in

the

microcomputer

memory.

using

only

16

connection

lines.

This

starting

state

allows

the

selection

and

sewing

of

any

stitch

programme.

6

1230

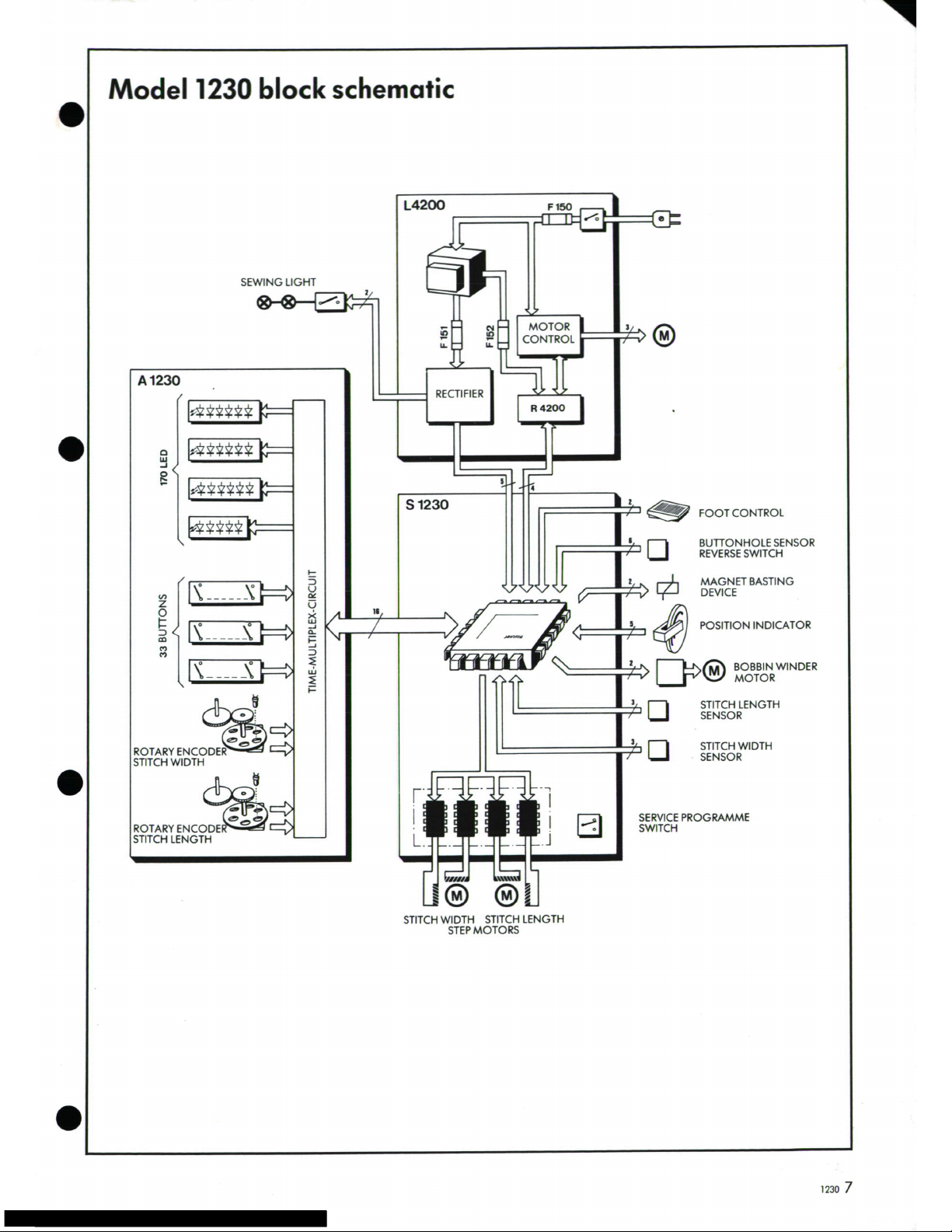

Page 7

Model

1230

block

schematic

L4200

F150

A

1230

A1230

RECTIFIER

J

FOOT

CONTROL

£

BUTTON

HOLE

SENSOR

S

REVERSE

SWITCH

D

-MAGNET

BASTING

DEVICE

0

(

POSITION

INDICATOR

S4

WIDH

OBBINWINDER

ROTARY

ENCODE

STITCH

WIGTHT

ROTAR

ENCOE

ZUSERVICE

PROGRAMME

ROITAY

LENCOD

STITCH

WIDTH

STITCH

LENGTH

STEP

MOTORS

1230

7

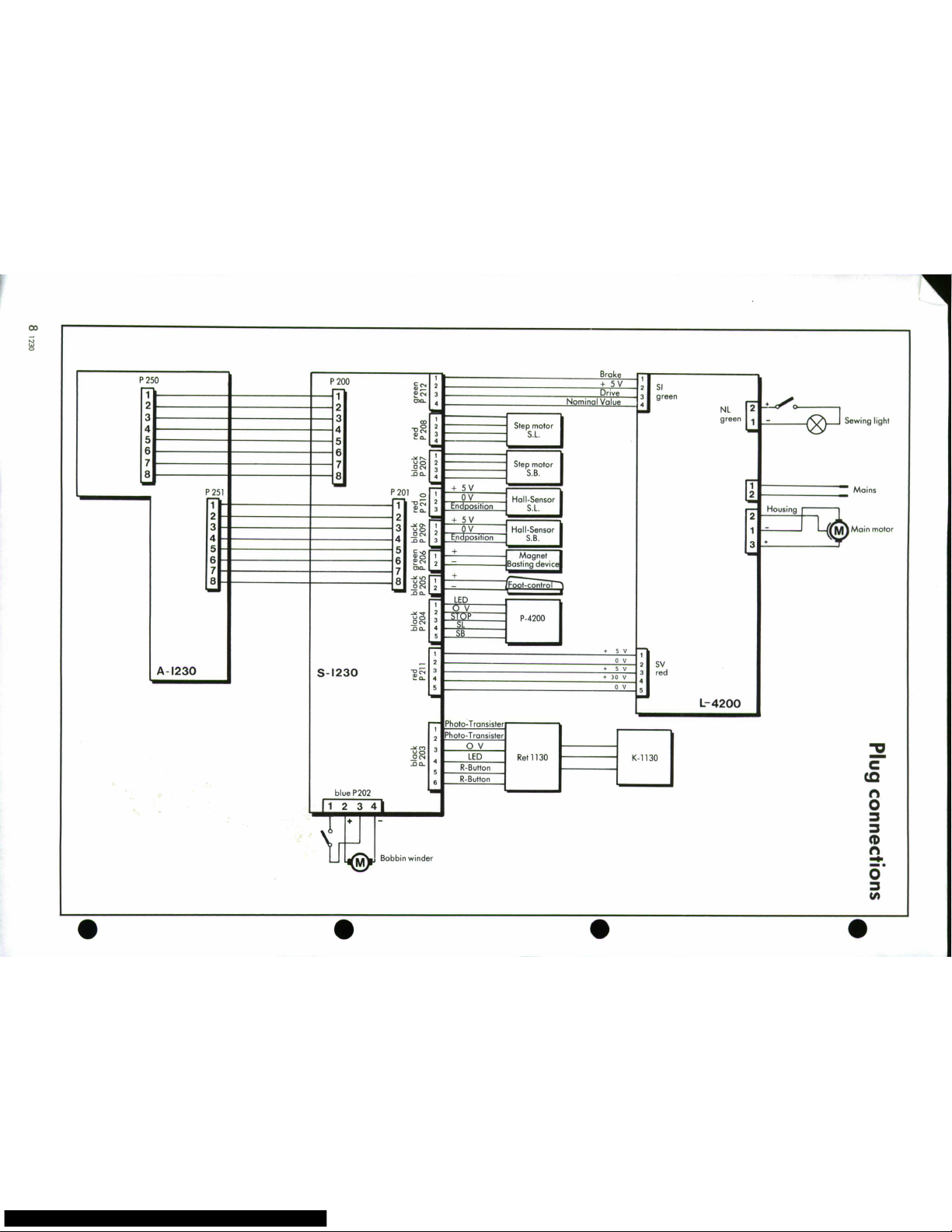

Page 8

0

I

Brake

P250

P

200

C

2

+!

5V

S

2

-2

S

E1"C4

3

Drive

green

2

2OX

4

Nominal

Vau

4re

-L

2~ig~

S

gr

me1

Sewing

light

44

2o

CL

S .

L .

5'

5

--

5

4

up

2

Step

motor

8

1

7__C_

4

S.B,

P

251

P2

+

5V

Mains

0

V

Hall-Sensor

1

3

S.L.

Housing

22

+5V

2

3

L

H

ll-Sensor

V,

M

ain m o r

4

4

n

osition

-S.B.

M

M

5

o

+

r

Magnet

7

6

-

asting

device

78

.8

t

+'=

A-

O1230

A13

S-1230t"o303K+1s

0

2

-0

CL

200

L-L20

5

SB

a13

St123

13

K-1130

1C4

3

red

+3

Bobwiwinder

0 30

R

4

ED

Rt

110

K- 13

5

R-Button

•

•

•

•

Page 9

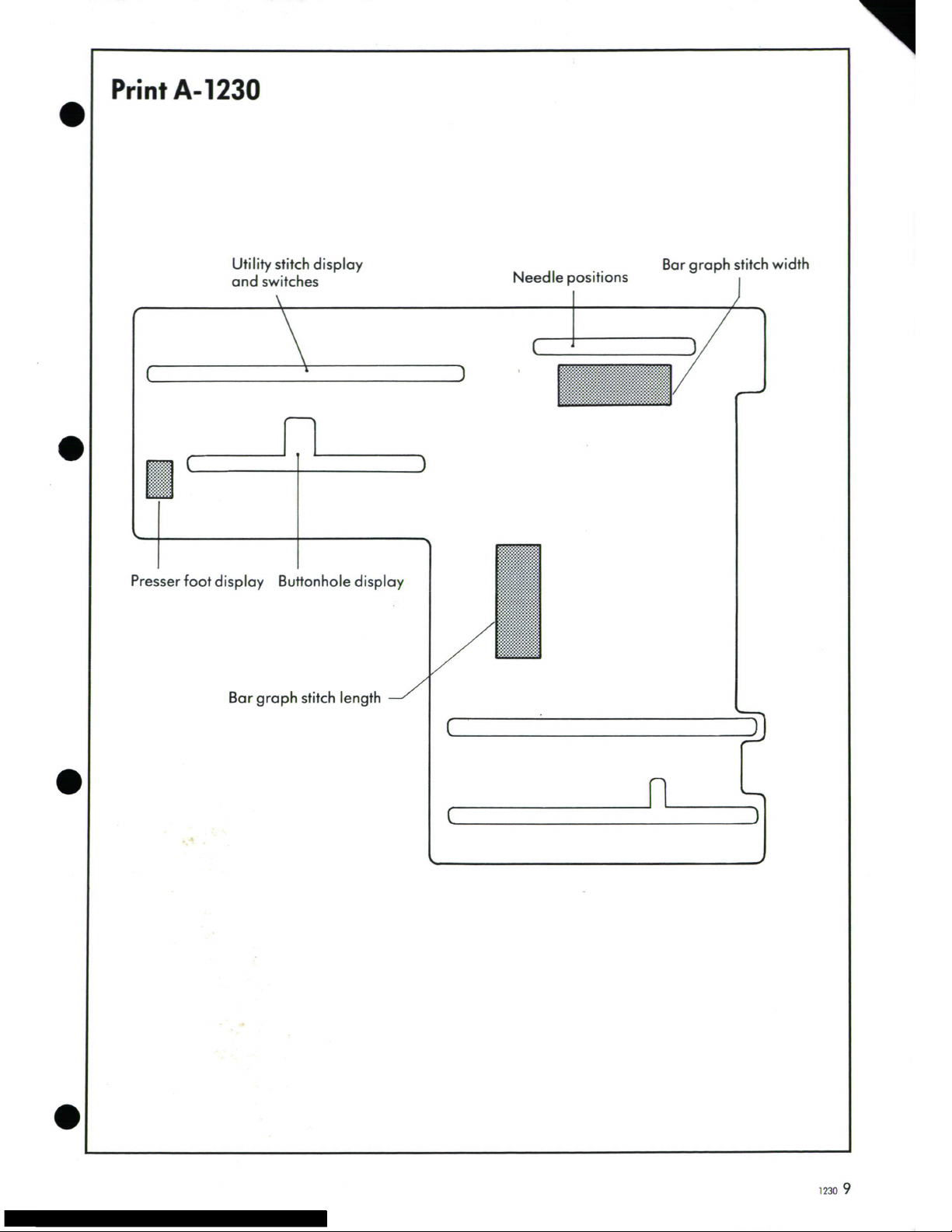

Print

A-1230

Utility

stitch

display

Needle

positions

Bar

graph

stitch

width

and

switches

Presser

foot

display

Buttonhole

display

Bar

graph

stitch

length

1230

9

Page 10

S-1230

Print

Data

lines

to

print

A-1230

Potentiometer

for

adjusting

buttonhole

sensor

A

Potentiometer

for

adjusting

buttonhole

sensor

B

Foot

control

2-pole

black

Control

signals

from/to

L-print

4-pole

green

Buttonhole

sensors

Reverse

switch

6-pole

black

L-

Stitch

length

sensor,

3-pole

red

Stitch

width

sensor,

3-pole

black

Position

indicator

5-pole

black

Power

supply

from

L-print

5-pole

red

Magnet

basting

device,

2-pole

green

Service

switch

Pos.

Service

I

Pos.

Normal

Bobbin

winder

motor

4-pole

blue

Stitch

length

step

motor

4-pole

red

Stitch

width

step

motor

4-pole

black

Warning!

If

print

S-1230

has

to

be

replaced,

then

buttonhole

adjustment

and

forward/reverse

feed

equalization

must

be

carried

out.

10

1230

Page 11

Print

L-4200

Important!

Never

fit

heat

sink

and

securing

screws

without

insulating

foil

or

insulating

washer,

because

a

short

circuit

will

occur.

The

heat

sink

with

its

Galvanically

insulating

foil

must

sit

fully

on

the

fixing

angle,

in

separated

order

to

achieve

best

results

in

transfering

heat

low

voltage

from

the

heat

sink

to

the

sewing

machine housing.

4-

Not

used

P157

P160

4

[

1

45V

41

I

Power

supply

for

P159

1-

print

S

and

A-4200

1Control

signals

to

print S-4200

Sewing

light

Equalization

of

speed

Connector

for

print

R-4200

Main

motor

Circuits

in

this

area

operate

at

dangerous

voltages.

Observe

the

F

Main

notice

on

page

17.

Mains

123011

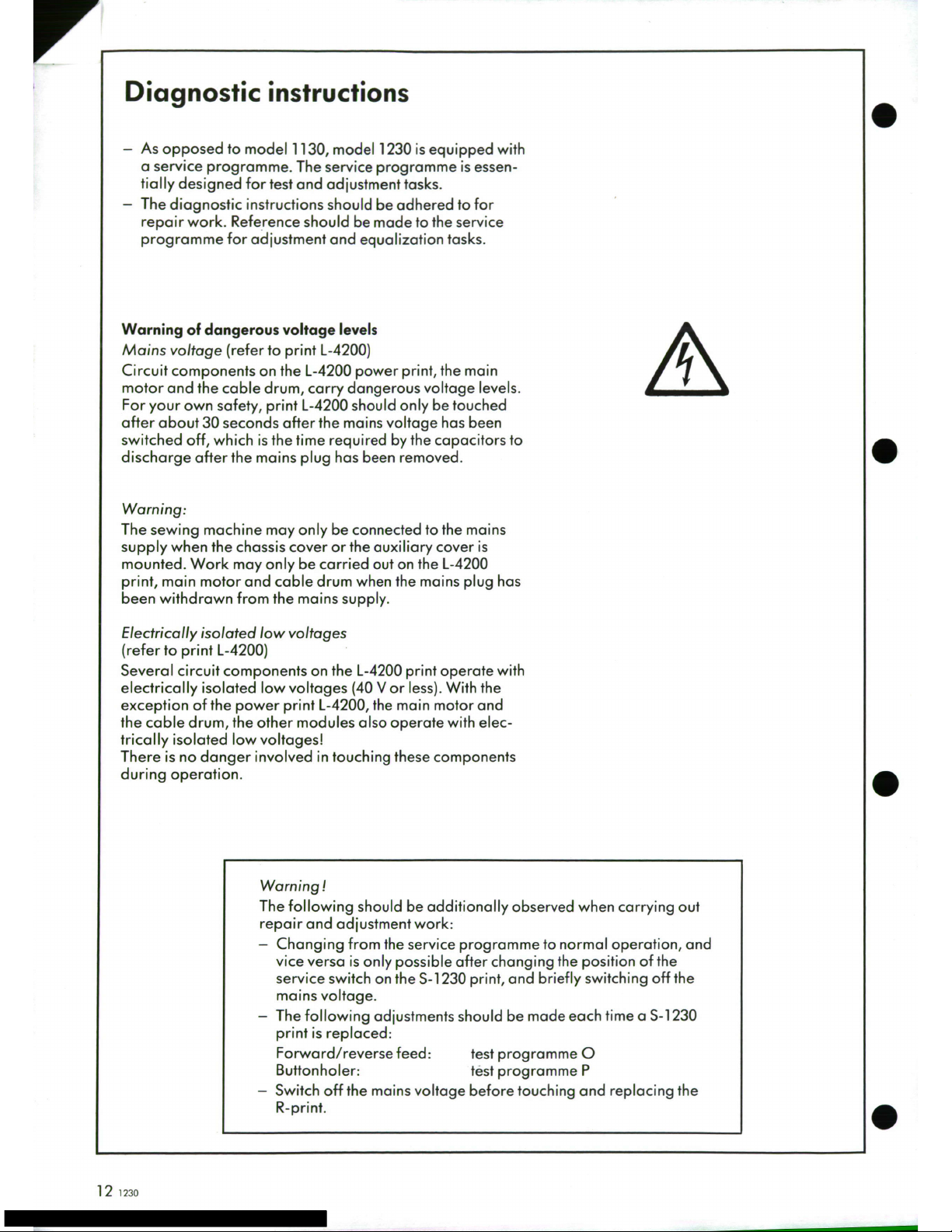

Page 12

Diagnostic

instructions

-

As

opposed

to

model

1130,

model

1230

is

equipped

with

a

service

programme.

The

service

programme

is

essen-

tially

designed

for

test

and

adjustment

tasks.

-

The

diagnostic

instructions

should

be

adhered

to

for

repair

work.

Reference

should

be

made

to

the

service

programme

for

adjustment

and

equalization

tasks.

Warning

of

dangerous

voltage

levels

Mains

voltage

(refer

to

print

L-4200)

Circuit

components

on

the

L-4200

power

print,

the

main

motor

and

the

cable

drum,

carry

dangerous

voltage

levels.

For

your

own

safety,

print

L-4200

should

only

be

touched

after

about

30

seconds

after

the

mains

voltage

has

been

switched

off,

which

is

the

time

required

by

the

capacitors

to

discharge after

the

mains

plug

has

been

removed.

Warning:

The

sewing

machine

may

only

be

connected

to

the

mains

supply

when

the chassis

cover

or

the

auxiliary

cover

is

mounted.

Work

may

only

be

carried

out

on

the

L-4200

print,

main

motor

and

cable

drum

when

the

mains

plug

has

been

withdrawn

from

the

mains

supply.

Electrically

isolated

low

voltages

(refer

to

print

L-4200)

Several

circuit

components

on

the

L-4200

print

operate

with

electrically

isolated

low

voltages

(40

V

or

less).

With

the

exception

of

the

power

print

L-4200,

the

main

motor

and

the

cable

drum,

the

other

modules

also

operate

with

elec-

trically

isolated

low

voltages!

There

is

no

danger

involved

in

touching

these

components

during

operation.

Warning!

The

following

should

be

additionally

observed

when

carrying

out

repair

and

adjustment

work:

-

Changing

from

the

service

programme

to

normal

operation,

and

vice

versa

is

only

possible

after

changing

the

position

of

the

service

switch

on

the

S-1230

print,

and

briefly

switching

off

the

mains

voltage.

-

The

following

adjustments

should

be

made

each time

a

S-1230

print

is

replaced:

Forward/reverse

feed:

test

programme

0

Buttonholer:

test

programme

P

-

Switch

off

the

mains

voltage

before

touching

and

replacing

the

R-print.

12

1230

Page 13

Test

adaptor

L-4200

The

power

supply

for

electrical

parts

which

are

con-

nected

to

print

L-4200

and

the

main

motor

control

are

checked

with

the

aid

of

the

test

adaptor.

"

When

all

LEDs

A

to

E

ligth

up,

then

the

power

supply

for:

-

the

step

motors

-

the

logic

circuit

-

the

sewing

light

is

correct.

Bobbin

winder

motor,

LED

E,

cannot

be

tested.

"

If

only

LED

B

doesn't

light

up,

then

the

voltage

for

the

logic

is

too

high

(more

than

5,5

V).

*

If

only

LED

C

doesn't

light

up,

then

voltage

for

the

logic

is

too

low

(less

than

4,5

V).

*

When

the

motor

switch

is

in

the

((on))

position,

the

electric

brake

is

released,

the

motor

receives

the

desired

value

and

will

run

at

the

set

speed.

LED

F

for

the

drive

signal

must

be

lit.

Speed

regulation

is

made

by

turning

the

potentiometer.

*

When

the

motor

switch

is

placed

in

the

((off)

position

the

signal

returns

to

zero,

and

the

electric

brake

should

engage.

The

motor

slows

down

to a stop.

LED

F

must

go

out.

TEST

-ADAPTER

L

4200

r

30V

SCHRITTMOTOR

STEP

MOTOR

r-Bl

C,5v

0

5V

LOGIC

Ri>4,5V

0

F

6V

O

NAEHLICHT

~1

SEWING

LIGHT

E30V

0

SPULERMOTOR

BOBBIN

WINDER

BERNINA

=

LAUFSIGNAL

DRIVE

SIGNAL

TOFF@0ON

Q

MOTOR

1230

13

Page 14

Power

supply

4200

The

power

supply

4200

delivers

current

for

the

logic

of

print

A-1

230

and

print

S-1

230,

the

step

motors,

the

sewing

light.

So

that

the

whole

machine

can

work

with

a

safe

low

voltage,

the

main

motor

receives

30

V

for

safety

reasons.

The

power

supply

is

useful

when

a

mechanical

adjust-

ment

is

to

be

made,

for

which

the

rigidity

plate

with

print

L-4200

has

to

be

removed.

Supply

apparatus

iI~1i4200

II~IIMotor

LW

IN

OFF

When

the

mains

switch

is

((on))

the

light

indicates

that

the

appliance

is working.

With

the

switch

in

the

((off))

posi-

tion,

the

appliance

is

turned

off.

Motor

switch

(ion)),

the

main

motor

will

rotate

slowly.

Adaptor

print

with

cord

ist

pluggable.

There

is

a

400

mA

fuse

at

the

rear.

Important

cl.

1230:

The

connection

for

the

bobbin

winder

motor

is

not

used.

14

1230

Page 15

Test-Panel

1230

37

( 5123456

=00

0o00M

SL

SB

HKALL~I

-

BLANCE

'3

..

SENSOR

-

POSITION

AUTO

84z

8+4+2+1

8

A

RET

5

Z

cn

0000.o0

000

~

HALL-

SENSOR

SL

SB

STOP

SL

SB

00j0

0*0-

1230

15

Page 16

Test-Programmes

with

Service-Panel

Manual

What

is

to

be

tested

1230

See

also

service

manual

1130

page

1

Hall

sensor

position

28

Page

64 a (see

also

BERNINA

=

for

stitch

length

Information

No.

78)

E

E2

Hall

sensor

position

28

cD

for

stitch

width

0

3

Sewing-off

(straight

stitch,

zigzag,

37

it

long

stitch

and

basting

stitch)

Cl)

0

o

Pinning

position

for

step

motors

29

Section

49, resp.

53

E

SL

and

SB

pages

37 + 41

E

0

Forward-reverse feed

34

Section

41,

pages

32 + 33

a

equalization

a-

Step

motor/Hall

27

Page

64

sensors

7

Position

indicator/

25

Page

62

P-print

8

Digital/analog

foot

control

31

9

Drive

signal

21

Page

58

10

Ret

button

33

11

Buttonholer potentiometer

35

Pages

69

+

70

equalization

16

1230

Page 17

LDanger

high

level

voltage!

Mains

voltage

(see

print

L-4200)

Circuits

on

the

power

print

L-4200,

the

main

motor

and

the

cord

drum

operate

at

dangerous

voltages.

As

some

capacitors

discharge

approx.

30

seconds

after

pulling

out

the

mains

plug,

you

should

wait

this

long

before

touching

print

L-4200.

Test-programm

model

1230

(service

operation)

1.

Test-programme

start

-

Remove

belt

cover

(service

instructions

model

1130,

section

6).

-

Set

service

switch

on the

S-print

into

service

position

(refer

to

Fig.

S-1

230,

page

10).

-

Switch-on

sewing

machine/D.C.

mains

adaptor

unit.

The

sewing

machine

is

now

in

service

programme

no.

6

(step

motors),

move

to

and

from

with

an

acustical

noise.

-

Push

clear

button

(min. 2 sec.).

-

Mount

service

panel.

The

sewing

machine

is

now

in

the

initial

state

of

the

service

operation.

The

individual

test

programmes

1

to

6

can

be

selected

from

this

state.

The

initial

state

can

always

be

selected

by

depressing

the

clear

button.

The

following

sensor

signals

can

now

be

checked:

-

Position

indicator/P-print

(test

5

model

1130).

-

Foot

control

digital

and

analog

(new).

-

Drive

signal

(partially

covered

in

test

1,

test

adaptor

model

1130).

-

Ret

button

(new).

-

Adjust

buttonholer

potentiometer

(partially

section

42

model

1130).

Termination

of

the

test-programme

-

Switch

off

the

sewing

machine/D.C.

mains

Attention:

adapter.

When

changeing

from

normal

operation -Service

-

Bring

the

service

switch

on the

S-print

into

the

operation

-

normal

operation.

normal

position.

-

Switch

off

the

machine/mains

adapter.

The

sewing

machine

can

now

be

operated

-

Bring

the

service

switch

into

the

desired

position.

normally.

-

Switch

on

the

machine/mains

adapter.

1230

17

Page 18

Fault

Possible

fault

on

Repair

instructions

Display

panel

and

sewing

light

-

L-4200

print

-

Test

A,

resp.

M

not

illuminated

-

Mains

cable

-

Test

D

Main

motor

not

running

Machine

(dead))

Main

motor

does

not

rotate

other

-

L-4200

print

-

Test

A,

resp.

M

functions

OK

-

R-4200

print

-

Replace

R-4200

print

after

switching

off

mains

voltage

-

S-1230

print

-

Replace

S-1230

print

-

Foot

control

-

Check

control,

replace

bobbin

winder

motor

foot

control,

if

nec.

test

K, L

-

Connection

between

S-1

230

and

-

Test

C

L-4200

prints

-

Connection

between

S-1

230

print

-

Test

E

and

foot

control

-

Main

motor

-

Check

motor

cable

and

plug

aReplace

motor

0

Bobbin

winder

motor

does

not

function,

-

S-1230

print

-

Replace

print

S-1230

other

functions

OK

-

Bobbin

winder

-

Replace

complete

bobbin

winder

Sewing

light

does

not

function

-

Lamps

-

Replace

lamps

-

Lamp

holder

-

Test

G

-

Print

L-4200

-

Test

A

Step

motors

do

not

position

-

Step

motor

print

S-1230

-

Test

Hi,

H2

-

Connection

between

S-1230

and

L-4200

prints

-

Test

C

Front

panel

LED

does

not

illuminate,

Print

A-1

230

-

Replace

print

A-1230

however

selected

function

is

executed

when

button

depressed

Page 19

Fault

Possible

fault

on

Repair

instructions

Selected

functions

not

executed

when

-

Print

A-1230

-

Replace

print

A-i230,

if

malfunction

button

depressed

still

occurs,

replace

print

S-1230.

Test

with

new

S-1

230,

print

and

old

A-1

230

print.

Automatic

buttonholing

does

not

-

Buttonhole

foot

-

TestPlP2

function

-

PrintS-1230

-

Print

Ret-1230

Basting

device

does

not

function

-

PrintS-1230

-

Replace

print

S-1230

-

Basting

device

magnet

-

Replace

magnet

and

adjust

Reverse

button

does

not

function

-

Print

S-1230

-

Start

service

test

programme,

depress

-

Print

Ret-1230

reverse

button,

LED

RET

must

illuminate,

if

not:

replace

print

S-1230

to

Z

or

if

nec.

Ret

print.

Irregular

stitch

width

or

length

-

Step

motor

-

Test

Hi

H2

-

Check

mechnicol

and

optical

parts

of

Bar

graphs

do

not

react

to

stitch

-

Operating

chassis

the

rotary

encoder

adjustments

-

PrintA-1230

-

Replace

print

A-1

230

Main

motor

stops

after

5

seconds

-

Print

P-4200

-

Test

F

-

Print

S-1230

-

Replace

print

S-1230

No

needle

stop

-

Print

P-4200

-

Test

F

-

Print

S-1230

-

Replace

print

S-1230

-

Print

L-4200

-

Test

A

Stitch

pattern

no.

32

is

to

short

-

Feed

equalization

-

Test

0

=

orto

long

'0_

_

_

_

_

_

__

_

_

_

_

_

_

_

__

_

_

_

__O_

__

_

_

_

_

_

_

_

Page 20

What

is

to

be

tested

What

to

adjust

Normal

condition

Print

L-4200

Switch

off

mains

supply

See

also

directive

in

Test

M

-

Fit

safety

cover

-

Connect

test

adaptor

L-4200

instead

of

the

sewing

light

(2-pole,

green),

connect

connecting

cable

to

print

S-4200

(4-pole

green,

control

signals)

and

connecting

cable

to

print

S-4200

(5-pole

red,

supply).

-

Set

the

switch

on the

(off

position.

Switch

on

mains

supply

-

LEDsAto

D

illuminate

-

Motor

rotates.

LED

F

illuminated.

Speed

can

be

controlled

by

the

-

Motor

switch

to

oon)

position

potentiometer.

(see

also

test

B)

Motor

brakes.

LED

F

no

longer

-

Motor

switch to

aoffo

position

illuminated

Important:

-

When

no

lights

A-D

illuminate

carry

ont

test

D

mains

cord.

-

Replace

print

L-4200

if

one

or

several

of

the

LEDs

A

to D do

not

illuminate.

Before

going

further,

test

the

new

L-print

using

test 9 to

determine

whether

the

L-print

failure

was

subsequent

to

failure

of

the

S-1

230

or

A-1

230

prints.

If

this

is

the

case,

then

these

faults

should

first

be

eliminated.

-

Replace

print

R-4200

if

the

voltages

A-D

are

available

but

the

motor

still

does

not

run.

Subsequently

replace

print

L-4200

if

the

motor

still

does not

run.

Page 21

What

is

to

be

tested

What

to

adjust

Normal

condition

Print

L-4200/

R-4200

-

Initial

state

of

service

operation

(page

17)

-

Select

test

3

(sewing

trial)

-

The

LED

(signal)

is

Iluminated,

-

Depress

foot

control

the

motor

rotates.

-4

a

Repair

instructions:

-

If

the

LED

osignab)

M

is

not

illuminated:

A

test

should

be

conducted

with

a

new

R-print

and

the

old

L-print.

If

still

faulty,

then

replace

L-print

and

repeat

test.

If

still

faulty,

replace

S-print,

and

if

necessary

check

the

cable

connection

L-/S-print

(refer

to

test

C,

page

22).

Page 22

What

is

to

be

tested

What

to

adjust

Normal

condition

Connection

of

print

S-1230

to

print

1230

-

Take out

mains

plug.

to

print

1230

a)

Disconnect

connectors

from

print

Flat

cord

5

pol,

red

connectors

L-

and

S-4200

Flat

cord

4

pol,

green

connectors

b)

Check

on the

upper

side

of

the

connectors

with

a

circuit

tester

or

ohmmeter

that

each

wire

is

continuous.

c)

Test

every

wire

as

described

in

b).

/

• --

-

High pitched

tone!

Cord

ok.

-

Ohmmeter

shows

a

small

resitance,

cord

ok.

Important:

If

there

is

no

high

pitched

tone,

or

the

display

of

the

ohmmeter

wavers

or

shows

infinite

resistance,

then

the

cord

is

defective.

Replace

connection.

Page 23

What

is

to

be

tested

What

to

adjust

Normal

condition

Mains

cord

(cord

reel)

-

Take

out

mains

plug.

a)

Disconnect

ina

plug

at

P155

on

print

L-4200.

b)

Connect

one

end

of

the

tester

to

the

plug,

then

test

every

wire

to

check

that

a

circuit

can

be

made.

-

Hith

pitched

tonel

Cord

ok.

-

Ohmmeter

shows

a

small

resistance,

cord

ok!

Important:

If

there

is

no

high

pitched

tone,

or

the

display

of

the

ohmmeter

wavers

of

shows

infinite

resitance,

then

the

cord

is

defective.

Replace

cord

reel.

Ila

W

I

0O

Page 24

What

is

to

be

tested

What

to

adjust

Normal

condition

Connection

of

print

S-1

230

to

foot

-

Take

out

mains

plug.

control

plug.

a)

Remove

2

pin

black,

foot

control

plug

from

print

S-1

230.

b)

On

the

upper

connection

side

of

the

print

check with

the

circuit

maker

or

ohmmeter

that a circuit

can

be

made

between

these

and

the

foot

control

plug.

c)

Both

connections

on

foot

control

plug

have

to

be

tested

as

described

above.

m/

-

Hith

pitched

tone!

Cord

ok.

Ohmmeter

shows a small

resistance,

cord

ok.

Important:

If

there

is

no

high

pitched

tone,

or

the

display

of

the

ohmmeter

wavers

or

shows

infinite

resistance,

then

the

cord

is

defective.

Replace

cord.

Page 25

What

is

to

be

tested

What

to

adjust

Normal

condition

Print

P-4200

-

Initial

state

of

service

operation

(page

17)

a)

Using

the

handwheel

-

LEDs

SL,

SB

and

stop

not

illuminated

bring

needle

to

its

zero

position

(lowest

pos.) on

the

service

panel

b)

Rotate

handwheel

forwards

and

check

table

to

the

right

LED

LED

LED

SL

SB

STOP

on

on

off

on

on

on

on

off

on

off

off

on

off

off

off

'I

a

Important:

__

If

the

print

does

not

function

as

required

per

the

table,

then

repeat

tests

a)

and

b)

using a new

print.

If

there

are

still

discrepancies

then

refit

the

old

print,

replace print

S-1230,

and

repeat

tests

a)

and

b).

wo

N,

Page 26

0%

What

is

to

be

tested

What

to

adjust

Normal

condition

Lamp

holder

-

Mains

switch

on.

-

Sewing

light

burns.

a)

Switch

on

sewing

light.

El

L2

.--

4

2-pin

green

Important:

If

the

sewing

light

doesn't

function

and

both

bulbs

are

intact,

then

the

connections

from

L 1,

L2

and

S

to

the

plug

can

be

checked

with

the

circuit

tester

or

ohmmeter.

The

switch

S

can

be

tested

by

putting

the

test

probes

in

the

plug

openings,

and

by

switching

on

and

off

there

must

be

continuity

and

blockage

in

the

circuit.

To

be

sure,

the

same

test

must

be

made

with

the

2-pin

green

plug.

L1

and

L2

can

be

testes

for

continuity

on

the

plug

openings.

Faulty

parts

must

be

exchanged.

0

0

0

Page 27

What

is

to

be

tested

What

to

adjust

Normal

condition

Step

motors,

print

S-1230

-

Initials

tate

of

service

operation

-

Step

motors

rotate

back

and

forth,

(page

17)

feed

dog

and

needle

bar

must

move

-

Select

service

test

programme

6

If

a

step

motor

does

not

rotate,

then

the

fault

can

either

lie

with

the

step

motor,

or

print

S-1230.

The

faulty

components

can

be

identified

by

swapping

the

connections

(plug

P208

with

P207,

step

motors.

Hall

sensors

-

Initial

state

of

service

operation

-

LEDs

for

the

Hall

sensors

on

the

(page

17)

service panel

should

flash

at

the

same

Select

service

test

programme

6

frequency

as

the

stepping

motor

a-

Select

service

test

programme

1

SB

motion

and

2

SL

for

Hall

sensor

position

Zcheck

(test

H2

page

28).

If

the

check

LED

of

the

Hall

sensors

does

not

flash,

then

the

fault

can

lie

in

the

Hall

sensor,

the

mechanical

part

or

40

aw

the

step

motor.

Replace

defective

step

motor

(see

manual

1130,

pages

35

to

41

).

-

Connect

the

removed

motor

and

Hall

sensor

to

print

S-1

230

and

energize

with

the

4200

supply

unit.

-

Manually

slide

magnet

over

the

Hall

sensor.

-

Select

service

test

programme

1

for

-

LED

SB

must

illuminate

SB

step

motor.

-

Select

service

test

programme

2

for

-

LED

SL

must

illuminate

SL

step

motor

SL.

If

the

LED

does

not

illuminate,

replace

the

Hall

sensor

and

adjust

the

step

motor

to

its

zero

position

(service

test

programme

5

,

see

test

0).

Page 28

W

What

is

to

be

tested

What

to

adjust

Normal

condition

Position

Hall

sensor

S.L.

Initial

state

of

service

operation

The

Hall

sensor

position

for

stitch

length

(page

17)

is

displayed

as

a

binary

number

in

the

(Hall

sensor

position))

field.

The

value

Service

programme

no.

1

must

lie

between

2

min.

and

14

max.

M

1023456

0

o0o

1.Example:

8+4+2+1

i~~

W0

0

0

0

-/00-0

illuminated

8 +

2

=

10

OK

112

CD

8+442+1

f

I

2.

Example:

8+4+2+1

00I

"''

10,,

-

illuminated

8

+

4

+

2

+

1

=15

not

OK

a

Position

Hall

sensor

S.B.

Service

programme

no.

2

Same

procedure

as

above,

the

value

must

lie

between

1

min.

and

7

max.

Repair

guide:

If

the

values

cannot

e

reached

then

the

pinion

and

the

magnet

support

must

be

replaced.

(The

freeness

of

movement

in

the

mechanics

must

be

checked.)

Page 29

What

is

to

be

tested

What

to

adjust

Normal

condition

Pinning

position

of

step

motors:

-

Initial

state

of

service

operation

refer

to

section

49,

or

53

model

1130

(page

17)

(pages

41

and

37).

-

The

step

motors

are

activated

to

the

-

Select

service

test

programme

4

step

position

for

pinning.

1

S

En

-6

Page 30

What

is

to

be

tested

What

to

adjust

Normal

condition

Foot

control

When

a

fault

in

the

foot

control

is

-

Reading

(infinite)

suspected,

first

carry

out

test

L.

Connect

the

multimeter

to

the

foot

con-

trol,

and

switch

to

the

range

ohms.

a)

Foot

control

not depressed.

Running

of

main

motor

Needle

stop

down

b)

Depress

the

foot

control

at

the

rear

-

Reading

10

k9

(needel

stop

down).

c)

Depress

the

foot

control

slowly

at

the

-

Reading

varies

rom

4

toO

k9

front.

Important:

If the

foot

control

is

defective,

open

the

foot

control

cover.

Carry

out

tests

a),

b)

and

c)

on

both

contacts.

If

these

give

correct

readings,

replace

the

cord

reel.

If

a

fault

persists,

then

change

the

regulater

housing.

0

Page 31

What

is

to

be

tested

What

to

adjust

Normal

condition

Foot

control

digital/analog:

-

Start

service-programme

-

Connect

foot

control

to

the

machine.

-

Depress

slowly

forwards.

-

LEDs

((analog

and

digitab

are

illuminated.

-I

Repair

instructions:

-

The

s-print

should

be

replaced

if

only

the

((analog

or

dligitak

LED

is

illuminated.

-

The

foot

control

is

defective

if

neither

of

the

LEDs

is

illuminated

{regulater

or

cable).

Page 32

What

is

to

be

tested

What

to

adjust

Normal

condition

Print

A-4200

Switch

mains

supply

off

Print

S-4200

-

Connect

up

the

4200

supply

unit

to

the

....

sewing

light,

main

motor,

connecting

cable

to

print

S-1230

(4-pole

green,

control

signals),

the

connecting

cable

to

print

S-1230

(5-pole

red,

supply).

-

Switch-on

supply

unit.

-

Check

display

panel

-

Bar

graphs

can

be

adjusted.

For

each

button

depressed,

the

associated

LED

illuminates.

-

Start

service

programme

(page

17).

-

Step

motors

rotate

back

and

forth.

Select

service

test

programme

6.

Check

LEDs

SL

and

SB

flash

at

the

same

frequency

as

stepping

motor

motion.

-

Motor

switch

<on>

-

Motor

runs

Important:

Directive:

If

the

above

tests

all

function

Print

S-1230

must

be

replaced,

and

the

test

repeated

if

the

display

panel

is

not

with

the

mains

device,

then

the

fault

can

illuminated,

or

if

step

motors

do

not

rotate.

Replace

print

A-1

230

if

faults

occur

on

only

be

in

the

L-print.

See

test

A.

the

display

panel.

-

If

the

motor

doesn't

run,

exchange

the

motor.

0

0

0

0

Page 33

*

___

___

What

is

to

be

tested

What

to

adjust

Normal

condition

Ret-Button

-

Initial

state

of

service

operation

(Reverse

button)

(page

17)

-

Depress

ret-button

-

LED

Ret>

is

illuminated

I/-

,Z

Ret-button

z

0

Repair

instructions:

-

LED

Ret

is

not

illuminated:

-

A

check

should

first

be

made

as

to

whether

the

switch

is

being

actuated.

If

this

is

not

the

case,

then

the

switch

activater

should

be

mechanically

adjusted

(travel

increased)

until

the

switch

is

actuated.

The

following

procedure

shold

be

followed

if

the

LED

(Ret)

is

still

not

illuminated.

-

Remove

the

P203

6-pole

black

plug

connection

at

the

S-print.

-

Connect

new

Ret-print.

-

Manually

actuate

the switch,

LED

(Ret)

illuminates.

-

Replace

Ret-print.

-

Re-adjust

buttonholer/potentiometer.

CA)

Page 34

What

is

to

be

tested

What

to

adjust

Normal

condition

Equalization

of

the

forward/reverse

-

The

stitch

programmes

no.

28

or

feed.

no.

32

and

the

buttonhole

are

active

in

this

programme.

The

forward/

Directive:

reverse

feed

can

now

be

equalized

First

of

all

the

zero

pos.

of

the stitch

with

the

+

and -buttons

during

length

crank

must

be

checked

(see

sewing,

and

at

full

speed.

The

current

chapter

2,

page

40

Service-Manual

selected

value appears

in

the presser

cl.

1130).

foot

display

(between

0

and

8).

Lower

values:

return

feed

greater

-

The

stitch

pattern

must

be

correct

at

Higher

values:

forward

feed

greater

all

speeds.

-

The

neutral

position

is

at

value

4.

The

selected

value

is

only

then

stored,

when

the

clear

button

is

actuated.

(Normal

value

lies

between 2 and

6).

0

-U

a

0"1

0

Page 35

What

is

to

be

tested

What

to

adjust

Normal condition

-

Automatic

buttonholer

a)

Testing

and

adjustment

I

'H

-

PrintS-1230

-

Initial

state

of

service

operation

(page

17).

-

Print Ret-1130

-

Select

service-programme

5.

-

Bo-

Press

button

for

buttonholing.

-

Mount

buttonhole

foot.

-

Lower

feed-dog.

-

Lower

presser-foot

lifter

lever.

-

Clip

the

adjusting

filter

on

the presser

foot

bar

from

the

right

hand

side.

Slide

it

to

its

highest

position

until

it

V

audibly

clicks

into

place.

With

a

small

screwdriver

rotate

potentiometer

vauto

A ) on

print

S

1230

clockwise

to

its

endstop

(LED

A

does

not

illuminate).

Slowly

rotate

the

potentiometer

in

the

opposite

a

direction,

simultaneously

sliding

the

acarriage

of

the

buttonhole

foot

until

LED

A

just

starts

to

flash.

no.

000.354.70.01

Potentiometer

((auto

B

can

now

be

adjusted

in a

similar

fashion

using

LED

B.

Note:

In

order

to

allow

the

foot

carriage

to

be

moved

easily,

two

smooth

pieces

of

material

should

beplaced

between

the

needle

plate

and

the

foot

cariage.

(Alternatively

use

knee

lever

or lifter

lever

to

weaken

the

pressure

of

the

material

presser

bar.)

U,

Page 36

What

is

to

be

tested

What

to

adjust

Normal

condition

a)

Sewing

a

buttonhole

lights-up

I

-

Press

button

for

required

buttonholer

AUTO

(button

13,

or

14)

-

sews

the

first

bead

-

Depress

foot

control

-

As

soon

as

the

first

bead

has

reached

the

correct

length,

press

button

for

automatic buttonholer.

_m

-

sews

the

first

bar

tack,

then

the

second

bead.

-

LED

changes

to

f

lights-up

-

If

the

two

beads

have

been

sewn

with

-

sews

the

second

bar

tack,

casts

over

differing

densities

then

check

and

then

stops

sewing.

forward/reserve

equalization

using

service

programme

5.

-

Machine

returns

to

initial

position.

In

normal

operation

a

correction

is

possible

with

the

balance

buttons

+.

Important:

The

following

components

should

be

replaced

if

equalization

faults

occur

after

setting

potentiometer

A

+

B,

when

sewing

automatic

buttonholes.

Buttonhole

foot

-

S-1230

print

-

Ret-print.

Please

do

not

forget

to

execute

new

equalization.

*

Page 37

What

is

to

be

tested

What

to

adjust

Normal

condition

The

stitch

length,

width,

LMR

and

the

-

Select

service-programme

3

-

The

machine

can

now

be

sewn-off.

automatic

long

stitch

(not the

basting

stitch)

L.C.R.

Straight

stitch

Stitch

length

and

stitch

width

can

be

adjusted

Longstitch

0

Note:

If

the

normal

condition

is

not

achieved

then

test M must

be

carried

out

first.

Yb

Page 38

What

to

adjust

Normal

condition

Switch

on

bobbin

winder

Bobbin

winder

runs

Switch

off

bobbin

winder

Bobbin

winder

stops

Switch

on

sewing

light

Sewing

light

comes

on

Switch

off

sewing

light

Sewing

light

goes

out

Main

motor

Fully depress

foot

control

Speed

of

sewing

machine

1050

rpm

Stop

from

fastest

speed

Motor

brakes,thread

take-up

lever

is

in

its

highest

position

Press

foot

control

backwards

Machine

positions

in

lower

needle

position

Reverse

button

Sew

forwards

Transport

forward

Press

reverse

button

Transport

reverse

Release

reverse

button

Transport

forward

Basting

device

magnet

Sew

using

basting

device

Every

sixth

stitch

is

sewn

Sew

using

automatic

long

stitch

Every

second

stitch

is

sewn

Sew

using

automatic

buttonholer

Forward

bead

is

the same

length

as

the

return

bead

LED

((AUTO))

lights

up

I!

Stitch

1,

depress

foot

control

for a short

time

Upper

needle

stop

Stitch

1,

press

lower

needle

stop

button

LED

lights

up

Depress

foot

control

for

a

short

time

Lower

needle

stop

Function-tests

electronic

38

1230

Page 39

What

to

adjust

Normal

condition

Rotary

encoder

Adjust

the stitch

width

and

stitch

length

with

the

knobs

Turn

to

the

right

Bar

graph

on

the

display

increase

Turn

to

the

left

Bar

graph

on

the

display

decrease

To

check

the

electrical

transport

equalization,

Sewn

patterns

must

be

closed

sew

using

stitch

28

Press

all

function

buttons

and

check

LEDs

All

LEDs

should

light

up

Press

all

stitch

selection

buttons

The

respective

LED

should

light

up.

one

after

the

other.

Function-test

electronic

1230

39

Loading...

Loading...