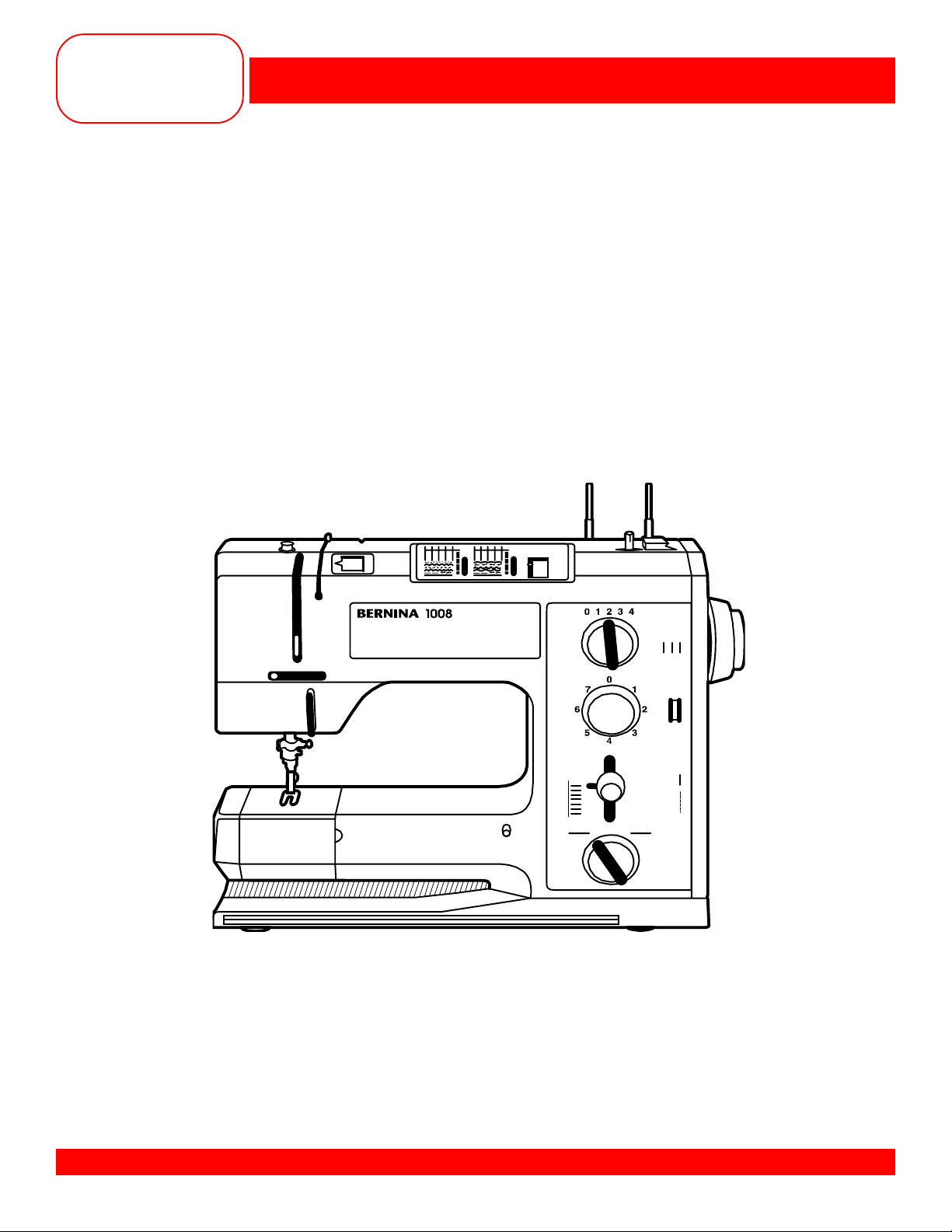

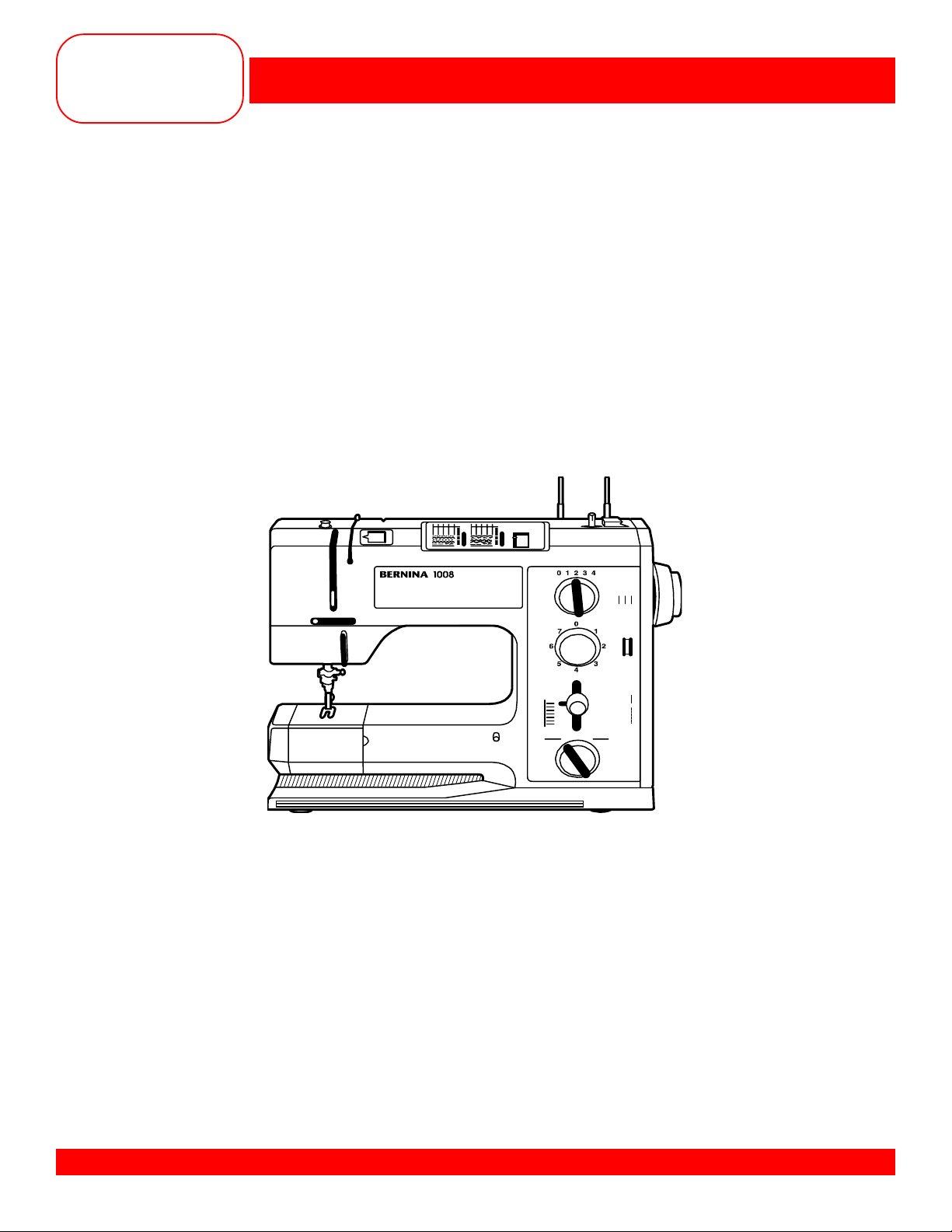

Bernina 1008 Owner's Manual

MASTERING

YOUR

BERNINA

®

BERNINA® Electronic 1008

MASTERING YOUR

BERNINA

Electronic 1008

®

OWNER’S WORKBOOK

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/1

MASTERING

YOUR

BERNINA

®

BERNINA® Electronic 1008

Table of Contents

SECTION A Pages 3-15

Care and Feeding of Your Machine

SECTION B Pages 16-30

Let’s Start WIth The Basics

SECTION C Pages 31-47

On The Edge

SECTION D Pages 48-61

Gather It Up and Tuck It Down

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/2

MASTERING

YOUR

BERNINA

MASTERING YOUR

®

BERNINA® Electronic 1008

®

BERNINA

Electronic 1008

OWNER’S WORKBOOK

Section A

Care and Feeding of Your Machine

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/3

MASTERING

YOUR

BERNINA

®

Care and Feeding of Your Machine

Machine Set Up

Owner’s manual pg.____

• Storage of accessories

• Attach cords foot control and machine

• Power switch – light on/off function

Owner’s manual pg.____

• Extension table (optional)

Presser Feet

Owner’s manual pgs.____

• Importance of using the correct foot

• Stitch selection lever

• Overview of included presser feet

• Can also use one-piece BERNINA® presser feet

Feed Dog

Owner’s manual pg. ____

Threads

Owner’s manual pg. ____

• Types of thread

• Uses for each type of thread

Needles

Owner’s manual pg.____

Bobbins

Owner’s manual pg.____

• Removing the bobbin case

• Winding a bobbin

• Use bobbin thread cutter

• Clip the thread close to the case before

removing the bobbin

Threading the Upper Thread

Owner’s manual pg.____

• Two vertical spool pins – Owner’s manual pg.___

• Optional supplementary thread guide

• Optional BERNINA® thread stand

• Thread machine with the presser foot up until

ready to thread the needle

BERNINA® Electronic 1008

SECTION A

Threading the Needle

• Side thread cutter – Owner’s manual pg.____

• After the needle is threaded, put the thread

under the presser foot

• Lower the presser foot

• Insert the thread into the cutter; it is cut to the

proper length to begin sewing

Needle Positions

Owner’s manual pg. ____

• Five positions

Practical/Decorative Stitches

Owner’s manual pgs.____

• Stitches built into the machine

• Uses for the stitches – Owner’s manual pgs.____

• How to select stitches – Owner’s manual pgs.____

- selection lever

- red vs. green stitches

Straight Stitching

• Seam measuring – stitch plate marks – Owner’s

manual pg.____

- the following measurements are indicated on

the stitch plate: ¼”, 3/8”, ½”, 5/8”, ¾”, and 1”

- the horizontal lines to the far back and the

line in front of the needle are 5/8” from needle

• Optional piecing guide attaches to the bed of

the machine.

• Right and left seam guides and Seam Guides

with Rulers are available as optional accessories

for the one-piece BERNINA® presser feet

• Straight stitch throat plate available

• Basting - Owner's manual pg.___

- maximum stitch length and loosened the

needle tension helps in removal of stitches

Topstitching/Edgestitching

Owner’s manual pgs.____

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/4

MASTERING

YOUR

BERNINA

Satin Stitches

• Thread bobbin case finger to adjust tension

• Can taper while sewing

• Stabilizer – important to the success of stitches

Changing the Light Bulb

Owner’s manual pg.____

Cleaning the Feed Dog

• Periodically remove thread fluff and fabric fuzz

which collects under the stitch plate. Refer to

manual for step-by-step instructions (pg.___).

Cleaning and Lubricating the Hook

• See Owner’s manual page ____ for step-by-step

cleaning and oiling instructions

®

BERNINA® Electronic 1008

Cleaning the Outside of the Machine

• Wipe with damp cloth. If needed, use a solution

of water and a few drops of liquid soap.

IMPORTANT: Never use oil, alcohol, or

solvents of any kind on any part of the

external surface of the machine.

Here’s an idea...Use your birthday

month as a reminder to have your

BERNINA

®

machine serviced. Take

it to an authorized BERNINA

technician during the month

of your birthday and you’ll

never have to remember

when it was last serviced.

®

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/5

MASTERING

YOUR

BERNINA

®

BERNINA® Electronic 1008

THREADS

Poor quality or the wrong type of thread can cause poor stitches on any machine. Thread passes through

the eye of the needle approximately 37 times in a “see-saw” action before it forms a single stitch. Poor

quality thread results in crooked and looped stitches, puckered seams, frayed thread, and/or needle

breakage. To achieve quality stitches, a sewing machine needs three things: correct thread, correct size

needle, and properly adjusted thread tensions.

Several factors such as the fiber, twist, ply, finish, and size of thread must be considered for use with today’s

fabrics for fine stitches.

Staple – refers to the length of fibers used to twist together to form a single ply. Domestic thread

fiber lengths are usually 1½” to 2½” long while European threads use 5½” to 6½” lengths.

Ply – the number of single strands twisted together to make a single thread.

Roll – the tendency of thread to roll to the right or left during stitching, causing the stitch to

appearslightly crooked. Poor quality threads are more likely to roll.

Twist – the crimping of fibers which causes them to interlock firmly into a single ply. Thread should

not untwist during stitching. This will cause skipped stitches, thread breakage, crooked stitches, and

weak spots in seams.

Right twist – most American threads are twisted to the right, causing some rolling.

This gives average stitch quality.

Left twist – Most commercial and imported threads are twisted to the left, giving better

than average stitch quality. Left twist resists rolling and makes a larger loop for the hook

point to enter, reducing skipped stitches.

Wearable art embellishment has necessitated the creation and marketing of many new thread types, such

as Sulky’s rayons and metallics. Made in West Germany, these are left twist threads; Mettler and Isacord

threads are also left twist. To test the twist of a thread: while holding the spool in the left hand, roll the strand of

thread towards you with one thumb. Left twist will tighten, right twist will loosen.

Fiber – refers to the typ eof material used to produce the thread. Some commonly used threads:

• Polyester 2 ply – such as Metrosene 100. Good for clothing construction on man-made,

natural or blended fabrics. Will tolerate heat up to 450° Fahrenheit. Also Isacord

embroidery thread – excellent for embroidery, very abrasion resistant.

• Polyester 3 ply cordonnet – topstitching or buttonhole twist – such as Mettler 30/3.

• Cotton 2 ply – such as Mettler 60/2 – excellent for French Machine Sewing, delicate

machine embroidery, and darning.

• Cotton 2 ply – such as Mettler 30/2 – loose twist for a soft, shiny look in machine

embroidery, applique, and buttonholes.

• Cotton 3 ply – such as Mettler 50/3 – excellent for clothing construction on natural fibers.

Tighter twist than embroidery cotton thread and less puckering on problem fabrics. Cotton

thread stretches less than polyester.

• Rayon – a lustrous embroidery thread. Weaker than cotton, it is used for decorative work only.

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/6

MASTERING

YOUR

BERNINA

®

BERNINA® Electronic 1008

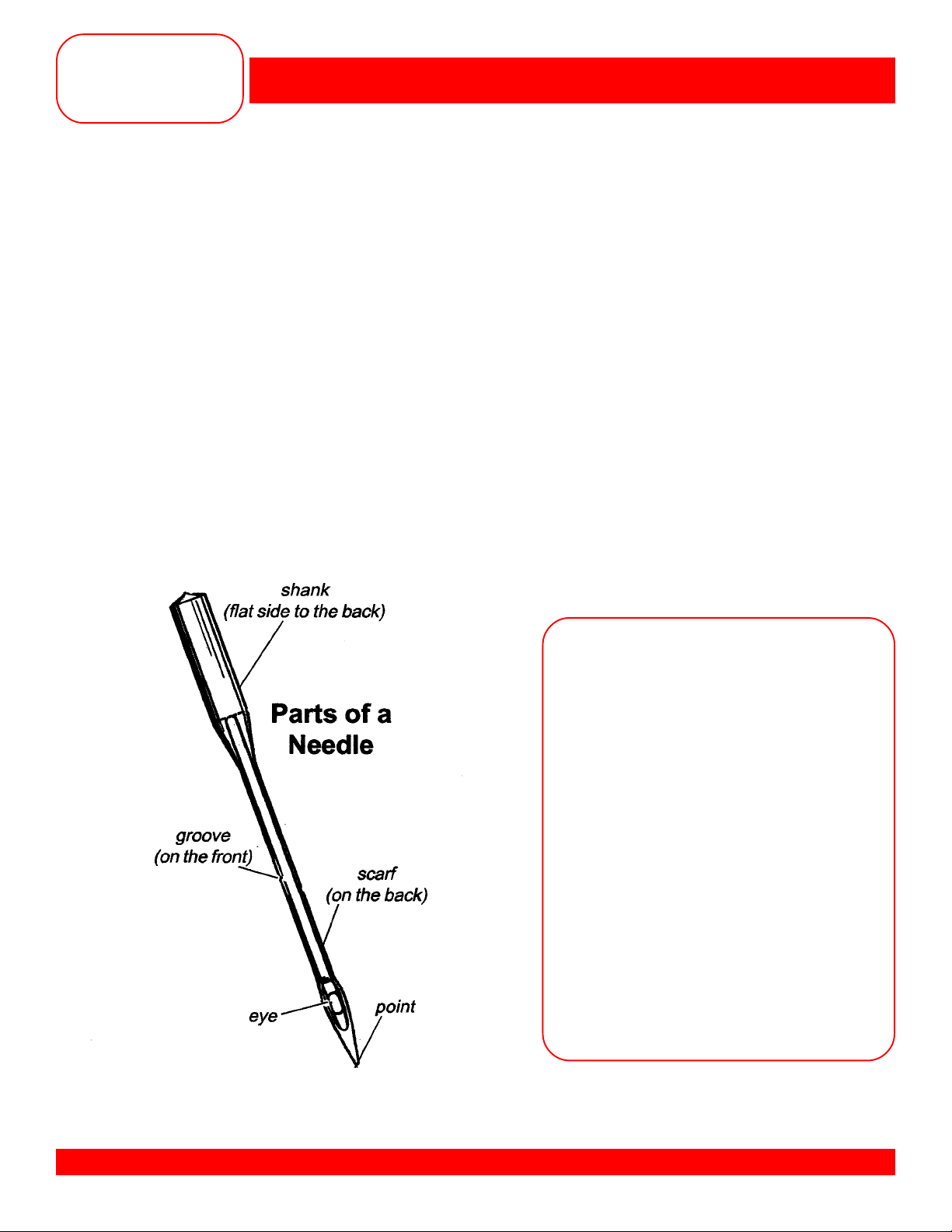

NEEDLES

Along with thread, needles are very important to stitch formation. Many “mechanical” problems and damage

to fabrics can be traced to a bent, damages, or incorrect size or type needle. Approximately 60% of all

needles made are discarded at some stage of production. When selecting the correct needle for any sewing

project, three things must be considered:

Needle system – 130/705H

Needle point – to assure stitch formation and avoid fabric damage

Needle size – small size for lightweight fabrics; larger needle for heavier fabrics

If the needle is:

Too small – the thread can’t stay in the groove to form a loop to be picked up by the hook point

Bent – thread loop forms too far away from hook point; hook can’t enter loop to form stitch

Blunt – needle won’t pierce fabric so no thread loop forms to make a stitch

Need To Know

• Needle should be changed every 4-6

hours of sewing. The needle is the most

inexpensive part in your sewing machine

but is one of the most crucial for getting

good results and keeping your machine

running well. Don’t let false economy

keep you from doing what is best for

your sewing projects and your machine.

• European needles are chrome-plated

to glide in and out of fabric easily.

• The selected thread should fit in the

groove on the front of the needle. If it

isn’t protected by the groove, a needle

with a larger groove should be used.

• Always make sure the needle is fully

inserted as high as possible when

installing a new one.

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/7

MASTERING

YOUR

BERNINA

Ball Point

Stretch

Stretch

Double

Universal

Double

Universal

Triple

(Drilling)

Jeans

Jeans

Double

70-90

70-90

2.5/75

4.0/75

60-110

1.6/70-

8.0/100

3.0/90

70-90

4.0/100

®

SEWING MACHINE NEEDLES

Has a rounder point. 70 for

lingerie, nylon, jersey; 80 for

T-shirt; 90 for sweatshirt fleece.

A stretch needle has a more

rounded point and a blue anticling coating which helps to

prevent skipped stitches in knits

and elastic. Sometimes used on

Ultrasuede

Two ballpoint needles on one

shank; each needle has a large

scarf. Used for hemming and for

stitching on knit fabric.

A compromise between a sharp

and a ballpoint needle; can be

used on both wovens and knits.

60 – very fine batiste

70 – broadcloth

80 – trigger and gabardine

90 – denim and twill

100 & 1 10 – canvas

Two needles attached to one

shank. Used for pintucks, hems,

and decorative work.

Three needles attached to one

shank. Used to create mock

smocking and other decorative

effects.

Has a sharp point and a shaft

that is less prone to flex. The

sharpness of the needles makes

it better for use on denim and

woven fabrics where a clean

stitch is desired.

Two Jeans needles attached to

one shank. For topstitching on

denim with heavy thread; can

also be used for decorative

stitching with metallic thread.

®

, vinyl, and plastic.

BERNINA® Electronic 1008

Microtex

Sharp

(Schmetz)

Microfiber

(Lammertz)

Quilting

Topstitch

Embroidery

(Schmetz)

Metafil

(Lammertz)

Metafil

Double

Wing

Double

Wing

Leather

60-90

assort’d

(75 &

90)

80-100

75-90

3.0/75

100120

100

80-90

A sharp point with a thin shaft.

60-90 corresponds to the weight

of the fabric; as the fabric gets

heavier, the number is higher.

The thin, tapers point of this

needle causes less damage to

fabric when seaming and cross

seaming.

A sharp point with a large eye

and deep groove. For use with

heavier fabrics – the large

groove cradles heavier threads.

Sharp needle with a large eye

and groove; also has a coating

and a larger scarf. For use with

embroidery thread – prevents

shredding of rayon or metallic

threads. Two threads may be

used through the eye of an 80

or 90 needle.

Two Metafil needles attached to

one shaft; for double needle

work with embroidery threads.

Sharp pointed needle with a noncutting wedge of metal on each

side. Needle makes a hole in the

fabric without cutting the threads

of the fabric. Used for decorative

and heirloom work, such as

hemstitching. Works best on

natural fibers or on the bias.

One regular needle and one wing

needle attached to a single shaft.

Use the same as a Wing; makes

one large and one regular hole.

Point is a sharp cutting wedge.

Used for sewing leather only. Not

for vinyl or simulated leathers.

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/8

MASTERING

YOUR

BERNINA

®

BERNINA® Electronic 1008

NEEDLE POSITIONS

Fabric: Firmly woven fabric, 4” x 6”

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidery

Presser Foot: Reverse Pattern Foot #1

Owner’s manual pg.____

• The 1008 has 5 fixed needle positions.

• Fold fabric in half to 2” x 6”.

• Select Straight Stitch. The needle position can be set

to the left or right using the knob in the center of the

stitch width knob.

• Position the fold of the fabric on the 1” mark on the

right side of the stitch plate.

• Sew about 6 stitches and stop.

• Move the needle one position to the left.

• Sew another 6 stitches and stop again.

• Repeat until all three positions have been sewn.

• Raise the needle out of the fabric. Leaving the fabric

under the foot – move the needle position back to

center.

• Sew about 6 stitches and stop.

• Move the needle one position to the right.

• Sew about 6 stitches and stop.

• Move the needle one more position to the right – sew

another 6 stitches and stop again.

• Repeat until all three positions have been sewn.

Contrasting color

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/9

MASTERING

YOUR

BERNINA

®

BERNINA® Electronic 1008

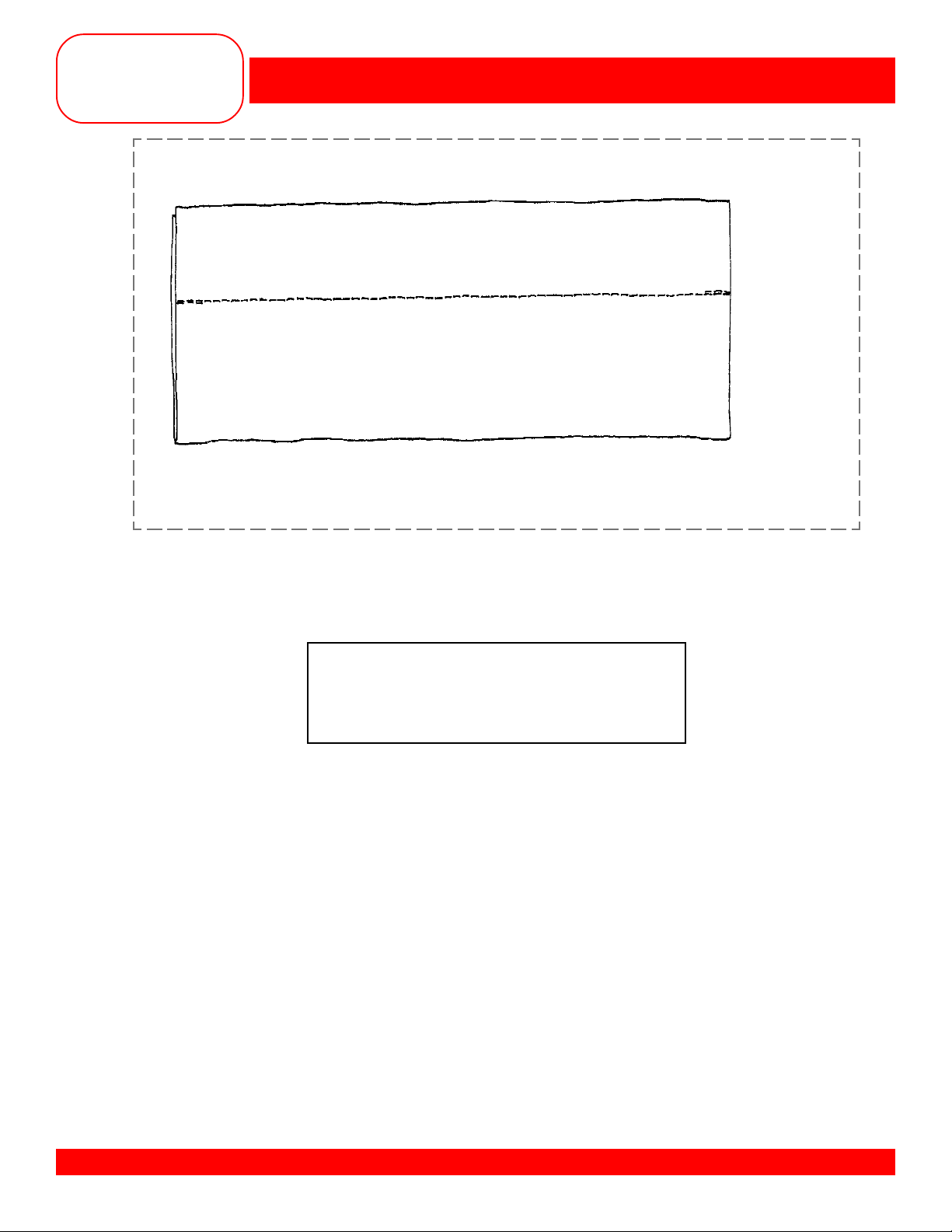

SEAMING

Fabric: Firm fabric – 2 pieces, 4” x 6” each

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidery

Contrasting color

Presser Foot: Reverse Pattern Foot #1

Owner’s manual pg.____

• Find the 5/8” guide line on the stitch plate.

• Place fabric pieces right sides together and

align them with the guide line.

• Sew a 5/8” seam on one 6” edge.

• Sew a 2” seam along the opposite edge.

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/10

MASTERING

YOUR

BERNINA

®

BERNINA® Electronic 1008

BASTING

Fabric: Firm fabric – 2 pieces, 4” x 6” each

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidery

Presser Foot: Reverse Pattern Foot #1

Owner’s manual pg.____

• Place fabric pieces right sides together.

• Select Straight Stitch #1; adjust the length to 5mm

• Baste a

MASTERING YOUR BERNINA® 1/10/02

5

/8” seam along one edge of the fabric.

Note: Loosening the top tension makes the stitches easier to remove.

Contrasting color

Electronic 1008/11

MASTERING

YOUR

BERNINA

®

BERNINA® Electronic 1008

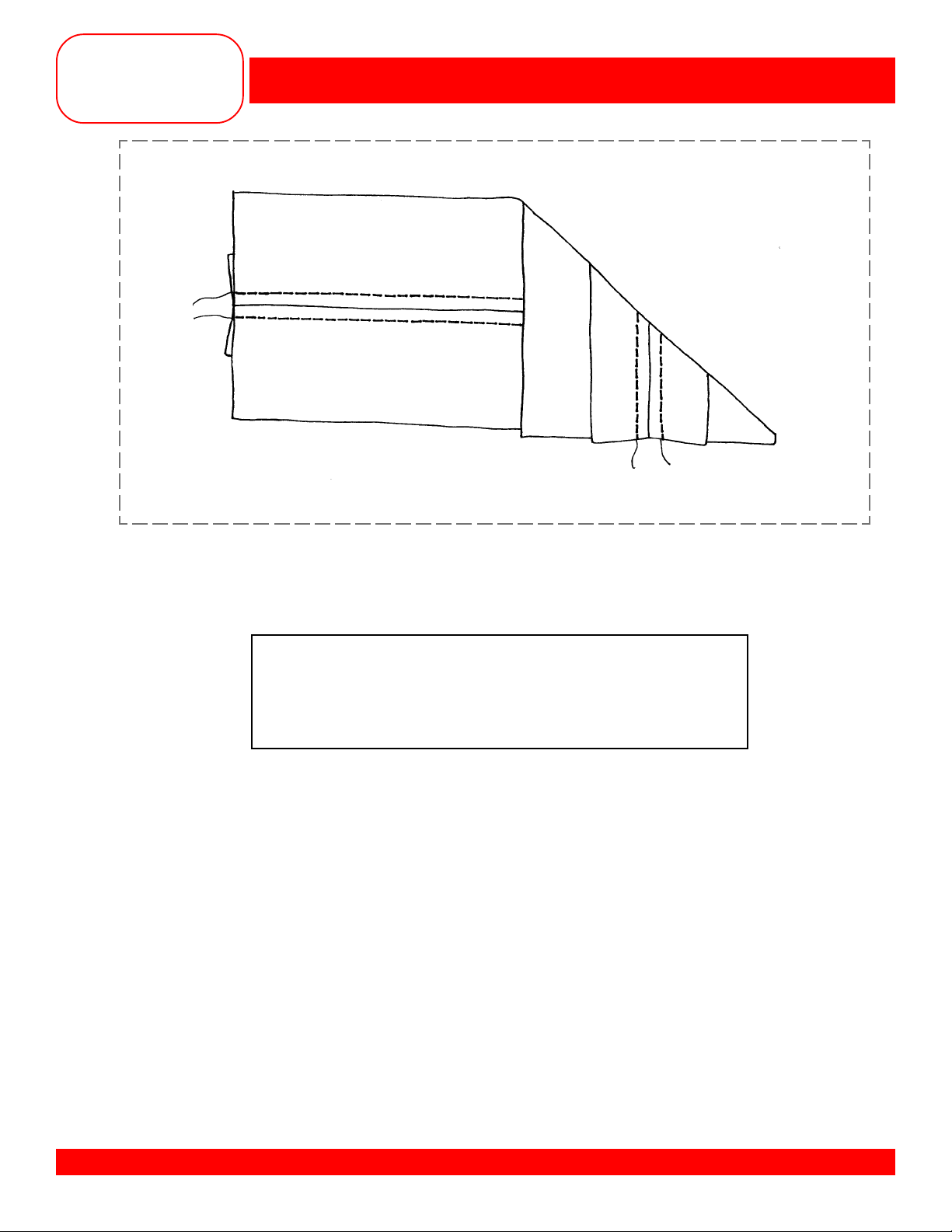

TOPSTITCHING/EDGESTITCHING

Fabric: Firm fabric – 4” x 6”

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidery

Contrasting color

Presser Foot: Edgestitch Foot #10 (optional accessory)

Owner’s manual pg.____

• Cut fabric in half to create 2 pieces each 2” x 6”.

• Sew two pieces together with a

• Press the seam open.

• From the right side, position the blade of the foot in the ditch of the seam.

• Select Triple Straight Stitch #9/red.

• Move the needle position 1 place to the left (half left).

• Sew the length of the seam.

• Select the longest stitch length.

• Move the needle position 2 places to the right (far right).

• Start at the top of the seam as before.

• Sew down the length of the seam again.

5

/8” seam on the 6” sides.

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/12

MASTERING

YOUR

BERNINA

®

BERNINA® Electronic 1008

SECURING STITCHES

Fabric: Firm fabric, 3” x 6”

Needle: 90/14 Embroidery

Thread: 30 wt. cotton embroidery

Presser Foot: Reverse Pattern Foot #1

Owner’s manual pg.____

• Fold each fabric piece in half to 1½” x 6”.

• Find the

• Select Straight Stitch #1/green and sew a few stitches.

• Engage the Reverse Lever for about 3/8”; the machine will sew in reverse as long as the lever is engaged.

• Continue stitching the seam and secure the end in the same manner.

5

/8” seam line on the guide plate.

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/13

MASTERING

YOUR

BERNINA

®

BERNINA® Electronic 1008

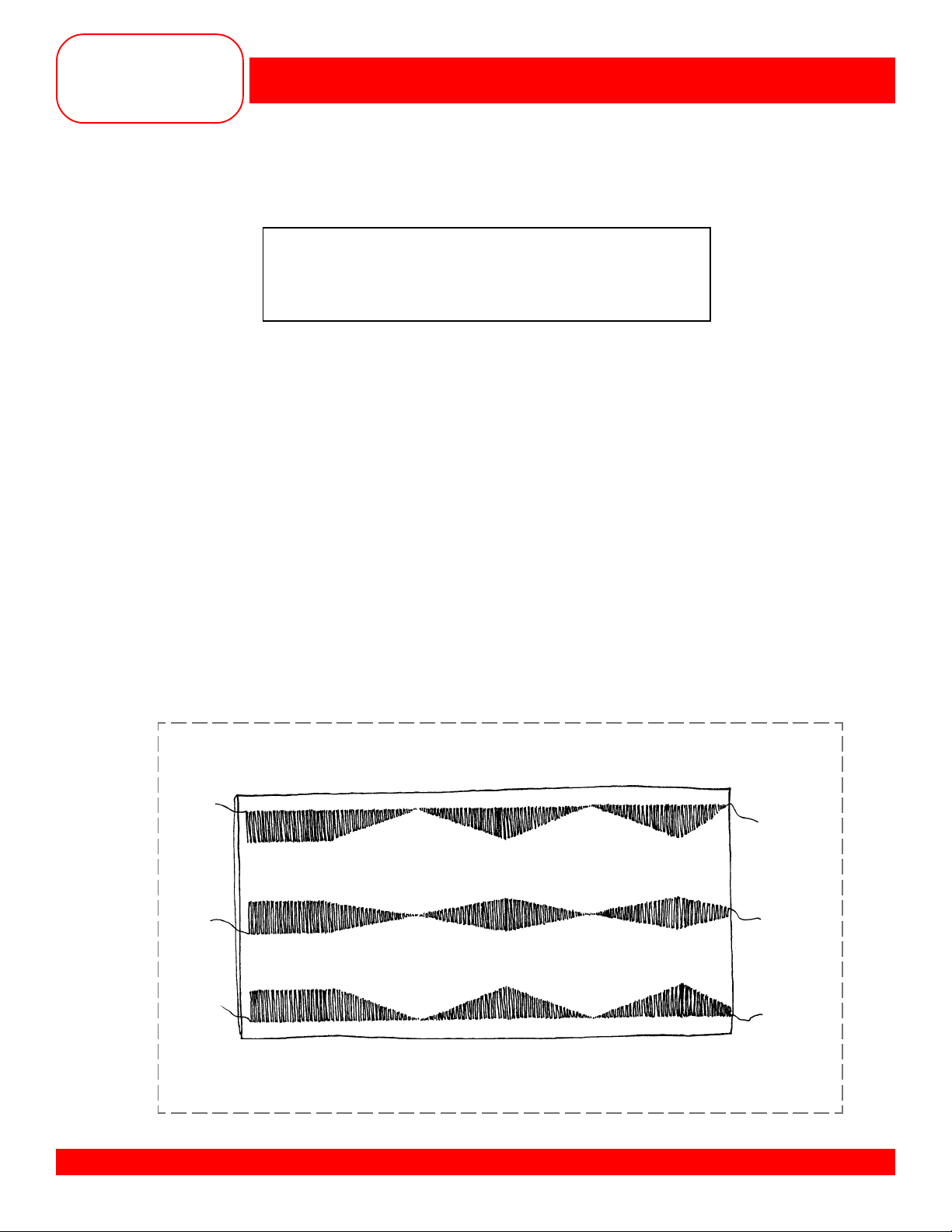

SATIN STITCH

Fabric: Firm fabric – 2 pieces, 3” x 6” each

Needle: 90/14 Embroidery

Thread: 30 wt. Cotton Embroidery

Presser Foot: Reverse Pattern Foot #1

Owner’s manual pg.____

• Fold fabric in half to 3” x 6”. Use stabilizer as needed.

• Select Zigzag Stitch #2/green. Change the stitch length to satin stitch and the stitch width to 5.5mm.

• Thread the bobbin thread through the hole in the finger of the bobbin case.

• Move the needle position all the way to the left.

• Position the raw edge of the fabric on the 3/8” line (on the right side of the stitch plate).

• Sew down this edge about 1”. While continuing to sew, turn the stitch width knob to taper the stitch to

0mm. Then widen the stitch back to maximum. Repeat until the stitching reaches the end of the fabric.

• Position the fold of the fabric on the 3/8” line (on the left side of the stitch plate).

• Move the needle position all the way to the right and stitch along the right side of the fabric, tapering

and widening the stitching while sewing.

• Move the needle position to the center and stitch down the center of the fabric, tapering and widening

the satin stitch while sewing.

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/14

MASTERING

YOUR

BERNINA

Hard Case

Slide-on Extension Table with Guide

Feet-ures

Edgestitch Foot #10

Stabilizers – Sampler Pack or type __________

Thread – Assortment or size ____ and type ____

Needles – Assortment or size ____ and type ____

Needle Threader

Bobbins – Baker’s dozen

Spool Bobbin Holders

Magnetic Pin Cushion

Magnetic Bobbin Holder

Straight Stitch Plate

Seam Sealant

Extra Thread Stand

Scissors - 6” or 7” Dressmaker’s shears ____

Left guide (matches right guide included with machine)____

Right and Left Seam Guides with Rulers

Set of Magnifying Glasses

®

BERNINA® Electronic 1008

WISH LIST

Care and Feeding of Your Machine

type __________

size ____ and type ____

size ____ and type ____

size ____ and type ____

size ____ and type ____

4” or 5” Trimming scissors ____

Thread nips ____

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/15

MASTERING

YOUR

BERNINA

MASTERING YOUR

®

BERNINA® Electronic 1008

®

BERNINA

Electronic 1008

OWNER’S WORKBOOK

Let’s Start With The Basics

MASTERING YOUR BERNINA® 1/10/02

Section B

Electronic 1008/16

MASTERING

YOUR

BERNINA

®

Let’ s Start With The Basics

Seams

Triple Straight Stitch – SL 2-3mm

Owner’s manual pg.____

• Jeans Foot #8 prevents needle deflection

• Non-Stick Straight Stitch Foot #53

• This stitch sews strong seams on heavy

fabrics

Zigzag – SL1mm SW1.5mm

Owner’s manual pgs.____

Vari-Overlock – SL1mm SW4mm NP right

Owner’s manual pg. ____

• Can be used with double needle for a

decorative hem on knits

• Overlock Foot #2 prevents the seam from

rolling as it is being sewn

Double Overlock – SL2mm SW5mm

Owner’s manual pg. ____

Flat Joining Seam - SL2mm SW4mm

Owner’s manual pg.___

BERNINA® Electronic 1008

SECTION B

Oversewing Edges

Owner’s manual pg.____

Hems

Blind Hem – Owner’s manual pg.____

• The Blind Hem Foot #5, along with the

blindstitch, produces a superior blind hem.

The zigzag part of the stitch is formed over

the guide on the foot, causing the stitch to

be slightly loose, so that the blind hem will

not pucker and does not form a tuck in the

fabric.

Hand Picked – Feet-ures, Unit B pg.____

Triple Zigzag – Feet-ures, Unit A pg.____

• This stitch is used for strong, visible hems

on firm, coarse fabrics such as denim and

canvas.

Double Needle – Feet-ures, Unit A pg.___

Neckline Hem – Owner’s manual pg.____

Stitching Corners

• Use the 5/8” markings on stitch plate.

• Turn handwheel counter clockwise to sink

needle into fabric.

MASTERING YOUR BERNINA® 1/10/02

Jeans – Feet-ures, Unit B pg.____

• Height Compensation Tool

Electronic 1008/17

MASTERING

YOUR

BERNINA

®

BERNINA® Electronic 1008

TRIPLE STRAIGHT STITCH

Fabric: Denim, 4” x 6”

Needle: 90/14 Jeans

Thread: All-purpose

Presser Foot: Reverse Pattern Foot #1

Edgestitch Foot #10 (optional accessory)

Owner’s manual pg.___

• Cut the fabric in half lengthwise forming two pieces, 2” x 6” each.

• Select the Triple Straight Stitch #9/red.

• Sew the two pieces together with a

• Press the seam open.

• Change to Edgestitch Foot #10 and adjust the needle position to stitch through the seam allowance.

• Adjust the stitch length to 3.5mm.

• With the guide of the foot in the ditch of the seam, topstitch the length of the seam on both sides.

5

/8” seam allowance using Reverse Pattern Foot #1.

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/18

MASTERING

YOUR

BERNINA

®

BERNINA® Electronic 1008

ZIGZAG SEAM

Fabric: Firm knit – 4” x 6”

Needle: 80/12 Universal

Thread: All-purpose

Presser Foot: Reverse Pattern Foot #1

Owner’s manual pg.___

• Cut the fabric piece in half lengthwise, creating two pieces, 2” x 6” each.

• Select the Zigzag Stitch #2/green – SW 1mm and SL 0.5mm.

• Position the fabric to produce a

• Stitch the seam.

• Clip one seam allowance in the middle.

• Press one part of the seam open and leave the other half closed, so the stitch is visible.

• Trim and mount the sample.

5

/8” seam down one side.

MASTERING YOUR BERNINA® 1/10/02

Electronic 1008/19

Loading...

Loading...