Bernal Sensor-Line S 401 Instruction Manual

Instruction manual

Sensor-Line S 401

Please keep this manual in a safe place.

S 401 GB - 1 - 03-06

G

B

B 190.028-GB

S 401 GB - 2 - 03-06

Index

1.0 Technical Data .................................................................................................... 3

2.0 General Instructions........................................................................................... 4

2.1 General safety instructions................................................................................ 4

2.2 Designated use................................................................................................. 4

2.3 Indication for operating...................................................................................... 4

3.0 Drive assembly ................................................................................................... 6

3.1 Scope of supply................................................................................................. 6

3.2 Required tools ..................................................................................................... 6

3.3 Installation requirements....................................................................................... 6

3.4 Assembly ............................................................................................................ 7

3.5 Installation......................................................................................................... 9

3.6 Initial operation................................................................................................ 13

3.6.1 Insert red/green light module.................................................................... 13

3.6.2 Functions and connections....................................................................... 14

3.6.3 Set-Up...................................................................................................... 15

3.6.3.1 Adjustment of force and travel ........................................................................15

3.6.3.2 Individual adjustments.....................................................................................15

3.6.4 Perform safety check................................................................................ 18

3.6.5 Warning notices........................................................................................ 18

3.6.6 Radio........................................................................................................ 18

3.6.6.1 Installation of the radio....................................................................................18

3.6.6.2 Set-Up of the radio.........................................................................................18

3.6.6.3 Testing the radio .............................................................................................18

4.0 Maintenance...................................................................................................... 19

5.0 Demounting and disposal................................................................................ 19

6.0 Failure analysis................................................................................................. 20

7.0 Operating Instructions radio system PICO, 868,5 MHz................................. 21

8.0 TÜV-Certificate.................................................................................................. 22

9.0 TÜV-Doors......................................................................................................... 22

10.0 EC-Manufacturer's Declaration ..................................................................... 23

11.0 EC- Manufacturer’s Declaration according to EC Directive........................ 24

12.0 Handing over................................................................................................... 24

S 401 GB - 3 - 03-06

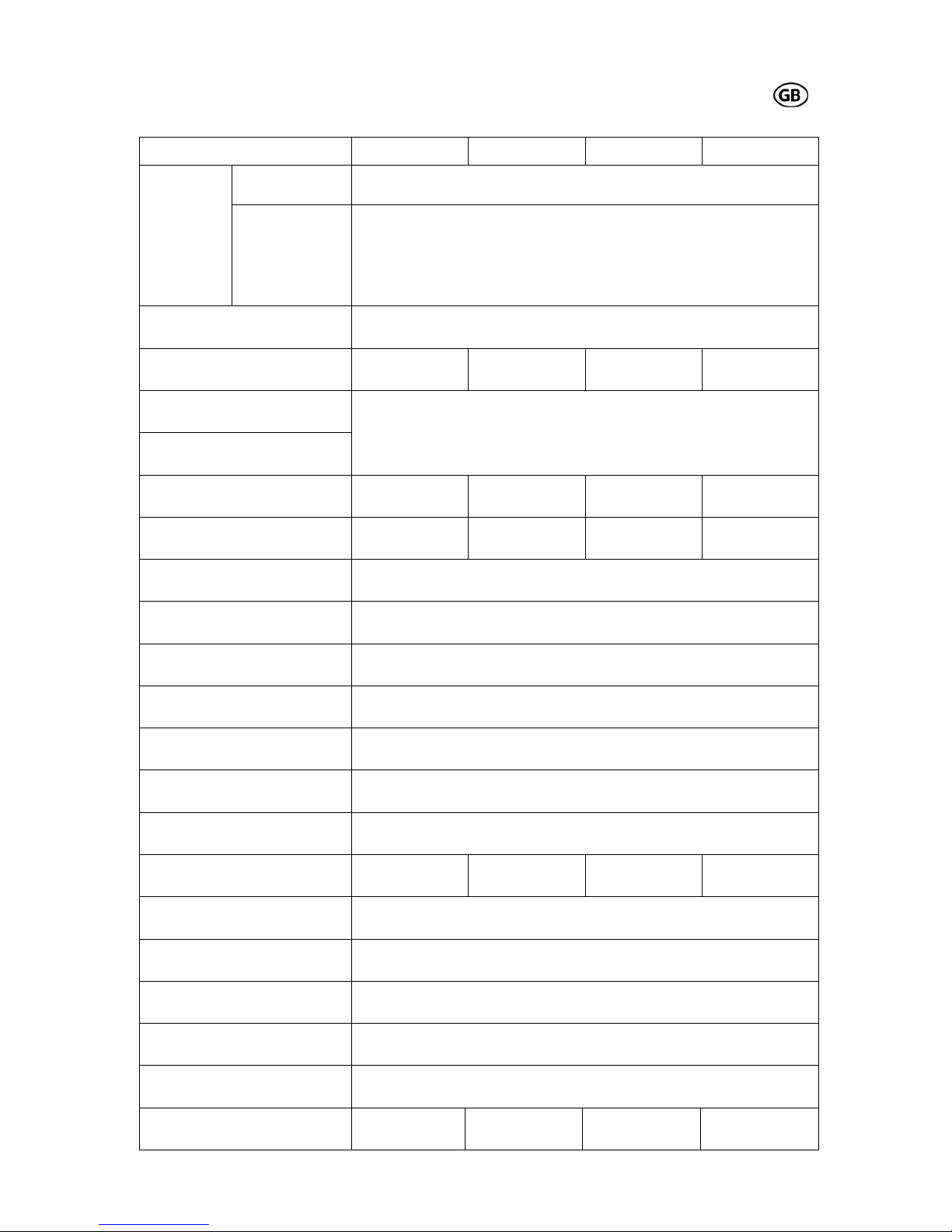

1.0 Technical Data

Description S 401-60 S 401-80 S 401-100 S 401-120

standard circuit

board

B 300.01

head

variations

optional red /

green light mod-

ule (red / green

light red/ green,

230VAC, 50Hz,

1A)

B 300.04

electric supply 230 V / 50 Hz

temporary peak load max. 600 N max. 800 N max. 1000 N max. 1200 N

motor voltage

circuit board voltage

0 – 24 VDC

motor power max. 110 W max. 120 W max. 150 W max. 180 W

tractive- /pressure power max. 600 N max. 800 N max. 1000 N max. 1200 N

switch-on-time 30%

speed (without load) max. 14cm/sec

lighting 40W/230V (E14)

duration of lighting 30-180 sec

Radio (standard delivery) 868,5 MHz

ambient temperature -20°C/ +40°C

idle running – power loss < 1 W

fusible cut-out

F1:3,15AT/250V

F2:6,3AT/250V

F1:3,15AT/250V

F2:6,3AT/250V

F1:3,15AT/250V

F2:10AT/250V

F1:3,15AT/250V

F2:10 AT/250V

minimum mounting height 35 mm

overall drive length 3,31 m

head height 145 mm

ca. weight (with 3,00m rail) ca. 18 kg

travel path (with 3,00m rail) 2,40 m (with extension up to 5,4 m possible)

max. area of door (smooth

running, good balanced doors)

8 m² 10 m² 12 m² 14 m²

S 401 GB - 4 - 03-06

2.0 General Instructions

This instruction manual is being released by

BERNAL without any warranty.

BERNAL reserves the right to make changes

or modifications on the equipment at any time

and on this manual without giving any prior

notes.

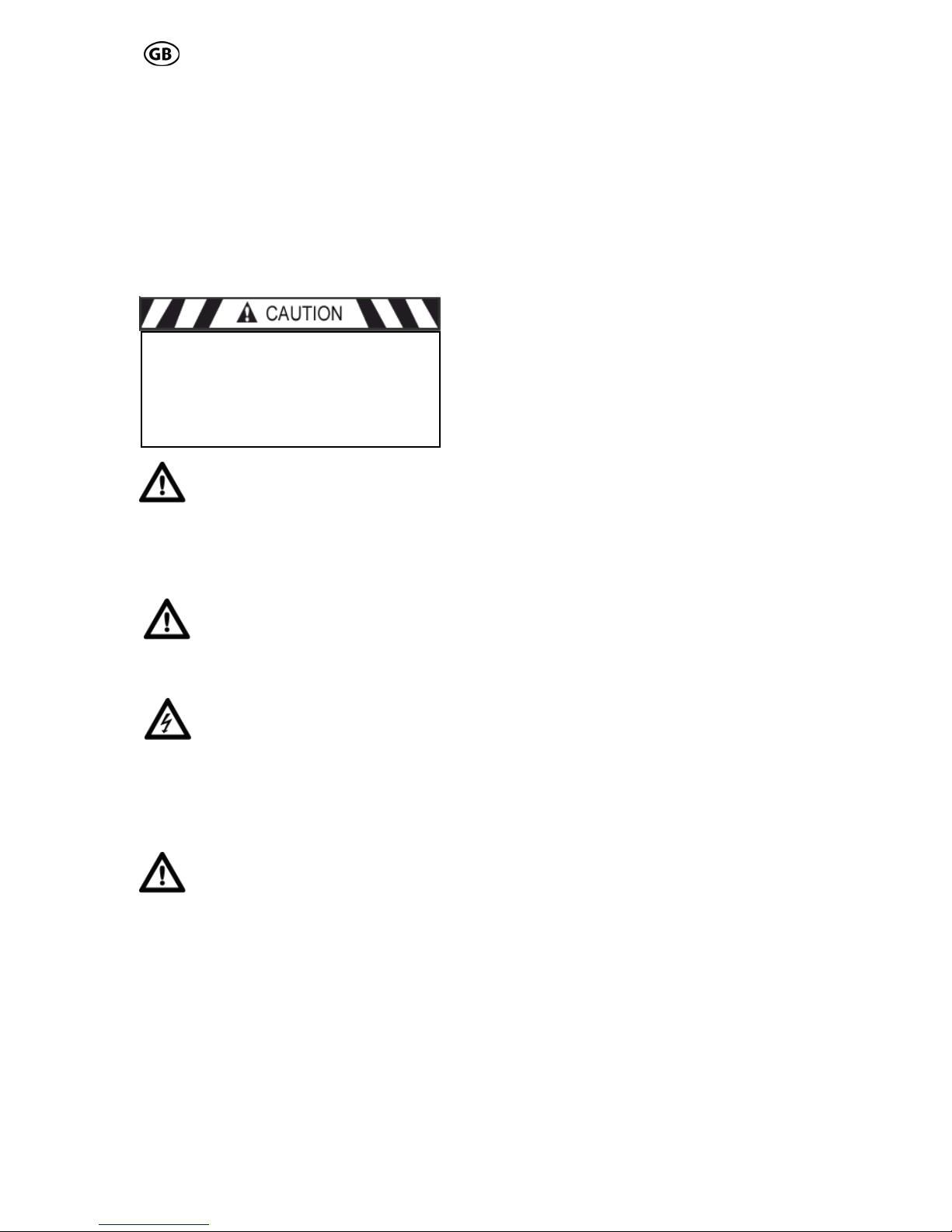

2.1 General safety instructions

Important Safety Instructions:

Qualified personnel should only

perform the assembly and installa-

tion of the garage door opener.

Faulty installation may lead to serious injuries! Disconnect power plug before any

work on the device is done. (except on test

and learning procedures) !

On installation the relevant regulations for the operational safety act

/ employers mutual insurance association have to be followed, e.g. UVV, DIN

EN 60335-1 and VBG4.

The electro installation has to be

performed by a qualified electri-

cian, and has to conform to the

relevant industrial safety regulations, according to DIN VDE 0100 and DIN VDE 0113.

The power point must be easily accessible

and at a max. distance of 50cm from the

opener head.

Do not operate the garage door

opener at all, until it is confirmed,

that the garage door is in accordance with the safety norm 98/37/EG and a

valid EC-Declaration of Conformity certificate is issued.

.

An improper installation or any change to the

opener without the manufacturers previous

approval, any warranty or product liability is

null and void. The installation has to be performed in accordance with this instruction. The

installation of foreign elements endangers the

safe operation of the opener and is not permitted.

You have to pay attention that the relevant national VDE-regulations for operating electrical

appliances are strictly adhered to.

We do not take any responsibility for the improper operating or maintenance of the door,

accessories and the opener.

2.2 Designated use

The garage door opener is designed only for

the operation with well-balanced swing- and

sectional doors in the non-commercial sector.

The recommended max. door measurements

are listed under 1. Technical Data. The door

has to be in accordance with the valid specifications (e.g. DIN EN 12604 and DIN EN

12605). Before mounting the opener, check

that the door can to be easily moved by hand.

FOR THE SAFETY AND LIFE OF PERSONS IT IS ABSOLUTELY NECESSAR

Y

TO FOLLOW ALL INSTRUCTIONS.

KEEP THESE INSTRUCTIONS

The opener is designed for the operation in dry

rooms.

The garage ceiling has to be constructed, so

that a safe attachment of the opener is assured.

2.3 Indication for operating

For garages without a second entrance, a

emergency release is necessary. A function

test of the emergency release has to be carried out monthly!

Do not hang on the cord of the emergency release with your weight!

Make sure, that the emergency release of the

opener does not collide with the roof rack or

any protrusions of the vehicle or the door.

Instruct all persons, who are using the garage door and opener, about a safe and

proper handling. Demonstrate and test the

reversion (with a 50 mm high obstacle at

max. 150 N) as well as the mechanical

unlocking.

Operate the door only, when you can see

the whole door area unobstructed. Pay attention, that there are no persons or any

objects in the door operating area.

Wait until the door stands still. Persons or

vehicles are only allowed in door operating

area, when the door is completely open and

at standstill.

S 401 GB - 5 - 03-06

oor, opener and extra installed safety ac-

ttention:

an shut down faster with weak,

hen service- or adjustment work is ur-

Do not permit children to

play with the automated garage door. Transmitters are

to be kept safe and away

from children !

Fixed accessories (like key switch or similar) have to be attached in sight of the door.

The accessory distance to the moving parts

of the door, and at a minimum mounting

height of 1,80m. Accessories have to be installed beyond the reach of children! Alert

stickers against pen in have to be put close

to the fixed key switch.

D

cessories have to be checked regularly.

See chapter 4 maintenance.

A

The door c

broken or damaged springs or a defective

counterweight. Under this circumstances

using the emergency release may lead to

uncontrolled movements of the door.

W

gently required, do not use the opener . A

badly balanced door, or a faulty garage

door drive may cause damage and injuries.

S 401 GB - 6 - 03-06

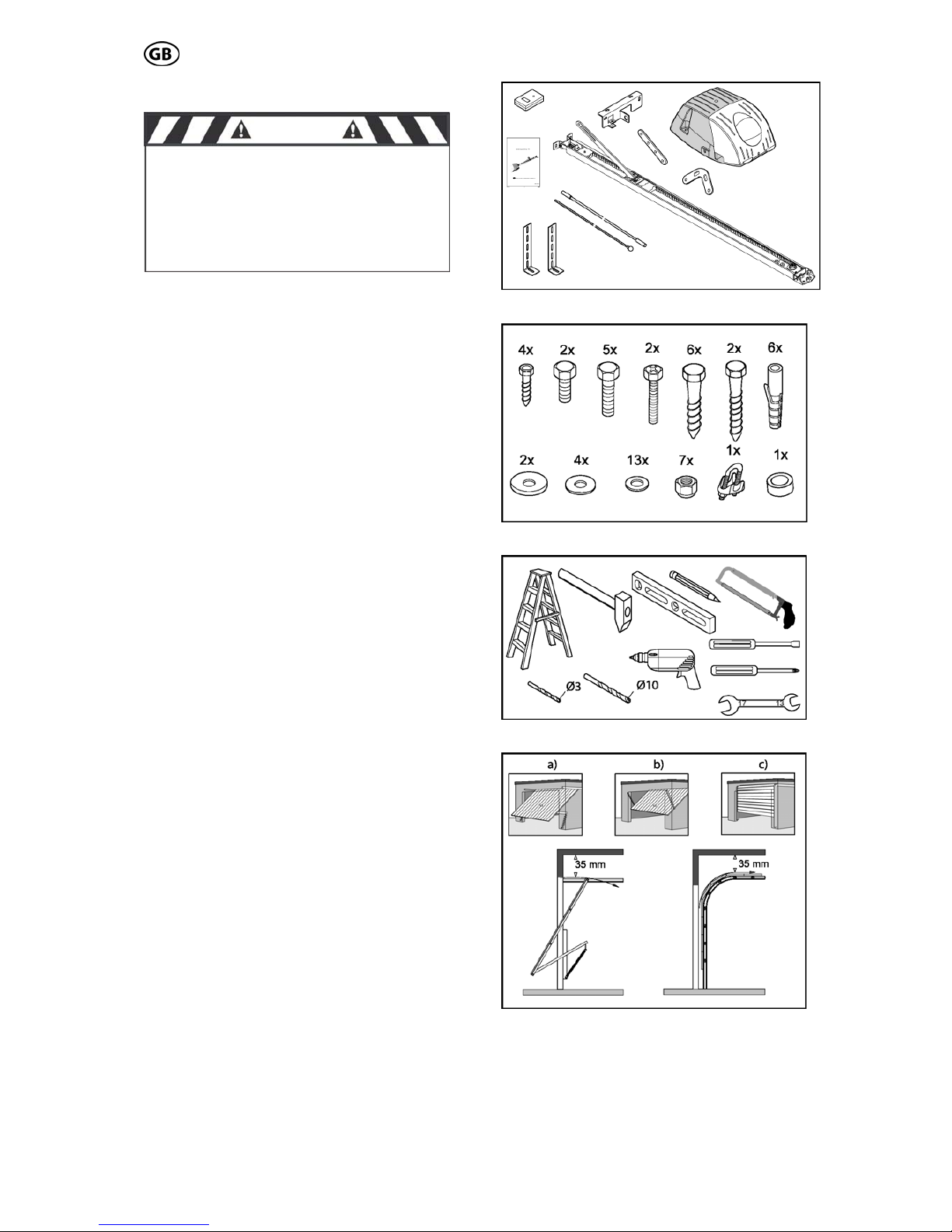

3.0 Drive assembly

3.1 Scope of supply

The scope of supply, as shown on the Fig. 1

and 2, may vary according to the drive version.

3.2 Required tools

For the assembly und mounting of the drive

the tools shown in Fig. 3 are required (not in

the scope of supply).

3.3 Installation requirements

The garage door opener is suitable for the

automation of spring balanced swing doors

(Fig. 4a) and sectional door (Fig. 4c).

(max. sizes see 1.0 technical data).

For an optimal attachment of the push rod to

the sectional door, a sectional door attachment

is available as an accessory.

For doors, that are non-protruding up-andover, a curved arm is available as accessory.

(Fig. 4b)

For the mounting a minimum lintel height of 35

mm is necessary (Fig. 4).

Fig.1

CAUTION

IMPORTANT INSTRUCTIONS FOR A

SAFE MOUNTING

ATTENTION – INCORRECT MOUNTING

MAY LEAD TO SERIOUS INJURY – ALL

MOUNTING INSTRUCTIONS HAVE TO

BE FOLLOWED

Fig. 2

Fig. 3

Fig. 4

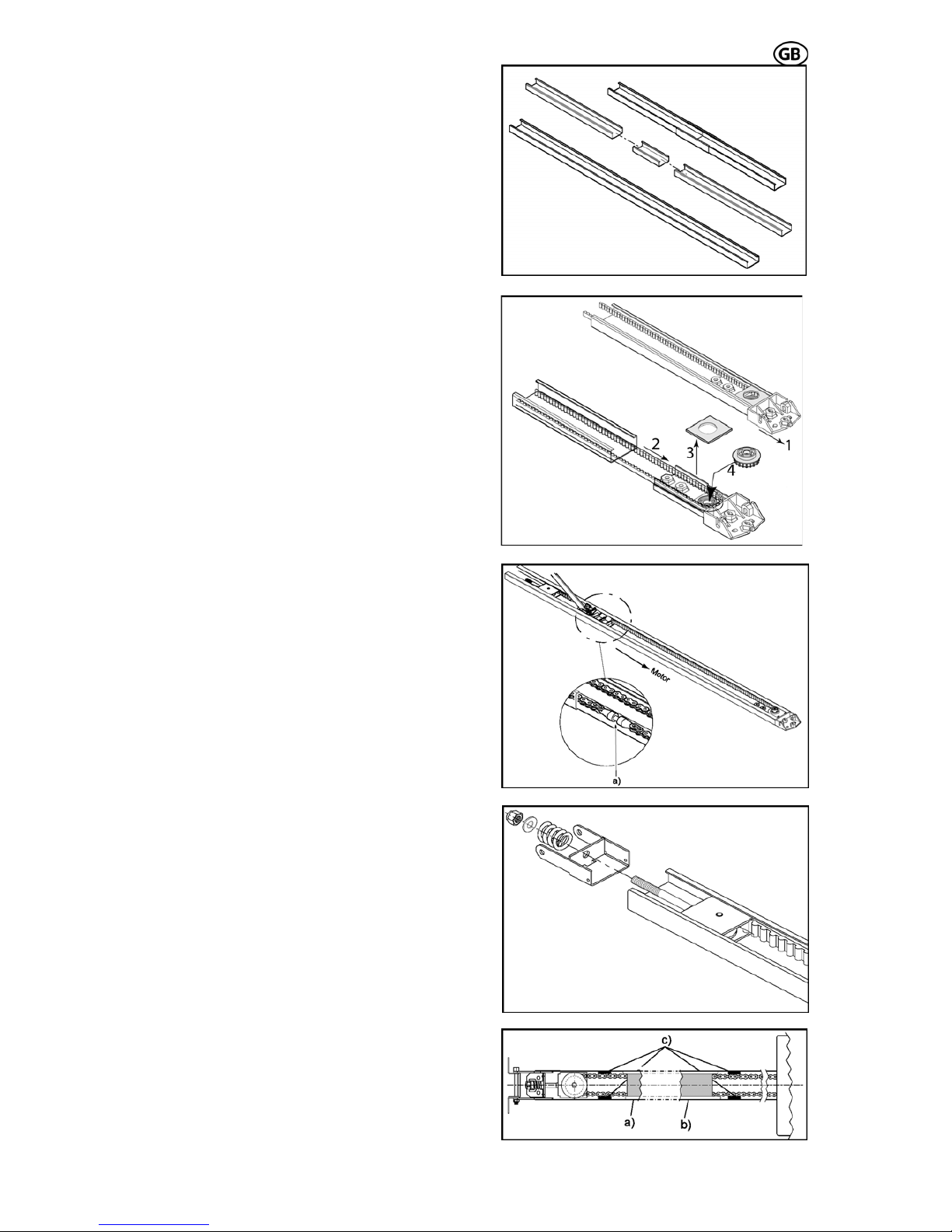

3.4 Assembly

Pre-assembly of rail

According to the version, the rails have to be

pre-mounted as requirements.

Put the rails together via the connection rail.

(Fig. 5) Slide the rails together to the stop position.

Pull the rear bracket (Fig. 6.1) together with the

belt (Fig. 6.2) out of the rail. Remove the

transportation covering (Fig. 6.3) and press the

pinion (Fig. 6.4) into the bearing. Take care of

the belt not being squeezed. Then attach the

transportation covering again and push the

complete rear bracket back into the rail.

S 401 GB - 7 - 03-06

Adjust the tension of the chain or belt by pulling the idler wheel towards the chain end.

Make sure, that the chain lock (Fig. 7a) is on

the left side of the rail. (Fig. 7)

Then push the tensioning bracket towards the

end of the chain and guide the coach bolt

through the hole of the tensioning bracket. Pay

attention that the coach bolt fits into the tensioning bracket.

Push the provided spring and washer on the

end of the coach bolt and screw the nut on the

coach bolt. (Fig. 8)

Paste rubber buffers

If you have a chain drive, we recommend sticking the provided rubber buffers to the inside of

the rail (Fig. 9c). Those serve to minimize the

noise caused, when the chain touches the rail.

Assure, that the rubber buffers are not in the

travel path of the trolley. The buffers have to

be put close to the end of the chain, so that the

trolley doesn’t touch them in door-closed- (Fig.

9a) or in door-open-position (Fig. 9b).

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

S 401 GB - 8 - 03-06

S 401 GB - 8 - 03-06

sion chain / belt

Turn the nut to tension the chain or belt

slightly. Fig. 10).

Trolley test

Check afterwards, that the trolley can easily be

moved by hand. To release the trolley, from

the chain lock, pushes the lever on the trolley

and at the same time move the trolley in the

rail (Fig. 11).

Make absolutely sure, that after this test the

trolley engages on the chain lock. To perform

this, move the trolley without holding the lever

over the chain/belt lock and the trolley engages automatically.

Assembly of door bracket

According to the installation situation the provided push rod components can be combined

as needed (Fig. 12).

If the length of the push rod is not sufficient, it

can be adjusted via the extension rod (Fig.

12a). In adoption with sectional doors, we recommend the use of a sectional door angle

(Fig. 12c). Then the provided door bracket

(Fig. 12b) has to be attached to the push rod.

For the assembly use the provided screws,

washers and nuts, and tighten them firmly.

Fig. 10

Pre-ten

Fig. 11

Fig. 12

Loading...

Loading...