Berko CPLAS, CPLAM, CPLAS-2125, CPLAS-2188, CPLAS-2250 Installation, Operation & Maintenance Instructions Manual

...

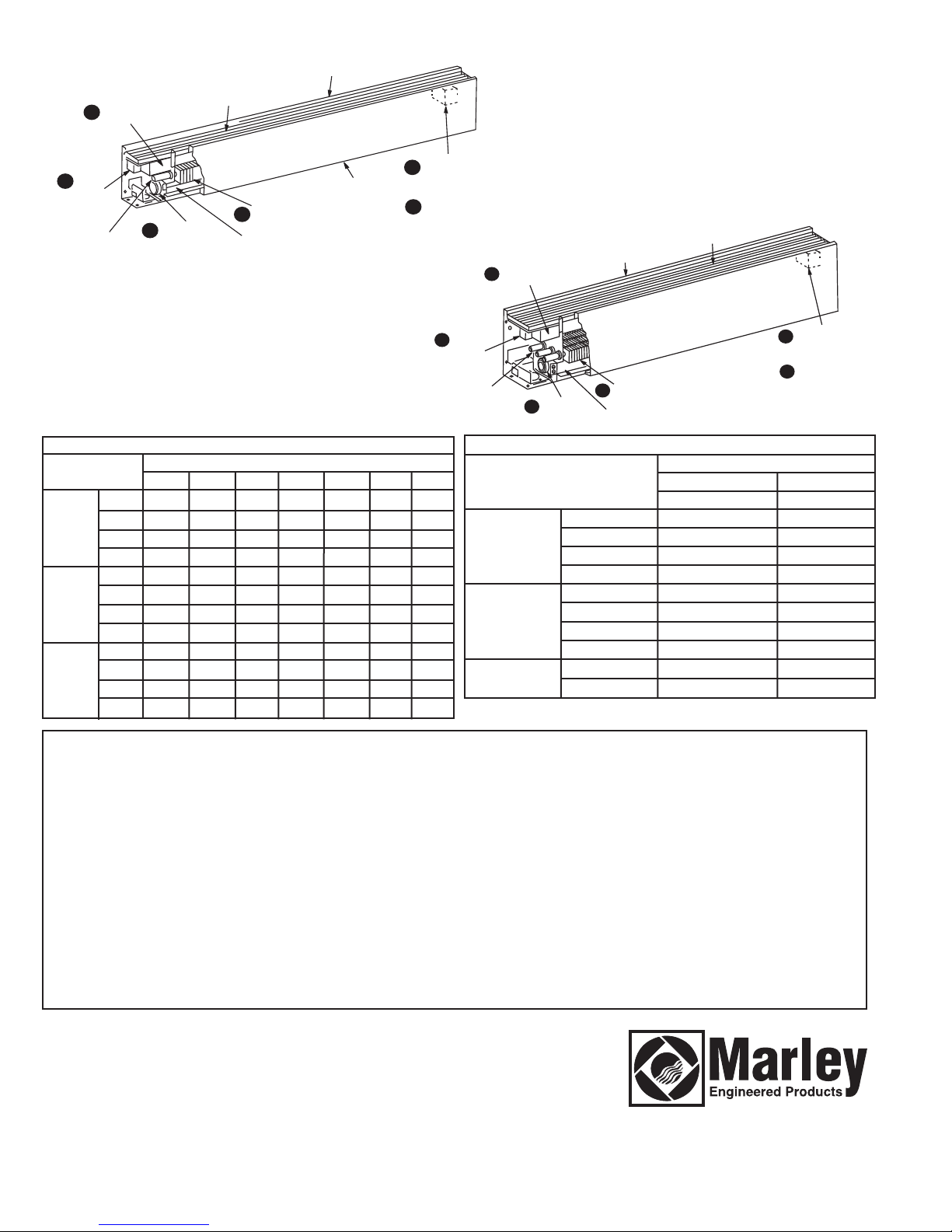

CPL Series Pedestal

Convection Heater

CPL Series

Convectors

Installation, Operation & Maintenance Instructions

IMPORTANT INSTRUCTIONS

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by Marley Engineered Products.

You have made a wise investment selecting the highest quality product in the heating industry.

Please carefully read the installation and maintenance instructions shown in this manual. You should enjoy

years of efficient heating comfort with this product from Marley Engineered Products... the industry’s leader in

design, manufacturing, quality and service.

... The Employees of

Marley Engineered Products

WARNING

WHEN USING ELECTRICAL APPLIANCES, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE

THE RISK OF FIRE, ELECTRIC SHOCK, AND INJURY TO

PERSONS, INCLUDING THE FOLLOWING:

1. Read all instructions before installing or using the heater.

2. A heater has hot and arcing or sparking parts inside. Do not

use in areas where gasoline or flammable liquids are used

or stored. Do not use in corrosive environment or any area

where explosive materials are used or stored.

3. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces. Keep combustible materials,

such as furniture, pillows, bedding, papers, clothes, and curtains away from heater.

RECEIVING

1. Each Pedestal Heater is shipped in two cartons. One carton

contains the heater, the other contains the pedestals.

2. Material when shipped was in good order and Marley

Engineered Products hold clear bill of lading, therefore any

concealed damage must be reported at once to the carrier

for inspection and settlement.

!

4. To prevent a possible fire, do not block air intakes or

exhaust in any manner.

5. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock or

fire, or damage the heater.

6. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit coming to heater

is disconnected at main disconnect or service panel before

installing or servicing this heater.

7. This heater is not for residential or household use.

Note:

It is advisable to store cartons in a central area to be

drawn upon as needed per room requirements. If called for on

order, the cartons will have been tagged with proper room

number.

SAVE THESE INSTRUCTIONS

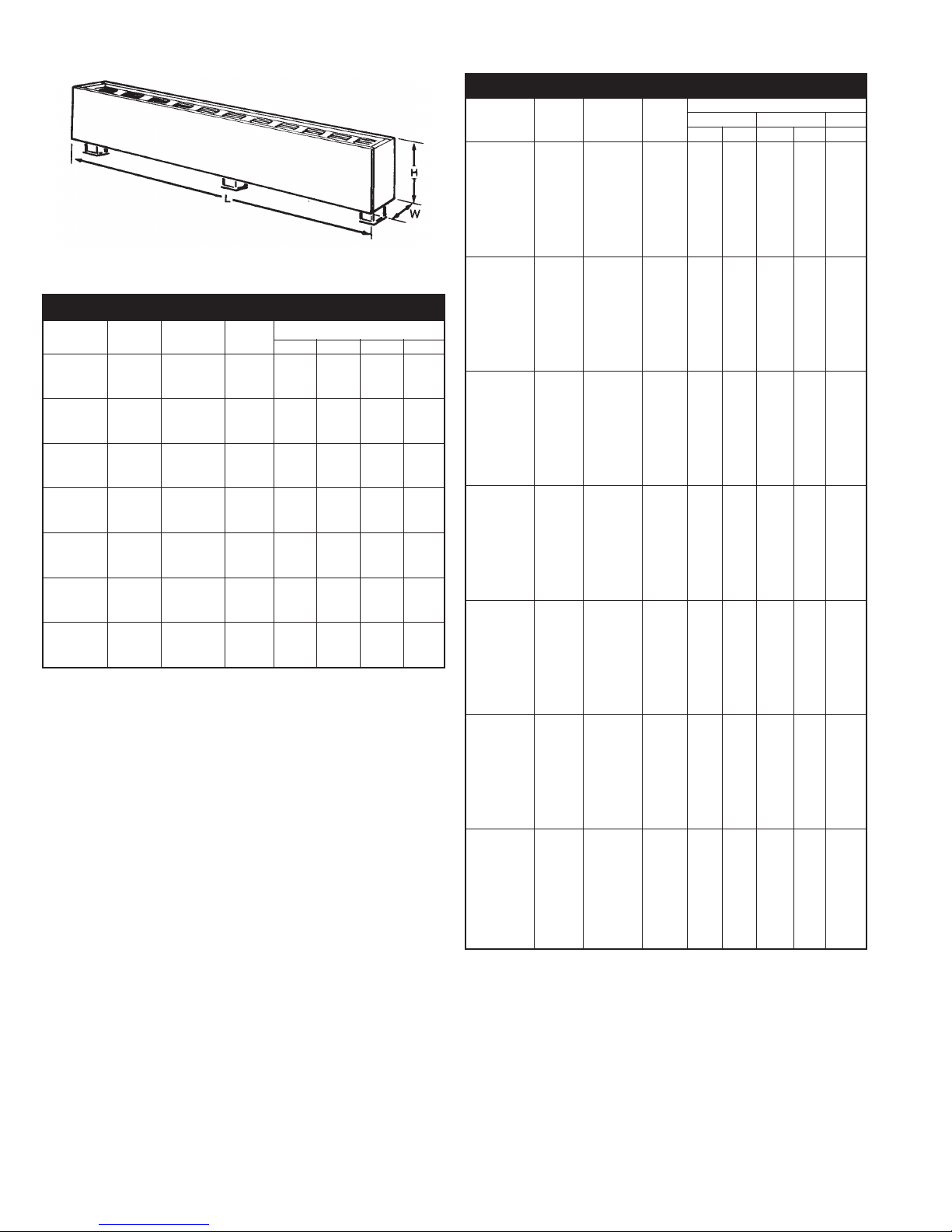

SPECIFICATIONS

Figure 1

Table A

Model CPLAS (H=5 1/2”; D=3”)

Catalog Length Total Amperage

Number* “L” Watts/Ft. Watts 120V 208V 240V 277V

-2125 125 250 2.4 1.2 1.0 0.9

-2188 28” 188 375 3.1 1.8 1.6 1.4

-2250 250 500 4.2 2.4 2.1 1.8

-3125 125 375 3.1 1.8 1.6 1.4

-3188 3’ 188 564 4.7 2.7 2.4 2.0

-3250 250 750 6.2 3.6 3.1 2.7

-4125 125 500 4.2 2.4 2.1 1.8

-4188 4 188 750 6.2 3.6 3.1 2.7

-4250 250 1000 8.3 4.8 4.2 3.6

-5125 125 625 5.2 3.0 2.6 2.2

-5188 5 188 940 7.8 4.5 3.9 3.4

-5250 250 1250 10.4 6.0 5.2 4.5

-6125 125 750 6.2 3.6 3.1 2.7

-6188 6 188 1125 9.4 5.4 4.7 4.1

-6250 250 1500 12.5 7.2 6.2 5.4

-8125 125 1000 - 4.8 4.2 3.6

-8188 8’ 188 1500 - 7.2 6.2 5.4

-8250 250 2000 - 9.6 8.3 7.2

-10125 125 1250 - 6.0 5.2 4.5

-10188 10’ 188 1875 - 9.0 7.8 6.7

-10250 250 2500 - 12.0 10.4 9.0

* Prefix with: CPLAS

Clearance Chart

For safe and efficient operation, maintain at least the following

Minimum clearances at all times:

Bottom of heater to finished floor

Watts/Ft Heater Length Bottom Inlet Front Inlet

125, 188 and 250 1-3/4” (44 mm) 0” (0 mm)

376 500, 625, and 750 3” (76 mm) 0” (0 mm)

Note:

If pedestals are to be imbedded into floor, see Figure 2a

for minimum exposed dimensions.

Top of heater to bottom of Drapes above heater:

Minimum 12 inches (305 mm)

Important Note:

vinyl blinds) may become damaged by the heated air from the

heater and should not be installed above the heater.

Front of heater to full length drapes in front of heater:

Bottom of drapes and floor - minimum 2 1/2 inches (64 mm)

Top of drapes and ceiling - minimum 1/2 inch (13 mm)

Front of heater and nearest fold of drape - minimum 2 inches

(51 mm)

Certain fabrics and vinyl materials ( such as

Table A (continued)

Model CPLAM (H=7”; D=5”)

Amperage

Catalog Length Total 208V 240V 277V

Number** “L” Watts/Ft Watts 1Ø 3Ø 1Ø 3Ø 1Ø

-2125 125 250 1.2 - 1.0 - 0.9

-2188 188 375 1.8 - 1.6 - 1.4

-2250 250 500 2.4 - 2.1 - 1.8

-2375 28” 375 750 3.6 - 3.1 - 2.7

-2500 500 1000 4.8 - 4.2 - 3.6

-2564 564 1125 5.4 3.1 4.7 2.7 4.0

-2625 625 1250 6.0 3.5 5.2 3.0 4.5

-2750 750 1500 7.2 4.2 6.2 3.6 5.4

-3125 125 375 1.8 - 1.6 - 1.4

-3188 188 564 2.7 - 2.4 - 2.0

-3250 250 750 3.6 - 3.1 - 2.7

-3375 3’ 375 1125 5.4 - 4.7 - 4.0

-3500 500 1500 7.2 - 6.2 - 5.4

-3564 564 1690 8.1 4.7 7.4 4.3 6.1

-3625 625 1875 9.0 5.2 7.8 4.5 6.7

-3750 750 2250 11.0 6.5 9.4 5.4 8.1

-4125 125 500 2.4 - 2.1 - 1.8

-4188 188 750 3.6 - 3.1 - 2.7

-4250 250 1000 4.8 - 4.2 - 3.6

-4375 4’ 375 1500 7.2 - 6.2 - 5.4

-4500 500 2000 9.6 - 8.3 - 7.2

-4564 564 2250 10.8 6.2 9.4 5.4 8.0

-4625 625 2500 12.0 6.9 10.4 6.0 9.0

-4750 750 3000 14.4 8.3 12.5 7.2 10.8

-5125 125 625 3.0 - 2.6 - 2.2

-5188 188 940 4.5 - 3.9 - 3.4

-5250 250 1250 6.0 - 5.2 - 4.5

-5375 5’ 375 1875 9.0 - 7.8 - 6.7

-5500 500 2500 12.0 - 10.4 - 9.0

-5564 564 2820 13.5 7.8 11.8 6.8 10.2

-5625 625 3125 15.0 8.7 13.0 7.5 11.3

-5750 750 3750 18.0 10.4 15.6 9.0 13.5

-6125 125 750 3.6 - 3.1 - 2.7

-6188 188 1125 5.4 - 4.7 - 4.0

-6250 250 1500 7.2 - 6.2 - 5.4

-6375 6’ 375 2250 10.8 - 9.4 - 8.1

-6500 500 3000 14.4 - 12.5 - 10.8

-6564 564 3380 16.2 9.4 14.1 8.1 12.2

-6625 625 3750 18.0 10.4 15.6 9.0 13.5

-6750 750 4500 21.6 12.5 18.7 10.8 16.2

-8125 125 1000 4.8 - 4.2 - 3.6

-8188 188 1500 7.2 - 6.2 - 5.4

-8250 250 2000 9.6 - 8.3 - 7.2

-8375 8’ 375 3000 14.4 - 12.5 - 10.8

-8500 500 4000 19.2 - 16.7 - 14.4

-8564 564 4500 21.6 12.5 18.7 10.8 16.2

-8625 625 5000 24.0 13.9 20.8 12.0 18.0

-8750 750 6000 28.6 16.5 15.0 14.4 21.6

-10125 125 1250 6.0 - 5.2 - 4.5

-10188 188 1875 9.0 - 7.8 - 6.7

-10250 250 2500 12.0 - 10.4 - 9.0

-10375 10’ 375 3750 18.0 - 15.6 - 13.5

-10500 500 5000 24.0 - 20.8 - 18.0

-10564 564 5640 27.2 15.7 23.5 13.6 20.4

-10625 625 6250 30.0 17.3 26.0 15.0 22.6

-10750 750 7500 36.0 20.8 31.3 18.1 27.0

** Prefix with: CPLAM

Top of heater to bottom of window sill:

Minimum 12 inches (305 mm)

2

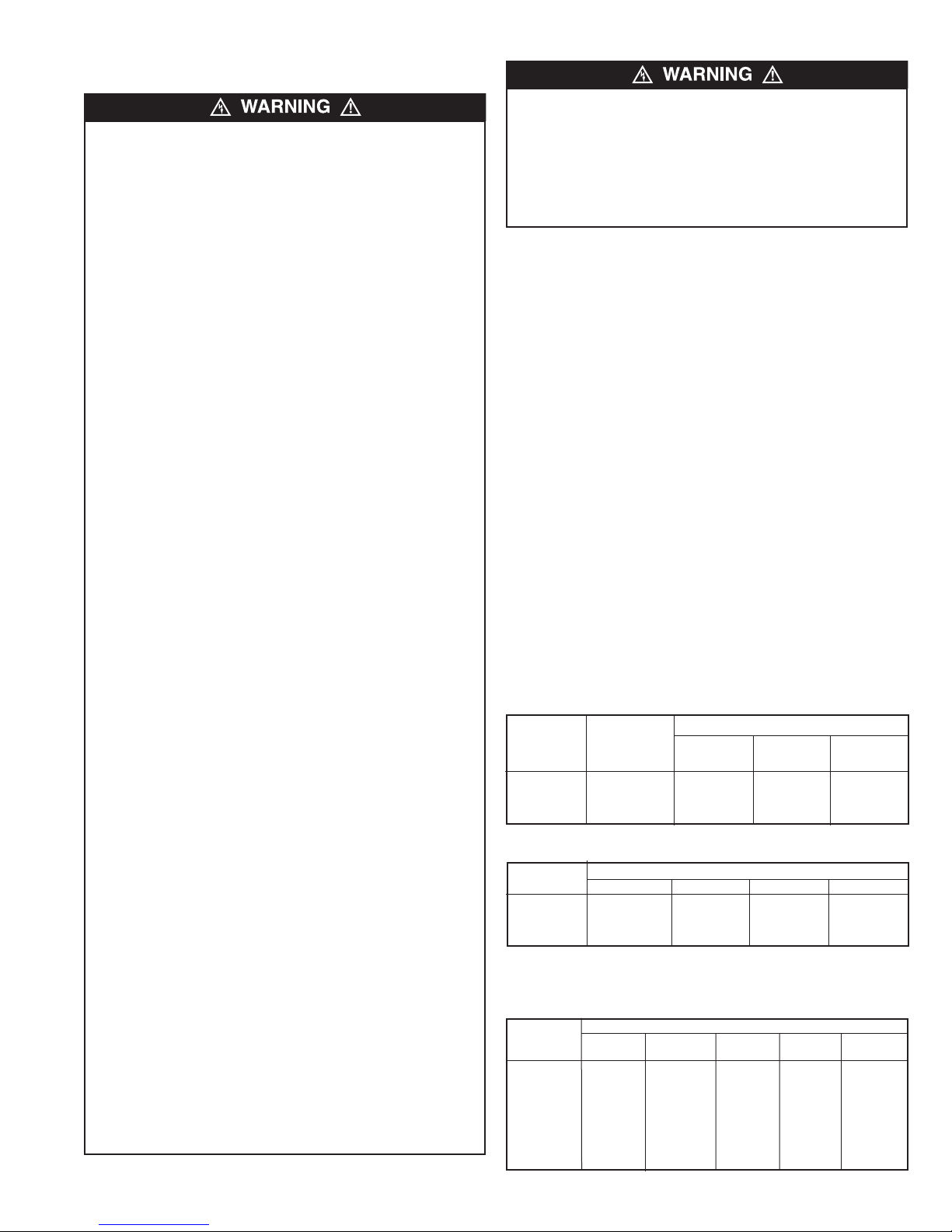

INSTALLATION INSTRUCTIONS

TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK

OR INJURY TO PERSONS, OBS

1. Before installing this heater, remove and discard shipping

pads located within heater. Check to make sure heater is

not damaged.

2. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit coming to heater

is disconnected at main disconnect or service panel before

installing this heater.

3. Wiring procedures and connections must be in accordance

with the National Electrical Code (NEC) and local codes.

Refer to Wiring Diagram on heater and Figure 7. Make sure

all electrical connections are tight to prevent possible overheating. Use Copper Supply Wire Only.

Note:

Supply wiring is to enter heater through one of the

pedestal bases. For pedestal bases not used for wire routing,

covers supplied with pedestal kits must be used.

4. Verify the electrical power supply voltage matches the volt-

age rating as printed on the heater nameplate.

CAUTION - Never connect a heater to a voltage greater than

the nameplate voltage as this will damage the heater and

could cause a fire.

5. Do not install the heater against combustible low-density

cellulose fiberboard surfaces, against or below vinyl wall

coverings, or below any materials that may be damaged by

heat such as vinyl or plastic blinds, curtains, etc. This

heater is supplied with pedestals for floor mounting (supplied in separate carton). See instructions supplied with

pedestal kits.

6. Do not install heater below an electrical convenience recep-

tacle (outlet).

CAUTION

7.

– Heater operates at high temperatures. Keep

electrical cords (including telephone and computer cables),

drapes, and other furnishings away from heater. For efficient and safe operation, we recommend maintaining a minimum of 6 inches (152 mm) clearance above and in front of

the heater at all times.

8. To reduce the risk of fire, do not store or use gasoline or

other flammable vapors or liquids in the vicinity of the

heater.

9. Do not install heater upside down or in any position other

than as shown in this manual. Caution label with word

“TOP” must be at the top when heater is installed.

10. Do not recess heater in wall or install heater inside any type

enclosure as this will cause heater to overheat and could

create a hazard.

11. When mounting heater, use care to secure heater

pedestals to building structure and avoid damaging internal

heater components.

12. Do not remove or bypass the safety limit control (thermal

protector) as this could allow heater to become a fire hazard – see heater wiring diagram supplied with heater.

13. The factory installed wires inside wireway are used to connect the built-in controls. Limit the maximum current to no

more than 45 total amps for CPLAM models (35 amps for

CPLAS models). Refer to instructions and current capacity

rating as provided with the accessory.

14. Heaters that are not installed end to end must have end

caps installed to cover exposed ends of heater.

ERVE THE FOLLOWING:

15. All field wiring brought in to heater must be rated minimum 75°C.

16 Do not allow objects to be placed on top of heater as they

may be damaged or create a fire hazard.

17. Before energizing, make sure that heater is completely

assembled with grille, front cover, end caps and any

accessories installed.

Rough-in Wiring

1. Branch circuits for the heaters shall be enclosed in 1” rigid

conduit for CPLAS, or 1- 1/4” rigid conduit for CPLAM

heaters.

2. Run branch circuit of proper voltage and wire size, in rigid

conduit, to location of left or right junction box as indicated

on heater wiring diagram. Wire entry to heater is through

either end pedestal.

Note:

When pedestal is not used for wire entry, pedestal base

must be covered with cover plate (supplied with pedestal). See

Figure 3.

3. When installing heaters on existing floors, the threaded end

of the rigid conduit must extend 7/8” to 1” above finished

concrete. Conduit must be threaded a minimum of 3/8”.

4. Basic heaters are prewired and can be connected to branch

circuit at either end. Heaters with controls are prewired for

connection to branch circuit at one end only (refer to heater

wiring diagram), however, heater can be wired from opposite

end by running wires through heater wireway.

5. If it is necessary to run wires through the heater wireway,

use Table B to size the field installed wiring.

Table B. Sizing Field Installed Wiring

Copper Maximum no.

wire size of wires Up to 3 4 to 6 7 thru 9

75º C in wireway Conductors Conductors Conductors

No. 12 AWG 9 11.5 amps 9.3 amps 8.1 amps

No. 10 AWG 8 17.4 amps 14.0 amps 12.1 amps

No. 8 AWG 4 24.0 amps 21.0 amps –

Table C. Maximum Length of Heater Run

(CPLAS - 1PH)

Watts/Ft. of Maximum allowable length of heater run (feet)

the heaters 120 Volts 208 Volts 240 Volts 277 Volts

125 33 58 67 77

188 22 38 44 51

250 16 29 33 38

Note:

For mix of watt densities, calculate amp draw. Do not

exceed values indicated in step 6 above.

TABLE D. Maximum Length of Heater Run

(CPLAM - 1PH and 3PH)

Watts/Ft. of Maximum Allowable Length of Heater Run (Feet)

the Heaters 208 Volts 208 Volts 240 Volts 240 Volts 277 Volts

125 74 - 86 - 99

188 49 - 57 - 66

250 37 - 43 - 49

376 24 - 28 - 33

500 18 - 21 - 24

564 16 27 19 32 22

625 14 24 17 29 19

750 12 20 14 24 16

1Ø 3Ø 1Ø` 3Ø 1Ø

Maximum allowable current

3

Thermostat

24 amps @ 120-240 VAC

22 amps @ 277 VAC

Pilot duty– 125 VAC (all voltages)

Transformer relay

CPLAS units: 22 amps @ 120-240 VAC

19 amps @ 277 VAC

CPLAM Units: 25 AMPS @ 120-240 VAC

22 AMPS @ 277 VAC

Power relay

25 amps @ 120-277 VAC- see wiring

diagram on heater

Disconnect switch

20 amps @ 120-277 VAC

Locknut

ousing

H

6. The factory installed wires in the heater wire way can be

loaded up to 35 amps in CPLAS and up to 45 amps in

CPLAM units. Refer to Table C and D for maximum length of

heater run when the heaters are connected in parallel.

7. Standard 75˚C wiring must be used in junction boxes,

wire-

way and blank sections.

Room Layout

Refer to heating plans for exact room arrangements of heaters

(with or without thermostat and/or relays and/or switches and

accessories.)

Heater

Heater Capacity

(Watts.Ft. Heater Length)

125, 188 and 250 Watts/Ft.

376, 500, 564, 625 and 750

Watts/Ft.

Leveling

Nut

Locknut (Do

Not Loosen

Or Remove)

Floor

Line

A

Pedestal

Dimension “A”

(Minimum Mounting

Height Above Floor)

Locknut

1-3/4”

3”

Welded

Bracket

3/8”

Figure 2a. Pedestal Imbedded in Floor

Heater Catalog Number Height Above Floor (Dim. “A)

CPLAS 2-5/8” 3-3/8”

CPLAM 3-7/8” 4-5/8”

Locknut

Leveling

Nut

Locknut (Do

Not Loosen

Or Remove)

Rigid

Conduit

A

Floor

Line

Min. Max.

Welded

Bracket

Pedestal

Figure 2b. Surface-Mounted Pedestal

B

Pedestal

Dimension “B”

(Minimum Height

Above Floor)

3-1/4”

Heater

2-7/8” (5” Heaters)

4-1/8” (7” Heaters)

Heater

Base Mounting

Holes - 1/4” Da.

(Suitable

Fasteners By

Others)

2”

eveling

L

ut

N

over Plate (Used

C

nly When Pedestal Is

O

ot Used For Wire

N

ntry)

E

Figure 3.

over

C

Pedestal

over

C

ounting

M

crews

S

Mounting Height

Refer to Figure 2a. for typical mounting of heaters and pedestals

imbedded in floor; refer to Figure 2b. for surface-mounted

heaters and pedestals.

Note:

Up to 3/4” thick floor covering, such as carpet, tiles,

linoleum, etc., may be installed around and under the heater.

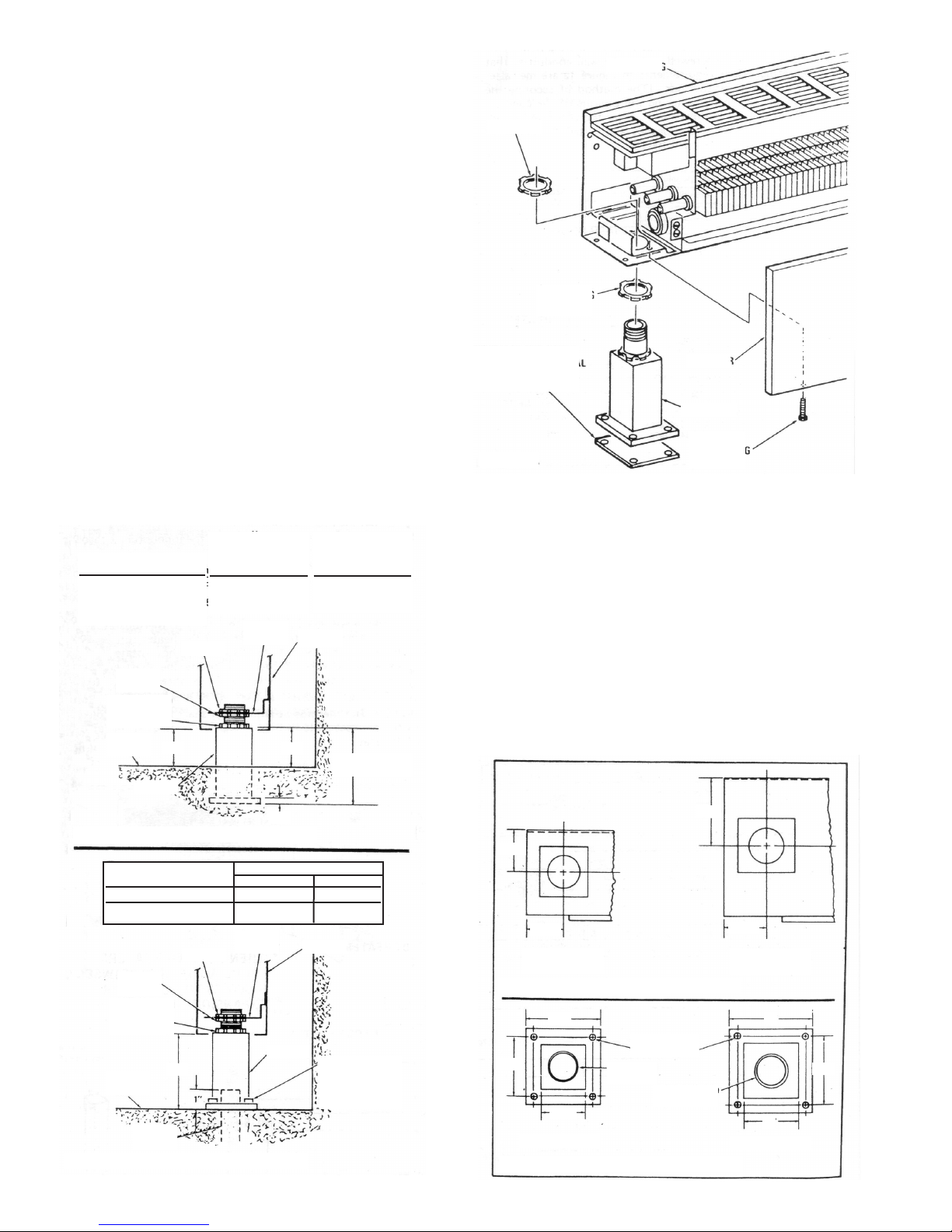

Pedestal Installation

(Surface-Mounted to Existing Floor)

Note:

For ease of installation, it is important that the sequence

of operations indicated below be followed in order.

1. Remove front cover by removing mounting screws (Fig. 3)

2. Remove the top lock nut and the leveling nut from each

pedestal. (Do not loosen or remove the bottom lock nut.)

2-1/2”

1-7/16”

1-7/16”

Figure 4a. End Pedestal Locations

2.75”

0.250” Dia.

2.125”

1.625”

Mounting Holes

1” Threaded

Pipe

1-1/4” Threaded

Pipe

Figure 4b. Pedestal Details

4

1-9/16”

3”

2.5”

2”

ocknut

L

ooden Jig

W

8”

2

1-7/16” (CPLAS)

1-9/16” (CPLAM)

-7/16” (CPLAS)

1

1-9/16” (CPLAM)

1-7/16” (CPLAS)

1-9/16” (CPLAM)

1-7/16” (CPLAS)

1-9/16” (CPLAM)

edestal

P

ypical Set-Up of Heater

T

edestal Using Jigs To

P

aintain Proper Positioning

M

uring Concrete Pouring.

D

6”

3

33-1/8” (CPLAS)

32-7/8” (CPLAM)

8-13/16”

2

32-13/16”

44-13/16”

60”

3-Foot Heater

7-1/8” (CPLAS)

5

6-7/8” (CPLAM)

5

2”

7

1-9/16” (CPLAM)

69-1/8” (CPLAS)

68-7/8” (CPLAM)

4”

9

1-7/16” (CPLAS)

1-9/16” (CPLAM)

1-7/16” (CPLAS)

5-Foot Heater

93-1/8” (CPLAS)

92-7/8” (CPLAM)

28-Inch Heater

25-1/8” (CPLAS)

24-7/8” (CPLAM)

4-Foot Heater

48”

5-1/8” (CPLAS)

4

4-7/8” (CPLAM)

4

NOTE: HOLES IN JIGS SHOULD BE

1-3/8” FOR CPLAS HEATERS, OR

1-11/16” FOR CPLAM HEATERS.

* WHEN BUTTING HEATERS,

LEAVE A 1/16” GAP BETWEEN

6-Foot Heater

HEATERS TO ALLOW FOR

EXPANSION.

8-Foot Heater

1-7/16” (CPLAS)

1-9/16” (CPLAM)

36-13/16”

76-13/16”

Figure 5.

3. Screw one pedestal onto threaded rigid conduit protruding

from floor.

4. Install remaining pedestal(s) in heater and secure by

installing lock nut finger tight.

5. Install heater onto the pedestal which is screwed on the rigid

conduit. Position heater in desired location and mark

pedestal mounting hole locations on floor. Then remove the

heater and the one pedestal from the rigid conduit.Remove

the remaining pedestal(s) from the heater.

6. Drill holes in floor (Fig. 4b) and install threaded inserts (or

equivalent for 1/4” mounting bolts (inserts and bolts supplied

by installer.)

7. Reinstall the one pedestal on the rigid conduit, then secure

all other pedestals (with cover plates) to the floor with four

1/4” bolts through each pedestal flange.

Pedestal Installation

(Imbedded in New Concrete Floor)

When a heater installation is to be imbedded in a new concrete

floor, the pedestals are first installed in the concrete, then the

heater installed after the concrete has set. It is imperative that

the pedestals be installed in perfect alignment so that the holes

in order to achieve the required alignment, it is recommended

that the pedestals be held in place by the use of jigs during the

concrete pour. The jigs should be constructed of good quality 1”

x 4” lumber as shown in Figure 5. The pedestals are installed in

10-Foot Heater

120”

117-1/8” (CPLAS)

116-7/8” (CPLAM)

End

Cap

Housing

Accessory

Mounting

Holes

Mounting

Screws

End Cap

End Cap Data

Heater Catalog Number

Description CPLAS CPLAM

End Cap Left CPLAS-ECL(R) CPLAM-ECL(R)

End Cap Right CPLAS-ECR(R) ASH07-ECL(R)

(R) Suffix on catalog number refers to accessories with 120 VAC receptacle.

Figure 6.

5

the jigs and then positioned for the concrete pour. One end

pedestal must be screwed onto rigid wall conduit so that the

mounting height requirements in Figure 1a are met after pouring

of the finished floor. (The method of securing the pedestals and

jigs in place during the pouring of the concrete is at the option of

the installer.) After the concrete has set, remove the jigs from

the pedestals and install the heater as indicated in steps Seven

or Eight.

Installation of Single Unit

Note:

For ease of installation, it is important that the sequence

of operations below be followed in order.

1. Remove front cover by removing mounting screws (Fig. 3)

2. Install end caps (must be purchased separately) on both

ends of the heater housing. Refer to Figure 6 for details of

end cap installation.

3. Install leveling nut on each installed pedestal, then position

heater on pedestals. Adjust the leveling nuts until the heater

is level and at the desired mounting height. Then install and

tighten the pedestal lock nuts.

4. Run proper size branch circuit to the junction box through the

appropriate end pedestal.

5. Following the wiring diagram secured to the heater, make

electrical connections.

6. Replace front cover and secure with mounting screws. (See

Figure 3.)

7. If the heater is equipped with a built-in thermostat, adjust the

shaft to the mid-range and let the heater run for a few hours.

If the room temperature is too hot, rotate the shaft counterclockwise; if too cool, rotate the shaft clockwise until a comfortable temperature is obtained. Let room temperature stabilize after each setting change. The heater will automatically cycle around this set point on the thermostat.

Note:

If a thermostat or disconnect switch is provided in the

heater, these components are accessible through the grille

openings at the left or right end of the heater.

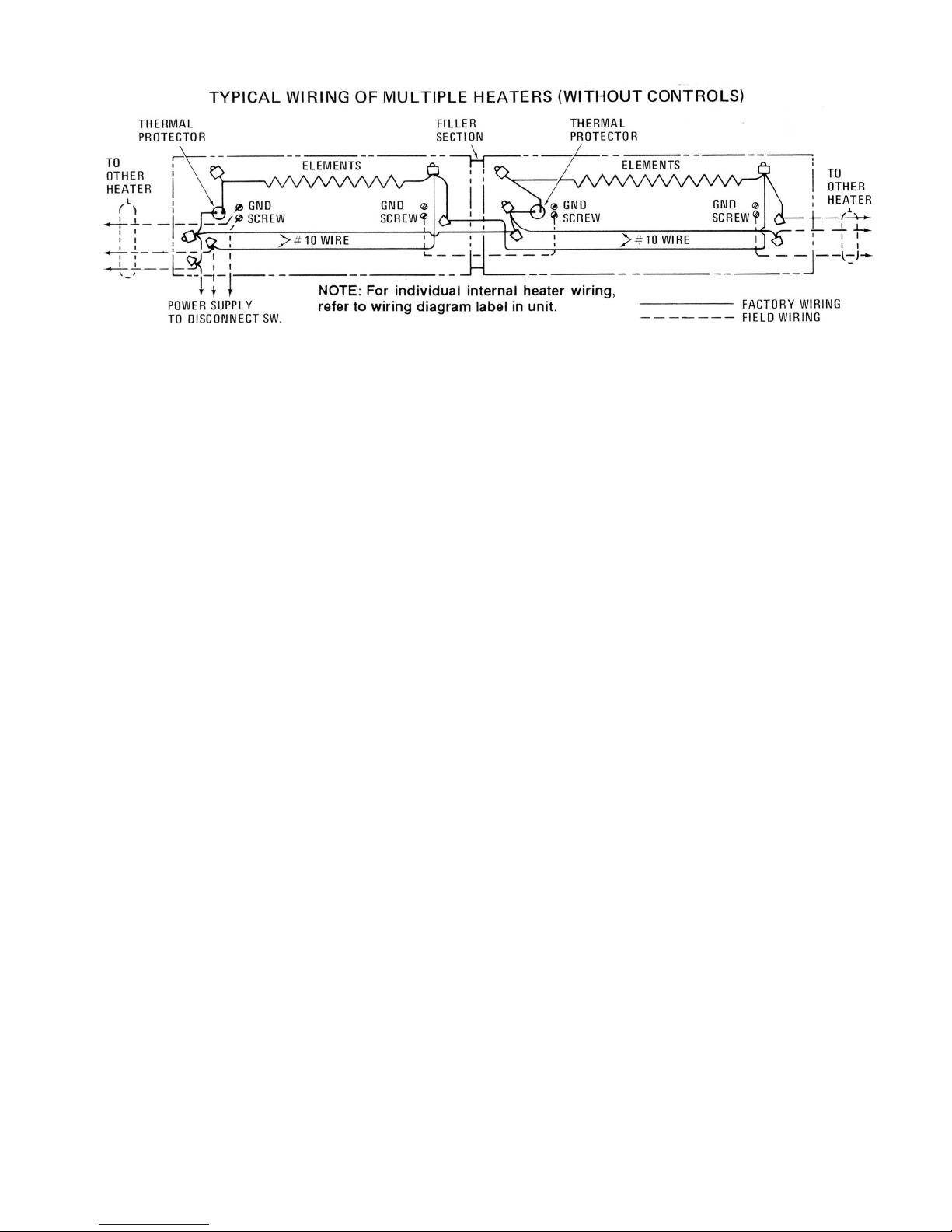

Installation of Multiple Units

Note:

For ease of installation, it is important that the sequence

of operations indicated below be followed in order.

1. Remove front cover by removing mounting screws (Figure

3.)

2. Install end caps on the outer end of the first and last heater

(or blank section ) in a run using four No. 6 screws supplied

with end caps. (Refer to Figure 6 for details of end cap

installation.)

3. Run proper size branch circuit to the junction box through

heaters and blank sections (if applicable) on pedestals.

Note

: When butting heaters end to end, be sure to position

heaters carefully to insure proper alignment. Leave a 1/16” gap

between heaters to allow for expansion.

4. Adjust the leveling nuts until the heaters are level and at the

desired mounting height. Then install and tighten the

pedestal lock nuts.

Note

: 75˚C field wiring may be run through the blank section

wireway.

5. Following the wiring diagram secured to the heater, make the

electrical connections. Refer to Figure 7 to connect the other

heaters in parallel. Grounding of the other heaters is accomplished by connecting a jumper wire (not supplied) between

the two adjacent heaters.

6. Replace front covers, and secure with mounting screws.

(Figure 3.)

OPERATION INSTRUCTIONS

1. This heater must be properly installed before it is used.

2. If the heater is equipped with a built-in thermostat, adjust the

shaft to the mid-range and let the heater run for a few hours.

If the room temperature is too hot, rotate the shaft counterclockwise; if too cool, rotate the shaft clockwise until a comfortable temperature is obtained. Let room temperature stabilize after each setting change. The heater will automatically cycle around this set point on the thermostat.

Note:

If a thermostat or disconnect switch is provided in the

heater, these components are accessible through the grille

openings at the left or right end of the heater.

MAINTENANCE INSTRUCTIONS

For efficient and safe operation and to extend the life of the

heaters, they should be cleaned and inspected for damage at

least annually (preferably at the beginning of the heater season)

or more often in dirty environments. Other than cleaning, your

heaters require no other preventative maintenance.

1. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit(s) coming to

heater is/are disconnected at main disconnect or service

panel before servicing this heater. Allow heater to cool

before cleaning to prevent a possible burn.

NOTE:

sure all power is disconnected to heater before cleaning or

servicing.

2. Use care when cleaning element fins to avoid damaging

1. The user can perform periodic cleaning of the outer cabinet.

2. Heater cabinet may be cleaned using a damp cloth to

4. A vacuum cleaner and/or compressed air may be used to

5. After cleaning and servicing, always reassemble replacing

Important Note:

the heaters including one or more over-temperature limit controls (Thermal Protector) - see Wiring Diagram on heater for

specific controls provided. These safety controls are provided to

cycle the heater off to maintain safe temperatures in the event of

a blockage or other abnormal condition. DO NOT remove or

bypass these important safety controls as they are provided to

limit the temperatures and prevent a possible fire in the event

the heater is subjected to an overheating condition. If it is determined that the heater is cycling off on the safety controls during

normal use, discontinue using the heater until it can be

inspected and repaired by a qualified service personnel.

More than one power source may enter heater. Be

fins. Note also that fins are sharp and may cause cuts so

avoid contact.

All other servicing is to be done by qualified service personnel.

remove dust that may have accumulated on surfaces. Do not

use harsh cleaners or waxes on surfaces since these could

damage the finish or discolor in use.

remove dust and lint that may have accumulated inside

heater around element fins. If heater must be disassembled

for cleaning, use care not to bend or damage the aluminum

fins.

any hardware removed, restore power and check to make

sure the heaters are operating properly

There are built-in safety devices provided within

6

Figure 7 - Wiring Diagram

7

6

3

2

1

4

5

GRILLE

2501-0253-VAR

B

ACK PANEL

2

701-0765-VAR

FRONT COVER

1

402-0316-VAR

H

EATING

ELEMENT

WIREWAY COVER

6

405-0053-VAR

O

VERLOAD

PROTECTOR

4

520-0007-VAR

POWER RELAY

(

OPTIONAL)

T

RANSFORMER

R

ELAY

(OPTIONAL)

ELEMENT BUSHING

1

213-2000-001

DISCONNECT

SWITCH

(OPTIONAL)

T

HERMOSTAT

(OPTIONAL)

6

3

2

1

4

5

GRILLE

2501-0254-VAR

BACK PANEL

2

701-0766-VAR

FRONT COVER

1402-0315-VAR

HEATING

ELEMENT

WIREWAY COVER

6405-0053-VAR

OVER LOAD

PROTECTOR

4520-0007-VAR

POWER RELAY

(OPTIONAL)

TRANSFORMER

RELAY

(OPTIONAL)

ELEMENT BUSHING

1213-2000-001

DISCONNECT

SWITCH

(OPTIONAL)

THERMOSTAT

(OPTIONAL)

Heating Element (Part No. Prefix 1802-2001)

Description Heater Length

28” 3’ 4’ 5’ 6’ 8’ 10’

25W/Ft. 120V 085 087 089 091 093 --

1

er 208V 086 088 090 092 094 095 096

p

Element 240V 048 054 060 066 072 077 081

277V 049 055 061 067 073 078 082

188 W/Ft. 120V 005 011 017 023 029 --

per 208V 002 008 014 020 026 032 036

Element 240V 001 007 013 019 025 031 035

277V 000 006 012 018 024 030 034

250W/Ft. 120V 004 010 016 022 028 --

per 208V 003 009 015 021 027 033 037

Element 240V 002 008 014 020 026 032 036

277V 001 007 013 019 025 031 035

Built-In Controls (Optional)

escription Part Number

D

PLAM CPLAS

C

Disconnect Switch 5216-0125-000 5216-0124-000

Transformer 120 Volt R13700002B001 410043001

Relay 208 Volt R13700002B002 410043002

240 Volt R13700002B003 410043003

277 Volt R13700002B004 410043004

Power 24 Volt 5018-2006-000 5018-2006-000

Relay 120 Volt 5018-2006-001 5018-2006-001

208/240 Volt 5018-2006-002 5018-2006-002

277 Volt 5018-2006-003 5018-2006-003

Thermostat 1 Pole 5813-0024-000 5813-0024-000

2 Pole 5813-0023-000 5813-0023-000

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that

such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts

2. Purchase Replacement Parts

3. General Product Information

Note:

When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

Part No. 5200-2211-001

1-800-642-4328

1-800-654-3545

www.marleymep.com

ECR 38636

01/11

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Loading...

Loading...