Berkel MB Installation Manual

Installation Instructions

"/

push

fof Type

O P E RATION AND

1. Pre-Installation

Before

package,

shipping

unit.

with

belt

Maintenance).

check motor

phase

installation of

a careful check should

damage

which may

If damage is found, file

delivering carrier. Check

tension

(see paragraph

Before connecting

nameplate

voltage. Make

and

freely without striking the fan

object.

propeller

power

Note the direction arrow

make sure

and

is connected

2. Installation Procedures.

packages

shutter,

are shipped completely

housing, fan and

installation.

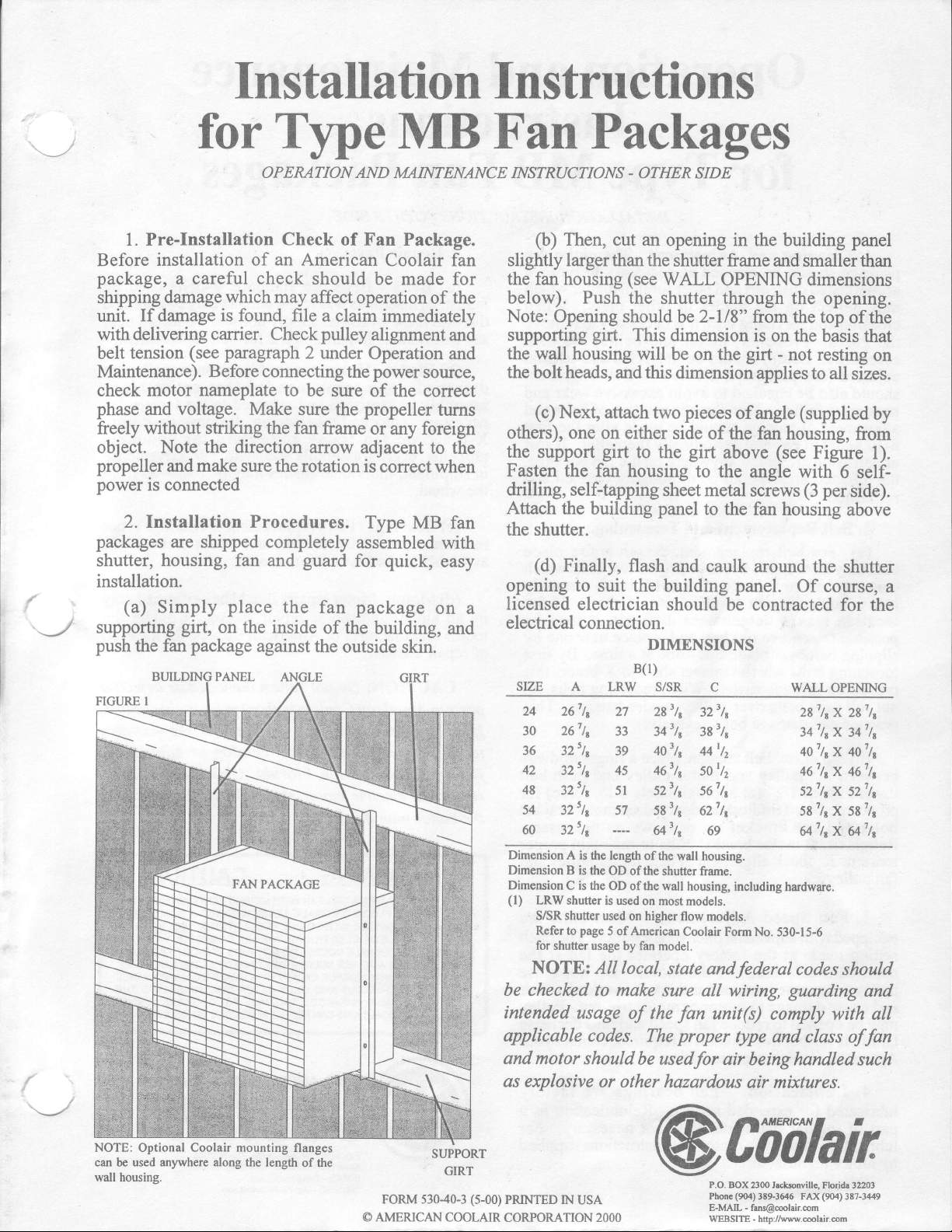

(a)

Simply

supporting

the fan

place

girt,

on the

package

Check

an

American

affect

2

to be

sure the

the rotation is

guard

the fan

inside

against

MB

A,UINTENANC E INSTRUCTIONS - OTHER

of Fan

operation

a claim immediately

pulley

under Operation

the

sure of the correct

frame

assembled

for

package

of the

the

outside skin.

Package.

Coolair fan

be made

of

alignment

power

propeller

source,

tums

or any foreign

adjacent

correct

Type

to the

when

MB fan

with

quick,

easy

on a

building, and

for

the

and

and

Fan

(b)

Packages

Then,

cut an opening in the building

slightly larger than

the

below).

Note:

supporting

the

the

others), one

the support

housing

fan

Push

Opening should

girt.

housing

wall

heads,

bolt

(c)

Next, attach two

and this

on either side

girt

Fasten the fan

drilling,

Attach

the

opening to

licensed

electrical

SIZE A LRW

24 26'/,

30

36 32t/,

42

48

s4

60

Dimension

Dimcnsion

Dimension

(l)

self-tapping

the building

shutter.

(d)

Finally,

suit the

electrician

connection.

26'r,

32tr,

32t/,

32tr,

32t/,

A is

the length of

B is the

C is the OD

LRW

shutter is

.

shutter

S/SR

page

Refer to

for shufter usage

27

33

39 4otr,

4s 46t

51 sztr,

57

OD of the

used on most

uscd

5 ofAmerican

NOTE: All local,

be

checked to make

intended

usage of

applicable codes.

andmotor

as explosive

shouldbe

or other

SID E

the shutter frame and smaller

(see

WALL

the

shutter

This dimension

will

be on the

OPENING dimensions

through

be2-l/8"

the opening.

from

the top

is on the

-

girt

not

dimension applies

pieces

of angle

(supplied

of the fan housing,

to the

housing

girt

above

to the angle

sheet metal

panel

to the fan housing

flash and caulk

building

should

DIMENSIONS

B(l)

S/SR

28tr,

34t/r 38%

/,

'/,

58

64tr, 69

the wall housing.

shutter frame.

of the wall

higher

on

by fan model.

be contracted

C

32t/,

44'/2

so'/,

56'1,

62'/,

housing, including

models.

flow

models.

Coolair

Form No.

state andfederal

sure

all wiring,

the

The

usedfor

unit(s)

fan

proper

air beinghandled

hazardous

(see

with

scrbws

(3

around the

panel.

Of course,

WALLOPENING

28'rrx 2Btr,

34'lrx

40'lrx 40'/,

46'rrx

sz'lrx 52't,

ss%x ss%

64'lrx @'r,

hardwarc.

530-15-6

codes should

guarding

comply

type

and class offan

air mixtures.

panel

than

of the

basis that

resting

to all

sizes.

from

Figure

6 self-

per

side).

above

shutter

for the

34'1,

46'1."

with

such

on

by

1).

a

and

all

NOTE: Optional

can

used anywhere along the

be

wall housing.

Coolair

mounting flanges

length

of the

FORM 53040-3

AMERICAN

@

SUPPORT

GIRT

(5-00)

COOLAIR

PRINTED rN

CORPORATION 2OOO

USA

@crnnir

P.O. BOX 2300

Phone

E-MAIL - fms@mlair.om

WEBSITE - http:/nvw.@hir.@m

tekeovillc, Flor.id. 32203

(904)

389-3646 FAX

(904)

387-3,149

Operation

and

Instructions

Maintenance

Type MB

Adjustment. The entire fan

cleaned as necessary to remove

unit,

2 below).

This same inspection

periodically

Cleaning

l.

package

iccum-ulated

should

dust,

mav collect

cleining

the

accessible.

adjusted

should

premature

'adiustment

8-i0

or

the

and servicing

guard.

(see paragraph

also be

failure.

of tension should be hrade after the first

of use

hours

corrosion

affected

Propeller, motor and belt(s) are

Belt(s) should be

are

area should be thoroughly cleined

for

and

be

dirt and other

the blades or other

on

checked to avoid excessive wear

and

found anywhere

refinished.

2. Belt

(a)

assembly

connect shaft

just

enough

location

possible

-slippine

loos'eniig

procedurl

not roll new belts over

practice

(b)

between

inward about l/2"

proper

bolts

Retiehten all motor

tension.

pulley.

fan

3.

equipped with adjustable

Replacement and Tensioning.

For belt

from

replacement,

frame

removing

by

to X-brace. Tilt or lift

for belt to clear end

makes

detachment difficult,

to remove old belt and replace new

over blade tips - one it a

belt

which

bolts

corinect shaft to X-brac6,

is made easier. When

pulleys

can damage belts severely.

To check belt tension,

pulley

fan

tension.

and motor

(at

approximately 5 lb.

To

adjust tension, loosen

and tap bracket up

bracket

Recheck alignment

Fan Speed Adjustment.

pitch

setting made at the factory

maximum safe

pulley

to increase fan speed

and cause damage

may be opened

CFM.

lffurther information is'required,

American Coolair

load for

the motor.

as this will overload

to motor

t6

reduce fan speed and

representative.

INSTALI.ATION

foreign

riratter which

parts.

it is

necesslary to remove

INSTRUCTIONS - OTHER SIDE

When

then

inspected

and tension

Belt alignment

and

of belts and

thereafter. If

on the

fan

rust

packase.

a-nd

detach entire

blade

the two bolts which

blade assemblv

of shaft. If fair

it may

one

be

bv

time. Bv firJt

this

replacing

under

place

a finger

pulley

belts, do

tension. This

midway

push

and

beit

force) for

motor

bracket

or down as necessary.

bolts to maintain

of belt, motor

Most

motorpulley.

operates the fan

DroDer

pull'ey

units

pitch

The

at the

ind

are

Do not close

motor

or motor trip-out.

Pulley

ihus decreas'e

contact

your

Fan

Packages

5. Repair Parts.

(a)

Belts

-

Belts are standard V-belts used

industrial machines and replacements may be obtained

through local industrial supply houses. To install

instructions in

see

(b)

Blades - If one or

damaged, it is recommended that

assembly

necessar!

X-brace

propeller,

in

shipment, individual blades may be removed from

be

repair and

on

bearing

paragraph

2 for

more

belt

blades on

removed and returned

rebalancing.

Remove

fan frame and ieturn

assembly and shaft.

replacement.

propeller

entire

to the factorv

the complete

Forconvenience

belt,

blade

shaft hom

the wheel.

(c)

Bearings - Field replacement

recommended. Disassemble

assembly to

(d)

Motor- Motorrepairs should

an

by

authorized

factory for repairs.

the

motor

and

repair station.

motor manufacturer or American

repair

of

parts

If repairs

terms in American

factory

repairs

the motor

station.

CAUTIONz

to American

under

Do not return

Coolair

warranty

without

are claimed, see warranty

Coolair

catalog

at Jaclcsonville, Florida. Claimsfor watanty

to electric motor should be made

manufacturer.

of bearings is not

return

entire blade

performed

be

only

Contact the

Coolair

for

location

damaged or defective

prior

authorization.

or contact the

directly to

WARNING

DO NOT INSTALL FAN WTH

FLOOR

OF

COMPLIES WITH

UNLESS

APPLTCABLE CODES.

FOR A POWER

ugsERVrcE

TECHNICIAN AND

POWER

PRECAUTIONS

OR GRADE LEVEL WTHOUT

ELECTRICAL WIRING

SOURCE

EXCEPT

SOURCE.

CAN RESULT IN SERIOUS INJURY OR

MOVING PARTS WTHIN 8 FEET

OSHA REGULATIONS. DO NOT

ry!WRE

DISCONN€CT

BY A

QUALTFTED

AFTER DISCONNECTING

ONLY

FAILURE

A GUARD THAT

COMPLIES

WTHOUT PROV|DTNG

TO

WITH ALL

AT THE FAN ITSELF.

MATNTENANCE

OBSERVE

THESE

DEATH,

USE

THE

on

are

for

4. Lubrication. Fan bearings

lubricated

part

lubricatiori''of

motor manufacturer.

bv

for extended service. Relubrication

of regular

maintenance is

electric motor,

see instructions supplied

necessary.

not

are factory

as a

For

P.O. BOX 2300 Jrck$nville

(904)

Phone

E-MAIL - fs@6l.ir.om

WEBSITE

3893646

fAX

-

hup://w.@lair.@m

Florida 32203

(904)

387-3449

Loading...

Loading...