Berkel EASY LINE, RED LINE 250, Home Line 250, RED LINE 220, RED LINE 300 Instruction Manual

...

Red.

Since 1898.

RED LINE

HOME LINE

EASY LINE

INSTRUCTION MANUAL - US

EN

FR

MANUEL D’INSTRUCTIONS - US

ES

MANUAL DEL USUARIO - US

PT

MANUAL DE INSTRUÇÕES - US

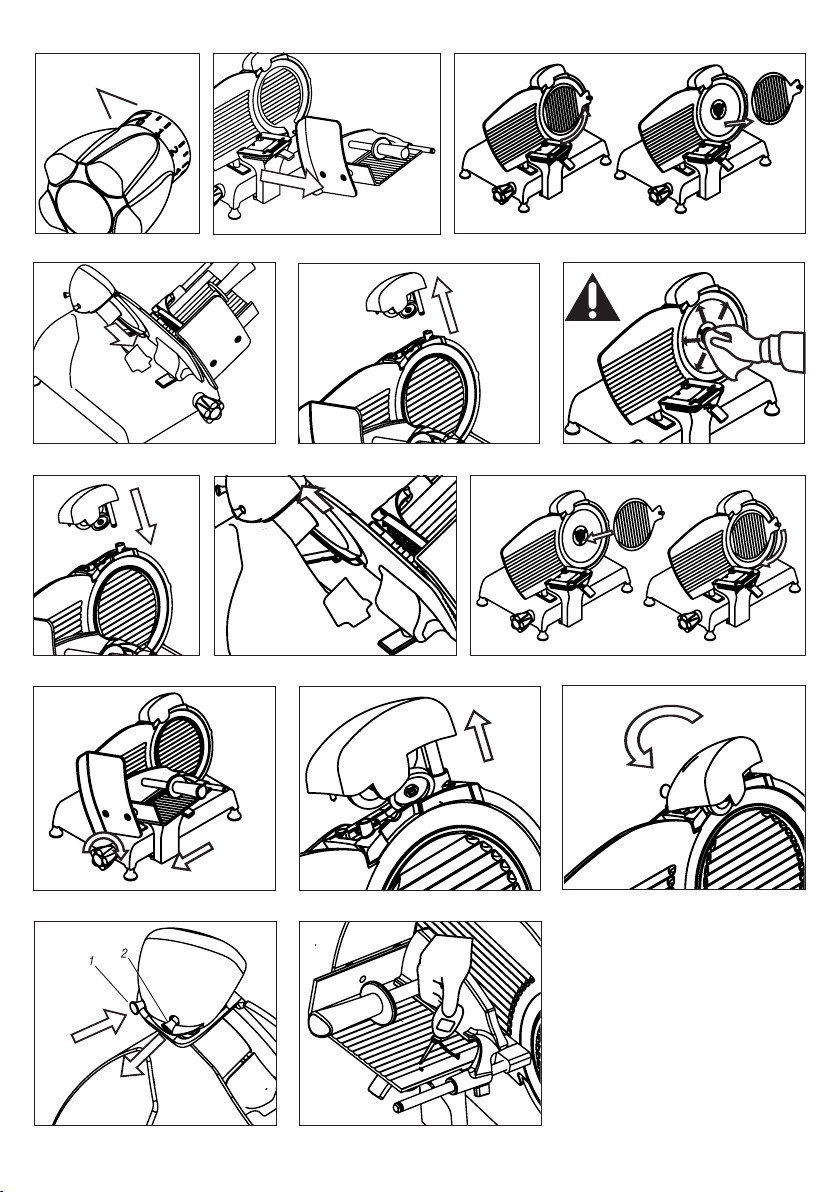

(A)

(B)

(C)

SAFETY

(D) (E) (F)

(G)

(L) (M) (N)

(O) (P)

(H) (I)

2

EN

USER MANUAL - US: Electric Slicers Red Line - Home Line - Easy Line

MODELS:

RSEGMD (Home Line 250) - RSEGS/RSEGM/RSEGL/RSAGS/RSAGM/RSAGL (Redline 220/250/300)

ESEGS/ESEGM/ESEGL/ESAGS/ESAGM/ESAGL (Easyline 220/250/300)

8

9

14

19

3

4

7

17

6

15

1

2

5

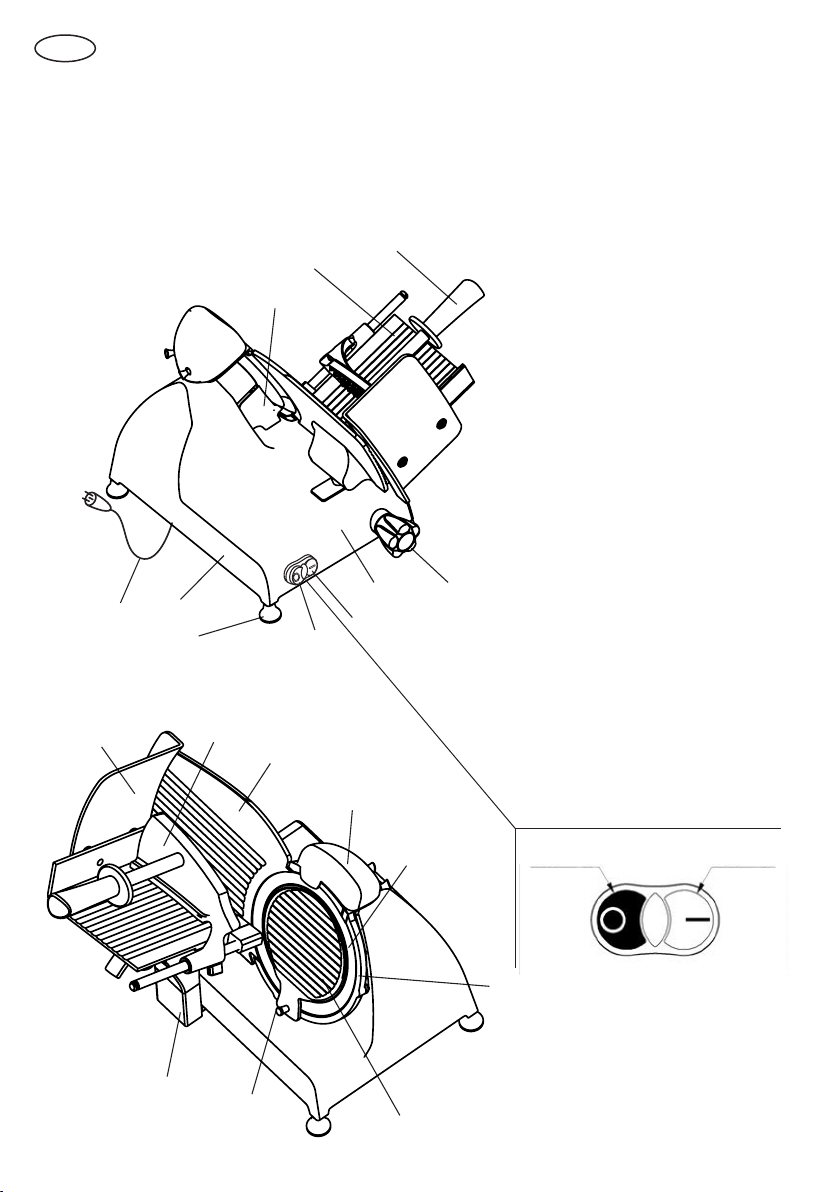

OF THE MACHINE

1. Start button

2. Stop button

3. Identication plate,

technical informations

4. Foot

5. Thickness adjustment knob

6. Thickness gauge plate

7. Safety guards

8. Meat table

9. Product press holder knob

10. Blade

11. Safety ring (blade guard)

12. Sharpener (optional)

13. Blade cover knob

14. Slice guard

15. Baseplate

16. Plate support

17. Product press holder

18. Blade guard disk

19. Power cable

12

GENERAL PLAN

Fig. 1

16

13

10

18

OFF 2 ON 1

11

3

IMPORTANT

SAFEGUARDS

- Read all the instructions

before using the machine;

- to protect against risk of

electrical shock do not put

the slicer in water or other

liquid;

- close supervision is necessary when any appliance is

used near children;

- this product is not intended to be used by children;

- unplug from outlet when

not in use, before putting on

or taking off parts, and before cleaning;

- avoid contacting moving

parts. Never feed food by

hand. Always use completely assembled slicer with

meat table (8) and product

holder (17);

- do not operate any appliance with a damaged cord

or plug or after the appliance malfunctions, or is

dropped or damaged in any

manner. Contact the manufacturer at their customer

service telephone number

indicated in the “Service”

section for information on

examination, repair, or adjustment;

- the use of attachments

not recommended or sold

by the manufacturer may

cause re, electric shock or

injury;

- do not use outdoors;

- do not let cord hang over

edge of table or counter;

- blade is sharp. Handle

carefully when cleaning;

4

- operate the machine only

if properly trained and in

perfect psycho-physical

conditions;

- do not use the machine in

any way other than what indicated in this manual;

- use the machines only in

full structural, mechanical

and system efciency;

- install the machine in conformity to the instructions

indicated in the “Installation” section;

- install the machine in a

location out of the reach

of personnel unauthorised

to operate it and especially

out of the reach of minors;

- stay highly concentrated

when using the machine

and avoid any distraction

during use;

- do not allow the machine

to be used by others who

have not read and fully understood the content of this

manual;

- do not wear baggy clothing or clothing with open

sleeves;

- do not allow anyone else,

other than the operator, to

approach during product

cutting operations;

- do not remove, cover or

modify the tags located on

the machine body and, in

case of damage of these, replace them promptly;

- do not remove the transparent guards and do not

modify or bypass any mechanical and electrical protective devices;

- slice only the permitted

products, do not attempt

cuts on prohibited type

products;

- always keep clean and dry

the sliced product resting

surface, the work area all

around the machine and the

operator oor area;

- do not use the machine as

a resting surface and do not

place any objects on it other

than food used for cutting

operations;

- do not use the slicer when,

due to normal wear, the

distance between the edge

of the blade and the blade

guard ring exceeds 6 mm

(0.2 in). In this case, contact Van Berkel USA, Inc. to

change the blade;

- do not use the machine

with temporary or non-insulated cables, power strips

or extension cords;

- periodically check the condition of the power cable on

the machine body. When

necessary, have qualied

personnel replacing it;

- immediately stop the machine in the event of a defect, abnormal operation,

suspicion of breakdown, incorrect movement, unusual

noises;

- use protective gloves for

cleaning and maintenance

operations;

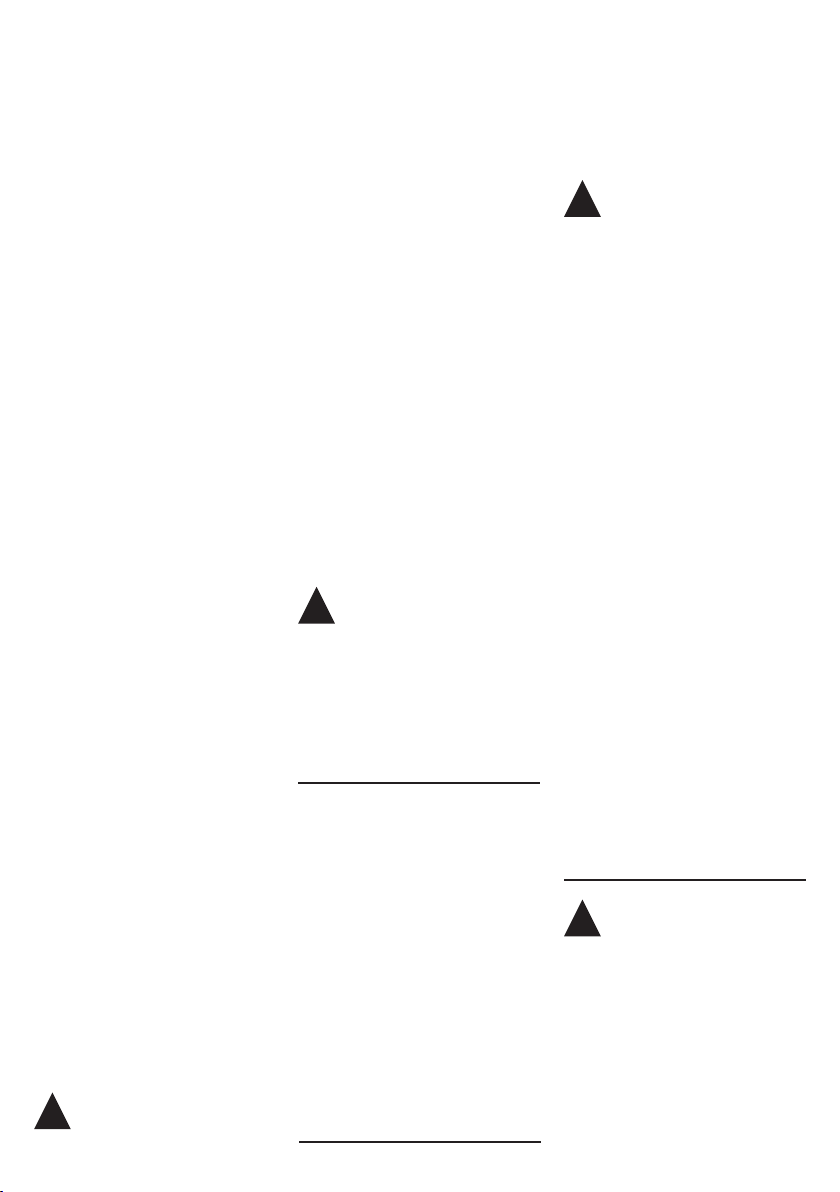

- place and remove the

goods to be sliced on the

meat table only with the

carriage completely pulled

back and with the thickness

adjustment knob placed in

the safety position (on the

position 0) - Fig. (A);

- for movement of the meat

table during cutting operations use only the handle

located on the arm or the

product presser grip;

- never put your hands on

the food product while slicing. Always keep your hands

behind the protection devices and far from the blade;

- use of cutting accessories

which were not provided by

the manufacturer with the

machine is prohibited.

The manufacturer declines

any responsibility coming

from inappropriate use,

modications and/or repairs

carried out by the user or

unauthorised personnel, use

of replacement parts that

are not original or not specic for the machine model.

The machine shall not be

used in open areas and/or

areas which are exposed to

atmospheric agents and in

environments with vapours,

fumes or corrosive and/or

abrasive powders, with risk

of re or explosion and in

any case where the use of

antiexplosive components

is required.

RESIDUAL RISKS: The safety ring around the blade is

made in conformity to all

the standards but, in order

to allow the sharpening

operations, the protection

in the sharpening area may

not entirely eliminate the

risk of cutting.

WARNING! Risk of

!

injury from sharp

blade! During the blade

cleaning and sharpening

operations, pay extra attention to keep your hands

as far as possible from the

unprotected area. Use of

protective gloves is recommended.

SAVE THESE

INSTRUCTIONS!

Operating conditions:

- Temperature from -5°C

(23°F) to +40°C (104°F)

- Max. humidity 95%

Do not slice:

- frozen food products;

- food products with bones;

- any other product not intended for food use.

WARNING! Motor

!

may overheat! After

a maximum 15 minutes

of continuous use, switch

OFF the machine and allow

to cool down.

DESCRIPTION

Circular blade slicer machine suitable for cutting

only the food products of

the types and within the

dimensional limits indicated in this manual. The main

parts of the machine are

shown in the general component diagram reported

in picture 1. This product is

for household use only.

INSTALLATION OF

THE MACHINE

Install the machine on a

at, smooth and dry surface

suitable for supporting the

weight of the machine itself plus the products to be

sliced.

WARNING! Verify

!

that there are no obstacles to the meat table

travel and to the loading of

products.

The machine must be installed in the immediate vicinity of an approved standard outlet connected to an

electrical supply system,

which is in conformity with

the prevailing regulations

for:

- magneto-thermic protec-

tion;

- automatic differential

switch;

- earthing system.

Before carrying out electrical hook up verify that

the characteristics of the

electrical power supply is in

accordance with those indicated on the machine information plate.

OPERATION

WARNING! Risk of in-

!

jury from sharp blade!

Check that the thickness

adjustment knob (5) is in

the safety position (on the 0

position) - Fig. (A).

1. Pull the meat table (8) all

the way back (towards the

operator) in the loading position - Fig. (L);

5

2. lift the product holder

(17) into the standby position;

3. place the product to be

sliced on the meat table

near the operator side wall.

Block it with the product

holder applying slight pressure;

4. adjust the slice thickness.

Activate the blade (10) by

pressing the start button

(1). Grip the product holder

handle (9) and start an alternative cutting motion;

5. at the end of the cutting

operations return the slice

thickness adjustment knob

to the safety position and

pull the meat table back.

Stop the blade motion by

pressing the stop button (2).

CLEANING

Before using, clean the machine at least once a day –

or more often if necessary

– and always after a long

period of inactivity.

WARNING! Risk of

!

electric shock! Be-

fore cleaning, disconnect

the plug from the electrical

mains socket and place the

thickness adjustment knob

in the safety position.

WARNING! Risk of in-

!

jury from sharp blade!

Check that the thickness

adjustment knob (5) is in

the safety position (on the 0

position) - Fig. (A).

Products for cleaning:

6

use only hot water and biodegradable mild detergent,

using a soft, spongy cloth

and a semi-rigid nylon brush

for the sharp areas of the

plate and the product holder. Do not clean the machine

with jets of water or steam

or similar methods.

Dismantling:

- the meat table (only for

the machine equipped with

the meat table removable

mechanism):

1) with the thickness adjustment knob in the safety position, pull back the

carriage all the way until

the travel limit toward

the operator; 2) use the

meat table release lever,

keeping the support at

the travel limit in order to

free the meat table from

its support. To correctly

carry out the operation it

may be necessary to act

simultaneously also on

the thickness adjustment

knob, rotating it slightly

with respect to the safety position; 3) extract the

product holder unit sliding the meat table from

its support - Fig. (B);

- the blade cover:

1) rotate the blade cover

90° counter clock-wise

using the special knob; 2)

a spring facilitates the extraction of the blade cover - Fig. (C);

- the slice deector:

remove the slice deector following the direction

shown in the gure - Fig. (D);

- the sharpener (only for

the machine equipped with

sharpener):

remove the complete

sharp unit pulling it upward - Fig. (E).

WARNING! Risk of in-

!

jury from sharp blade!

For the cleaning operations

of the sharp areas of the

plates, the product holder

and the blade, use of protective gloves is also recommended.

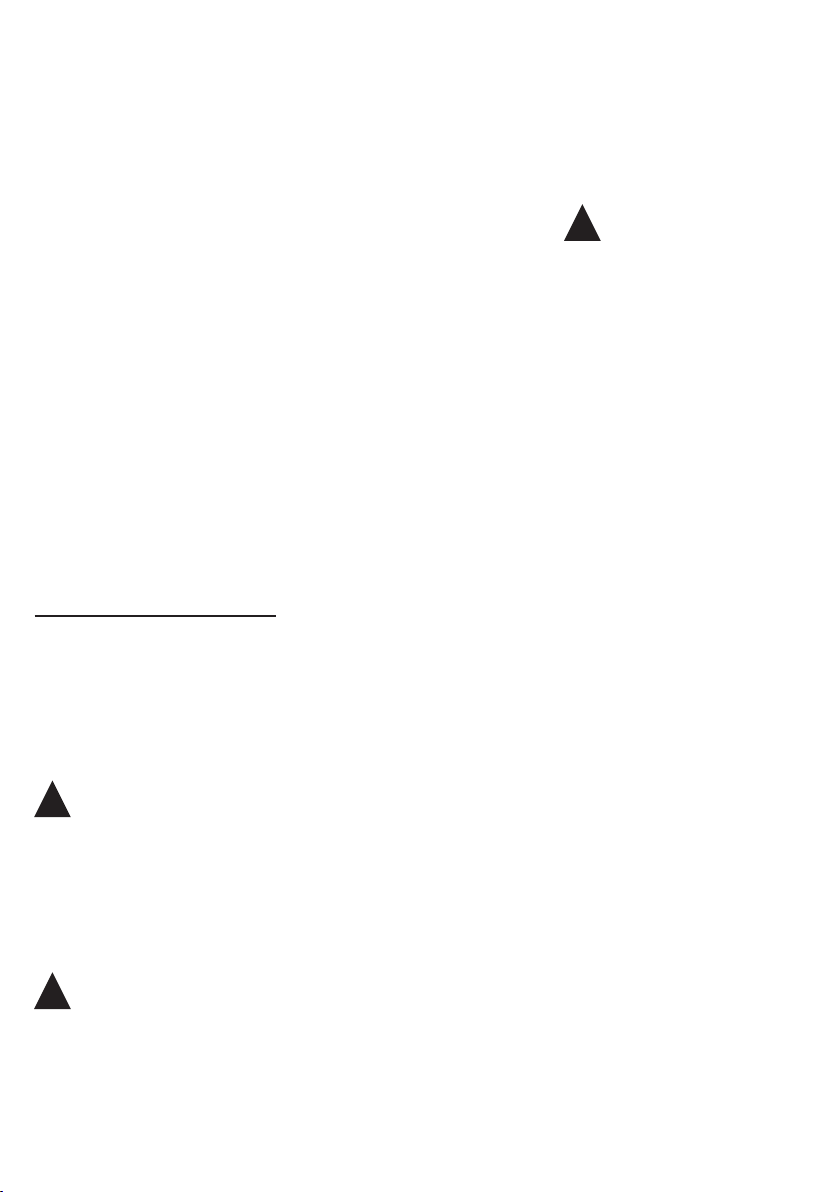

Cleaning:

- the blade: press a damp

cloth on the surface of the

blade and move it slowly

from the center toward the

outside on the blade cover

side and the opposite side Fig. (F). In the same way dry,

it using a dry cloth. NEVER

turn on the machine while

cleaning the blade;

- the safety ring: use a soft

brush to clean the area between the blade and the

safety ring. Be careful NOT

to put your hands close to

the blade;

- the machine body: use a

damp cloth or a sponge,

rinsing frequently with hot

water. Dry carefully.

Reassembling:

- the sharpener (only for

the machine equipped

with sharpener): insert the

sharpener unit as shown in

the gure - Fig. (G) - until it

comes to a stop in the correct position;

- the slice deector: posi-

tion the slice deector in its

seat - Fig. (H);

- the blade cover: reassemble

the blade cover and rotate it

90° clockwise until it locks

into its initial position - Fig (I);

- the meat table (only for

the machine equipped with

the meat table removable mechanism): insert the

meat table on the carriage,

verify that the securing lever returns to the initial

position, verify that the carriage slides freely and check

the correct operation of the

thickness adjustment knob.

MAINTENANCE

Blade Sharpening

(only for the machine

equipped with sharpener)

Frequency and duration of

sharpening depend on the

use of the equipment.

WARNING! If the ma-

!

chine is equipped with

its specic optional sharpener, follow the instructions. Otherwise, contact

the manufacturer or to one

of the Authorized Service

Centers (see SERVICE).

For sharpening, follow the

instructions:

1. position the thickness

adjustment knob in the

safety position - Fig. (A);

2. pull the meat table all

the way back - Fig. (L);

3. raise the sharpener Fig. (M) - and rotate it to

position it in the sharpening conguration -

Fig. (N);

4. release the sharpener;

5. activate the blade by

pressing the start button;

6. carry out sharpening

of the blade pressing

sharpening spring button for 10-15 seconds

- Fig. (O-1);

7. release the above-mentioned button;

8. pull and hold the nishing spring button for

2-3 seconds and release

the button - Fig. (O-2);

9. stop the blade motion

by pressing the stop

button;

10. raise the sharpener and

rotate it to its original

position;

11. release it until it stops;

12. proceed with cleaning

the slicer.

Lubrication

After a regular period of

use, it may be necessary

to lubricate the carriage

guides. We recommend executing this operation every

3 months. For lubrication,

only use acid free oil (we

recommend Vaseline oil).

Do not use vegetable oil.

SERVICE

No user-serviceable parts

are inside. Refer servicing

to qualied personnel. All

the repair and replacement

operations (like blade replacement, replacement

of the motor belt, replacement of the sub-basaplate

electrical system components, repair of structural parts, repair and/or

re-placement of sub-baseplate components, or

similar) shall be executed

exclusively by personnel

authorized by the manufacturer.

In the event service is needed, please contact Van

Berkel USA, Inc. where the

cost of repair or electrical

or mechanical adjustment

can be estimated before the

repair is undertaken. You

may also return your food

slicer to Van Berkel USA,

Inc. for servicing. Please include your return address

and a brief description of

the problem or damage

to the slicer on a separate

sheet inside the box.

Send your slicer, insured

and postage prepaid to:

Van Berkel USA, Inc.

8578 NW 23rd Street

Miami, FL 33122 - USA.

Retain evidence of shipping

for your protection.

Phone Number - Service Department: (786) 261-0766.

E-mail – Service Depar tment:

service@berkelinternational.

com.

WARRANTY AND

RESPONSIBILITY

Van Berkel USA, Inc. (“Van

Berkel”) warrants to the

rst and original buyer of

new equipment that said

equipment, when installed

in accordance with our instructions within North

7

America and subjected to

normal use and care, is free

from defects in material or

workmanship for a period

of one (1) year from the date

of original purchase (“Warranty Period”). Van Berkel

will repair or replace, at our

option, any product or part

that is defective in material

and workmanship without

charge if the product is returned to us postage prepaid with dated proof of

purchase and serial number

within the Warranty Period. This warranty does not

apply to commercial use or

any product abuse.

VAN BERKEL SPECIFICALLY DISCLAIMS ANY

IMPLIED WARRANTY OF

MERCHANTABILITY OR

EXPRESSED OR IMPLIED

WARRANTY OF FITNESS

FOR A PARTICULAR PUR-

POSE. VAN BERKEL SHALL

NOT BE LIABLE FOR ANY

INCIDENTAL OR CONSE-

QUIENTIAL DAMAGES TO

BUYER OR ANY THIRD

PARTY, INCLUDING,

WITHOUT LIMITATION,

LOSS OF PROPERTY, PERSONAL INJURY, OR STATUTORY OR EXEMPLARY

DAMAGES, WHETHER IN

NEGLICENCE, WARRANTY, STRICT LIABILITY OR

OTHERWISE.

This warranty is not transferable and is limited to the

rst and original buyer from

a Van Berkel Authorized

Channel of Distribution. No

warranty is given to subsequent transferees.

8

THE FOREGOING WARRANTY PROVISIONS ARE

A COMPLETE AND EXCLU-

SIVE STATEMENT OF THE

WARRANTY BETWEEN

THE BUYER AND SELLER.

VAN BERKEL NEITHER

ASSUMES NOR AUTHORIZES ANY PERSONS TO

ASSUME ANY OTHER OBLIGATION OR LIABILITY

IN CONNECTION WITH

SAID EQUIPMENT.

Example of items not covered under warranty, but

not limited to just these

items:

1. acts of God, re, water

damage, burglary, accident,

theft, vandalism;

2. freight damage;

3. improper installation or

alteration of equipment;

4. use of generic or aftermarket parts;

5. repairs made by anyone

other than a Van Berkel

designated servicer;

6. periodic maintenance of

equipment including but

not limited to lubrication

and sharpening, and other

adjustments required due

to installation set-up or normal wear;

7. replacement of worn

blades, knives, stones, knobs,

accessories, and miscellaneous expendable supply items;

8. cleaning of equipment;

9. misuse or abuse.

DEMOLITION OF

THE SLICER

The machines are comprised of:

- aluminium/magnesium alloy structure;

- inserts and various components and stainless steel;

- electrical parts and electrical cables;

- electric motor;

- plastic material, etc.

If dismantling and demolition are entrusted to third

parties, use only companies

authorised for disposal of

the above-mentioned materials. Packaging materi-

als and appliances contain

recyclable materials. Your

appliance contains valuable materials that can be

recovered or can be recyclable. Separation of the

remaining waste materials

into different types facilitates the recycling of valuable raw materials. Leave

the appliances at a collection point. You can obtain

information on disposal

from your local authorities.

Troubleshooting

PROBLEM REASON REMEDY

The machine does not start when

the on button is pressed

The machine starts when the on

button is pressed but the operation

indicator light does not turn on

Lack of power or defective

control circuit

The indicator light may be

defective

Check that the plug has been

correctly inserted. If the machine

still does not start, contact the

Service Center

Do not use the machine with the

indicator light off. Contact the

Service Center

The machine does not stop when

the stop button is pressed

The control circuit may be

defective

Immediately stop the machine,

removing the plug from the mains

outlet. Contact the service center

9

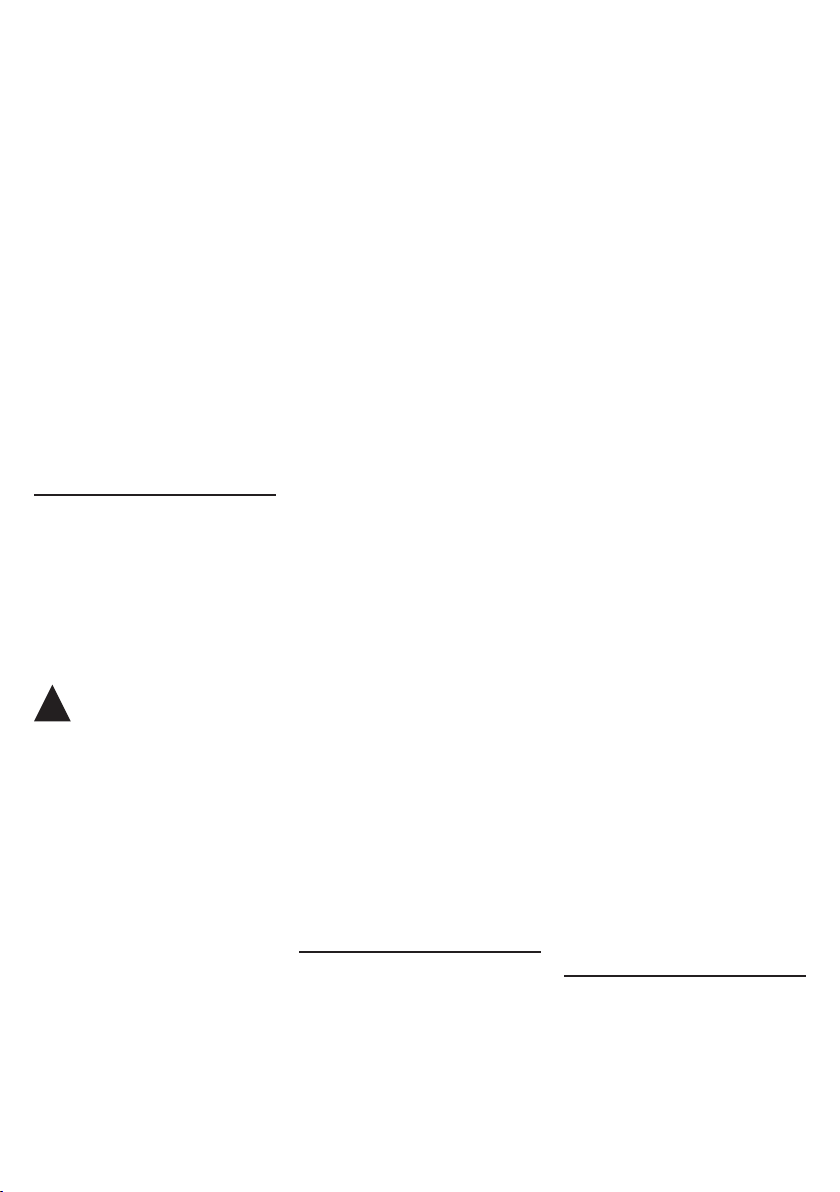

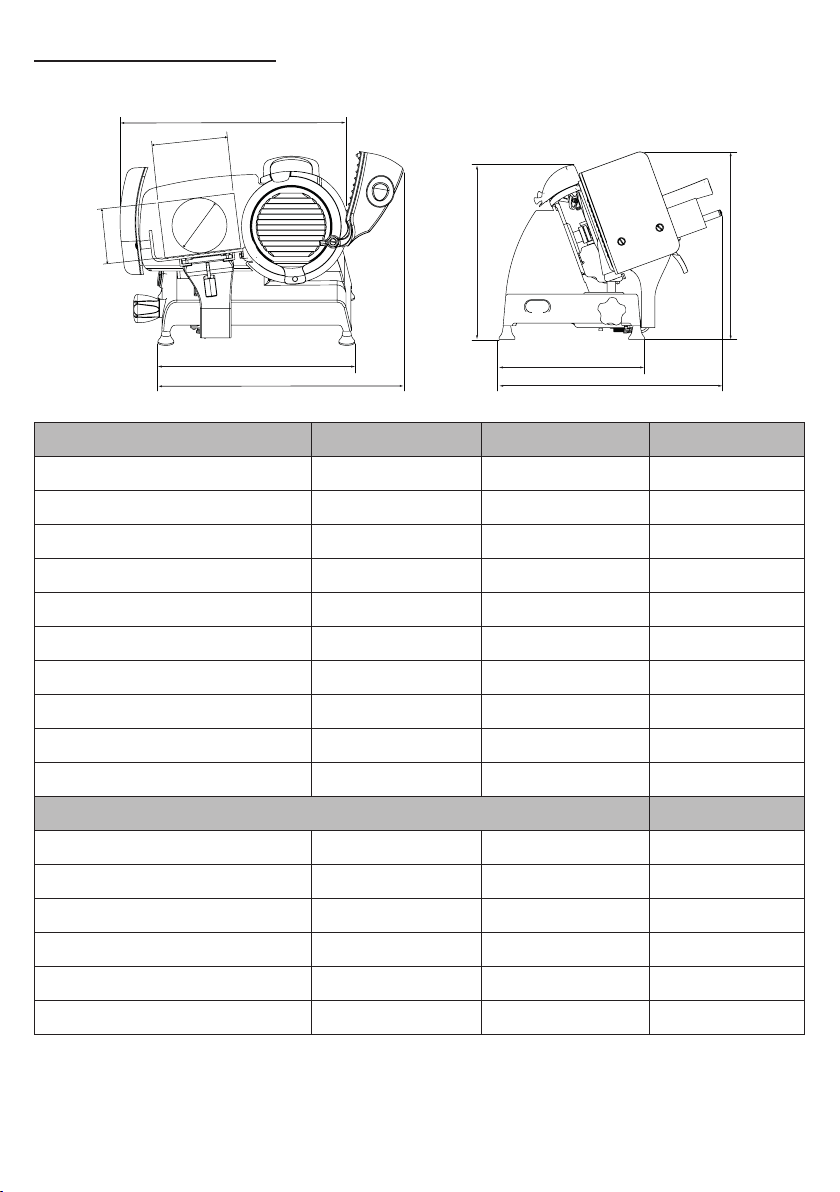

TECHNICAL CHARACTERISTICS

I

B

C

A

G

H

L

E

F

MODEL 220 250 300

A 168 mm 178 mm 230 mm

B 185 mm 185 mm 245 mm

C 160 mm 175 mm 225 mm

D 395 mm 395 mm 480 mm

E 320 mm 320 mm 380 mm

F 505 mm 505 mm 475 mm

G 390 mm 390 mm 430 mm

H 435 mm 435 mm 485 mm

I 490 mm 515 mm 635 mm

L 580 mm 570 mm 630 mm

SPECIFICATIONS

D

Circular cutting capacity 168 mm 178 mm 230 mm

Rectangular cutting capacity 185x160 mm 187x175 mm 245x225 mm

Max slice thickness 14 mm 14 mm 12 mm

Blade diameter 220 mm 250 mm 300 mm

Weight 22 Kg 22 Kg 27 kg

Motor raiting 0,19 kW 0,19 kW 0,21 kW

Note: As we actually strive to improve our products, specications are necessarily subject to change

without notice.

10

FR

MANUEL D’INSTRUCTIONS - US: Trancheuses électriques Red Line - Home Line - Easy Line

MODÈLES:

RSEGMD (Home Line 250) - RSEGS/RSEGM/RSEGL/RSAGS/RSAGM/RSAGL (Redline 220/250/300)

ESEGS/ESEGM/ESEGL/ESAGS/ESAGM/ESAGL (Easyline 220/250/300)

8

9

14

19

3

4

7

17

6

15

1

2

5

PRINCIPAUX

1. Bouton de démarrage

2. Bouton d’arrêt

3. Plaque d’identication,

données techniques

4. Pied d’appui

5. Poignéè de réglage de

l’épaisseur de la tranche

6. Plaque de la jauge

d’épaisseur (écran)

7. Protection de sécurité

8. Plateau port-aliment

9. Poignée du presse-aliment

10. Lame

11. Anneau de sécurité

12. Aiguisoir (en option)

13. Poignée du couvre-lame

14. Deecteur de tranche

15. Base

16. Support du plateau

17. Presse-aliment

18. Disque pare-lame

19. Câble d’alimentation

12

ÉLÉMENTS

Fig. 1

16

13

10

18

OFF 2 ON 1

11

11

Loading...

Loading...