Berkel 932, 933 Service Manual

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

Service Manual

SERVICE MANUAL

932 & 933

SEMI AUTOMATIC SLICERS

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

2

Service Manual

CONTENTS

Table of Contents:

1 INTRODUCTION

2 SAFETY

3 ELECTRICAL DIAGRAMS

4 TECHNICAL INFORMATION

5 APPENDICES

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

3

Service Manual

1 INTRODUCTION

Table of Contents:

1.0 INTRODUCTION

The Berkel 932 and 933 slicers are stainless steel robust slicers designed for

continuous use, these slicers are IP33 rated.

The slicers have a simple electronic control and are easy to operate.

The carriage can be moved either automatically or manually.

2 SAFETY

Table of Contents:

2.0 SAFETY

Page

2.1 Safety devices 4

2.2 Products that can’t be sliced 4

CAUTION! ALWAYS READ AND FULLY UNDERSTAND THE USER

INSTRUCTIONS BEFORE OPERATING THIS EQUIPMENT

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

4

Service Manual

2.1 Safety devices

The machine will not self start after a voltage drop

Fixed metal ring around the blade which is non removable

The thickness plate is locked when the carriage is tilted.

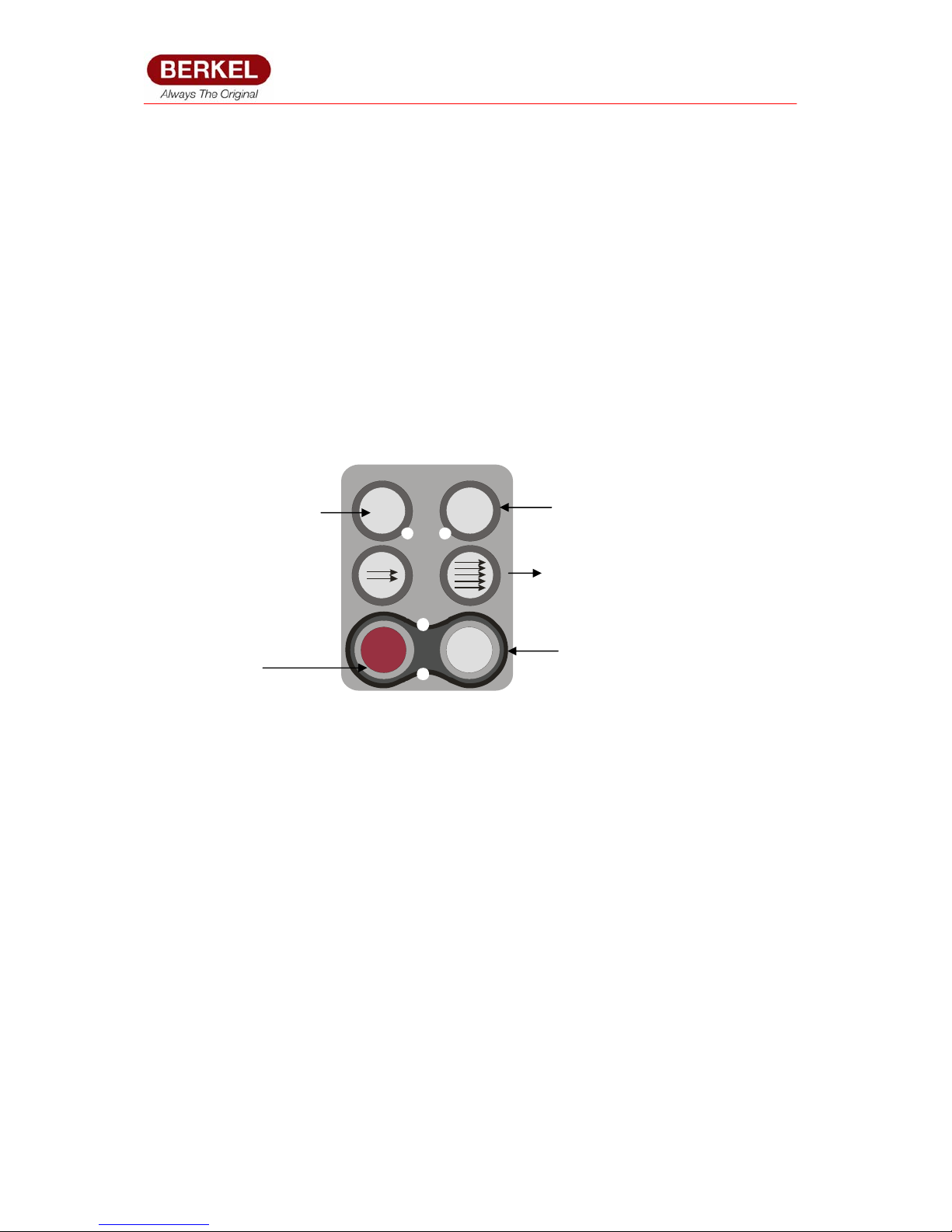

Emergency switch ‘OFF’ button (See below)

2.2 Products that can’t be sliced

Non food items

Food with bones

Deep frozen food products

Note: To slice quantities of cheese the Teflon coated option is recommended

O

I

0

manual

0 / I

> 1 sec

Automatic

I

Emergency OFF

button

Switch ON to

standb

y

Manual – knife runs

only when held down

for > 1 second. Or

Auto carriage switch

OFF

Automatic carriage

turn ON

Carriage speed decrease /

increase buttons: From 32 to

52 table strokes / min in

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

5

Service Manual

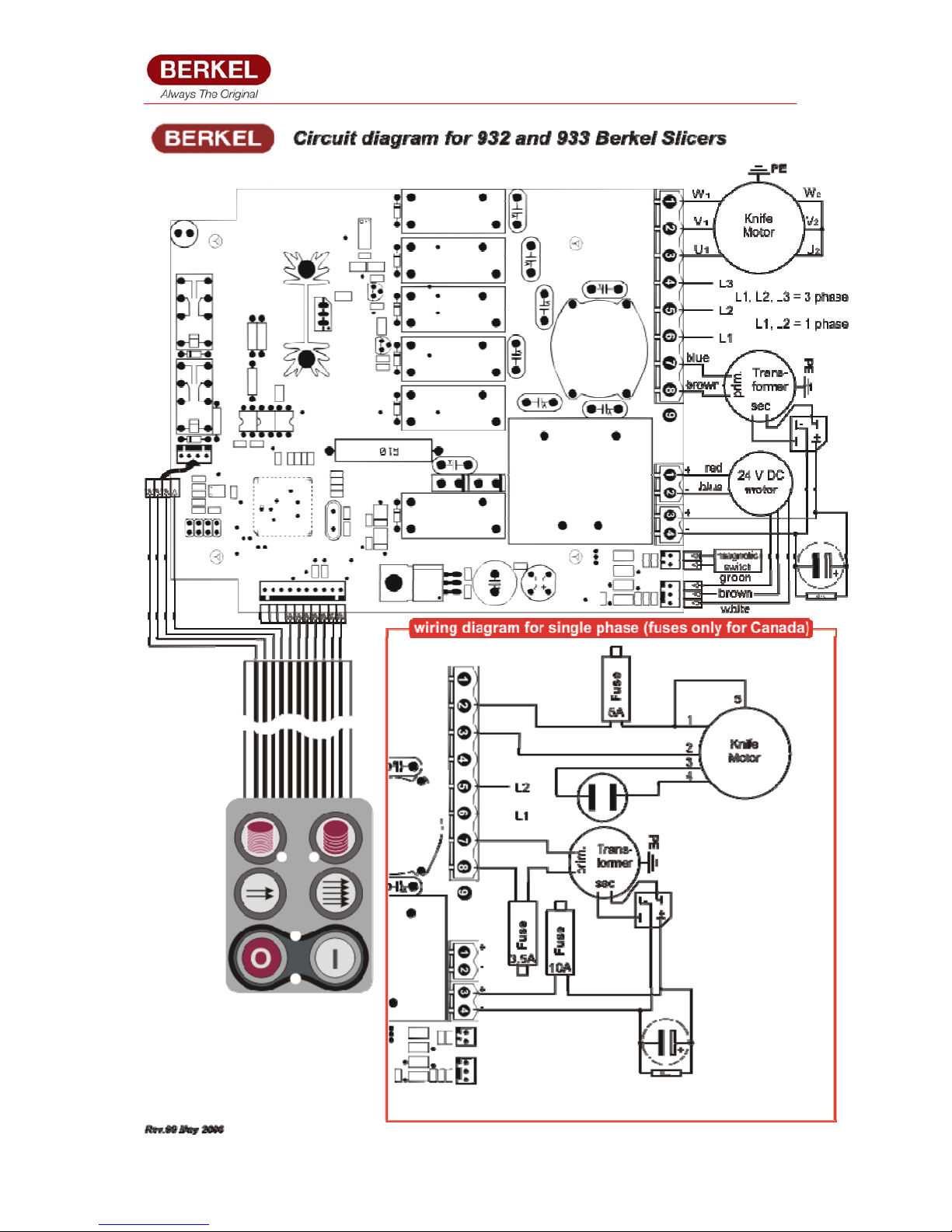

3 ELECTRICAL DIAGRAMS

Table of Contents:

Page

3.0 ELECTRICAL DIAGRAM 6

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

6

Service Manual

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

7

Service Manual

4 TECHNICAL INFORMATION

Table of Contents:

Page

4.1 TECHNICAL DATA 8

4.2 MAINTENANCE 9

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

8

Service Manual

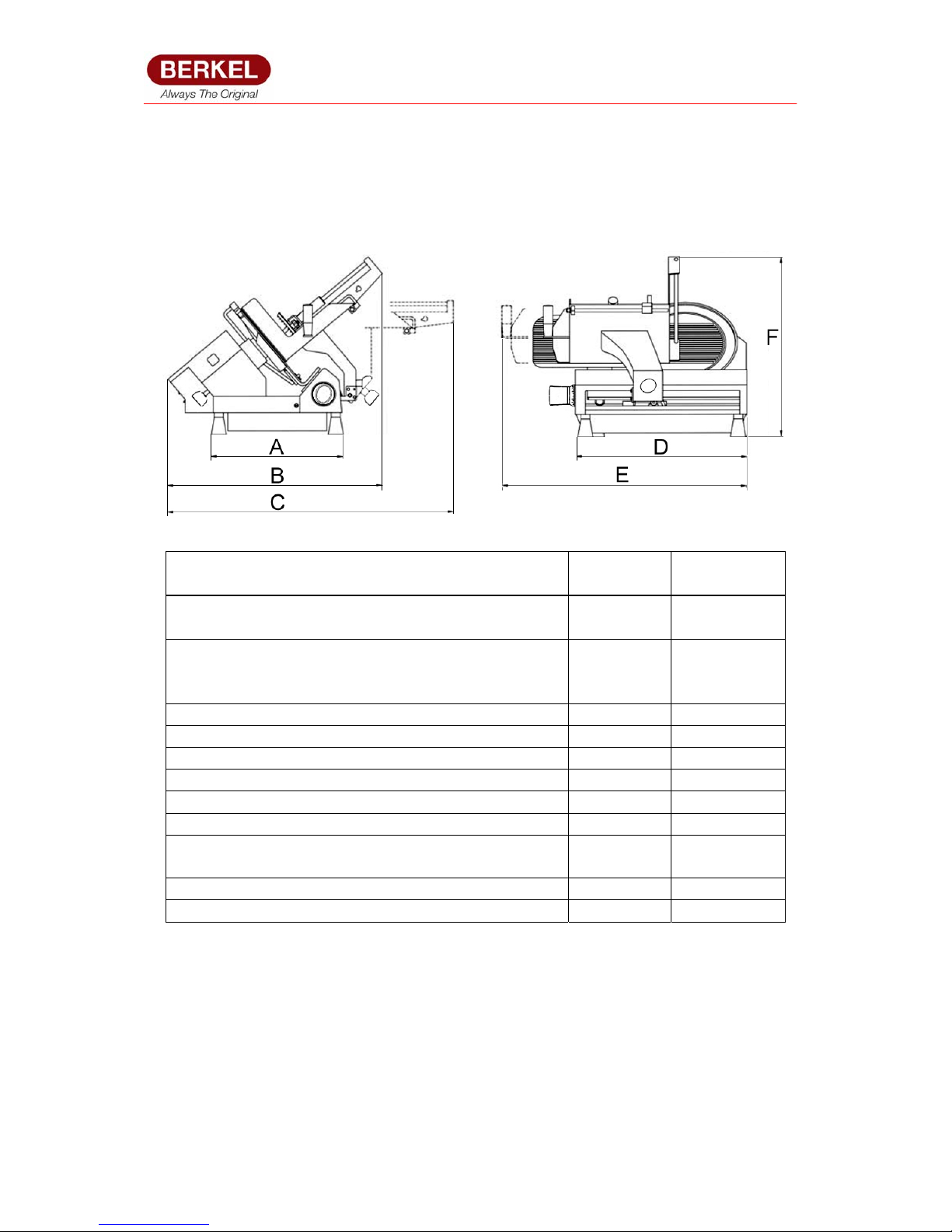

4.1 TECHNICAL DATA

MODELS BERKEL

932

BERKEL

933

KNIFE DIAMETER: mm

: inches (approximate)

330

13

350

14

CUTTING CAPACITY: Rectangular

mm : Round

320 x

220h

220

320 x 235h

235

Maximum slice thickness mm 25 25

Dimension: M 680 680

Overall Dimension: L 1000 1000

Overall Dimension: F 950 950

Footprint Dimension: D 480 480

Footprint Dimension: A 390 390

Maximum distance between the pusher and

gauge plate

300 300

Speed of table 32 - 52 32 - 52

Motor power rating 1 PHASE 0.6kW 0.6kW

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

9

Service Manual

4.2 MAINTENANCE

SERVICE CHECKLIST

1 Ensure that when the index knob is set to zero that the knife is safe –

not exposed.

2 Check all interlocks whether mechanical or electrical function

correctly.

3 Check that all safety guards are in place, are fitted correctly and are

not damaged

4 Check all moving parts and lubricate where necessary

5 Ensure the knife is sharp

6 Remove the knife using the customers knife remover and check for

safety also check condition of knife screws and knife bearing

7 Check drive belt and re-tension or replace if necessary and check

tension of chain drive for carriage and tension if required

8 Visually check the electrical components of the machine including the

mains lead & plug, keypad etc…

9 Check the wear on the knife has not exceeded a gap between the

knife and finger guard of 6mm.

10 If necessary move the gauge plate up to the knife edge as per factory

setting

11 Liaise with the customer to see if they have noticed any problems

12 Clean any sharpening dust off the machine and ask the customer to

check the first slice just in case!

If you find any hazardous problems with the machine i.e. interlock not functioning

then inform the customer that the machine is not safe to be used and note the issue

on your TJR.

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

10

Service Manual

5 APPENDICES

Table of Contents:

Page

5.1 OPTIONS 10

5.2 RECOMMENDED PARTS 10

5.3 EXPLODED VIEWS WITH PARTS LISTINGS 11

5.1 OPTIONS

Teflon coating on knife, gauge plate, centre plate and meat table top

Top clamp meat table

5.2 TECHNICIANS RECOMMENDED PARTS

PART NUMBER DESCRIPTION QTY

B9S-2.24 Countersunk screw (Knife screw) 4

B92-009-014 Sharpener stone - fine 2

B92-2.6 Blade 330mm, 932 1

B93-2.6 Blade 350mm, 933 1

BS936-312 Knife remover 330mm 1

G350-313 Knife remover 350mm 1

B9S-52.32 Switch foil 1

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

11

Service Manual

5.3 EXPLODED VIEWS AND PART NUMBERS

Page

5.3.1 932/933 Machine body (Drawing 1) 12

5.3.2 932/933 Blade drive unit (Drawing 2) 14

5.3.3 932/933 Knife hub (Drawing 3) 16

5.3.4 932/933 Thickness plate complete with support (Drawing 4) 18

5.3.5 932/933 Index knob and cam assembly (Drawing 5) 20

5.3.6 932/933 Meat table and support (Drawing 6) 22

5.3.7 932/933 End piece holder assembly (Drawing 7) 24

5.3.8 932/933 Product fence (Drawing 8) 26

5.3.9 932/933 Sliding carriage support (Drawing 9) 28

5.3.10 932/933 Electrical components (Drawing 10) 30

5.3.11 932/933 Carriage chain drive (Drawing 11) 32

5.3.12 932/933 Chain cog assembly (Drawing 12) 34

5.3.13 932/933 Plate for sliding support (Drawing 13) 36

5.3.14 932/933 Auto / manual lever (Drawing 14) 38

5.3.15 932/933 Electronic PCB & Transformer (Drawing 15) 40

5.3.16 Additional Parts 42

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

Service Manual

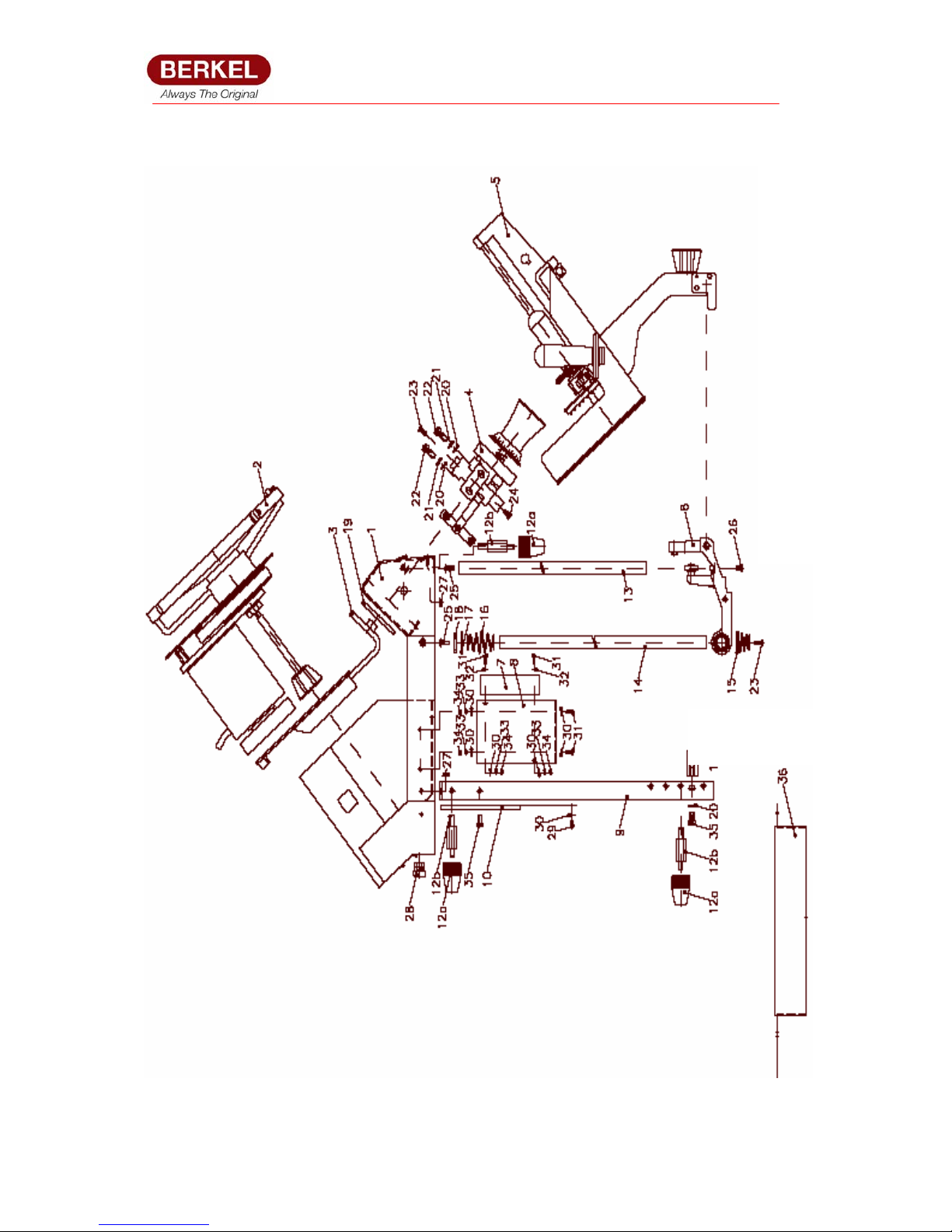

5.3.1 932 / 933 Machine body (Drawing 1)

900 Series 932-933 Date 11-06-08 SM - Code SC1- Rev. 0.1

13

Service Manual

5.3.1 932 / 933 Machine Body (Drawing 1)

REF PART NO DESCRIPTION

1 B9S-1 Machine Body Complete

2 B92-2 Blade drive unit complete assembly (drawing 2)

B93-2 Blade drive unit complete assembly (drawing 2)

3 B92-3 Thickness plate complete with support (drawing 4)

B93-3 Thickness plate complete with support (drawing 4)

4 B9S-4 Adjusting lever complete assy (Drawing 5)

5 B9S-5 Carriage complete assy (drawing 6)

6 B9S-6 Sliding support complete assy (drawing (9)

7 B9S-7 Electric complete assy ( drawing 10)

8 B9S-8 Fixing plate for electric components

9 B9S-9 Fixing bar for feet

10 B9S-10 Cover sheet for motor Distance piece for fixing bar

11 B9S-11 Distance piece for fixing bar

12a B9S-12a Foot

12b B9S-12b Distance piece for foot

13 B9S-13 Guiding shaft for carriage support. Short

14 B9S-14 Guiding shaft for carriage support

15 B9S-15 Conical pressure spring

16 B9S-16 Double conical pressure spring

17 B9S-17 Washer

18 B9S-18 Stop ring

19 B9S-19 Sealing

20 B9S-20 Washer

21 B9S-21 Spring washer

22 B9S-22 Cylindrical screw

23 B9S-23 Countersunk screw

24 B9S-24 Hexagon screw

25 B9S-25 Cup screw

26 B9S-26 Countersunk screw

27 B9S-27 Hexagon nut with flange

28 B9S-28 Strain relief

29 B9S-29 Lens head screw

30 B9S-30 Washer

31 B9S-31 Cylindrical screw

32 B9S-32 Washer

33 B9S-33 Toothed disk

34 B9S-34 Hexagon nut

35 B9S-35 Cylindrical screw

36 B9S-36 Bottom plate

Loading...

Loading...