Berkel 909A User Manual

Model 909A

C

Safety and Convenience Features

Berkel Model 909A manual gravity feed slicer features

Berkel’ s time proven hollow ground stainless steel knife,

built-in, single lever, dual action sharpener and many safety

features. The permanent, tapered guard covers the non-slicing

portion of the knife even when the sharpener and center

plate are removed. The gauge plate interlock prevents the

product table from being removed unless it is in the full

forward or home position and the gauge plate is closed.

Removing the product table locks the gauge plate in the

closed position. The center plate interlock prevents the slicer

from operating if the center plate is removed. A built-in timer

automatically shuts off the unit after 15 seconds of non-use.

Units are easy to clean and disassemble quickly without tools.

Accessories

❏ Stainless steel vegetable ❑ 4” Extension NSF

chute with pusher legs (set of 4)

❏ Skewers with coring tool ❏ SURE-LOCK LIFT™

❏ Sharpening kit ❏ Slaw tray

❏ Receiving tray ❏ Juice cup

❑ Product fence

Item #

Model 909A

Manual Gravity Feed Slicer

Standard Features

➤ 2-speed, 1/2 HP, totally enclosed and permanently

lubricated knife motor

➤ Furnished in 115/60/1, 5.5/4.5 amp, AC, ETL listed; also

available in 1/3 HP, 230/60/1, 2.9 amp, AC, ETL listed

➤ Low 12/5 VDC circuitry for added operator protection

➤ Finish is stainless steel and sanitary burnished aluminum;

unit disassembles quickly without tools for easy cleaning

➤ Nominal 12-1/2” (318 mm) diameter, hollow ground,

hardened and polished forged stainless steel knife

➤ Precise slice adjustment to a thickness of

27/32” (21 mm)

➤ The carriage handles food up to 11” (280 mm) wide,

by 6” (152 mm) high or 8” (203 mm) diameter

➤ Rear-mounted, stainless steel meat pusher extends over

the entire length of the product table

➤ Ergonomic style handle for ease of use

➤ Built-in, top-mounted, two stone knife sharpener with

single lever , dual-action system for a lasting, razor-sharp

edge

➤ Permanent, tapered knife ring guard covers non-slicing

portion of knife even when the sharpener and center

plate are removed

➤ Center plate interlock prevents the slicer from running

when center plate is removed

➤ No-Volt release prevents activation of the slicer in the

event of power interruption; operator must restart the

slicer

➤ Gauge plate interlock prevents removal of the product

table until it is in the full forward or home position and the

gauge plate is fully closed; once table is removed, gauge

plate cannot be reopened

➤ Built-in timer automatically shuts the slicer off after

15 seconds of non-use

➤ Q-P-Q nickel plated transport slide rod with reservoir wick

for reduced wear

➤ On/off, 3-position, moisture protected switch with

power light

➤ Attached 6-foot, flexible, 3-wire cord and plug for

grounded receptacle

Options

1/3 HP, 230/60/1, 2.9 amp, AC, ETL listed

❏

Manual Gravity Feed Slicer Model 909A

Approved By:

Date

Berkel Company • 4406 Technology Drive • South Bend, IN 46628-9700

574-232-8222 • 800-348-0251 • FAX 888-888-2838 • www.berkel.com

Form #SPC08-0902N

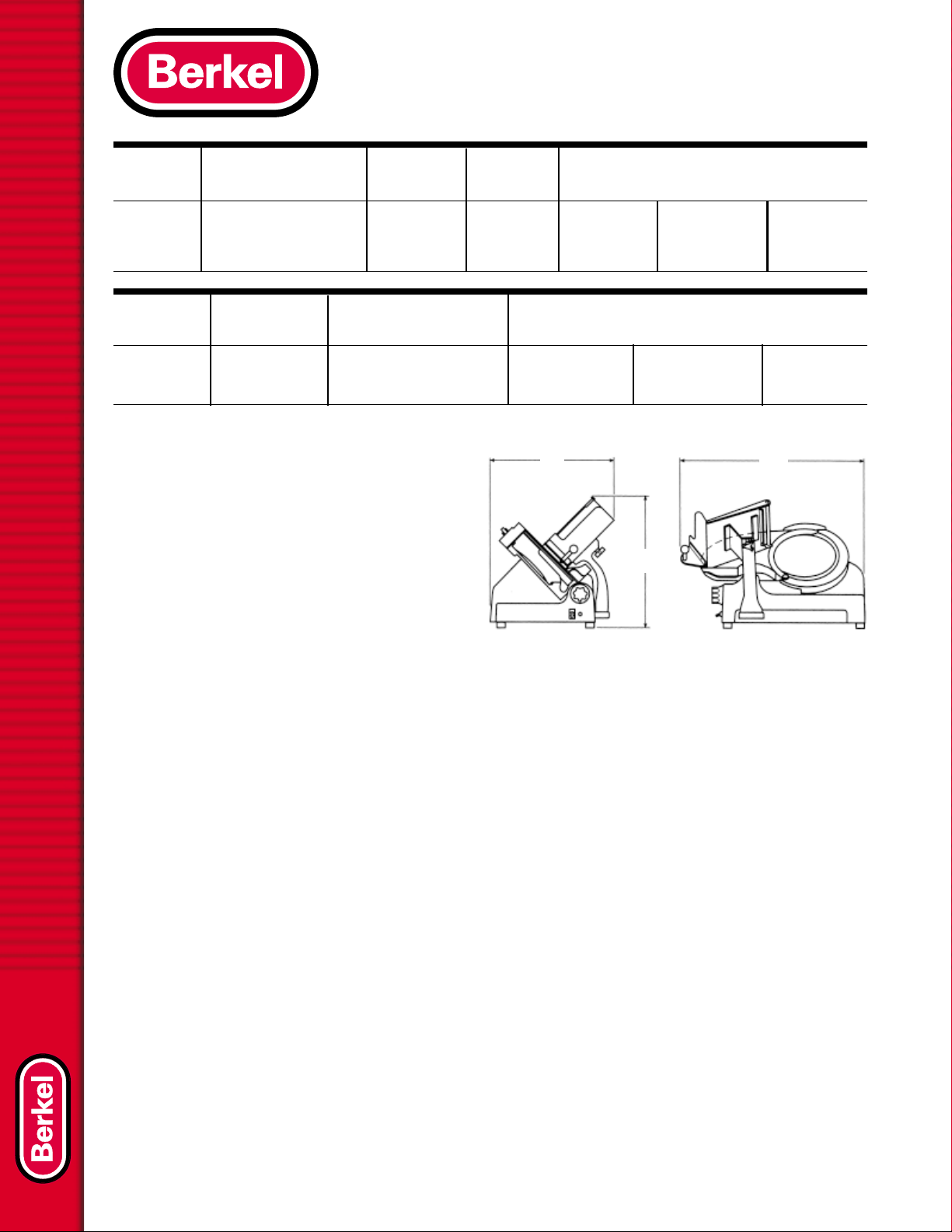

Model No. Cutting Slice Knife Product Dimensions

Capacity Thickness Dia. Width A Depth B Height C

909A 11” (280 mm) wide to 27/32” 12-1/2” 20” 29” 21”

6” (152 mm) high (21 mm) (318 mm) (508 mm) (737 mm) (533 mm)

8” (203 mm) dia.

Motor Electrical Weight Box Dimensions

2-speed 115/60/1 Net 90 lbs. (41 kg) 32” 26” 27”

1/2 HP Ship 120 lbs. (55 kg) (813 mm) (660 mm) (686 mm)

Specifications

Motor: 2 speed, 1/2 HP, totally enclosed, permanently

lubricated ball bearings, thermally protected.

Electrical: Furnished in 115/60/1, 5.5/4.5 amp, AC,

ETL listed. Also available in 1/3 HP, 230/60/1, 2.9 amp,

AC, ETL listed. Low 12/5 VDC circuitry for added

operator protection.

Finish/construction: All food contact areas are

stainless steel including the pusher, gauge plate,

product table, center plate and knife; sanitary burnished

aluminum ring guard and one-piece base with non-slip

feet. Slicer disassembles quickly without tools

for easy cleaning.

Knife: Nominal 12-1/2” (318 mm) diameter, hollow

ground, hardened and polished forged stainless steel.

Cutting Capacity: Carriage handles food up to

11” (280 mm) wide by 6” (152 mm) high or 8”

(203 mm) diameter .

Slice Thickness: Precision gear system with eccentric

gear to prevent backlash, provides infinite slice

adjustment and consistent cuts of hard or soft foods

from tissue thin to 27/32” (21 mm).

Full Gravity Feed: Full 45° angle feed requires less

mechanical pressure. Equipped with stainless steel,

rear-mounted pusher that covers the entire length of

the product table to hold product and minimize waste.

Manual Gravity Feed Slicer Model 909A

An optional, screw-in weight is also available. Ergonomic

style handle for ease of use.

Knife Sharpener: Built-in, top-mounted, two stone,

single lever , dual-action system for a lasting,

razor-sharp edge. Unit is removable and submersible

for easy cleaning.

Knife Ring Guard: Permanent, tapered guard covers

non-slicing portion of knife edge even when the

sharpener and center plate are removed.

Model 909A

Manual Gravity Feed Slicer

Width Depth Height

A B

C

Center Plate Interlock: Deactivates the slicer when center

plate is removed. Slicer will not run.

Gauge Plate Interlock: Prevents removal of table until

gauge plate is closed and the product table is in the full

forward or home position. Once product table is removed

the gauge plate is locked and cannot be opened.

No-Volt Release: Prevents activation of the slicer in the

event of power interruption. Operator must restart slicer.

15 Second Timer: Built-in timer automatically shuts off the

slicer after 15 seconds non-use.

On/Off Switch: Highly reliable, moisture resistant, 3position switch activates the knife motor; with power light.

Q-P-Q Nickel Plated Transport Slide Rod with

Reservoir Wick: E-nickel plated rod undergoes Q-P-Q

impregnation increasing the lubricity of the stainless steel

reducing wear properties of the rod and bushings.

Cord and Plug: Attached 6-foot, flexible, 3-wire cord and

plug for grounded receptacle.

Warranty: All parts, service and travel coverage for one

year , excluding wear items.

As we continually strive to improve our products, specifications

are necessarily subject to change without notice.

Berkel Company • 4406 Technology Drive • South Bend, IN 46628-9700

574-232-8222 • 800-348-0251 • FAX 888-888-2838 • www.berkel.com

Form #SPC08-0902N Made in the U.S.A. © 2002 Berkel Company Litho in U.S.A.

Loading...

Loading...