Page 1

vbOnline Pro Condition Monitoring System

Datasheet

Bently Nevada Machinery Condition Monitoring

Description

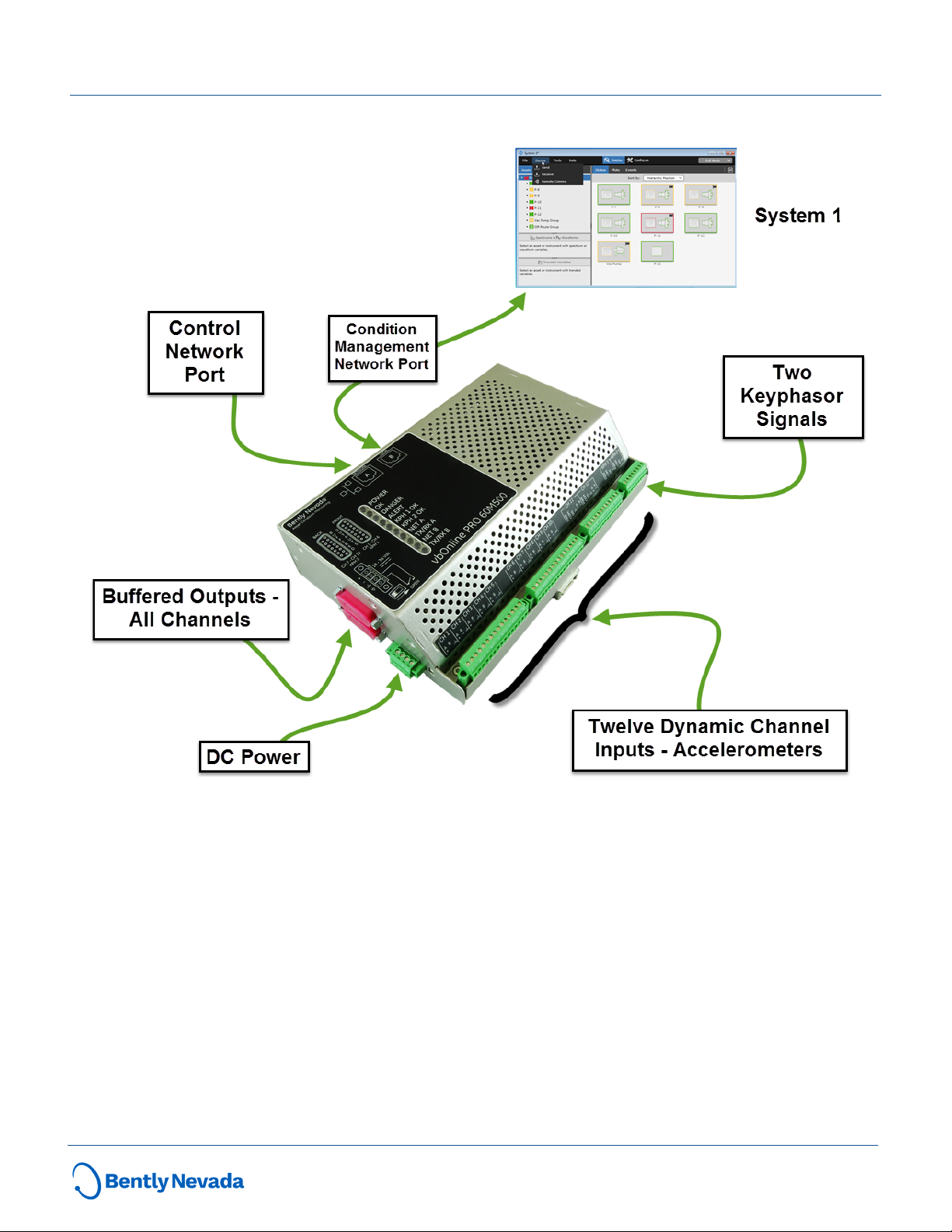

The vbOnline Pro Condition Monitoring System uses

sophisticated signal processing algorithms together with

machinery operating states to monitor assets continuously.

This system is part of a condition based maintenance program

that identifies problems before assets begin to fail.

Benefits of the vbOnline Pro Condition Monitoring System are:

n Cost savings from reduced machinery down time

n Early detection of bearing defects

n Reduction of damage to assets

The monitoring system's key features are:

n Signal conditioning

n Alarming

n Speed inputs

n Control system communication

The vbOnline Pro Condition Monitoring System

communicates with System 1 via dual Ethernet connections.

The monitoring system uses 24 bit analog/digital conversion

and 40 kHz bandwidth to monitor rolling element bearing

machinery and gearing.

Sophisticated signal processing algorithms extract

measurement and health indices from each accelerometer

point. The algorithms can be custom tuned to specific bearing

and gear box characteristics.

The vbOnline Pro vbOnline ProCondition Monitoring System

exports trended measurements like direct, bias, speed, gap as

well as channel NOT OK status to third party systems such as

DCS via Modbus over ethernet.

The vbOnline Pro Condition Monitoring System components

are the vbOnline Pro monitor, System 1, Bently Nevada

Monitor Configuration software, transducers, and cables.

Document: 113M5326

Rev. D

Page 2

vbOnline Pro Condition Monitoring System

Datasheet

Figure 1: vbOnline Pro Condition Monitoring System Components

2/10 113M5326 Rev. D

Page 3

vbOnline Pro Condition Monitoring System

Datasheet

on Network B

Specifications

Electrical Specifications

Inputs

Minimum Input

Power

Maximum Input

Power

Maximum Current 1.7 A

Maximum Inrush

Current

Maximum Inputs

Dynamic Range 110 dB @ fs = 102.4 ksps

Signal/Noise Ratio 110 dB @ fs = 102.4 ksps

A/D Conversion

Bandwidth 0 to 40kHz

Outputs

Buffered Signal

Outputs

Two Independent Ethernet Ports

Network A

Network B

Power LED

OK LED

Danger LED Indicates a Danger Alarm condition

Alert LED Indicates an Alert condition

Kph 1 OK LED

Kph 2 OK LED

Net A Indicates Network A has a valid link

TX/RX A

Net B Indicates Network B has a valid link

TX/RX B

18 Vdc

36 Vdc

2.7 A

Less than 5 ms

12 dynamic signals

2 Keyphasor signals

Sigma-Delta

24 bits nominal

Two 15 pin DSUB connector 550 ohm

output impedance

10/100BaseT

Network DHCP Port

10/100BaseT

Local Static IP Port

LEDs

Indicates when a proper power input

is present

Indicates when the system is

functioning properly

Indicates Keyphasor signal 1 is

triggering

Indicates Keyphasor signal 2 is

triggering

Indicates network traffic is flowing

on Network A

Indicates network traffic is flowing

Accuracy

Direct pk or rms ± 1.1%

Bias +0.8 V / -1.34 V

Dynamic Data

Configurable

Synchronous

Waveforms

Spectral Lines 100 to 12,800 in increments of 2X

Spectrum

Frequency Range

Supported

Frequency Range

Spectral Resolution 100 to 12,800 in increments of 2X

Spectrum Window

Types

Demodulation

Bandwidth

Update Rate

Data Storage

Up to 8192 samples

User Configurable up to 40 kHz

0 Hz to 40,000 Hz

Hanning

125 Hz to 10 kHz

18 preset options

Up to once every 10 minutes

User configurable

8 hours

Typical

No alarms

Keyphasor Signal Inputs

Speed Range 1 to 120,000 rpm

1 to 100 rpm ± - 0.1 rpm

Speed Accuracy

100 to 10,000 rpm ± 1 rpm

10,000 to 120,000 rpm ± 10 rpm

Supported Transducers

Acceleration

Channels

Keyphasor Channels

Compatible with constant current

accelerometers

Proximity switches such as

Turck Ni8–M18T–AP6X7M

Bently Nevada Proximity Probes

3/10 113M5326 Rev. D

Page 4

vbOnline Pro Condition Monitoring System

Datasheet

Physical

8.88 X 5.89 X 2.17 inches

Dimensions

Weight

Mounting DIN Rail Mounting

225 X 150 X 55 mm

See "Graphs and Figures" on page7

1.4 kg

3 lbs

Environmental Limits

Operating

Temperature Range

Storage

Temperature Range

Relative Humidity

Pollution Degree

-40 °C to +70 °C

-40 °F to 158 °F

-45 °C to +85 °C

-49 °F to 185 °F

0% to 95% non-condensing for

operation and storage

Pollution Degree 2

Working voltage < 30 Vrms or 60 Vdc

4/10 113M5326 Rev. D

Page 5

vbOnline Pro Condition Monitoring System

Datasheet

SPECIFIC CONDITIONS OF USE:

Compliance and Certifications

For a detailed listing of country- and productspecific approvals, refer to the Approvals Quick

Reference Guide (document 108M1756), at

Bently.com.

EMC

Standards

EN 61000-6-2 Immunity for Industrial

Environments

EMC

EN 61000-6-4 Emissions for Industrial

Environments

Directives

2014/30/EU

Electrical Safety

Standards:

Electrical Safety

EN 61010-1

Directives

2014/35/EU

Hazardous Area Approvals

1. The device shall be installed in an

additional enclosure that provides an

ingress protection rating not less than

IP54 and meets the enclosure

requirements of IEC 60079-0.

2. The equipment shall only be used in an

area of not more than pollution degree 2,

as defined in IEC 60664-1.

3. Transient protection shall be provided

that is set at a level not exceeding 140%

of the peak rated voltage value at the

supply terminals to the equipment.

4. Tightening torque range is 2.0 in-lbf [0.22

N-m] minimum / 2.2 in-lbf [0.25 N-m]

maximum.

WARNING

HAZARDOUS

ENVIRONMENT

DO NOT DISCONNECT OR OPEN

EQUIPMENT UNLESS POWER

HAS BEEN SWITCHED OFF OR

THE AREA IS KNOWN TO BE

NON-HAZARDOUS.

For a detailed listing of country- and productspecific approvals, refer to the Approvals Quick

Reference Guide (document 108M1756), at

Bently.com.

Class I, Zone 2

AEx nA IIC T4 Gc

Class I, Division 2

Groups A, B, C and

CSA/NRTL/C

ATEX/IECEx

D

Install per drawing

115M4822

T4 @ Ta = -40 °C ≤

Ta ≤ +70 °C

II 3 G

Ex nA IIC T4 Gc

Ex ec IIC T4 Gc

Install per drawing

115M4822

T4 @ Ta = -40 °C ≤

Ta ≤ +70 °C

5/10 113M5326 Rev. D

Page 6

vbOnline Pro Condition Monitoring System

Datasheet

Ordering Information

For the detailed listing of country and product specific

approvals, refer to the Approvals Quick Reference

Guide (108M1756) available from www.Bently.com.

60M500 - AA - BB

A: Agency Approvals

00 None

05

B: System 1 License

00 None

01 One

Sensors and Cables

Part Number Description

AS3100S2-Z2

AM3100T2-Z

AP3500T2-Z1

AP3500S2-Z1

330780

330180

330980

200355

287844

284613-050

284613-030

Multi Approvals (CSA, IECEx, ATEX)

Accelerometer, Side Exit

100 mV/g

0.7 - 10,000 Hz

Accelerometer, Top Exit

100 mV/g, 0.4 - 14,000 Hz

Accelerometer, Top Exit

500 mV/g, 0.2 - 2,300 Hz

Accelerometer, Side Exit

500 mV/g, 0.2 - 3,700 Hz

See 3300 XL NSv

Proximity Transducer System

datasheet,

document 147385,and

3300 XL 8mm Proximity Transducer

System datasheet,

document 141194.

3300 XL 11mm Proximity Transducer

System

3300 XL 8mm Proximity Transducer

System

3300 XL NSV Proximity Transducer

System

Low Frequency Accelerometer 100

mV/g

0.2 - 10,000 Hz

Accelerometer Mounting Stud

1/4 -28 to M8x1.25 SST

Accelerometer Cable

15.2 m (50 ft) with straight connector

Accelerometer Cable

9.1 m (30 ft) with straight connector

Part Number Description

Accelerometer Cable

284622-050

284622-030

138131

323314-01

323314-02

15.2 m (50 ft) with right angle

connector

Accelerometer Cable

9.1 m (30ft) with right angle

connector

CAT5 Cable

Minimum cable length is 3 feet.

Maximum cable length is 320 feet.

Cable lengths are 3, 6, 10, 25, 40, 50,

75,

85, 100, 120, 150, 200, 250 and 320

feet.

Buffered output cable

15-pin DSUB to 7 SMA connectors

Buffered output cable

15-pin DSUB to 7 BNC connectors

Accessories

Bently Nevada Monitor

Configuration Software DVD

100M9465-01

BNMC Software is included with

vbOnline Pro Condition Monitoring

System for user administration, IP

configuration and firmware updates.

Miscellaneous

104M2708-01 Spare Power Input Connector

104M3960-01 Spare Input Connector Ch 1-10

104M3961-01 Spare Input Connector Ch 11-12

104M3962-01 Spare Input Connector KPH 1-2

6/10 113M5326 Rev. D

Page 7

vbOnline Pro Condition Monitoring System

Datasheet

Graphs and Figures

Dimensions shown are in inches (millimeters)

Figure 1: vbOnline Pro

7/10 113M5326 Rev. D

Page 8

vbOnline Pro Condition Monitoring System

Datasheet

Figure 2: vbOnline Pro - Side View

Figure 3: vbOnline Pro - Top and Bottom Views

8/10 113M5326 Rev. D

Page 9

vbOnline Pro Condition Monitoring System

Datasheet

Figure 4: Recommended Minimum Clearance Window for Cable Terminations and

Monitor Cooling

9/10 113M5326 Rev. D

Page 10

vbOnline Pro Condition Monitoring System

Datasheet

Copyright 2019 Baker Hughes, a GE company, LLC ("BHGE") All rights reserved.

Bently Nevada, Orbit Logo, Keyphasor and System 1 are registered trademarks of BHGE in the United

States and other countries. All product and company names are trademarks of their respective holders.

Use of the trademarks does not imply any affiliation with or endorsement by the respective holders.

This product may be covered by one or more patents, please see Bently.com/legal for current status.

The information contained in this document is subject to change without prior notice.

1631 Bently Parkway South, Minden, Nevada USA 89423

Phone: 1.775.782.3611 Bently.com

10/10 113M5326 Rev. D

Loading...

Loading...