Page 1

Recycle Disassemble Instruction

(Dismantled Information)

Requirements according to ANNEX VII of DIRECTIVE 2012/19/EU

on waste electrical and electronic equipment (WEEE)

Materials and components with hazardous content

LCDs may contain hazardous substances like Pb and BFRs which are covered by

exemptions under the RoHS directive. However, the majority is present in the printed

circuit boards assembly. In order to reduce emissions as much as possible, a complete

disposal of the old appliance is required. This treatment may only be performed in

authorized handling plants.

Product Name: Interactive flat panel

Model No.: RP8602

Page 2

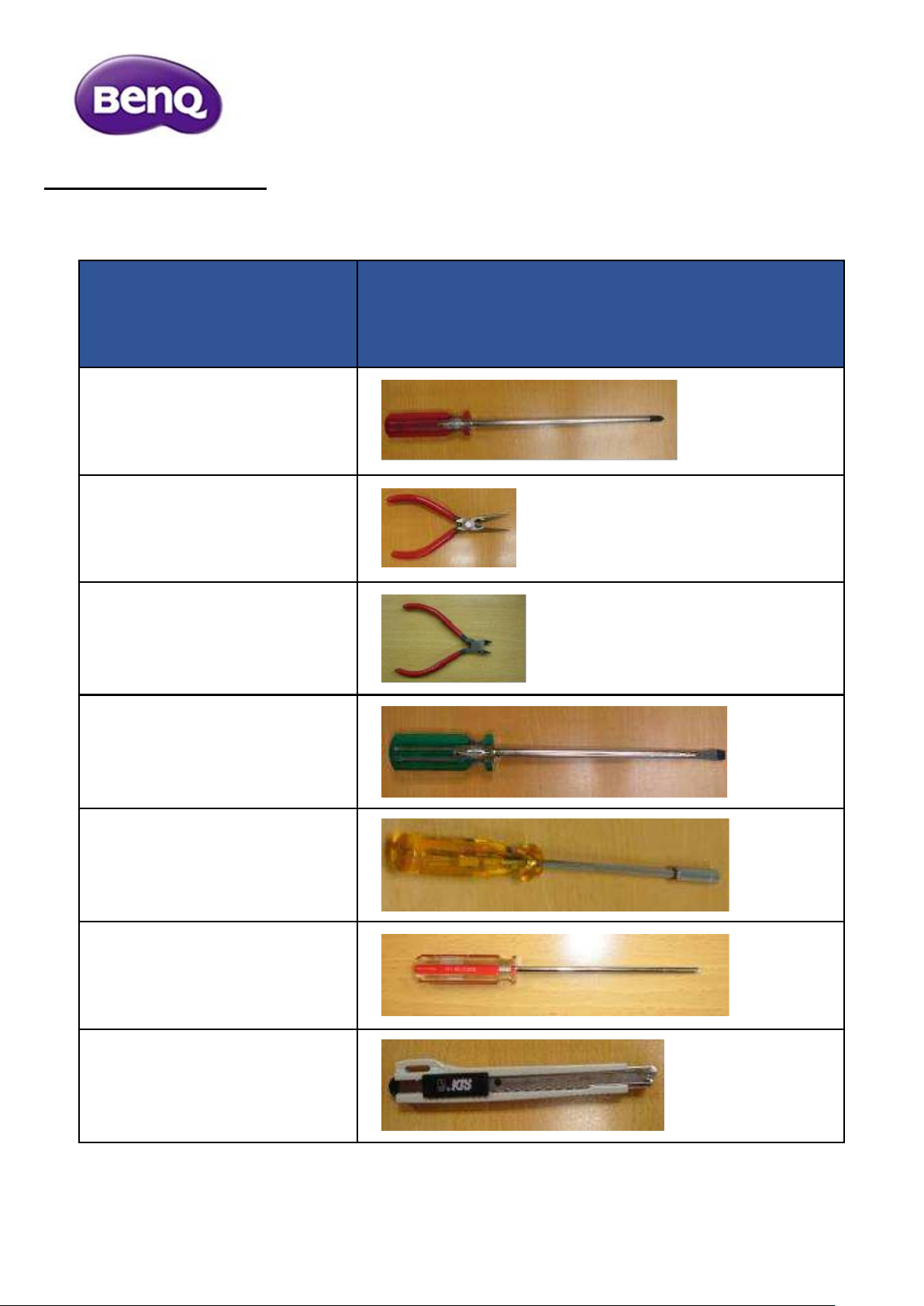

Disassembly Tools

Tool

picture

Philips Screwdriver for M3

screw

nosed pliers

Diagonal Cutting Pliers

Slotted screwdriver

Six Point Sockets

Philips Screwdriver for M2.5

screw

knife

Page 3

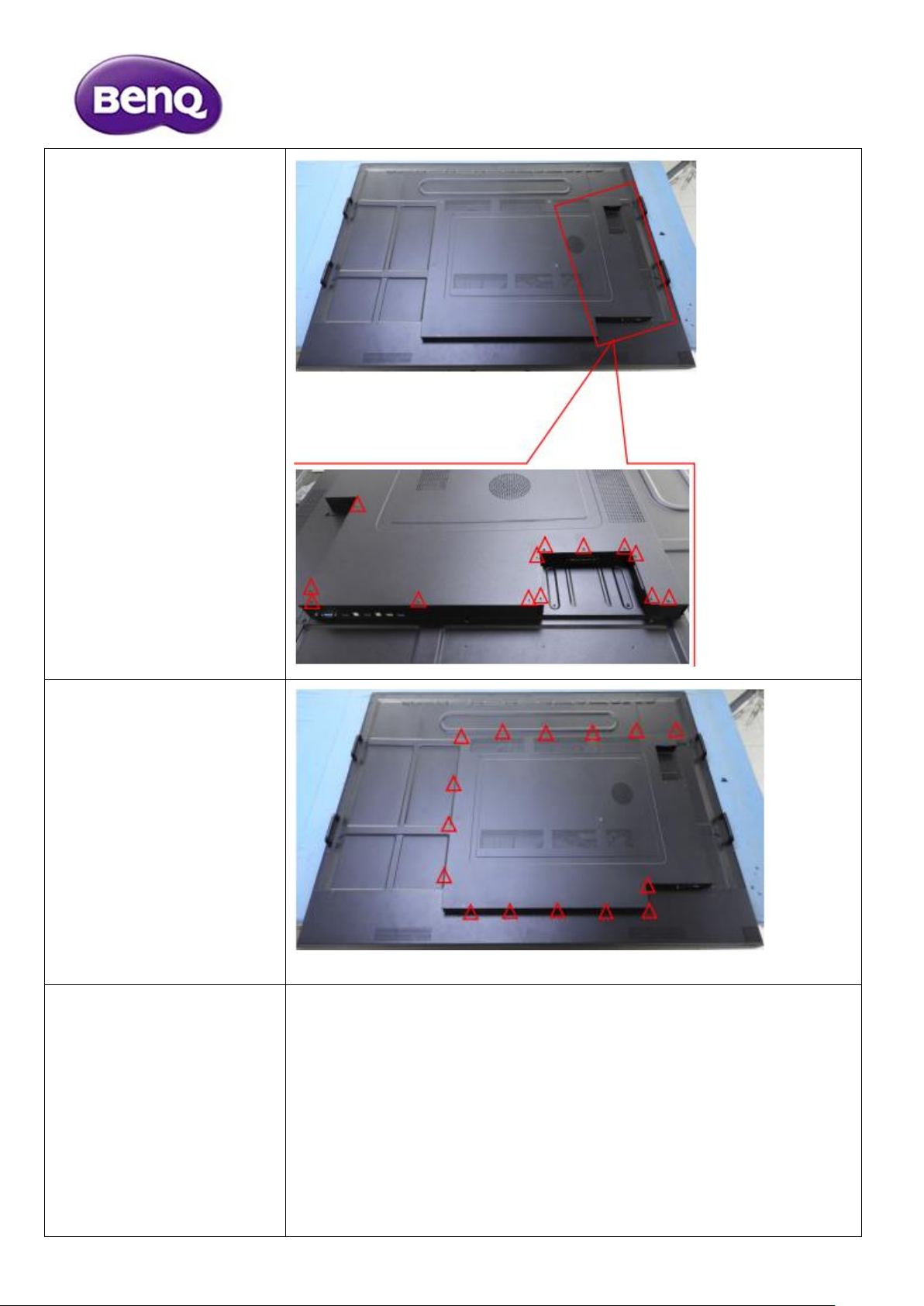

Disassembly process

Dismantle 4 pieces of

M8 x 20mm P head

flat tail ,elastic pad black

galvanized

machinery screws.

Dismantle 3 pieces of

M3 × 6mm meson head

nickel plating mechanical

screws.

Page 4

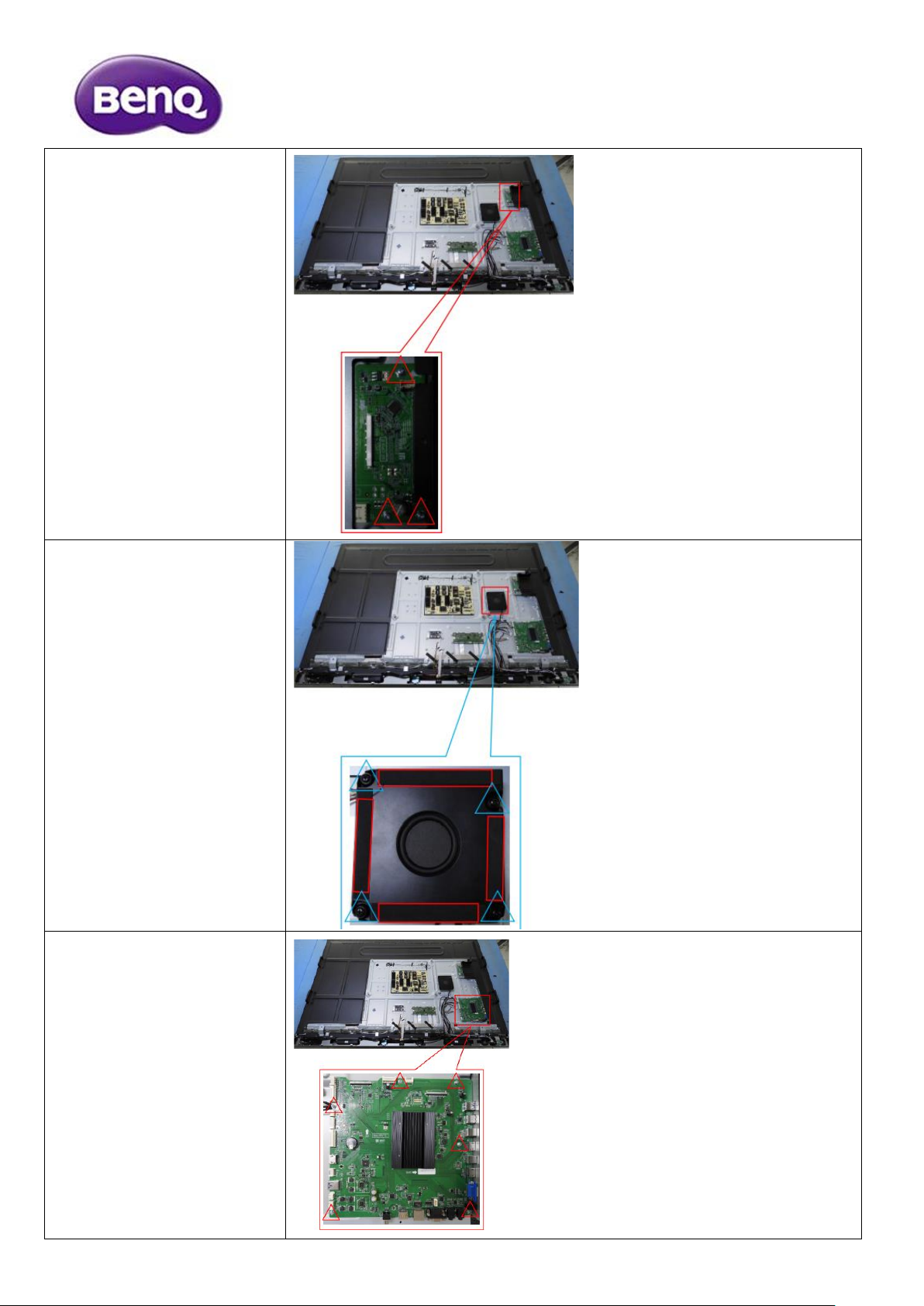

Dismantle 16 pieces of

M3 × 6mm meson

head nickel plating

mechanical screws.

1、Dismantle 15 pieces

of M4 × 6mm flat

round head nickel plating

mechanical screws.

2、Open the back cover.

1、Dismantle 3 pieces of

M4 × 6mm flat round

head nickel plating

mechanical screws.

2、Dismantle 1 piece of

Ф4 x 5 mm round head

toothed pads blue zinc

plating machine screw.

Page 5

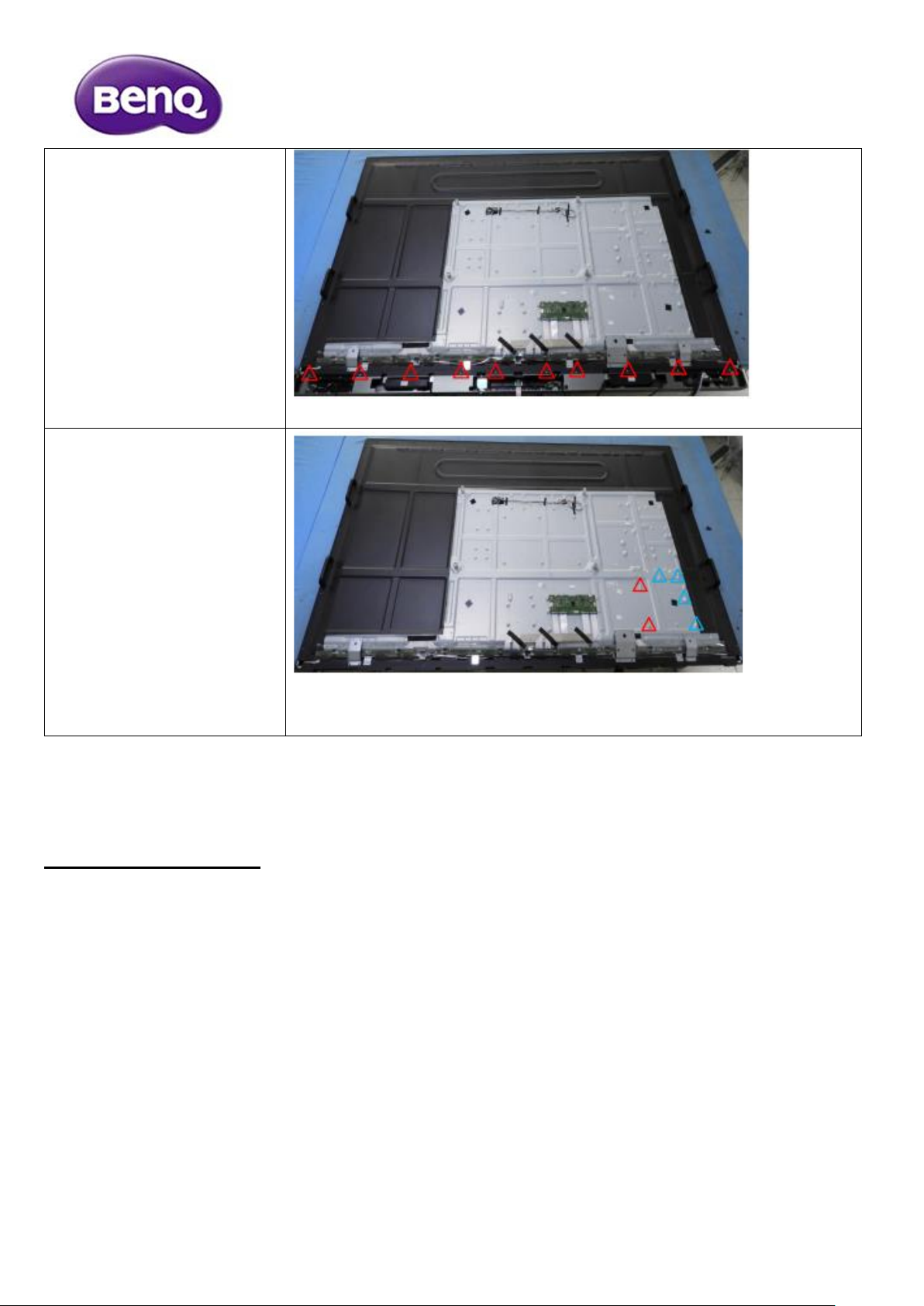

3、Remove the AC

bracket.

1、Dismantle 8 pieces of

M3 × 6mm meson

head nickel plating

mechanical screws.

2、Dismantle 7 pieces of

M4 × 6mm flat round

head nickel plating

mechanical screws.

3、Remove the back

shell at the bottom.

1、Dismantle 2 pieces of

M4 × 6mm flat round

head nickel plating

mechanical screws.

2、Remove the IO

baffle.

Page 6

1、Dismantle 3 pieces of

M3 × 6mm P head, flat

tail, elastic pad, flat pad,

blue galvanized

mechanical screws.

2、Remove the USB

board.

1、Dismantle 4 pieces of

M3 × 6mm P head, flat

tail, elastic pad, flat pad,

blue galvanized

mechanical screws.

2、Remove the MIC

board.

Page 7

1、Dismantle 3 pieces of

M3 × 6mm P head, flat

tail, elastic pad, flat pad,

blue galvanized

mechanical screws.

2、Remove the OPS

board.

1、Dismantle 4 pieces of

M5 × 8mm meson

head black galvanized

mechanical screws.

2、Separate the EVA

pad from the sound.

1、Dismantle 7 pieces of

M3 × 6mm P head, flat

tail, elastic pad, flat pad,

blue galvanized

mechanical screws.

2、Remove the

motherboard.

Page 8

1、Dismantle 6 pieces of

M3 × 6mm P head, flat

tail, elastic pad, flat pad,

blue galvanized

mechanical screws.

2、Remove the power

panel.

1、Dismantle 2 pieces of

M3 × 6mm P head, flat

tail, elastic pad, flat pad,

blue galvanized

mechanical screws.

2、Dismantle 2 pieces of

M3 × 4mm meson

head nickel plating

mechanical screws.

3、Remove the OPS

iron bracket.

1、Dismantle 3 pieces of

M3 × 6mm P head, flat

tail, elastic pad, flat pad,

blue galvanized

mechanical screws.

2、Remove the iron

support.

Page 9

1、Dismantle 3 pieces of

M3 x 5mm

flathead flat tail blue zinc

plating machinery

screws.

2、Remove the iron

support.

1、Dismantle 4 pieces of

M3 × 6mm P head, flat

tail, elastic pad, flat pad,

blue galvanized

mechanical screws.

2、Remove the horn

bracket.

1、Dismantle 3 pieces of

M4 × 6mm flat round

head nickel plating

mechanical screws.

2、Remove the IO

baffle.

Page 10

1、Dismantle 3 pieces of

M3 × 8mm P head, flat

tail, elastic pad, flat pad,

blue galvanized

mechanical screws.

2、Remove the

shielding can.

1、Dismantle 8 pieces of

M3 × 6mm P head, flat

tail, elastic pad, flat pad,

blue galvanized

mechanical screws.

2、Remove 8 plastic

buckles.

1、Dismantle 6 pieces of

M3 × 6mm P head, flat

tail, elastic pad, flat pad,

blue galvanized

mechanical screws.

2、Remove 6 rear shell

supports.

Page 11

1、Dismantle 10 pieces

of M3 × 8mm P head,

flat tail, elastic pad, flat

pad, blue galvanized

mechanical screws.

2、Remove aluminum

profile assembly.

1、Dismantle 2 pieces of

M3×3mm H =11mm flat

tail Blue zinc plating

machinery hexagon

studs.

2、Dismantle 4 pieces of

M3×2.5mm H =5mm flat

tail Blue zinc plating

machinery hexagon

studs.

Disassembly Time

Total time: about 35 minutes

Loading...

Loading...